Low-force high-efficiency simulated moon rock drilling core bit

A coring bit and force technology, which is applied in the aerospace field, can solve the problems of continuous and reliable collection of lunar soil samples and increase the risk, and achieve the effects of improving crushing capacity, high coring rate, and efficient chip removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0024] The present invention will be described in detail below with reference to the accompanying drawings and examples.

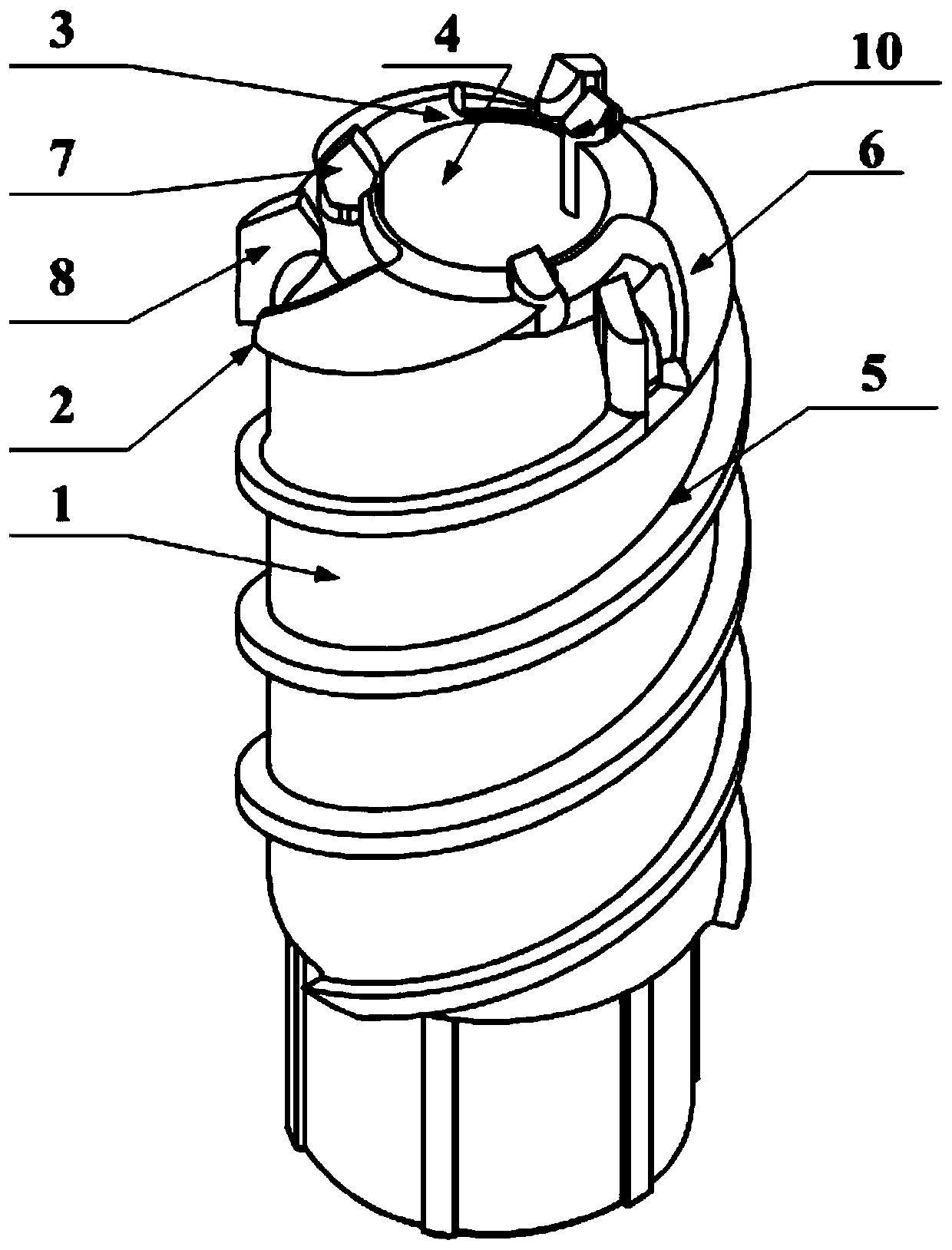

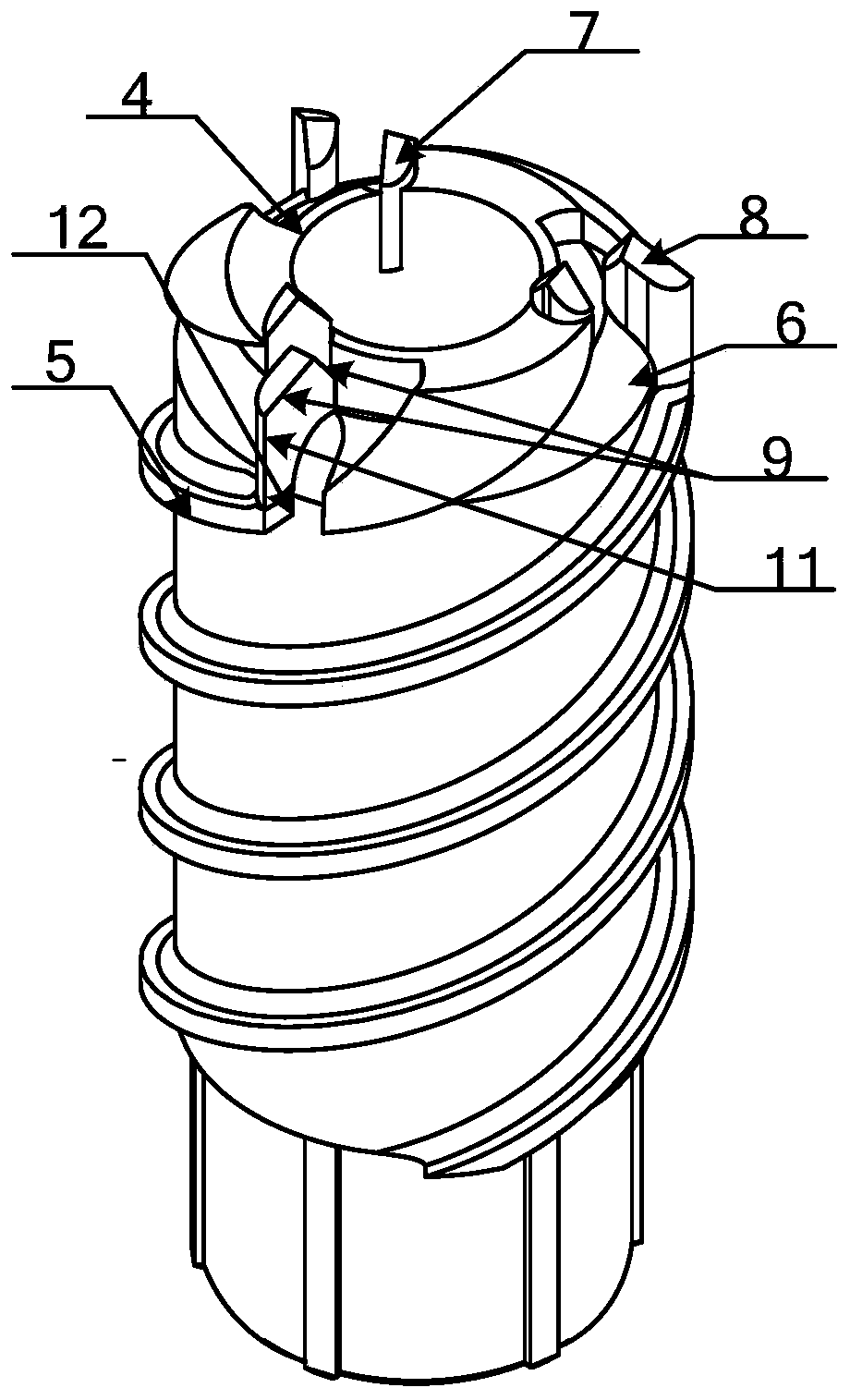

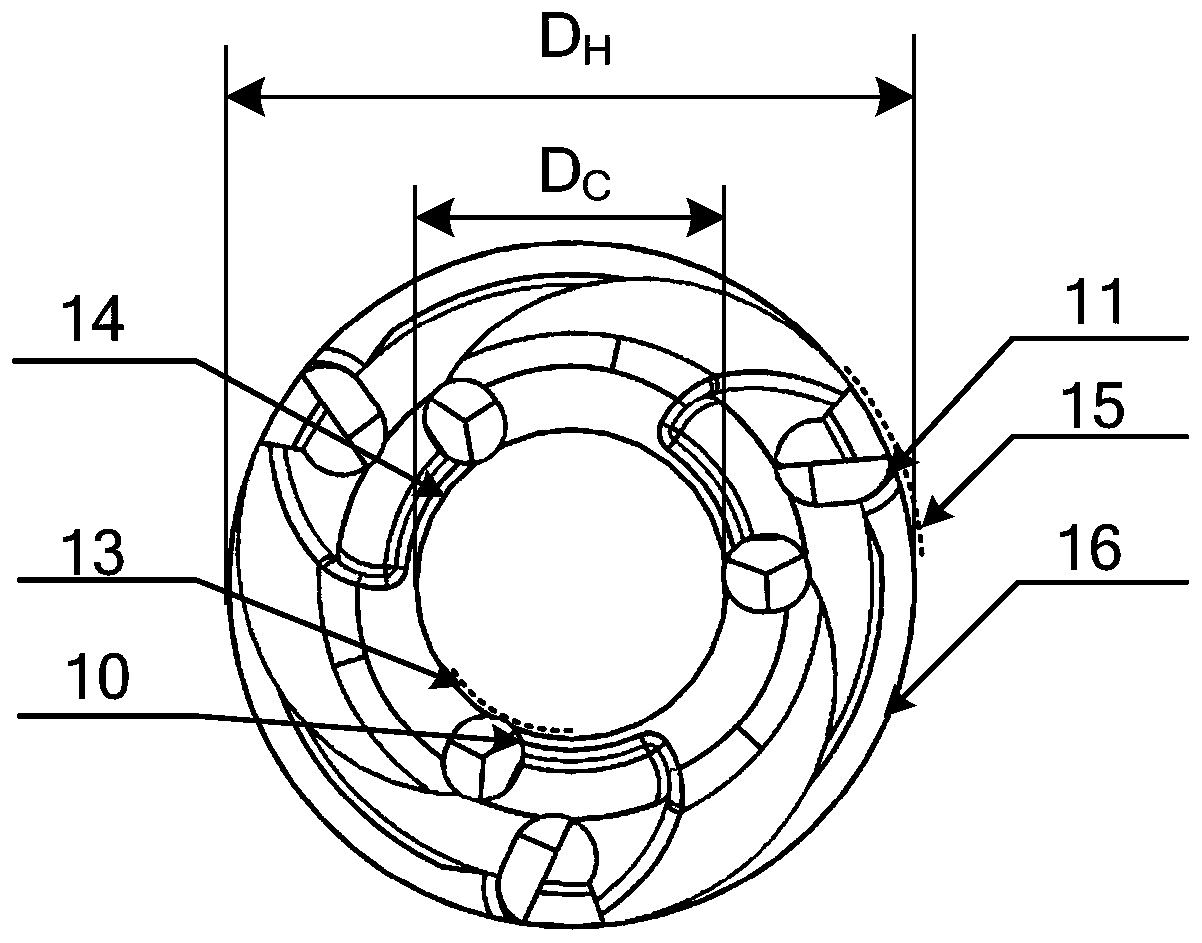

[0025] like Figure 1-Figure 4 As shown, the low-force high-efficiency simulated moon rock drilling core bit includes a hollow cylindrical drill body 1, the end of the drill body 1 is provided with an ellipsoidal head 2, and the ellipsoidal head 2 The top end is retracted radially to form a barrier ring 3, and a coring channel 4 is formed between the inner surface of the drill body 1 and the barrier ring 3, and the outer surface of the drill body 1 is provided with three drill pipe helical wings 5 for chip removal. The surface of the ellipsoidal head 2 is processed with three ellipsoidal helical wings 6 for chip removal. The ellipsoidal helical wings 6 and the drill pipe helical wings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com