Twin wire press and method for dewatering a fibre suspension

A suspension and press technology, applied in the press section, paper machine, paper machine wet end, etc., can solve the problems of damaged fiber paper web, white water cannot be removed, high friction, etc., to reduce friction load, quantity and size reduction , the effect of high dry matter content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

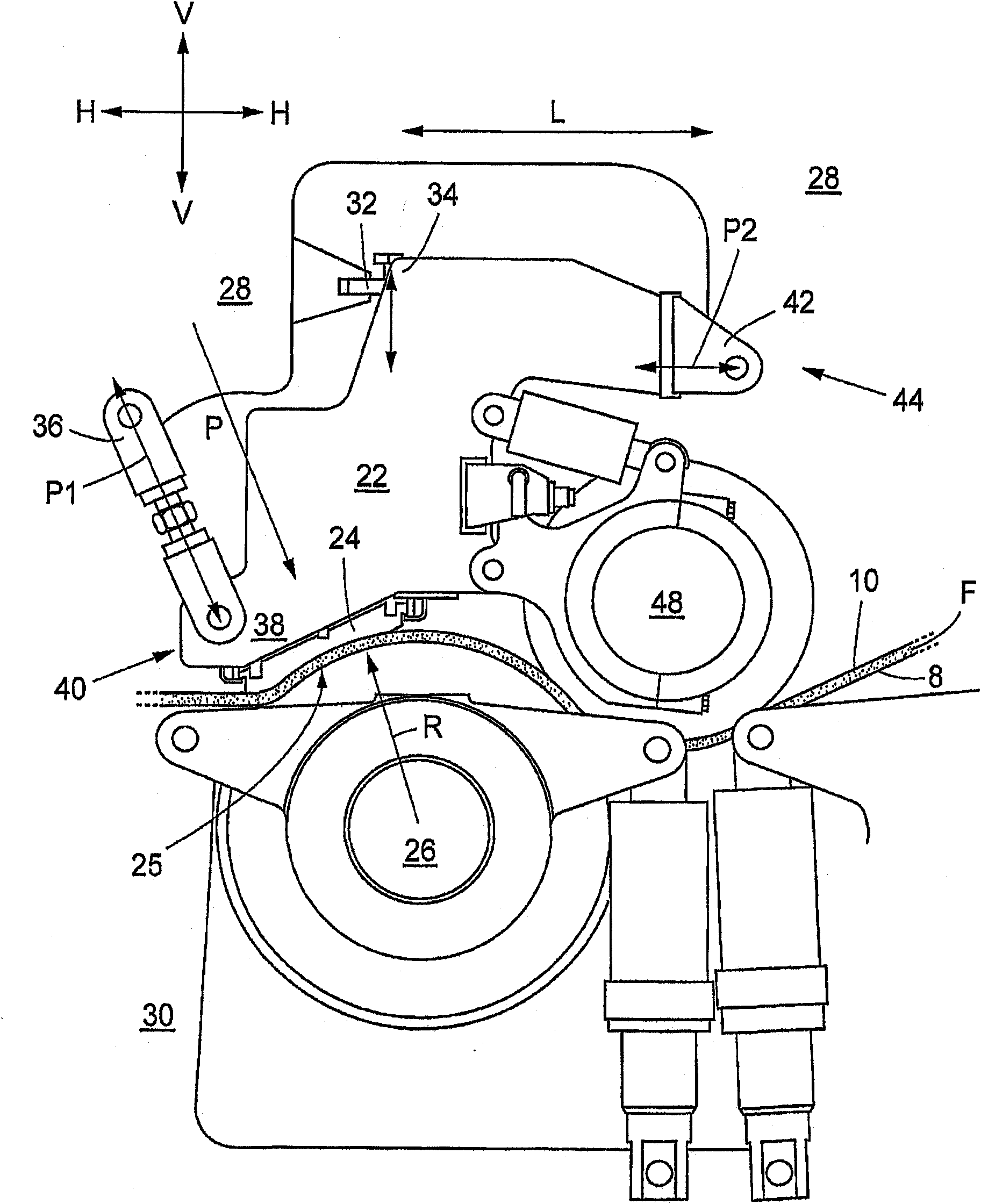

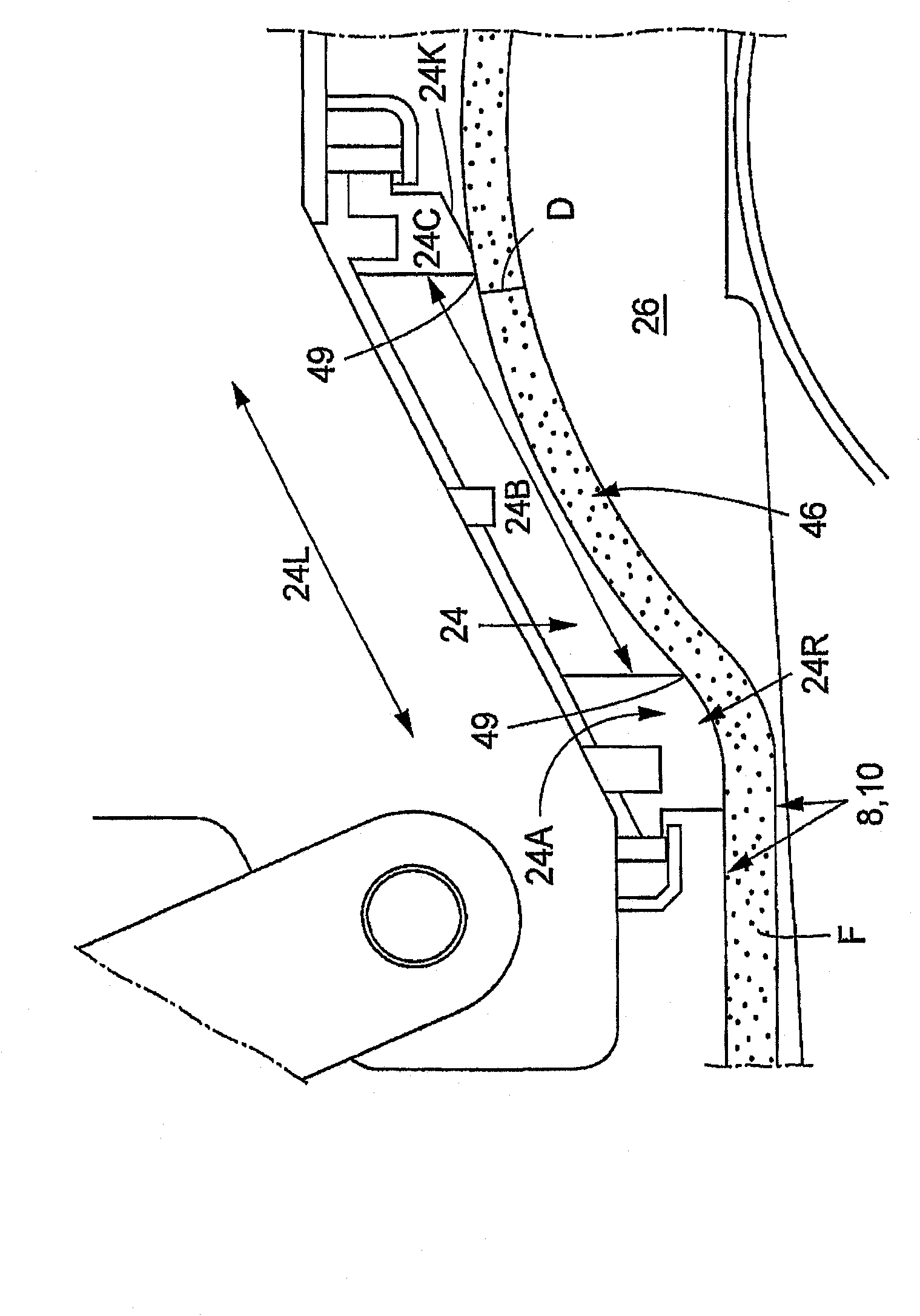

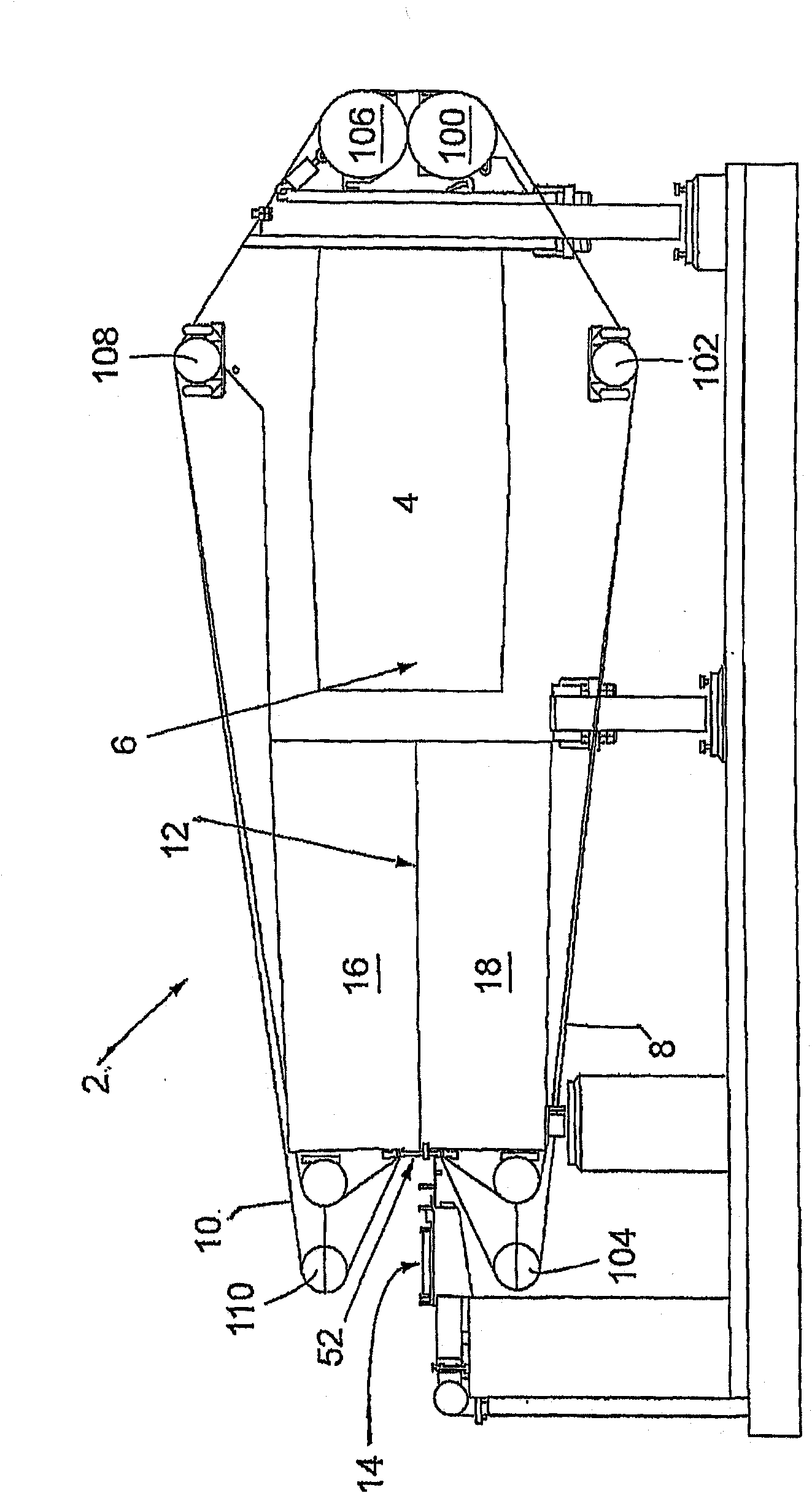

[0034] figure 2 A twin wire press 2 with a roll arrangement 4 is shown according to an embodiment of the invention. The roller arrangement 4 has an inlet section 6 . Figure 1A - B shows a partial view and an enlarged view of the inlet section 6 in the roll arrangement 4 of the twin wire press 2 according to an embodiment of the invention. The twin wire press 2 comprises a continuous lower wire 8 and a continuous upper wire 10, both of which define an elongated dewatering space 12 in which the fiber suspension is dewatered during the movement of the wires 8, 10. The twin wire press comprises a headbox 14 and two dewatering tables 16, 18 for supplying the fiber suspension to the dewatering space 12 at the inlet end of the dewatering space, the two dewatering tables respectively supporting the upper and lower network. A fibrous web F is formed between the two wires. Viewed from the direction of wire movement, a roll arrangement 4 is arranged after the dewatering tables 16, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com