Equipment for washing and/or dewatering pulp and inserts for preventing rewetting of pulp

A technology of inserts and equipment, which is applied in the direction of washing/replacing pulp treatment liquid, pulp dehydration, chemical instruments and methods, etc., can solve the problems of complex manufacturing and a large number of welding, etc., to simplify manufacturing, reduce wear, increase stability and strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

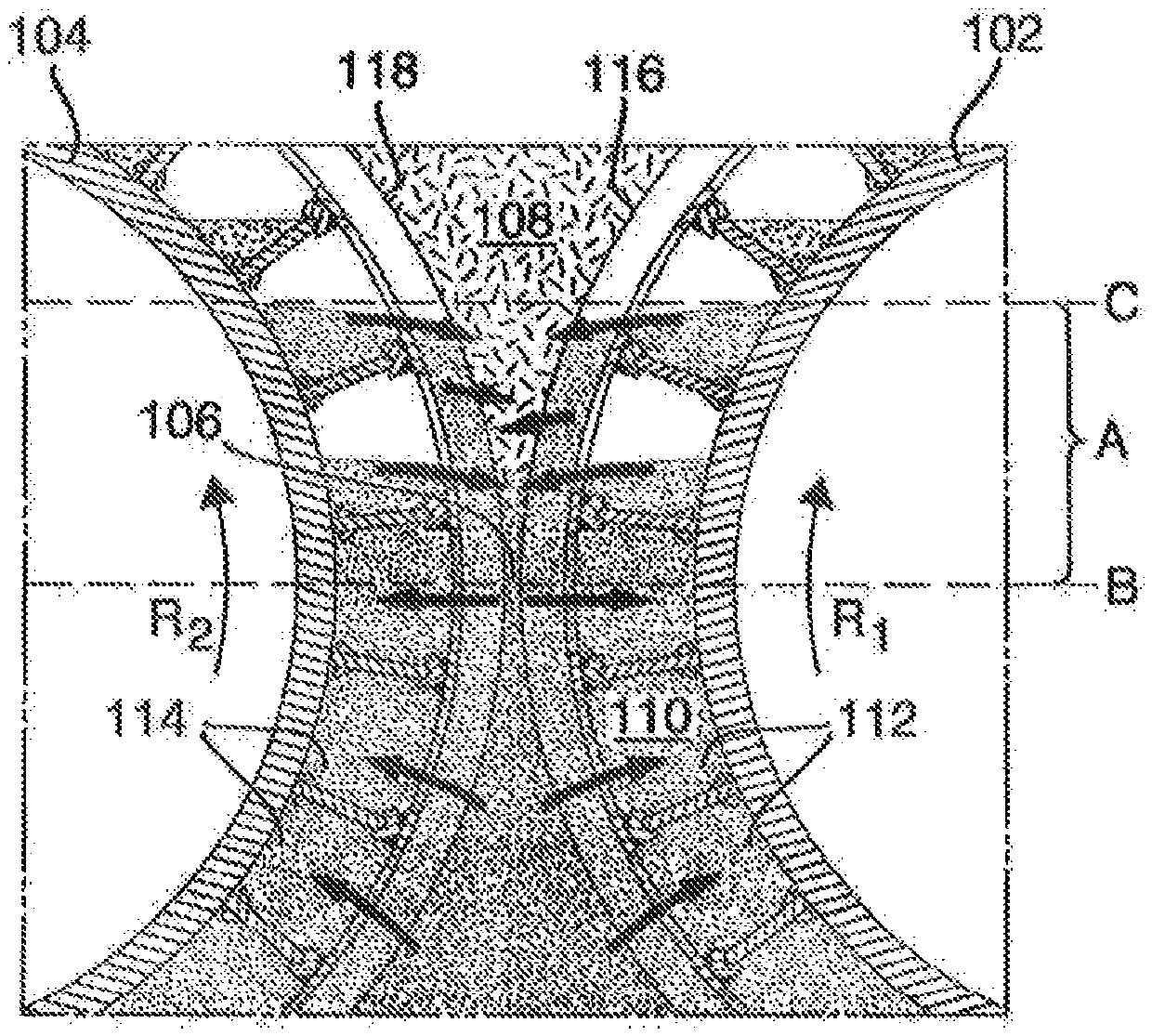

[0025] figure 1 Rewetting is shown in relation to a roll press with two cooperating press rolls 102, 104 counter-rotating in directions of rotation R1 and R2, respectively, the pulp 108 being fed in the direction of rotation R1, R2 of the press rolls 102, 104 And up through the nip 106 formed between the press rolls 102,104. Within the nip 106 , a liquid called filtrate is pressed from the pulp into a plurality of filtrate channels 112 , 114 through the permeable cover elements 116 , 118 of each press roll 102 , 104 .

[0026] After the press nip 106 , the pressure of the pulp 108 is reduced and the filtrate 110 that has not yet exited the filtrate channels 112 , 114 returns through the cover elements 116 , 118 , wetting and diluting the pulp 108 . exist figure 1 , rewet is shown by arrows from each filtrate channel 112 , 114 to the rewet region A above the nip 106 . The pulp 108 has a maximum dryness at a first point B before the rewet zone A, while the pulp 108 leaving th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com