A rake bucket rock loader

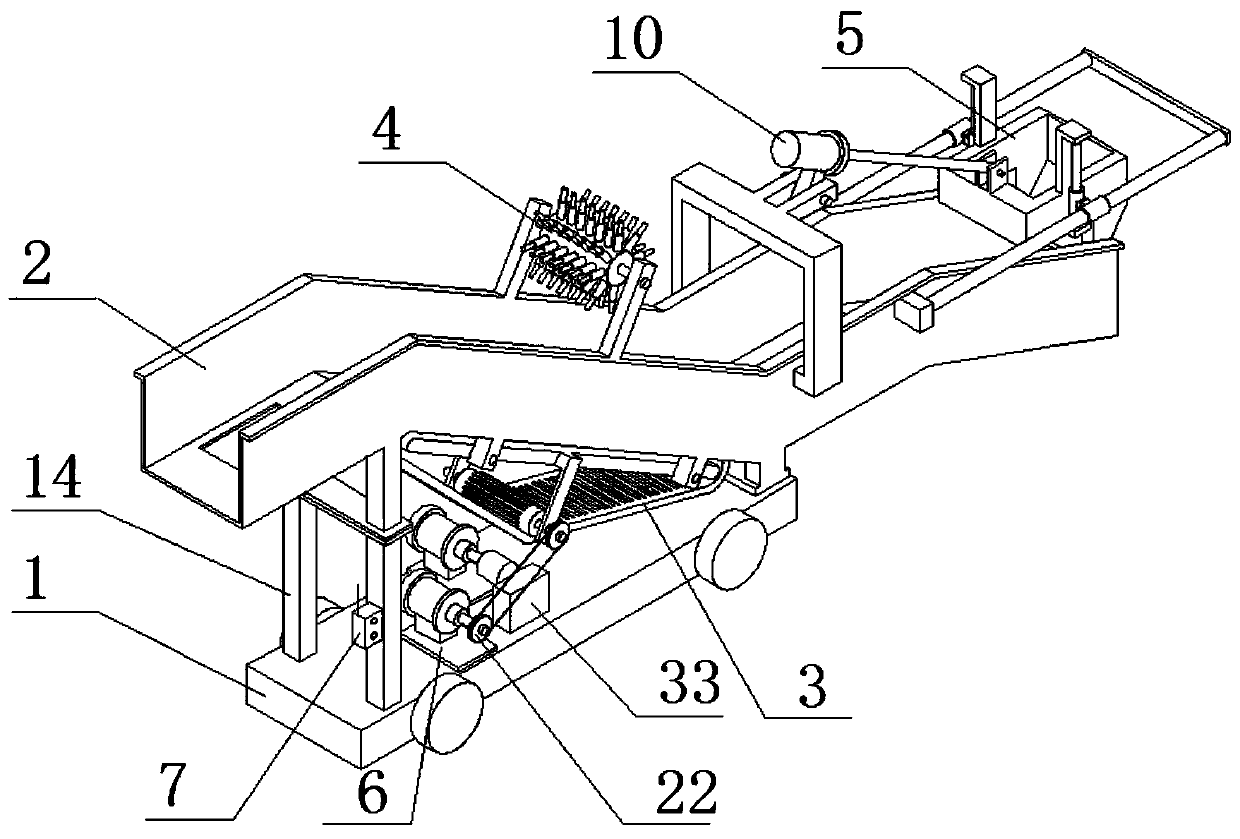

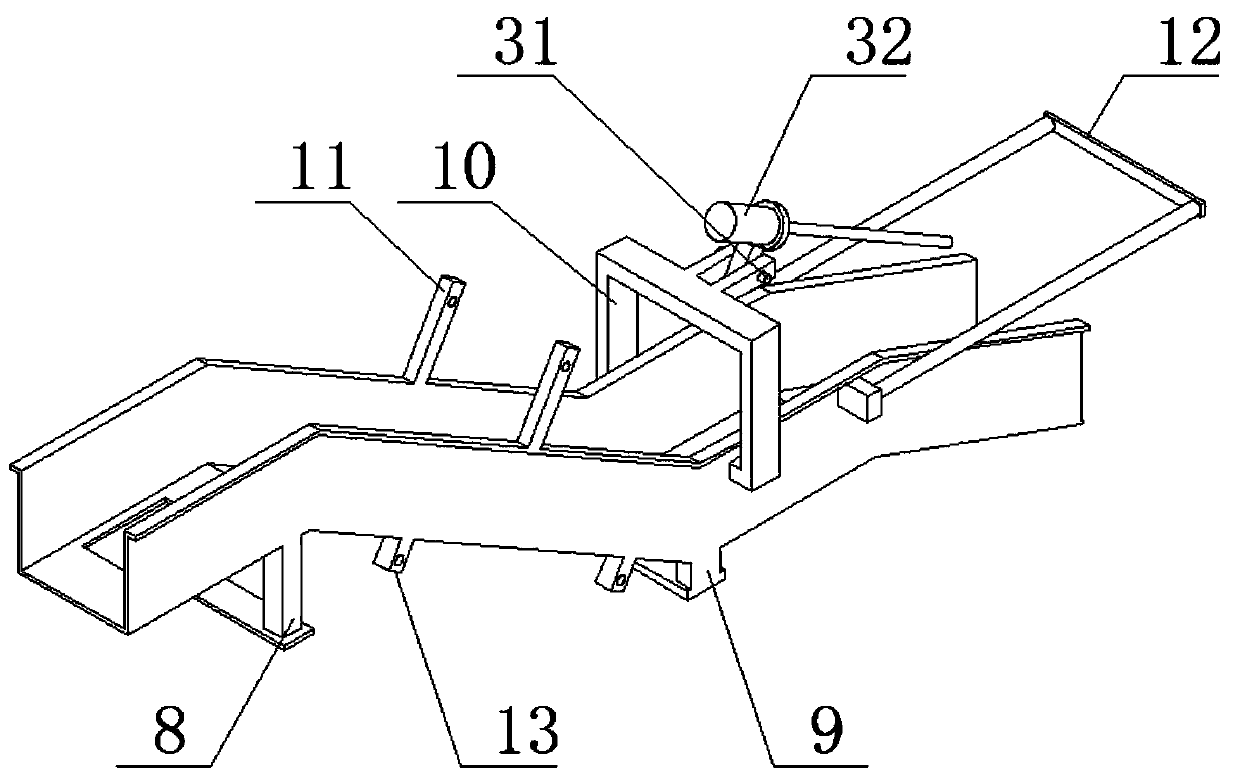

A rake-bucket rock loader and rake-bucket technology, which is applied to conveyors, loading/unloading, transportation, and packaging, can solve problems such as increasing the load of the drive motor, reducing the life of the drive motor, and accidentally falling off and hurting people. Effects of frictional load, impact reduction, and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

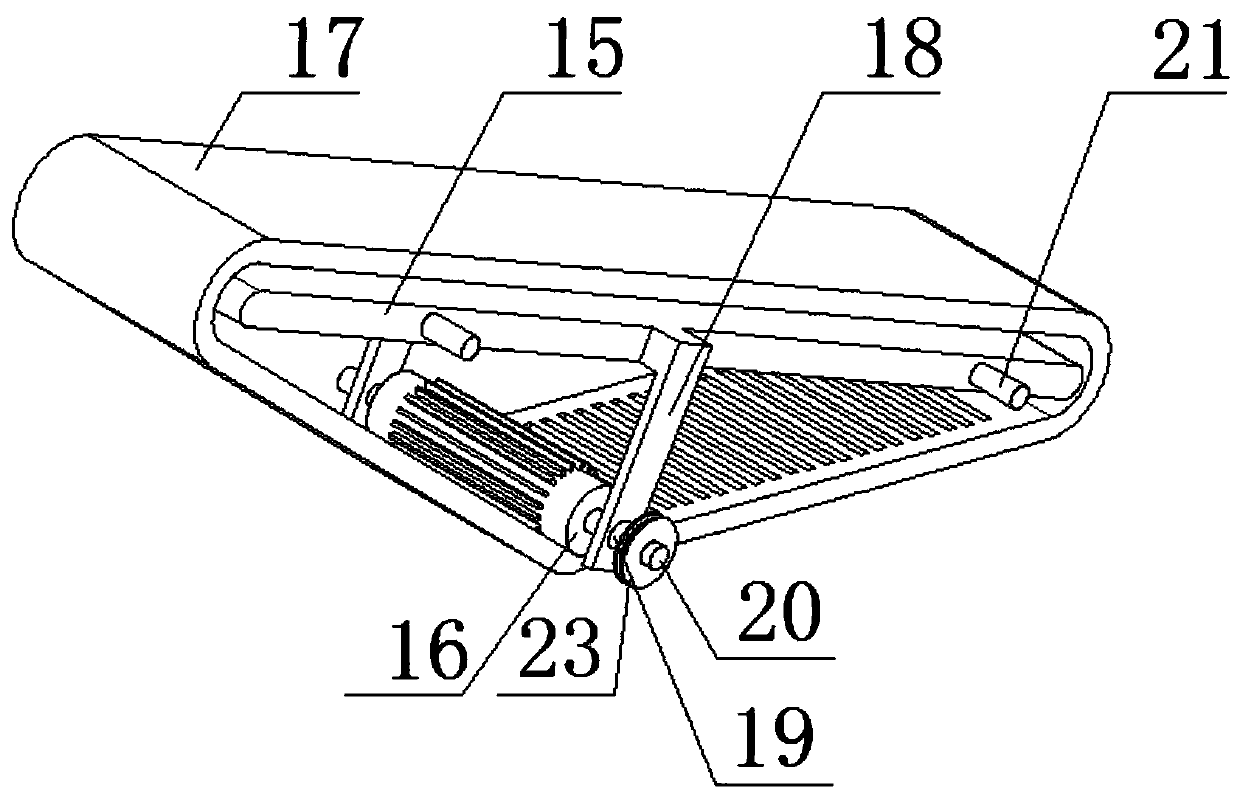

[0031] As a preferred embodiment of the present invention, the elastic rubber cover 38 is provided with a cylindrical rod 39 .

[0032] As a preferred embodiment of the present invention, a travel switch 40 is provided inside the fixed rod 35 , a laser transmitter 41 is provided at one end of the contact rod 37 , and the travel switch is connected to the laser transmitter 41 through wires.

[0033] As a preferred embodiment of the present invention, the control buttons include a bucket button, a delivery button and a magnetic suspension button, and the control buttons are connected with the drive motor 6, the oil supply motor and the coil through wires.

[0034]Working principle: first connect the control electric box 7 to the external power supply, and the external power supply provides electric energy to the rail saw machine. When it is necessary to collect external rock materials, manually press the bucket button, and the oil supply motor starts to drive the hydraulic pump t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com