Technical method of weft preparation before dyed yarn weaving

A process method and pre-weaving technology, applied in the direction of liquid/gas/steam yarn/filament processing, etc., can solve the problems of yarn quality reduction, improve the quality of weft yarn, eliminate the bottleneck of weft yarn supply, and shorten the production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0039] Pure cotton yarn-dyed plain plain fabric, warp and weft yarn count: Ne 40×Ne 80 / 2, warp and weft density: 120 threads / inch×80 threads / inch

[0040] 1. Loose yarn

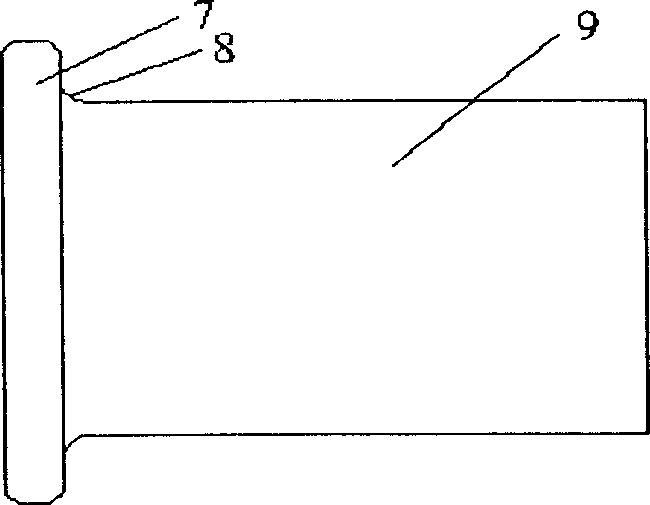

[0041] Parallel yarn dyeing bobbin, bobbin winding density: 0.38g / cm 3

[0042] 2. Yarn dyeing

[0043] Process: Parallel bobbin dyeing—water-soluble liquid paraffin and softener in the same bath (bath ratio is the same as the traditional process, the amount of liquid paraffin added is 6g / L)—centrifugal dehydration—drying; the concentration of water-soluble liquid paraffin is 46%.

[0044] 3. Weaving

[0045] Loom: Toyota JAT610 Air Jet Loom

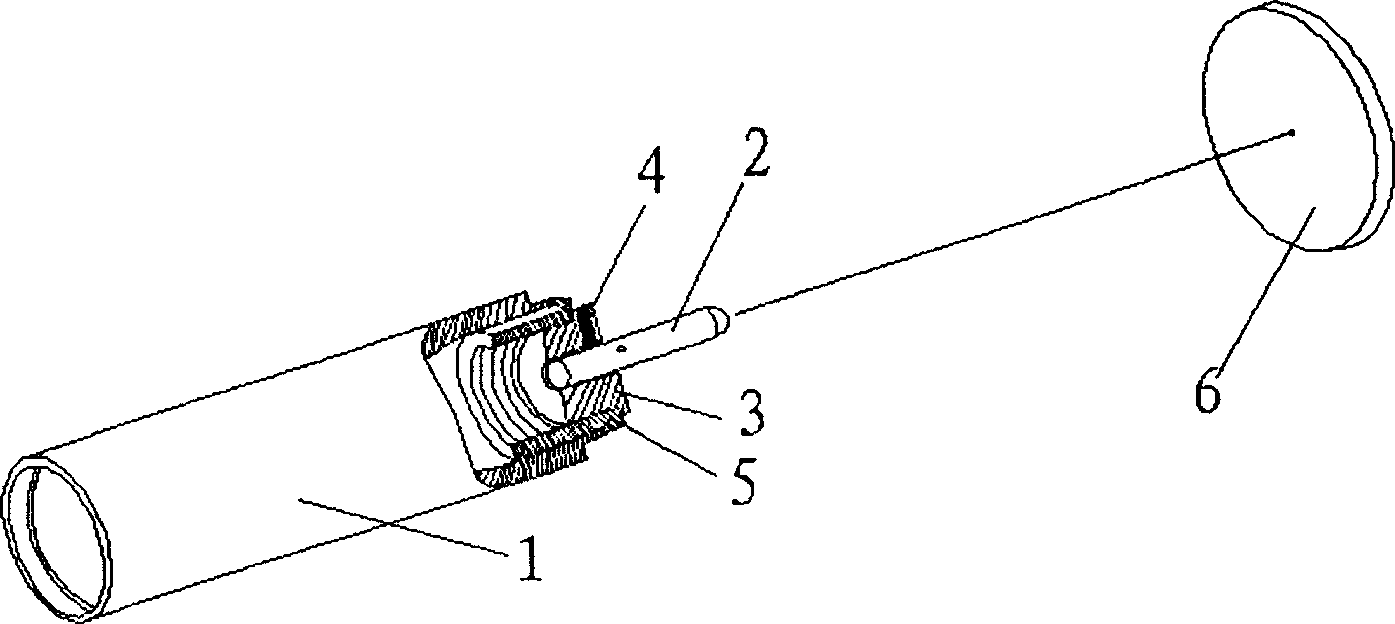

[0046] Process: install the bobbin stabilization ring—correct and adjust the position of the bobbin—place the inner yarn auxiliary unwinding ring—weaving.

[0047] Compact spinning Ne 80 / 2

Process of the present invention

traditional craft

increase rate

Unevenness (CV%)

10.1

10.49

3.9%

Neps +140% / km

46

...

example 2

[0060] Pure cotton yarn-dyed plain twill fabric, warp and weft yarn count: Ne 80 / 2×Ne 50 / 1, warp and weft density: 144 threads / inch×110 threads / inch.

[0061] 1. Loose yarn

[0062] Parallel yarn dyeing bobbins, bobbin winding density: 0.38g / cm 3

[0063] 2. Yarn dyeing

[0064] Process: Parallel bobbin dyeing—water-soluble liquid paraffin and softener in the same bath (bath ratio is the same as the traditional process, the amount of liquid paraffin added is 6g / L)—centrifugal dehydration—drying; the concentration of water-soluble liquid paraffin is 46%.

[0065] 3. Weaving

[0066] Loom: PICANAL OMNI plus air jet loom

[0067] Process: Calibrate and adjust the position of the bobbin—place the inner yarn to assist the unwinding ring—weaving

[0068] Combed Ne 50

Process of the present invention

traditional craft

increase rate

Unevenness (CV%)

13.189

13.738

4.2%

Neps +140% / km

100.7

176.4

75.2%

Ne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com