Technical method of weft preparation before dyed yarn weaving

A process method and pre-weaving technology, which is applied in the field of weft yarn preparation before dyed yarn weaving, can solve problems such as yarn quality reduction, achieve the effects of improving weft yarn quality, reducing production costs, and shortening the yarn-dyed process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Pure cotton yarn-dyed plain plain fabric, warp and weft yarn count: Ne 40×Ne 80 / 2, warp and weft density: 120 threads / inch×80 threads / inch

[0036] 1. Loose yarn

[0037] Parallel yarn dyeing bobbin, bobbin winding density: 0.38g / cm 3

[0038] 2. Yarn dyeing

[0039] Process: parallel bobbin dyeing-water-soluble liquid paraffin and softener in the same bath (bath ratio is the same as the traditional process, liquid paraffin addition 6g / L)-centrifugal dehydration-drying; wherein the concentration of water-soluble liquid paraffin is 46%.

[0040] 3. Weaving

[0041] Loom: Toyota JAT610 Air Jet Loom

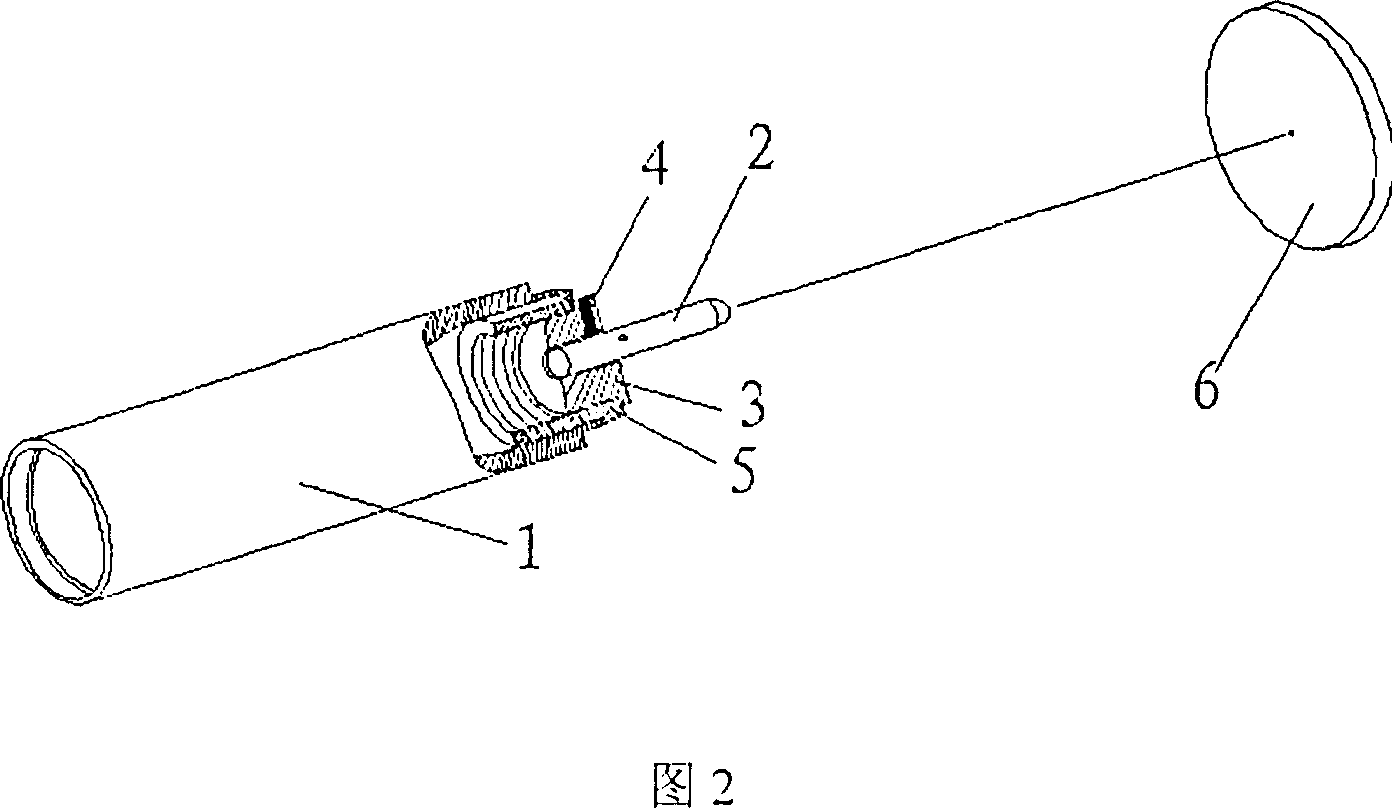

[0042]Process: install the bobbin stabilization ring - correct and adjust the position of the bobbin - place the inner yarn to assist the unwinding ring - weaving.

[0043] Compact spinning Ne80 / 2

Process of the present invention

traditional craft

increase rate

Unevenness (CV%)

10.1

10.49

3.9%

Neps +140% / km

46 ...

example 2

[0056] Pure cotton yarn-dyed plain twill fabric, warp and weft yarn count: Ne 80 / 2×Ne 50 / 1, warp and weft density: 144 threads / inch×110 threads / inch.

[0057] 1. Loose yarn

[0058] Parallel yarn dyeing bobbins, bobbin winding density: 0.38g / cm 3

[0059] 2. Yarn dyeing

[0060] Process: parallel bobbin dyeing-water-soluble liquid paraffin and softener in the same bath (bath ratio is the same as the traditional process, liquid paraffin addition 6g / L)-centrifugal dehydration-drying; wherein the concentration of water-soluble liquid paraffin is 46%.

[0061] 3. Weaving

[0062] Loom: PICANAL OMNI plus air jet loom

[0063] Process: Calibration and adjustment of bobbin position - placement of inner yarn auxiliary unwinding ring - weaving

[0064] Combed Ne 50

Process of the present invention

traditional craft

increase rate

Unevenness (CV%)

13.189

13.738

4.2%

Neps +140% / km

100.7

176.4

75.2%

Neps +2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com