Technology for spinning 40<S> high tenacity vortex viscose yarn and vortex viscose yarn

A technology of vortex spinning and viscose, which is applied in the direction of spinning machine, open-end spinning machine, continuous winding spinning machine, etc., and can solve the problem of low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

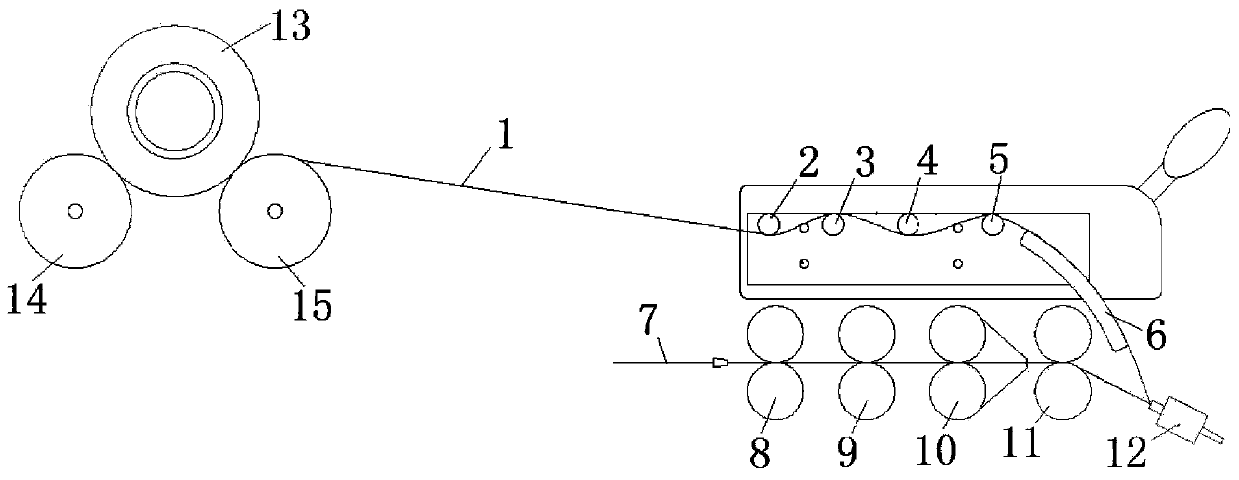

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: spun 40 with adding filament tension constant device and arc top godet wheel device on VORTEXⅢ870 vortex spinning machine S Take viscose yarn as an example, wherein the average length of viscose fiber is 38mm, and the fineness is 1.33dtex. The specific process steps are as follows:

[0034] (1) Start cleaning process

[0035] For ring spinning, the beater speed is 435r / min, the distance between the cotton feeding roller and the beater is 9mm, the distance between the dust bar and the dust bar is 8mm, the distance between the dust bar and the beater is 8mm at the entrance, and 18mm at the exit, and the beater- The distance between the stripping knives is 2.5mm, the speed of the comprehensive beater is 910r / min, the speed of the fan is 1330r / min, the speed of the lap roller is 10.8r / min, the dry weight of the lap is 380g / m, and the length of the lap is 32.2m; Vortex spinning, the beater speed is 440r / min, the distance between the cotton feeding roller and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com