Elevator apparatus of pony roll support

A lifting device and supporting frame technology, which is applied to the creel, transportation and packaging, textile and papermaking, etc., can solve the problems of increasing the difficulty of the manufacturing process, prone to assembly gaps, complicated preparation processes, etc., and achieves easy assembly and improved cost. Yarn quality, wear reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

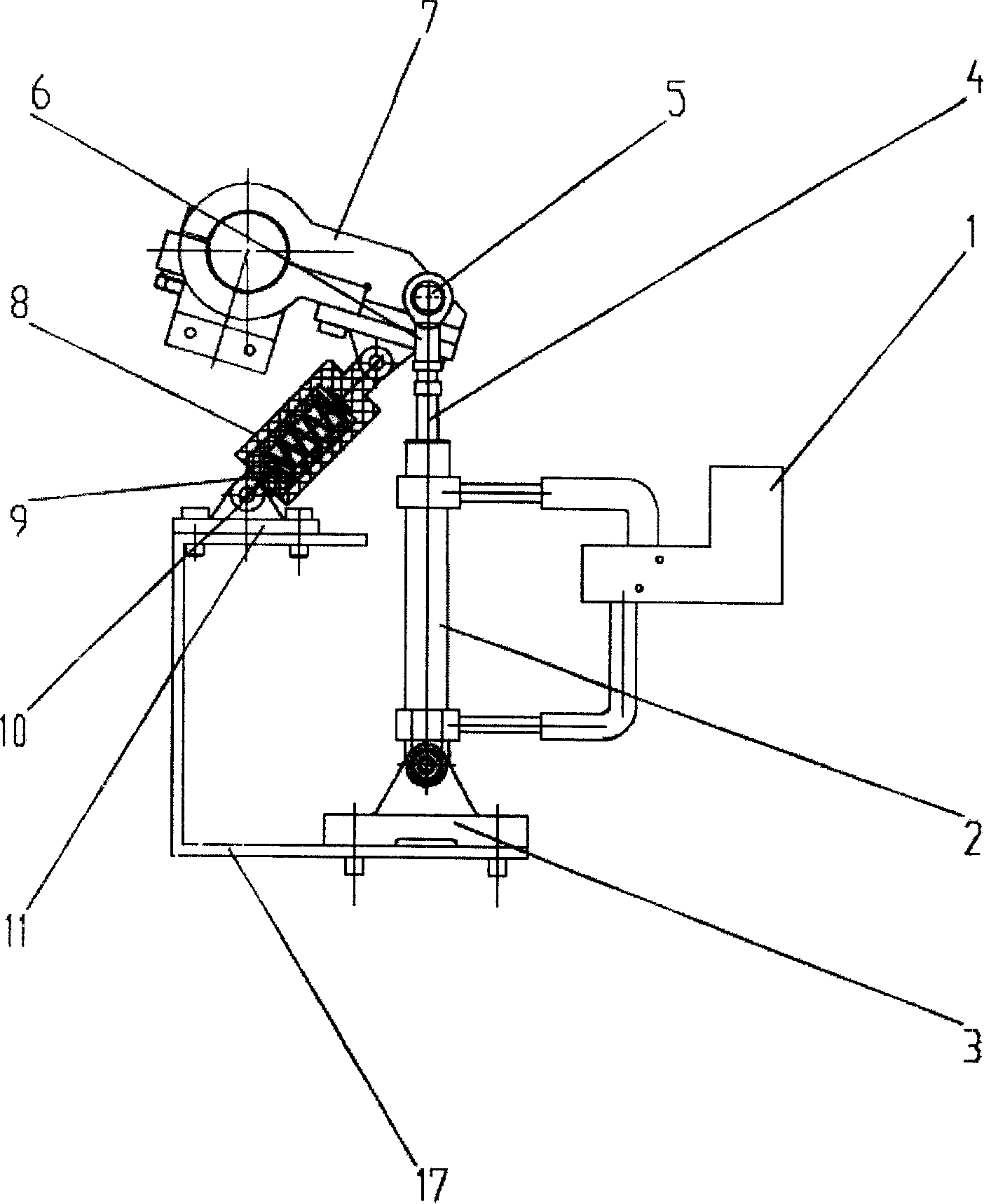

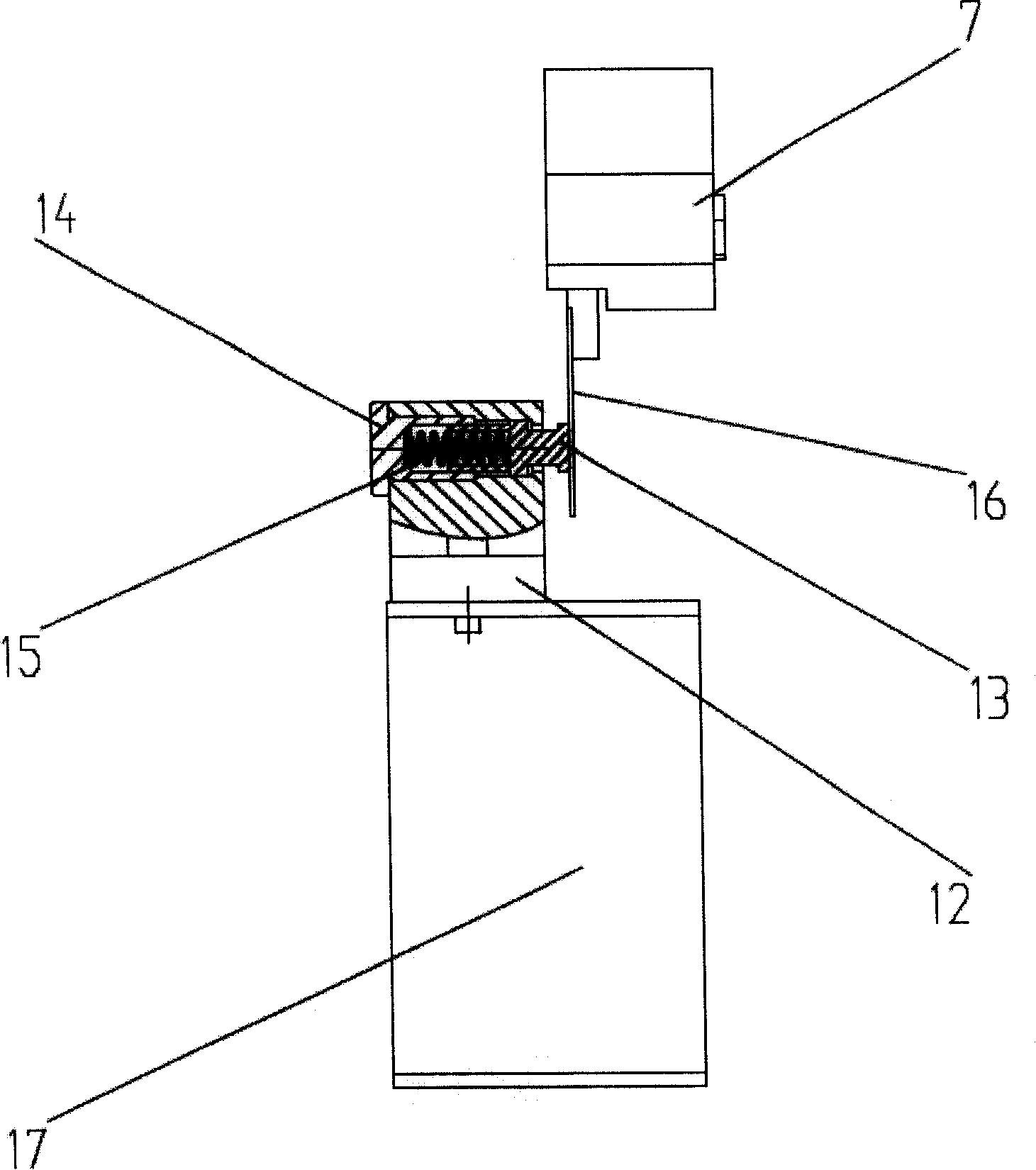

[0018] refer to figure 1 , figure 2 As shown, the lifting device of the bobbin support frame of the present invention includes a bobbin support frame and a lifting mechanism; its improvement is that the bobbin support frame 7 is provided with a fixing hole, and one end of a connecting piece 6 is tightly connected to the fixing hole by means of a fixing piece 5. Solid, the other end of the connector 6 is connected with the elevating rod 4 of the elevating mechanism, and the connection seat of the elevating mechanism is fixed on a base 17; a buffer mechanism is provided between the base 17 and the bobbin support frame 7. The lifting mechanism includes a solenoid valve 1, a cylinder body 2 and a cylinder body connecting seat 3; the solenoid valve 1 is connected to the cylinder body 2 through an air pipe, the lifting rod 4 on the upper part of the cylinder body 2 is connected to the connector, and the lower end of the cylinder body 2 is connected to the cylinder body The seat 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com