Stable steel tube straightening device

A steel pipe straightening technology, applied in the field of stable steel pipe straightening devices, can solve the problem of low bending degree of steel pipe straightening, and achieve the effect of not being easy to shift and preventing left and right shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

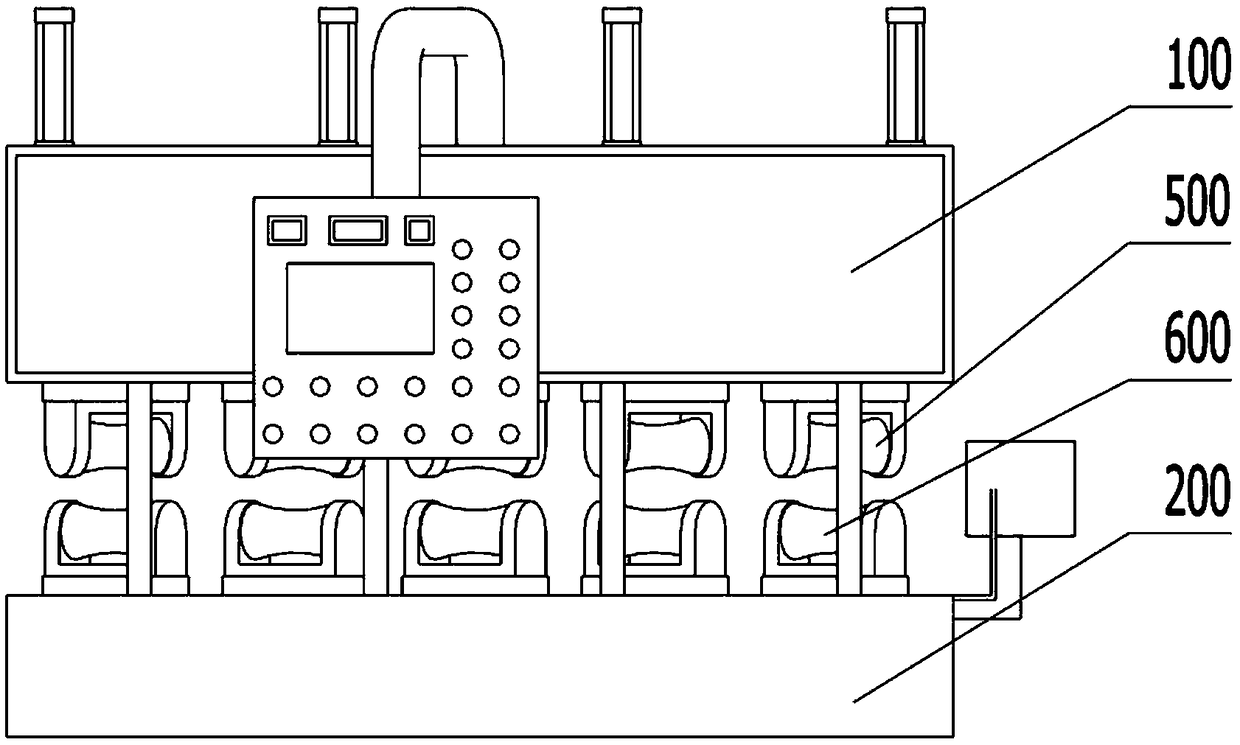

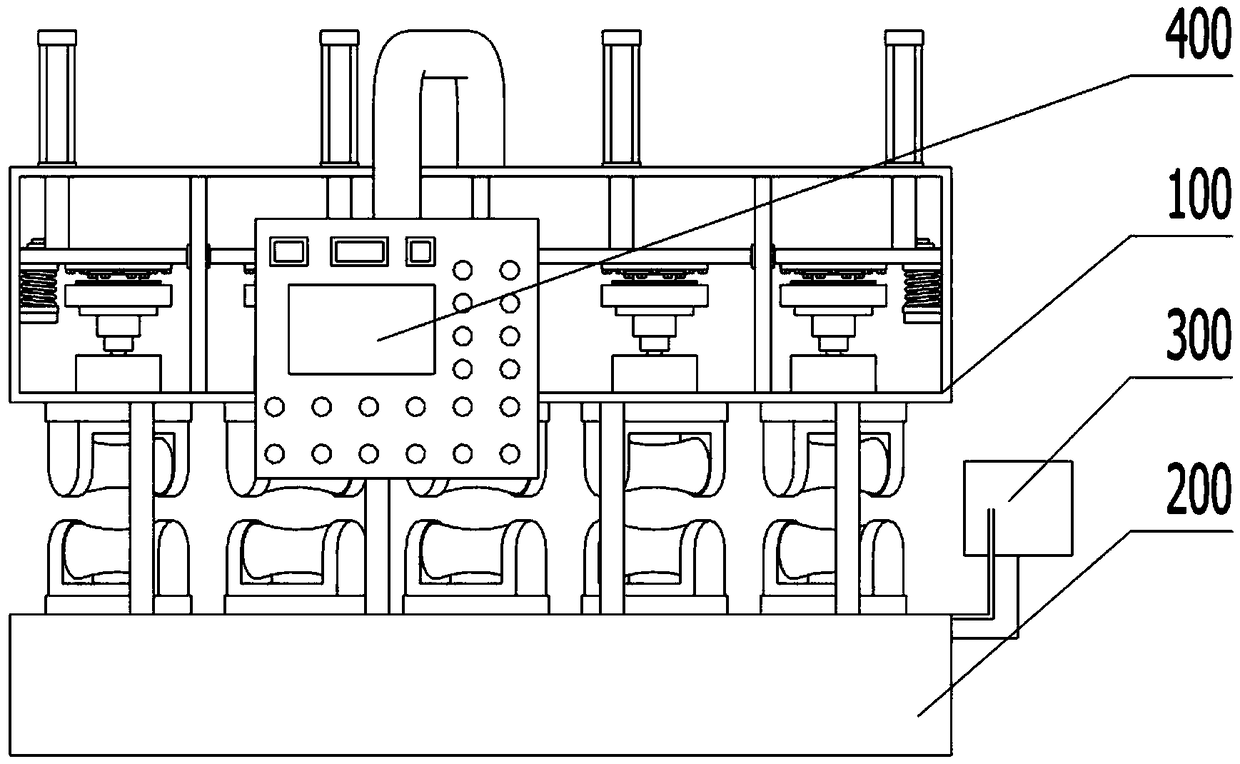

[0061] like Figure 1-3 As shown, a stable steel pipe straightening device includes: a first cabinet 100, the first cabinet 100 is provided with at least two first straightening rollers 500, the first straightening rollers 500 are arranged in a straight line, To straighten steel pipes; a second cabinet 200, the second cabinet 200 is arranged below the first cabinet 100, the second cabinet 200 is provided with a second straightening roller 600, and the second straightening roller 600 and the first straightening roller 500 are set to the same number; the direction adjustment device 800, the direction adjustment device 800 is respectively set corresponding to the first straightening roller 500 and the second straightening roller 600; each of the The direction adjustment device 800 is correspondingly connected to each of the first straightening rollers 500 or each of the second straightening rollers 600, the first cabinet 100 is provided with a pressing plate 110, and the bottom o...

Embodiment 2

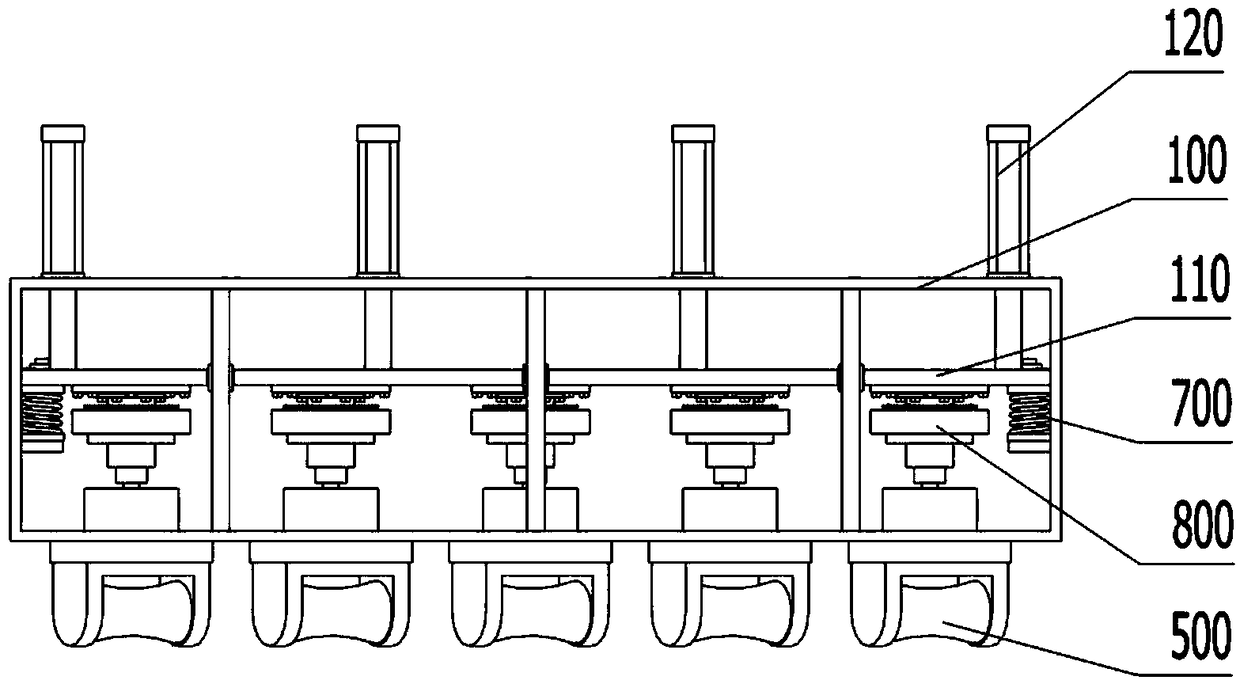

[0064] like figure 2 , Figure 7 As shown, a stable steel pipe straightening device, on the basis of the first embodiment, also includes: vertical rails 111, the vertical rails 111 are arranged symmetrically before and after the pressure plate 110; the first cabinet 100 is provided with telescopic cylinders 120, the telescopic cylinder 120 is connected to the press plate 110, and the telescopic cylinder 120 is correspondingly arranged above the vertical rail 111. By setting the press plate 110 and the vertical rail 111, the first straightening roller 500 on the press plate 110 can be Slide along the vertical rail 111, and the telescopic cylinder 120 pushes the pressure plate 110 to move on the vertical rail 111, so as to realize the straightening of steel pipes with different diameters;

[0065] Specifically, such as Figure 8-10 As shown, the vertical rail 111 is provided with a slider 112, the two sides of the slider 112 and the two sides of the vertical rail 111 are prov...

Embodiment 3

[0067] like figure 2 , Figure 11 As shown, a stable steel pipe straightening device, on the basis of Embodiment 2, also includes: an elastic device 700, the elastic device 700 is arranged on both sides of the pressure plate 110, and the first straightening roller is buffered by the elastic device 700 500 drops to prevent it from being too fast and directly pressing against the steel pipe to cause deformation of the steel pipe;

[0068] Specifically, such as Figure 12As shown, the elastic device 700 includes a long plate 710, which is horizontally fixed on the inner surface of the first chassis 100, a lower shell 720 is arranged on the upper side of the long plate 710, and a lower shell 720 is arranged on the lower side of the pressing plate 110. There is an upper shell 770, and a spring 730 is arranged between the upper shell 770 and the lower shell 720; the elastic device 700 also includes a through pipe 740, and the through pipe 740 is fixed on the long plate 710, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com