Patents

Literature

135results about How to "Avoid left and right offset" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

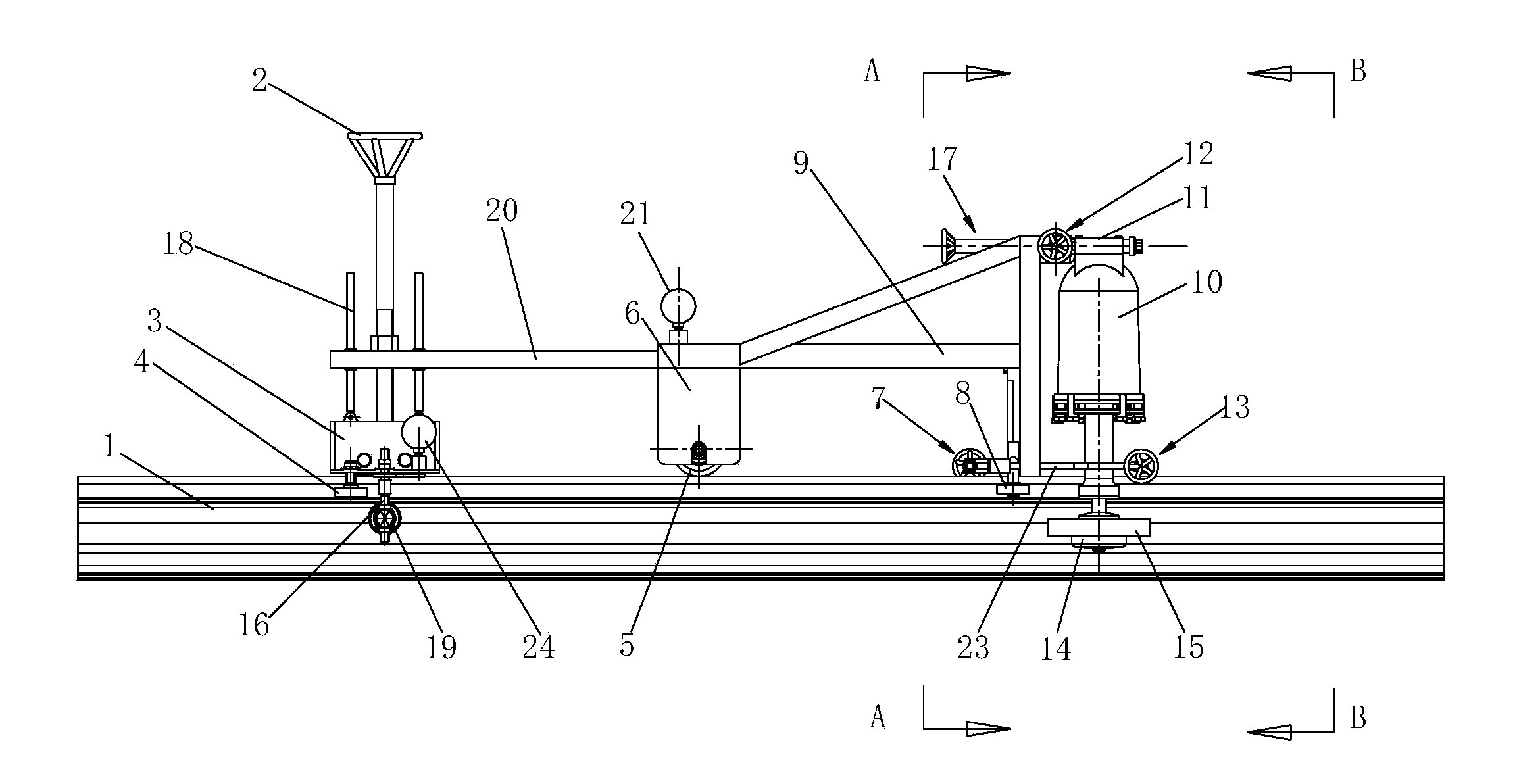

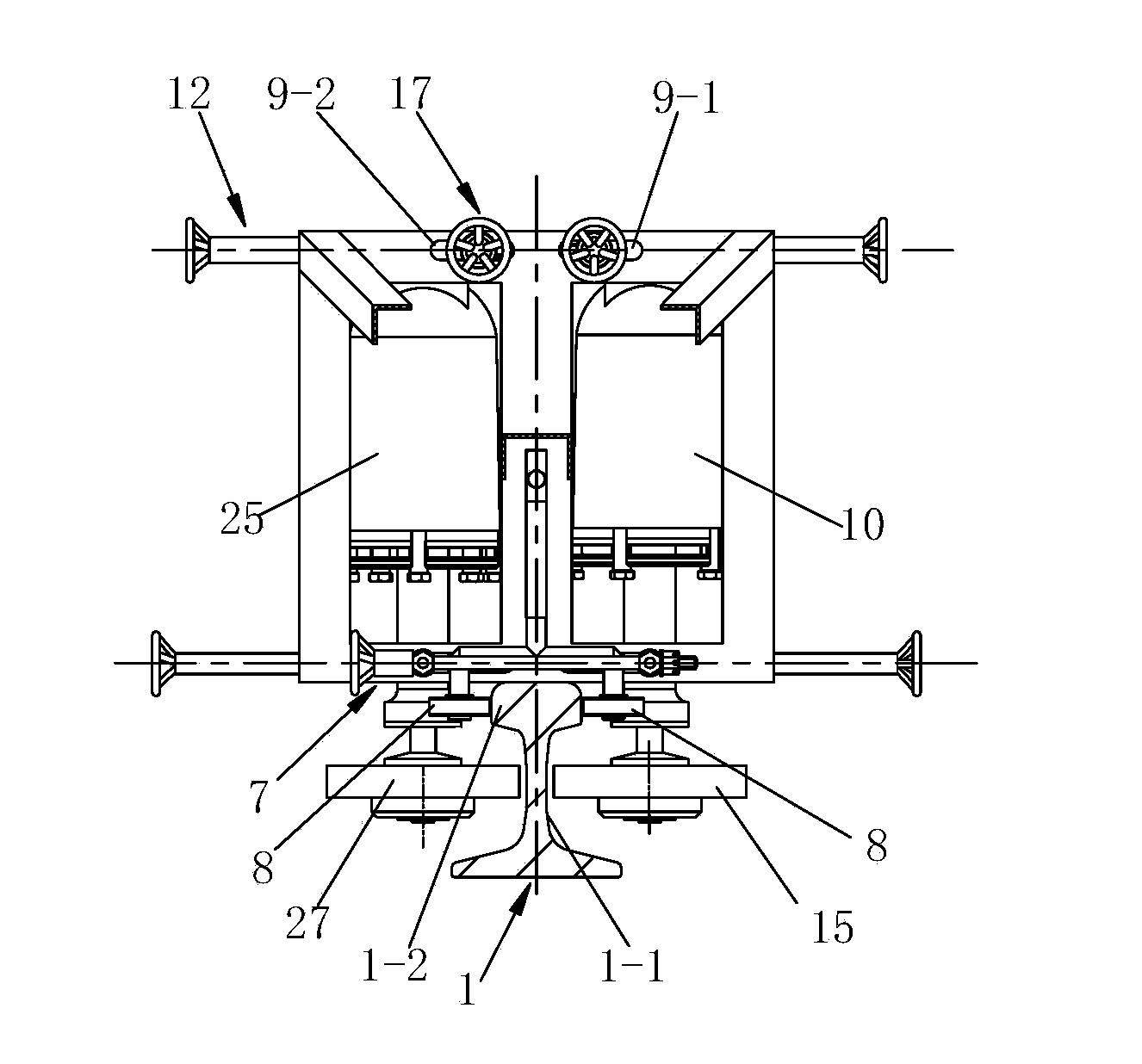

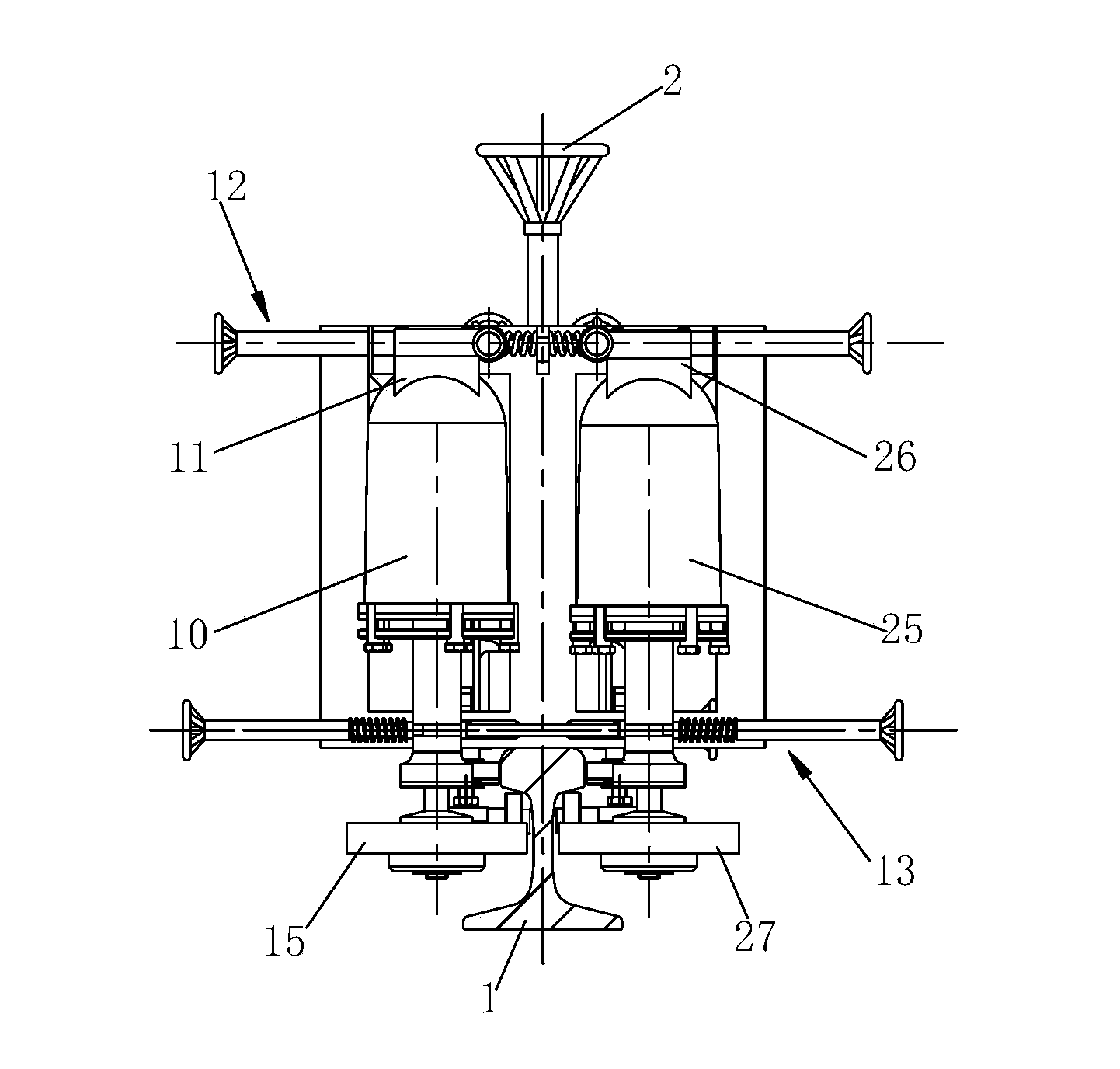

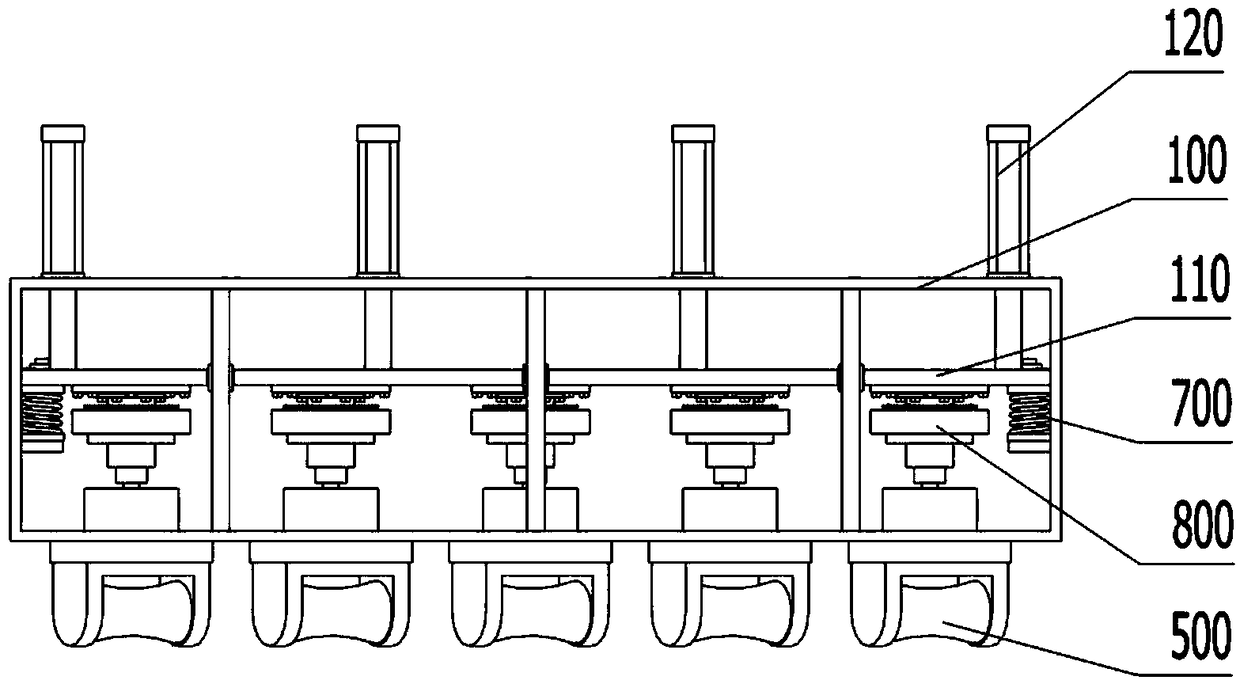

Rail web rust removal sander

The invention discloses a rail web rust removal sander. The rail web rust removal sander comprises a first abrasion wheel for sanding left side face of a rail web of a steel rail, a second abrasion wheel for sanding right side face of the rail web of the steel rail, and a main frame, wherein one end of the main frame is provided with a tail travelling frame while the other end thereof is provided with a first fixing frame and a second frame, a first work head for driving the first abrasion wheel to rotate is mounted on the first fixing frame, a second work head for driving the second abrasion wheel to rotate is mounted on the second fixing frame, the left and right sides of the tail travelling frame both are provided with travelling wheels travelling along the lower bottom surface of the rail jaw of the steel rail, two first guide wheels respectively travelling along the left side face and the right side face of the rail jaw of the steel rail are mounted on the tail travelling frame, and one end, away from the tail travelling frame, of the main frame is provided with two second guide wheels respectively travelling along the left side face and the right side face of the rail jaw. The rail web rust removal sander runs steadily, has a good sanding effect, and is simple in structure, convenient to disassemble and assemble, and convenient to generalize and use.

Owner:CHINA RAILWAY FIRST GRP CO LTD +1

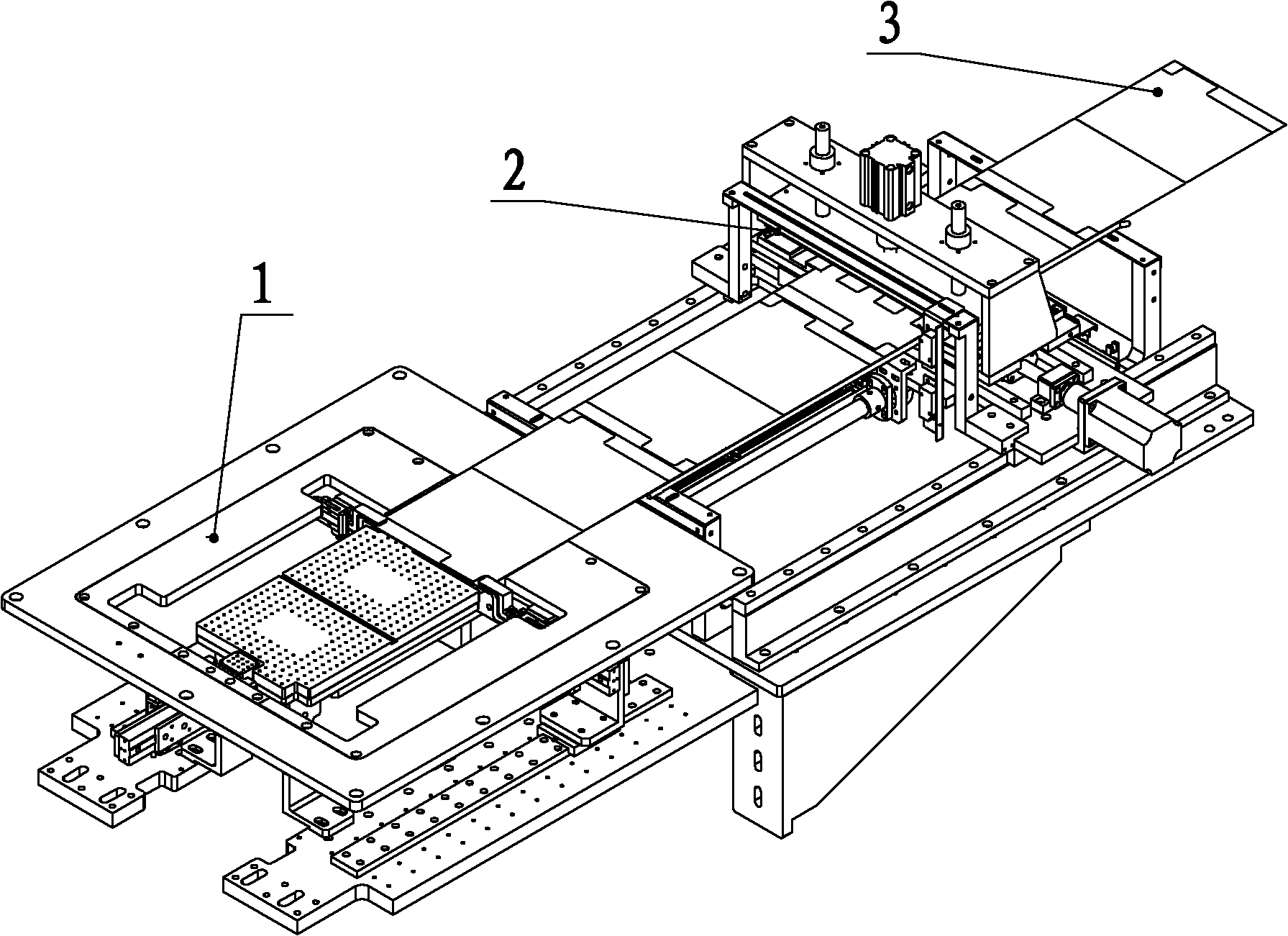

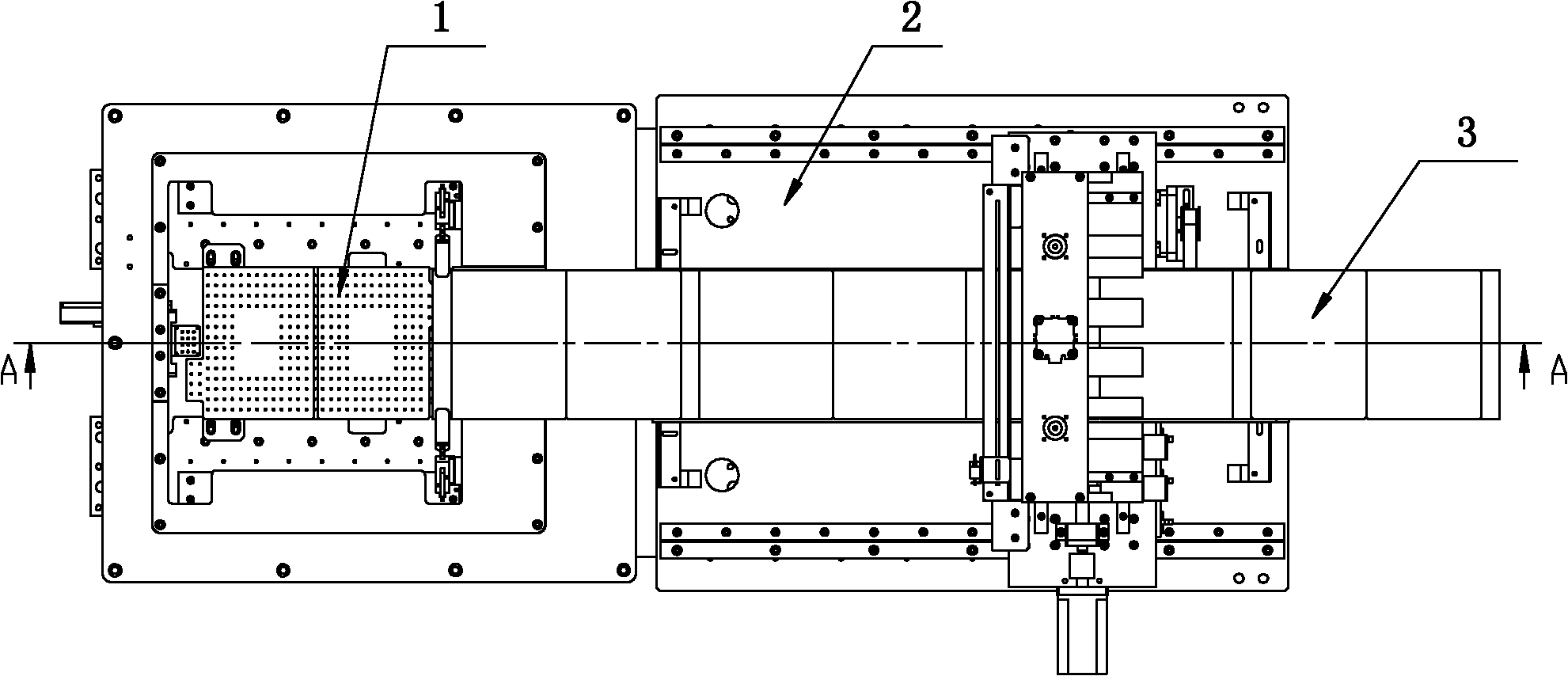

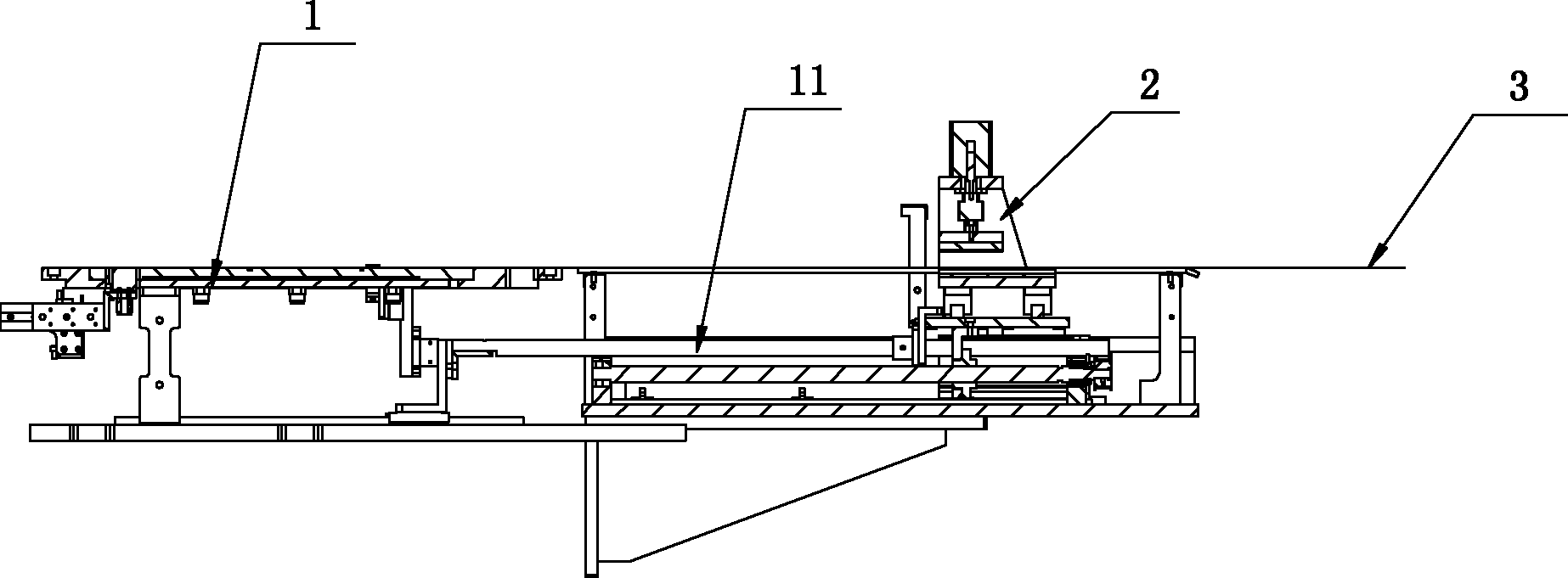

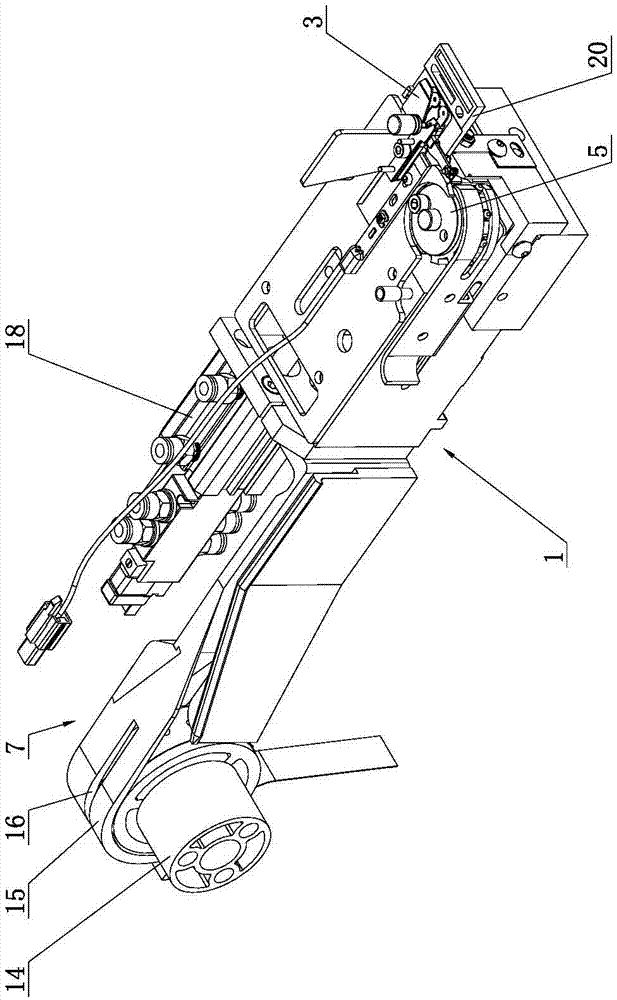

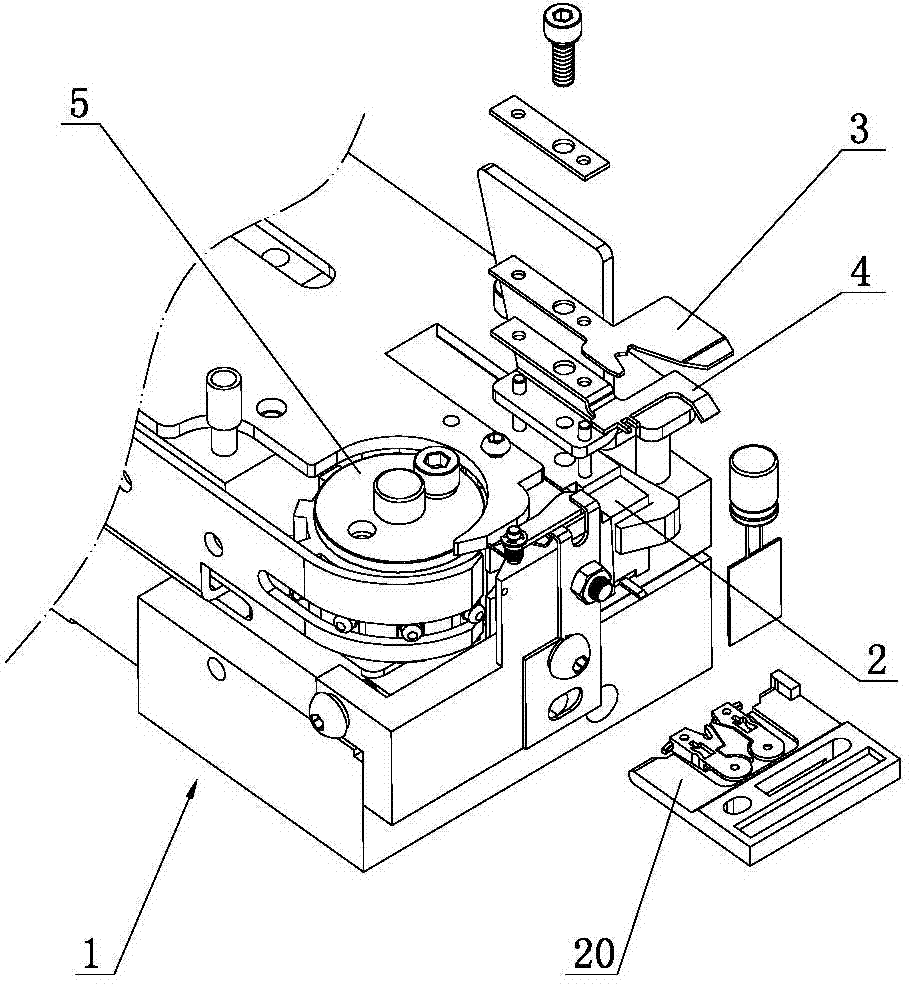

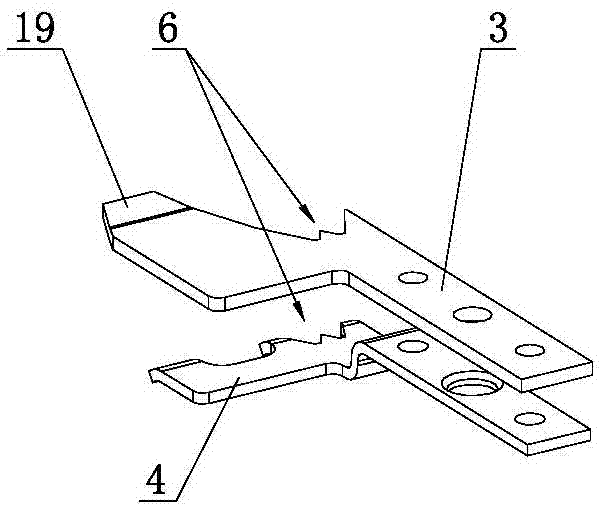

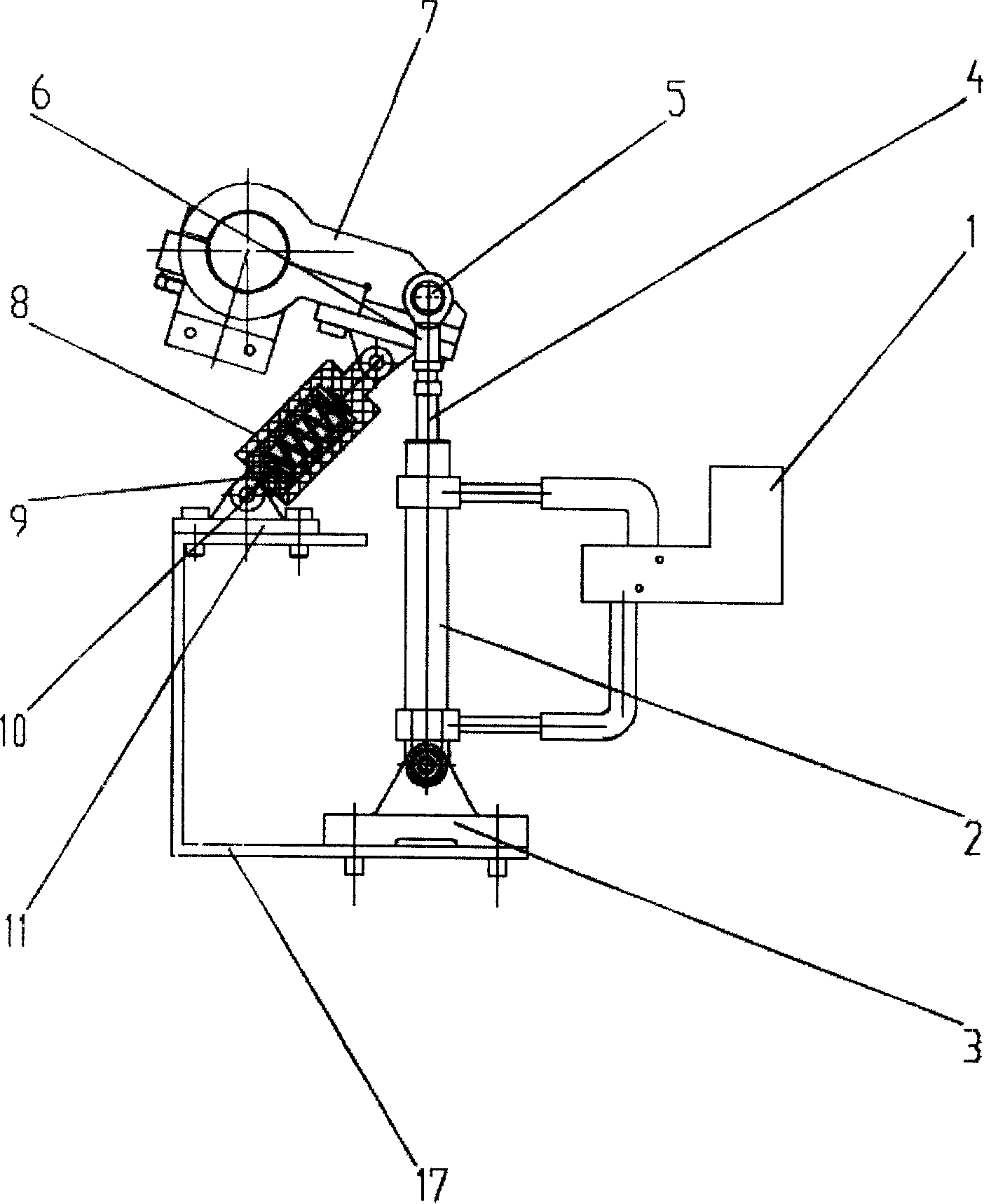

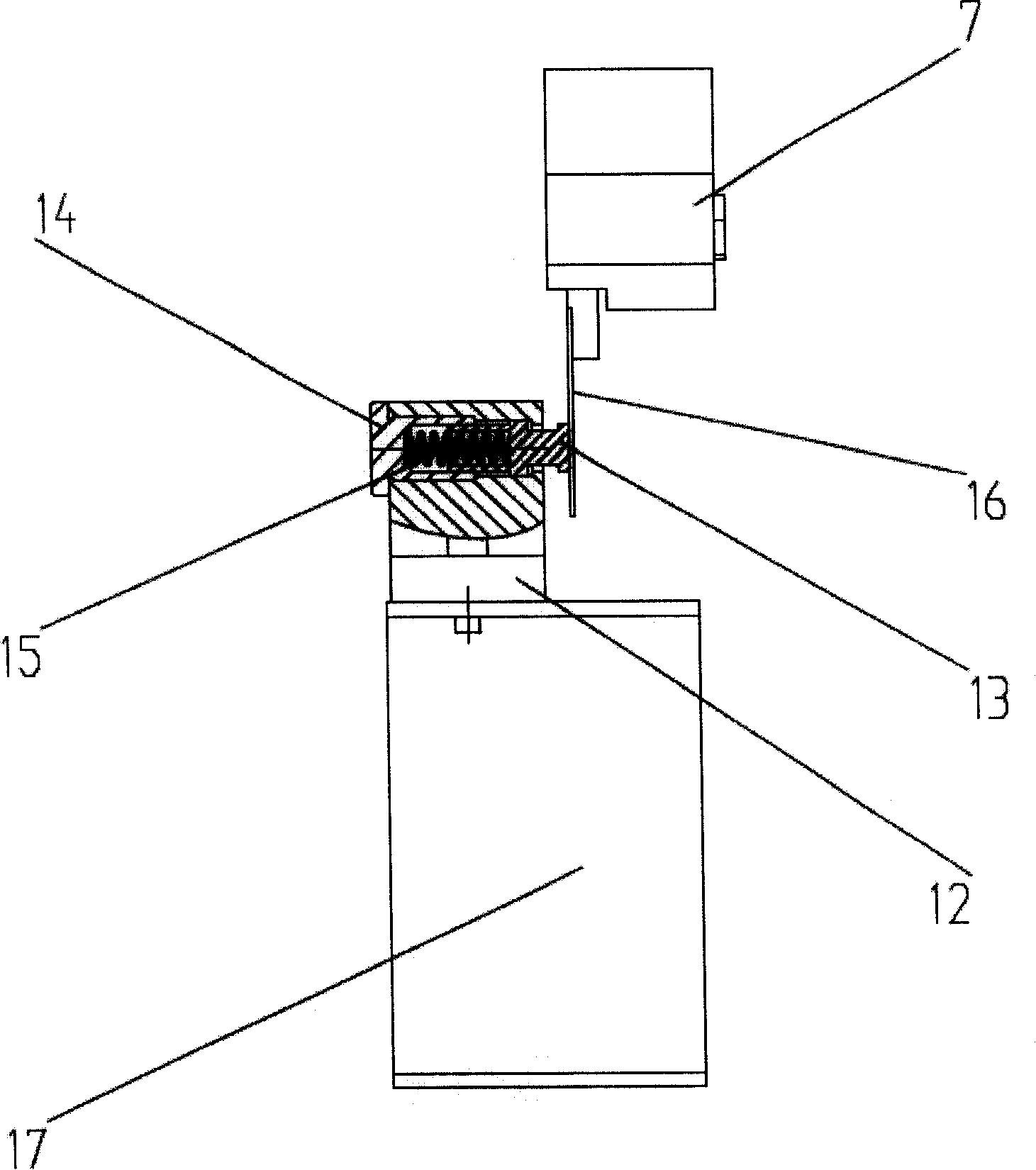

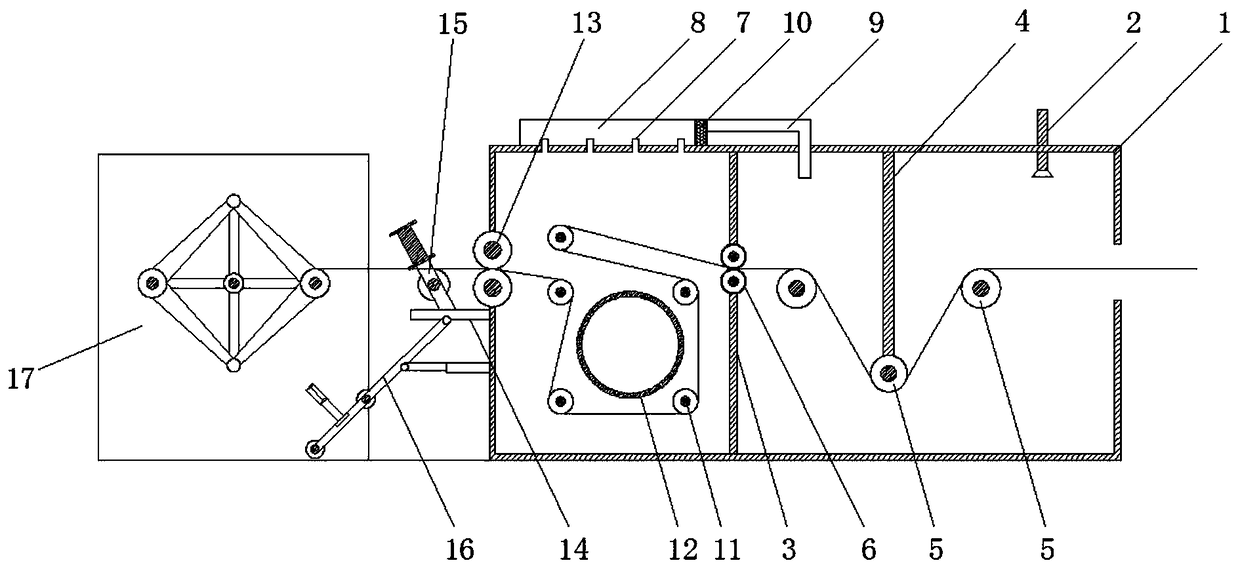

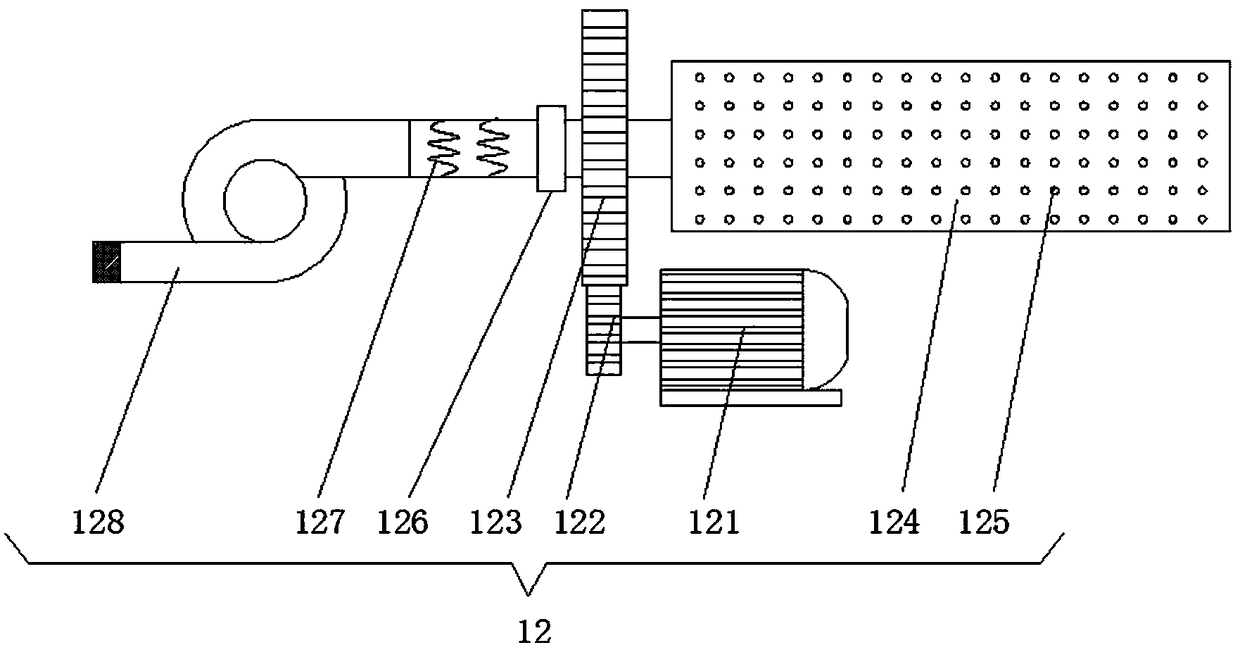

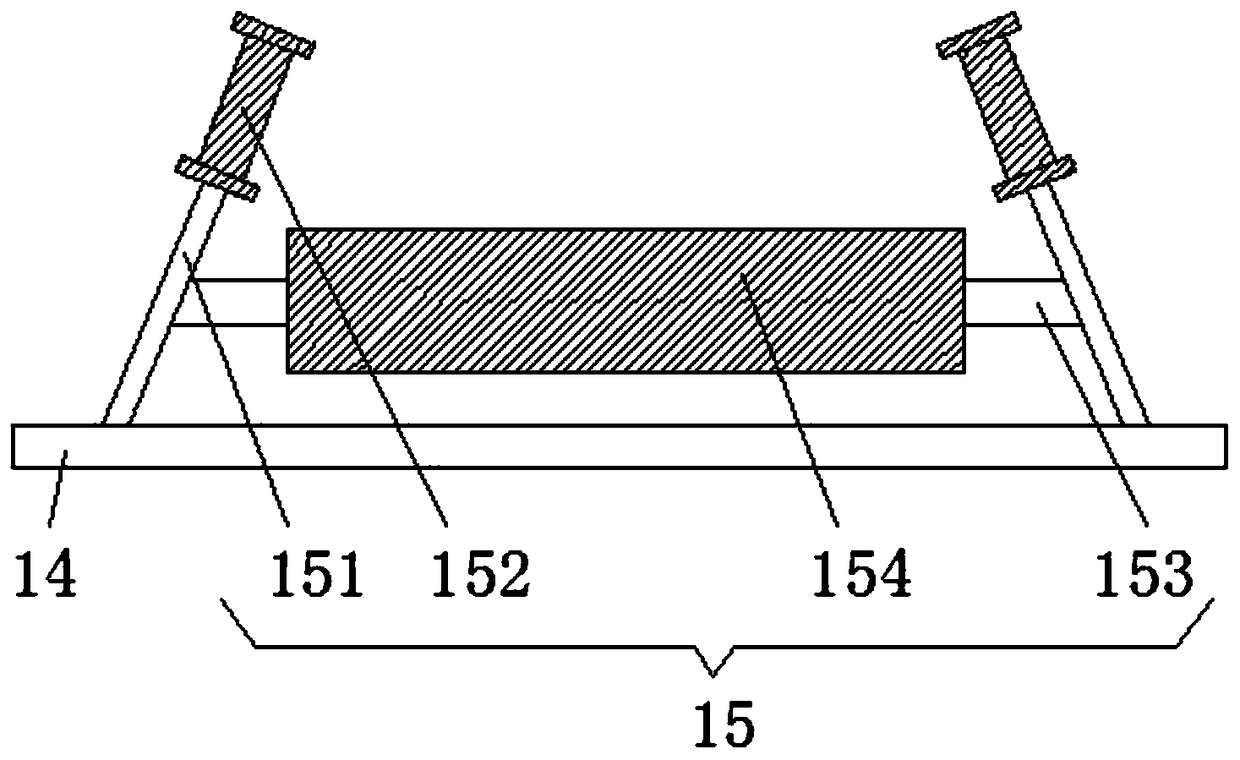

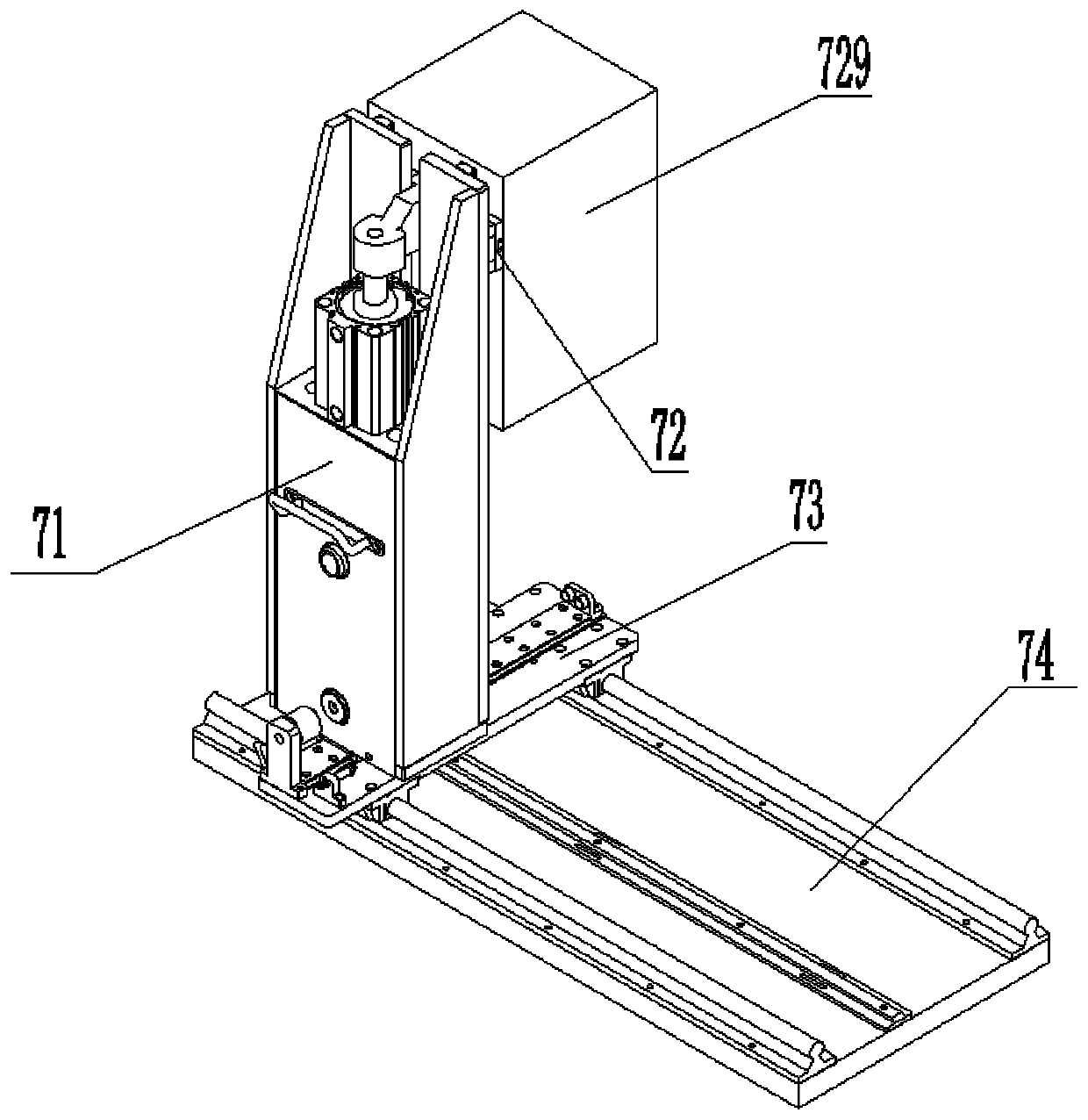

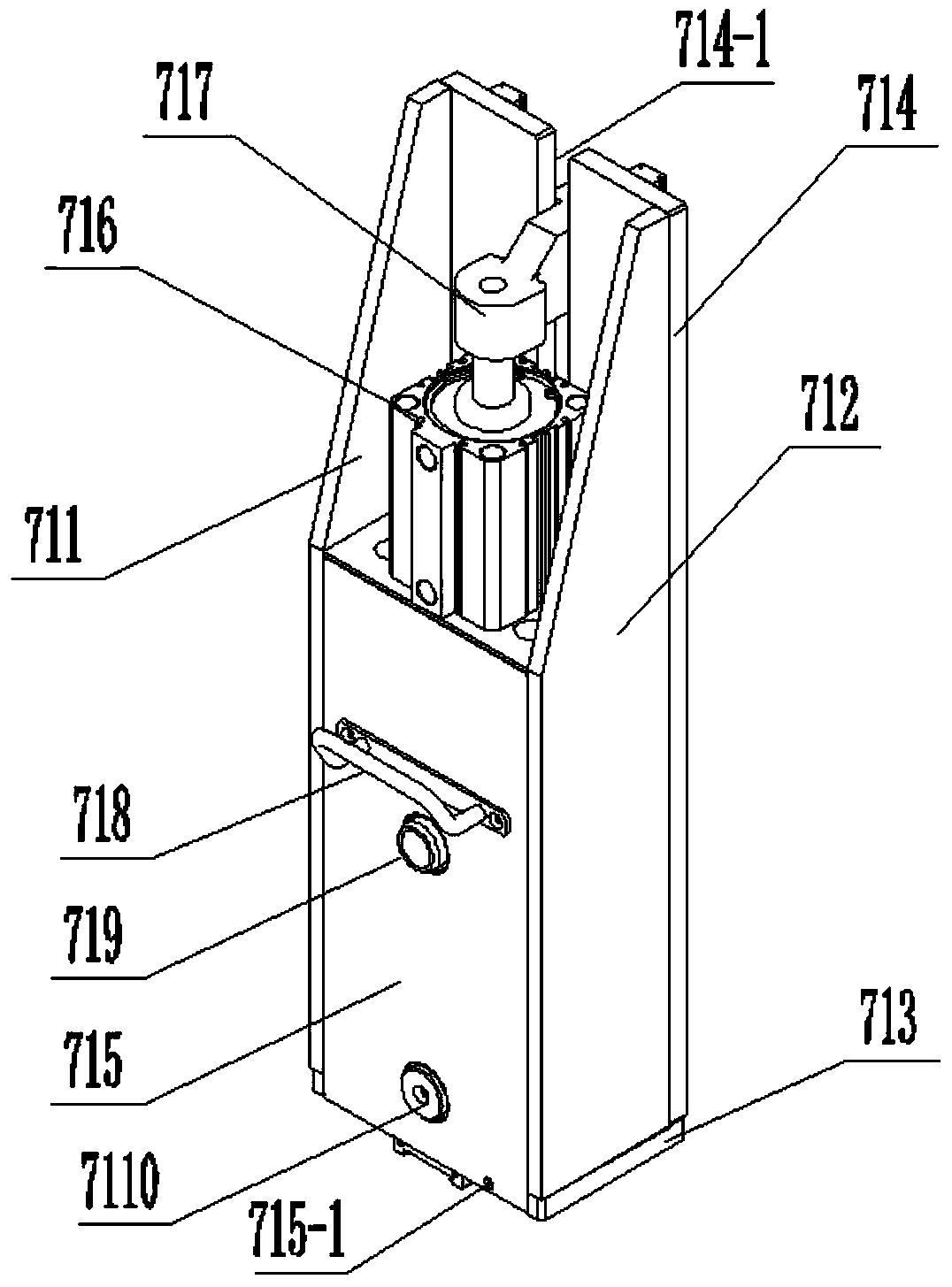

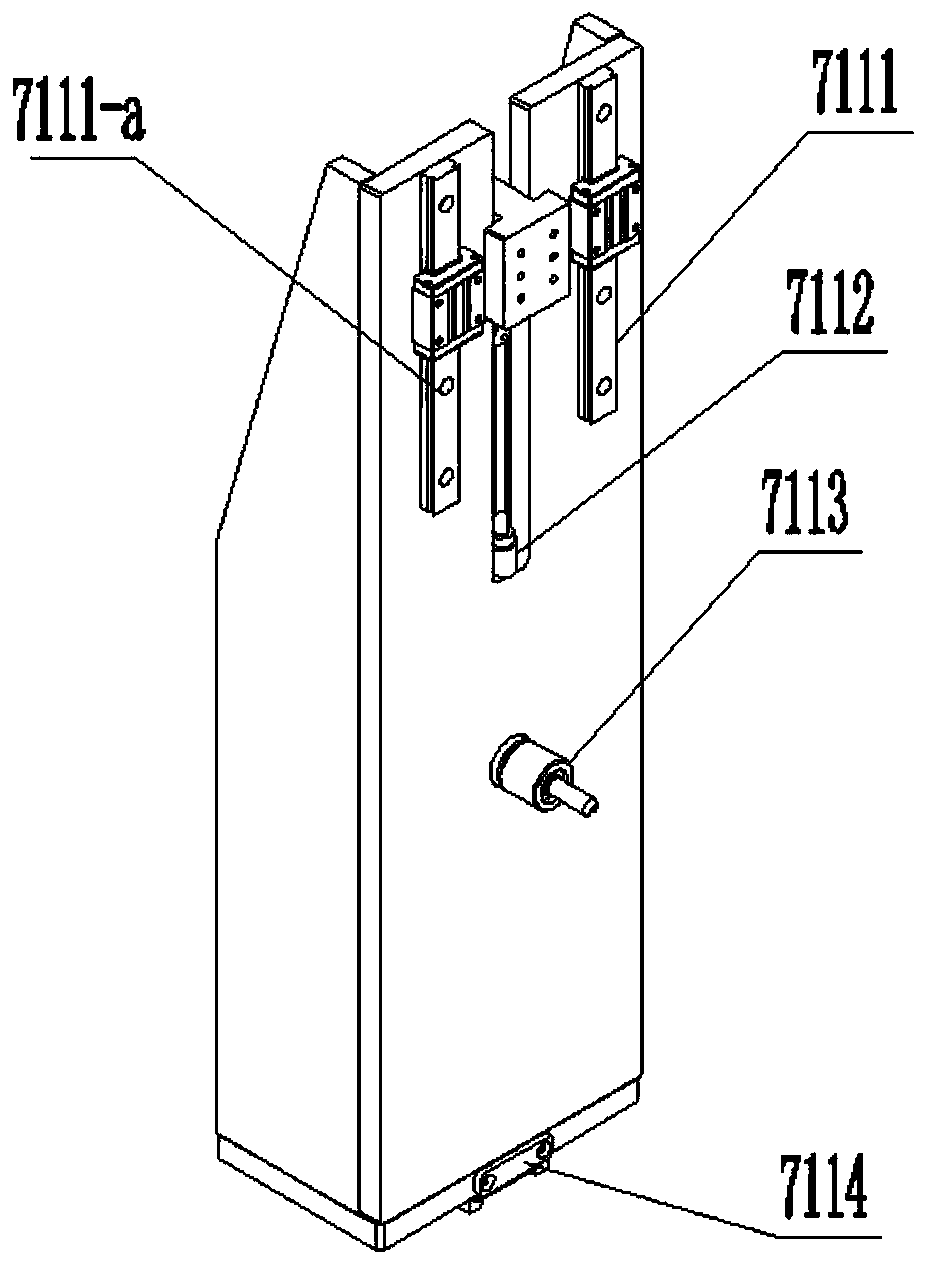

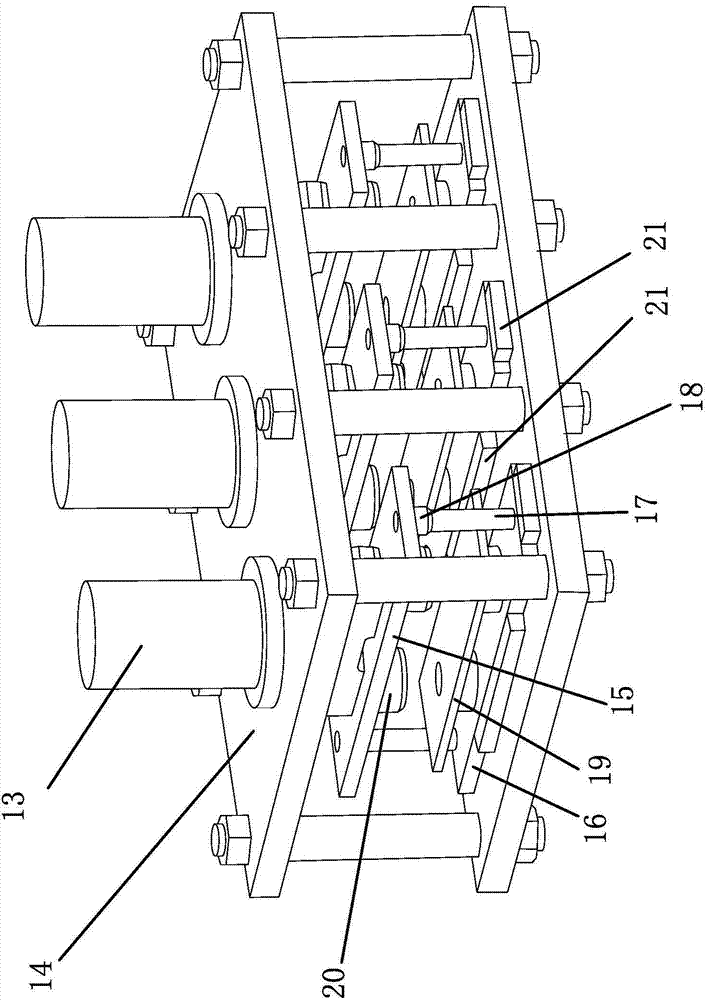

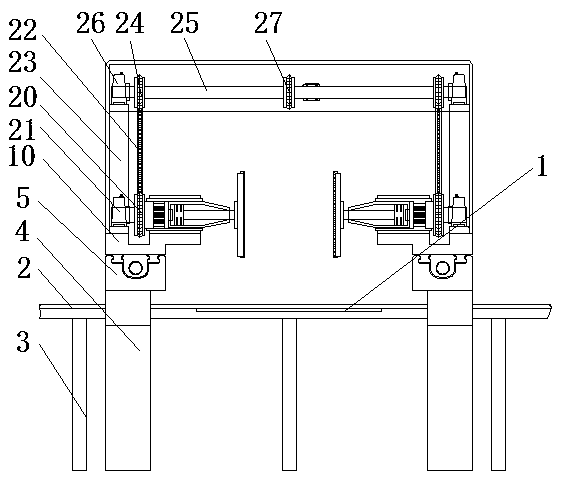

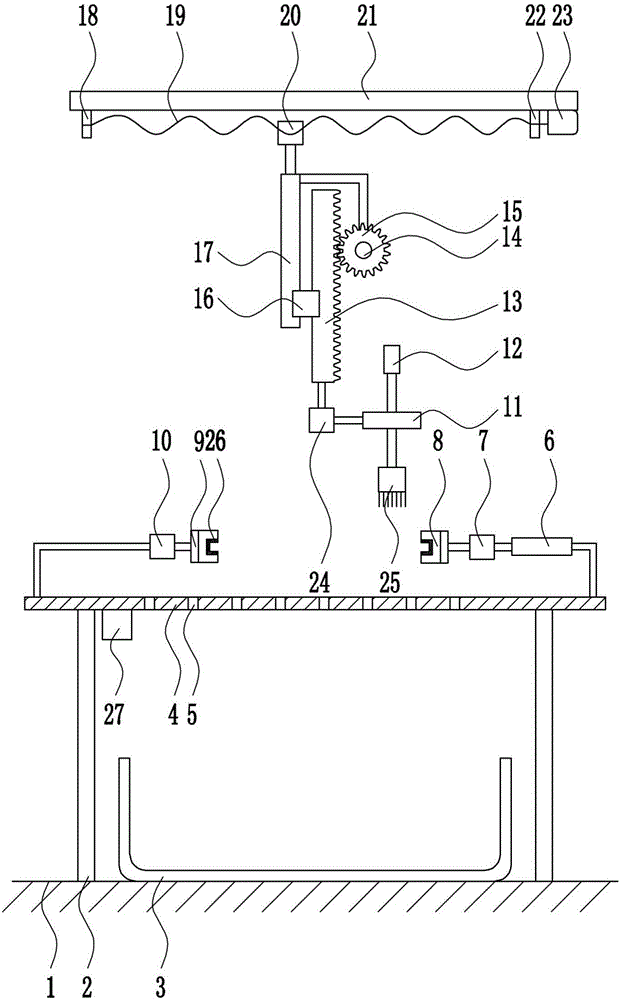

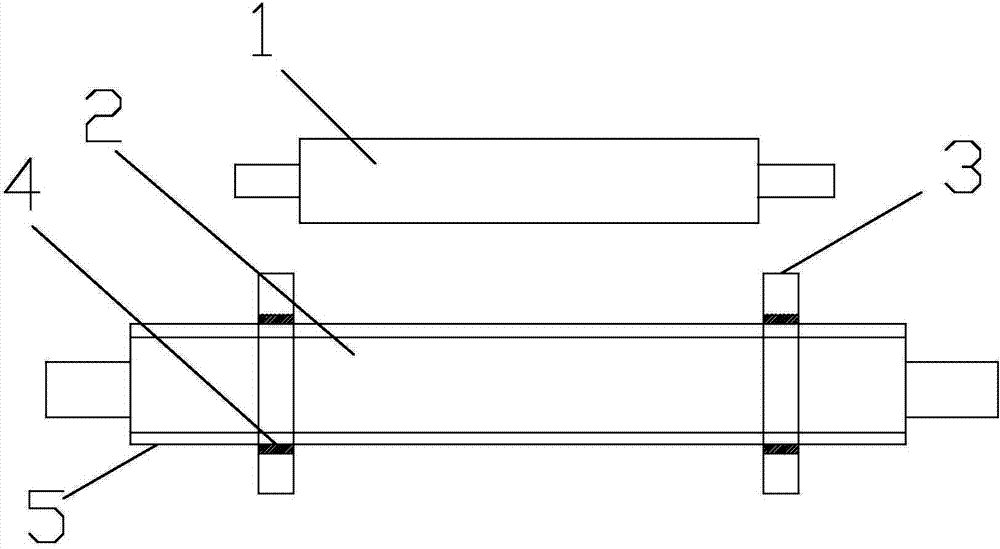

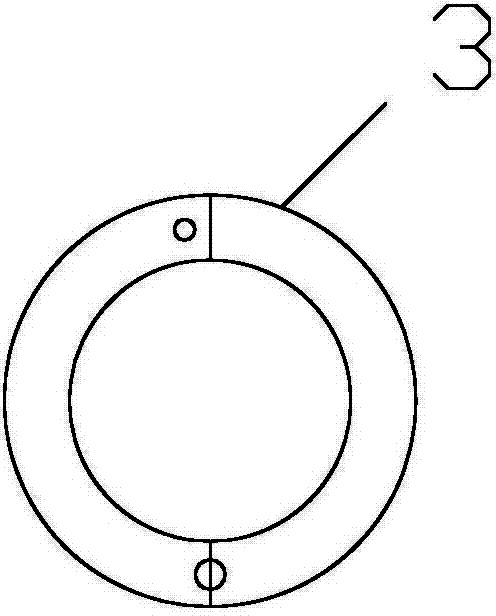

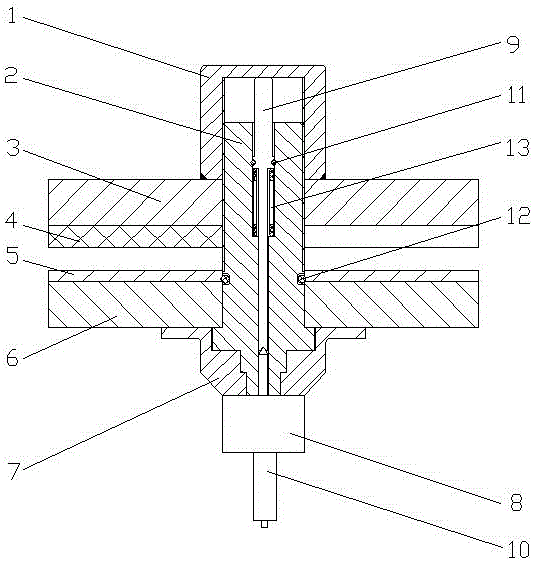

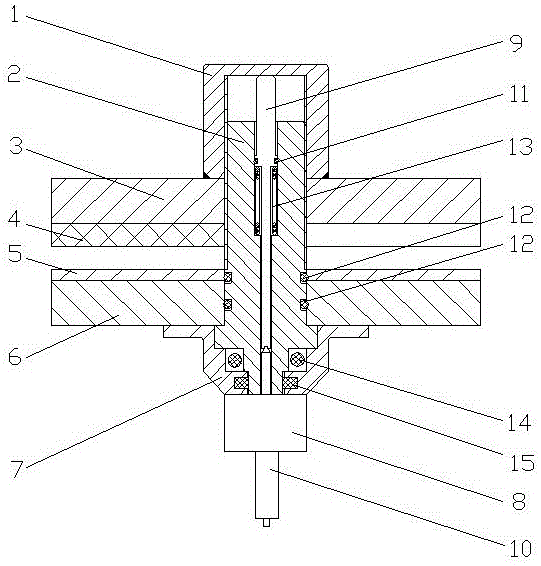

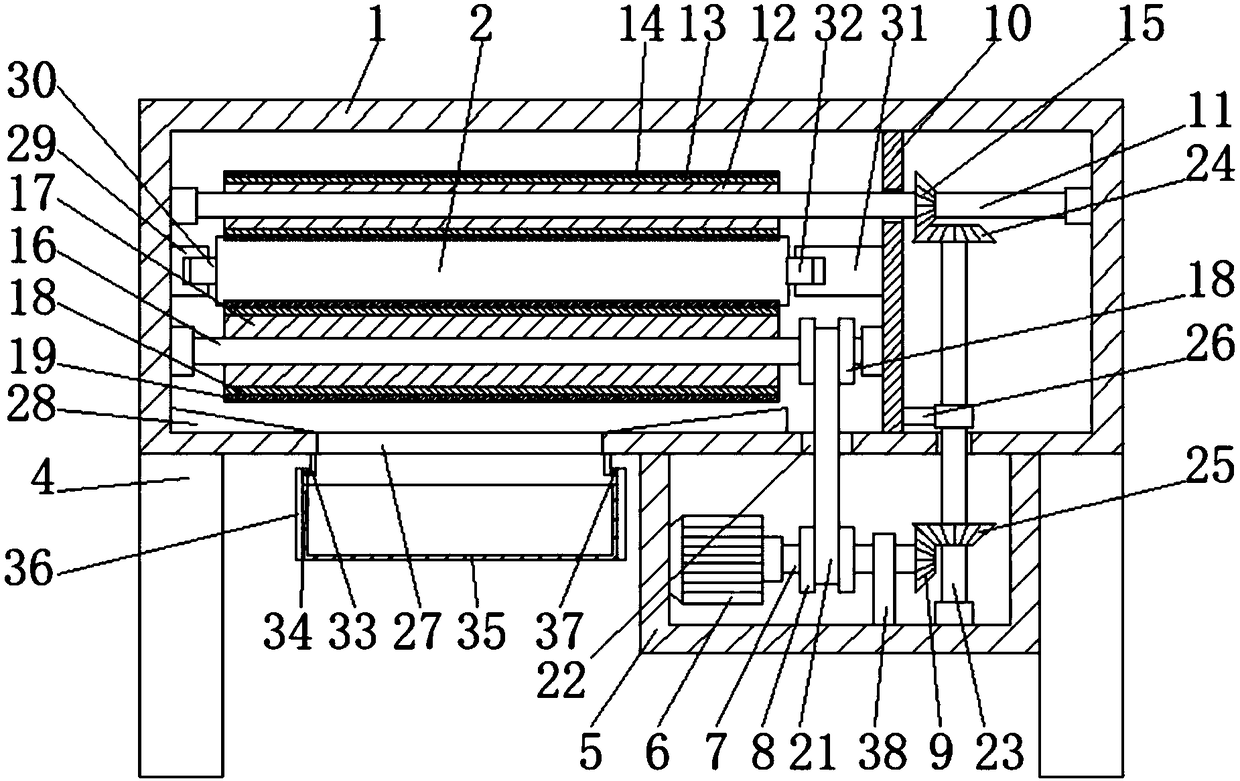

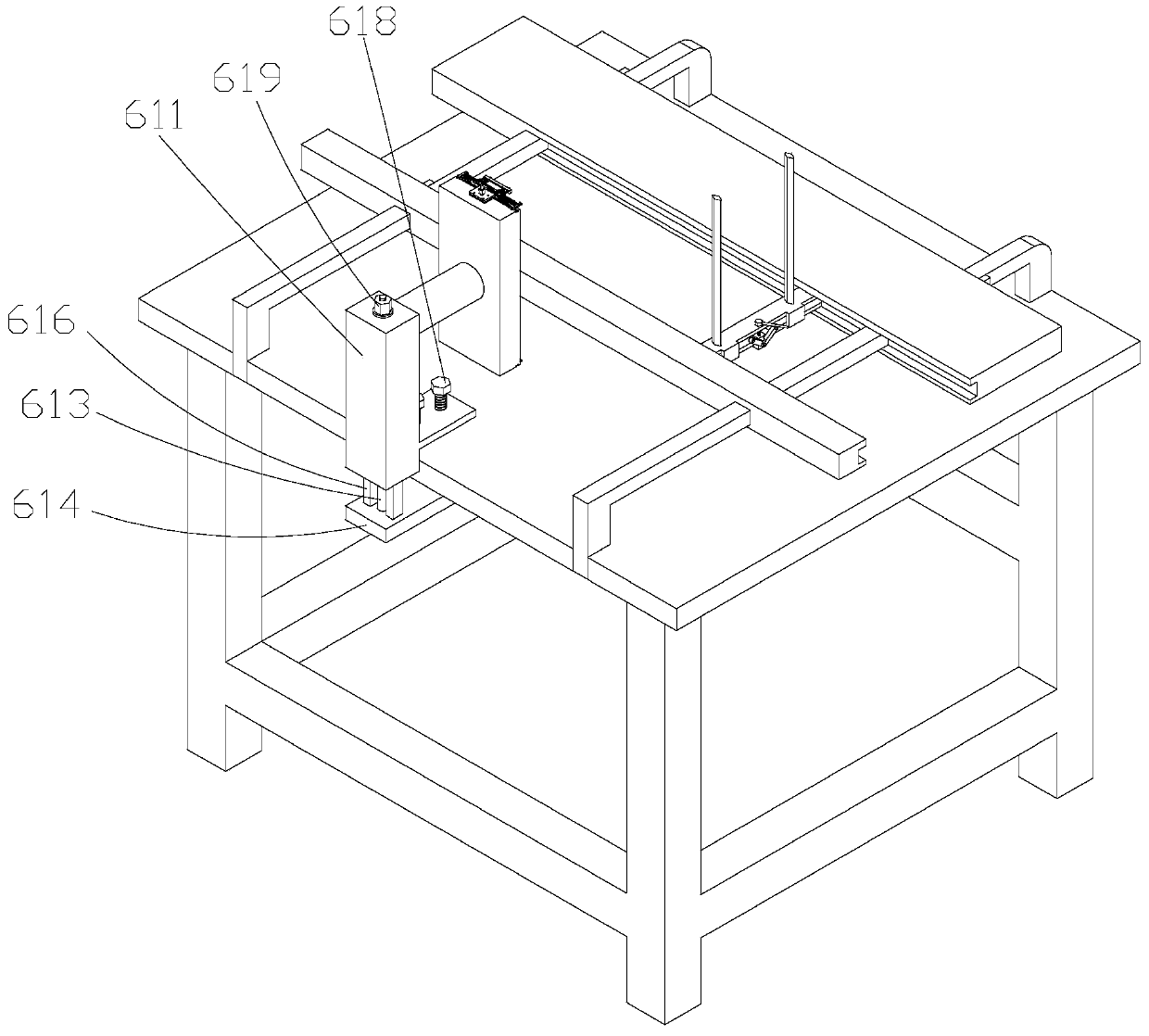

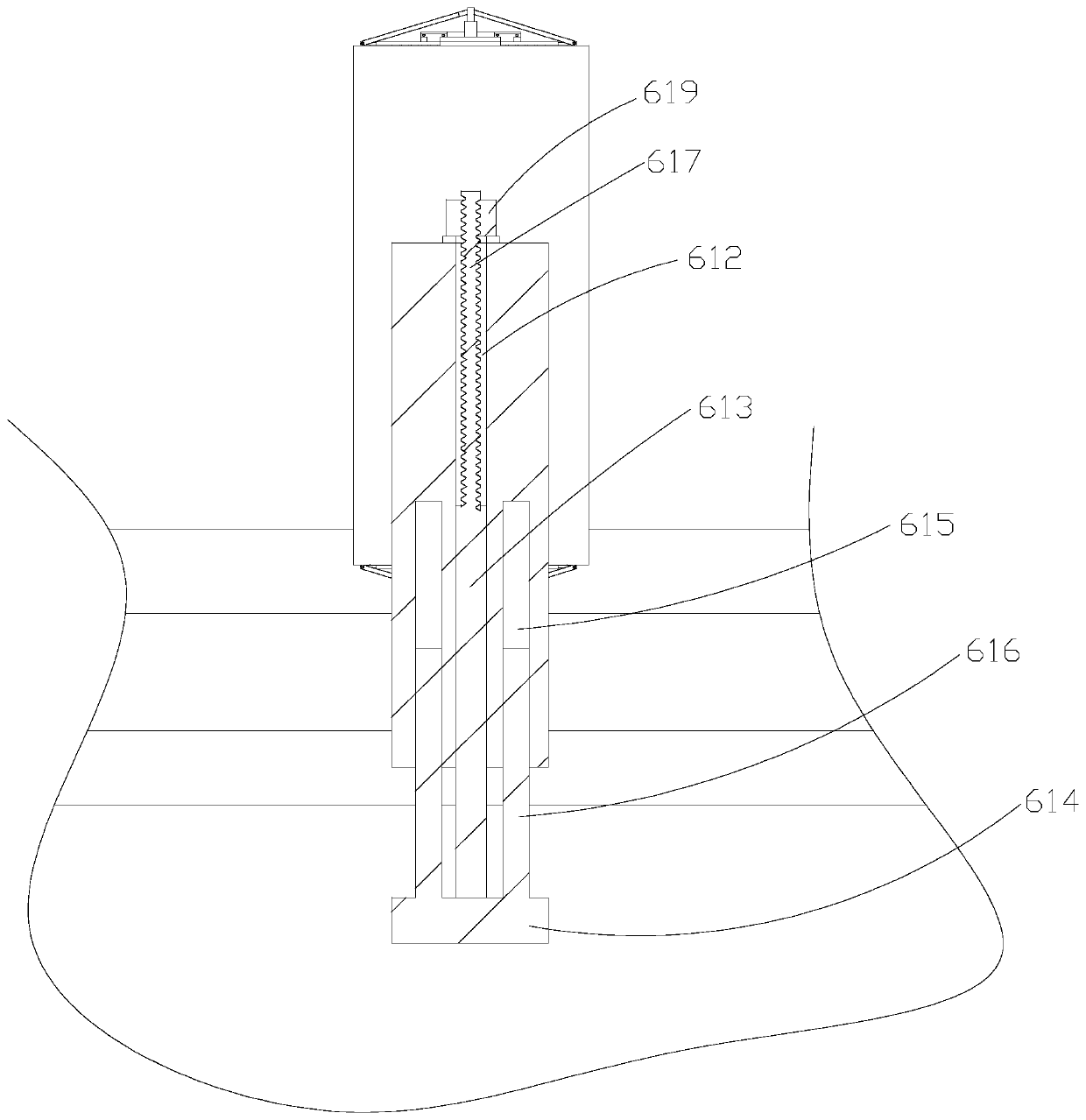

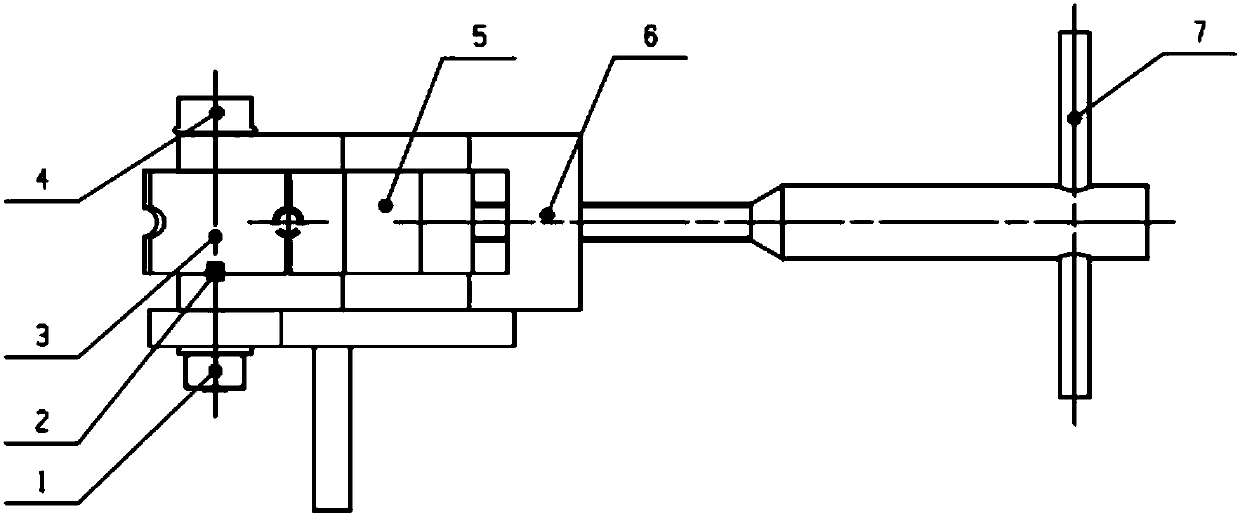

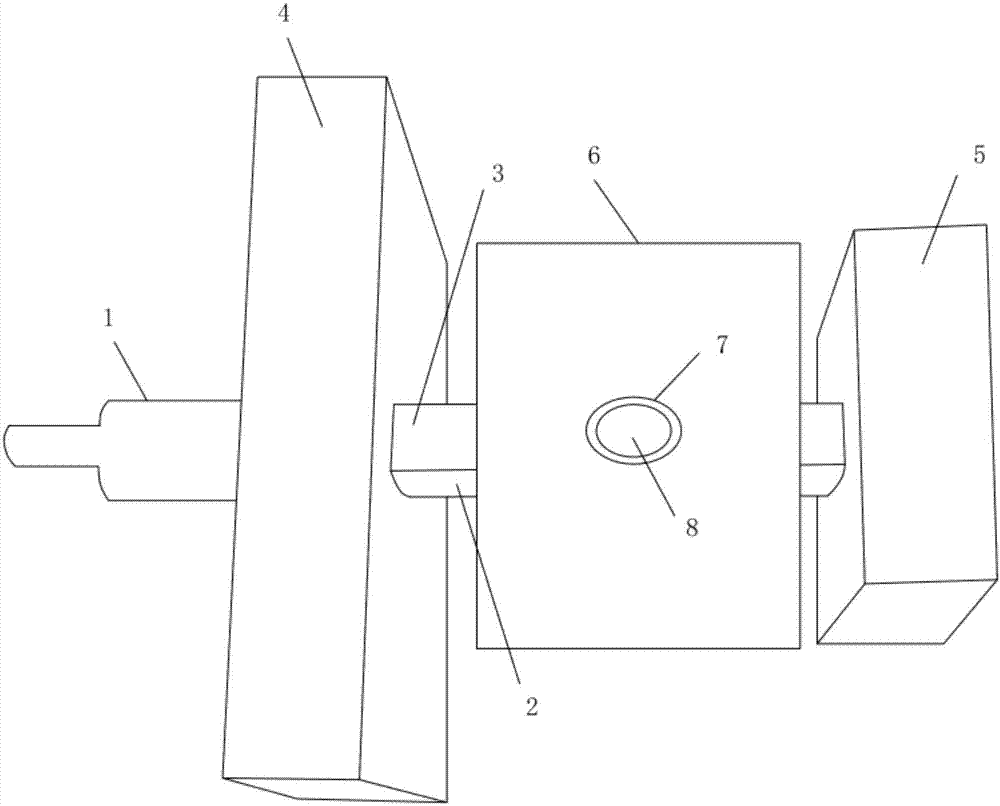

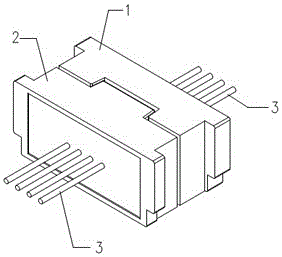

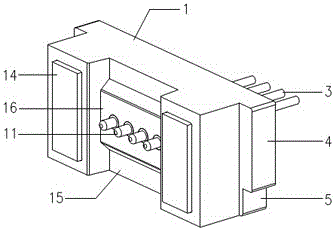

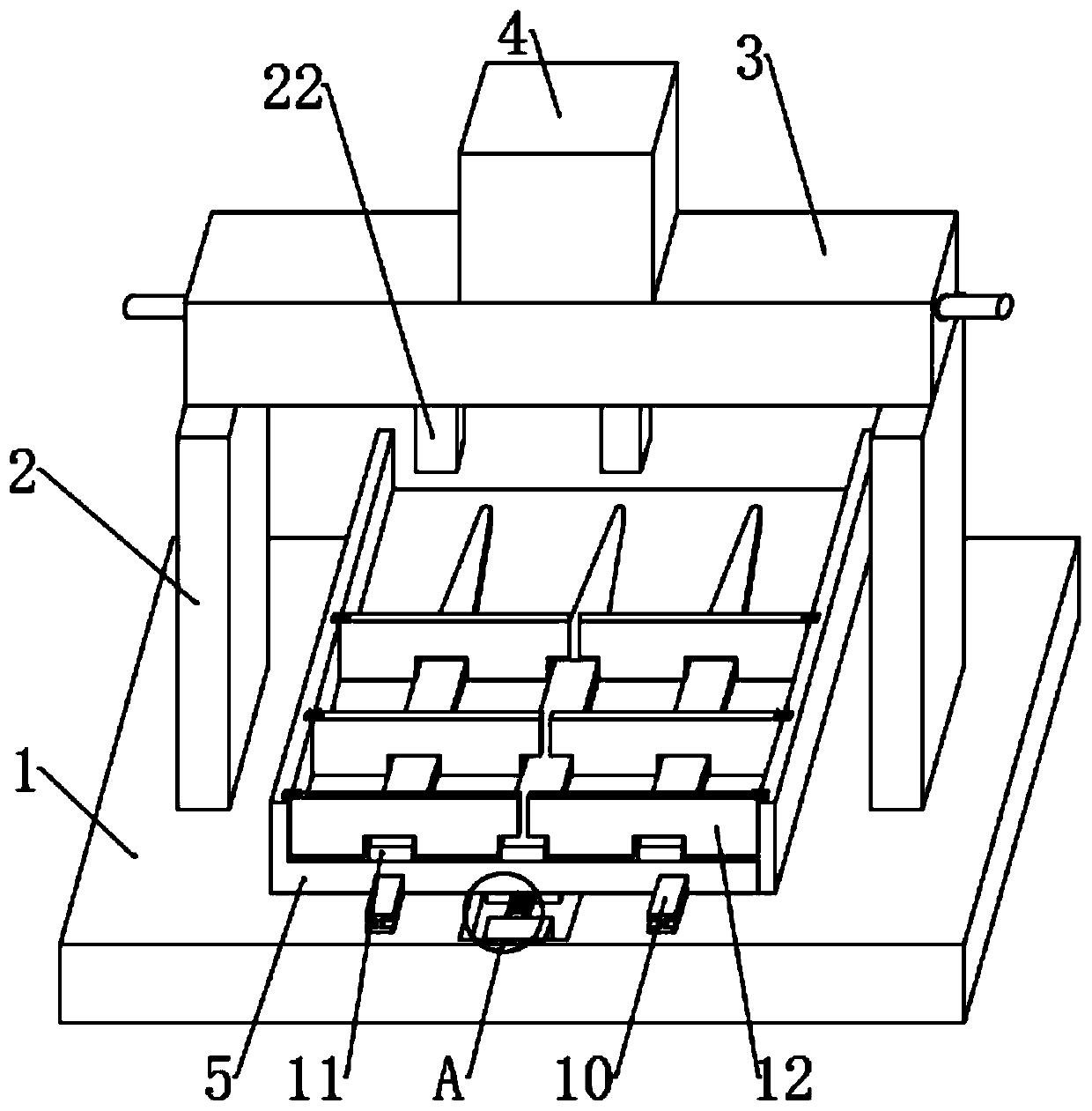

Pole piece feeding device

ActiveCN102642150AOvercome deformation and wrinklingAvoid left and right offsetMetal working apparatusManipulatorEngineering

The invention discloses a pole piece feeding device. The device comprises a material clamping manipulator part and a feeding fixed-length part, wherein the material clamping manipulator part comprises push rods and a first material clamping mechanism for clamping the front part of a pole piece; the feeding fixed-length part comprises a second material clamping mechanism for clamping the middle part of the pole piece and a feeding mechanism for driving the second material clamping mechanism to move back and forth; the first material clamping mechanism is installed at the front ends of the push rods; and the second material clamping mechanism is installed at the rear ends of the push rods. The device can be widely used for conveying and cutting such pole pieces as battery pole pieces and super capacitor pole pieces, can solve the problem that the pole pieces are easy to deform and wrinkle in the conveying process in the prior art, simultaneously avoids feeding fixed-length out of tolerance and left and right offset through fixed-length feeding and rectification control, reduces the size error of the pole piece and obviously improves the quality of the pole piece feeding process.

Owner:GEESUN AUTOMATION TECH

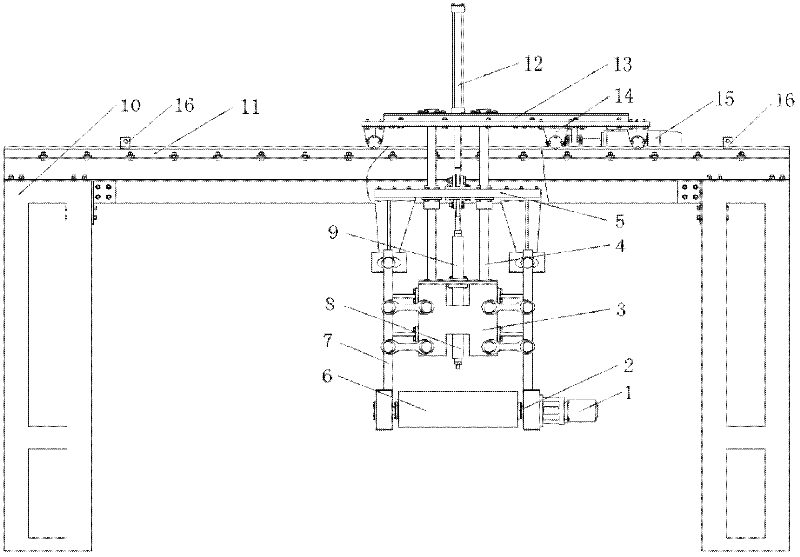

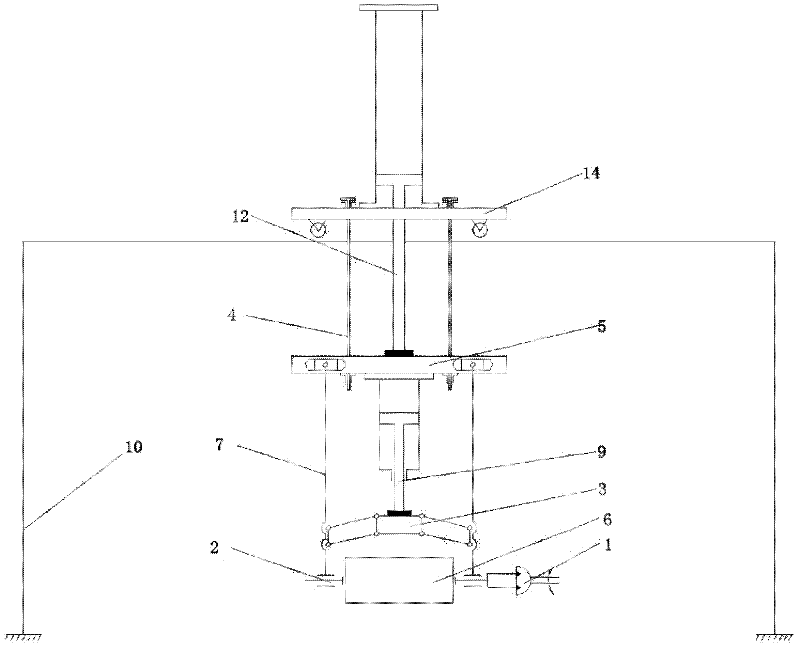

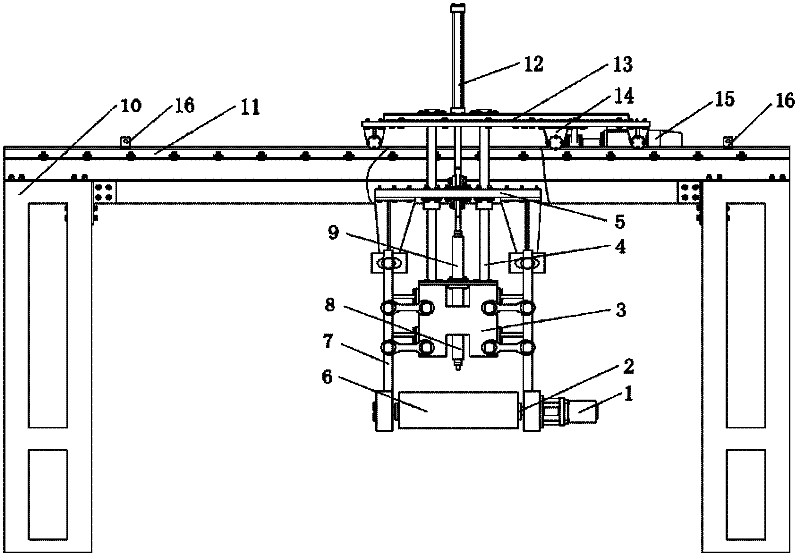

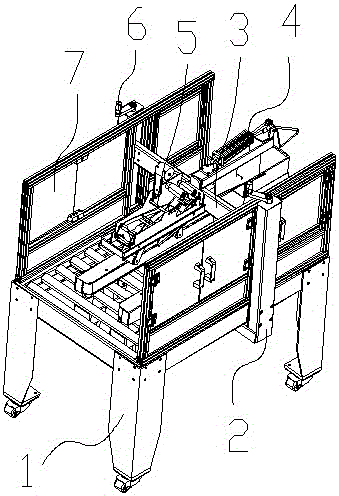

Multifunctional gantry type manipulator

InactiveCN102241013ARealize lifting movementLevel of achievementProgramme-controlled manipulatorProduction lineHydraulic cylinder

The invention relates to a multifunctional gantry type manipulator which comprises a gantry, wherein a rail is mounted on the gantry; a trolley system is mounted on the rail; a guide rod is fixedly mounted on the trolley system; a lifting hydraulic cylinder is also mounted on the trolley system; a piston end of the lifting hydraulic cylinder is connected to a support plate sleeved on the guide rod; holding arms are mounted at two ends of the support plate; the holding arms are moveably connected with the support plate; the two holding arms are connected with each other through a parallel four-rod mechanism; and a holding hydraulic cylinder is mounted between the lower side of the support plate and the parallel four-rod mechanism. The multifunctional gantry type manipulator can be used for automatically carrying and overturning articles (especially the articles with higher temperature and heavier weight), has the advantage of reducing the occupied area for carrying and overturning articles, and is suitable for production line, such as casting, forging, and the like.

Owner:CENT SOUTH UNIV

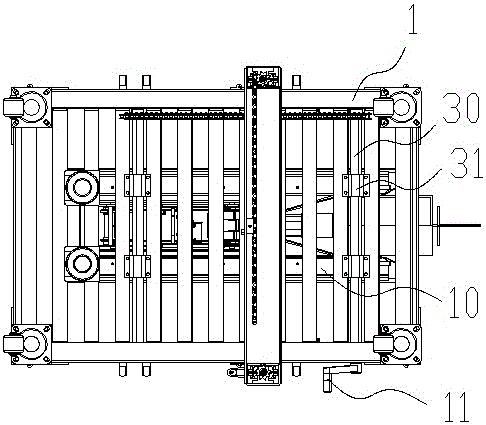

Small vertical element station feeding device

ActiveCN102781209AEasy to load and processImprove performance and stabilityElectrical componentsShortest distanceEngineering

The invention relates to the technical field of an LED (light emitting diode) insertion machine, in particular to a small vertical element station feeding device for an LED insertion machine. The small vertical element station feeding device comprises a station body, an active sliding block and a station driving mechanism which drives the active sliding block to move back and forth, wherein the active sliding block is provided with an upper pushing piece and a lower pushing piece which is arranged right below the upper pushing piece; a feeding wheel rotates intermittently and drives an element material belt to feed forward; when an electronic element on the element material belt stays ahead of the upper pushing piece and the lower pushing piece, the upper pushing piece and the lower pushing piece are driven to move forward together to enable two pins of the electronic element respectively to be embedded in two notches of two W-shaped grooves, so that the electronic element is prevented from offsetting leftwards and rightwards until the electronic element is pushed onto a chain clamp, and the feeding accuracy of the electronic element station is greatly enhanced. The distance between the two notches of each W-shaped groove is shorter so as to carry out feeding processing on the electronic element with shorter distance between the pins.

Owner:海宁经开产业园区开发建设有限公司

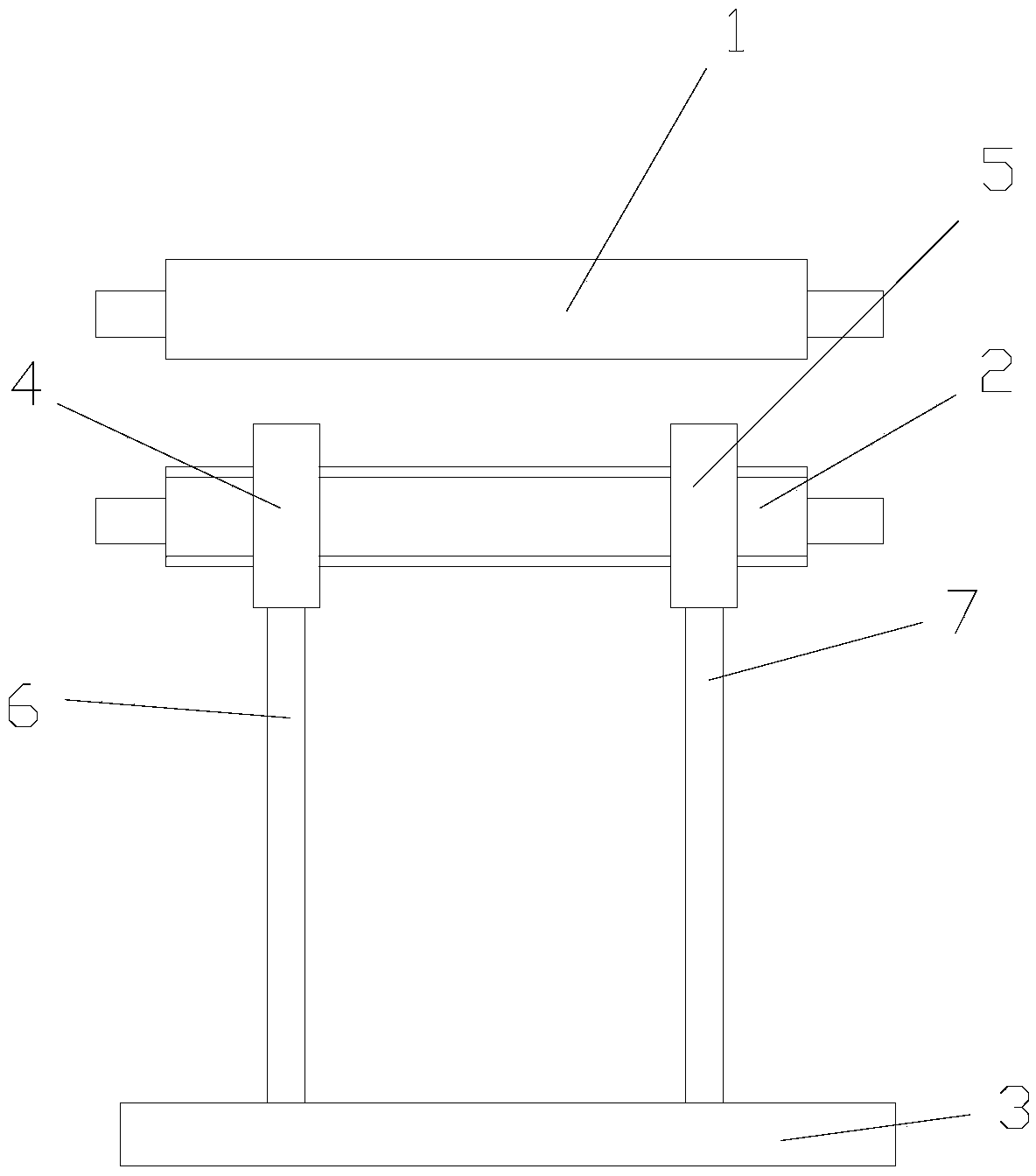

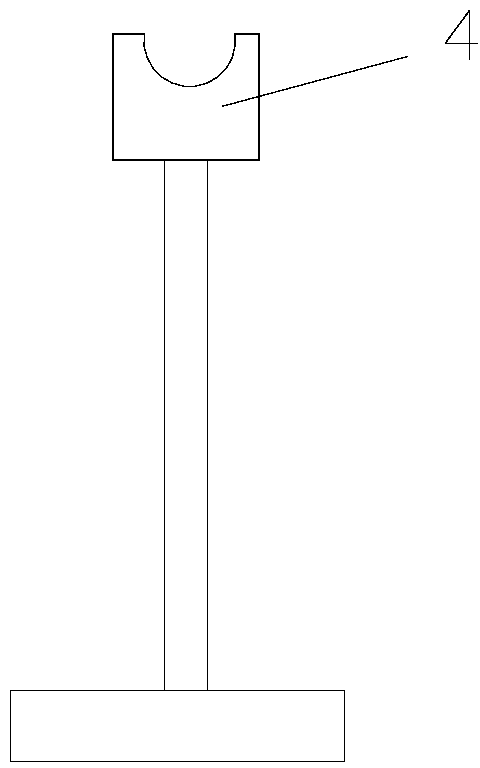

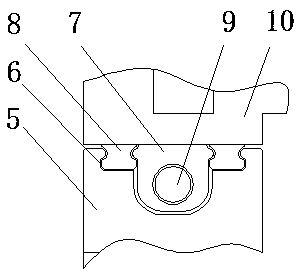

Elevator apparatus of pony roll support

InactiveCN101195452ALift up quickly and smoothlyAvoid left and right offsetFilament handlingCreelsBobbinBiochemical engineering

The invention provides a hoisting device for bobbin creels, which comprises a bobbin creel and a hoisting mechanism. The improvements of the hoisting device are that a fixing hole is arranged on the bobbin creel, one end of a connecting piece is fastened with the fixing hole by a built-in fitting, the other end of the connecting piece is connected with a lifting rod of the hoisting mechanism, and a connecting base of the hoisting mechanism is fixed on a base. A buffering mechanism is arranged between the base and the bobbin creel. The invention has the advantages of reasonable and simple structure, easy processing of main parts, convenient installation, operation and maintenance, improvement of production efficiency and low equipment failure rate. Besides, the invention can avoid oil leak problems, effectively improves yarn quality and has good application effect.

Owner:TIANJIN HONGDA TEXTILE MACHINERY

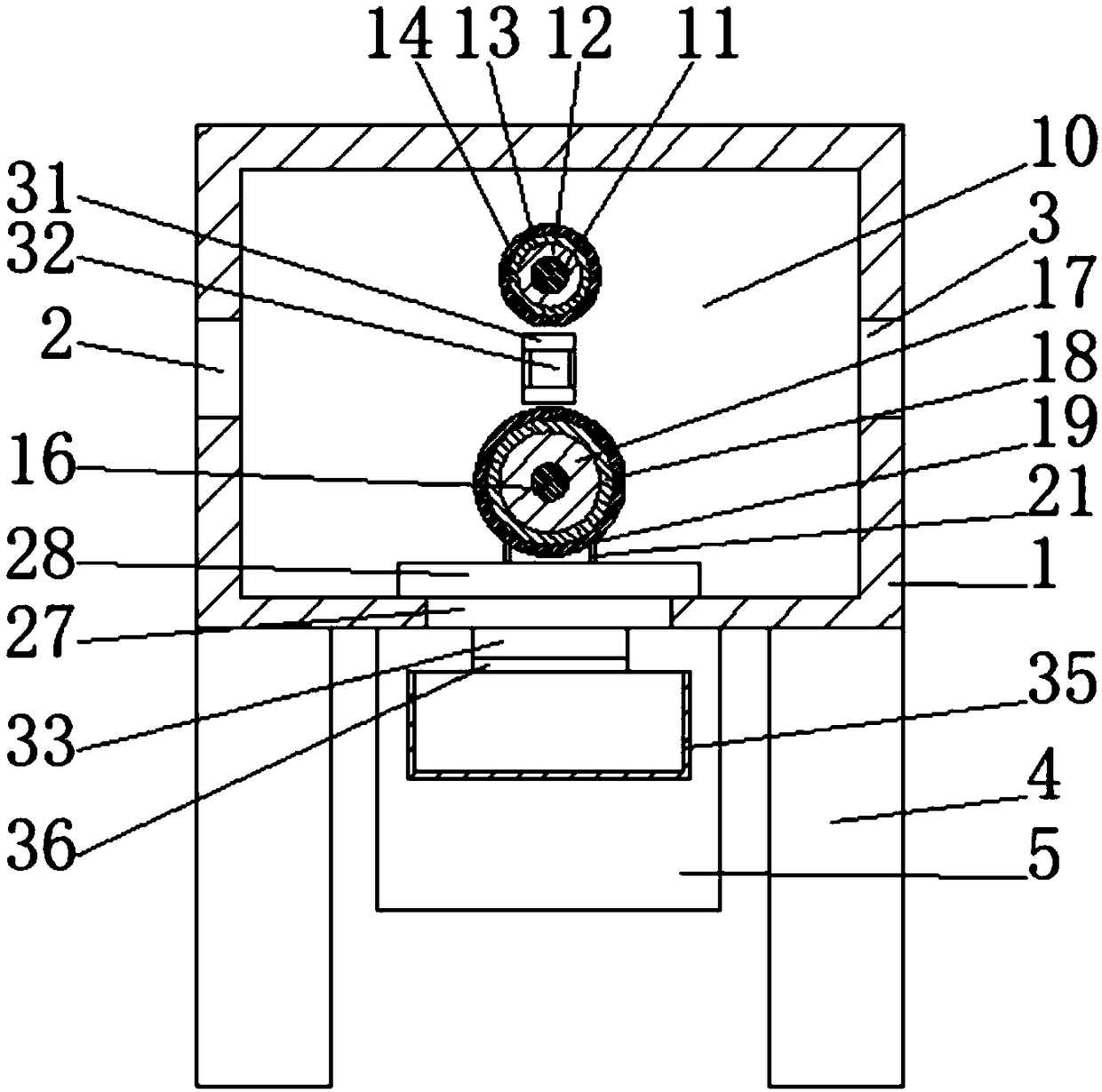

Non-woven fabric winding device with static electricity removal and drying functions

The invention provides a non-woven fabric winding device with static electricity removal and drying functions and relates to the technical field of non-woven fabric winding bundles. The non-woven fabric winding device with the static electricity removal and drying functions comprises a machine box. A partition and a fixing rod are fixedly arranged in the machine box. First pressure rollers are fixedly arranged on the partition. A water mist spray nozzle, exhaust ports and an air cover are fixedly arranged on the top of the machine box. Second conveying rollers and a wind-heat device are arranged on the left side of the partition. Second pressure rollers are arranged on a box body of the machine box. A support table is fixedly arranged on the outer wall on the left side of the machine box.A limiting device is fixedly arranged on the top of the support table. A cutting device is arranged on the bottom of the support table. A winding device is arranged on the left side of the machine box. The non-woven fabric winding device with the static electricity removal and drying functions is easy and convenient to use and high in automation degree and can realize the functions of static electricity removal, material compaction, material heating, material cutting and winding and the like.

Owner:江西美宝利实业有限公司

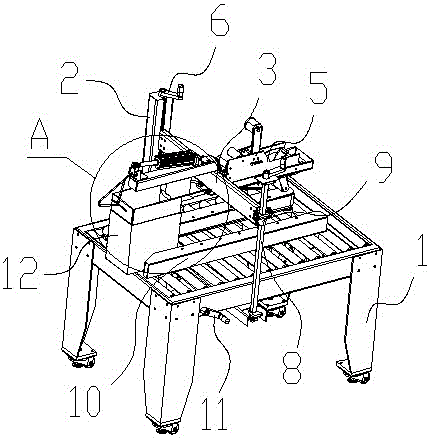

Automatic paper carton packaging machine

InactiveCN106809415AImprove efficiencyReduce manpower consumptionWrapper twisting/gatheringFront coverCarton

The invention relates to an automatic carton packaging machine, which includes a roller conveying frame. Mounting columns are arranged on the left and right sides of the roller conveying frame, and mounting blocks are arranged between the two mounting columns. The front and rear sides of the mounting block are provided with A capping device and a rubber sealing device that cooperate with each other, the capping device includes a front capping device that cooperates with the carton front cover, a side capping device that cooperates with the carton side cover, and a carton rear The rear gland device; the front gland device is set on the support seat on the installation block, the connecting plate is arranged under the support seat, and the front part is arranged in an upward arc shape under the connecting plate. The purpose of this invention is to provide an automatic carton sealing machine, which is equipped with a rubber sealing device on the roller conveying frame, and is provided with a matching gland device in front of the rubber sealing device, which can be used in order to place the front, rear, left, and right four The cover plate is pressed down, which greatly improves the efficiency of the entire package and reduces manpower consumption.

Owner:DONGGUAN UNIV OF TECH

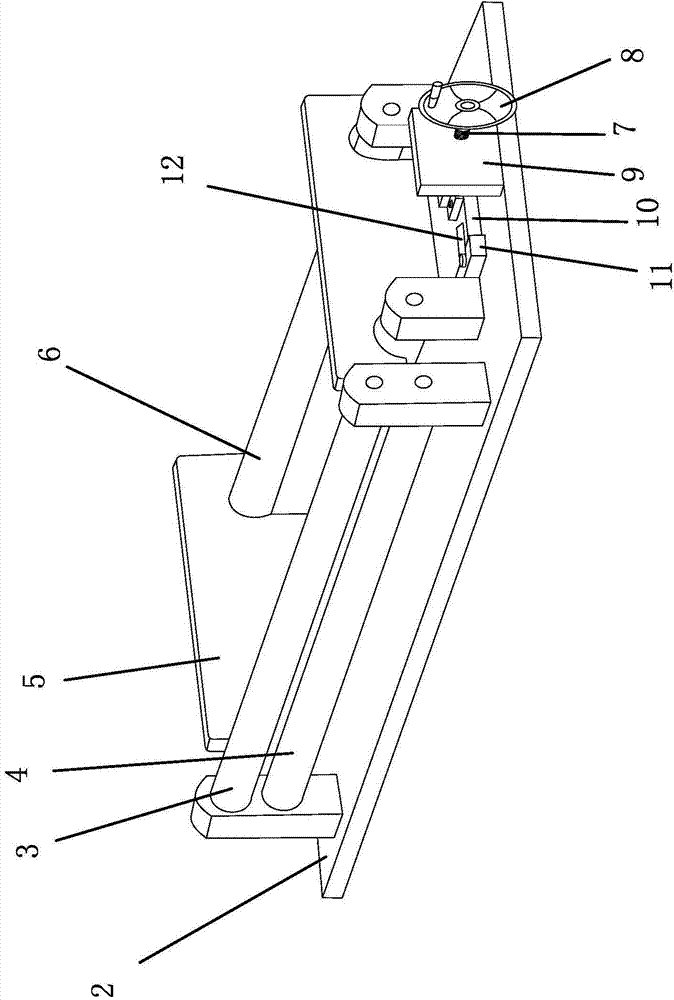

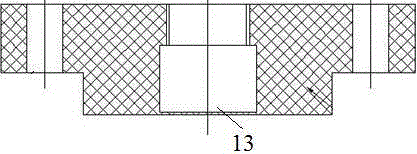

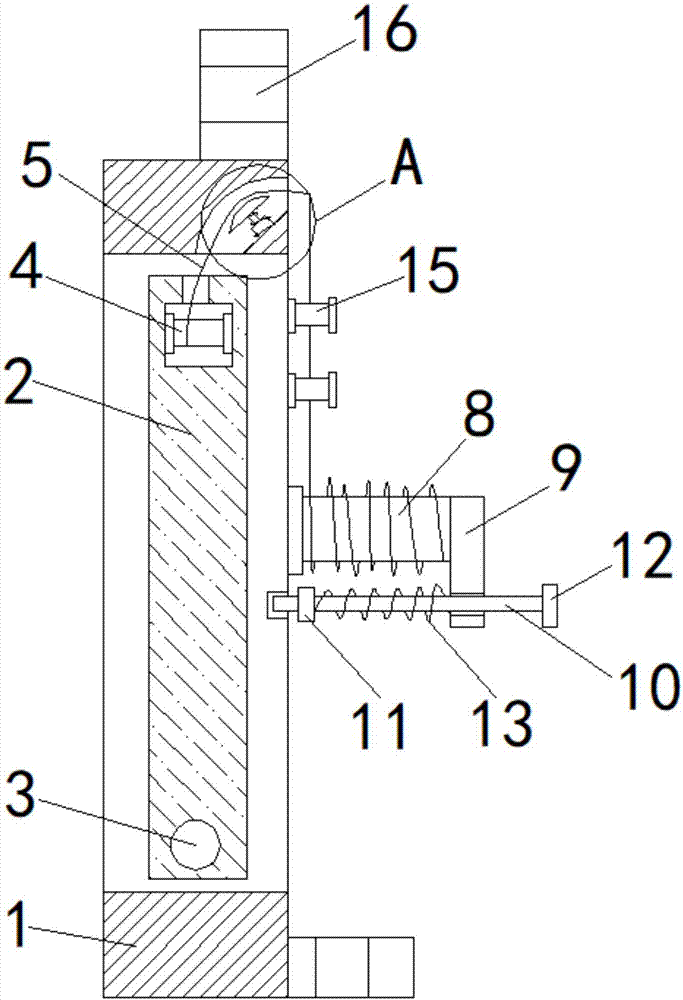

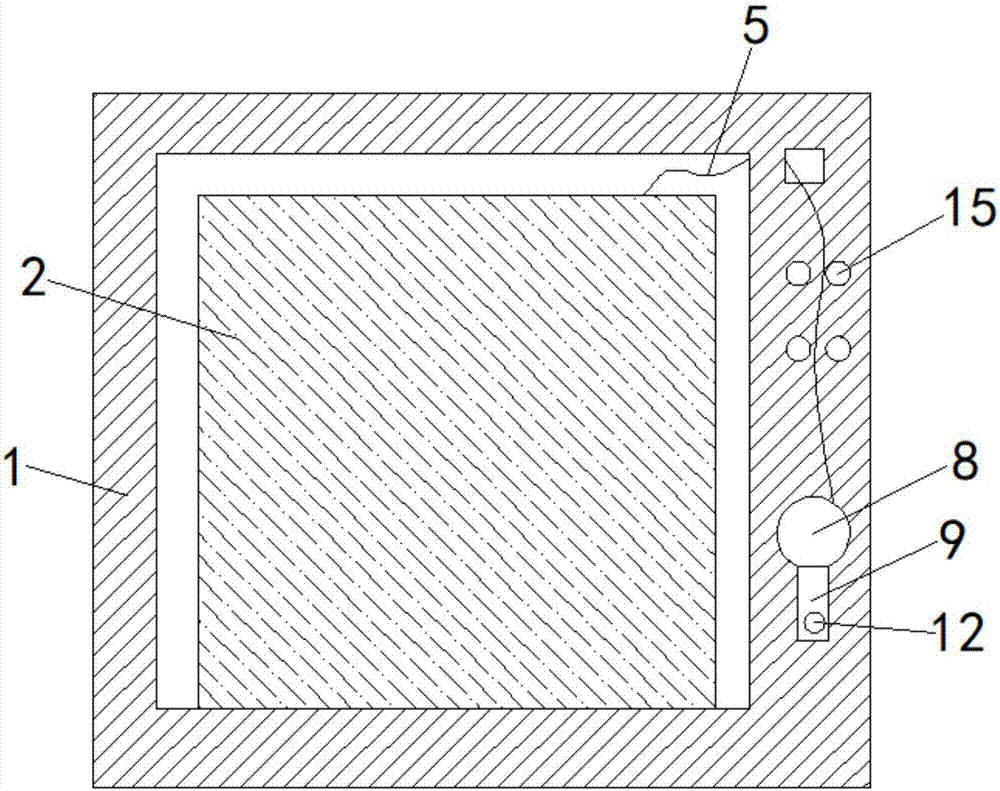

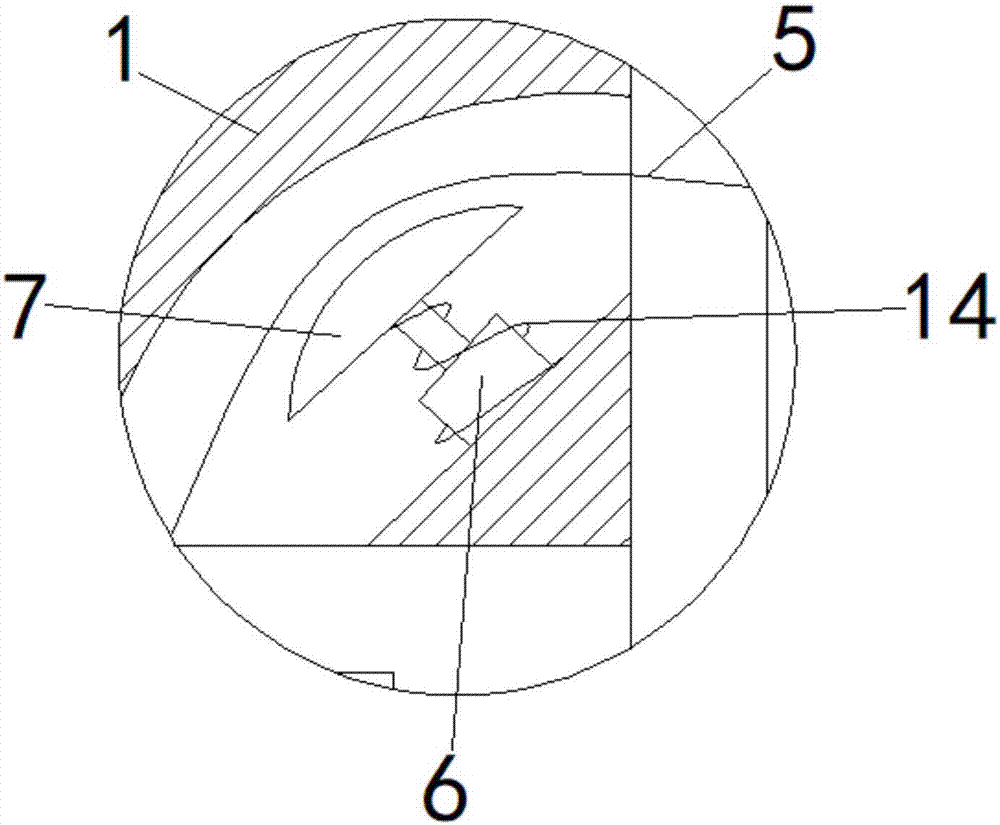

Centering and guiding device for steel strip processing

ActiveCN105414217AAvoid violent movementReduce gapWork treatment devicesMetal rolling arrangementsScrew threadSteel belt

The invention discloses a centering and guiding device for steel strip processing and belongs to the field of steel rolling equipment. The centering and guiding device comprises a base, an adjusting mechanism, a guiding mechanism and a centering mechanism, wherein the guiding mechanism comprises an upper horizontal roller and a lower horizontal roller, and two ends of the upper horizontal roller and two ends of the lower horizontal roller are fixed on supports on two sides of the base separately; the adjusting mechanism comprises a control hand wheel, an adjusting screw rod, nuts, flat keys and nut sleeves, two sections of threads are formed on the adjusting screw rod, each section of threads is matched with the corresponding nut, and the nut sleeves are arranged on the outer side surfaces of the nuts and fixedly connected with the flat keys on the nuts; the centering mechanism comprises sliding blocks and vertical rollers, the sliding blocks are fixedly connected above the nut sleeves, the vertical rollers are symmetrically arranged at two ends of each sliding block, and the vertical rollers are distributed on two sides of one end of the upper horizontal roller. According to the centering and guiding device for the steel strip processing, the position can be adjusted automatically according to the width of a steel strip, the vertical rollers are clamped on two sides of the steel strip all along, so that leftward and rightward offset of the steel strip is avoided, and the problems that the steel strip gets stuck, is flanged and is warped are also solved.

Owner:ANHUI CHUJIANG SPECIAL STEEL CO LTD

Spray head transfer mechanism used for ink-jet spraying and drive method thereof

ActiveCN110843362AEfficient storageEffective take outPower drive mechanismsPrinted circuit manufactureSpray nozzleTransfer mechanism

The invention discloses a spray head transfer mechanism used for ink-jet spraying and a drive method thereof. The spray head transfer mechanism comprises a lifting assembly, a grabbing assembly, a perpendicular motion assembly, a horizontal motion assembly and the like. The spray head transfer mechanism is a three-axial motion spray head transfer mechanism, the lifting assembly drives the grabbingassembly to transfer a spray head module, and moves in the horizontal direction and the vertical direction; and the spray head transfer mechanism is used for classified placing of the spray head module and replacing of the spray heads during ink-jet printing. Besides, in a spray head transfer process, the spray head module is placed on multiple stations. The spray head transfer mechanism used forink-jet printing is simple in structure, adopts mechanical positioning, is convenient and accurate in control, and avoids damaging a spray nozzle by collision in a spray head transfer process. The spray heads of different colors further can be placed and taken out in a classified mode, so that the spray heads needed for ink-jet spraying are quickly replaced efficiently.

Owner:GUANGDONG SYGOLE INTELLIGENT TECH CO LTD +1

Deviation-rectifying and material-collecting device for packaging bag

Owner:TIANJIN JINLICHENG PACKING

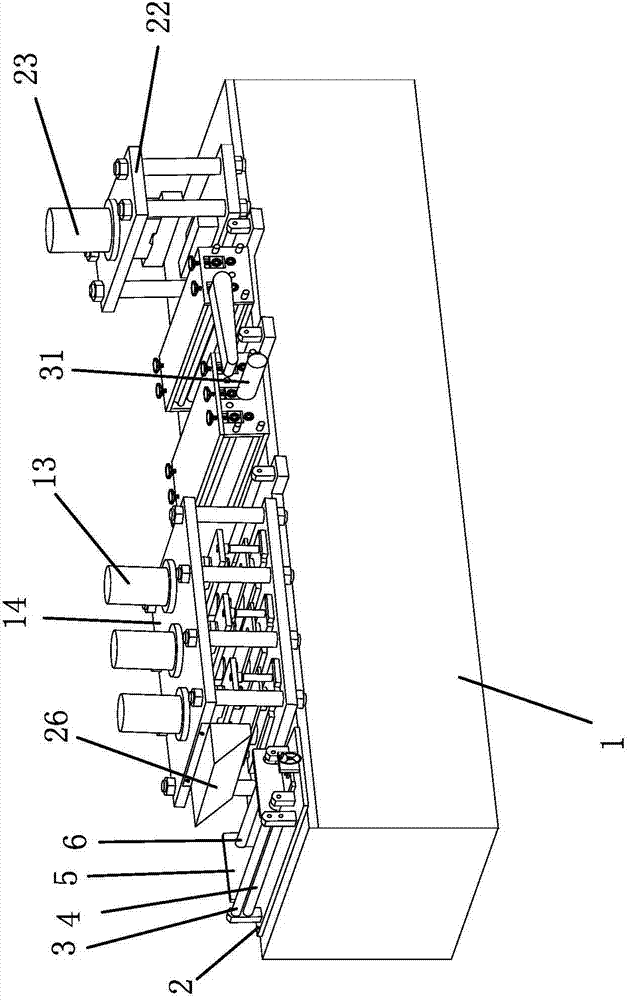

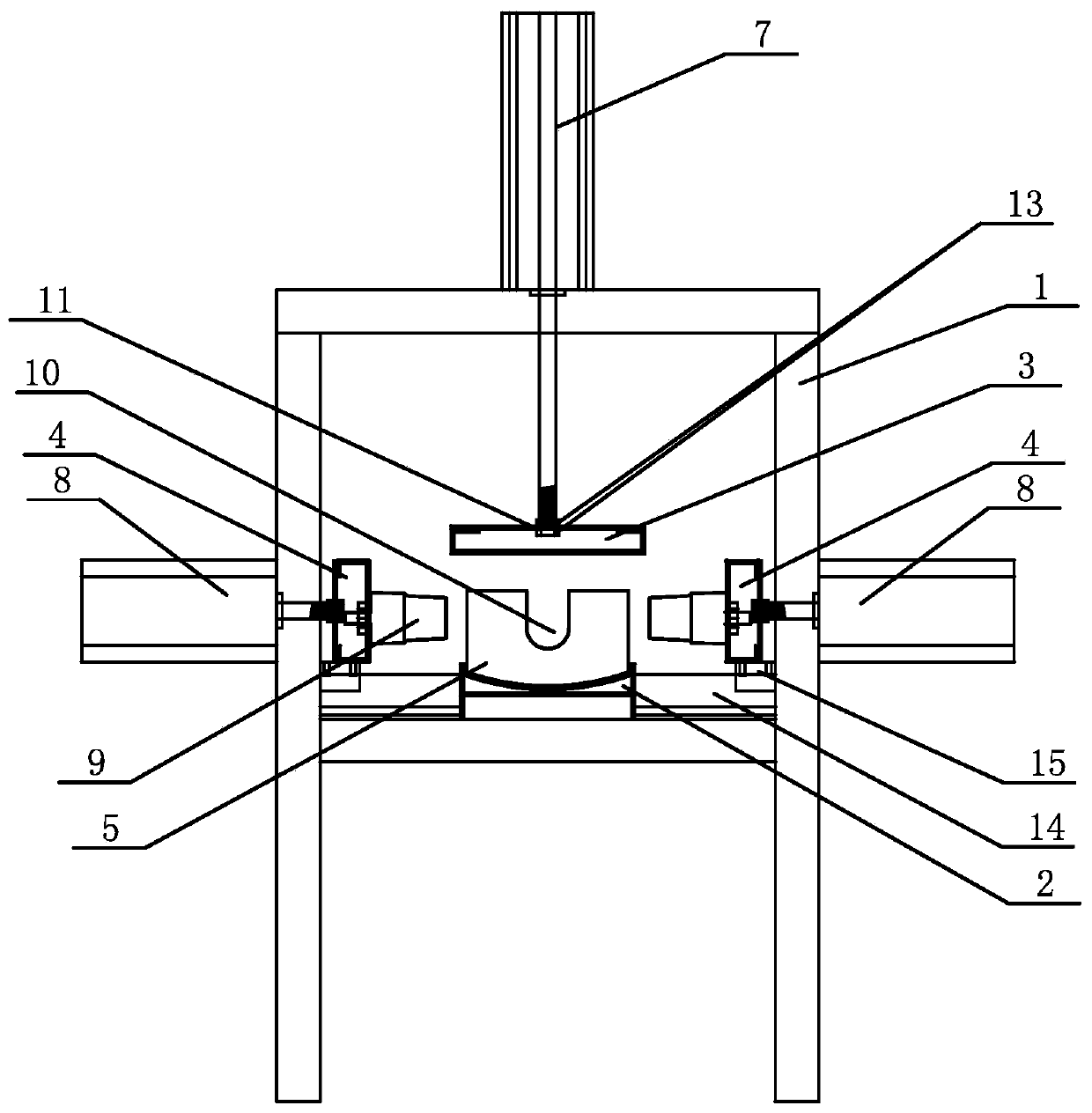

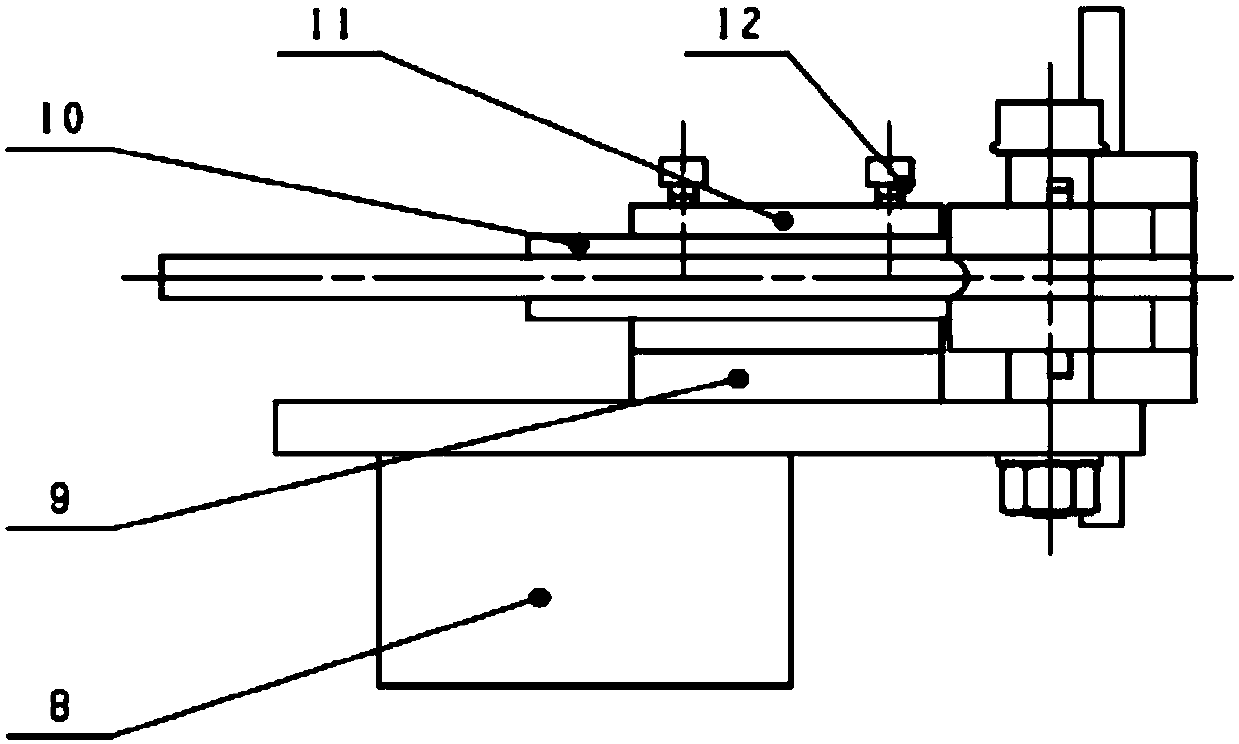

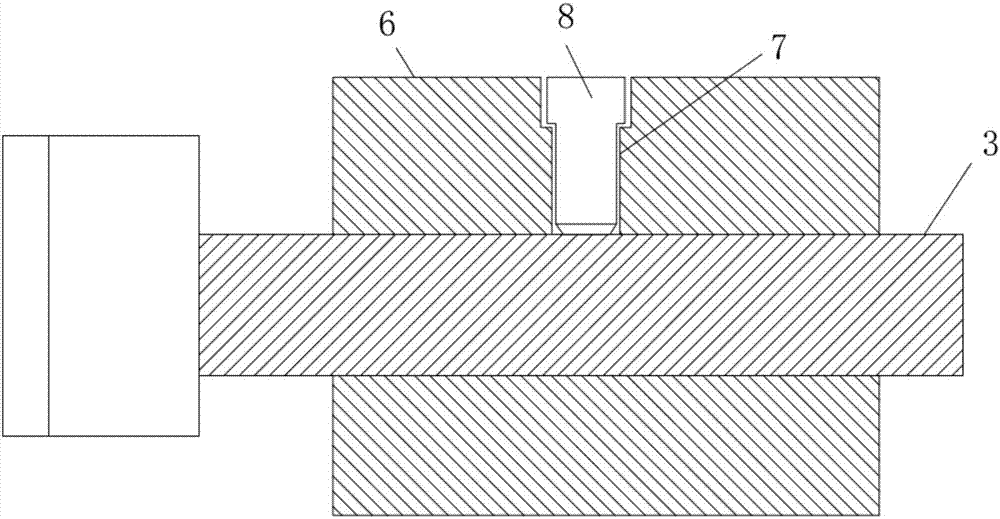

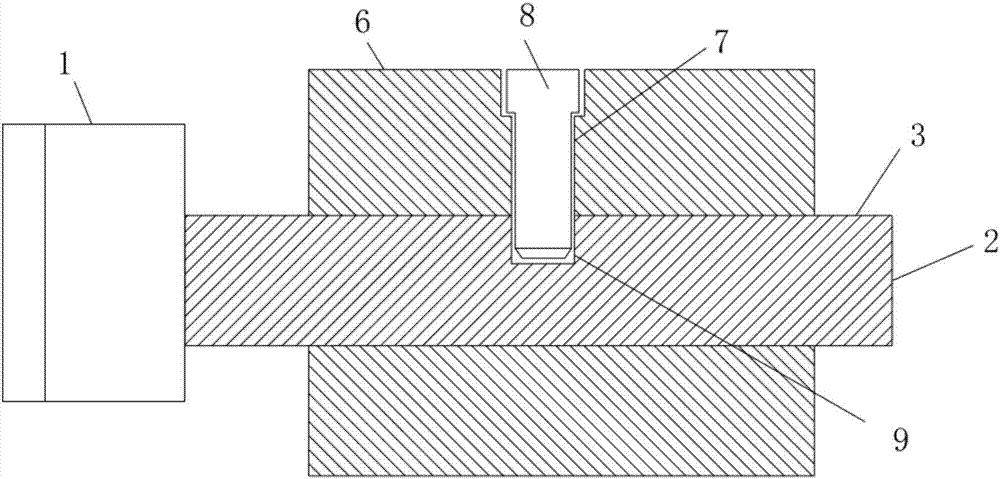

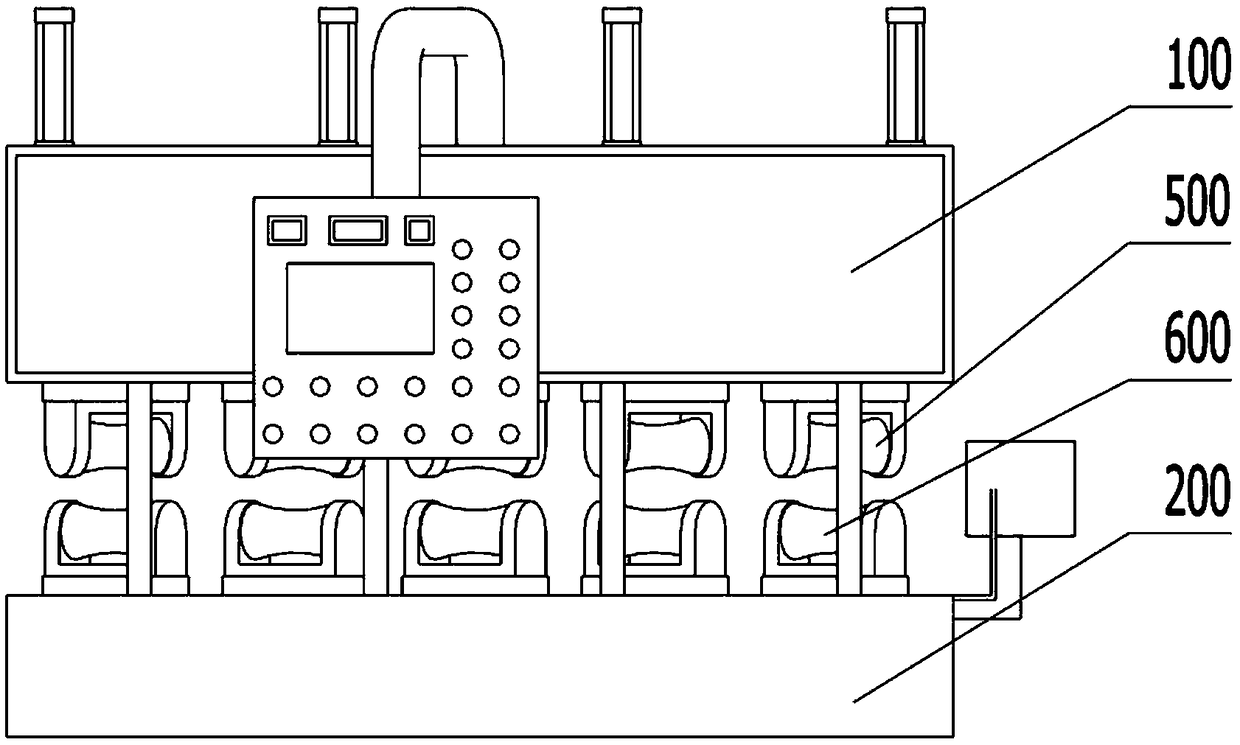

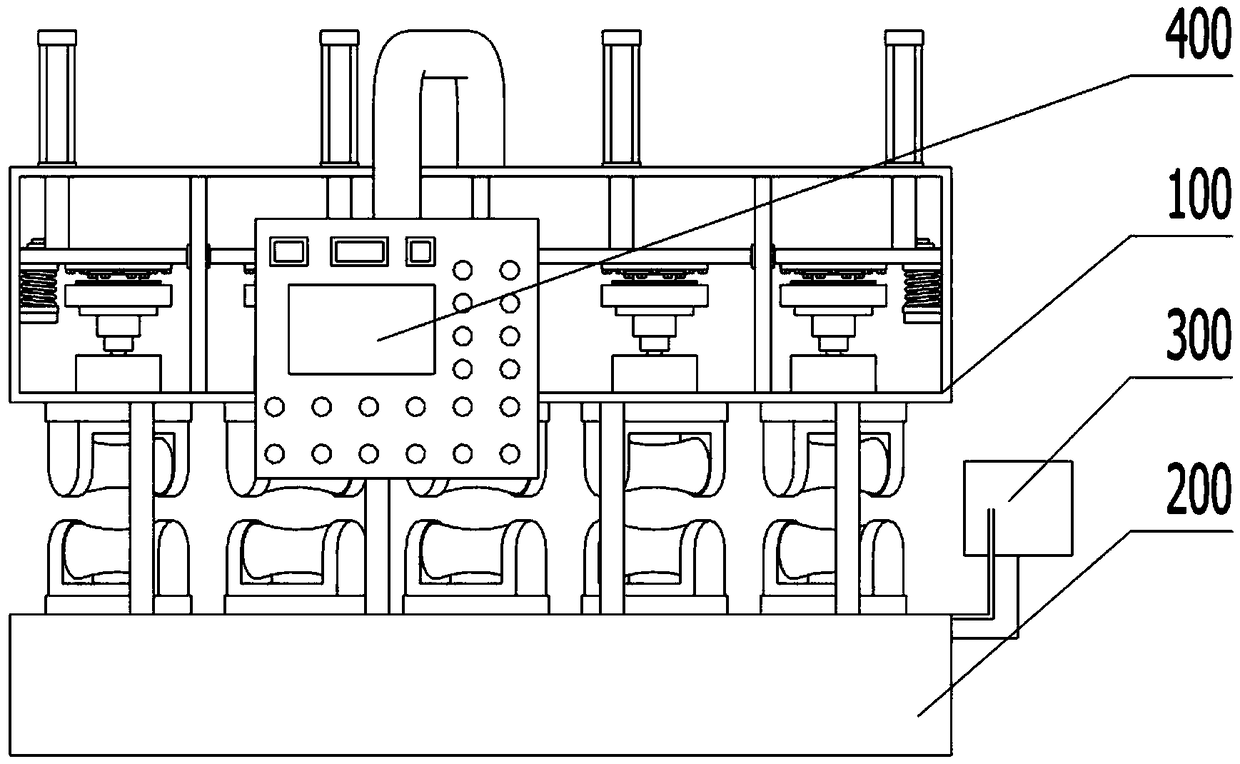

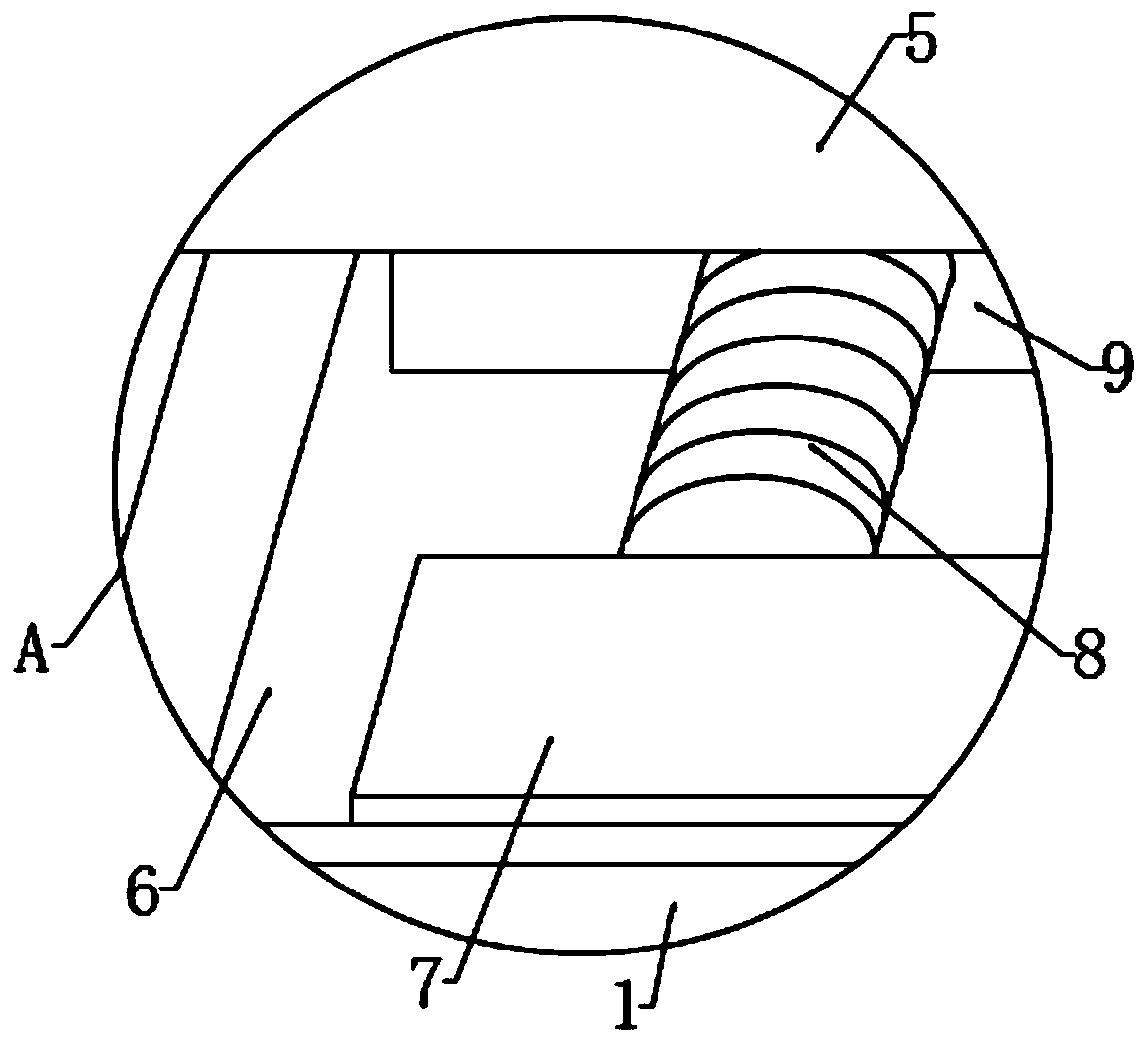

Header processing device

ActiveCN104759550AImprove processing efficiencyAvoid affecting processing qualityMetal-working feeding devicesPositioning devicesHydraulic cylinderPunching

The invention provides a header processing device, and belongs to the technical field of solar header processing. The header processing device comprises a frame, an adjusting mechanism, a punching mechanism, a feeding rib-rolling mechanism and a cutter mechanism; the adjusting mechanism comprises an adjusting plate arranged on the frame and an upper roller wheel and a lower roller wheel on the adjusting plate; the vertical plates capable of translating in parallel are arranged on the adjusting block; the outsides of the vertical plates are provided with driving pieces for driving the vertical plates to close towards a thin plate; the punching mechanism is located on the frame, and the punching mechanism comprises several oil cylinders, a punching die and an oil cylinder bracket; the punching die is situated between the oil cylinder bracket and the frame, and the feeding rib-rolling mechanism comprises a feeding machine and a rib-rolling machine; the cutter mechanism comprises a cutter frame, a hydraulic cylinder, and a fixing cutter and a moving cutter which can perform the opening and closing movements to each other; the moving cutter is interlinked to the lower end of the hydraulic cylinder, and the fixing cutter is located at the upper end of the frame. The header processing device is wide in suitability, and also can greatly improve the processing efficiency and quality of the processed product.

Owner:浙江瑞翔新能源科技有限公司

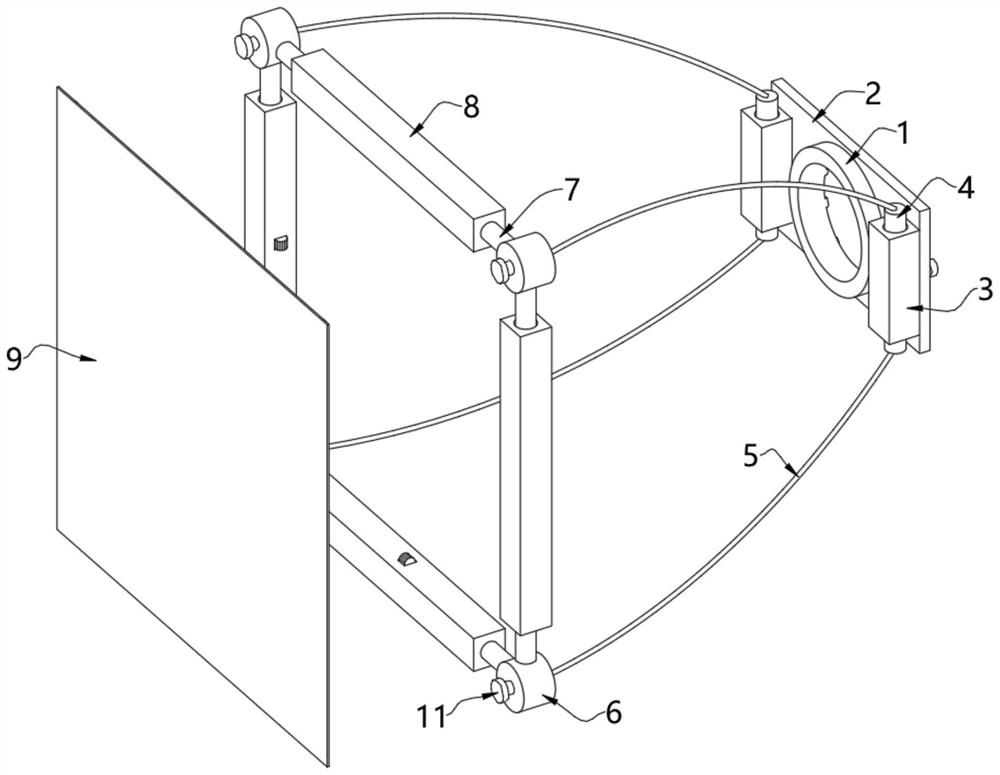

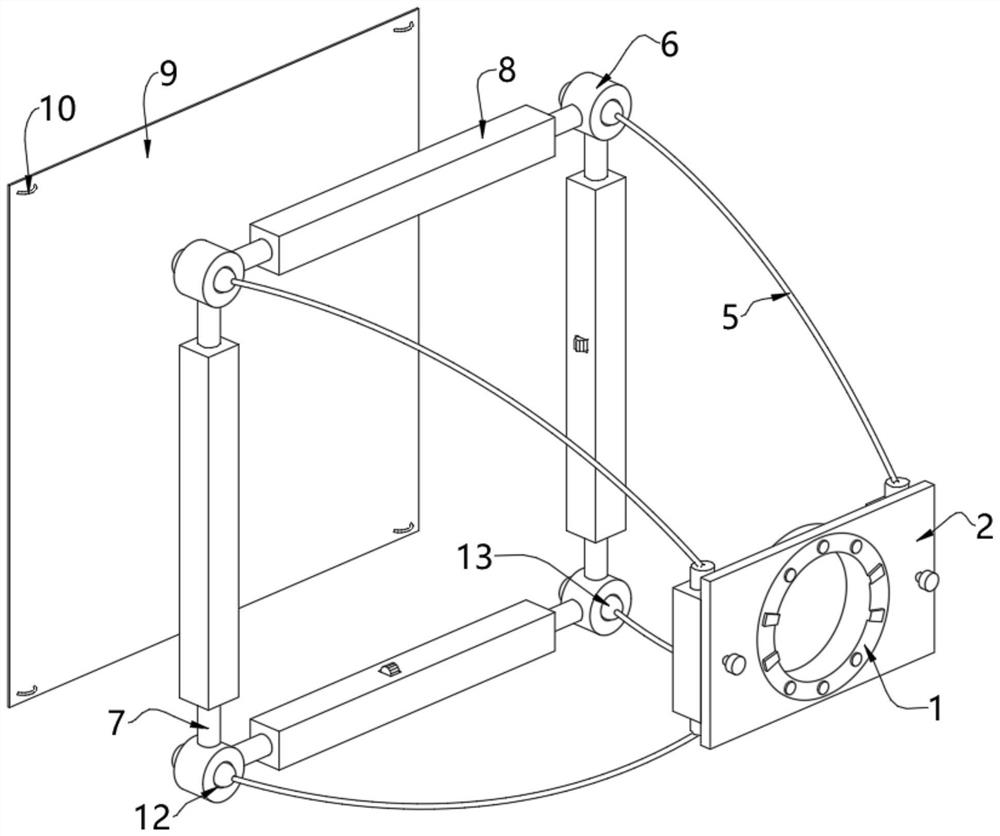

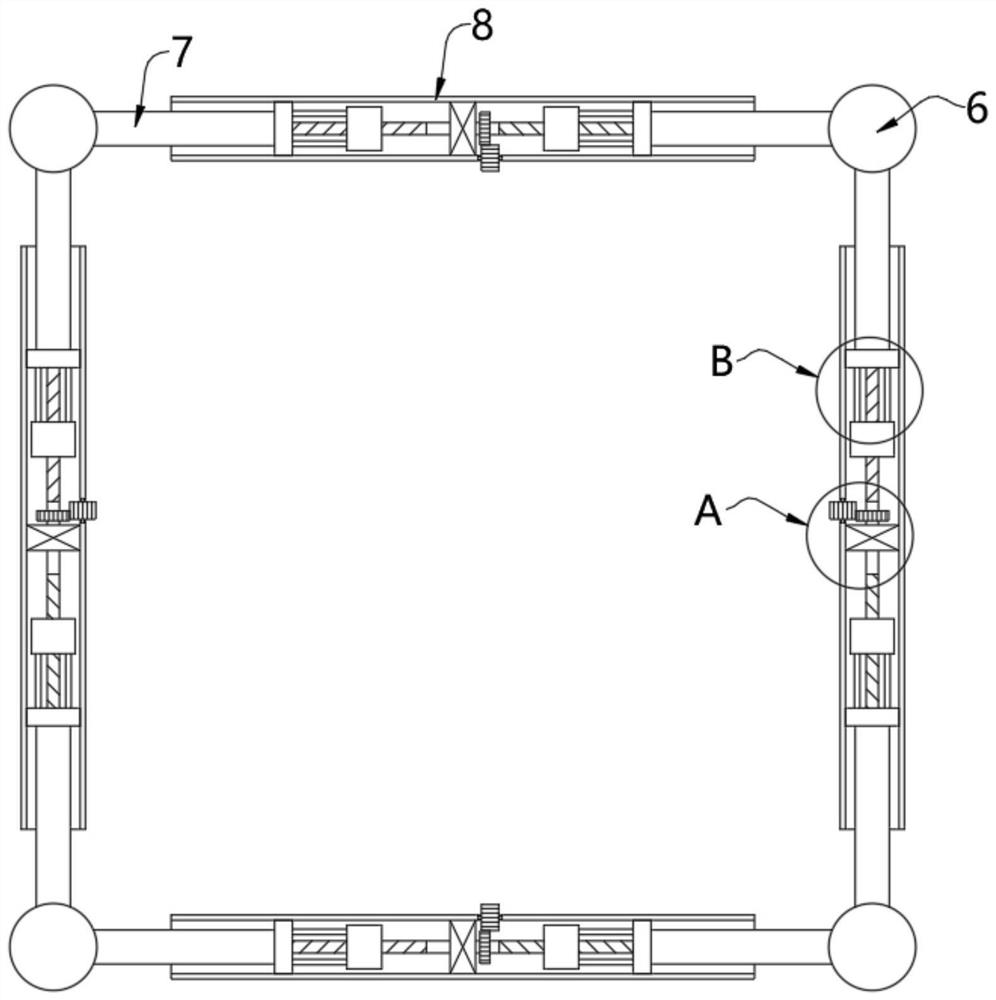

Photography lamp soft light box with adjustable size

The invention relates to the technical field of softboxes, and discloses a size-adjustable photoflood light softbox. The softwbox comprises a clamping ring, wherein a mounting plate is fixedly mounted on the outer wall of the clamping ring, fixing cylinders are fixedly mounted on the left side and the right side of the outer wall of the mounting plate correspondingly, and rotating columns are rotationally arranged in the two fixing cylinders correspondingly; and a locking device which is arranged in the fixed cylinder and is used for locking the position of the rotating column. Light rays emitted by the tail end of the lamp holder directly irradiate to the light blocking groove and can be blocked, direct light rays at the light blocking groove are prevented, light rays emitted by the side face of the lamp holder are evenly emitted out of light path channels of the multiple light gathering cylinders, the light rays can be reflected through the light reflecting balls on the inner walls of the light gathering cylinders, the light rays are circularly refracted in the light gathering cylinders and fully dispersed, and finally, the fully dispersed light rays are refracted by the reflective cloth and then projected to the soft light cloth, so the light rays at the soft light cloth are more uniform and soft, the situation that the middle is bright and the edges are dark is avoided, and the use effect of the soft light box is improved.

Owner:师大瑞利光电科技(清远)有限公司 +1

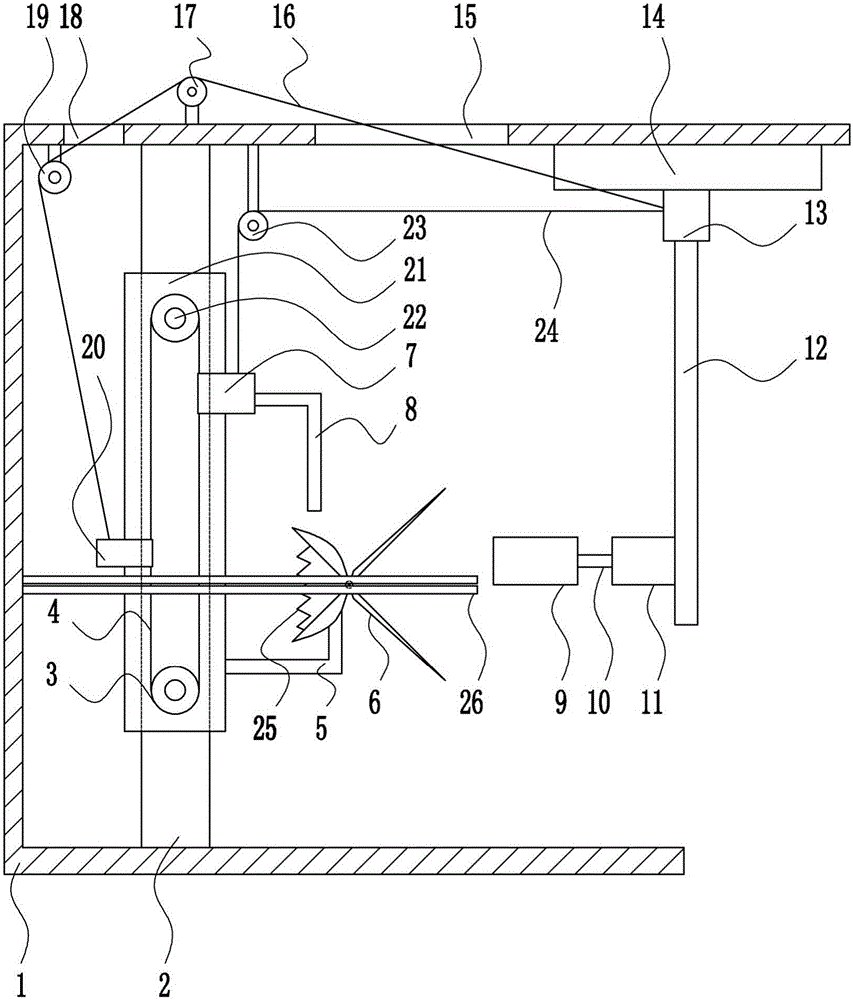

Convenient-to-use automatic turning and de-boxing device for goods checking

PendingCN110155744AEasy to adjust distance sizeAvoid left and right offsetBottle emptyingLoading/unloadingEngineeringAutomatic testing

The invention discloses a convenient-to-use automatic turning and de-boxing device for goods checking. The convenient-to-use automatic turning and de-boxing device for goods checking comprises a Y-axis conveyor belt, longitudinal plates and clamping plates, an X-axis conveyor belt is perpendicularly arranged below the Y-axis conveyor belt, moreover, a base is fixed at the lower ends of the Y-axisconveyor belt and the X-axis conveyor belt, supports are arranged on the outer sides of the Y-axis conveyor belt and the X-axis conveyor belt, and the longitudinal plates are arranged at the upper ends of the supports. According to the convenient-to-use automatic turning and de-boxing device for goods checking, laser through-beam sensors are arranged and can cooperate with a controller, when the laser through-beam sensors detect that boxed goods pass, other electrical elements on the convenient-to-use automatic turning and de-boxing device can be controlled through the action of the controller, so that box bodies are automatically clamped and are automatically turned for the goods pouring operation, moreover, the goods can be effectively separated from the box bodies, so that storage and arrangement are facilitated, compared with a traditional manual goods pouring mode, the burden of workers can be reduced, meanwhile, the goods arranging efficiency is greatly improved, and use by the workers is facilitated.

Owner:广西合浦县绿珠科技投资有限公司

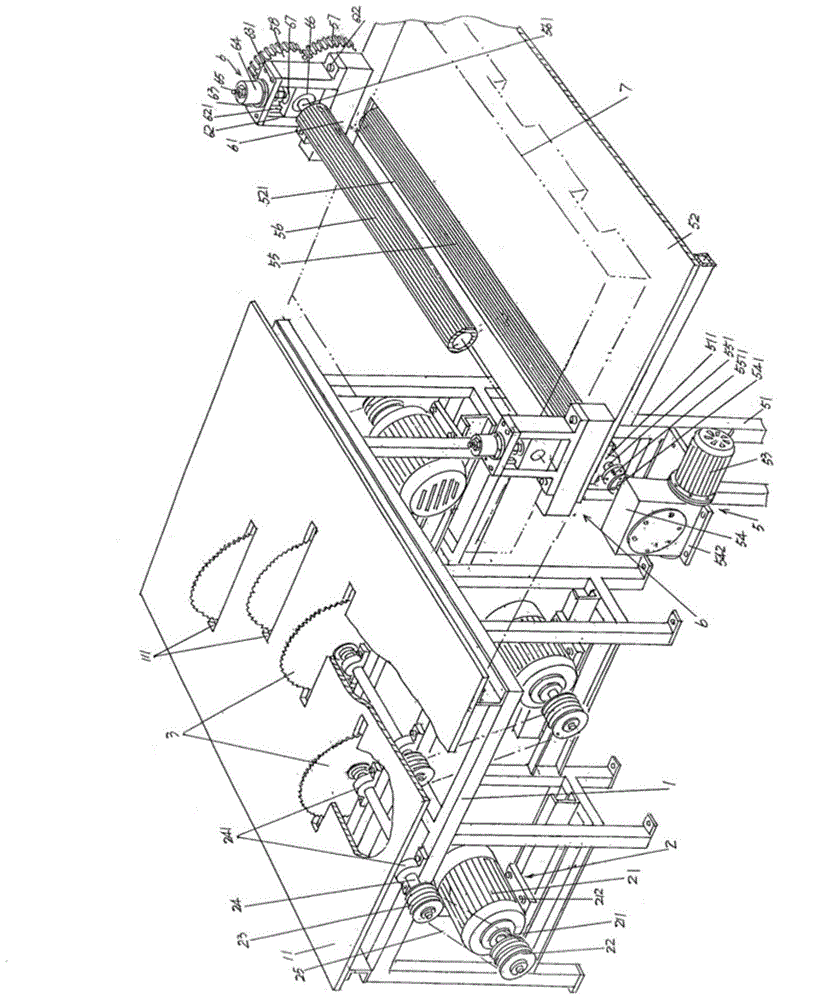

Waste plastic tray dismembering machine

InactiveCN103552105AIdeal Dismemberment EfficiencyAvoid bouncing up and downMetal working apparatusEngineeringUltimate tensile strength

A waste plastic tray dismembering machine belongs to the technical field of saw cutting machines and comprises a rack, a group of disk saw driving mechanisms and disk saws; a disk saw work platen is arranged at the upper part of the rack; the group of disk saw driving mechanisms are arranged on the rack in a staggering mode; the saw disks and the disk saw driving mechanisms are equal in number, and the saw disks are fixed on the disk saw driving mechanisms and probe out of the surface of one upward side of the disk saw work platen; spaces between every adjacent disk saws form the dismembering intervals. The waste plastic tray dismembering machine has an ideal efficiency on waste plastic trays, so the work intensity of a worker is reduced, the waste plastic trays are prevented from being quivered up and down and deviated left and right, and the safety is favorably guaranteed.

Owner:SUZHOU TONGDA MACHINERY

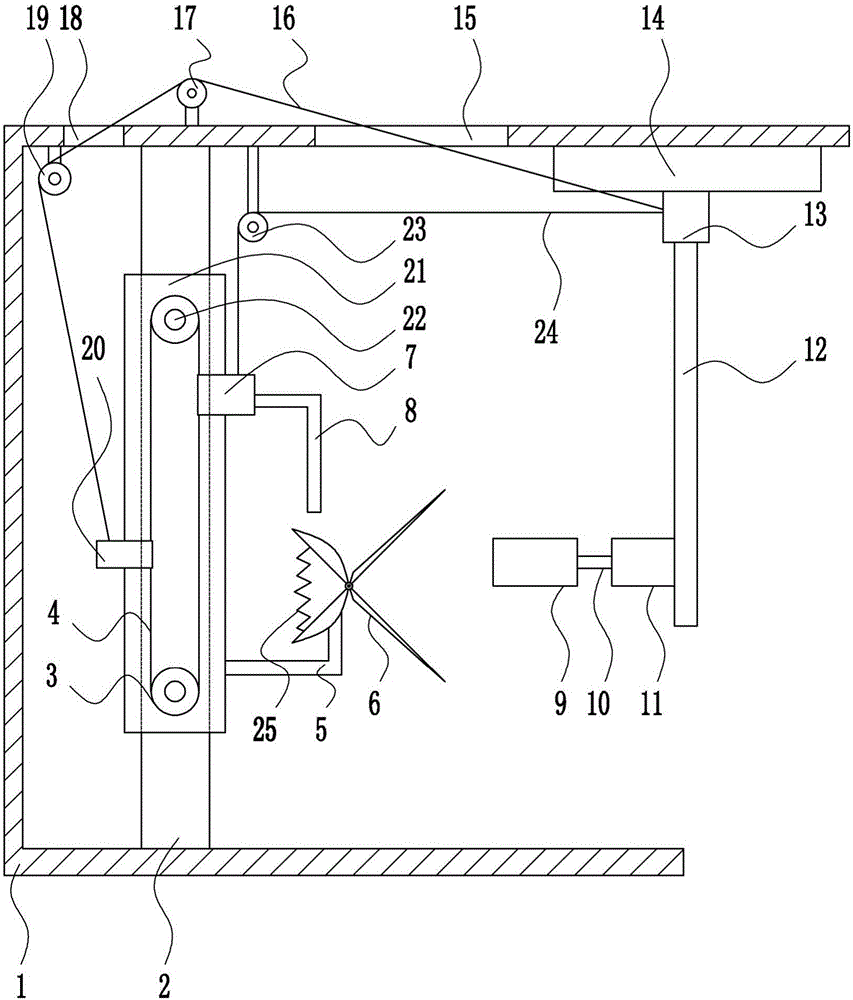

Efficient tailoring device for clothing factory

ActiveCN106087378AHigh precisionImprove collection efficiencySevering textilesIndustrial engineeringPulley

The invention relates to a tailoring device, in particular to an efficient tailoring device for a clothing factory. The technical problem to be solved is how to provide an efficient tailoring device high in tailoring efficiency for a clothing factory. In order to solve the technical problem, the efficient tailoring device for the clothing factory comprises a box, a base plate, a second electric wheel, a first pull rope, a first supporting rod, a pair of scissors, a third sliding block, a push rod, a roller, a rotating shaft, a servo motor, a second supporting rod, a first sliding block, a second sliding rail, a second pull rope, a first fixed pulley, a second fixed pulley, a second sliding block, a first sliding rail and a first electric wheel and the like. The base plate is arranged between the front wall and the rear wall in the box. The efficient tailoring device for the clothing factory has the advantages of high tailoring efficiency, tailoring length accuracy, simplicity in operation, convenience in the operation process and long service life. Besides, since a limiting plate and a limiting block are arranged, the tailoring accuracy can be further improved.

Owner:平湖凯隆新材料科技有限公司

Packaging bag material collecting device

InactiveCN103496194AAccurate limitAvoid left and right offsetContainer making machineryBiomedical engineeringEngineering

Owner:TIANJIN JINLICHENG PACKING

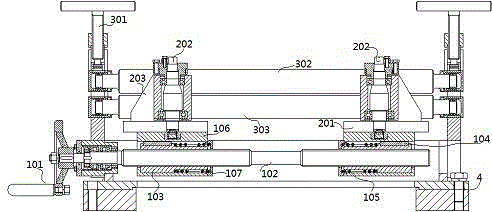

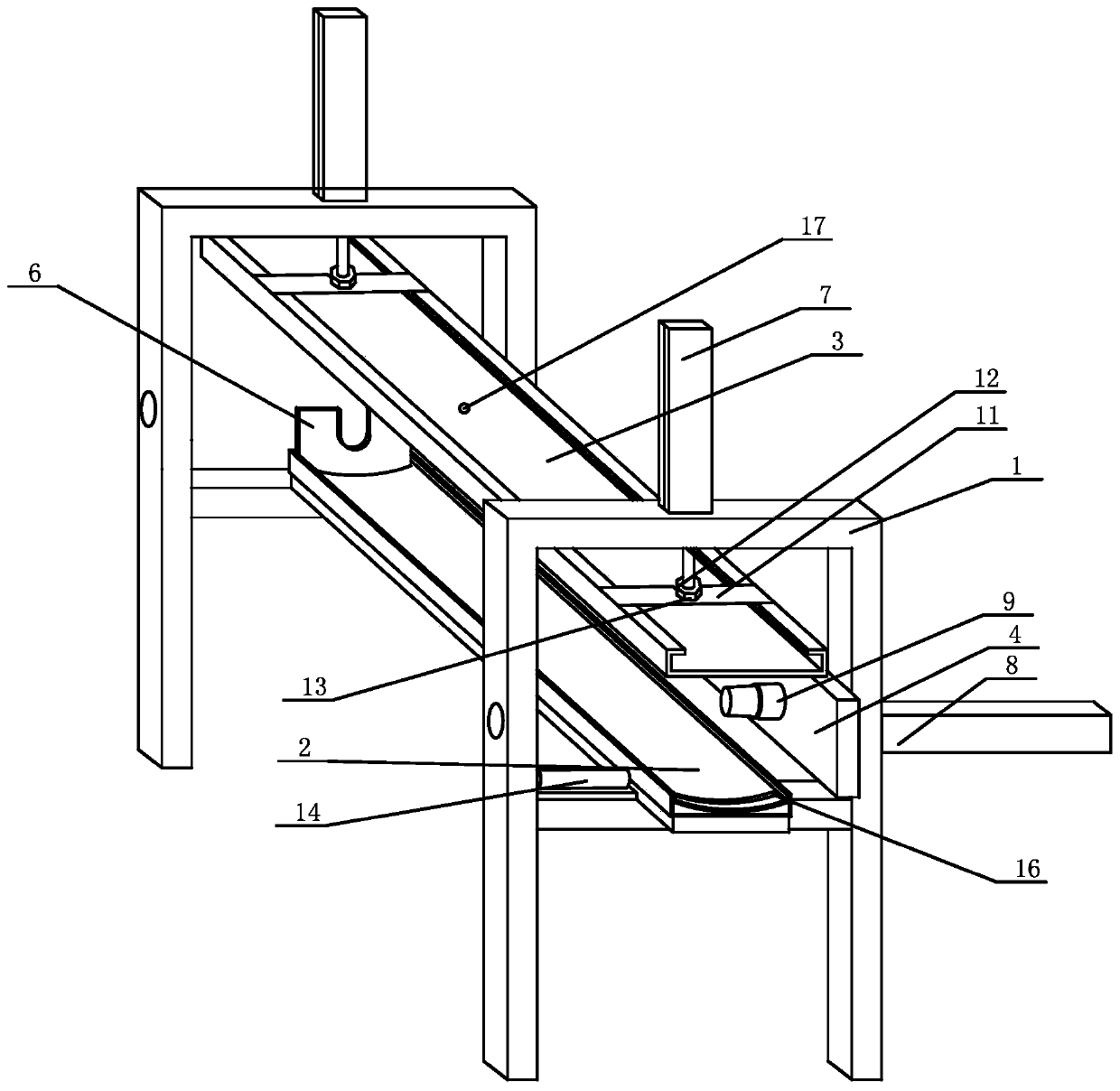

Fracture simulation adjusting mechanism of grouting expansion testing device

ActiveCN105842125ASpeed up the flowReal-time reflection of crack width changesDiffusion analysisInternal pressureSlurry

The invention discloses a fracture simulation adjusting mechanism of a grouting expansion testing device, and belongs to the technical field of grouting expansion testing equipment. The fracture simulation adjusting mechanism comprises adjusting parts and measuring parts, wherein the adjusting parts comprise a fastening screw nut, an adjusting bolt, an upper pressing plate, a visible plate, a lower pressing plate, a bottom plate, a gland and a servo motor; the fastening screw nut is fixed on the upper pressing plate; one end of the adjusting bolt is connected with the fastening screw nut; the other end of the adjusting bolt is connected with the servo motor; the gland is fixedly connected with the bottom plate; the measuring components comprise a displacement measuring rod and a displacement sensor; the displacement measuring rod is arranged inside the adjusting bolt; a first sealing ring is arranged on the displacement measuring rod; a second sealing ring is arranged on the adjusting bolt; a spring is mounted on the displacement measuring rod; the displacement sensor is connected with the servo motor. By adoption of the fracture simulation adjusting mechanism, multiple functions of balancing inner pressure, adjusting fracture width and measuring width are achieved, accurate basis can be provided for grouting construction and establishment of slurry expansion models, and the grouting effect can be ensured.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

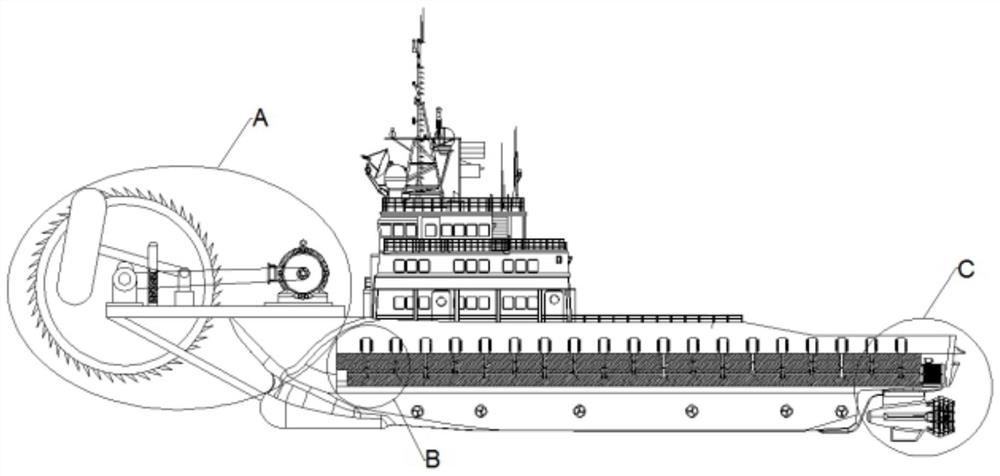

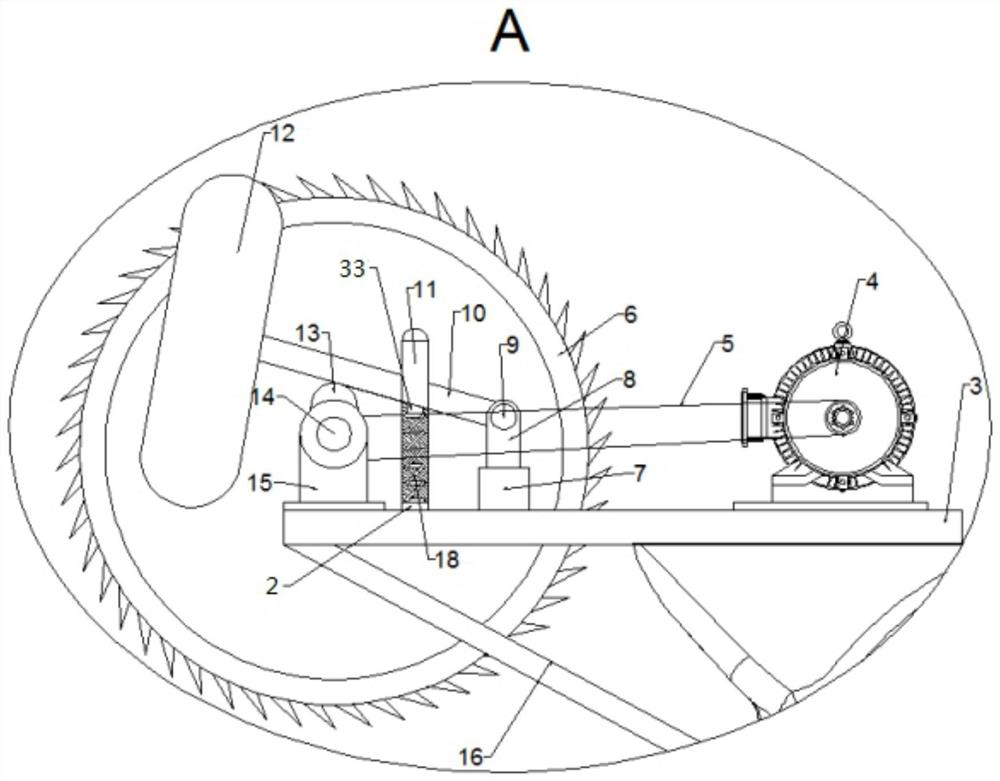

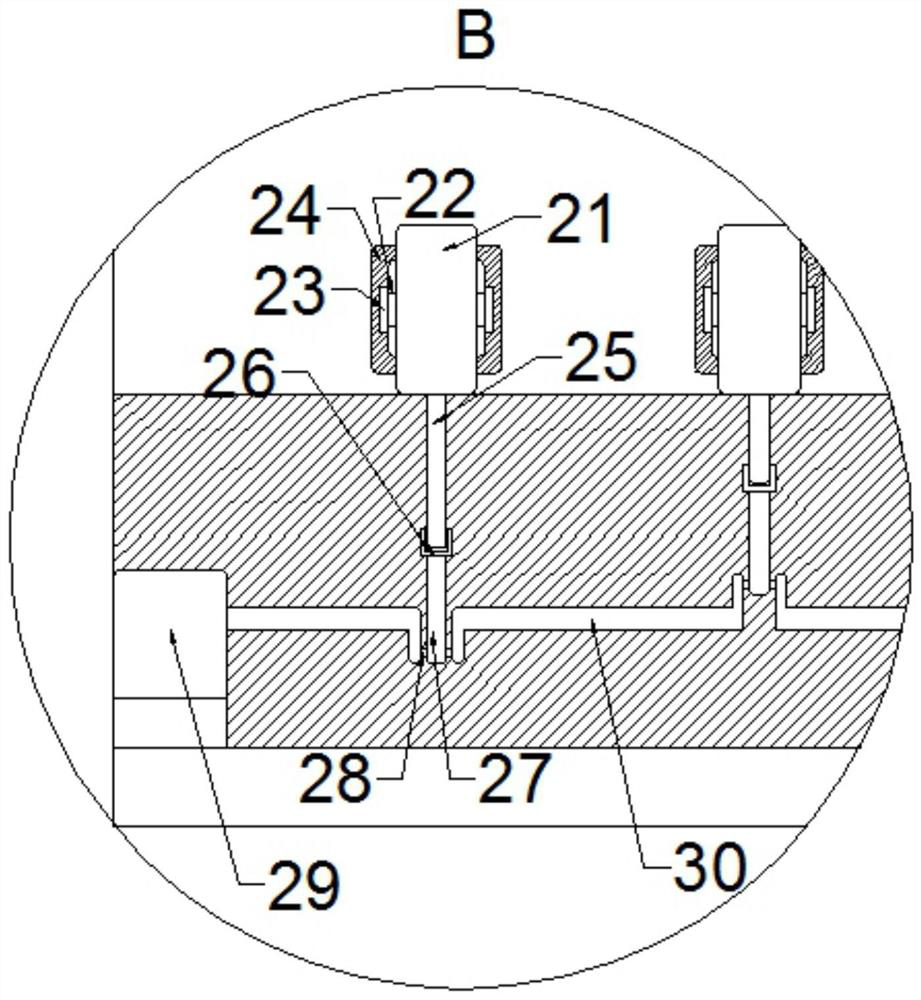

Icebreaker and icebreaking method thereof

InactiveCN112896438AEnsure safetyNo resonance phenomenonWaterborne vesselsIce breakersClassical mechanicsElectric machinery

The invention relates to the technical field of ships, in particular to an icebreaker and an icebreaking method. The icebreaker is characterized in that a fixed supporting plate is arranged at the head of the icebreaker, a supporting rib plate is fixedly connected to the bottom face of the fixed supporting plate, and a groove is formed in the middle of the front end of the fixed supporting plate; a motor seat, two heightened bases and four bearing supporting seats are arranged on the fixed supporting plate; two main motors are arranged on the motor base, the motors are connected with rotating shafts through belts, and saw blades are arranged on the rotating shafts. A bearing is arranged on the bearing supporting seat and is fixedly connected with the rotating shaft; two cams are further arranged on the rotating shaft, a lifting lug I is arranged on the heightened base, the lifting lug I is fixedly connected with a pin shaft I, the pin shaft I is fixedly connected with a hammer handle, the hammer handle is fixedly connected with a hammer body, and the hammer handle is located above the cams and is in contact connection with the cams. The ice breaker is simple in structure, reasonable in design and capable of breaking the ice surface with large thickness and effectively improving the ice breaking efficiency.

Owner:戚聿斌

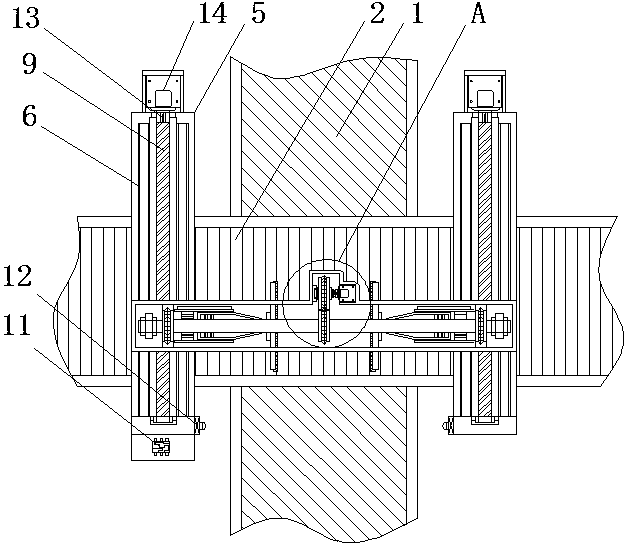

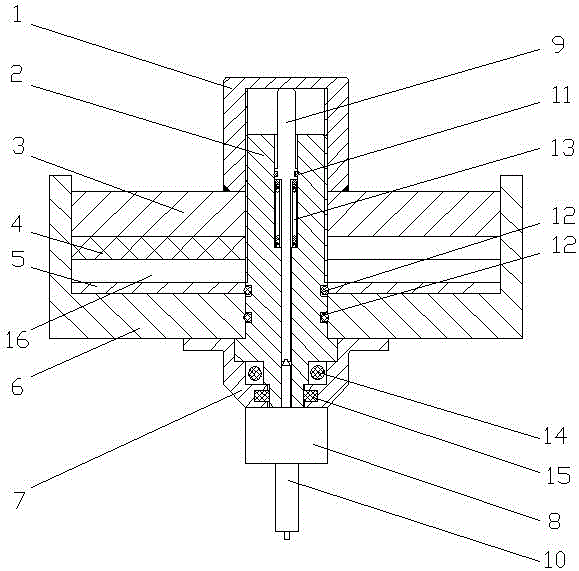

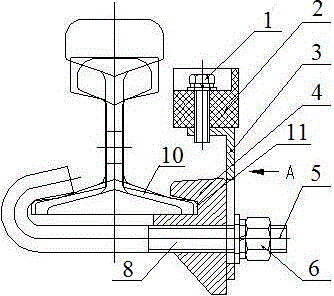

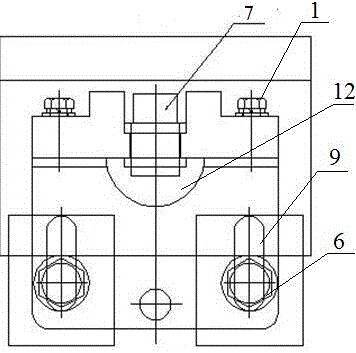

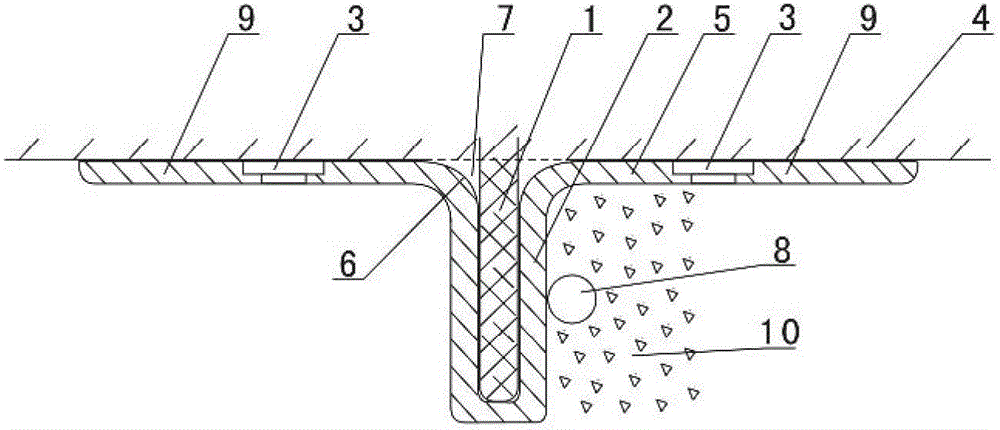

Rail sensor mounting structure and application

ActiveCN105923016AAvoid left and right offsetOvercome the problems of large engineering volume, high construction cost and long construction periodVehicle route interaction devicesArchitectural engineeringBuilding construction

The invention provides a rail sensor mounting structure and application. The rail sensor mounting structure comprises an iron clamp, a support and a lock bolt, wherein the iron clamp is fixed to a gauge rod on the outer side of a rail on one side and used for the gauge rod; the support is arranged on the outer side of the iron clamp for the gauge rod; and the lock bolt is used for fixing the iron clamp for the gauge rod and the support. The iron clamp for the gauge rod is provided with a first through hole. The lower end of the support is provided with a second through hole. One end of the lock bolt is fixed to the lower edge of a rail on the other side. The other end of the lock bolt penetrates through the first through hole and the second through hole and then is fixed through a nut. The top end of the support is provided with a fixing block. A sensor is mounted on the fixing block. By adopting the rail sensor mounting structure provided by the invention, the problems that traditional deep foundation pit type or cement foundation bed rails are large in construction amount, high in construction cost and long in construction cycle in the prior art are solved.

Owner:陕西航泰电气股份有限公司

Processing device for polishing bamboo wood

InactiveCN108544345ASolve the problem of small polishing area and low work efficiencyIncrease the polishing areaBelt grinding machinesGrinding/polishing safety devicesEngineeringPulley

The invention discloses a processing device for polishing bamboo wood. The processing device comprises a shell of which the rear side is provided with a feeding port, and the front side of the shell is provided with a discharging port; and four corners of the bottom of the shell are all fixedly connected to support legs, and the right side of the bottom of the shell is fixedly connected to a storage box. According to the processing device, through cooperative application of the shell, the feeding port, the discharging port, the support legs, the storage box, a motor, a rotating rod I, a belt pulley I, a bevel gear I, a partition plate, a rotating rod II, a connecting shaft I, an elastic sleeve I, a polishing abrasive belt I, a bevel gear II, a rotating rod III, a connecting shaft II, a belt pulley II, an elastic sleeve II, a polishing abrasive belt II, a belt, an opening, a rotating rod IV, a bevel gear III, a bevel gear IV and a fixed rod, the problems that an existing table type polishing machine can be used for polishing only one side in one time, the polishing area is small and the working efficiency is low are solved; the processing device has the advantages that the two sidesof a plate can be polished simultaneously, the polishing area is large, the working efficiency is high and the like, and the processing device facilitates people to use.

Owner:安吉铸卫竹木制品有限公司

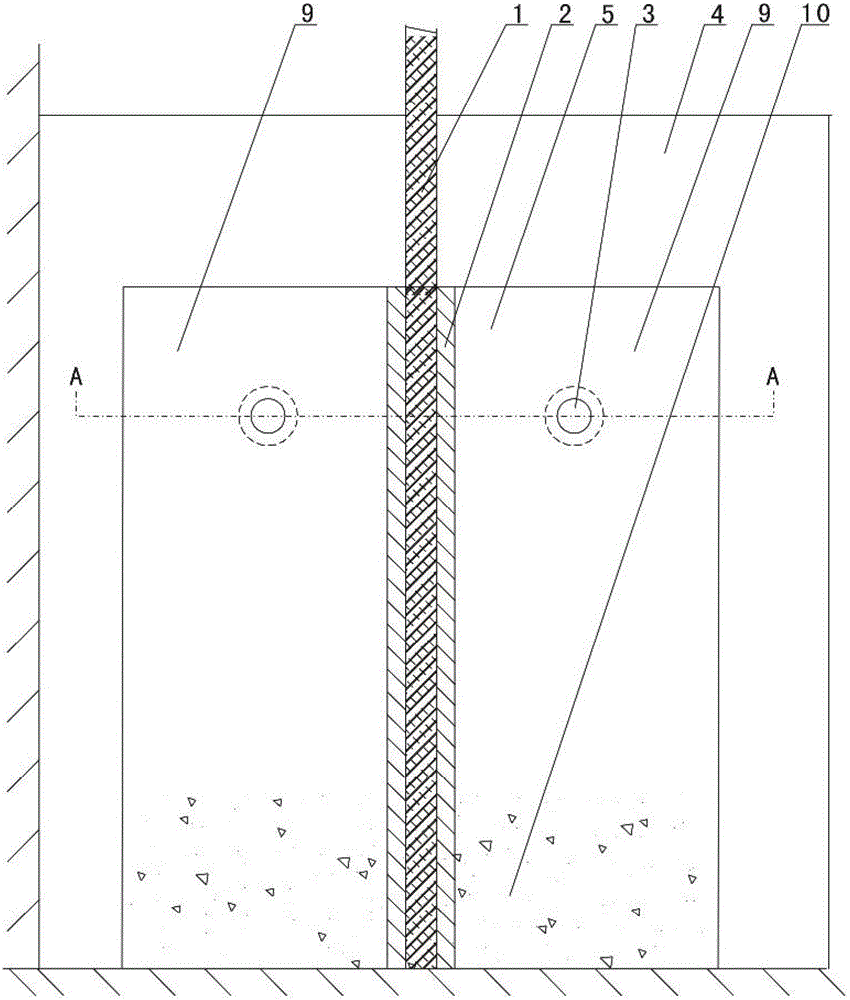

Protector for vertical rubber stanch belt

ActiveCN102767161BAvoid left and right offsetImprove the anti-leakage effectFoundation engineeringMarine site engineeringArchitectural engineeringMagnet

Owner:SINOHYDRO BUREAU 5

Header foaming frame

The invention provides a header foaming frame. The header foaming frame can be used to inject a material from the bottom of the header, can effectively guarantee the foaming density of the foaming material, and guarantees thermal insulation performance of a product. The header foaming frame comprises a frame, a bottom seat, a top pressing board, side pressing boards, a front limiting board, a rearlimiting board, a first air cylinder and a second air cylinder, wherein the bottom seat is horizontally arranged on the frame, the top pressing plate is located above the bottom seat, the first air cylinder is fixed at the upper end of the frame, a piston rod of the first air cylinder is connected with the top pressing plate, a material injection hole used for injecting the material into the header is formed in the top pressing plate, the quantity of the side pressing boards is two, the two side pressing boards are located on the left side and the right side of the bottom seat, the back surfaces of the side pressing boards are connected with a piston rod of the second air cylinder, the second air cylinder is fixed on the side face of the frame, end caps which can block connection holes intwo sides of the header are formed in the inner sides of the side pressing boards, the front limiting board and the rear limiting board are respectively and detachably arranged at two ends of the bottom seat, and positioning grooves are formed in the front limiting board and the rear limiting board.

Owner:HAINING YINUO ELECTRIC

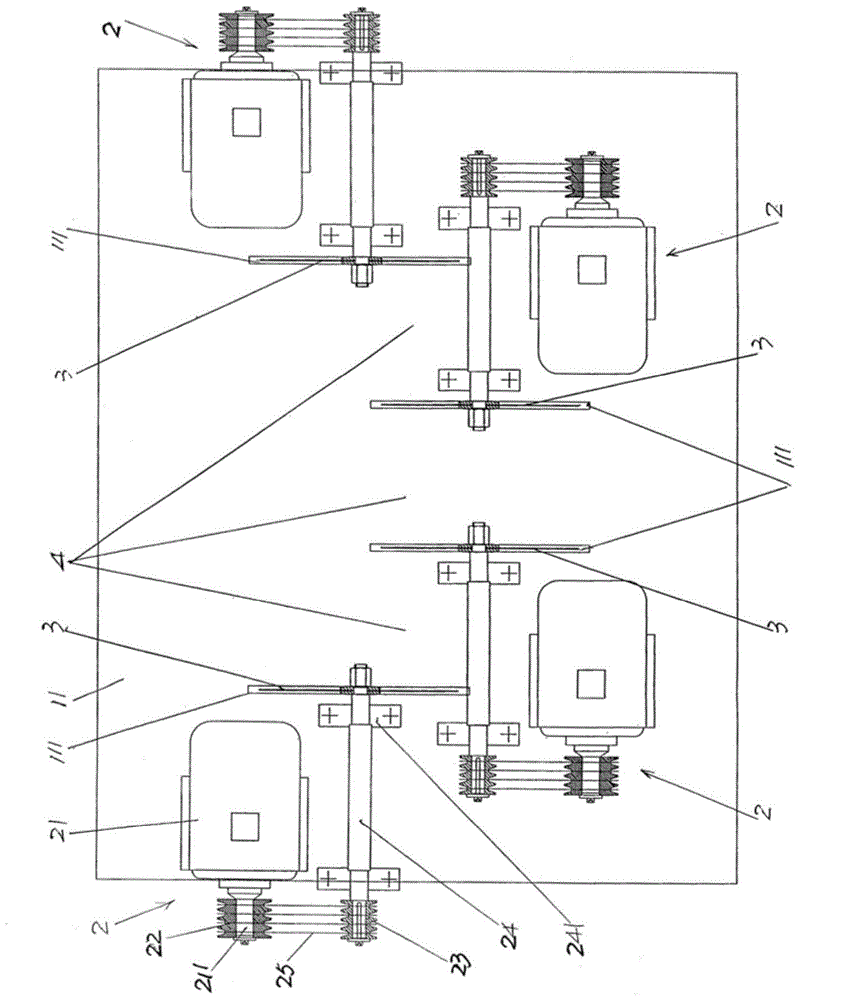

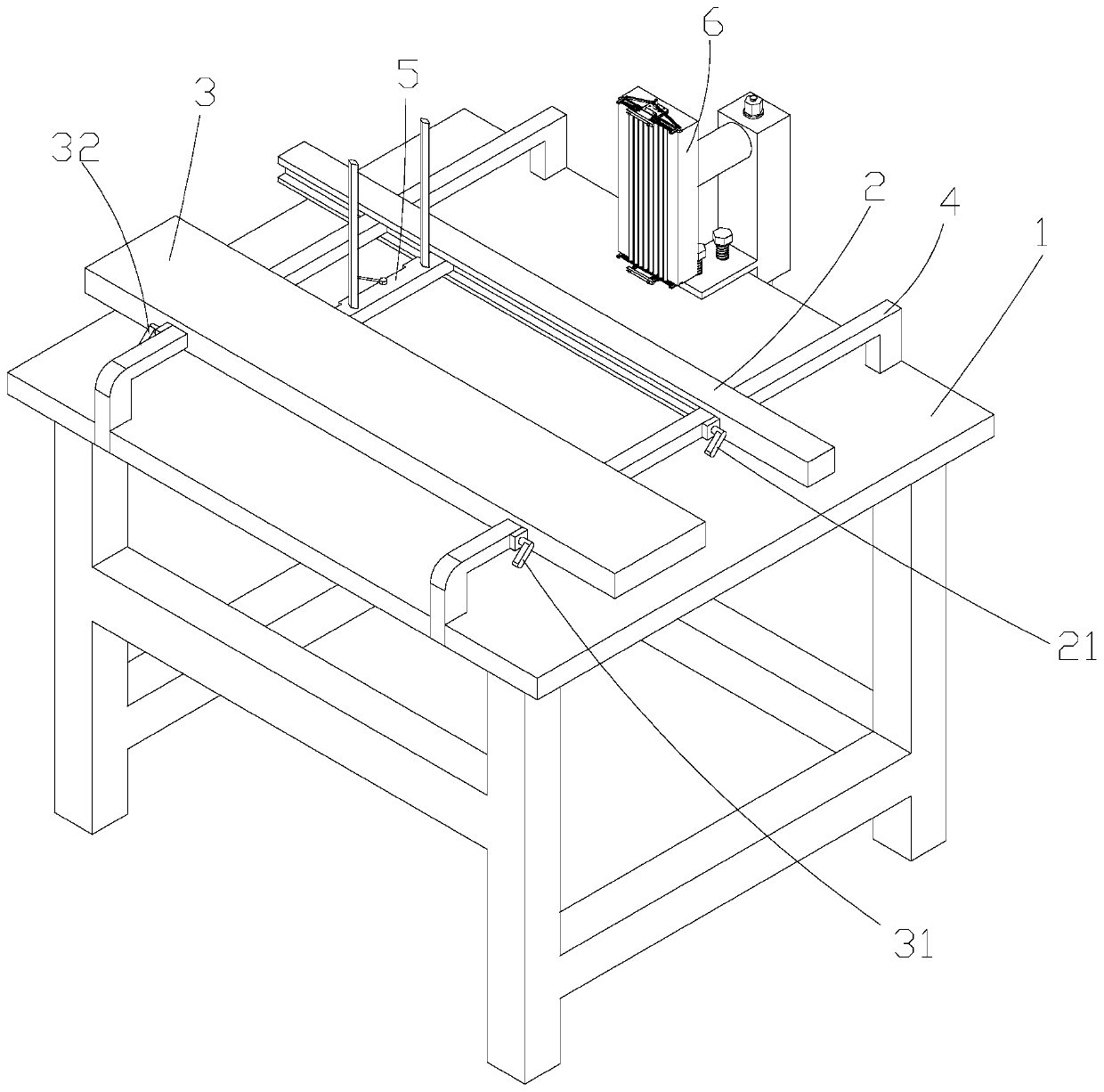

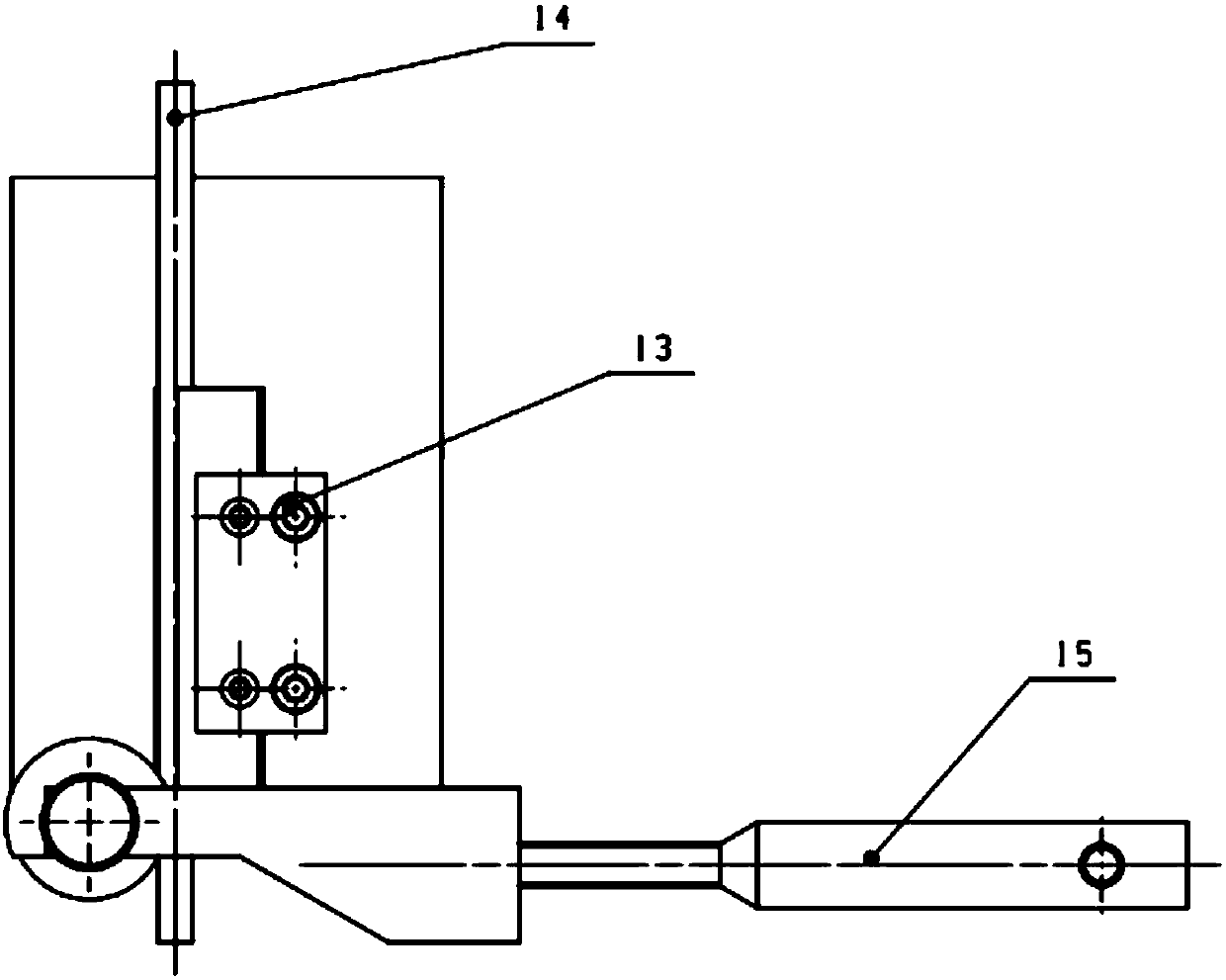

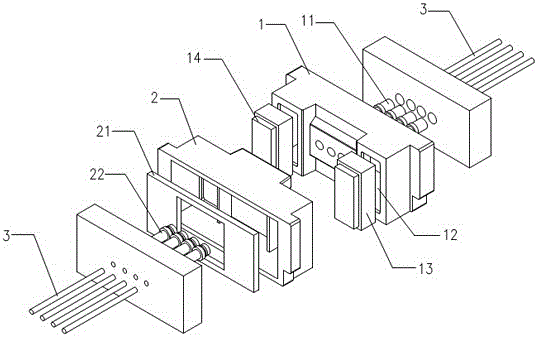

Iron core lamination method of iron core transformer

ActiveCN110379616AAvoid left and right offsetInductances/transformers/magnets manufactureTransformerEngineering

The invention discloses an iron core lamination method of an iron core transformer. The method comprises the following steps of preparation before lamination, device adjustment, lamination of an intermediate column sheet, lower yoke sheet lamination, rim charge lamination and upper yoke sheet lamination. In the step of device adjustment, mainly a lamination device is adjusted. The lamination device comprises a workbench, a first shoe plate positioned over the workbench, a second shoe plate arranged in parallel with the first shoe plate, a fixed guide rail penetrating both the first and secondshoe plates and fixed on the workbench, a first limiting leaning post arranged on both the first and second shoe plates, and a second limiting leaning post for limiting the tip of an intermediate column sheet. Iron cores of different specifications can be laminated via the method.

Owner:浦江星诚电气有限公司

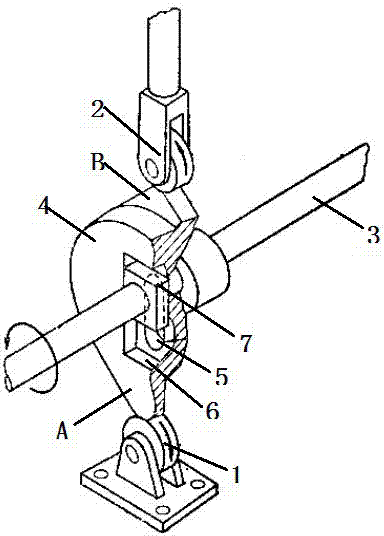

Manual pipe bending device

The invention discloses a manual pipe bending device which comprises a base, a press die unit and a bending unit. The base is a workbench arranged on the ground. The press die unit is mounted on the face of the workbench and used for supporting a pipeline and cooperating with the bending unit for acting. The bending unit is mounted on a mandrel fixed to one corner of the front end of the workbenchface and can rotate around the mandrel so as to bend the pipeline. According to the manual pipe bending device, small straight segment and continuous bent pipelines can be bent. The phenomenon of pipeline deviation can be effectively avoided. The manual pipe bending device has the beneficial effects of being easy to machine, low in cost, high in adaptability, simple and convenient to operate andthe like.

Owner:BEIJING POWER MACHINERY INST

Double cam mechanism

The invention belongs to the technical field of electric switches, and particularly relates to a double cam mechanism which comprises a fixed roller, a driven roller, a cam shaft and a double cam. A slotted hole is formed in the center of the double cam along the long diameter direction of the cam, the double cam is assembled on the cam shaft through the slotted hole, the double cam includes two cams with different base circle radiuses, the cam with the large base circle radius contacts with the driven roller, and the cam with the small base circle radius contacts with the fixed roller. Strokes of driven components of the cams can be enlarged under the permissive condition of the maximum pressure angles of the cams.

Owner:CHONGQING TIANZHIDAO SCI & TECH DEV

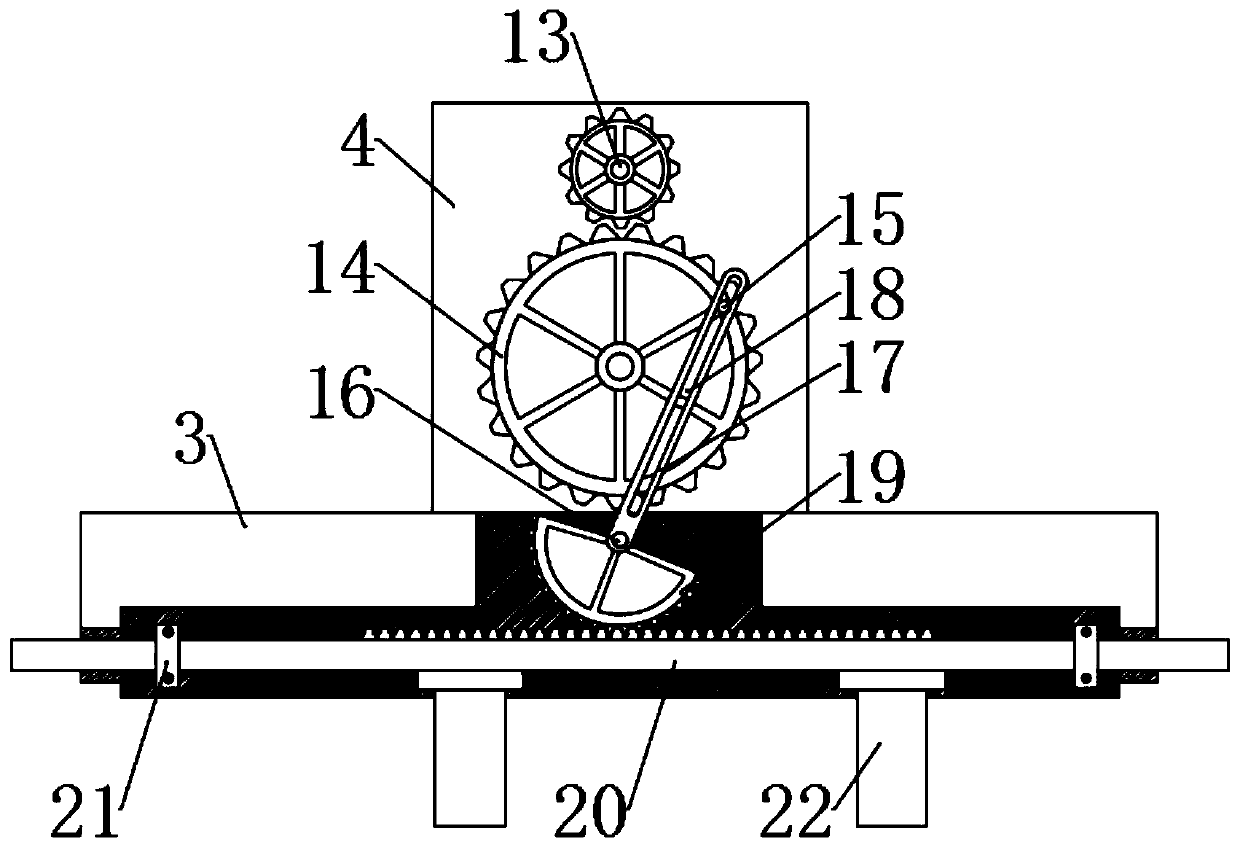

Novel diffusion furnace battery piece conveying device

PendingCN107316835AAvoid left and right offsetAvoid Push Boat Overload Alarm SituationsFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Disclosed is a novel diffusion furnace battery piece conveying device, comprising a central shaft and a synchronizing wheel. A fixing surface is arranged on an outer side wall of a mounting end of the central shaft, and two ends of the mounting end of the central shaft are rotatably inserted into a left mounting frame and a right mounting frame respectively. The synchronizing wheel is sleeved on the mounting end of the central shaft between the left mounting frame and the right mounting frame. An insertion hole penetrates through the synchronizing wheel, a drilling hole is formed in the fixing surface in correspondence to the insertion hole, a jackscrew is inserted into the insertion hole, and an end, close to the mounting end of the central shaft, of the jackscrew extends into the drilling hole. By changing a fixing manner of the synchronizing wheel, the fixing surface of the central shaft capable of more firmly fixing the synchronizing wheel is designed, the drilling hole is formed in the surface of the fixing surface, the jackscrew is inserted into the insertion hole of the synchronizing wheel and extends into the drilling hole, and therefore the synchronizing wheel can be effectively prevented from shifting leftwards and rightwards. Thus, a situation of a pusher overload alarm of a diffusion furnace is avoided, the downtime of the diffusion furnace is reasonably shortened, and therefore the yield during diffusion of silicon wafers can be improved.

Owner:TONGWEI SOLAR (ANHUI) CO LTD

An electronic seal connector

InactiveCN104103930BStable signalQuick plugCoupling contact membersCouplings bases/casesTransmission lineLateral projection

The invention relates to an electronic sealing connector, which is composed of a plug and a socket; a longitudinal groove is arranged in the middle of the front of the plug, and a transverse protrusion is arranged in the longitudinal groove, and a plurality of elastic probes are arranged on the transverse protrusion , the plugs on both sides of the transverse protrusions are provided with mutually symmetrical cavities, and the first magnetic block is installed in the cavities; the middle of the front of the socket is provided with longitudinal protrusions, and the sockets on both sides are provided with interfaces, and the interfaces are provided with There is a second magnetic block, the longitudinal protrusion is provided with a transverse groove, and a conductive column is arranged in the transverse groove; the ends of the conductive column and the elastic probe are connected to the signal transmission line, and are connected to the plug and the The socket package is fixed. This kind of electronic seal connector is in good contact, which can prevent the left and right or up and down deviation of the plug and the socket, and ensure the stability of the signal. Low.

Owner:SUZHOU KERU ELECTRONICS TECH

Stable steel tube straightening device

The invention discloses a stable steel tube straightening device and relates to the field of steel tube machining and manufacturing. The stable steel tube straightening device comprises a first machine box, a second machine box, direction adjusting devices, a feeding opening and vertical rails, wherein a pressing plate is arranged in the first machine box, the pressing plate is provided with at least two first straightening rollers which are linearly arranged, the second machine box is arranged below the first machine box, second straightening rollers are arranged on the second machine box, the second straightening rollers and the first straightening rollers are correspondingly arranged and are identical in number, the direction adjusting directions are arranged at the bottom of the pressing plate and correspond to the first straightening rollers and the second straightening rollers, each direction adjusting device is correspondingly connected to one first straightening roller or one second straightening roller, the vertical rails are symmetrically arranged in the front-back direction. Straightening of steel tubes of different diameters can be achieved.

Owner:江苏宏宝优特管业制造有限公司

Riveting machine for lady leather shoe production

The invention discloses a riveting machine for lady leather shoe production. The riveting machine comprises an operation table, vertical plates, a truss, a driving device and a sliding plate. The vertical plates are fixedly installed on the two sides of the upper surface of the operation table in the vertical direction. By arranging partition plates and partition rods, a plurality of leather shoescan be placed on the sliding plate at the same time. After the installation of a first row of leather shoes by means of the riveting machine, a lead screw motor is turned on. The lead screw motor drives a threaded rod to drive the sliding plate to move forwards. The riveting machine can install rivets on the next row of leather shoes. Therefore, the time is saved, and the efficiency is improved.The distance between the partition plates and the partition rods is the same as the size of leather shoes, so that the mounting position deviation of rivets or the asymmetry of left and right shoes due to the unfixed positions of leather shoes can be avoided. The defective rate is reduced. An I-shaped sliding rail is arranged. By means of the I-shaped sliding rail, the sliding plate can be guided.Meanwhile, the sliding plate is prevented from deviating leftwards and rightwards when the riveting machine collides with the sliding plate.

Anti-theft window convenient to open and close

InactiveCN107882494AAvoid left and right offsetEasy to open and closeShutters/ movable grillesMan-operated mechanismBobbinEngineering

The invention discloses an anti-theft window convenient to open and close. The anti-theft window comprises a main frame body and an anti-theft net plate, the anti-theft net plate is rotatably connected with the internal bottom of the main frame body through a rotary shaft, a mounting groove is formed in the top of the anti-theft net plate, a rotating rod is rotatably connected to the interior of the mounting groove, and a steel wire rope is fixedly connected to the rotating rod. A through port corresponding to the steel wire rope is formed in the internal top of the main frame body, a cushionplate is connected to the interior of the through port through a telescopic rod, and one side of the main frame body is rotatably connected with a winding cylinder. One end, away from the rotating rod, of the steel wire rope sequentially penetrates through the mounting groove and the through port to extend outwards, the end extended by the steel wire rope is arranged on the winding cylinder in a winding mode, one end, away from the main frame body, of the winding cylinder is fixedly connected with a handle, and a clamping rod is slidably arranged at one end of the handle in an inserted mode. Through arrangement of the steel wire rope and the winding cylinder, the anti-theft window can be more convenient to open and close under an emergency situation, and meanwhile, the opening and closingspeed of the anti-theft window is improved.

Owner:肇庆高新区鹰眼科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com