Fracture simulation adjusting mechanism of grouting expansion testing device

A technology of testing device and adjustment mechanism, which is applied in measurement devices, diffusion analysis, instruments, etc., can solve the problems of cumbersome operation, poor flexibility, poor glass plate strength, etc., to reduce rotational resistance, improve sealing performance, and enhance sealing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

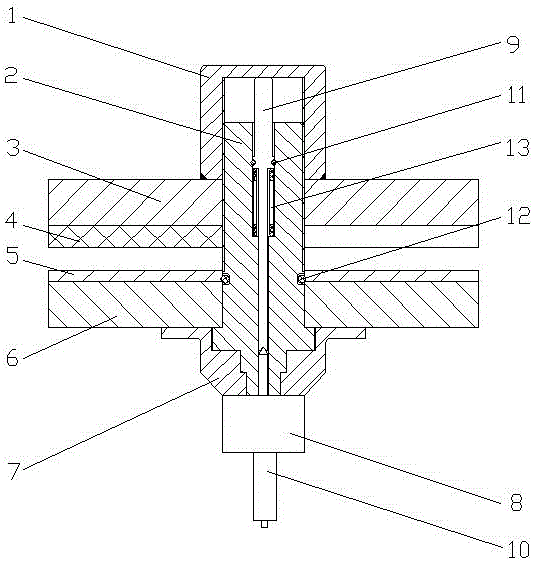

Embodiment 1

[0043] see figure 1 , a fissure simulation adjustment mechanism of a grouting diffusion test device, including an adjustment component and a measurement component, the adjustment component includes a fastening nut 1, an adjustment bolt 2, an upper pressure plate 3, a visible plate 4, a lower pressure plate 5, and a bottom plate 6 , the gland 7 and the servo motor 8 that drives the adjusting bolt 2, the fastening nut 1 is fixed on the upper platen 3, the adjusting bolt 2 runs through the upper platen 3 and the bottom plate 6 respectively, one end of the adjusting bolt 2 is connected to the fastening nut 1 connected, the other end is connected to the servo motor 8, the gland 7 is fixedly connected to the base plate 6; the measuring parts include a displacement measuring rod 9 and a displacement sensor 10, the adjusting bolt 2 is a hollow structure, and the displacement measuring rod 9 Placed in the adjusting bolt 2, the displacement measuring rod 9 is provided with a first seali...

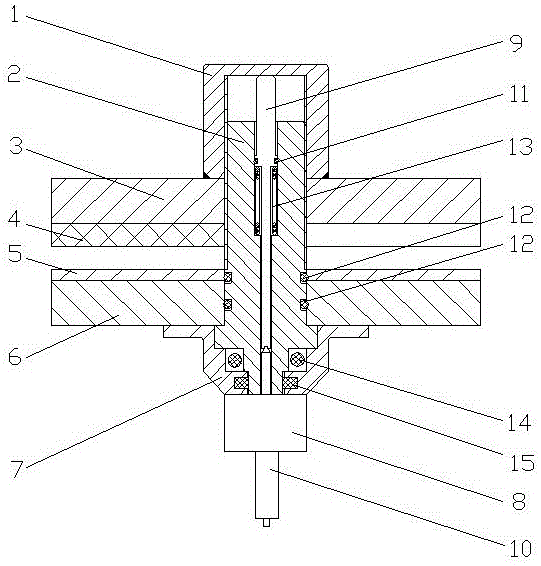

Embodiment 2

[0046] see figure 2 , a fissure simulation adjustment mechanism of a grouting diffusion test device, including an adjustment component and a measurement component, the adjustment component includes a fastening nut 1, an adjustment bolt 2, an upper pressure plate 3, a visible plate 4, a lower pressure plate 5, and a bottom plate 6 , the gland 7 and the servo motor 8 that drives the adjusting bolt 2, the fastening nut 1 is fixed on the upper platen 3, the adjusting bolt 2 runs through the upper platen 3 and the bottom plate 6 respectively, one end of the adjusting bolt 2 is connected to the fastening nut 1 connected, the other end is connected to the servo motor 8, the gland 7 is fixedly connected to the base plate 6; the measuring parts include a displacement measuring rod 9 and a displacement sensor 10, the adjusting bolt 2 is a hollow structure, and the displacement measuring rod 9 Placed in the adjusting bolt 2, the displacement measuring rod 9 is provided with a first seal...

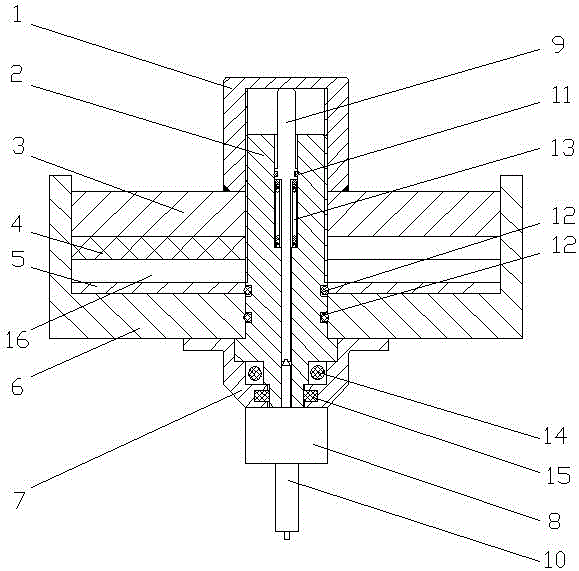

Embodiment 3

[0050] see figure 2 , a fissure simulation adjustment mechanism of a grouting diffusion test device, including an adjustment component and a measurement component, the adjustment component includes a fastening nut 1, an adjustment bolt 2, an upper pressure plate 3, a visible plate 4, a lower pressure plate 5, and a bottom plate 6 , the gland 7 and the servo motor 8 that drives the adjusting bolt 2, the fastening nut 1 is fixed on the upper platen 3, the adjusting bolt 2 runs through the upper platen 3 and the bottom plate 6 respectively, one end of the adjusting bolt 2 is connected to the fastening nut 1 connected, the other end is connected to the servo motor 8, the gland 7 is fixedly connected to the base plate 6; the measuring parts include a displacement measuring rod 9 and a displacement sensor 10, the adjusting bolt 2 is a hollow structure, and the displacement measuring rod 9 Placed in the adjusting bolt 2, the displacement measuring rod 9 is provided with a first seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com