Packaging bag material collecting device

A receiving device, packaging bag technology, applied in packaging, transportation and packaging, paper/cardboard containers, etc., can solve problems affecting product quality and aesthetics, packaging bag offset, etc., to improve aesthetics, prevent left-right offset , Improve the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

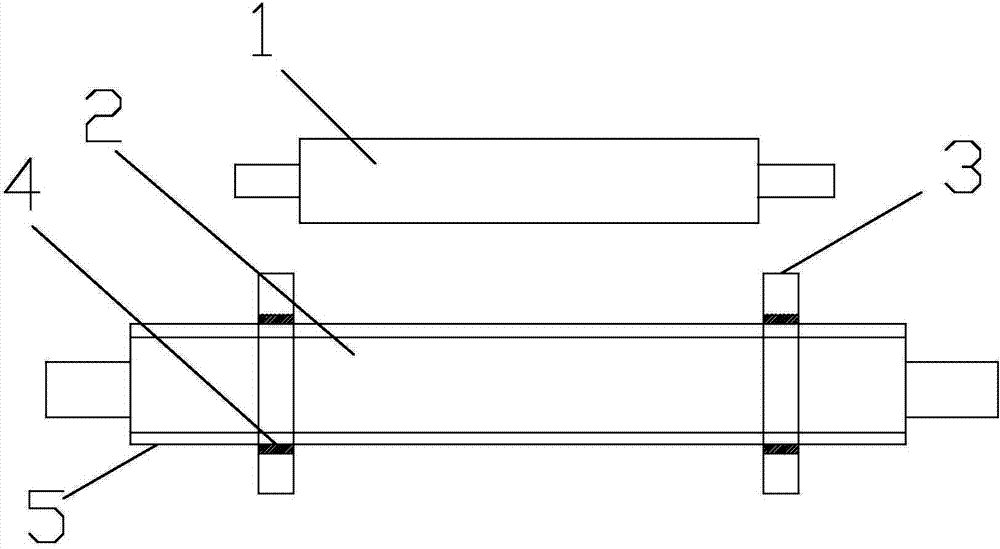

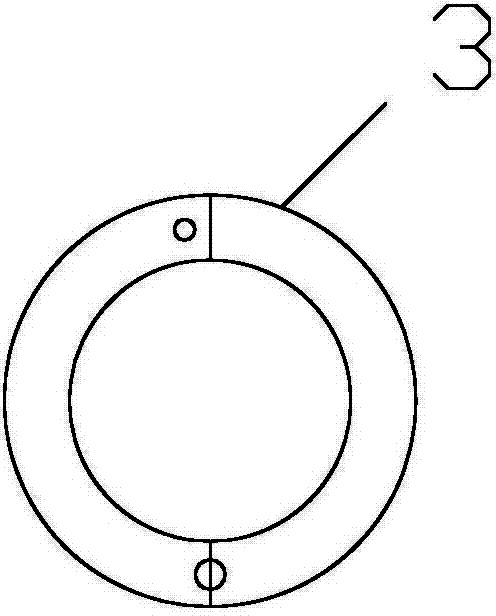

[0013] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Such as figure 1 As shown, a packaging bag receiving device includes a tension roller 1 and a receiving roller 2, and the two sides of the receiving roller are provided with limiting devices for limiting the left and right movement of the packaging bag, and the limiting devices are two A symmetrically arranged snap ring 3. The distance between the two snap rings is exactly the width of the packaging bag, and the distance between the two snap rings can be adjusted on the paper tube 5 .

[0014] In the present invention, the snap ring is mainly composed of two semicircular upper snap rings and lower snap rings, one end of the upper snap ring and the lower snap ring are hinged, and the other end is locked by a bolt. When the barrel is removed, the two snap rings can also be replaced accordingly, which is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com