Auto-eject gun-lock device with ring-mounted key

a gun-lock device and key-mounted technology, applied in the direction of weapons, weapon components, safety arrangements, etc., can solve the problems of insufficient barrier, inflicting damage to both, and failure of the chamber-engaging arrangemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

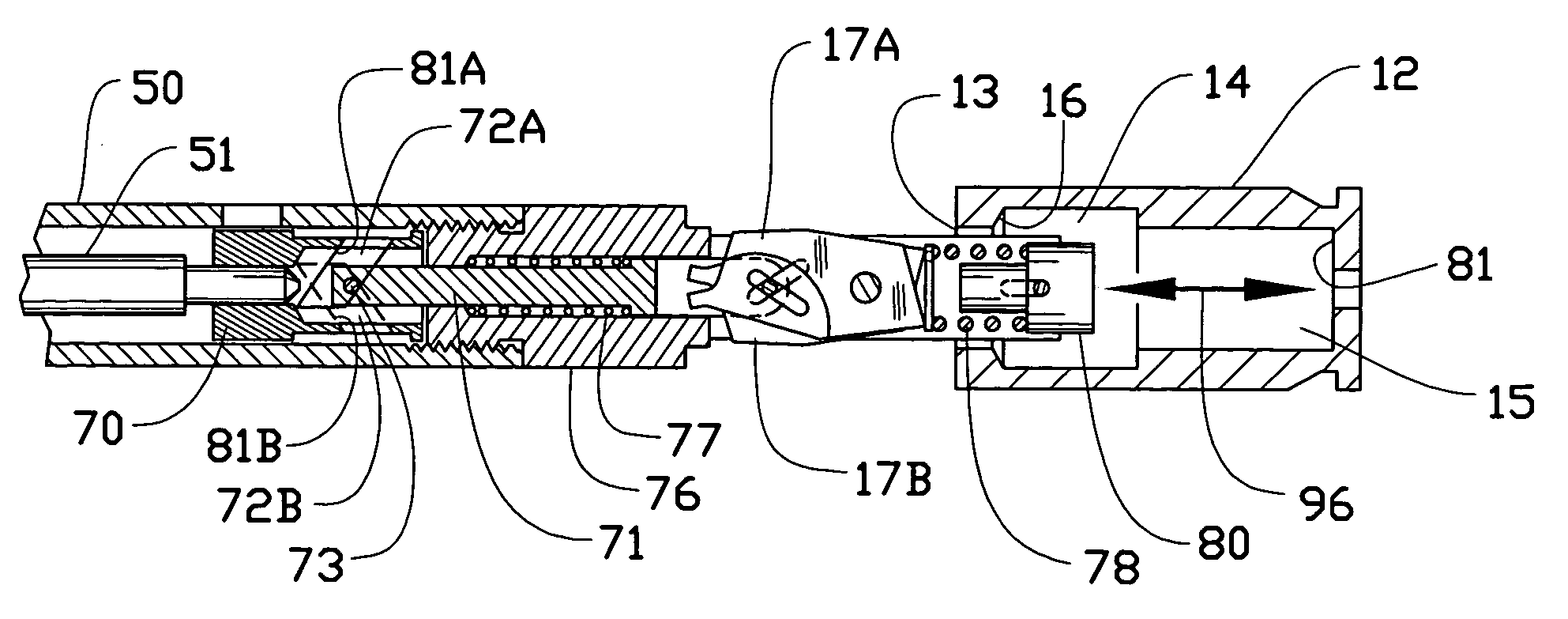

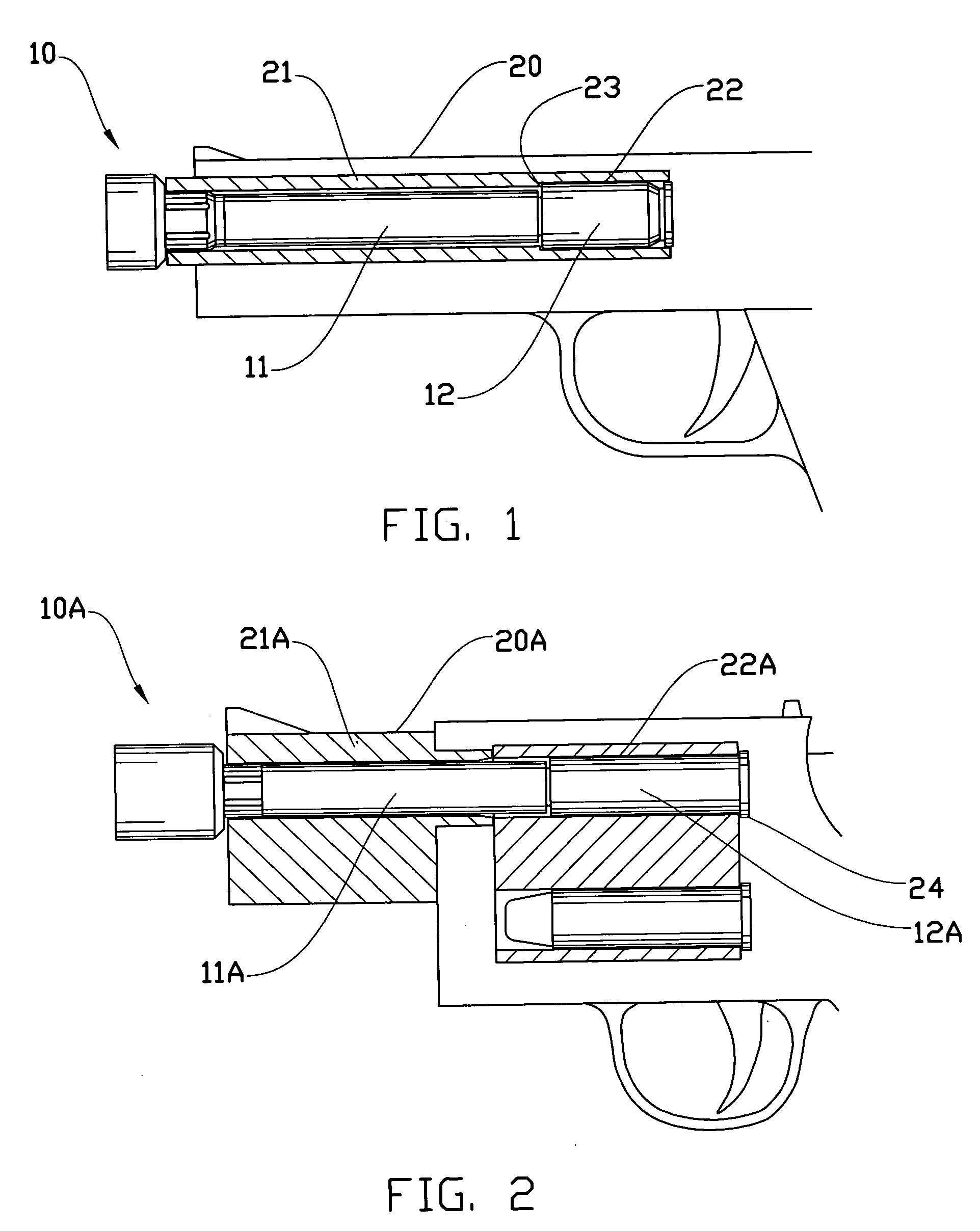

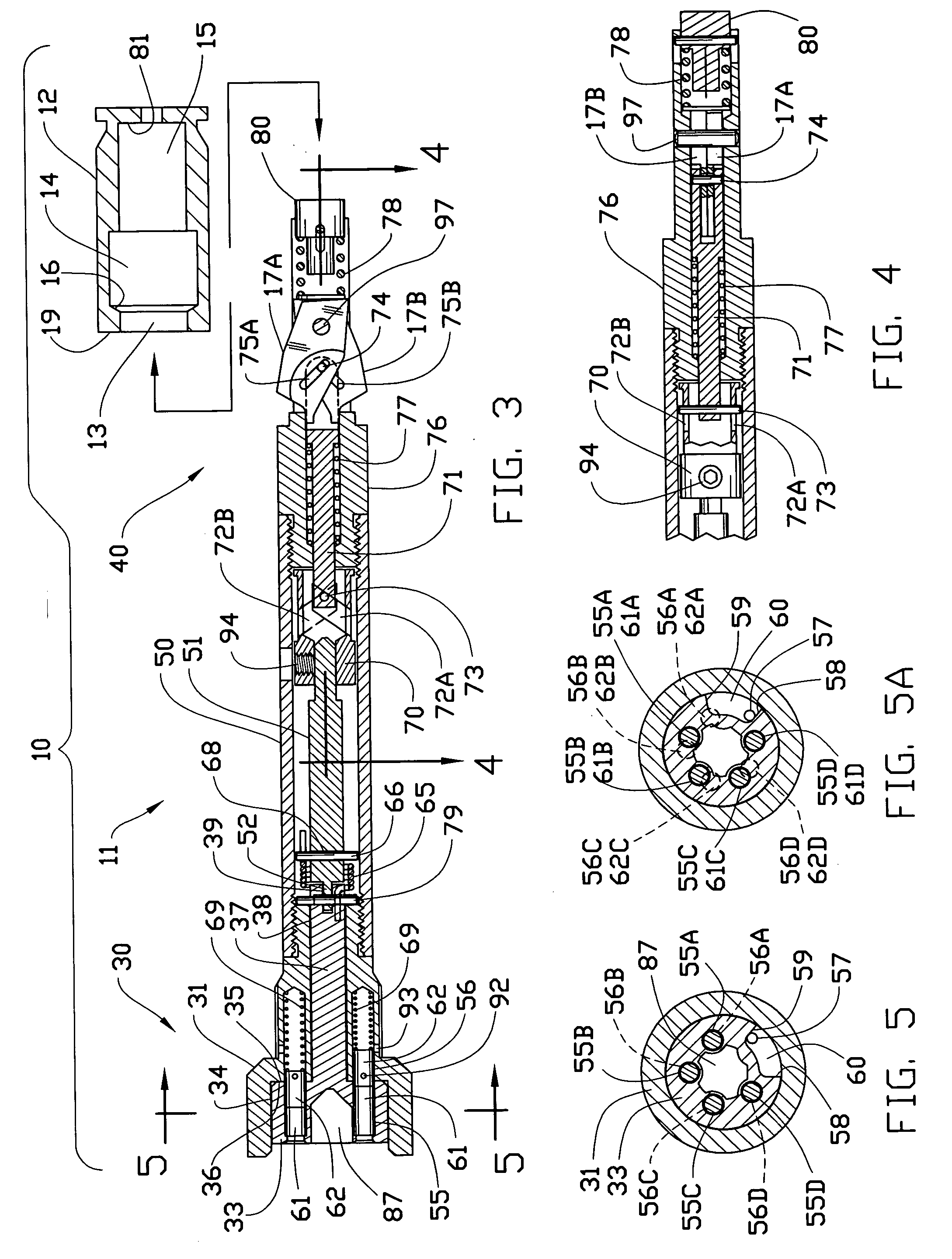

[0038]FIGS. 1-16 of the drawings illustrate various aspects of a gun-lock device 10 constructed according to the invention. Although the following discussions may reference specific features and functions of a large-bore semi-automatic handgun, the inventive concepts disclosed and claimed are not restricted to such. A gun-lock device constructed according to the invention may be configured for use with any handgun or a long gun of semi-automatic, revolver, or of other action type of any caliber size, so as long as the firearm has a barrel with a bore and a chamber.

[0039] The gun-lock device 10 of FIG. 1 includes a tubular assembly 11 which is inserted from the muzzle end of the barrel 21 of the firearm 20 and a chamber plug member 12 which is inserted into the chamber 22 from the breach end of a semi-automatic handgun of such caliber as .40 S&W. The gun-lock device 10A of FIG. 2 is a variation adapted to work with a revolver of such caliber as .357 Magnum, wherein a tubular assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com