Automatic reaming machine

A reaming machine, automatic technology, applied in reaming device, reaming device, metal processing machinery parts, etc., can solve the problems affecting the quality of reaming, low degree of automation, large size, etc. Compact and reasonable, the effect of improved reaming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

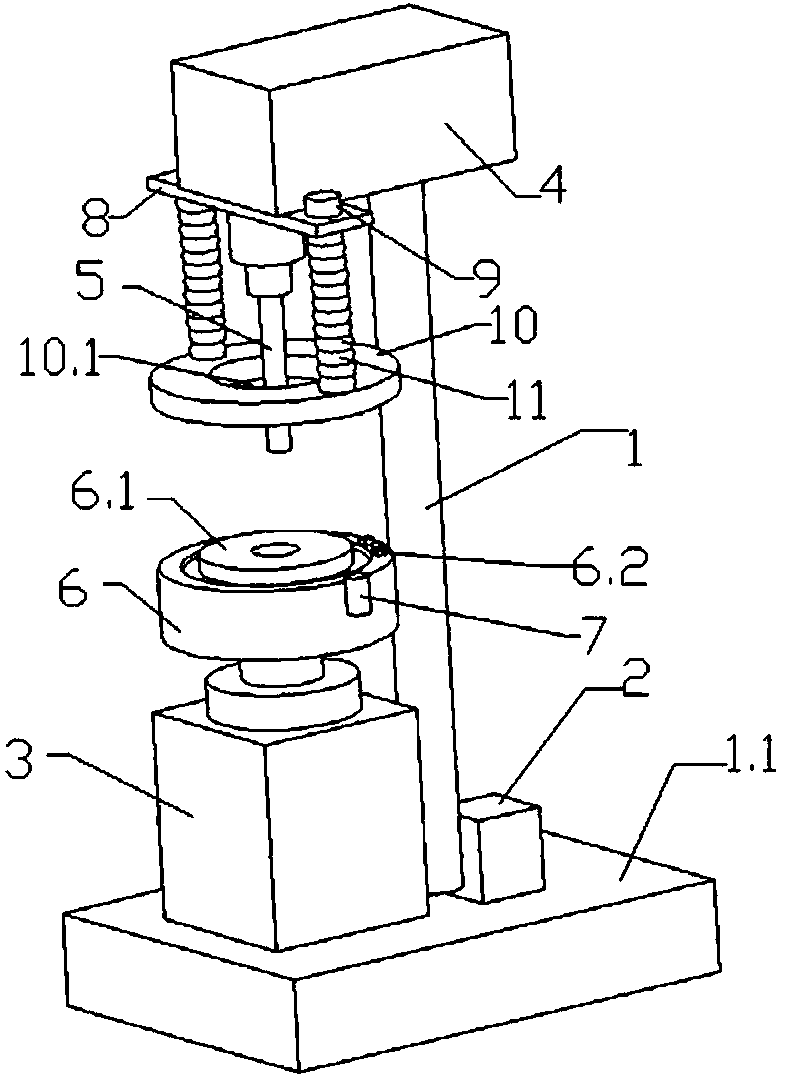

[0012] As shown in the figure, an automatic reaming machine includes a frame 1, which is different from the prior art in that it also includes a controller 2, a cylinder with a cylinder body installed on the frame base 1.1 and the piston rod facing upwards. 3. The body is installed on the top of the frame 1 and the motor 4 is set with the output shaft facing downward. A reamer 5 for reaming is mounted on the output shaft of the motor. In this embodiment, the controller 2 is installed on the frame base 1.1.

[0013] The piston rod of the cylinder is equipped with a positioning seat 6 for clamping and positioning the aluminum frozen motor casing, and the positioning seat 6 is formed with a positioning boss 6.1 matching the central concave hole at the bottom of the aluminum frozen motor casing. The positioning seat 6 is also provided with a limit block 6.2 whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com