Patents

Literature

67results about How to "Improve touch effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

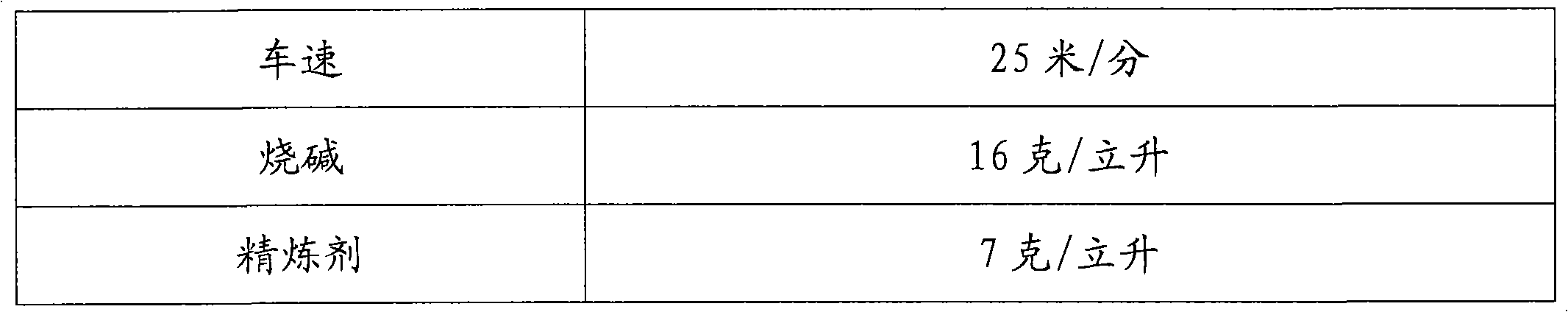

Machining process of peach skin cotton fabric

InactiveCN102031657APlasticityImprove touch effectBiochemical fibre treatmentTextile treatment by spraying/projectingTextile technologyPulp and paper industry

The invention belongs to the field of textile technology, in particular to a machining process of a peach skin cotton fabric. The machining process of the peach skin cotton fabric provided by the invention comprises the processes of turning and sewing, singeing, cooling and stacking, bleaching again by a jig dyeing machine, drying in a loose mode, sizing, mercerizing by a straight roller, brushing by carbon elements, dyeing by air flow, treating by cellulase in an air flow machine, drying in a loose mode, padding softeners in a loose mode, beating by air flow in a softening machine, tentering, pre-shrinking, and sorting and finishing. In the invention, the pretreatment processes of cooling and stacking and the process of dyeing by air flow are used for achieving the optimal effect of uniform and transparent dyeing; the automatic on-line detection technology is used for tracking the quality and processes to enable the production processes to be controlled at the critical optimal point, and all drying processes are carried out in a loose mode to keep the optimal hand feeling effect; and the processes of brushing by carbon elements, dyeing by air flow, treating by cellulase, beating by air and the like are used for ensuring that the fabric has delicate and plump peach skin hand feeling, plastic elasticity and delicate and clear cloth cover.

Owner:HUAFANG

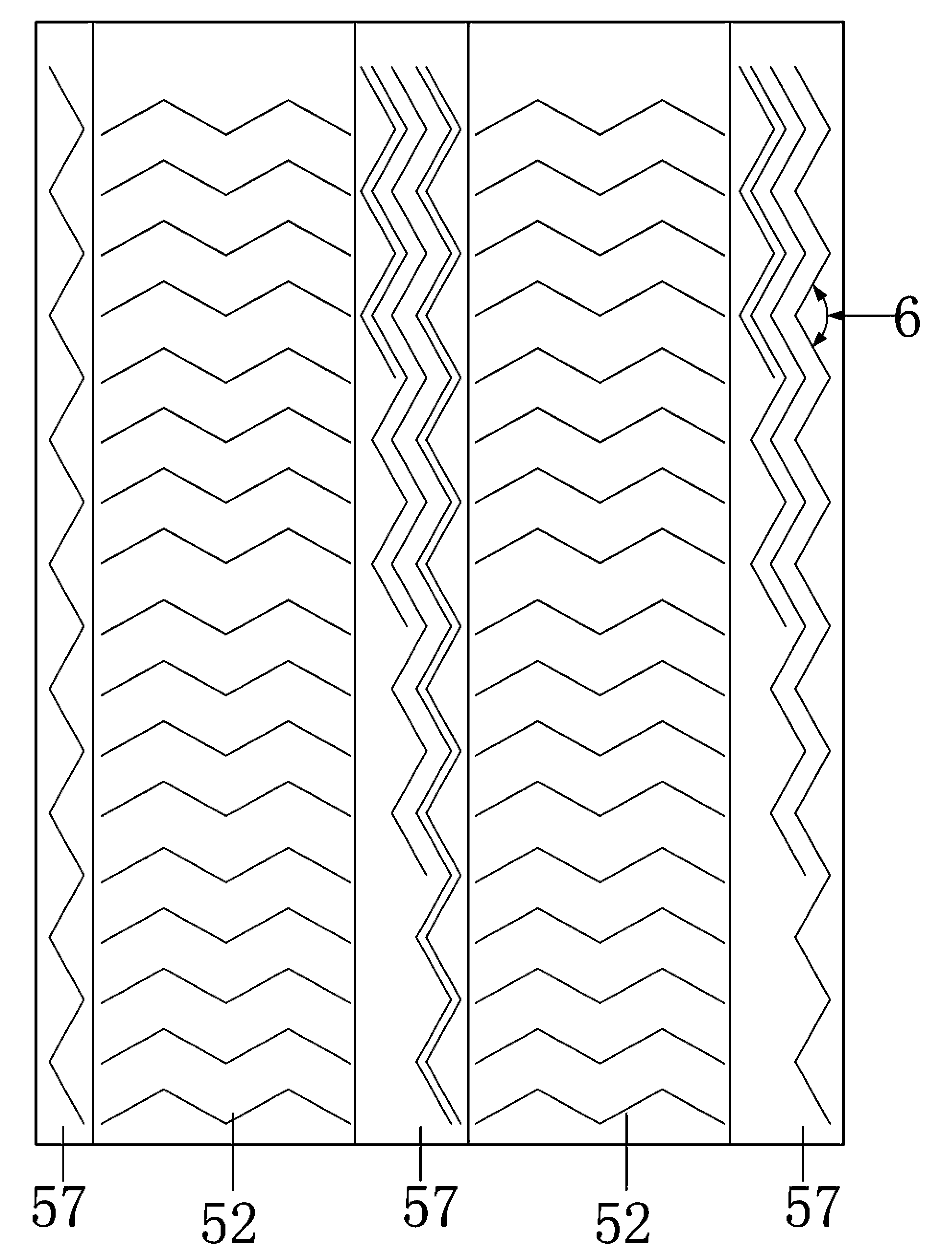

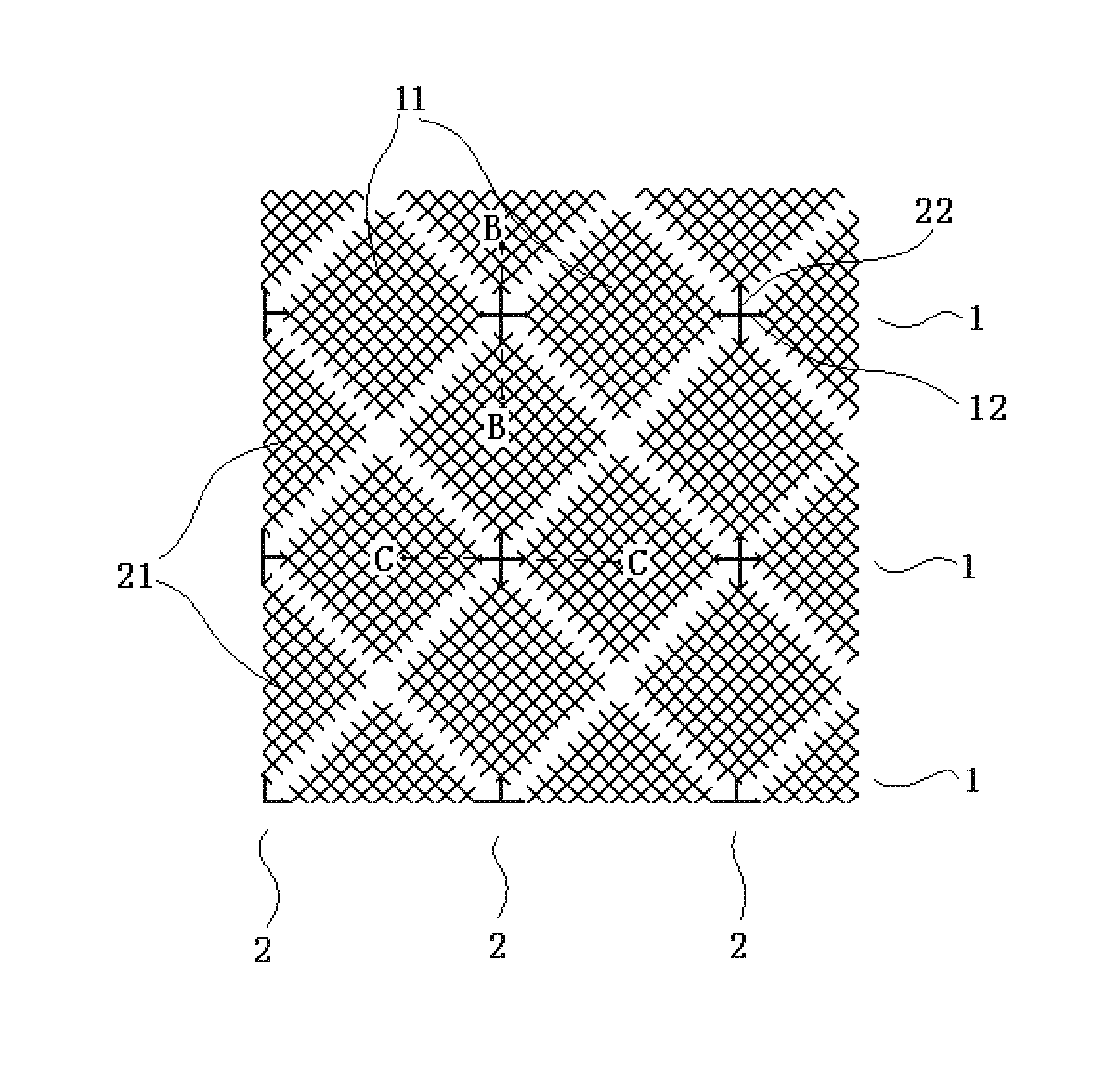

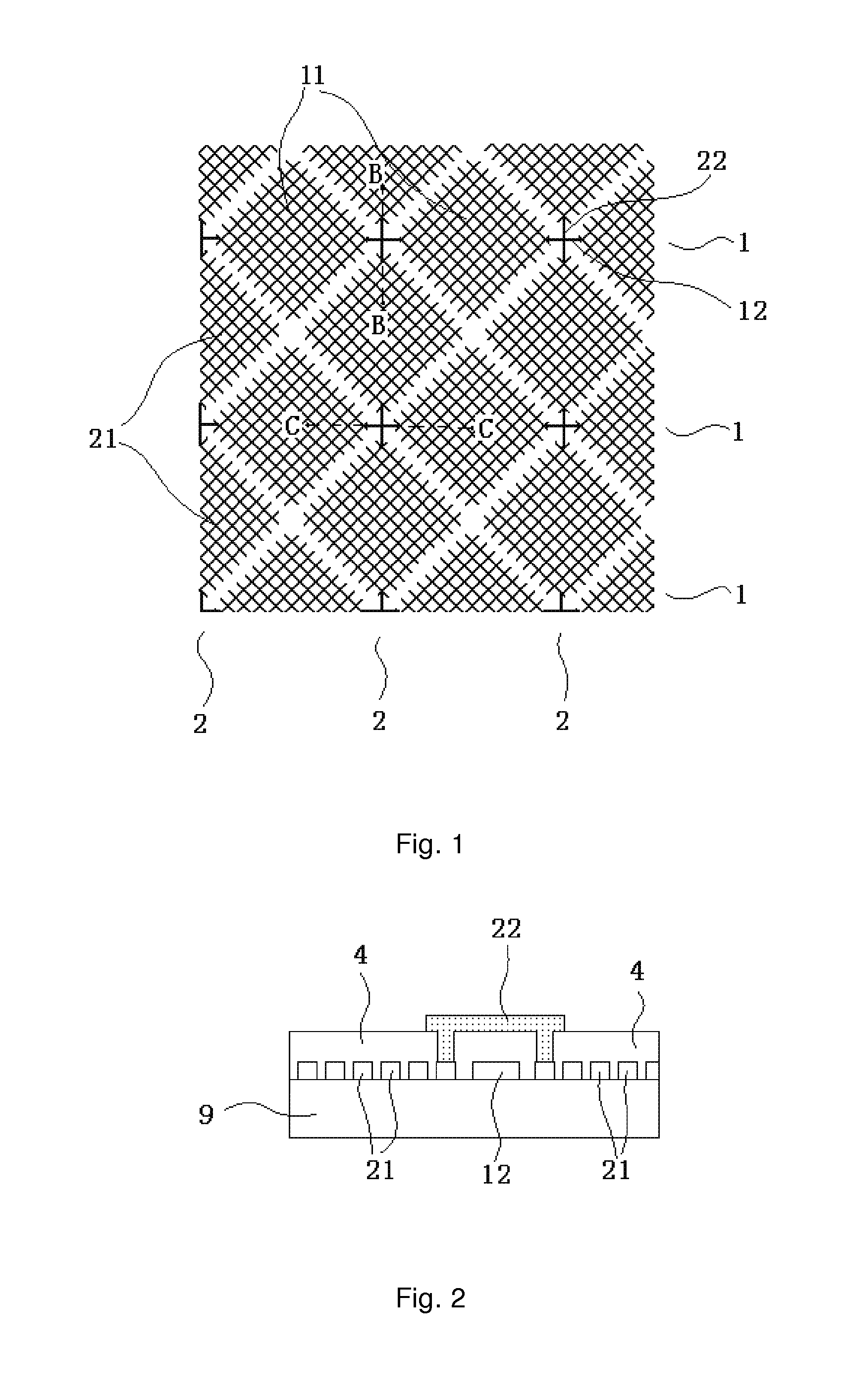

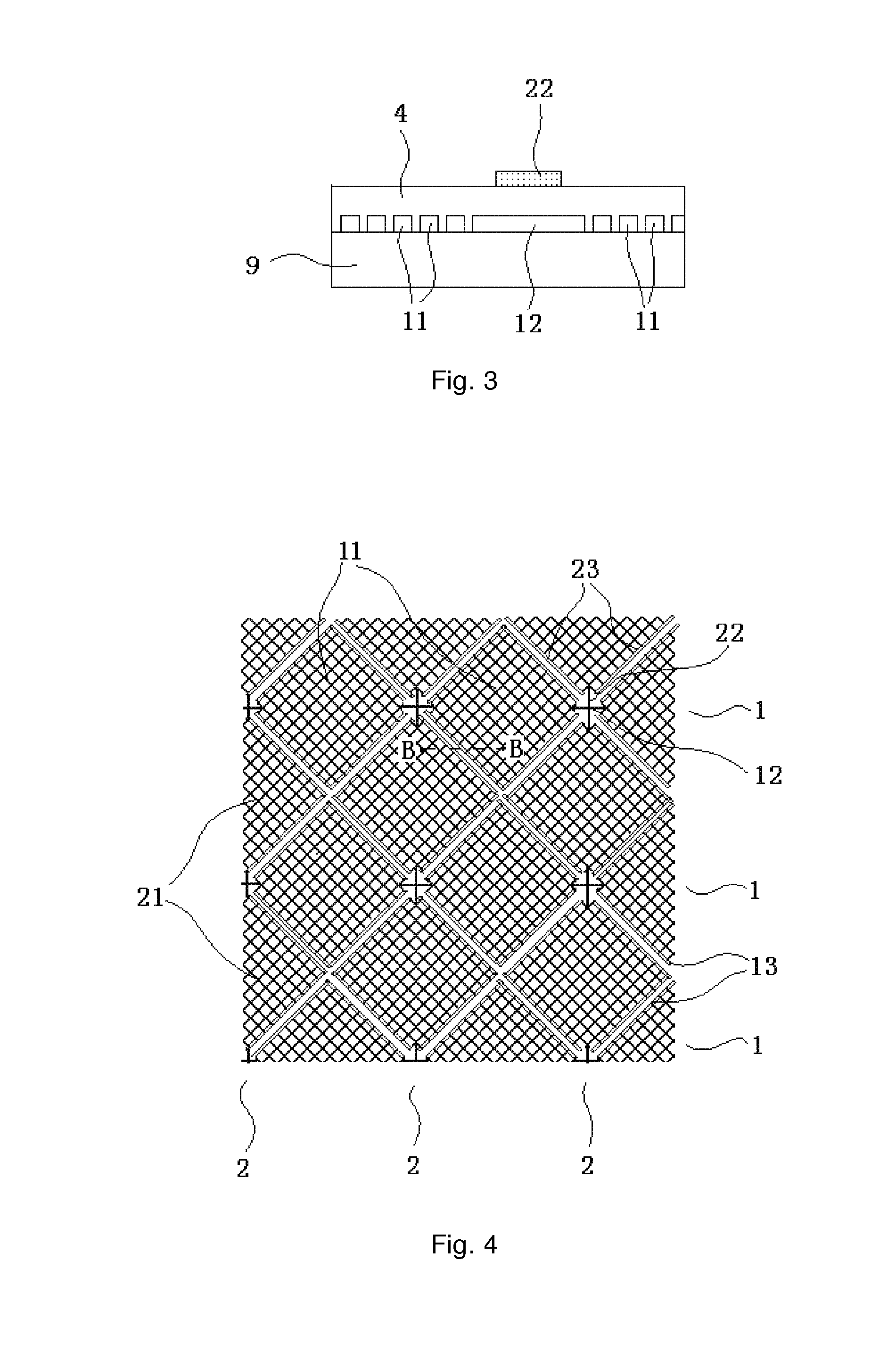

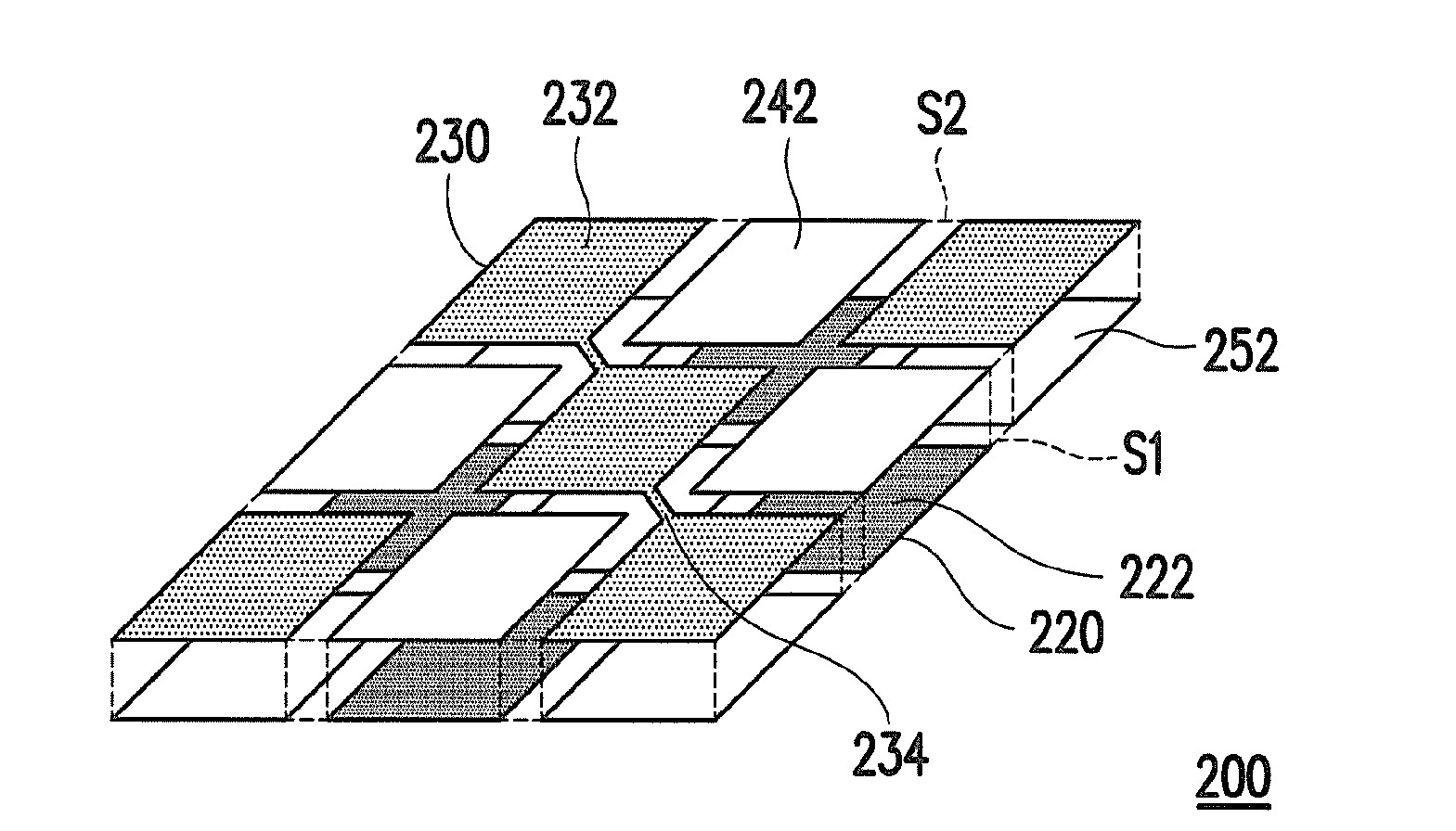

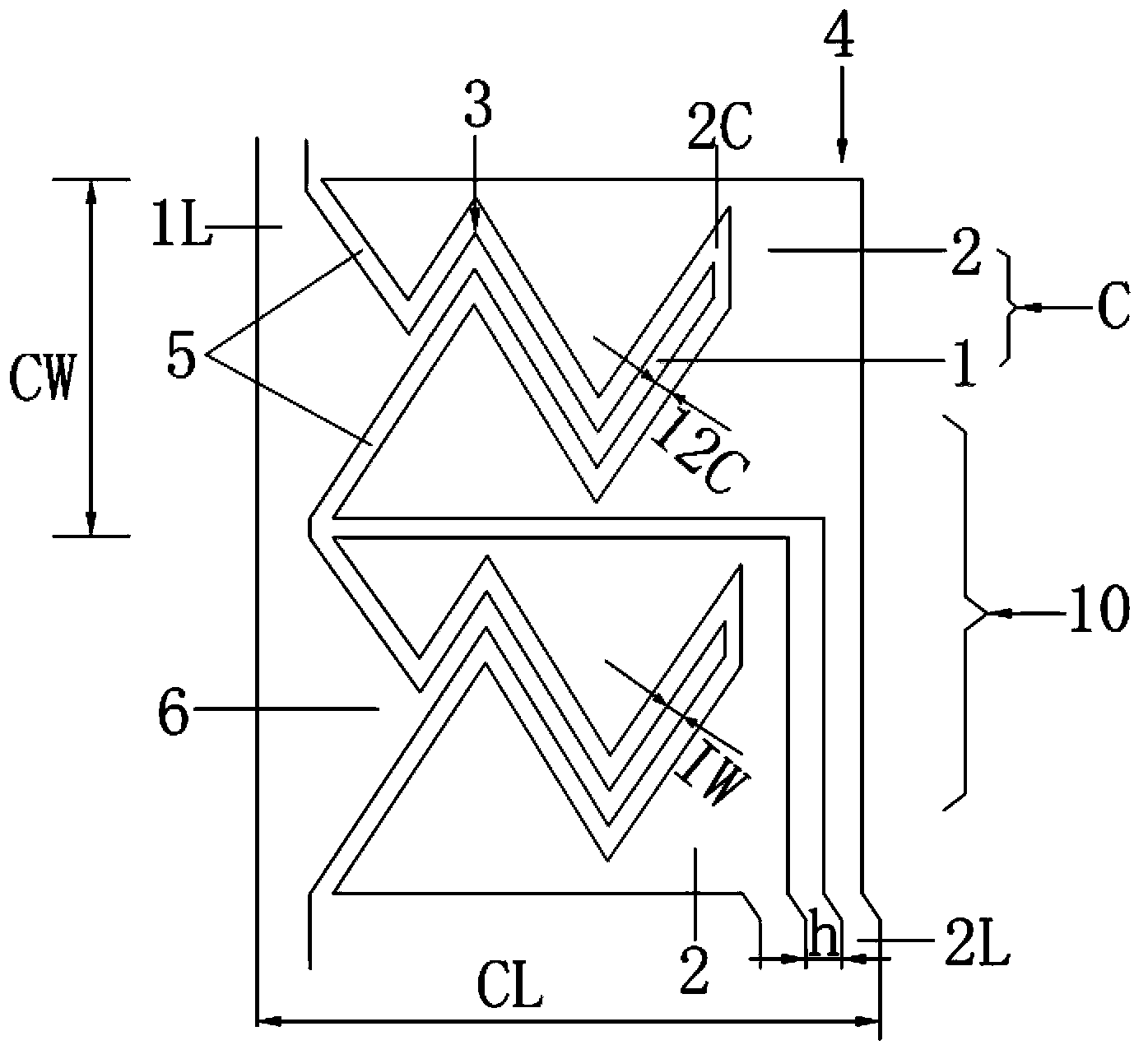

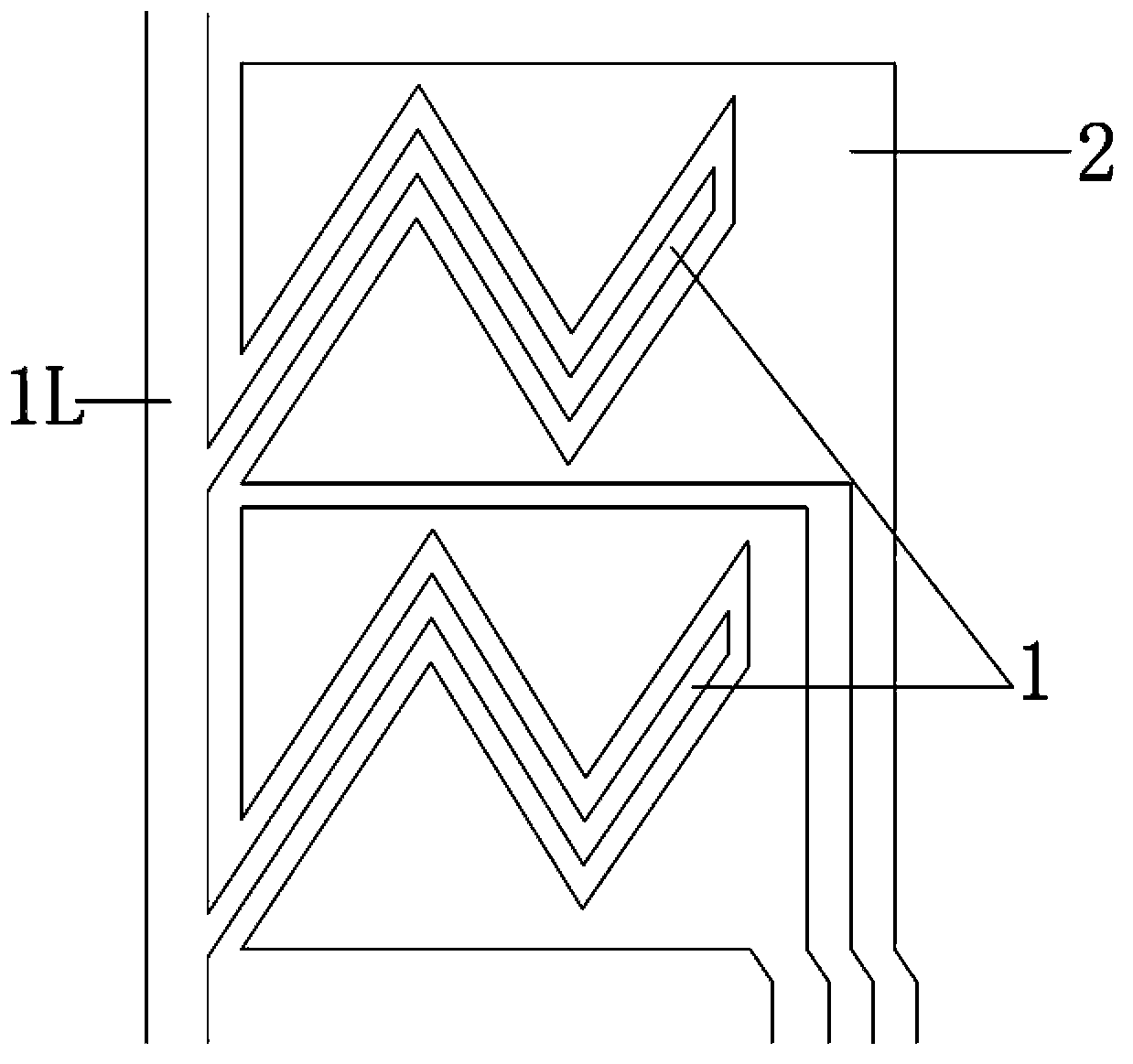

Capacitive touch screen and single-layer wiring electrode array

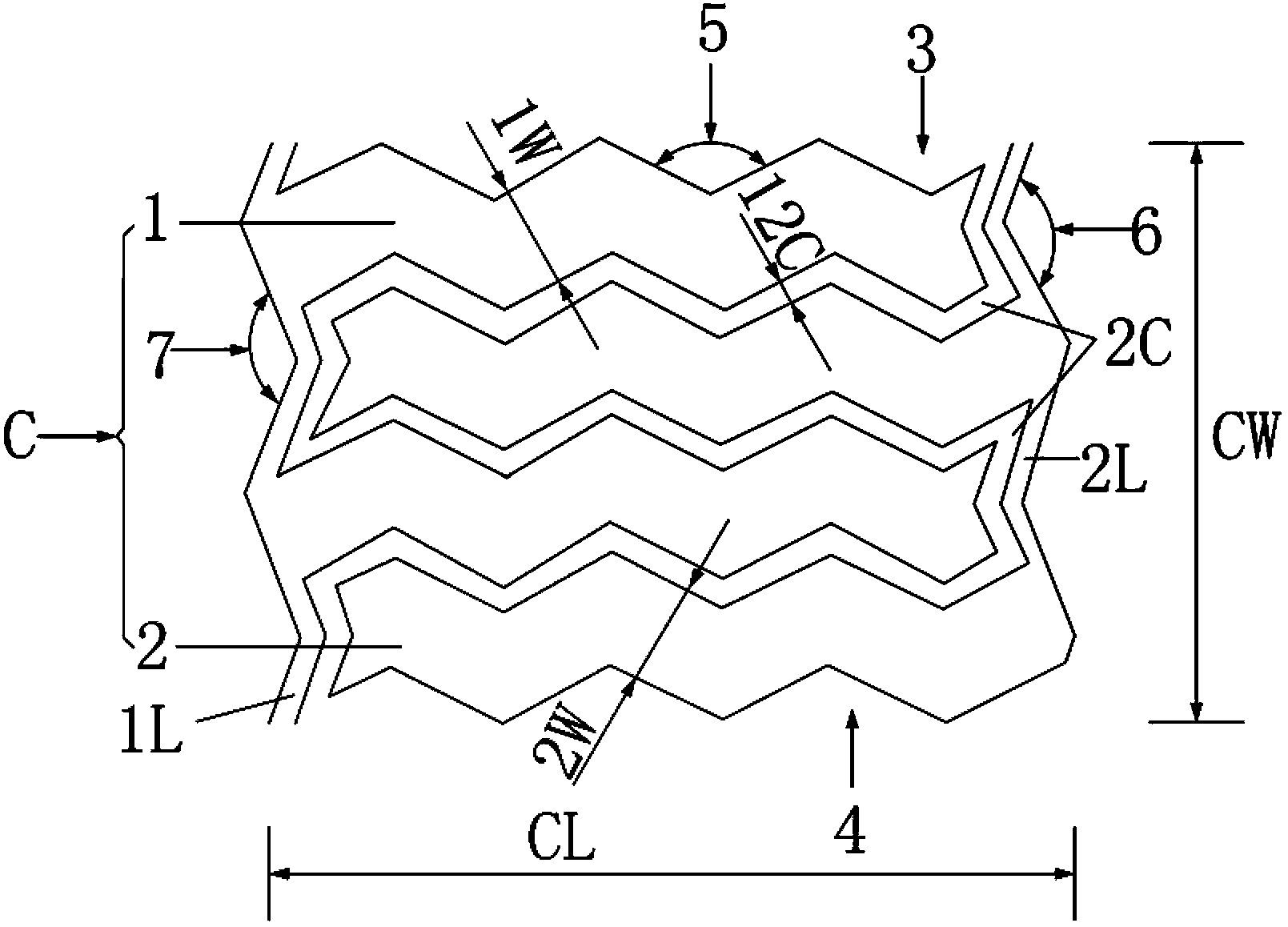

ActiveCN103576998AImprove the display effectEliminate StreaksDigital data processing detailsInput/output processes for data processingCapacitanceEngineering

A capacitive touch screen and a single layer wiring electrode array. The single layer wiring electrode array includes a capacitive region and a wiring region located on one plane; the wires of the wiring region are in a zigzag or a wave pattern. A capacitive touch screen comprising a single layer wiring electrode array, the capacitive touch screen including a substrate; a single layer-wiring electrode array, disposed on the substrate, the single layer wiring electrode array includes a capacitive region and a wiring region located on one plane, the wires of the wiring region are in a zigzag or a wave pattern; the wires of the wiring region connected to control ports corresponding to at least one or more integrated circuit chips respectively. The single layer wiring electrode array and capacitive touch screen makes the fabrication cost lower, the display effect better.

Owner:SILEAD

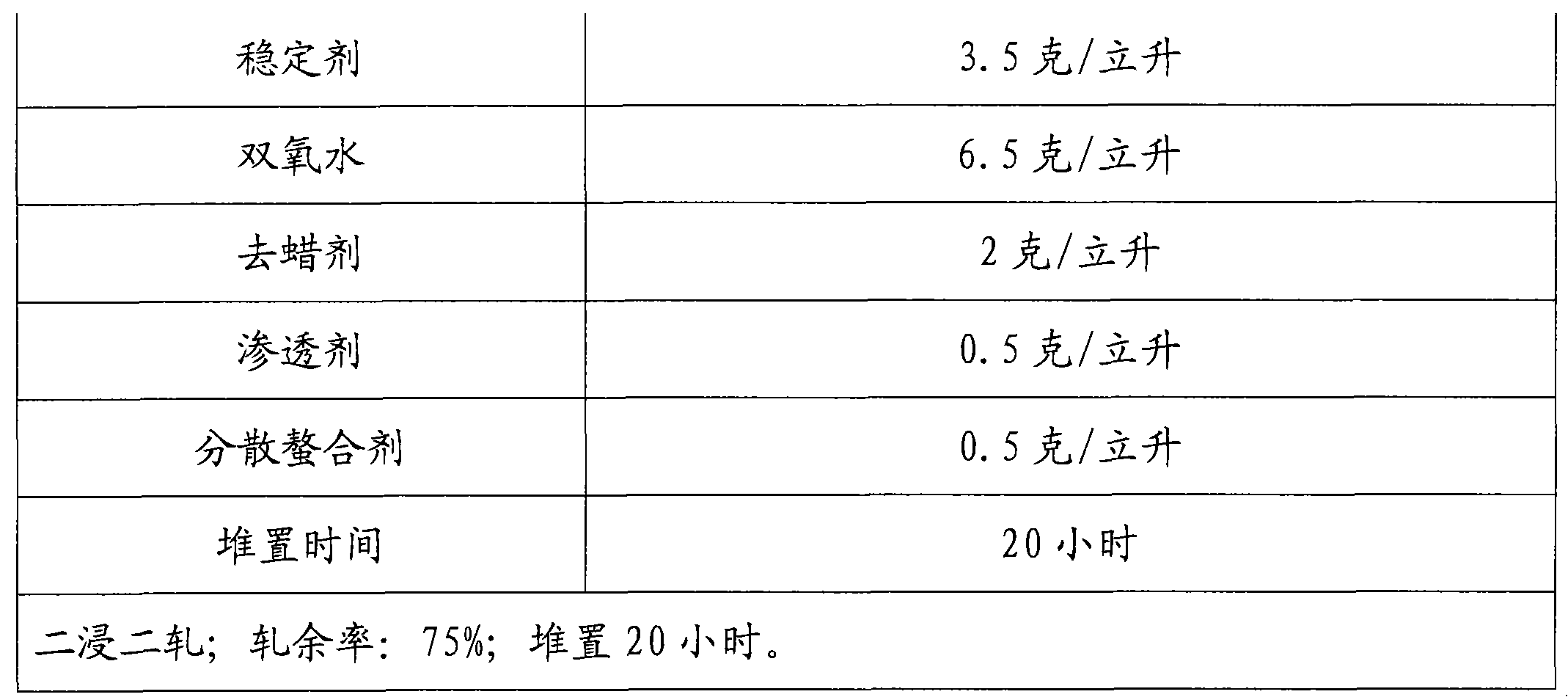

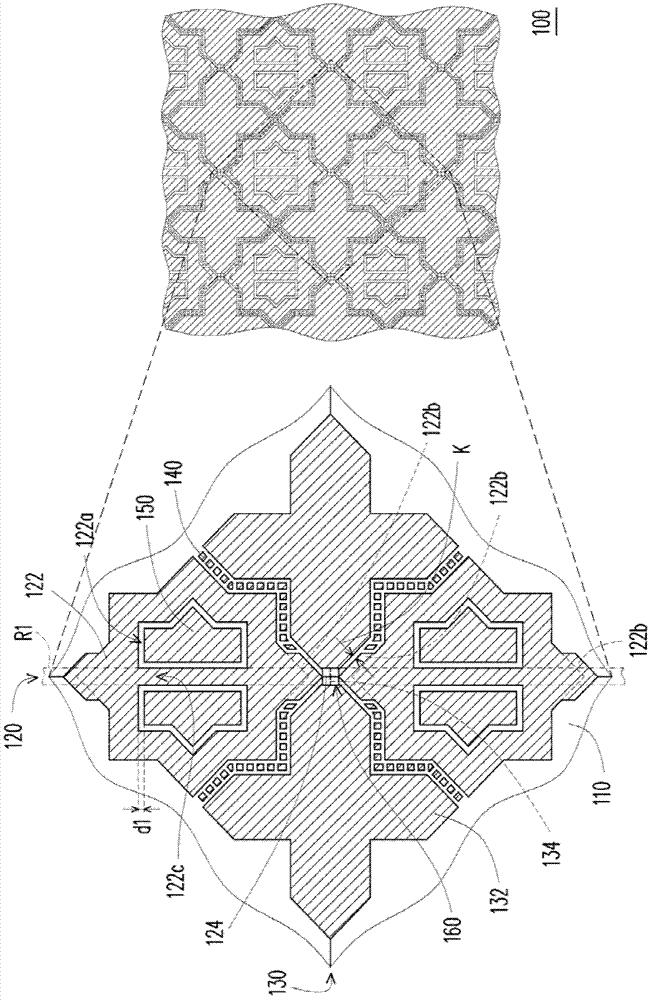

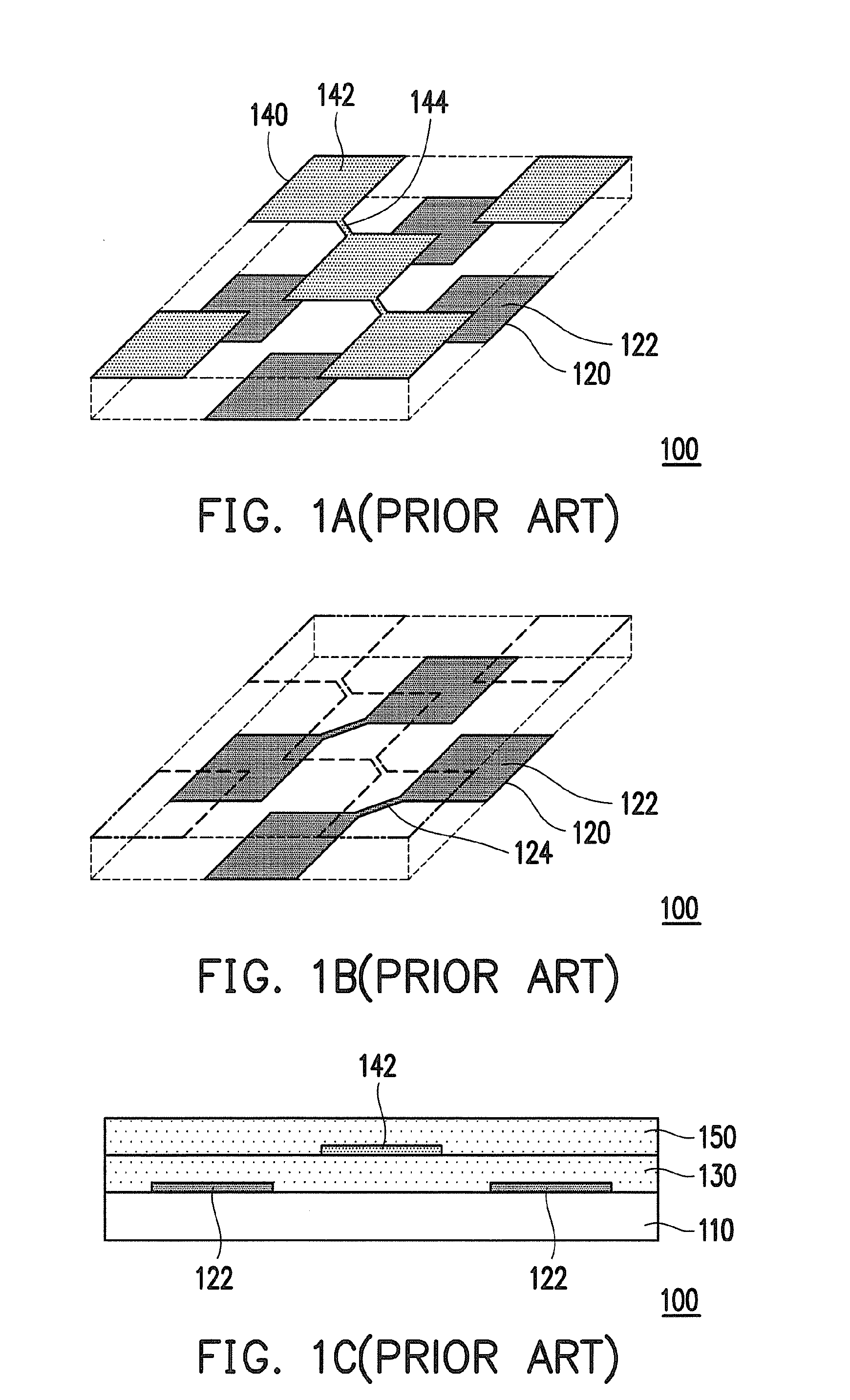

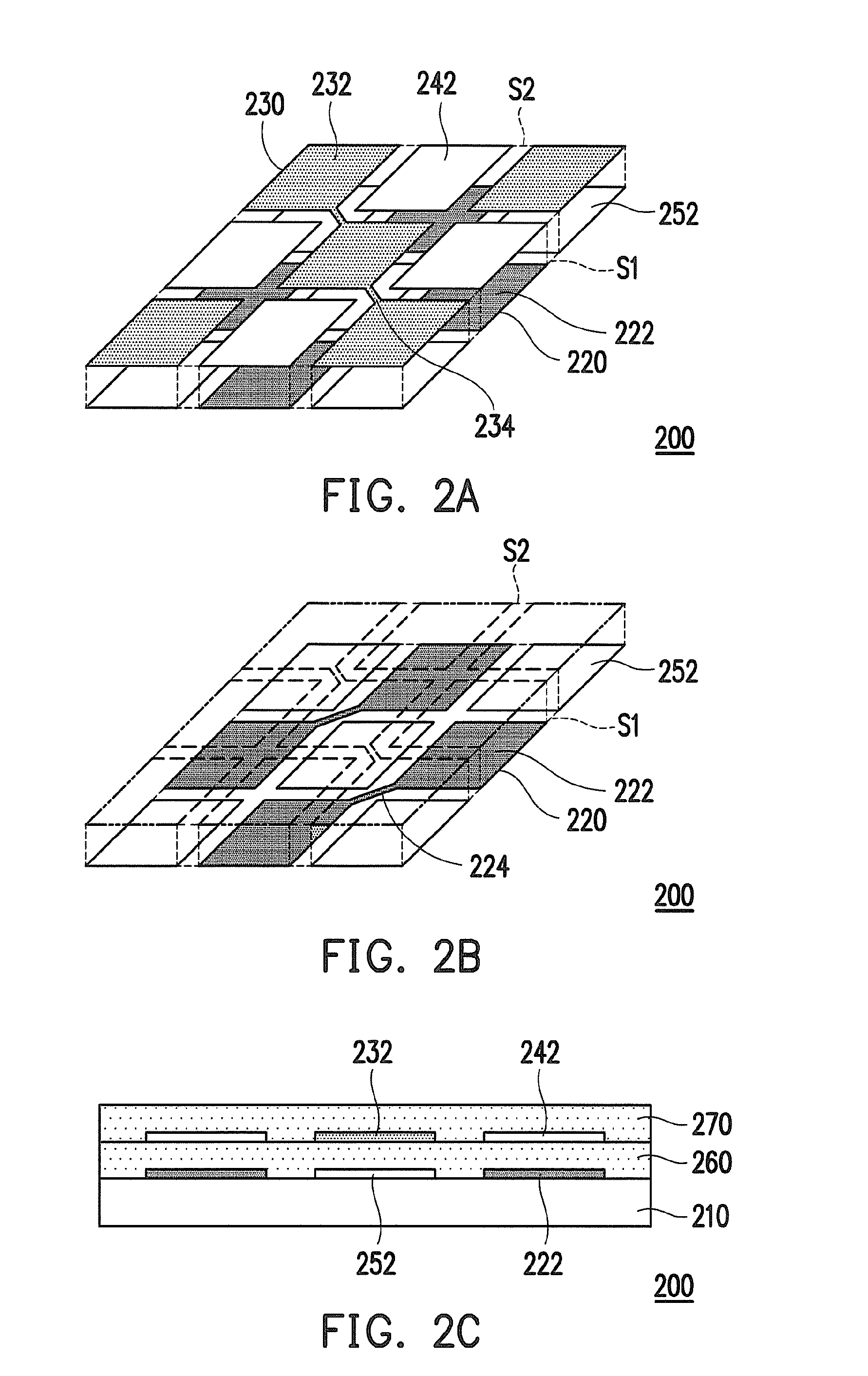

Touch panel and touch display device

InactiveCN103246409AGood touch effectLower resistanceInput/output processes for data processingBridge patternDisplay device

The invention provides a touch panel and a touch display device. The touch panel comprises a plurality of first and second electrode arrays which are located on a substrate and mutually electrically insulated. Each first electrode array comprises a plurality of first sensing pads and a plurality of first bridging patterns. The second electrode arrays located on the substrate and mutually electrically insulated are staggered with the first electrode arrays. Each second electrode array comprises a plurality of second sensing pads and a plurality of second bridging patterns. A plurality of first floating patterns are arranged between the first electrode arrays and the second electrode arrays. Each first sensing pad is provided with at least one extension part. No first floating pattern is arranged between each extension part and the second electrode array adjacent to the same.

Owner:DONGGUAN MASSTOP LIQUID CRYSTAL DISPLAY +1

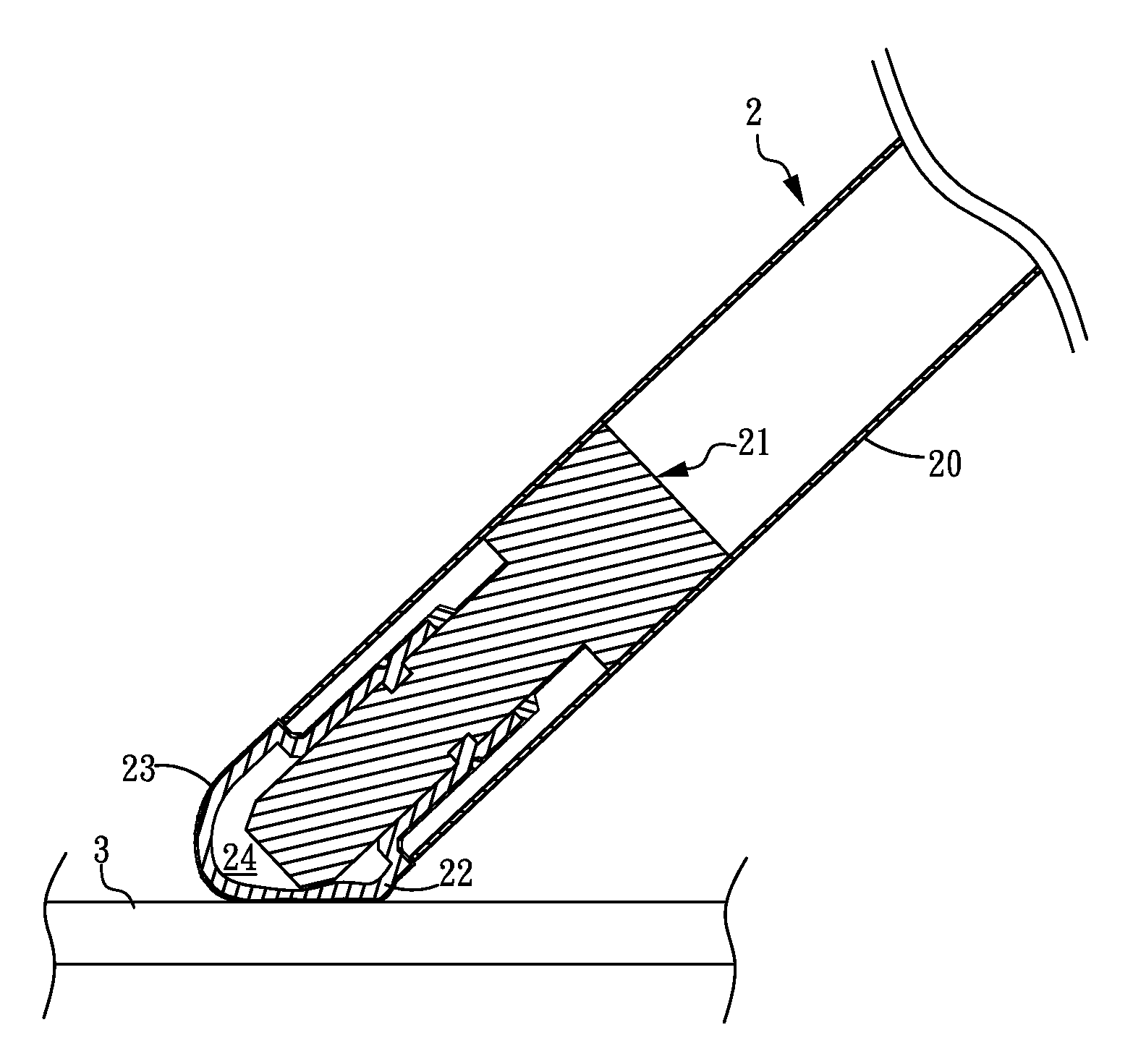

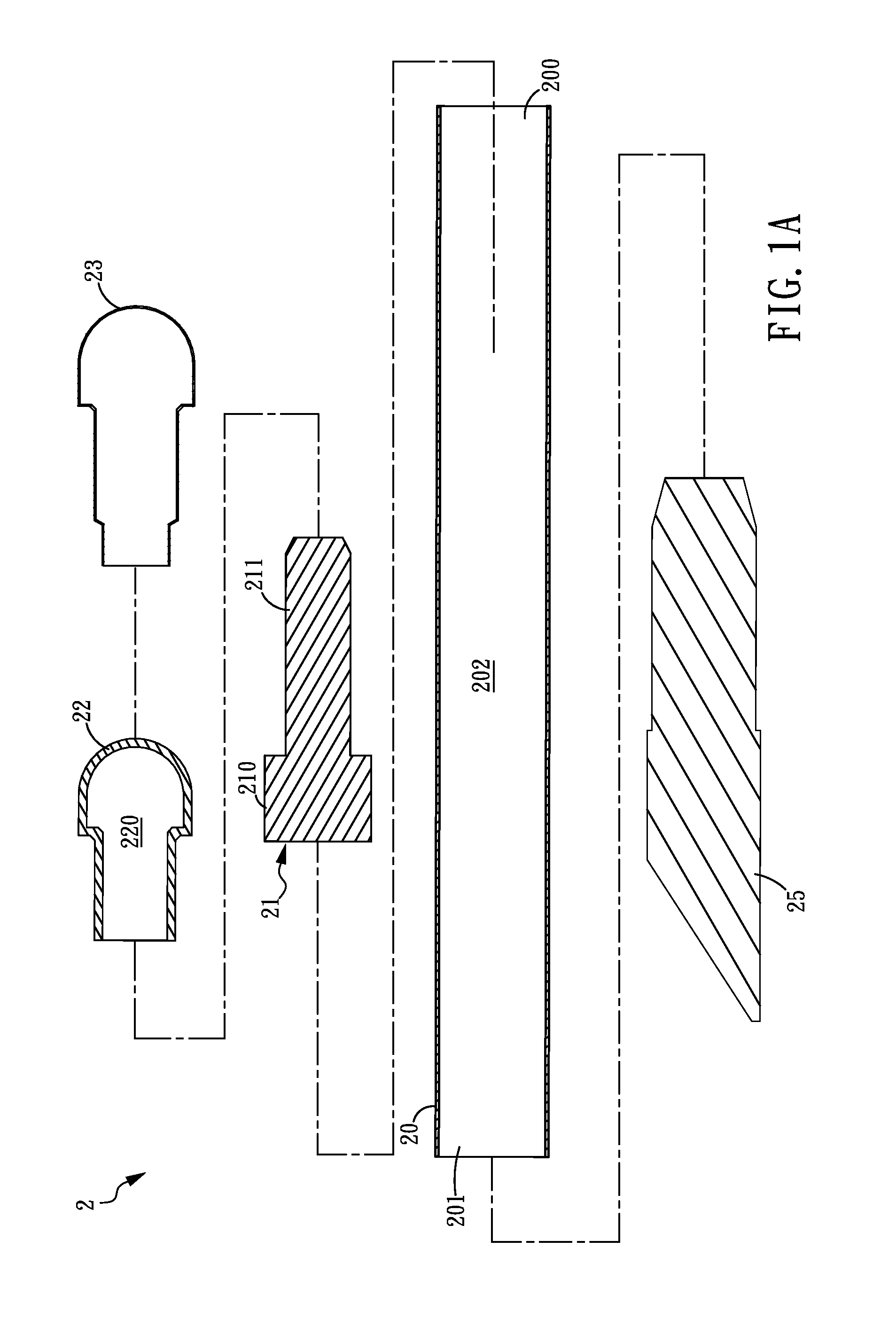

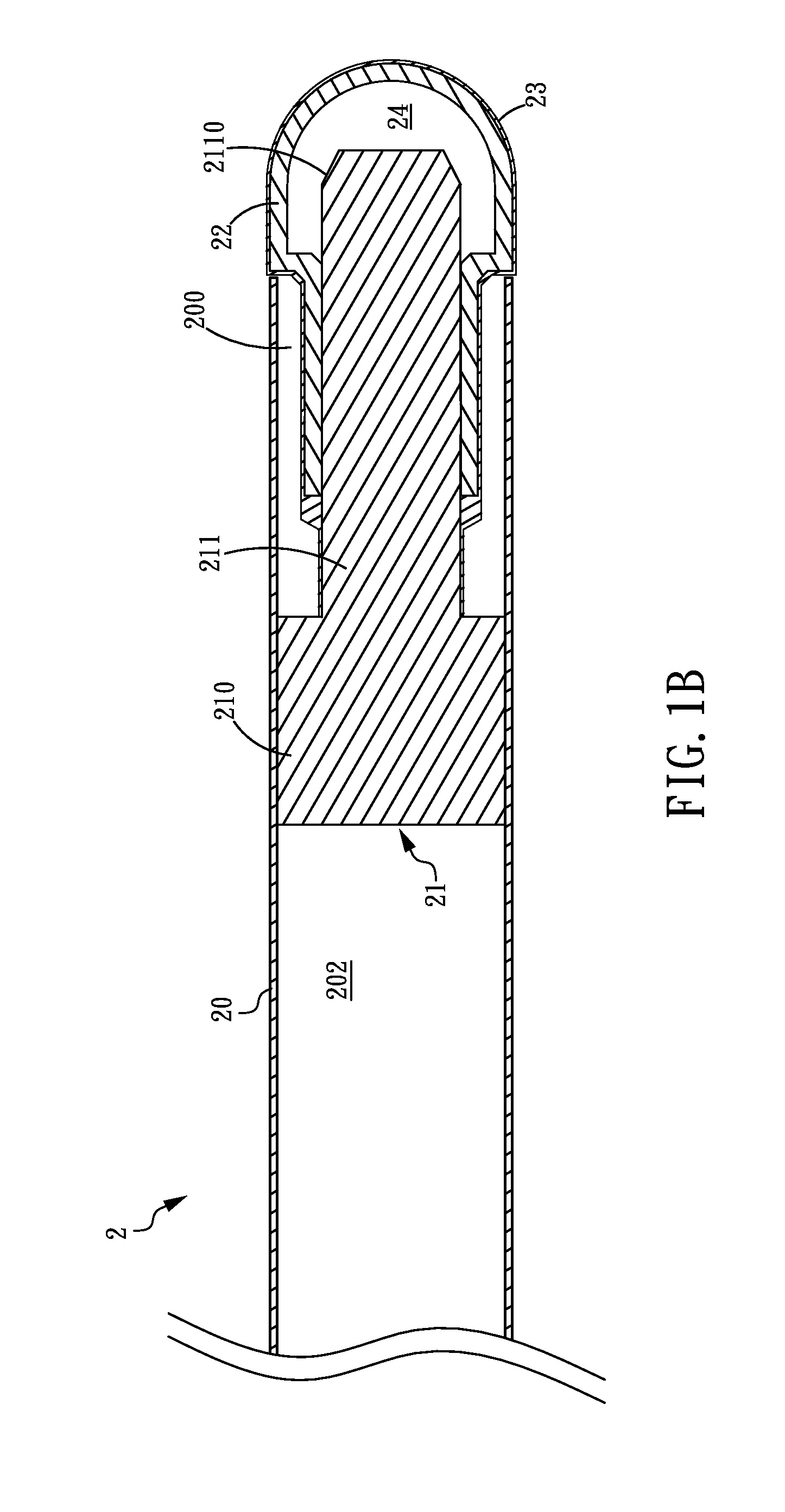

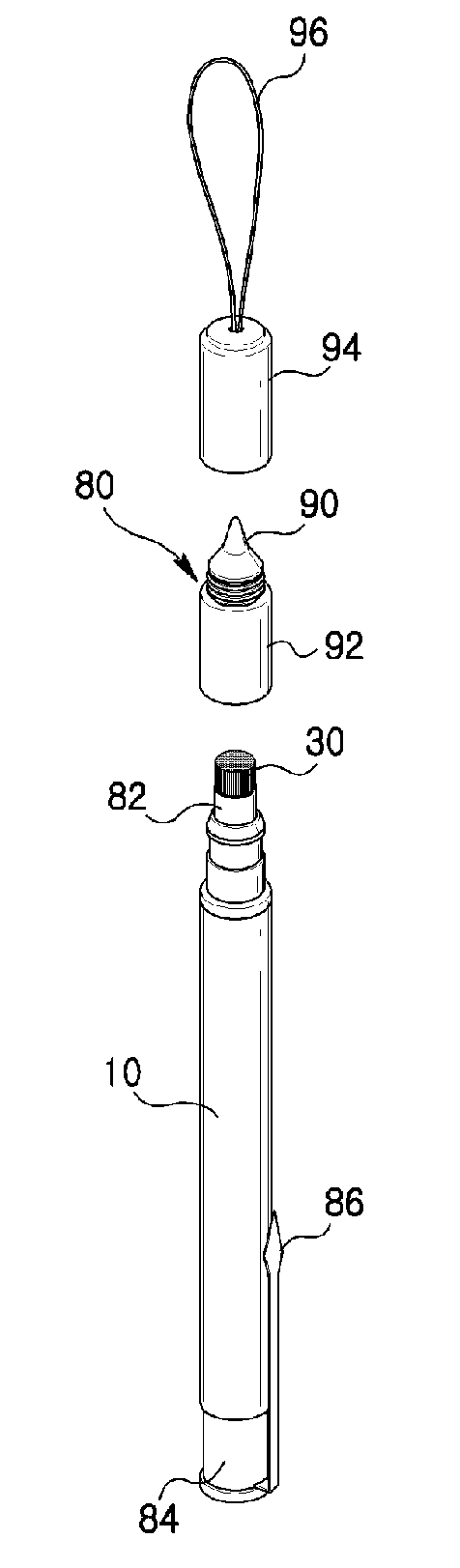

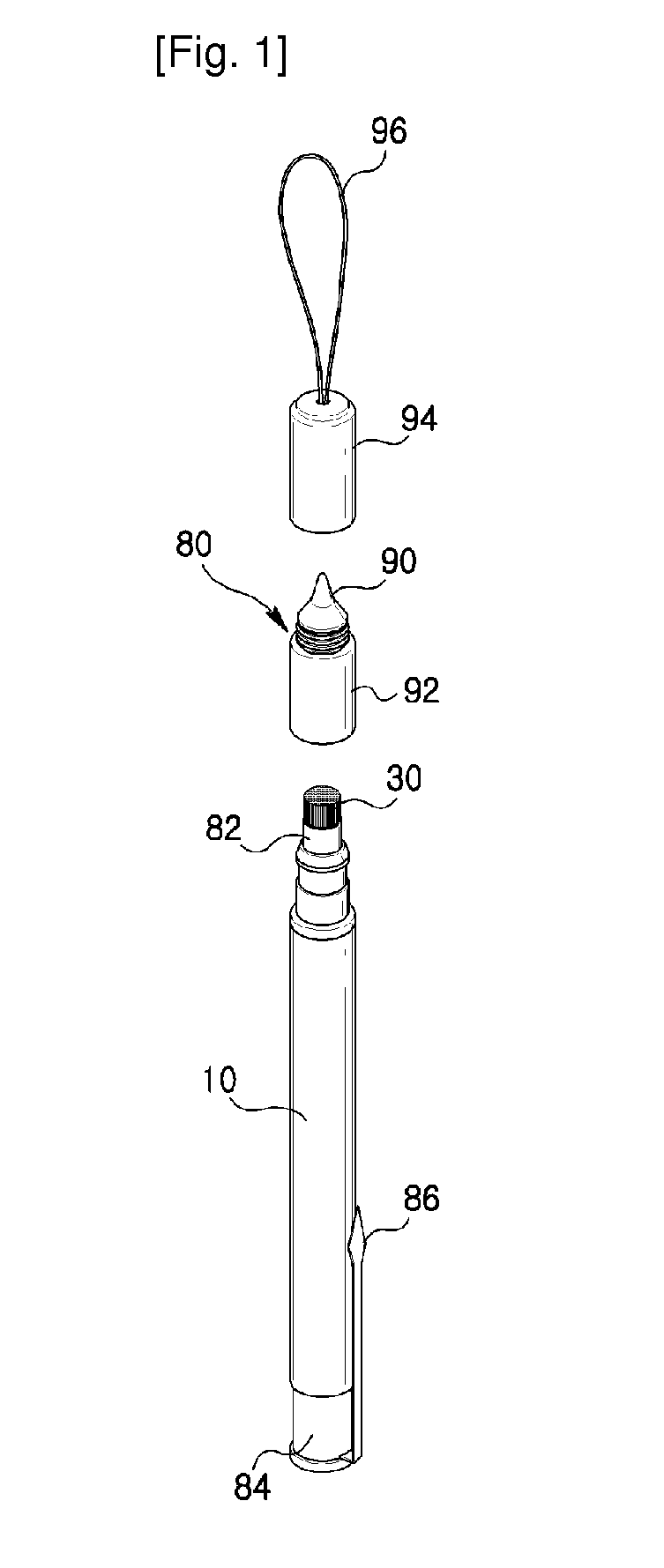

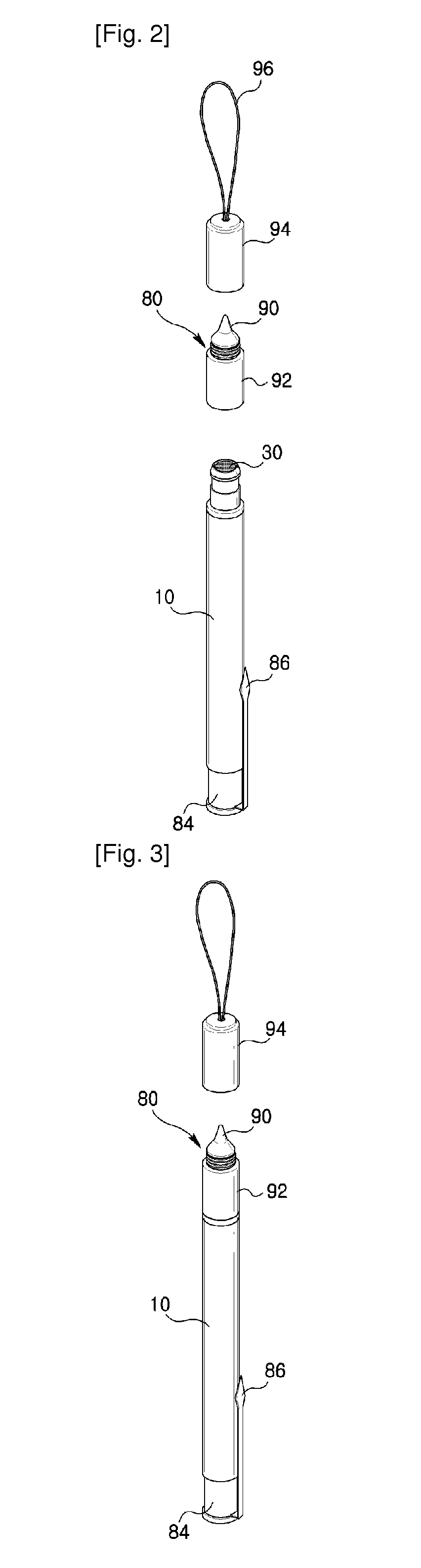

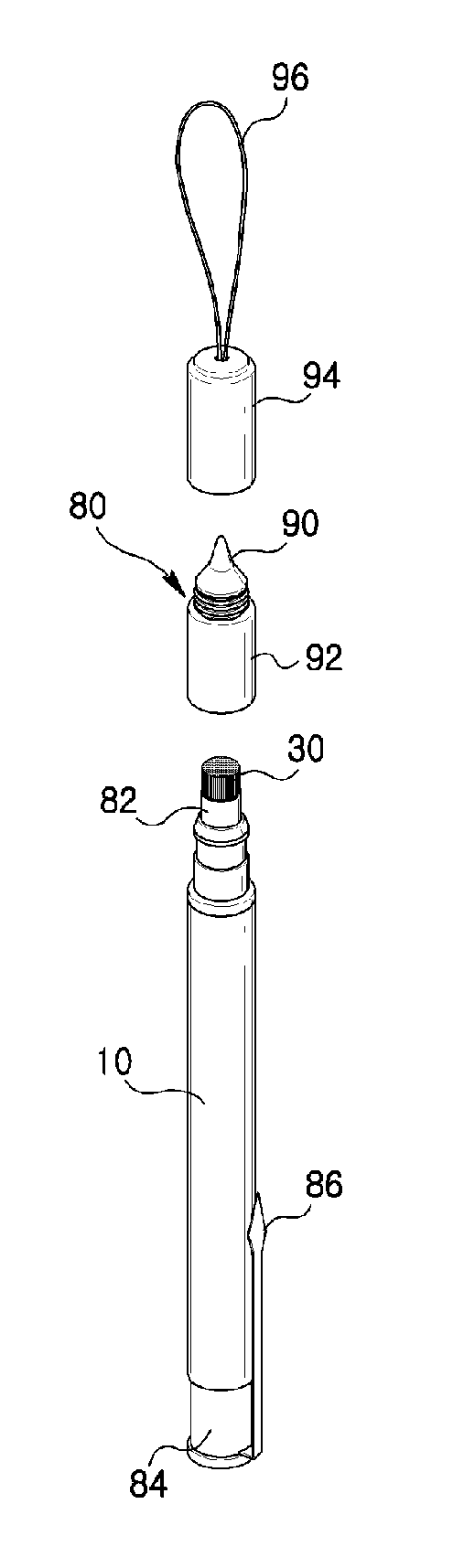

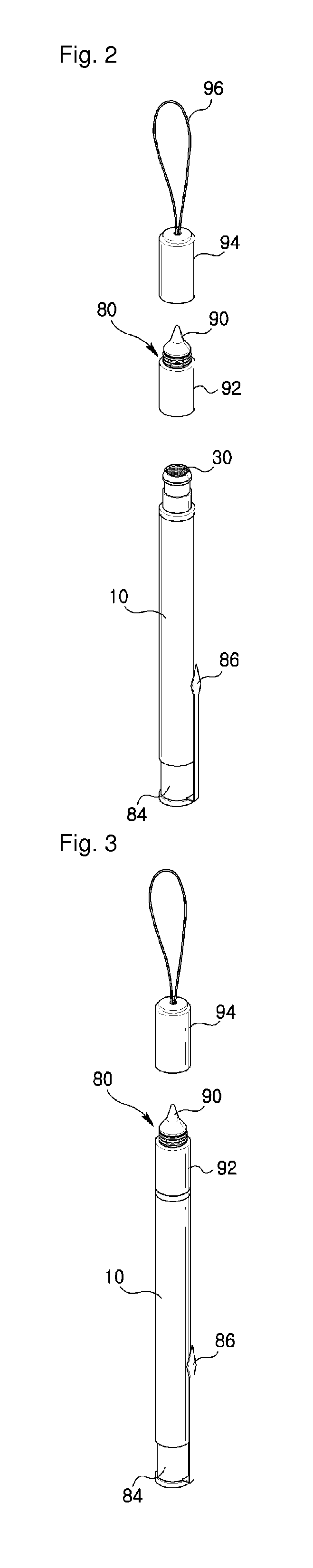

Touch pen

InactiveUS20120146960A1High sensitivityImprove touch effectInput/output processes for data processingTouchpadTouch panel

A touch pen comprises a penholder, an electrically conducting core, a flexible covering and fabric covering. The electrically conducting core is coupled to the penholder. The electrically conducting core is ensheathed in the flexible covering, while the fabric covering wraps around the flexible covering, wherein either flexible covering or fabric covering has electrical conductivity. In the present invention, the flexible covering and the fabric covering are shaped under the pressure exerted by the electrically conducting core and a touch panel so as to increase the contact area between the touch pen and the touch panel and, meanwhile, the fabric covering is capable of reducing the friction between touch pen and the touch panel, thereby improving the sensitivity and touch effect.

Owner:KOONER TECH TAIWAN

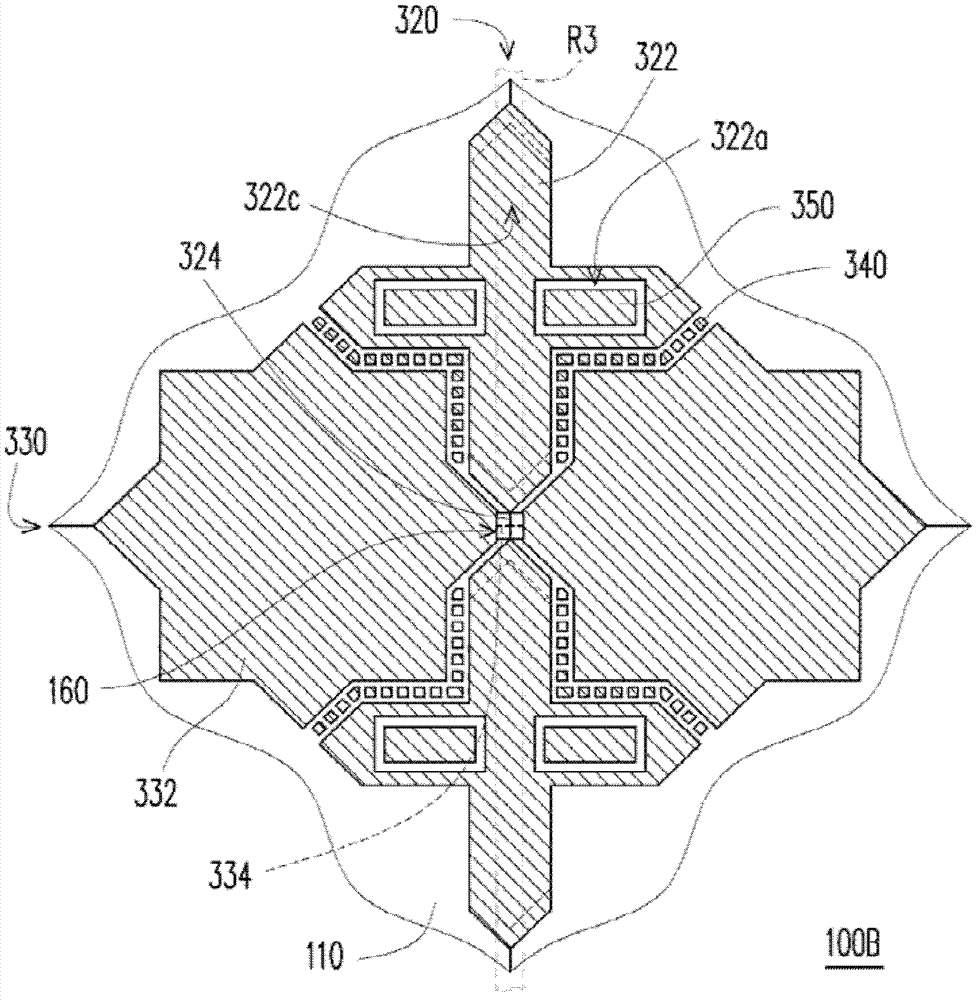

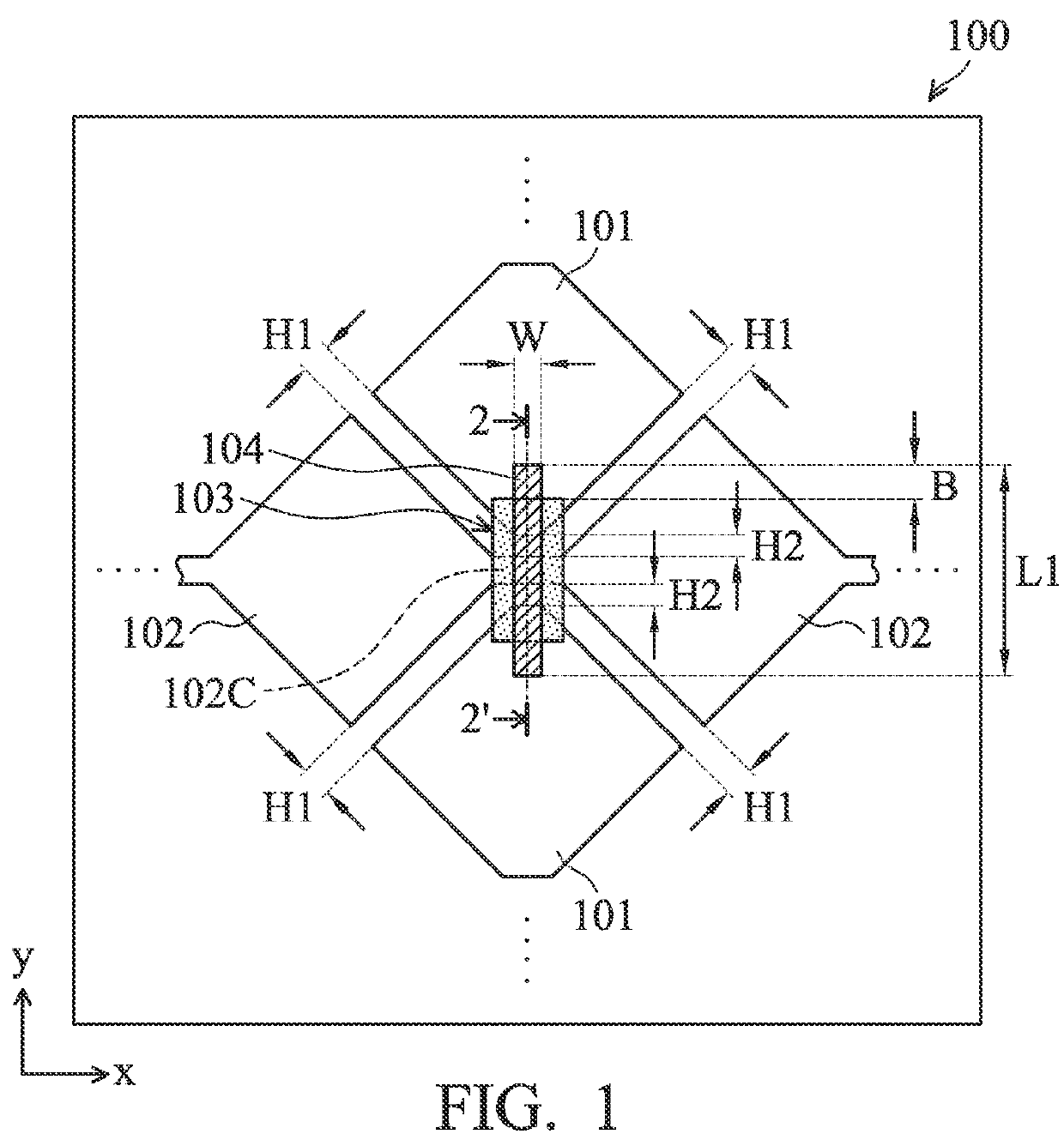

Touch substrate and touch screen

ActiveUS20160246405A1CapacitanceImprove signal-to-noise ratioInput/output processes for data processingTouchscreenMetal mesh

The present invention provides a touch substrate and a touch screen. The touch substrate comprises first electrodes and electrodes which intersect with each other, each first electrode includes a plurality of first metal meshes, adjacent first metal meshes are connected through a connection portion, each second electrode includes a plurality of second metal meshes, adjacent second metal meshes are connected through a connection bridge, the first metal meshes, the second metal meshes and the connection portion are in the same layer, and an insulation layer is provided between the layer in which the connection portion is located and the layer in which the connection bridge is located, at least a part of edges of the first metal mesh is provided with a first side strip thereat, the first side strip is adjacent to a corresponding second metal mesh and is connected to the first metal mesh.

Owner:BOE TECH GRP CO LTD +1

Touch panel and manufacturing method thereof

InactiveUS20140211109A1Improve touch effectImprove visual effectsNon-linear opticsInput/output processes for data processingColor shiftTransmittance

A touch panel and a manufacturing method thereof are provided. The touch panel has a double-layered sensing pad structure or a single-layered sensing pad structure. In the double-layered sensing pad structure, the sensing pads in each layer have corresponding dummy sensing pads in the other layer for compensating the difference of transmittance. In the single-layered sensing pad structure, the sensing pads are coplanar so that the problem of color shift can be overcome and the visual effect of the touch panel can be improved.

Owner:AU OPTRONICS CORP

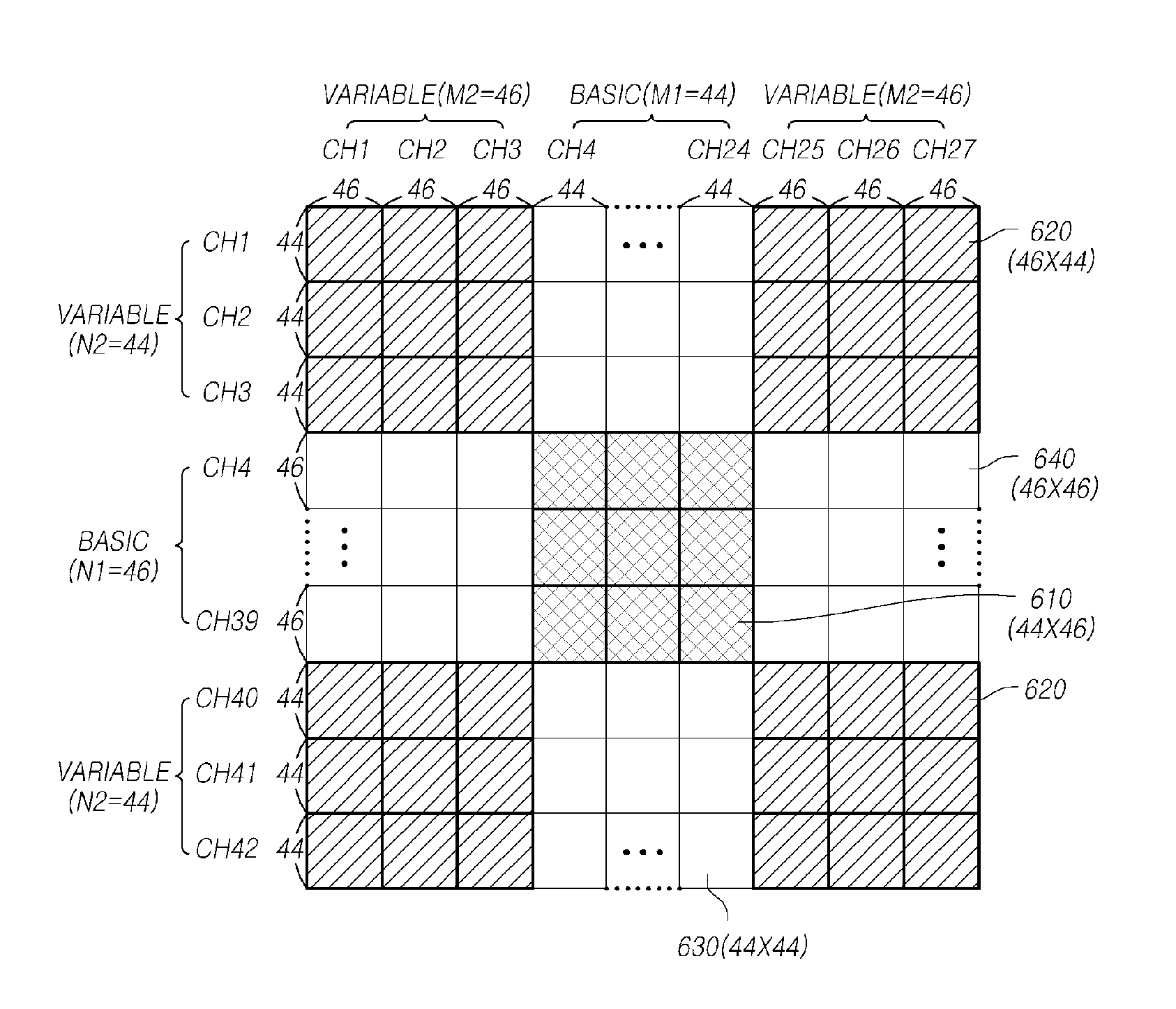

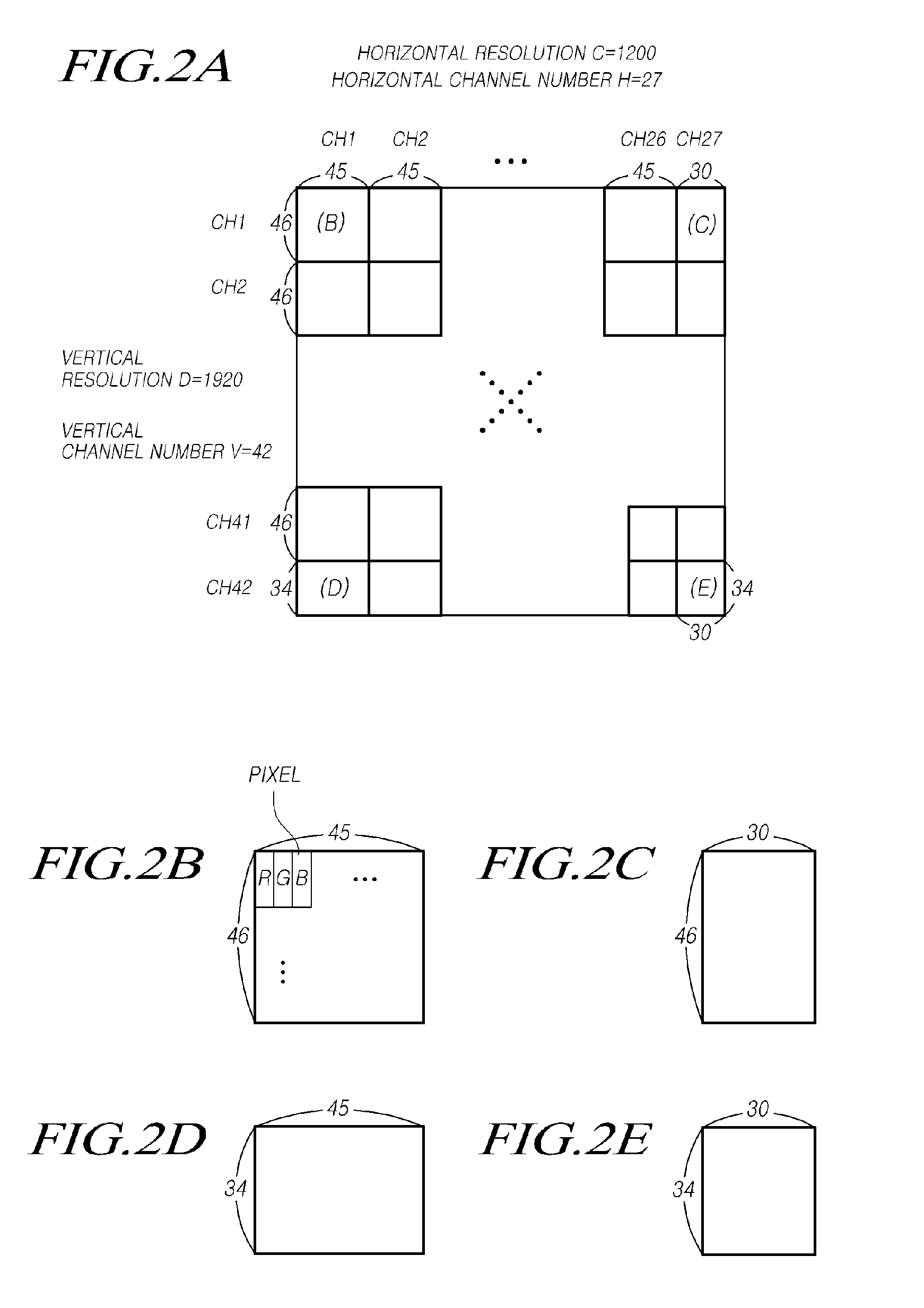

Display panel for display device

ActiveUS20150317019A1Improve touch effectUniform sizeDigital data processing detailsInput/output processes for data processingDisplay deviceHuman–computer interaction

The present disclosure provides a display panel for a display device including a touch electrode divided into first touch unit sensors having a first size and second touch unit sensors having a second size different from the first size. When a horizontal or vertical size of a second touch unit sensor is compared with a first touch unit sensor, the vertical size of the second touch unit sensor is smaller than that of the first touch unit sensor when the horizontal size of the second touch unit sensor is larger than that of the first touch unit sensor and the horizontal size of the second touch unit sensor is smaller than that of the first touch unit sensor when the vertical size of the second touch unit sensor is larger than that of the first touch unit sensor. Therefore, an area deviation of touch unit sensors forming a touch electrode is minimized and thus uniform and superior touch performance may be provided.

Owner:LG DISPLAY CO LTD

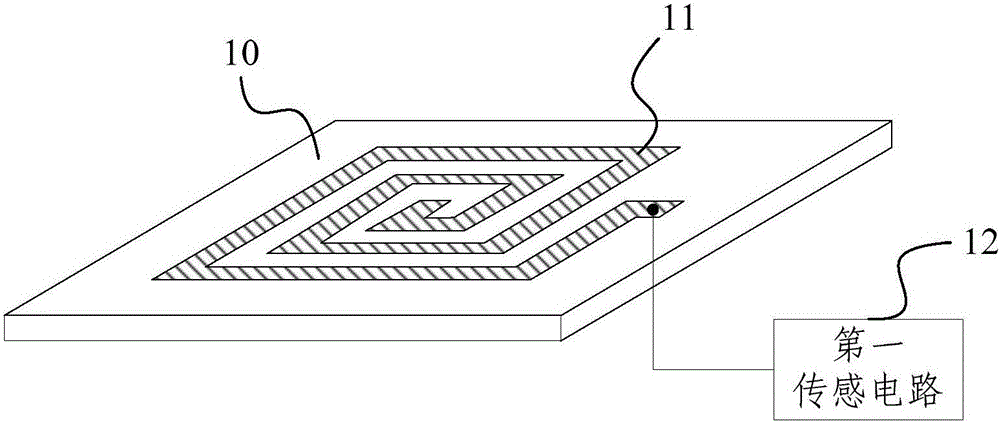

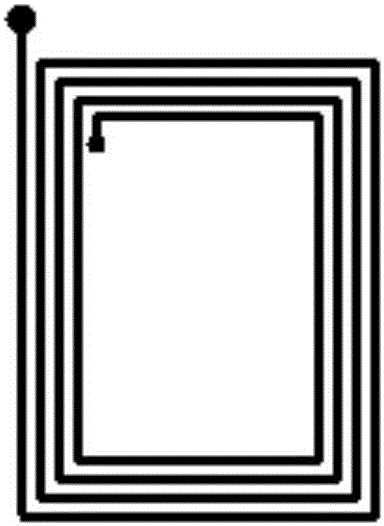

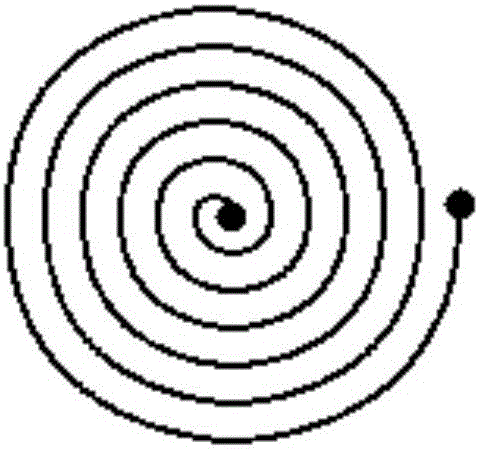

Touch sensing device, touch panel, display panel and display device

InactiveCN105786290AHigh precisionHigh sensitivityNon-linear opticsInput/output processes for data processingGraphicsTouch Senses

The invention provides a touch sensing device, a touch panel, a display panel and a display device, wherein the touch sensing device comprises an inductance graphics formed on a substrate, and a sensing circuit connected with the inductance graphics; the sensing circuit is used for applying a preset alternating current (AC) signal onto the inductance graphics and comparing a sensing signal coming from the inductance graphics with the preset AC signal for sensing a touch action. On this basis, the display panel can realize inductance type touch sensing. Compared with capacitive touch, the display panel can increase a touch sensing distance on a surface of the touch panel and improves the accuracy and sensitivity of touch, thus achieving a better touch effect.

Owner:BOE TECH GRP CO LTD

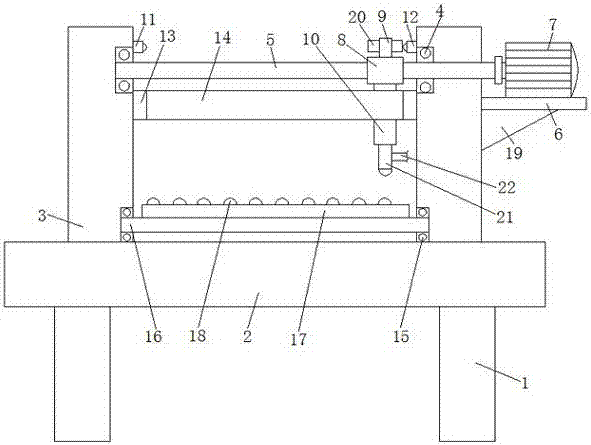

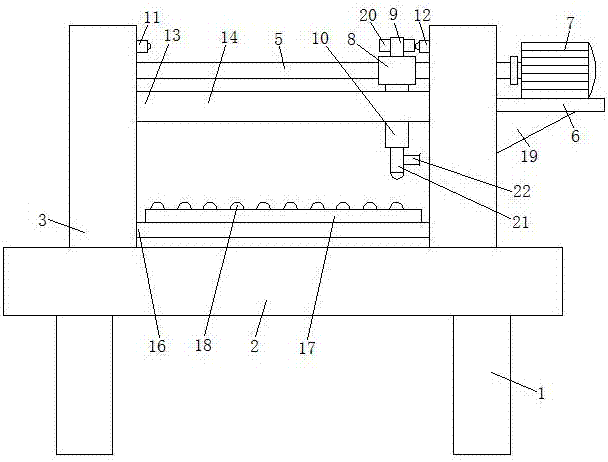

Automatic spraying device for leather processing

InactiveCN107159492ATo achieve the effect of positive and negativeAvoid shakingSpraying apparatusLeather surface finishingEngineeringNozzle

The invention discloses an automatic spraying device for leather processing. The automatic spraying device comprises supporting legs. An operation platform is fixedly connected to the top ends of the supporting legs. Supporting columns are fixedly connected to the upper surface of the operation platform. First bearings are fixedly connected to the top ends of the supporting columns. A thread rod is fixedly connected to the inner rings of the first bearings. One end of the thread rod penetrates through and extends to the surface of one supporting column, and the surface of the corresponding supporting column is fixedly connected with an installation base. A reciprocating motor is fixedly connected to the upper surface of the installation base. According to the automatic spraying device for leather processing, the effect that the reciprocating motor is controlled by travel switches to do forward and backward rotation is achieved, the left-right automatic reciprocating spraying effect is achieved for a nozzle, the problem that the installation base waggles and is unstable can be effectively avoided, the touch effect of an ejector rod on the left travel switch and the right travel switch can be effectively enhanced, and accordingly the problem that spraying is not uniform or the spraying efficiency is low when spraying is manually carried out or machines are manually operated for spraying is effectively solved.

Owner:袁静

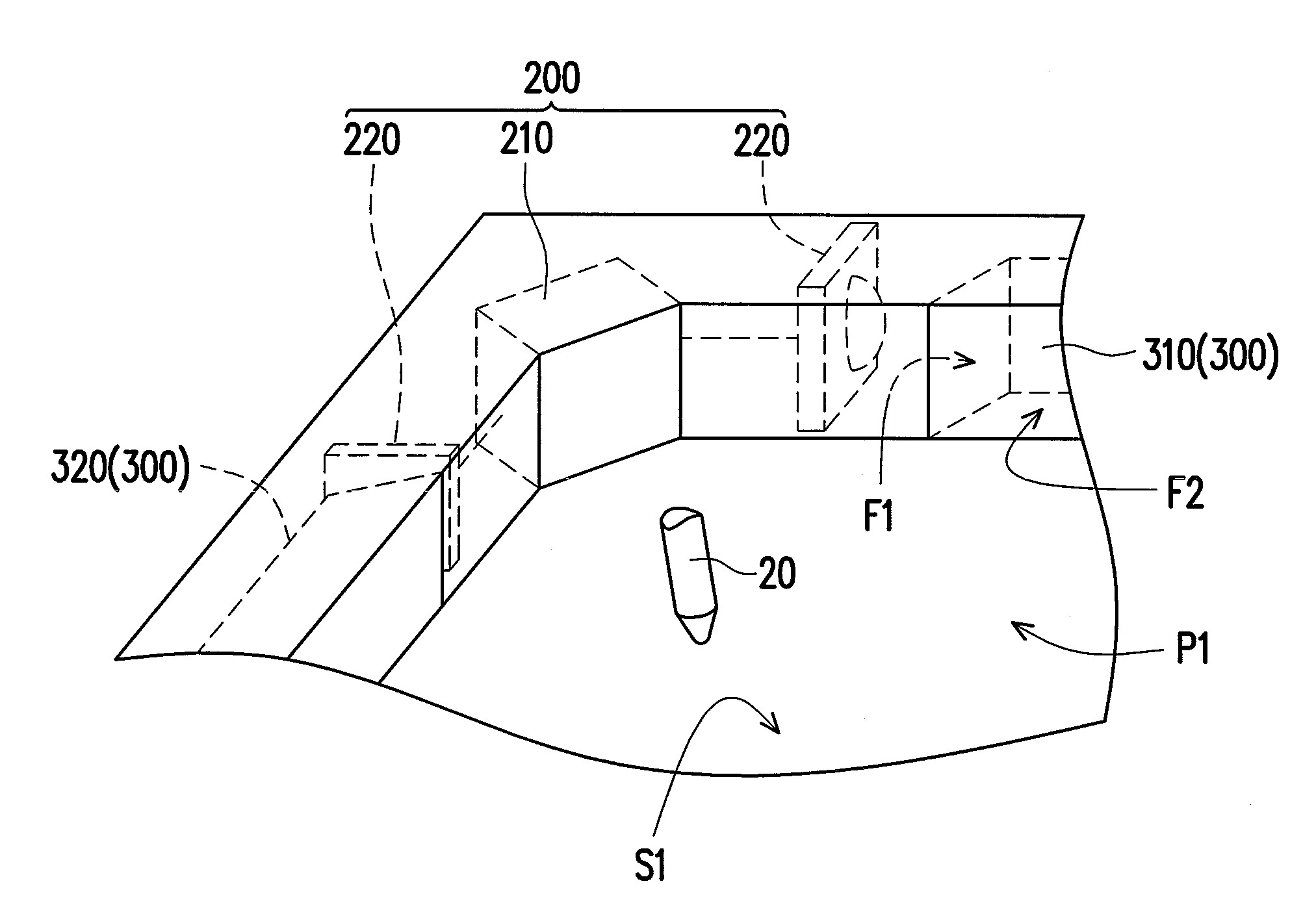

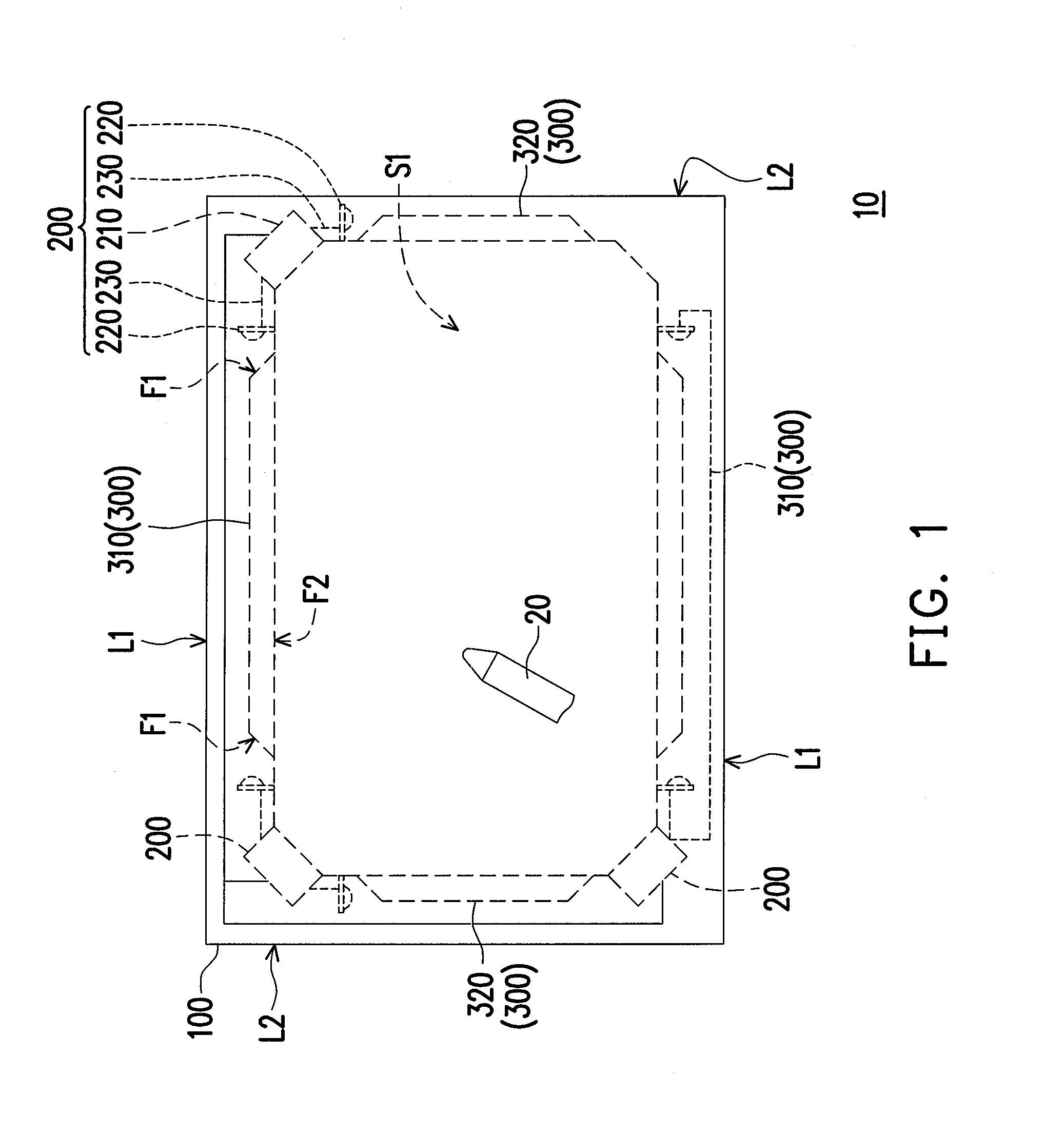

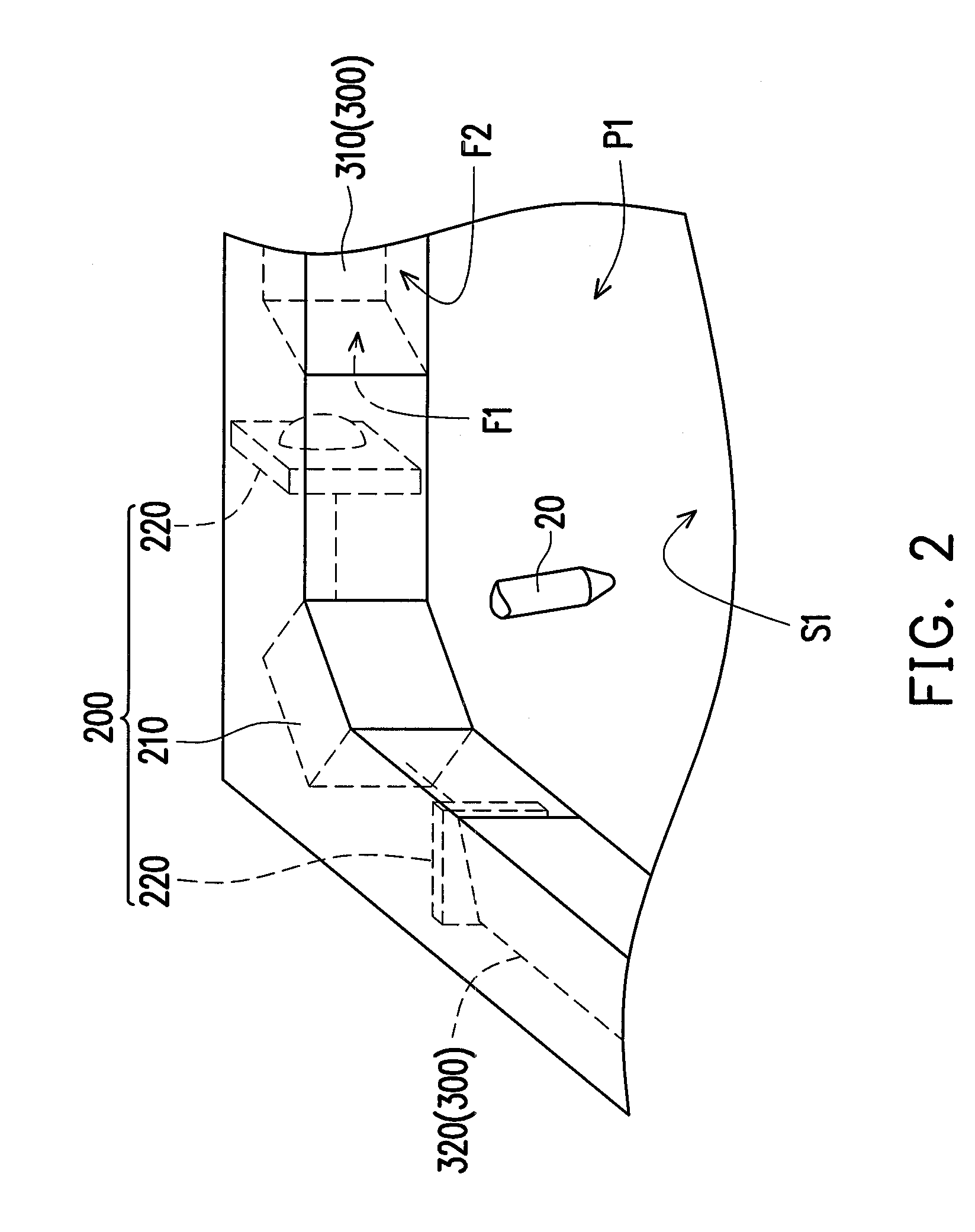

Optical touch-sensing display

InactiveUS20110096034A1Improve touch effectImprove lighting qualityInput/output processes for data processingTouch SensesLight guide

An optical touch-sensing display including a display device, at least three light guides, at least two optical touch-sensing devices and a transmission interface is provided. The display device has a display surface and a sensing space upon the display surface. Each of the light guides disposed at periphery of the display surface has two light incident surfaces and a light-emitting surface there between. Each of the optical touch-sensing devices disposed outside of the display surface includes a sensing module and a light source. When an object enters the sensing space, each sensing module senses a light variation induced by the object to generate a first signal, and then the first signals are transmitted to one sensing module and processed to a second signal, and then the second signal is output from the optical touch-sensing device through the transmission interface.

Owner:SONIX TECH

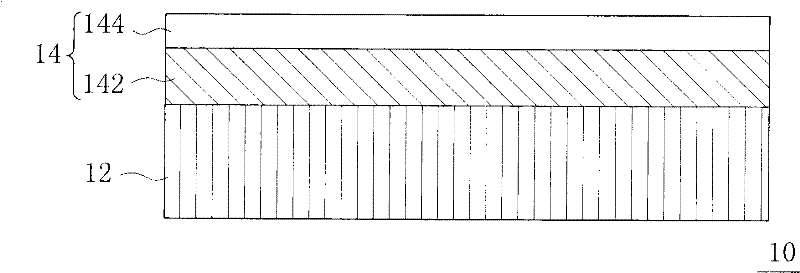

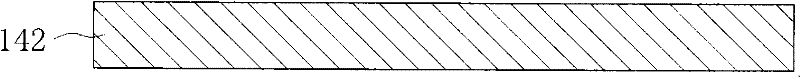

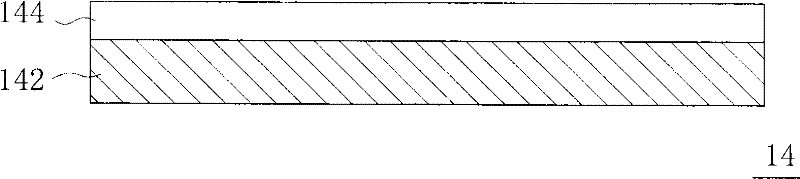

Touchpad and manufacturing method thereof as well as touch display panel with touchpad

ActiveCN102214024AGood touch effectPrevent beingInput/output processes for data processingComputer scienceAir bubble

The invention provides a touchpad and a touch display panel with the same. The touch display panel comprises a display panel and the touchpad, and the touchpad comprises a touch unit and a transparent protective layer, wherein, the touch unit is configured on the display panel and is positioned between the display panel and the transparent protective layer; the transparent protective layer is coated on the touch unit and is made from photosensitive resins; and the transparent protective layer and the touch unit of the touch display panel are tightly integrated. In addition, the invention further provides a manufacturing method of the touchpad. The touchpad has a better touch effect; the touch display panel has a better touch effect and better display quality; and by utilizing the manufacturing method of the touchpad, air bubbles are avoided between the transparent protective layer and the touch unit.

Owner:ECHEM SOLUTIONS

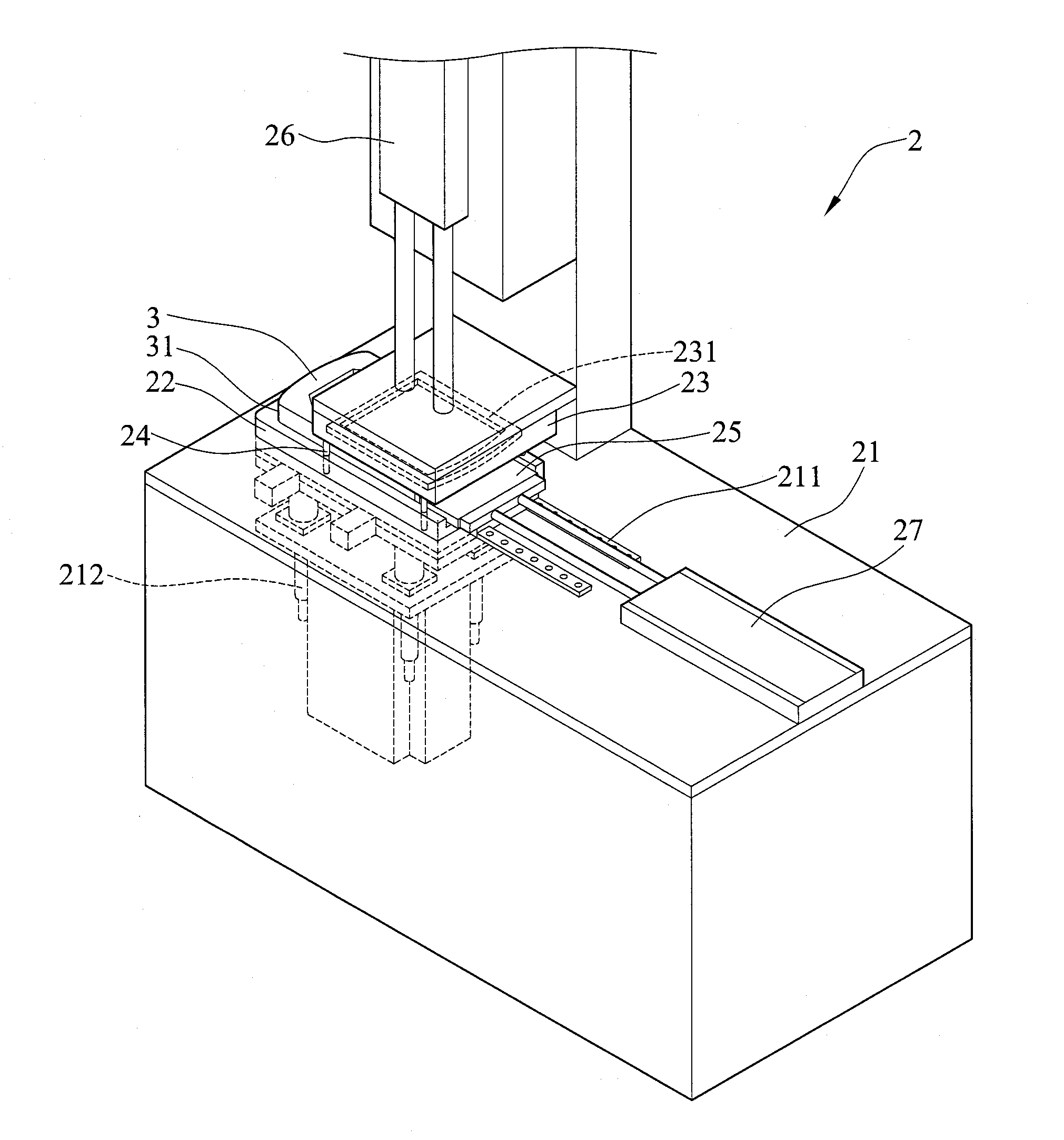

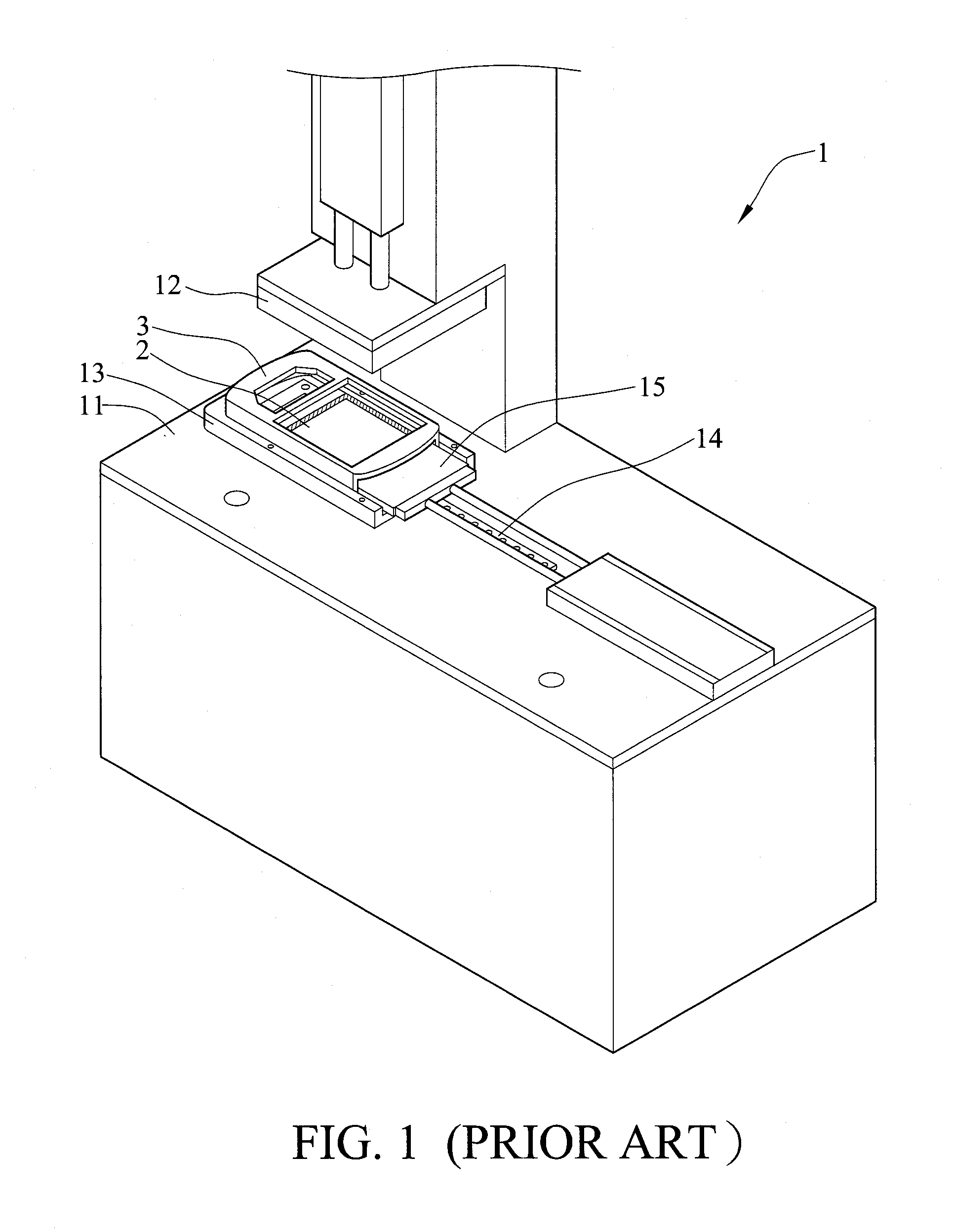

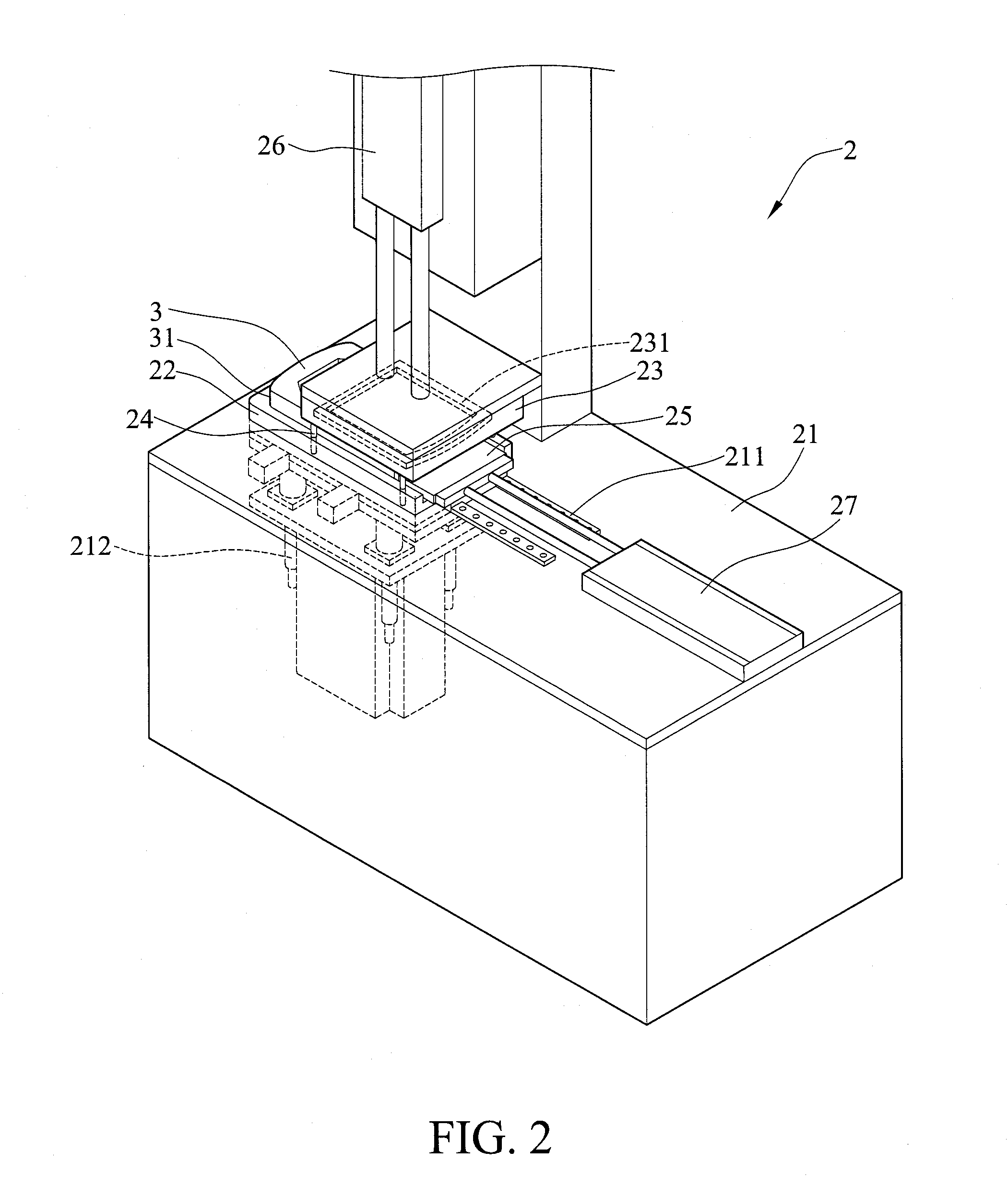

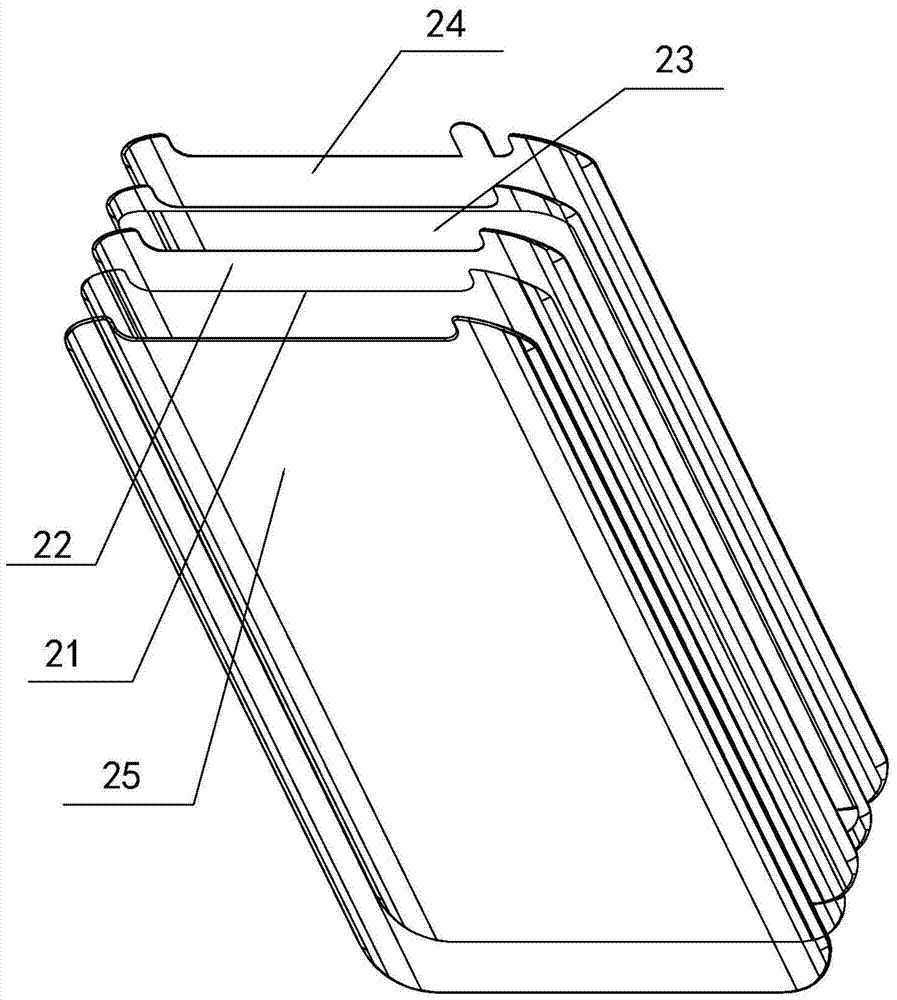

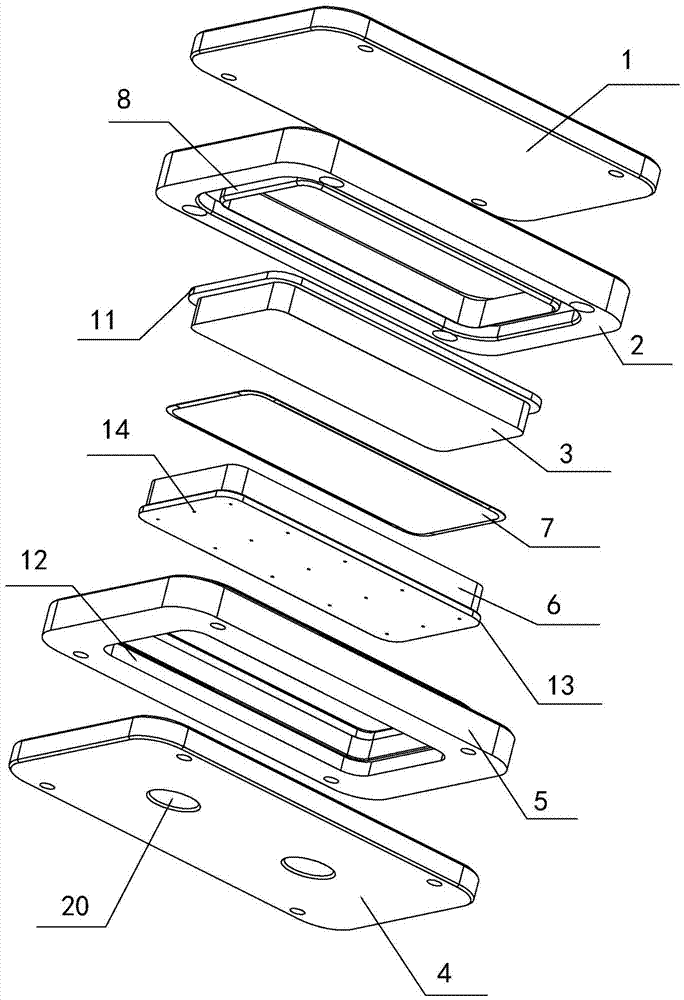

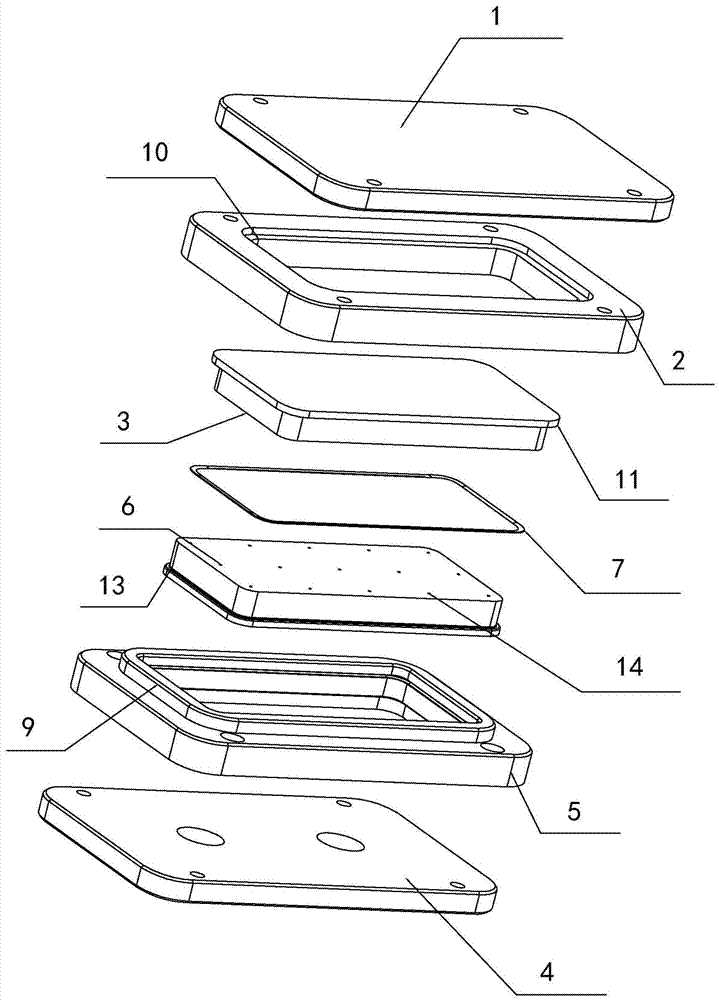

Pressing Device

InactiveUS20120291265A1Efficient pressingEffective movementMetal working apparatusPerpendicular directionTouch panel

A pressing device for attaching a touch panel to a casing is disclosed. The pressing device includes a main body, a pressing mechanism, a mounting base for mounting and positioning the casing, a plurality of guiding poles, and a carrier for carrying the touch panel. The guiding poles pass through the pressing mechanism for guiding the pressing mechanism to move in a perpendicular direction corresponding to the mounting base. The pressing mechanism has a protruding portion for pressing the casing, and the protruding portion is formed corresponding to the outline of the casing, such that the pressing force applied on the casing is even and the casing would not sway. The main body has a plurality of tracks, so as to have a carrier with a large area moving thereon. Thus, the carrier has sufficient area for carrying a touch panel.

Owner:ASKEY COMP

Processing method for 3D net-free glass film

ActiveCN107382037AGood touch effectEasy to operateLaminationLamination apparatusNumerical controlCutting glass

The invention protects a processing method for a 3D net-free glass film. The method comprises the following steps: (S1) cutting a piece of glass into approximate shape according to the size of a to-be-processed 3D net-free glass film; (S2) for carving holes corresponding to the glass film in the cut glass plate by using a numerical control machine tool; (S3) coating sweeping powder onto the glass film cut by CNC, driving a vacuum chuck to press the glass plate onto the sweeping machine by utilizing a vacuum pump in a sweeping machine and performing sweeping operation; (S4) placing the swept glass into different cleaning agents for cleaning in turn; (S5) placing the cleaned glass into a hot briquetting mold for thermally pressing, thereby changing the edge of the glass to be an arc hook face; (S6) placing the thermally pressed glass into a high-temperature chemical toughening furnace and performing temperature sensing treatment at 650 DEG C; (S7) placing the toughened glass into an AF workshop and coating nanometer anti-fingerprint oil; (S8) adhering a layer of anti-explosion glue to the glass film surface; and (S9) adhering a double faced adhesive tape to the inner layer of the glass film, thereby acquiring the end product.

Owner:SHENZHEN KANGCHENGTAI IND CO LTD

Touch display device

InactiveUS20160034076A1Shorten the lengthImprove touch effectCathode-ray tube indicatorsInput/output processes for data processingDisplay deviceComputer science

A touch display device is provided. The touch display device includes a display panel and a touch sensor disposed above the display panel. The touch sensor includes a plurality of first electrode units arranged along a first direction and separated from each other, and a bridge portion electrically connecting the first electrode units with each other. A plurality of second electrode units are arranged along a second direction perpendicular to the first direction and connected to each other through a connection portion. The connection portion intersects the bridge portion. An isolation portion is disposed between the bridge portion and the connection portion. A first distance is between the first electrode unit and the adjacent second electrode unit. A second distance is between the first electrode unit and the adjacent connection portion. The second distance is shorter than the first distance.

Owner:INNOLUX CORP

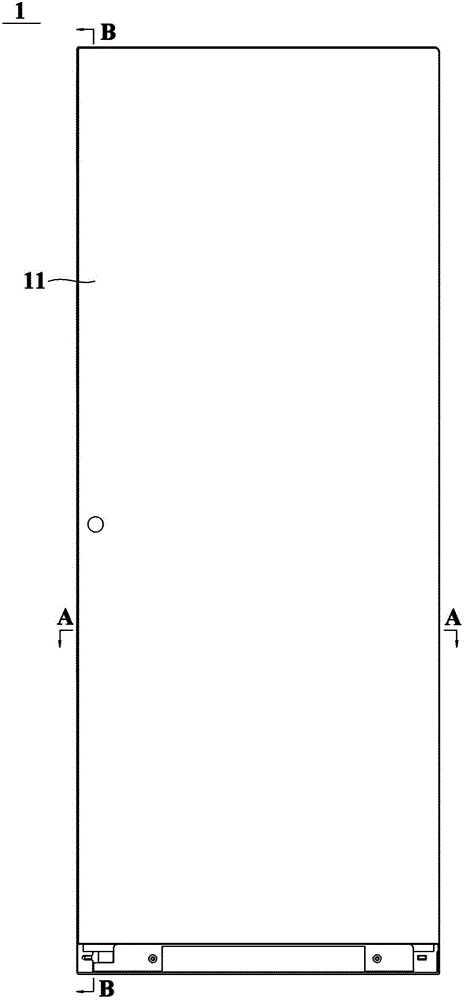

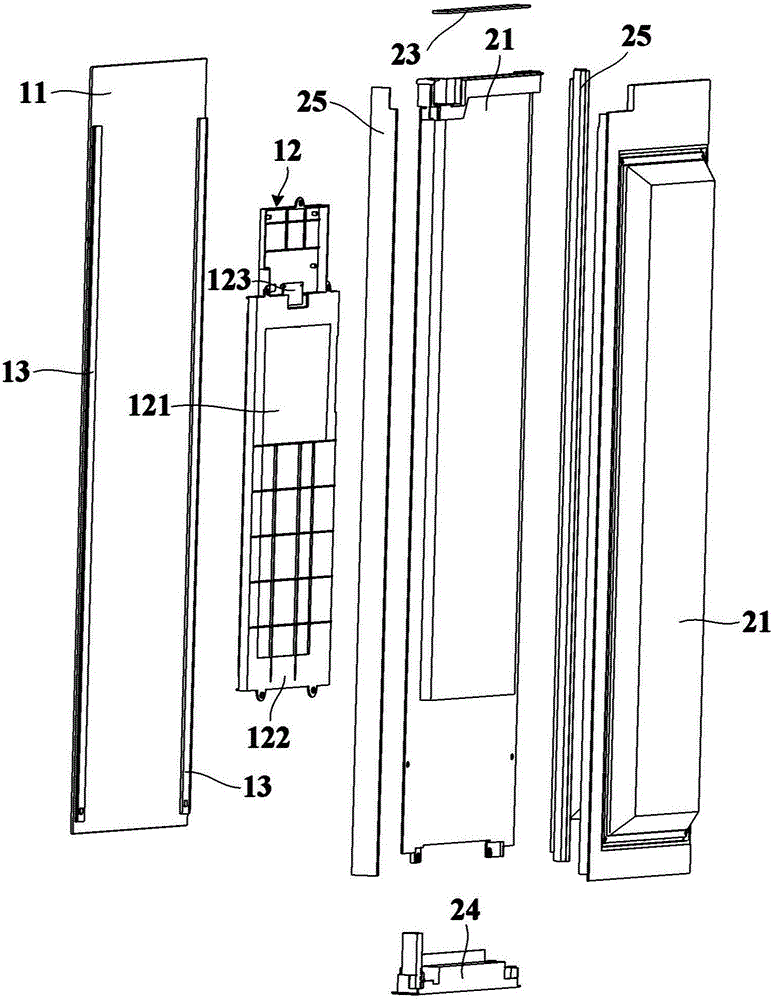

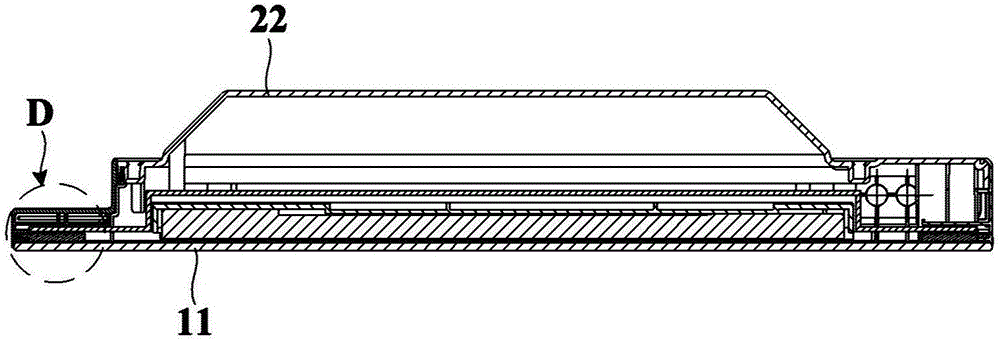

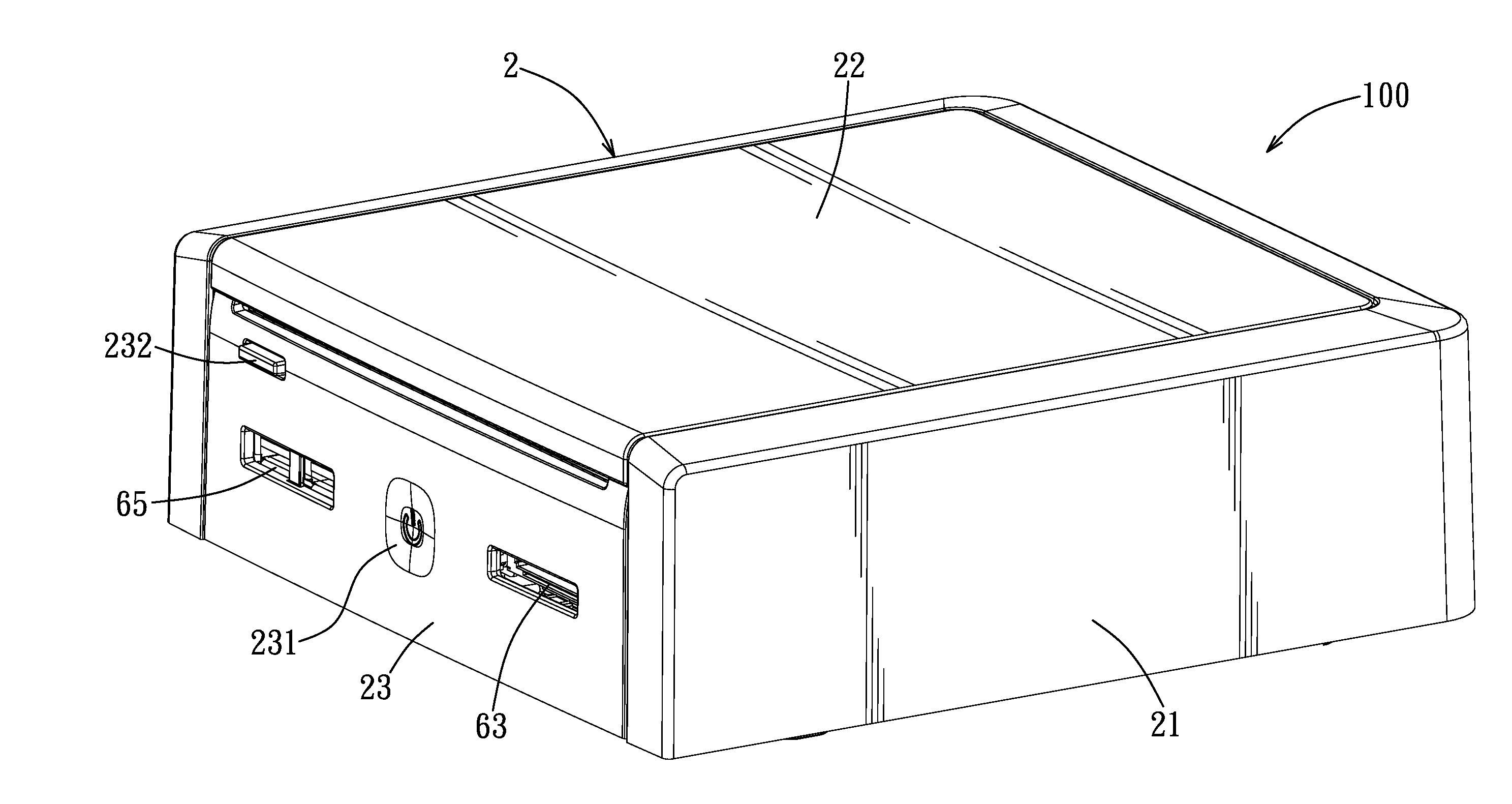

Refrigerating and freezing device, door for refrigerating and freezing device and installation method of door

ActiveCN106091552AImprove touch effectPrevent condensationDomestic cooling apparatusLighting and heating apparatusEngineeringSurface plate

The invention relates to a refrigerating and freezing device, a door for the refrigerating and freezing device and an installation method of the door. The door comprises a glass face plate, a display and control assembly and a door foamed assembly. The two transverse sides of the backward surface of the glass face plate are each provided with an installation support extending vertically. The display and control assembly is provided with a touch display screen and an installation plate frame. The door foamed assembly is provided with a front door lining, a back door lining, an upper decorative strip, a lower decorative strip and two side frames. A foamed heat preservation layer is formed among the front door lining, the back door lining, the upper decorative strip, the lower decorative strip and the two side frames. The touch display screen is fixed to the glass face plate through the installation plate frame and attached to the backward surface of the glass face plate in a fit manner. The glass face plate is installed on the front side of the door foamed assembly from top to bottom through the installation supports. The installation method of the door comprises the preassembly stage and the final assembly stage which are conducted in sequence. By the adoption of the refrigerating and freezing device, the door for the refrigerating and freezing device and the installation method of the door, the touch effect can be improved, condensation water is prevented from being generated on the touch display screen, and the display and control assembly is convenient to disassemble and maintain. The refrigerating and freezing device comprises a box and the door.

Owner:QINGDAO HAIER SPECIAL REFRIGERATOR CO LTD

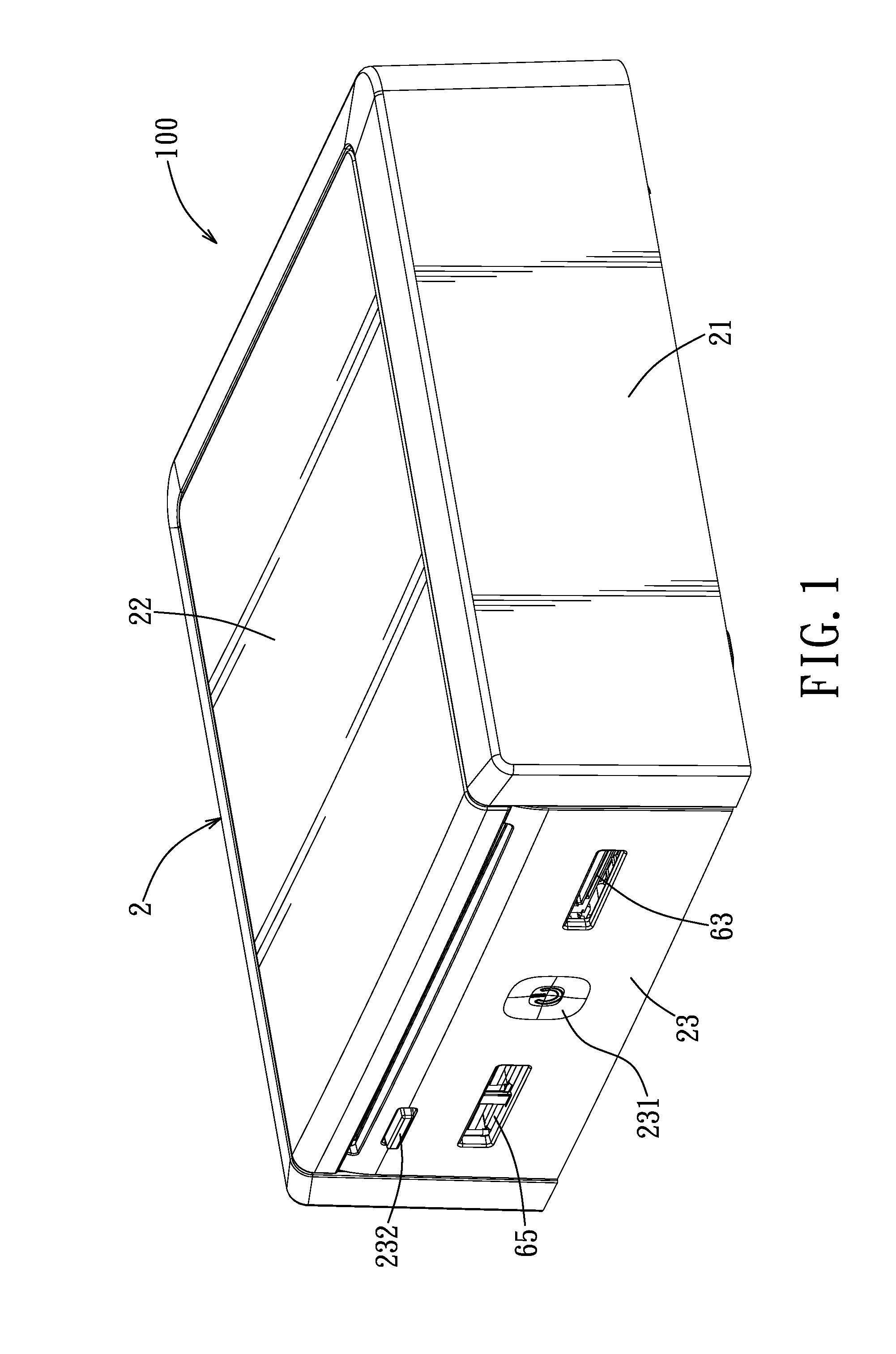

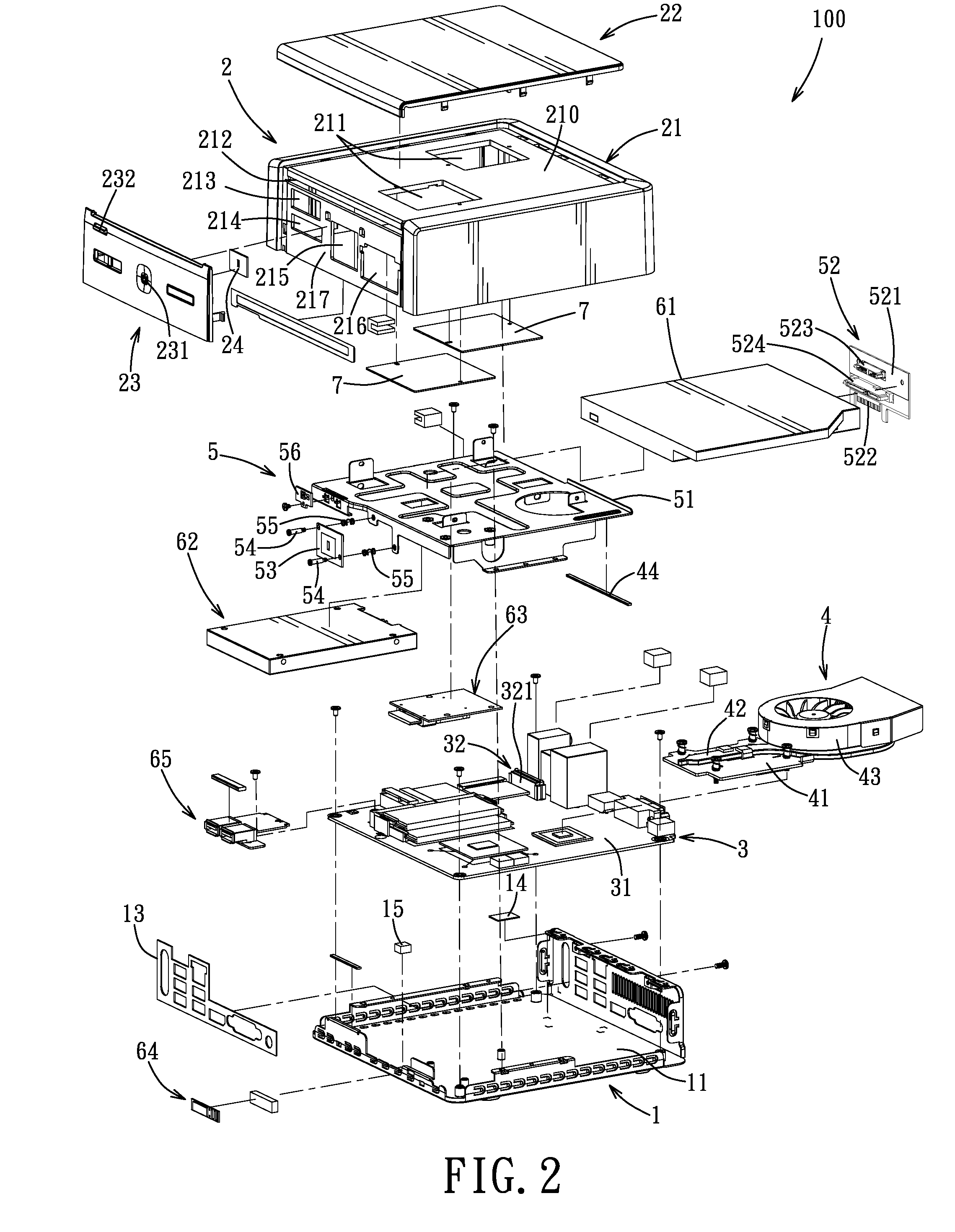

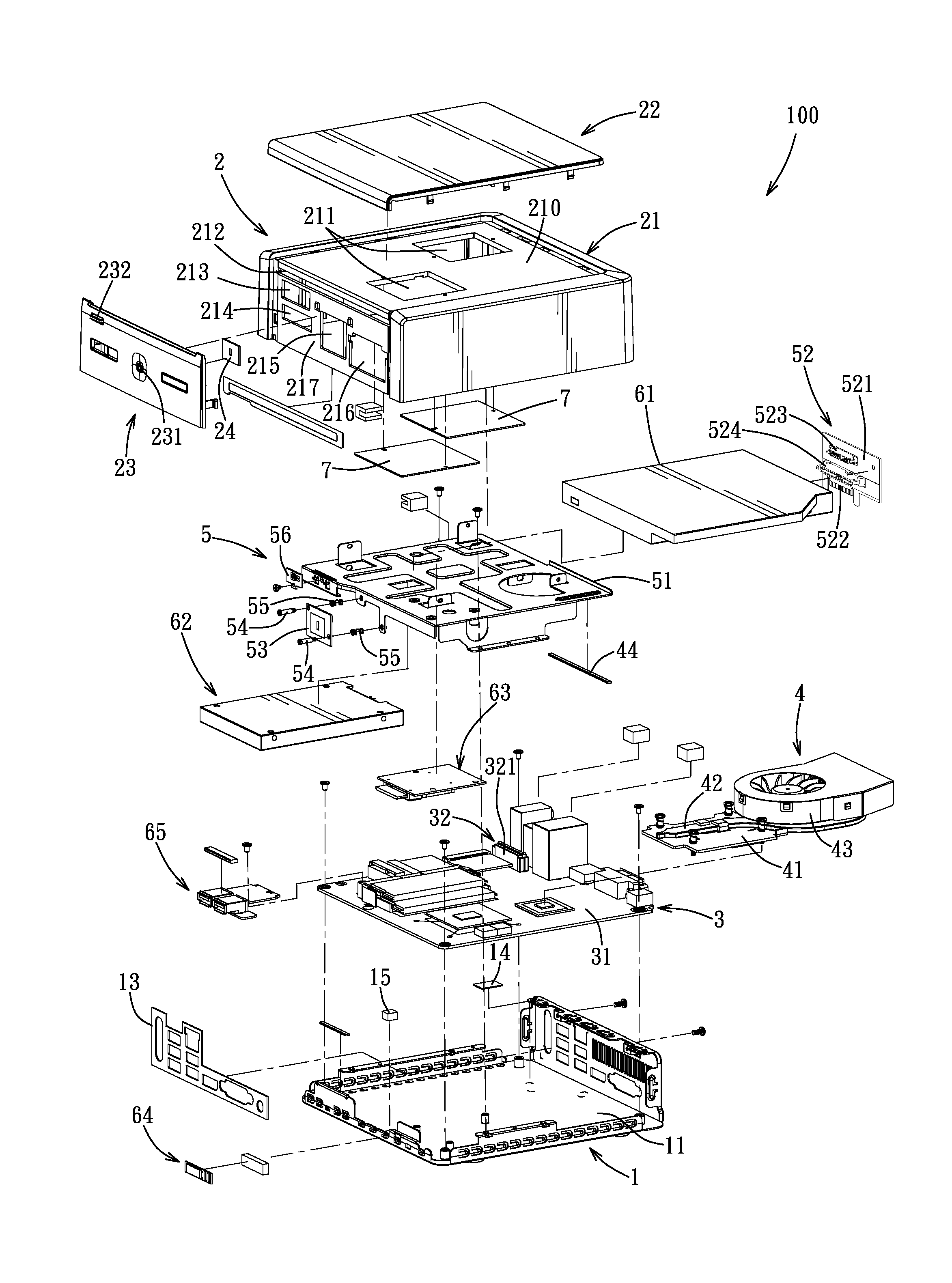

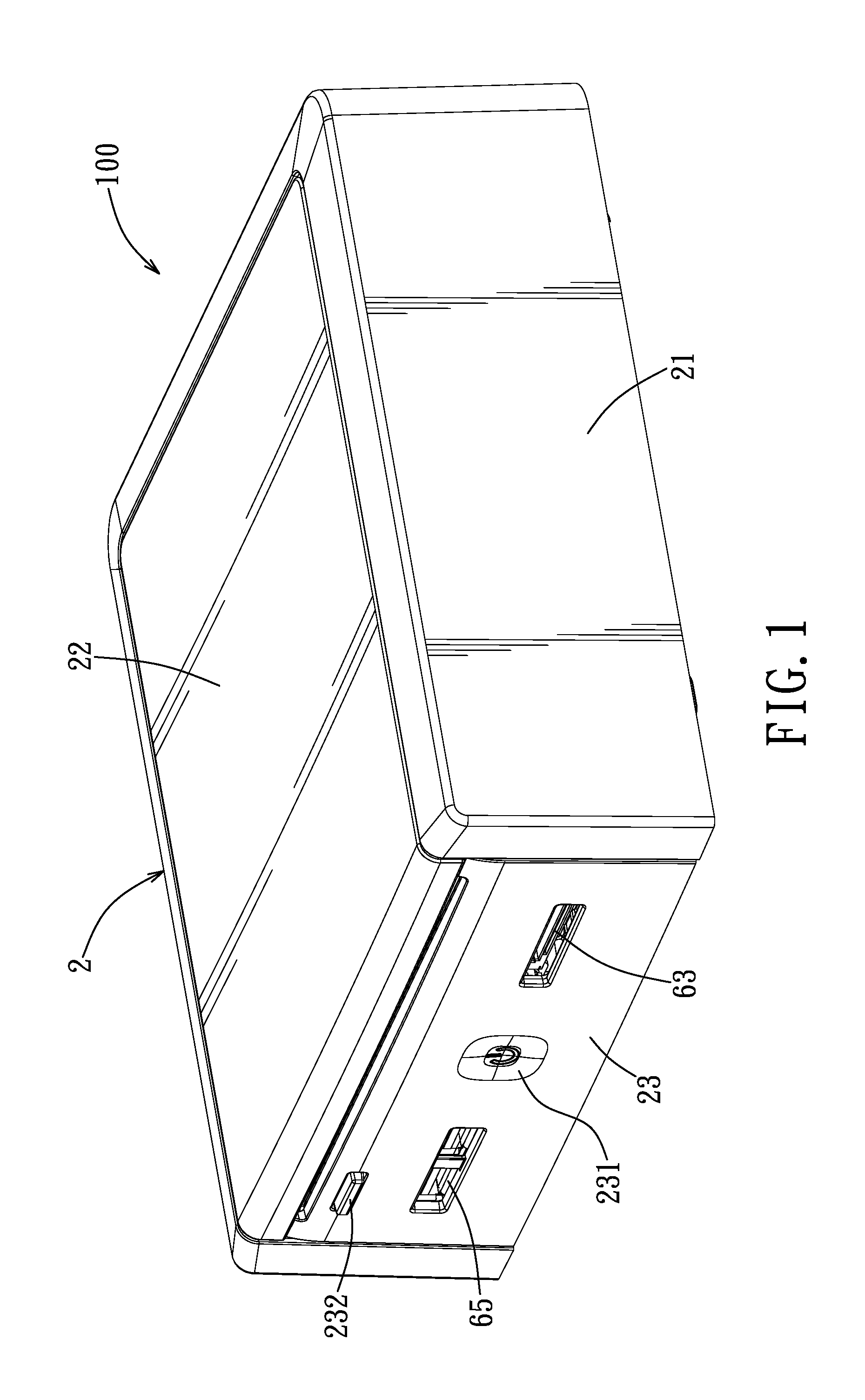

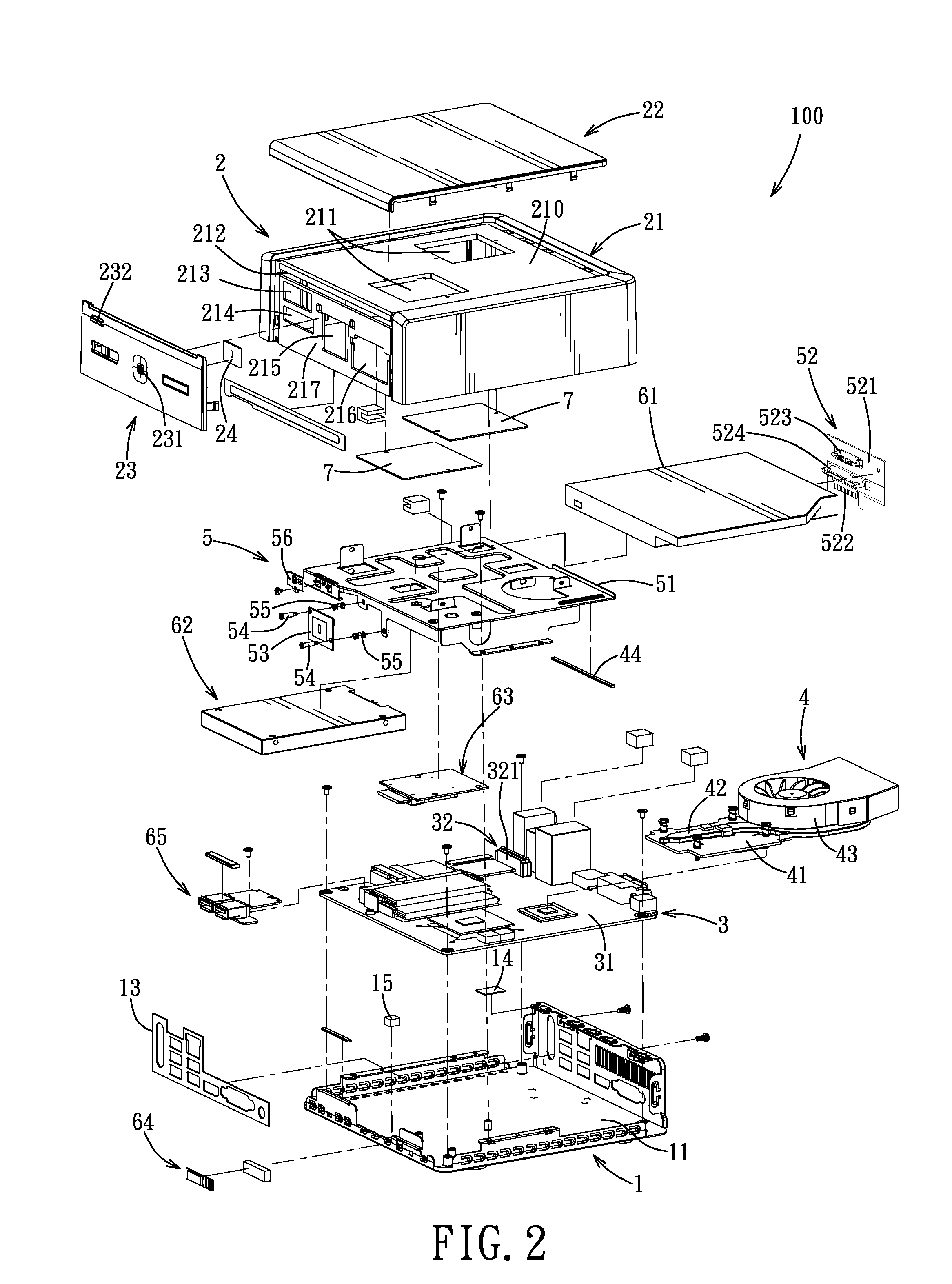

Frame module and computer having the same

InactiveUS20140337866A1Improve touch effectGood yield.\Coupling device connectionsApparatus modification to store record carriersElectrical connectionEngineering

A frame module is adapted to be disposed in a housing of a computer for fixing first and second electronic devices. The computer includes a motherboard unit with a socket connector. The frame module includes a frame body having top and bottom surfaces adapted to be connected respectively to the first and electronic devices. An adaptor board includes a board body connected transversely to a rear edge of the frame body and having an edge connector adapted to be inserted into the socket connector, and first and second electrical connectors for electrical connection with the first and second electronic devices, respectively.

Owner:AOPEN

Frame Module and Computer Having the Same

ActiveUS20120281349A1Excellent touch effectGood yieldCoupling device connectionsRecord information storageElectrical connectionMotherboard

A frame module is adapted to be disposed in a housing of a computer for fixing first and second electronic devices. The computer includes a motherboard unit with a socket connector. The frame module includes a frame body having top and bottom surfaces adapted to be connected respectively to the first and electronic devices. An adaptor board includes a board body connected transversely to a rear edge of the frame body and having an edge connector adapted to be inserted into the socket connector, and first and second electrical connectors for electrical connection with the first and second electronic devices, respectively.

Owner:AOPEN

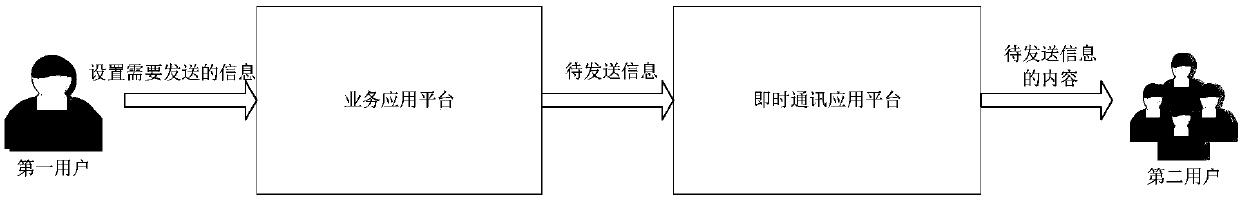

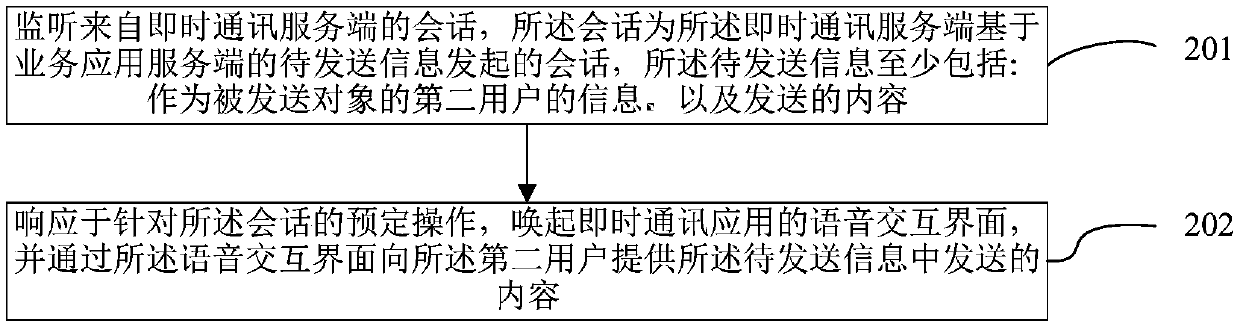

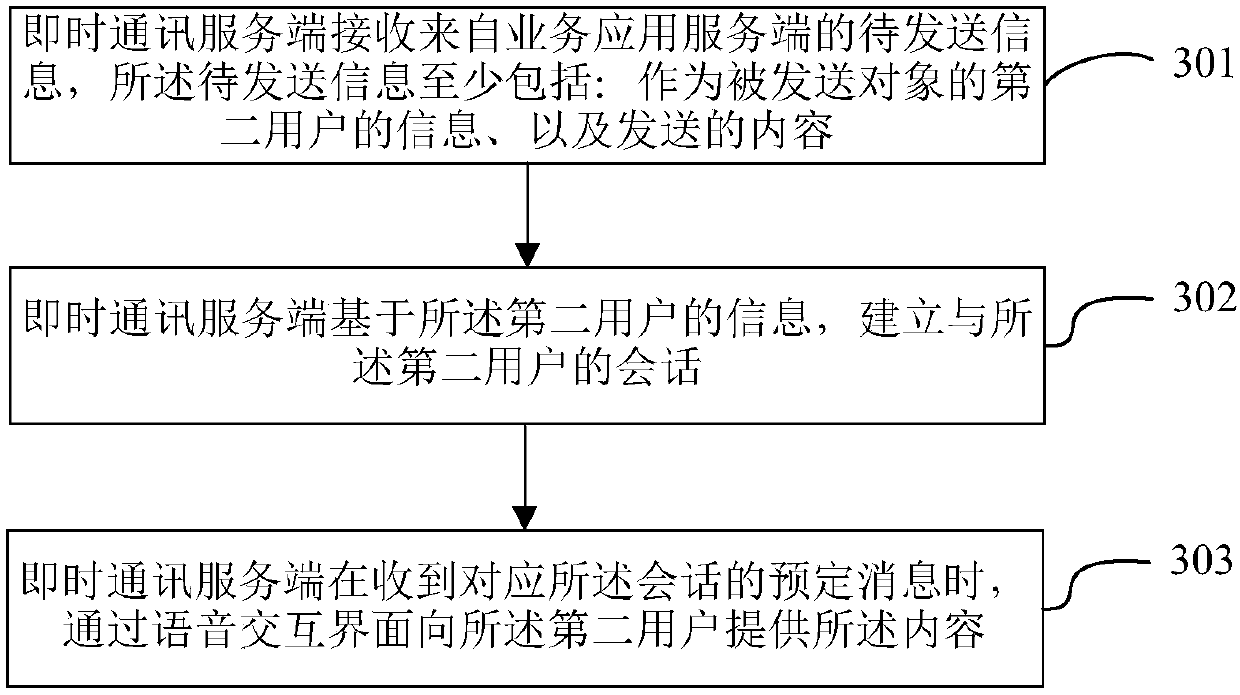

Information processing method and device

ActiveCN110138644AIncrease reachGood touch effectAutomatic exchangesData switching networksInformation processingInteraction interface

The invention discloses an information processing method and device, and the method can comprise the steps that an instant messaging server receives to-be-sent information from a business applicationserver, and the to-be-sent information at least comprises the information of a second user serving as a sent object, and the sent content; based on the information of the second user, a session is established with the second user; and when a predetermined message corresponding to the session is received, the content is provided for the second user through a voice interaction interface. According to the method and the device, the information touch rate can be greatly improved.

Owner:ALIBABA GRP HLDG LTD

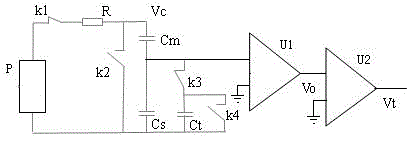

Dynamic setting method and circuit of touch screen control integrated circuit driving signal

InactiveCN104102405AExpand the range of optionsGuaranteed touch effectInput/output processes for data processingCapacitanceFree state

The invention belongs to the technical field of a capacitive touch screen integrated circuit, and particularly relates to a dynamic setting method of a touch screen control integrated circuit driving signal and a dynamic setting circuit adopted by the method. The method comprises the following steps: utilizing a driving signal generator which pre-stores a plurality of driving signals to successively apply each driving signal to a cell to be tested; connecting a test capacitor from two ends of the capacitor in a cell to be tested of an original control integrated circuit in parallel; simulating a touch state and a touch-free state; measuring response signals corresponding to the two states, wherein the driving signal corresponding to a response signal value with maximum difference is an optimal driving signal of the cell to be tested; and successively linking all cells to select optimal driving signals for all cells. The optimal driving signals are dynamically selected for touch screen cells, and a touch screen is fully guaranteed to exhibit optimal touch effect all the time.

Owner:山东芯艺电子科技有限公司

Touch input device

ActiveUS20130127793A1Easily damagedWide range of useInput/output processes for data processingEngineeringConductive materials

A touch input device comprises: a body made of a conductive material; a brush formed at one end of the body for external extraction, and which is made of a conductive material for touching a capacitive touch panel; and a unit for generating a clicking sensation which is installed within the body to generate a clicking sensation when the touch panel is touched by the brush, thereby enabling a user to sense a click when touching the touch panel, thus improving user convenience, enabling dragging to be smoothly performed, enabling pictures to be easily drawn, minimizing damage such as scratches or the like on the surface of the touch panel, and enabling the surface of the touch panel to be cleaned.

Owner:JUNG YOUNG WOO

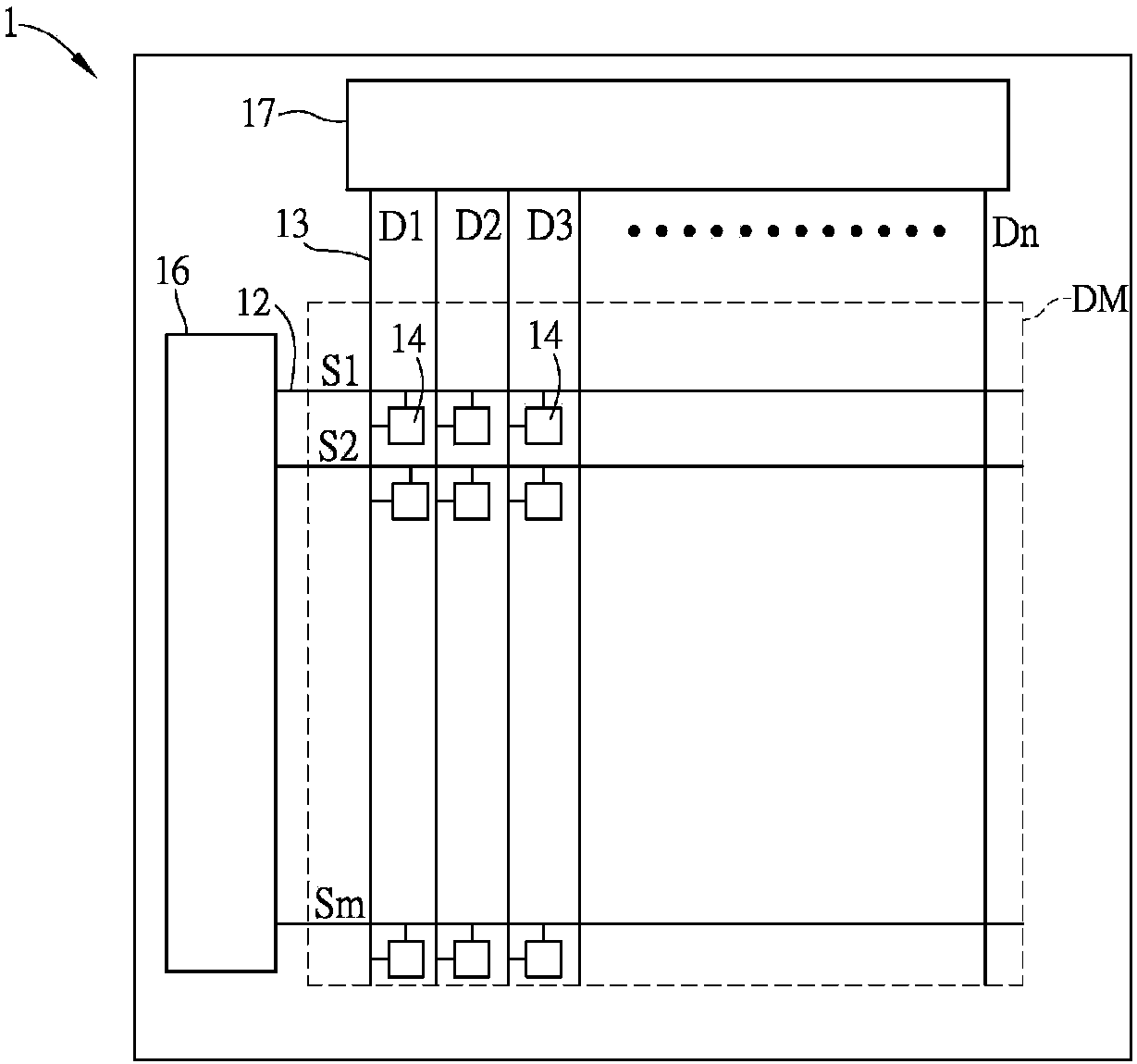

Touch control display device

InactiveCN107561759AImprove uneven distributionIncrease opening ratioStatic indicating devicesNon-linear opticsDisplay deviceComputer science

The invention discloses a touch control display device. The touch control display device comprises two substrates which are opposite, one display medium which is arranged between the inner sides of the substrates in a sandwiched mode, one gap material area which is provided with arrangement units, and one touch control matrix which comprises a plurality of touch control units, wherein the arrangement units are distributed between the inner sides of the substrates, each arrangement unit is formed in the mode that a plurality of sub-arrangement units are arranged in a line and column mode, in each one arrangement unit, part of sub-arrangement units are provided with gap materials, and the other sub-arrangement units are not provided with the gap materials; the touch control units are arranged along the sub-arrangement units which are provided with the gap materials.

Owner:HKC CORP LTD

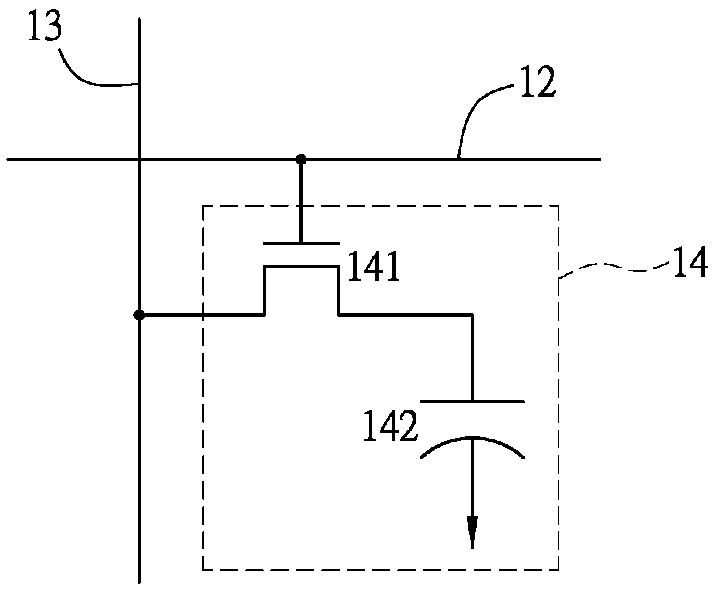

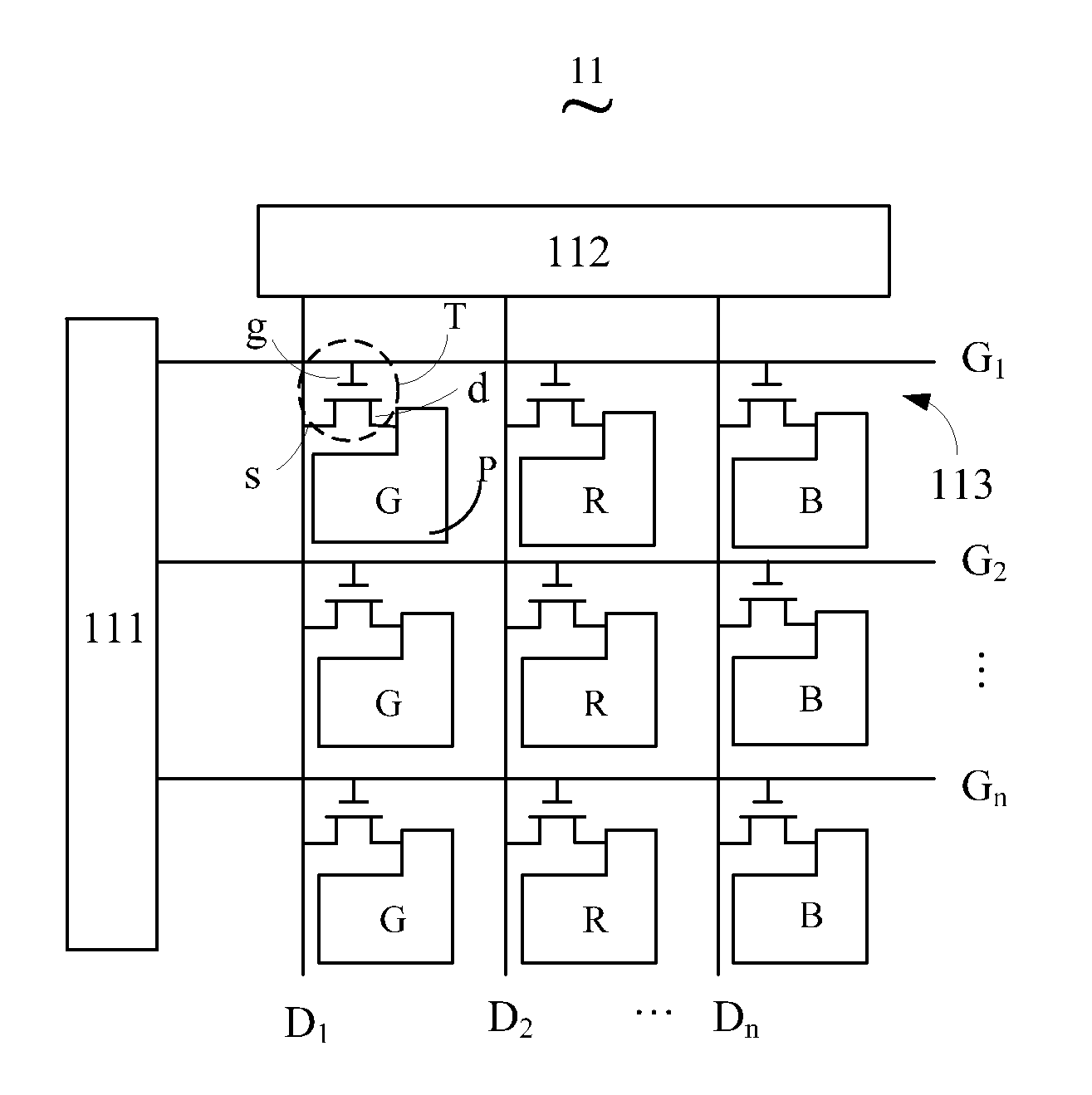

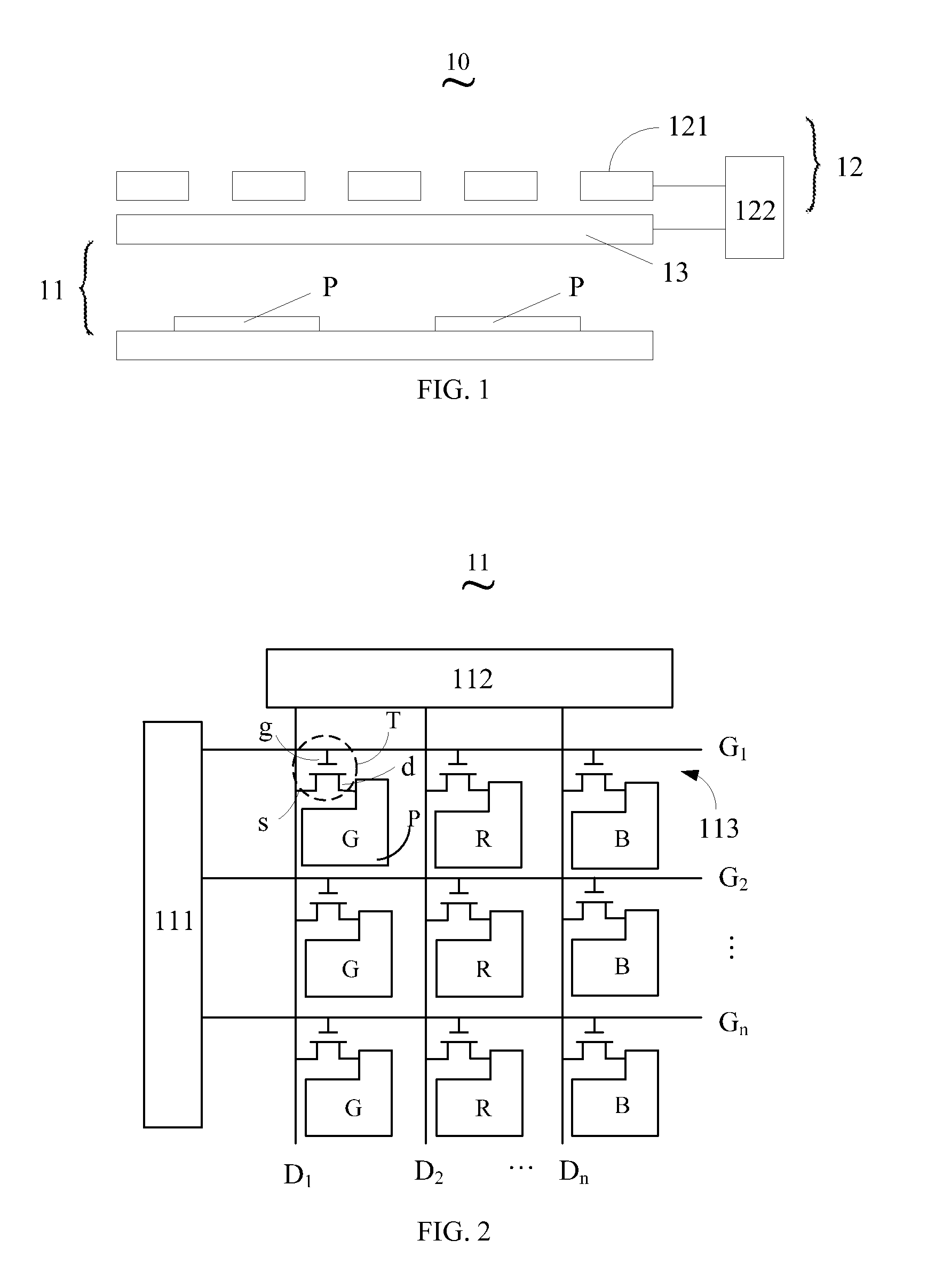

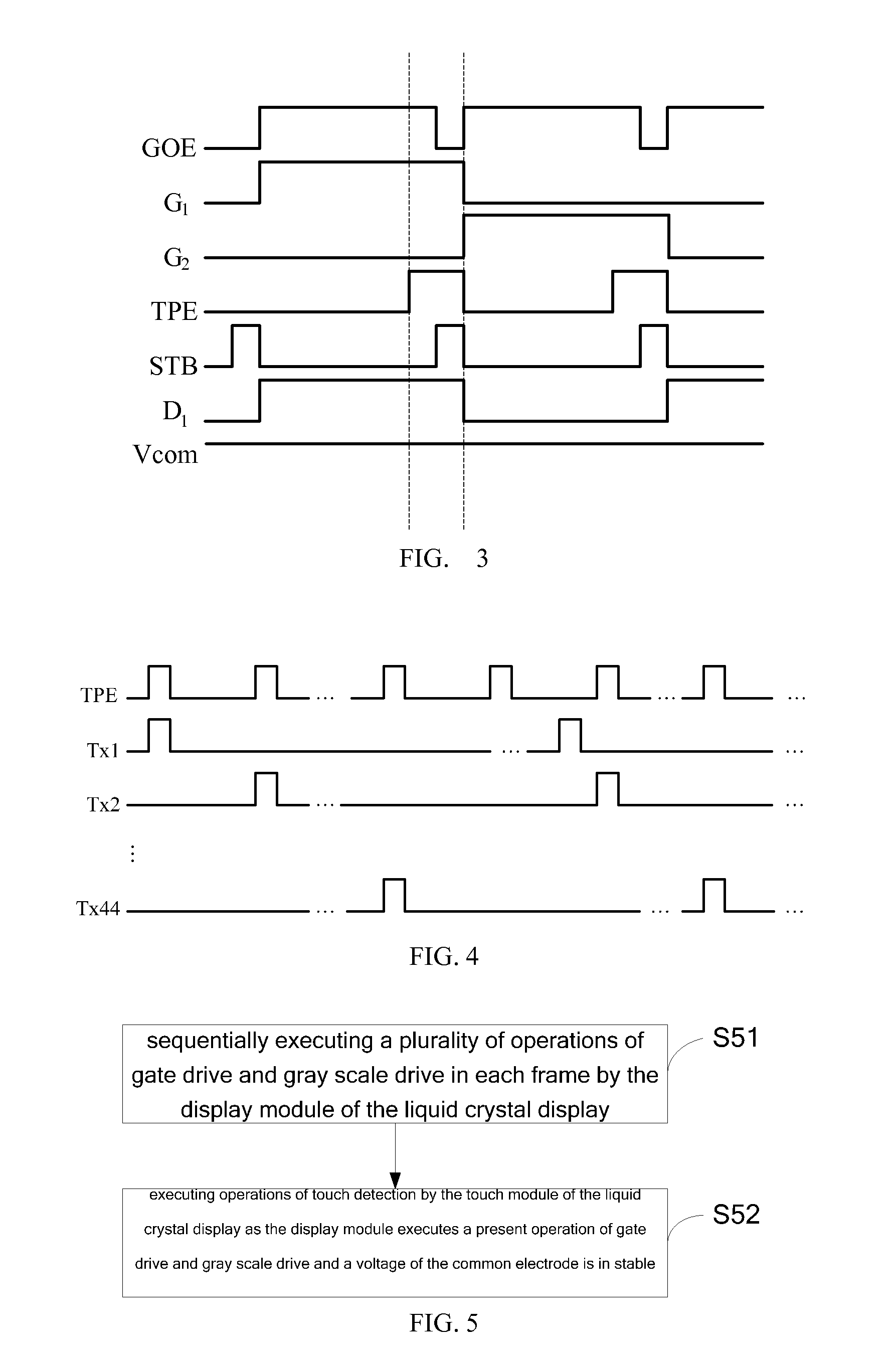

Liquid crystal display having touch function and touch detection method thereof

ActiveUS20160342277A1Improve display qualityImprove quality effectStatic indicating devicesNon-linear opticsLiquid-crystal displayTouch function

The present invention discloses a liquid crystal display having touch function and a touch detection method thereof. The liquid crystal display comprises a display module and a touch module, and the display module and the touch module share a common electrode. The display module sequentially executes a plurality of operations of gate drive and gray scale drive in each frame. The touch module executes operations of touch detection as the display module executes a present operation of gate drive and gray scale drive and a voltage of the common electrode is in stable. With the aforementioned arrangement, the present invention is capable of reducing the interference of the display signals and the touch signals to improve the display quality and touch effect.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

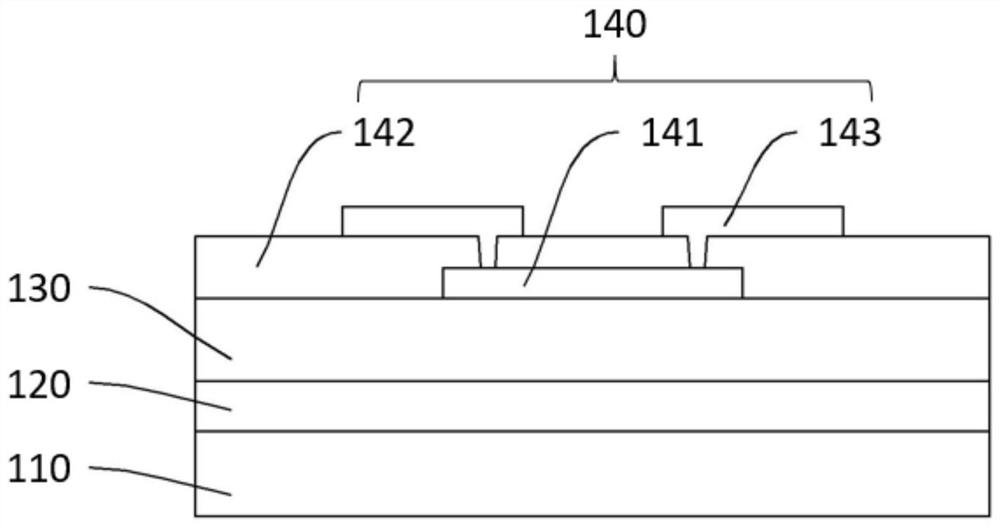

Display panel and mobile terminal

PendingCN114281206AGuaranteed normal transmissionWill not affect the light transmission functionSolid-state devicesInput/output processes for data processingComputational physicsTouch function

The invention discloses a display panel and a mobile terminal, the display panel comprises a conventional display area and a light-transmitting function display area, and the display panel comprises an array driving layer which comprises a thin film transistor layer and a transparent conductive layer; a first electrode layer; the light-emitting layer comprises first pixels arranged in the conventional display area and second pixels arranged in the light-transmitting function display area; the second electrode layer is arranged in the light-transmitting function display area and is provided with a penetrating opening at a position between the adjacent second pixels; wherein in the light-transmitting function display area, the transparent conductive layer comprises a plurality of touch electrodes which are arranged corresponding to the through openings. Wherein in the light-transmitting function display area, a transparent conducting layer is used for forming a touch control electrode, the touch control function of the light-transmitting function display area is achieved, meanwhile, the light-transmitting function of the area is not affected, and in addition, a through opening is formed in the position, corresponding to the touch control electrode, of the second electrode layer, so that normal transmission of a touch control induction signal is guaranteed.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

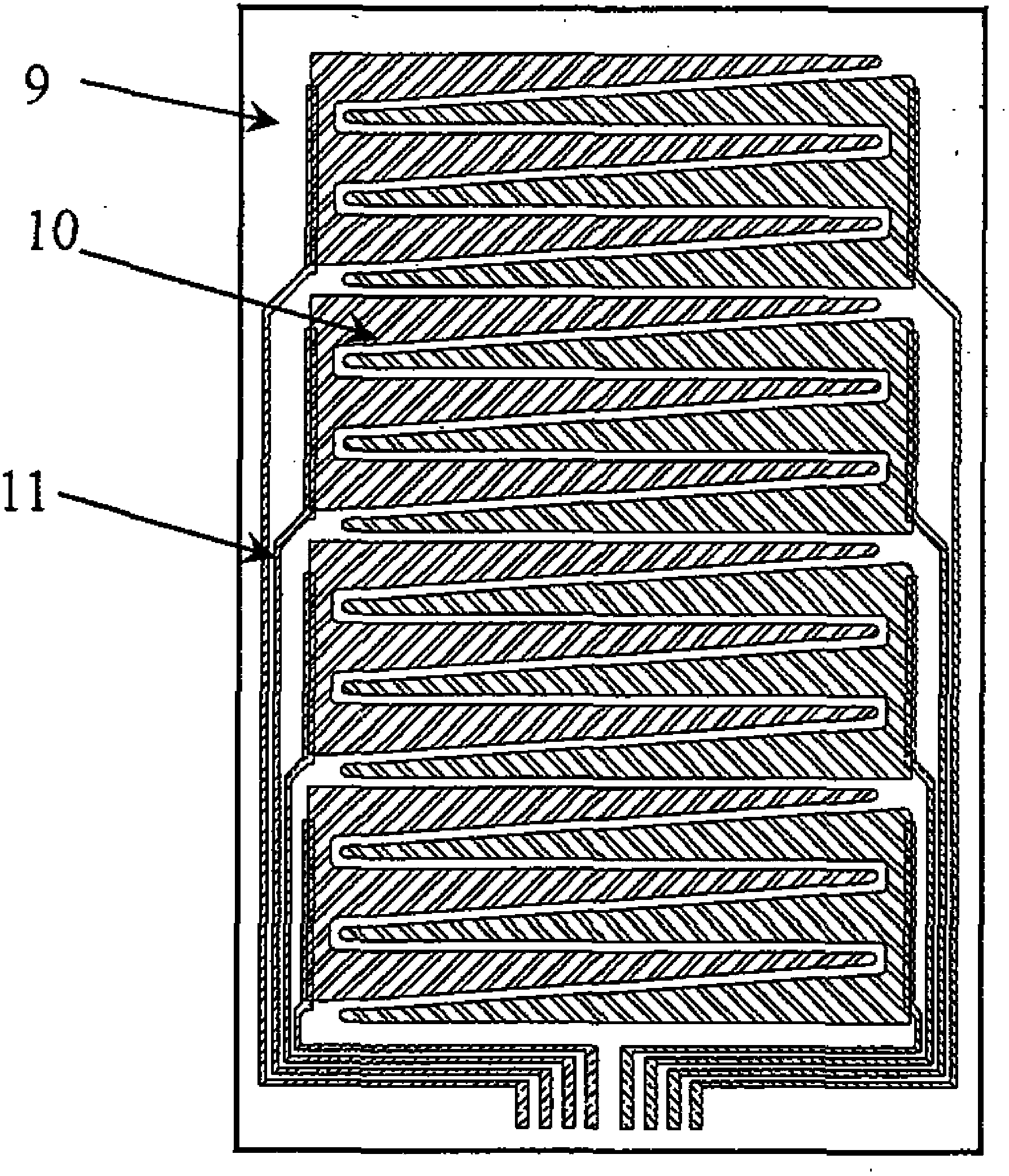

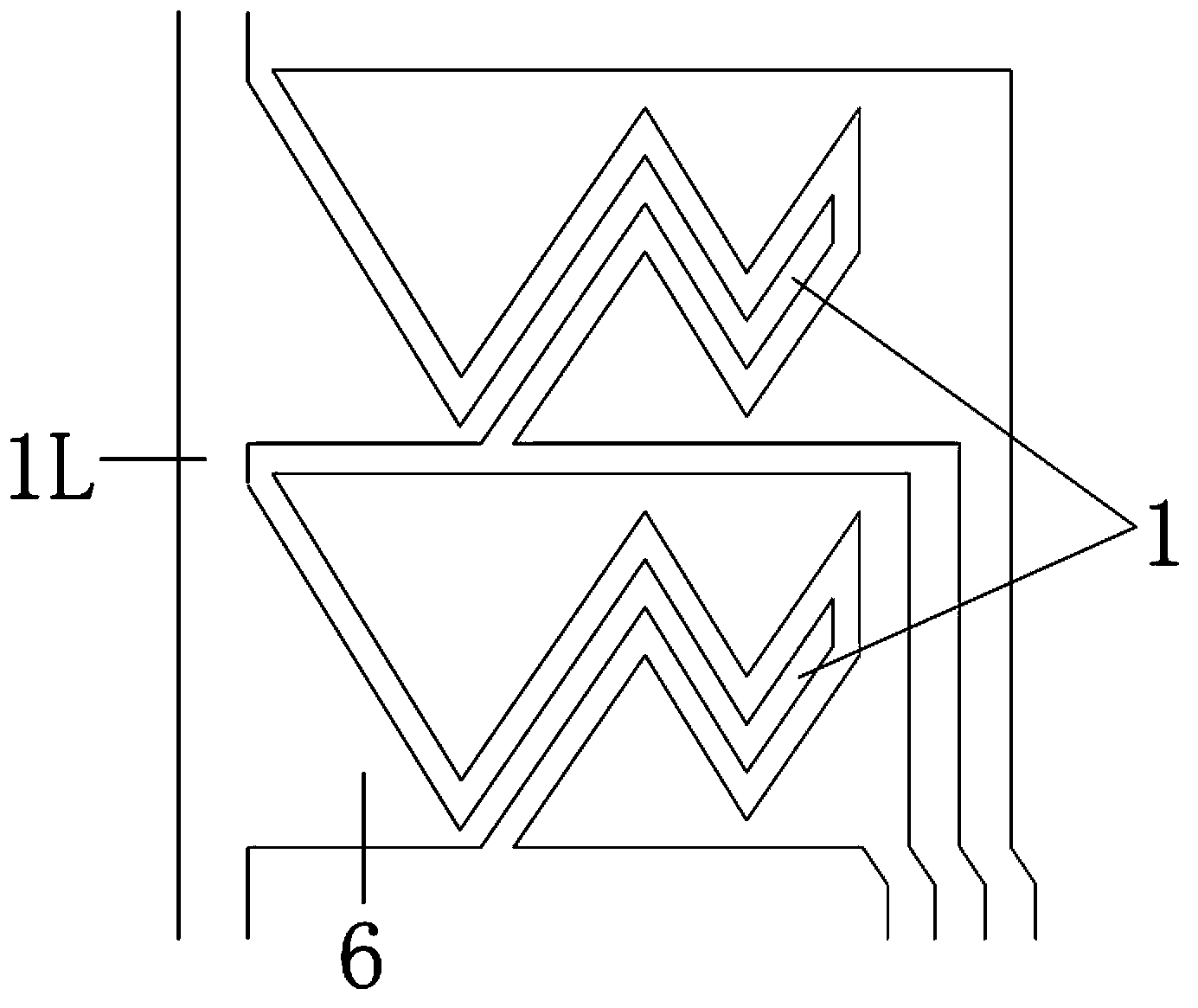

Capacitance touch screen and single-layer electrode array

ActiveCN103513830ASimple preparation processLow costInput/output processes for data processingCapacitanceWave shape

The invention relates to a capacitance touch screen and a single-layer electrode array. The single-layer electrode array comprises multiple unit capacitors which are sequentially arranged. Each unit capacitor comprises one or more inner electrodes on a plane and one or more outer electrodes corresponding to one or more inner electrodes. The inner electrodes are located in wave-shaped or zigzag grooves formed by the outer electrodes. The invention further relates to the capacitance touch screen comprising the single-layer electrode array. The capacitance touch screen comprises a substrate and an electrode array arranged on the substrate. The inner electrodes are connected through inner wires located on one sides of the inner electrodes in series. The outer electrodes are connected through outer wires located on the other sides of the outer electrodes in parallel. The inner wires and the outer wires are connected with corresponding control ports of a circuit board respectively. By means of the capacitance touch screen and the single-layer electrode array, equipment cost is low and the touch performance is high.

Owner:SILEAD

Glass embossed surface silk-screen printing process

InactiveCN112209631AGood visual effectImprove touch effectCoatingsOther printing apparatusPolymer scienceManufactured material

The invention belongs to the technical field of glass product manufacturing, and particularly relates to a glass embossed surface silk-screen printing process which comprises the following steps: selecting single-sided embossed glass with the thickness of 3-12mm as a raw material, conducting cutting, edging, chamfering and cleaning, and printing an embossed surface of the embossed glass on a silk-screen printing machine by adopting a customized screen plate and high-temperature ink, wherein the tension of the customized screen plate is 18+ / -2N / cm, the thickness of a film layer of the customized screen plate is 95+ / -10 [mu]m, the mesh number of the screen cloth is 150, the pressure of a scraper on the silk-screen printing machine is 0.5-0.7 MPa, and the hardness of the scraper is HS60-HS70;and carrying out drying, tempering, secondary cleaning and other processes, and conducting packaging. According to the invention, high-quality printing patterns with different patterns, dermatoglyph,similar stone, rock plates and the like can be realized on the uneven glass embossed surface, the visual aesthetic effect and the touch effect of the product are enhanced, the printing quality and the printing efficiency of the product are improved, and the labor intensity of workers is reduced.

Owner:焦作飞鸿安全玻璃有限公司

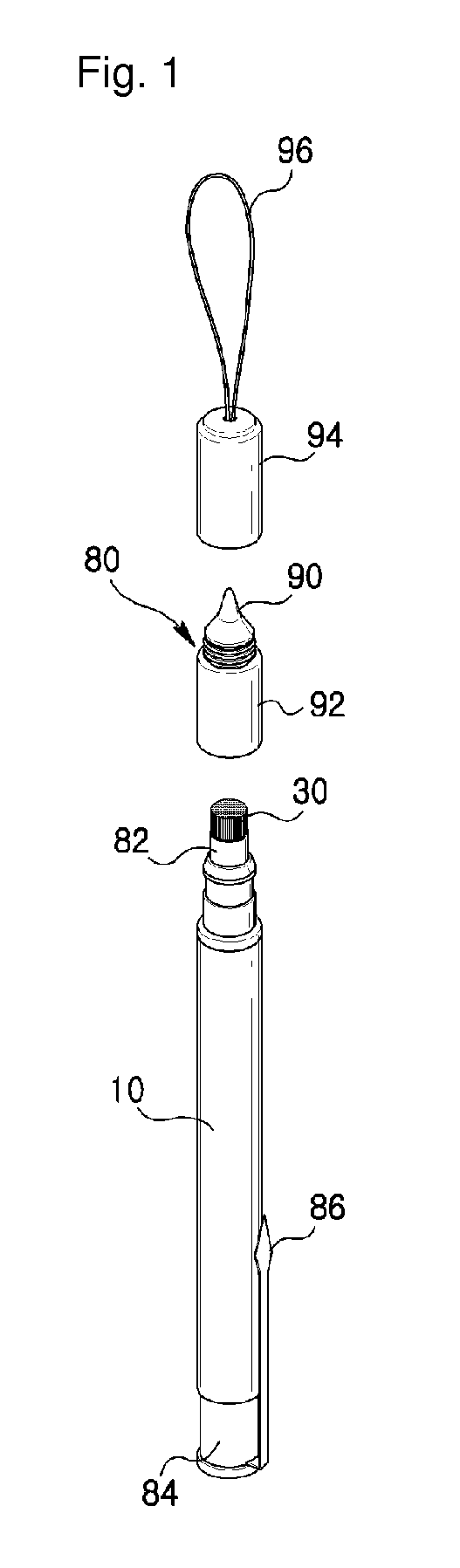

Touch input device

ActiveUS8994699B2Drag taskConvenient taskInput/output processes for data processingEngineeringConductive materials

A touch input device comprises: a body made of a conductive material; a brush formed at one end of the body for external extraction, and which is made of a conductive material for touching a capacitive touch panel; and a unit for generating a clicking sensation which is installed within the body to generate a clicking sensation when the touch panel is touched by the brush, thereby enabling a user to sense a click when touching the touch panel, thus improving user convenience, enabling dragging to be smoothly performed, enabling pictures to be easily drawn, minimizing damage such as scratches or the like on the surface of the touch panel, and enabling the surface of the touch panel to be cleaned.

Owner:JUNG YOUNG WOO

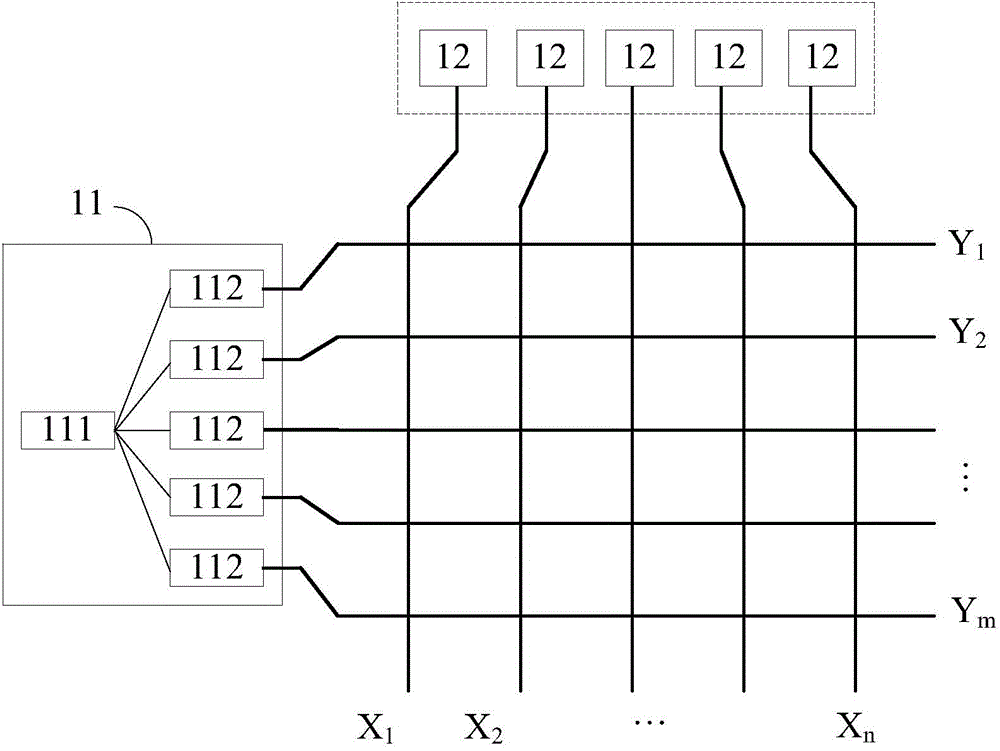

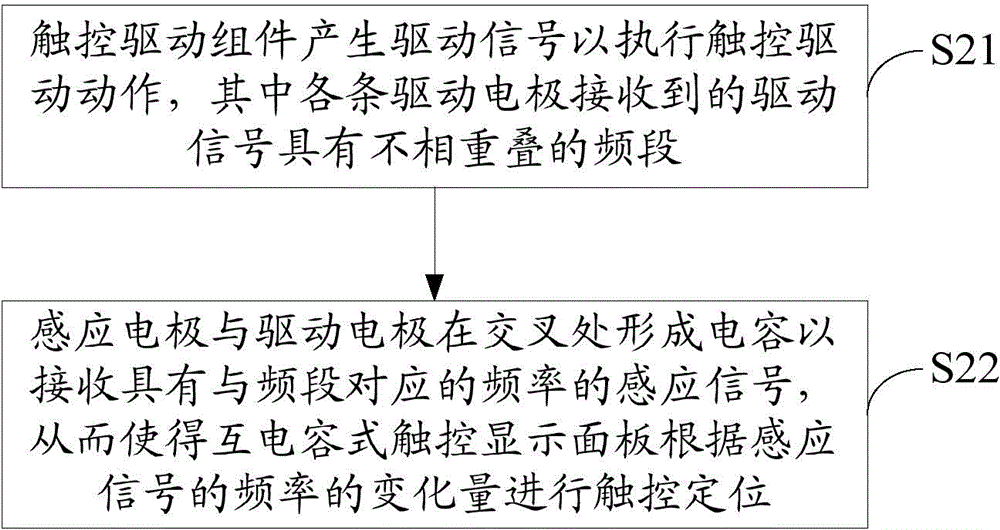

Mutual-capacitance touch display panel and touch detection method thereof

ActiveCN104793823AAvoid interferenceAvoid ghost spotsInput/output processes for data processingCapacitorFrequency band

The invention discloses a mutual-capacitance touch display panel and a touch detection method thereof. The touch detection method comprises the steps that a touch drive component generates drive signals to perform touch drive action, wherein the drive signals received by all drive electrodes have non-overlapping frequency bands; induction electrodes and the drive electrodes form capacitors at the cross positions to receive induction signals with the frequency corresponding to the frequency bands, and therefore the mutual-capacitance touch display panel can perform touch positioning according to the variable quantity of the frequency of the induction signals. According to the mutual-capacitance touch display panel and the touch detection method thereof, mutual interference among the drive signals received by all the drive electrodes can be avoided, the phenomena such as ghost points and touch failure are prevented from generating, and the touch effect is good.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Method for realization of anti glare effect of glass

The invention relates to a method for realization of anti glare effect of glass, AG anti glare treatment on both sides of the glass is performed for realization of anti glare effect, the method solves the problem that in the prior art, when the AG side is processed, residual acid liquid flows into non AG side to damage the non AG side so as to cause badness, two sides of the glass is etched to ensure the two sides are uniformly etched meanwhile non AG side acid leakage problem is solved radically. At the same time, the two sides of the glass have anti glare effect, and actual results can be controlled by double sided etching, so that the light transmittance effect is wider than original single-side AG effect, the product AG parameter partition also can be more detailed, and the glass has the advantages of good touch effect, even surface etching, and a more wide range of adjustment of the transmittance.

Owner:SUZHOU ANJIE TECH

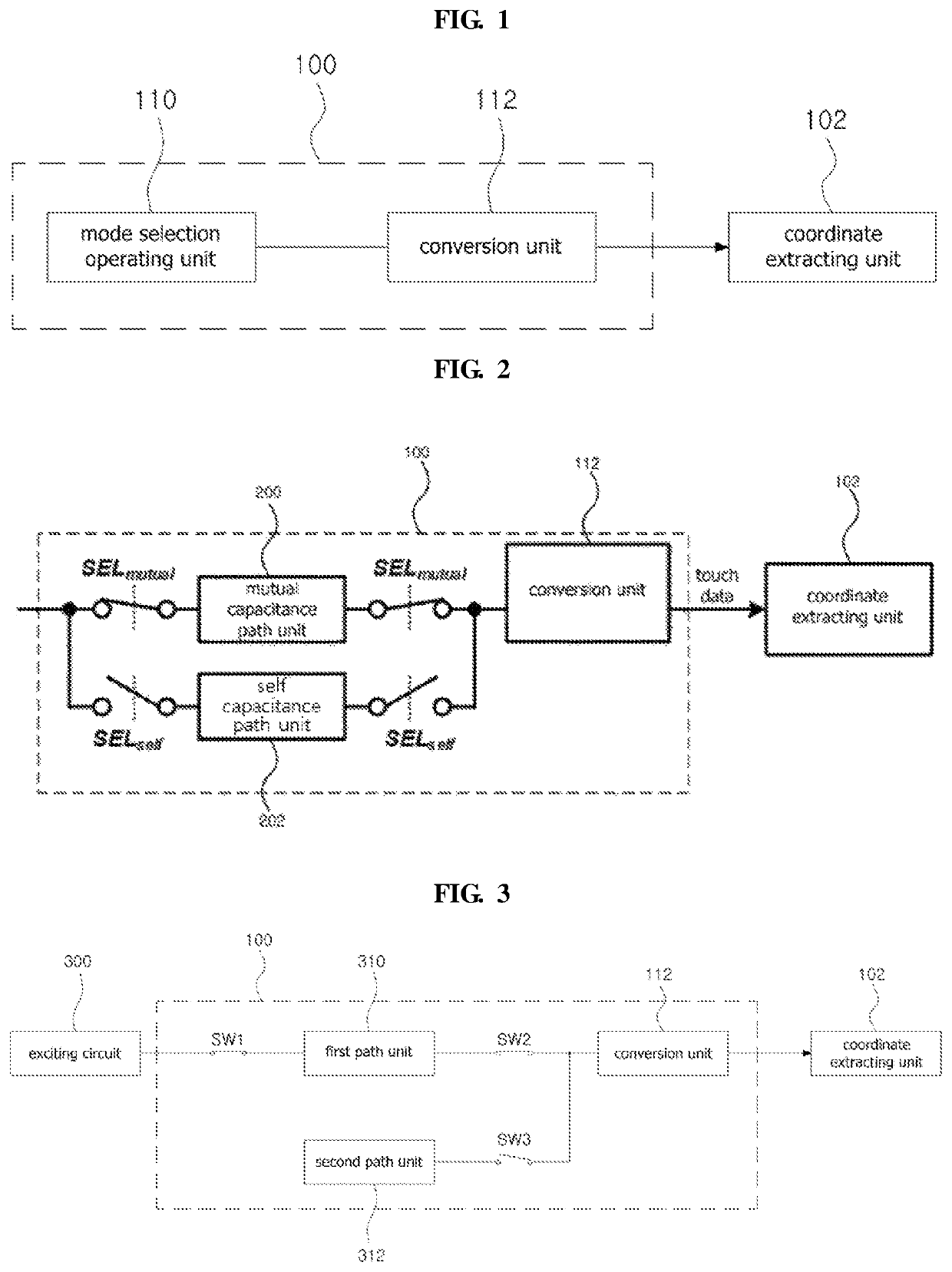

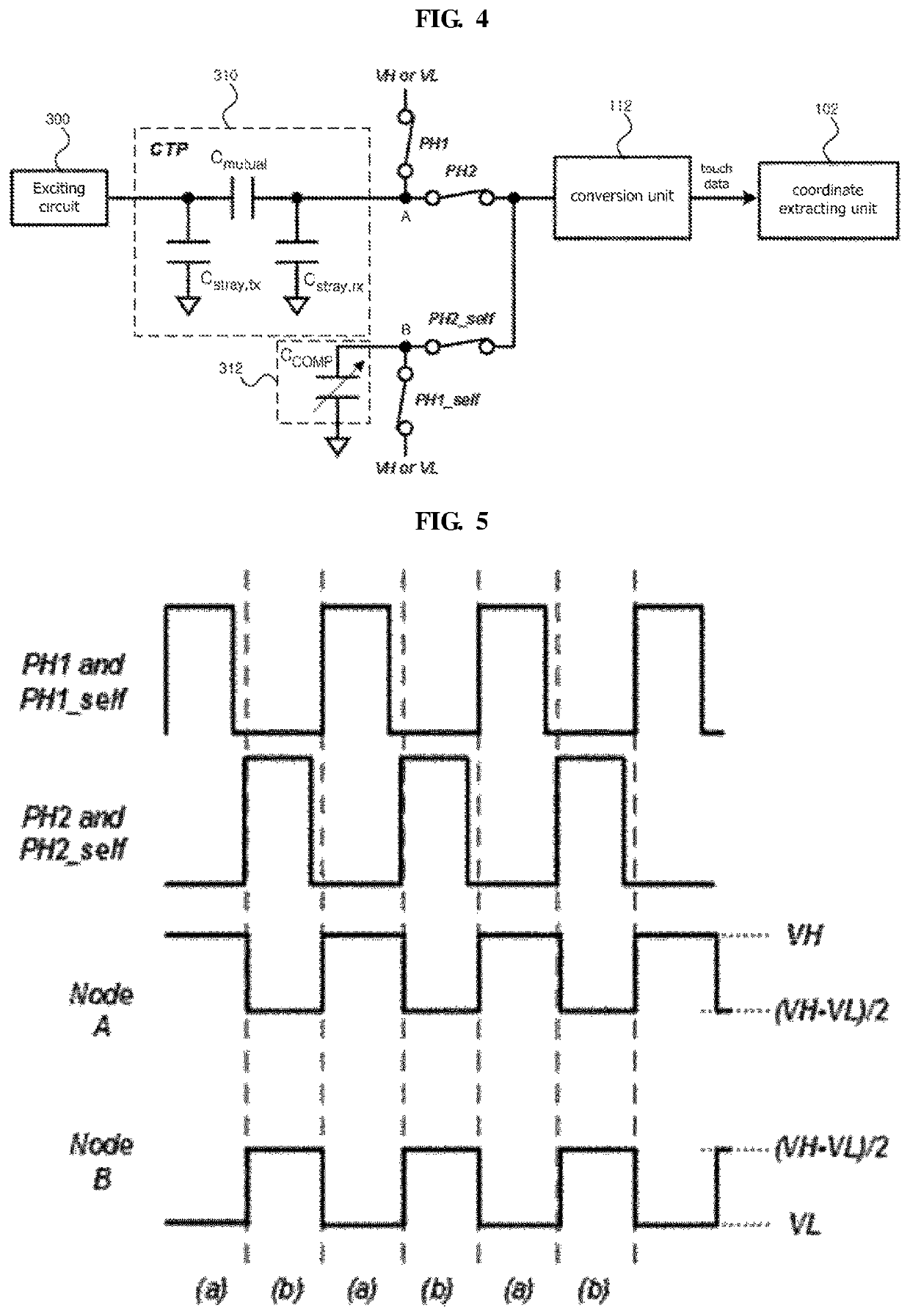

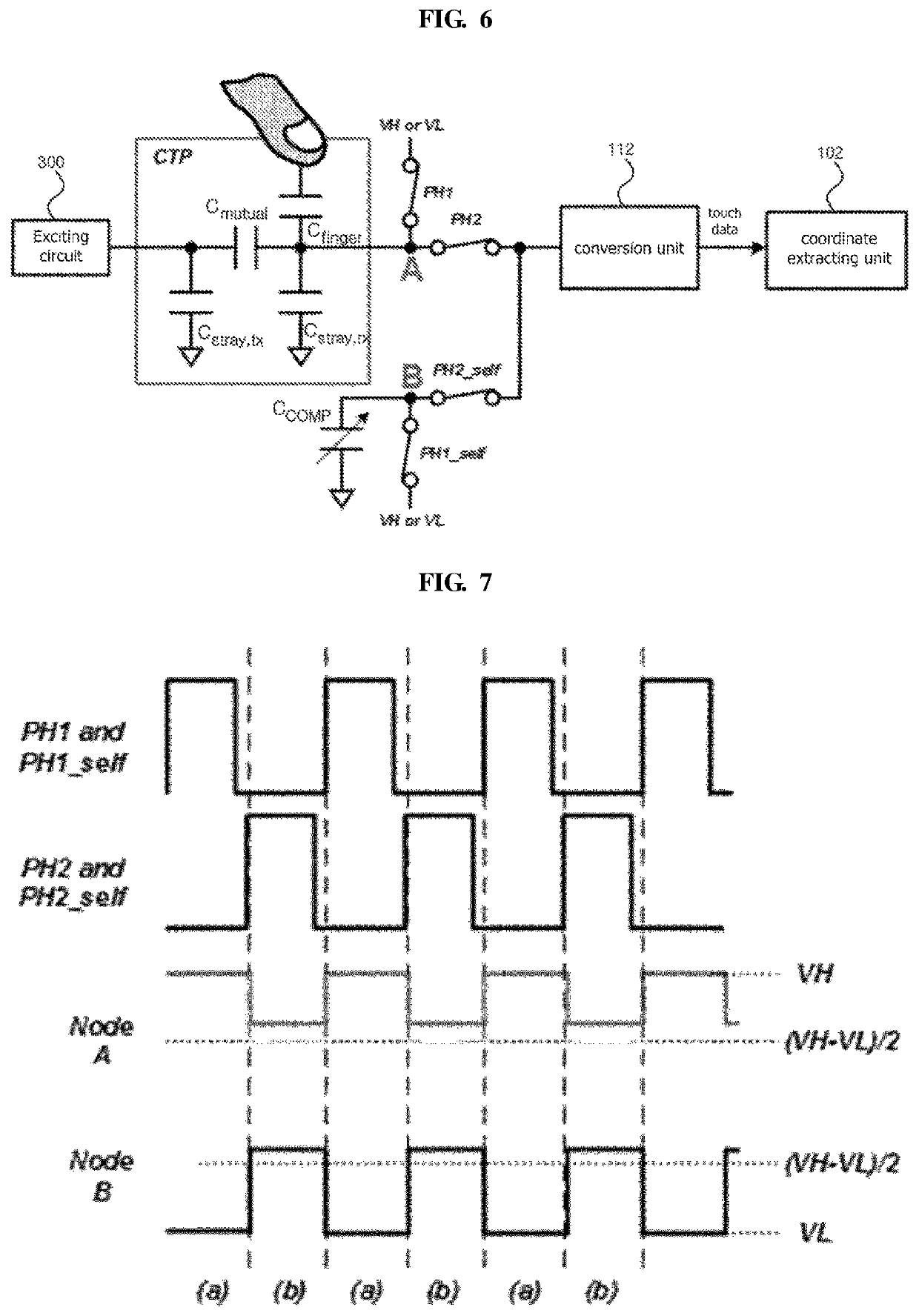

Driving circuit for a touch panel realizing modes using a sensing circuit and touch sensing method using the same

ActiveUS10627954B2Reduce complexitySmall sizeInput/output processes for data processingEngineeringComputer science

A driving circuit for a touch panel is disclosed. The driving circuit switches between a mutual capacitance sensing mode and a self capacitance sensing mode using the same sensing circuit. As such, the driving circuit for a touch panel implements a hybrid touch panel that is capable of sensing a touch in either a mutual capacitance sensing mode or a self capacitance sensing mode without requiring a complex and large driving circuit for separate sensing circuits for each mode.

Owner:IUCF HYU (IND UNIV COOP FOUND HANYANG UNIV)

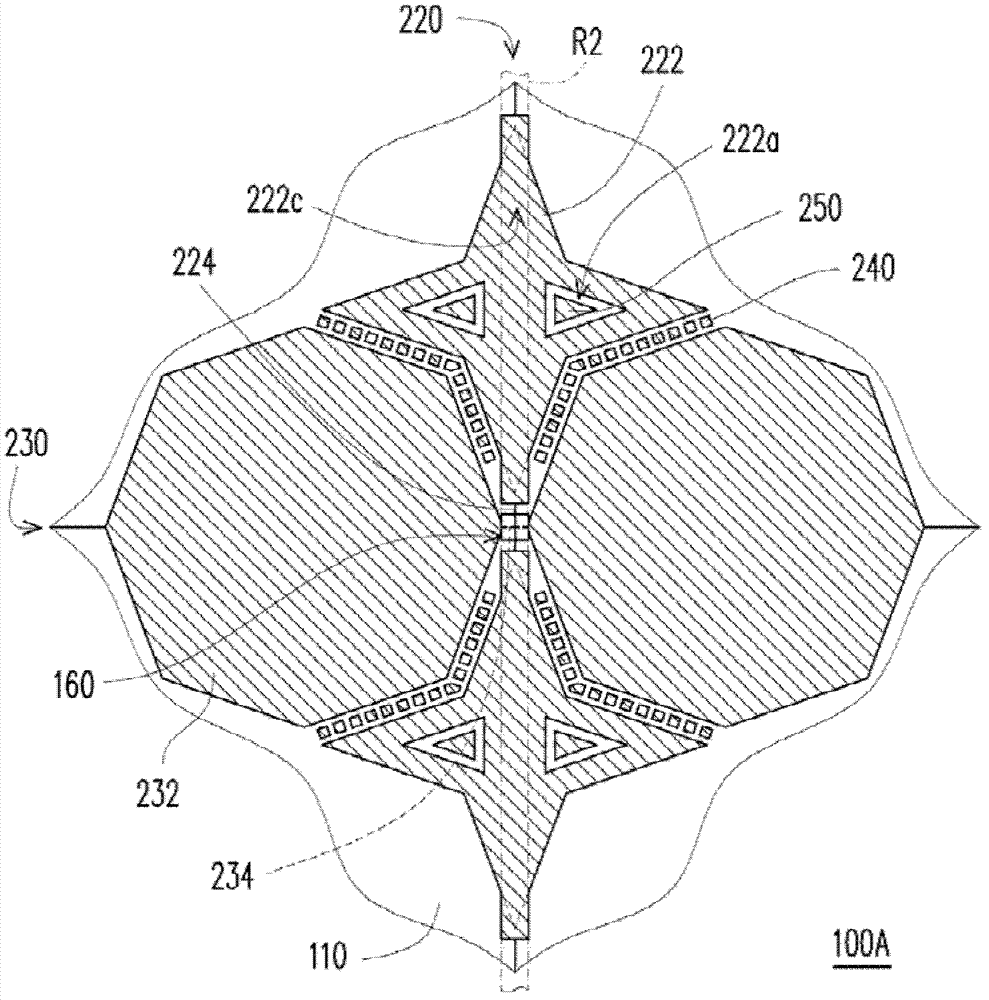

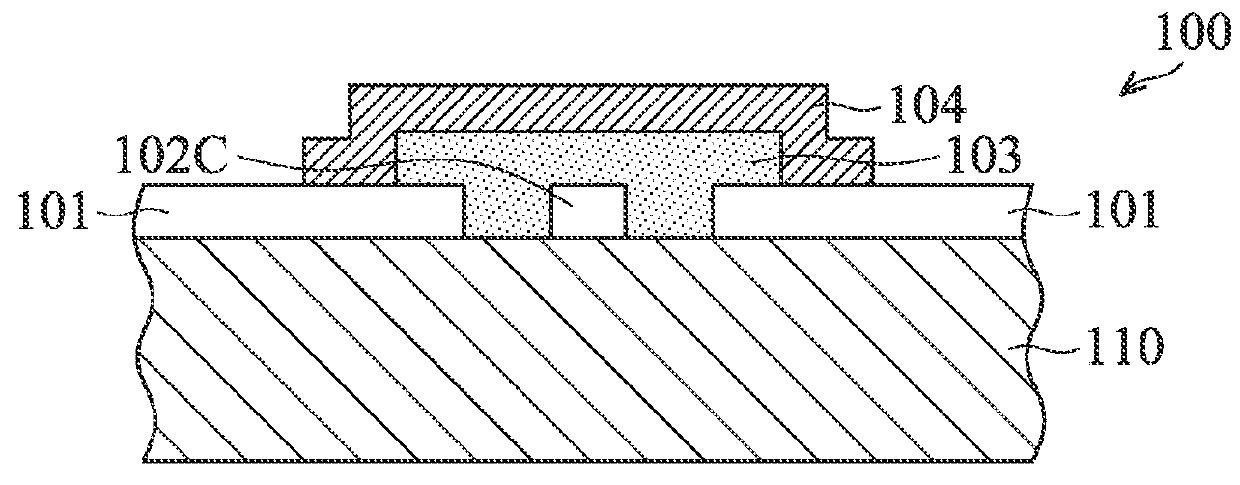

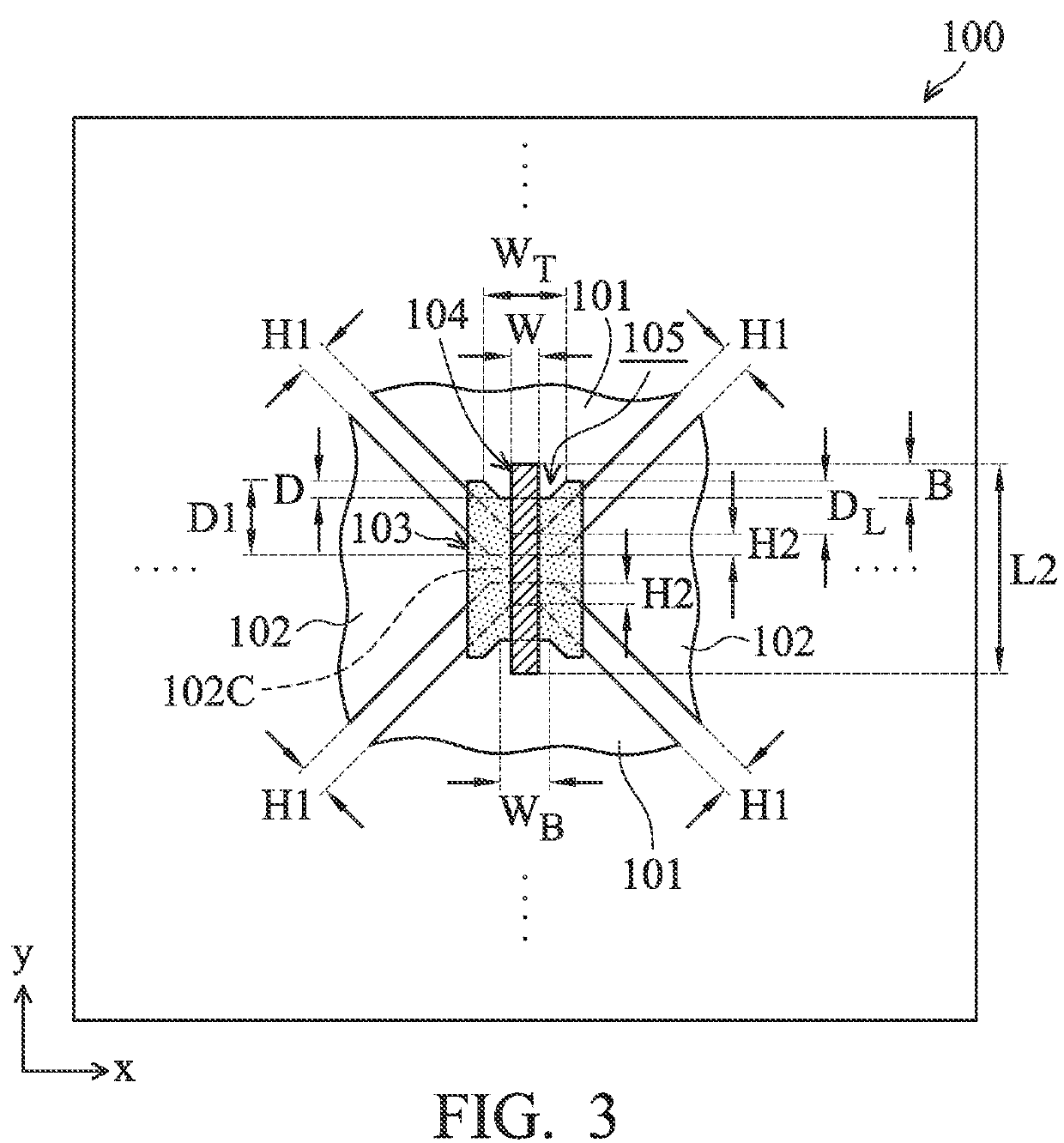

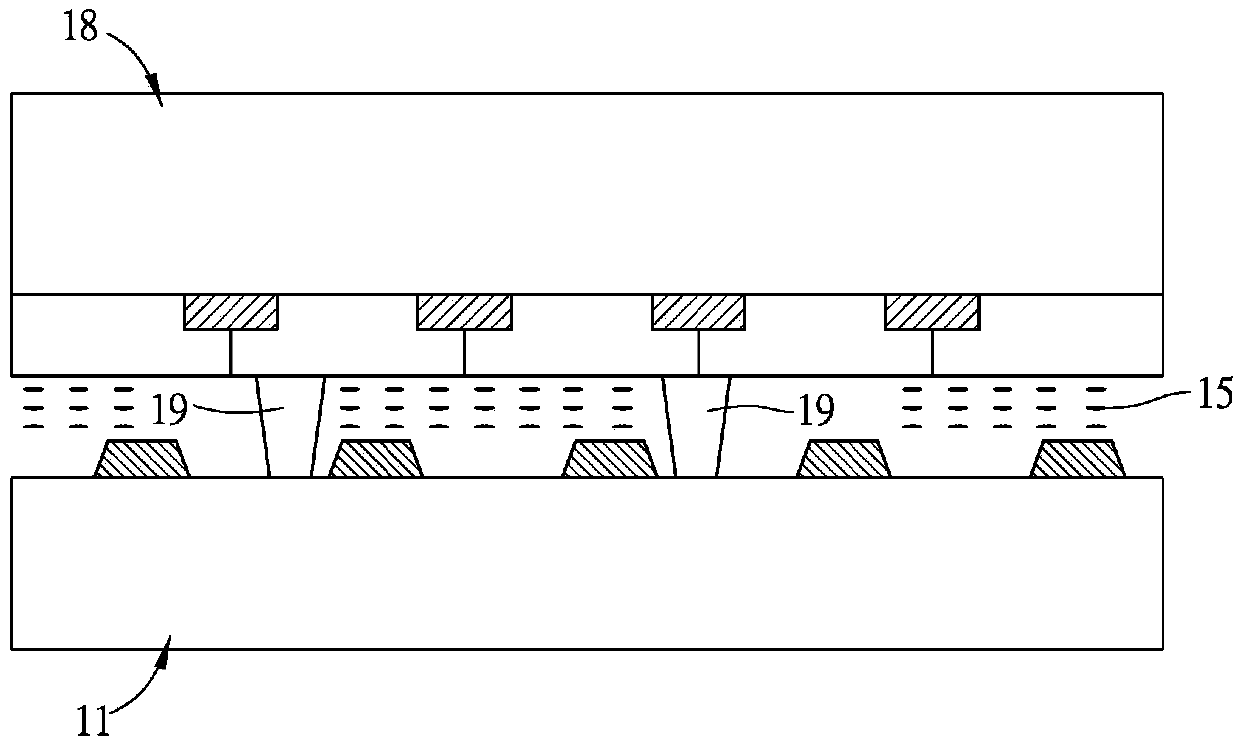

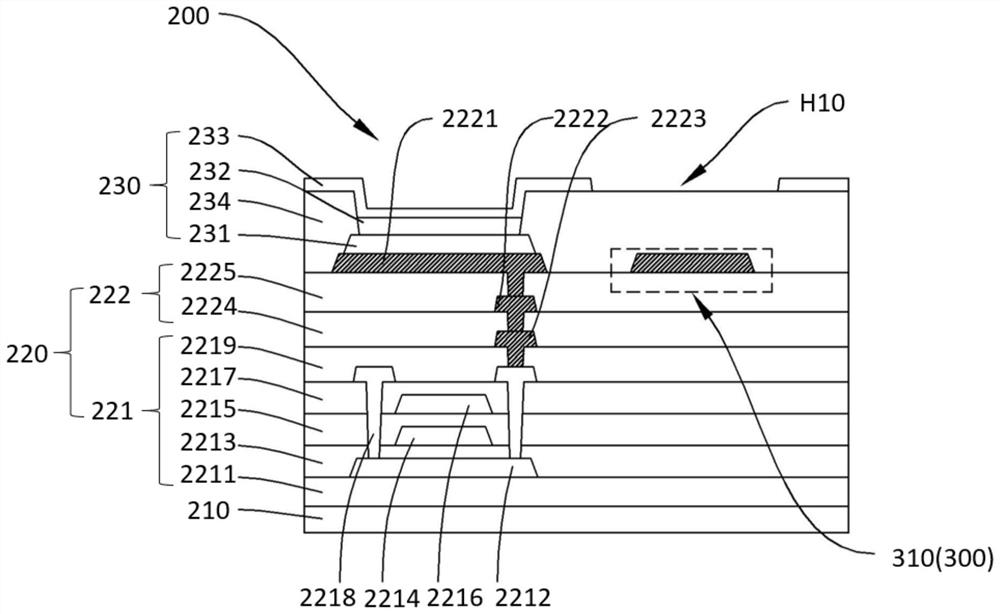

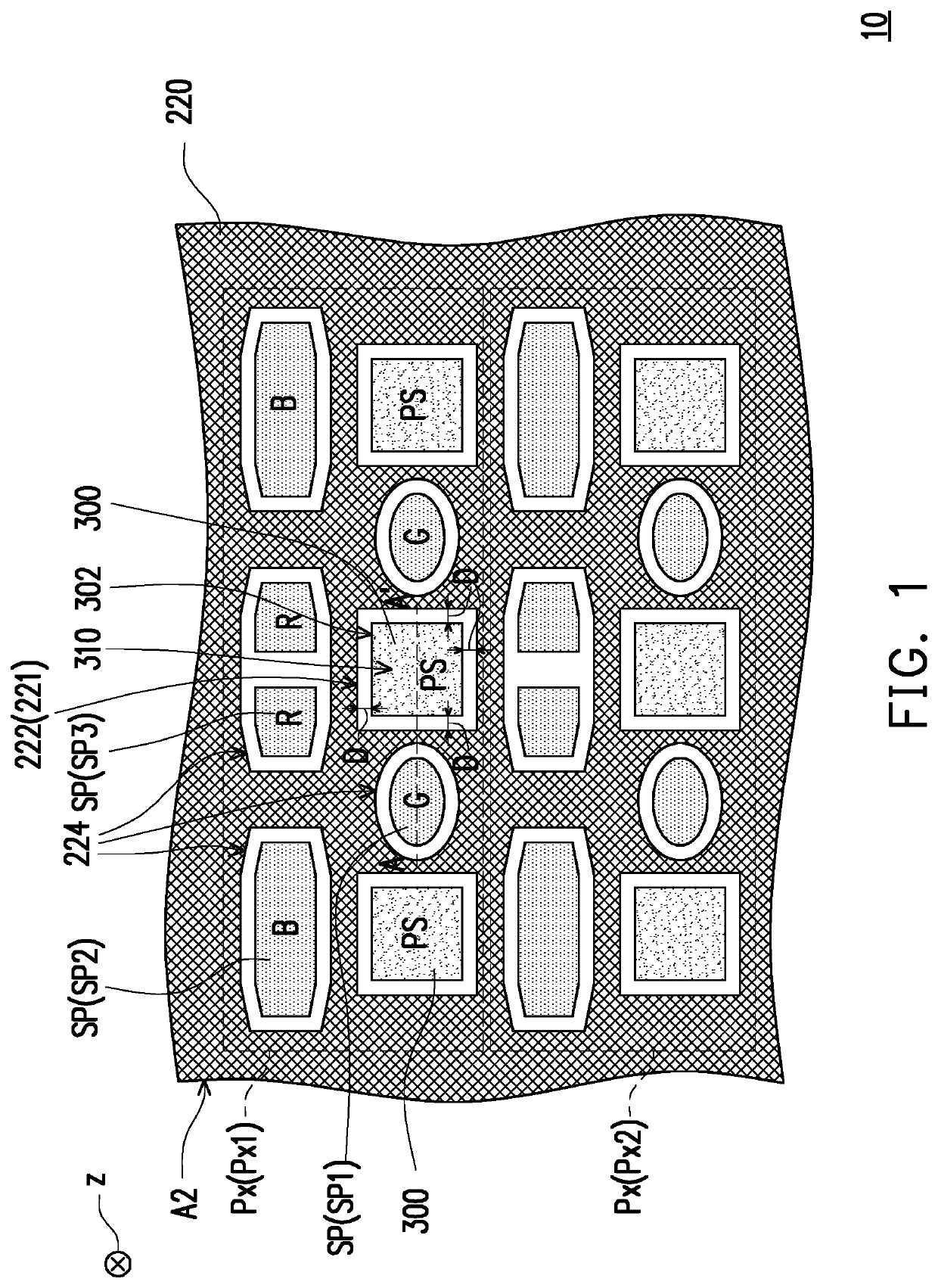

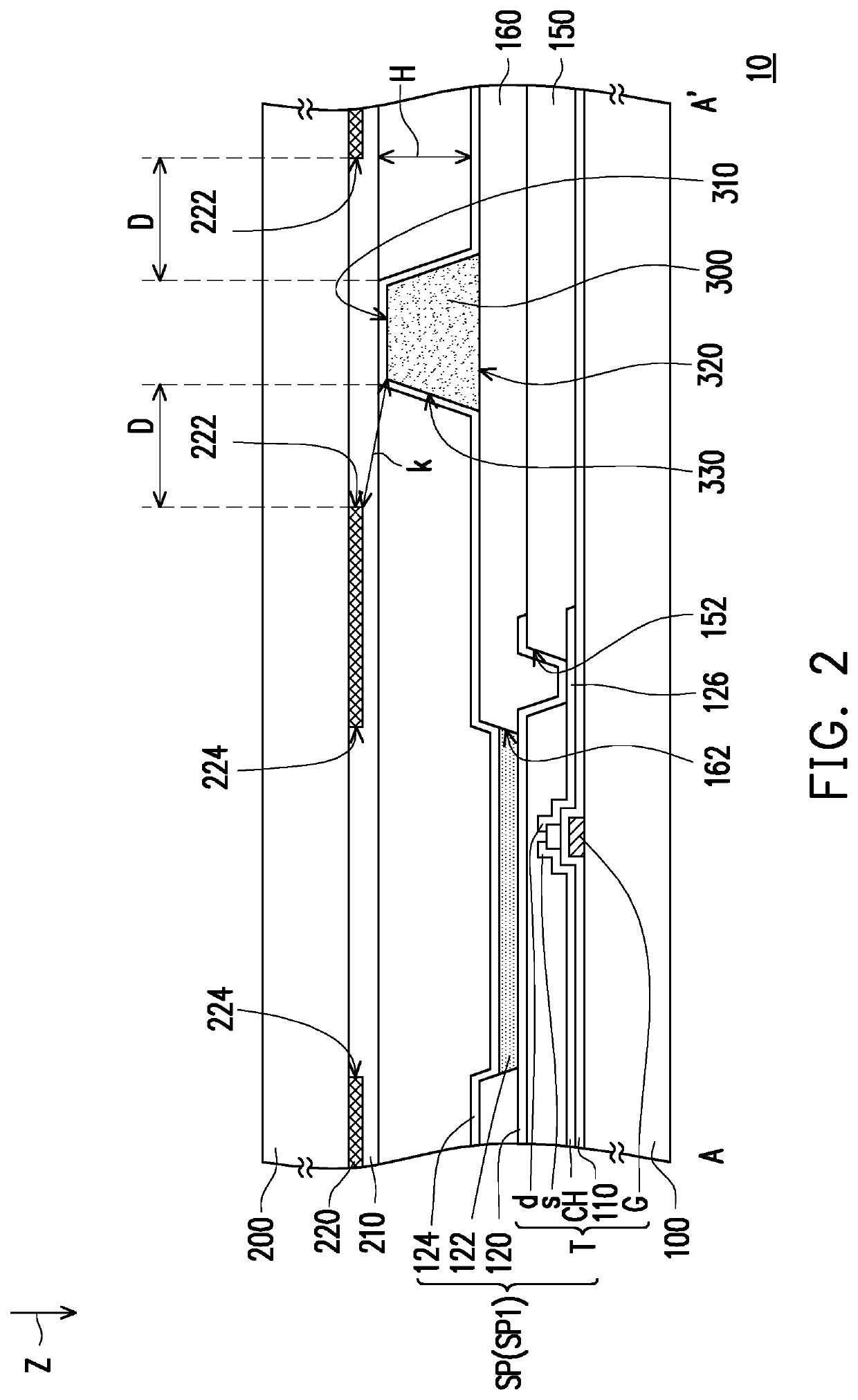

Touch display apparatus

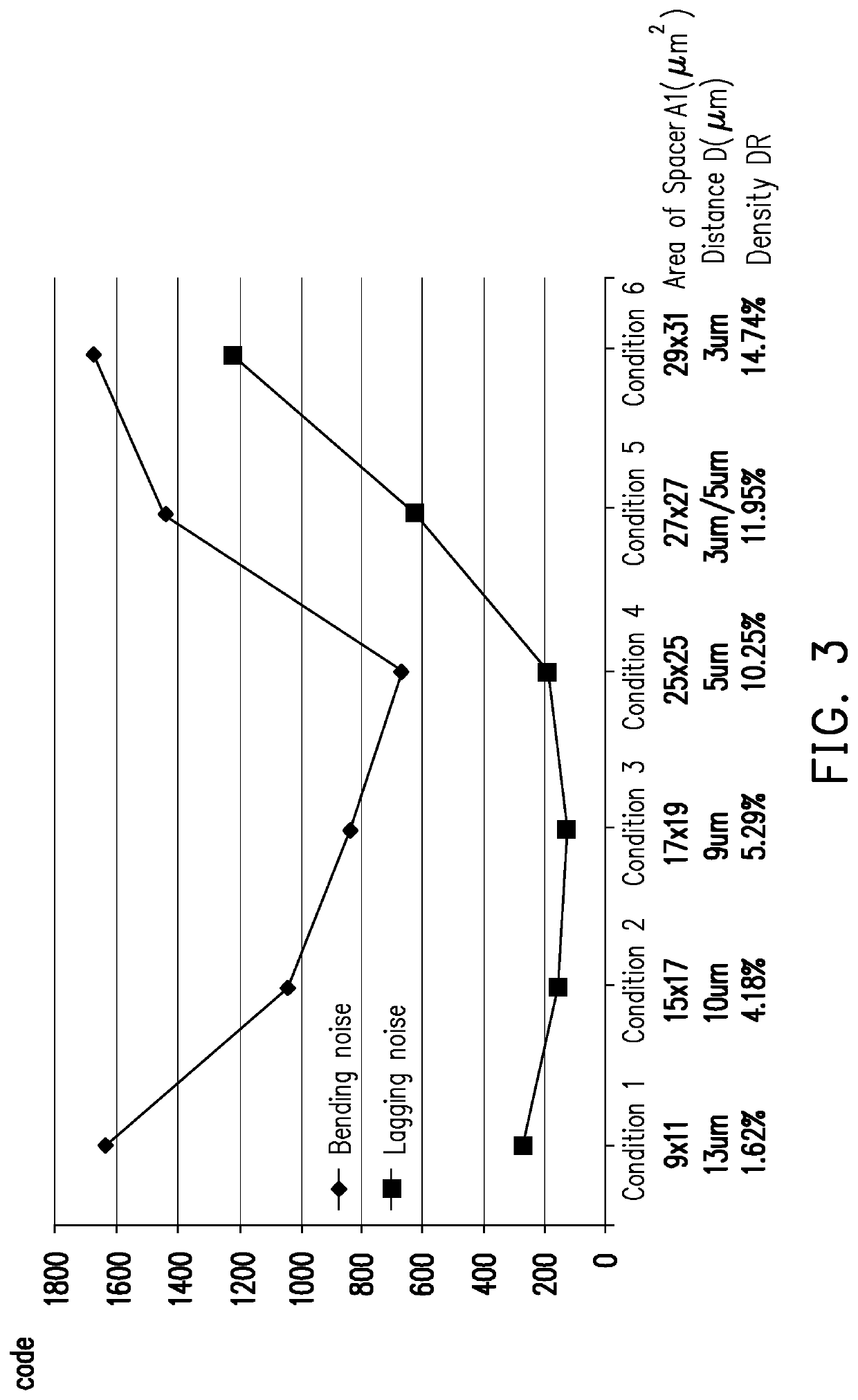

ActiveUS10509500B2Improve touch effectCapacitanceSolid-state devicesInput/output processes for data processingTouch SensesProjection direction

A touch display apparatus including a first substrate, a first sub-pixel, a spacer, a second substrate, and a touch-sensing electrode is provided. The first sub-pixel is disposed on the first substrate. The spacer is disposed on the first substrate. The touch-sensing electrode is disposed on the second substrate and has a first opening. The spacer is located inside the first opening in an orthogonal projection direction. A distance D is defined between an outline of an orthogonal projection of the spacer on the first substrate and an outline of an orthogonal projection of the first opening on the first substrate, and D≥5 μm.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com