Patents

Literature

43results about How to "Eliminate Streaks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

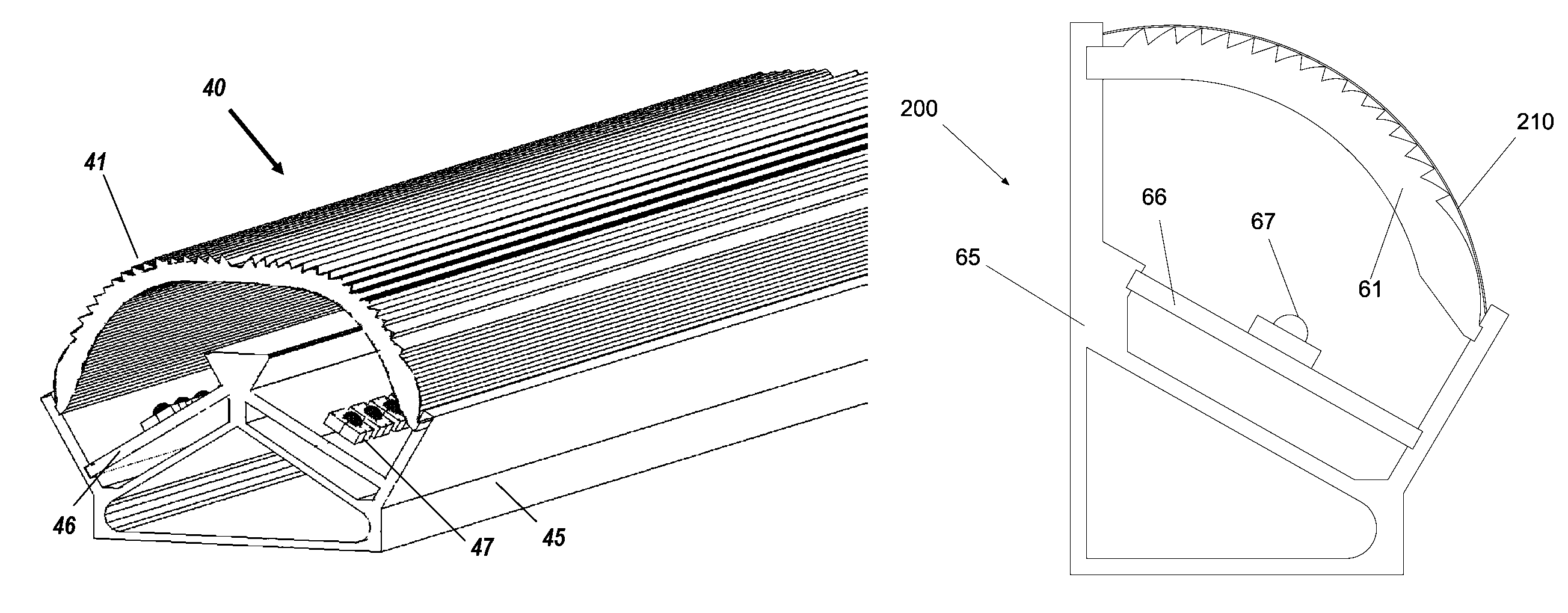

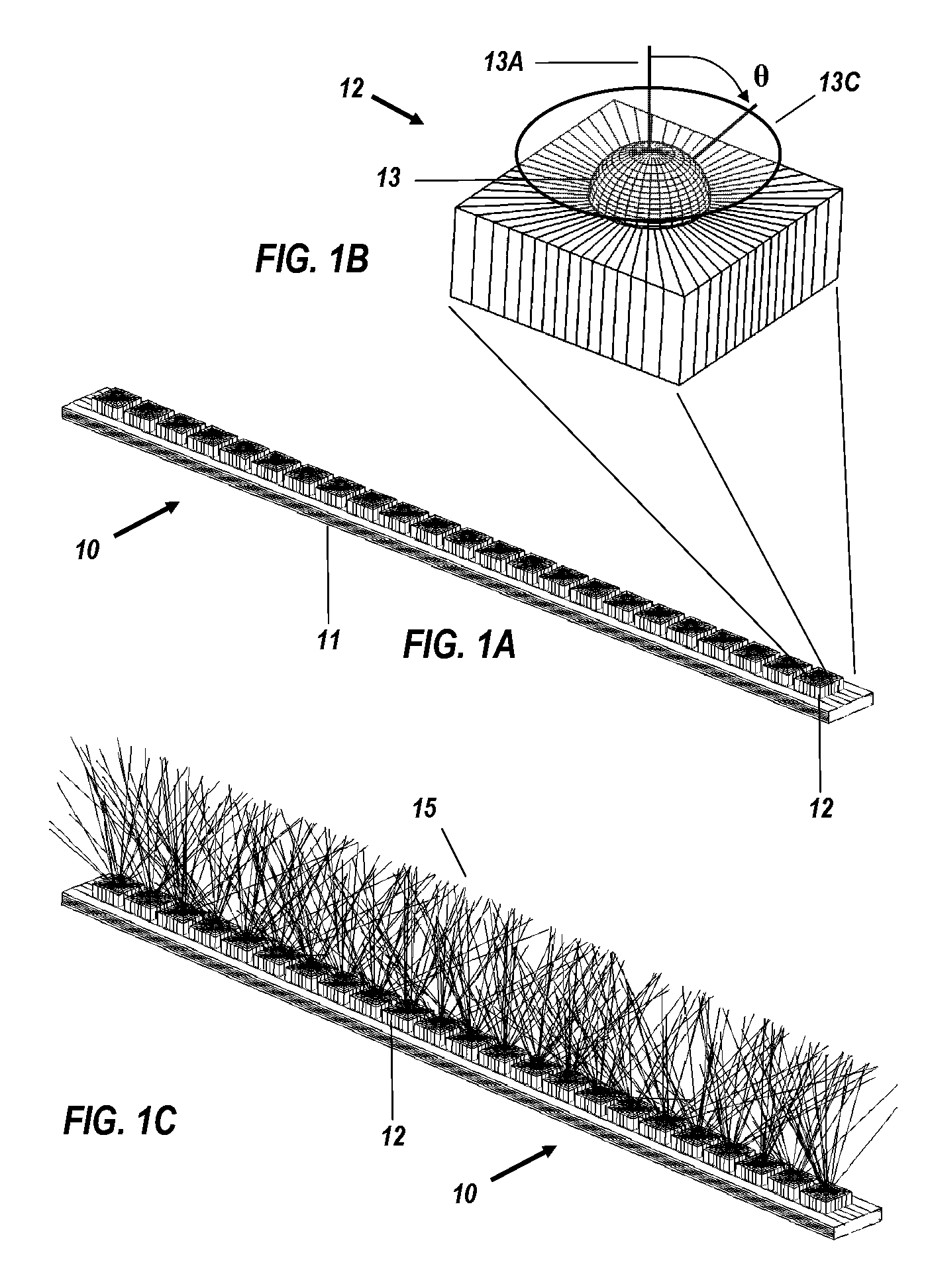

Linear illumination lens with Fresnel facets

ActiveUS7559672B1Large amount of processingImprove efficacyMechanical apparatusFurnace componentsCamera lensFresnel lens

A linear Fresnel lens for LED illumination is configured initially by using a meridional flux-assignment method and is then corrected by assessing the three-dimensional flux distribution of individual facets. The facet angles are slightly altered as required to produce uniformity. A variety of specialized lens shapes are generated, such as for illuminating shelves in commercial refrigerator food-display cases. The lens shapes are suitably thin for economical production by extrusion.

Owner:SEOUL SEMICONDUCTOR

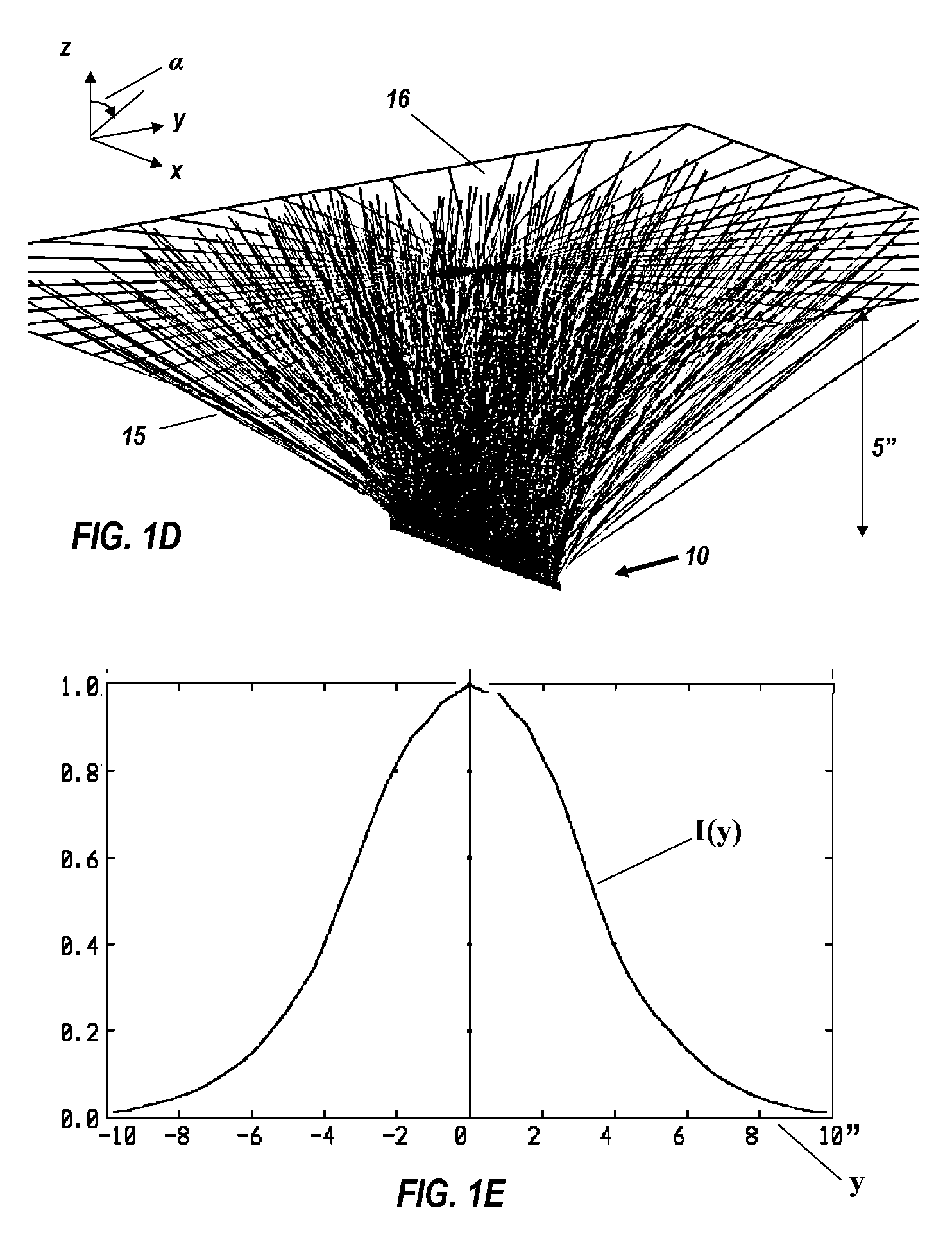

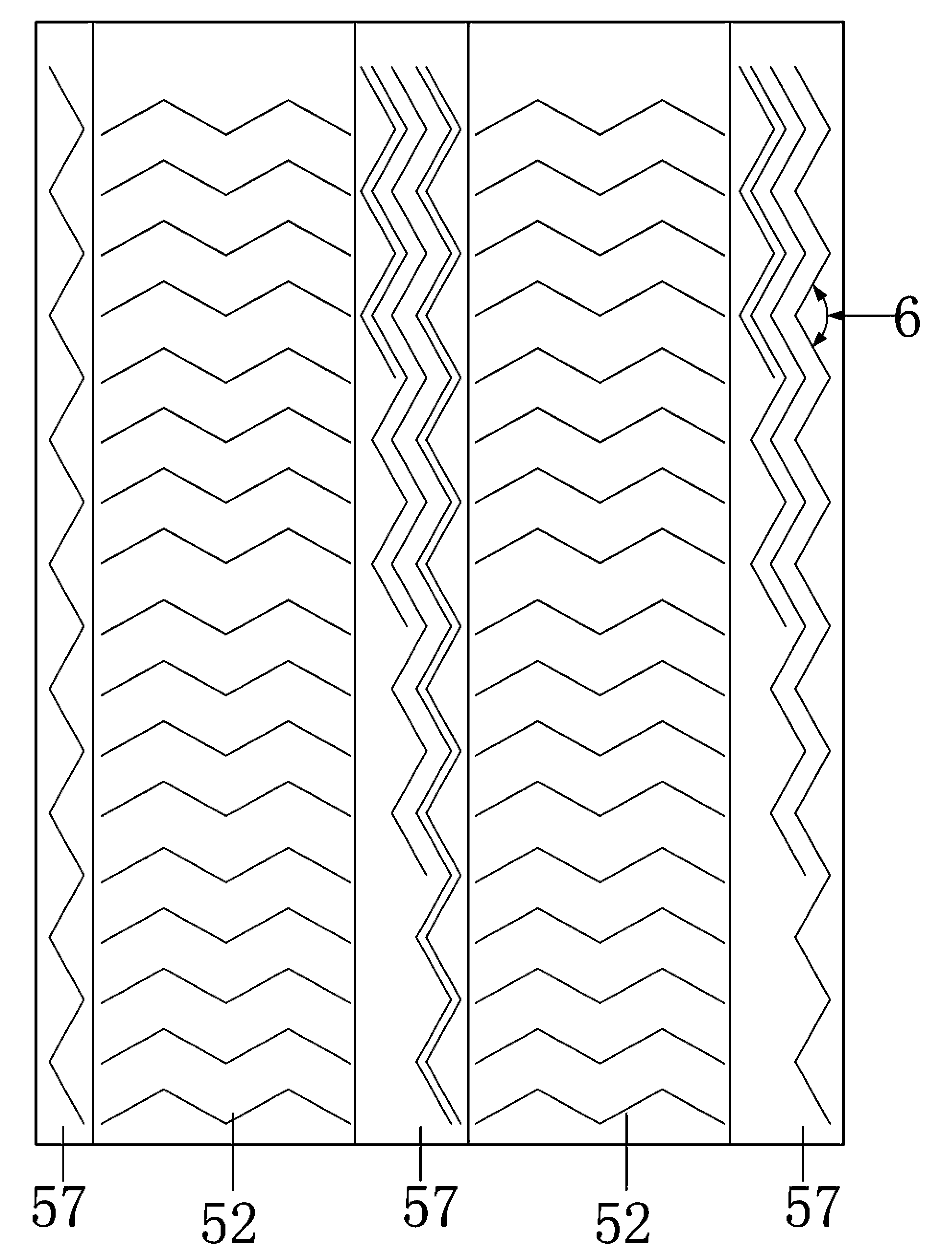

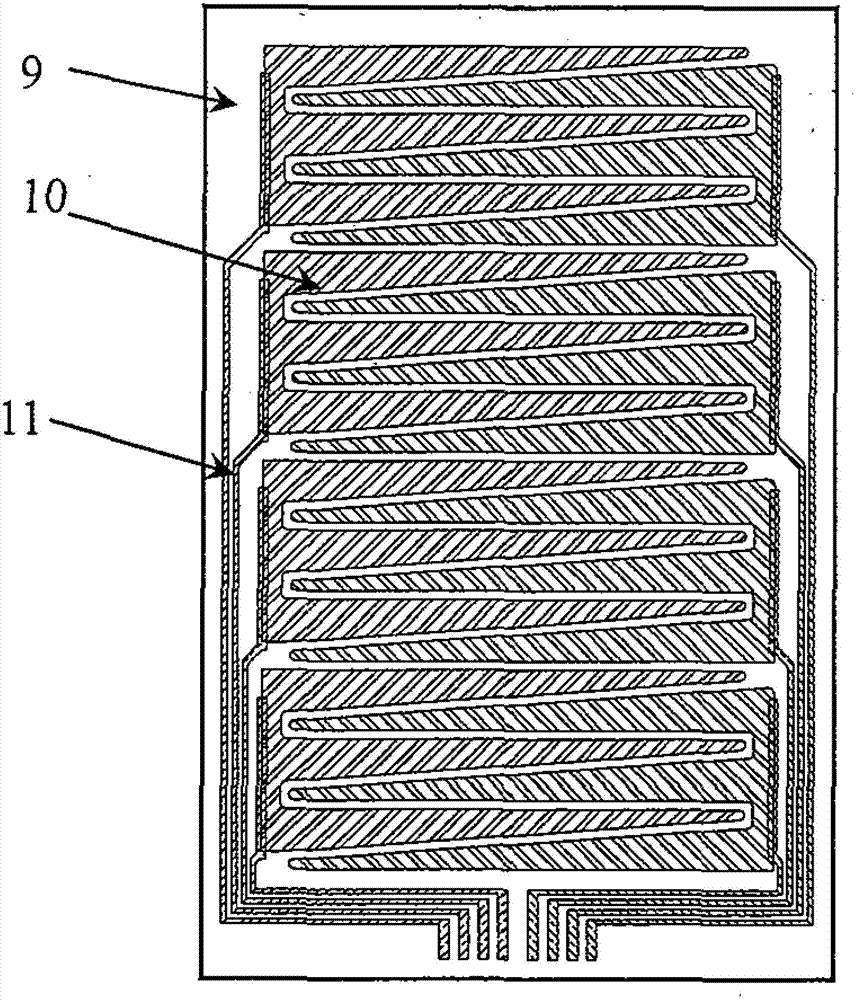

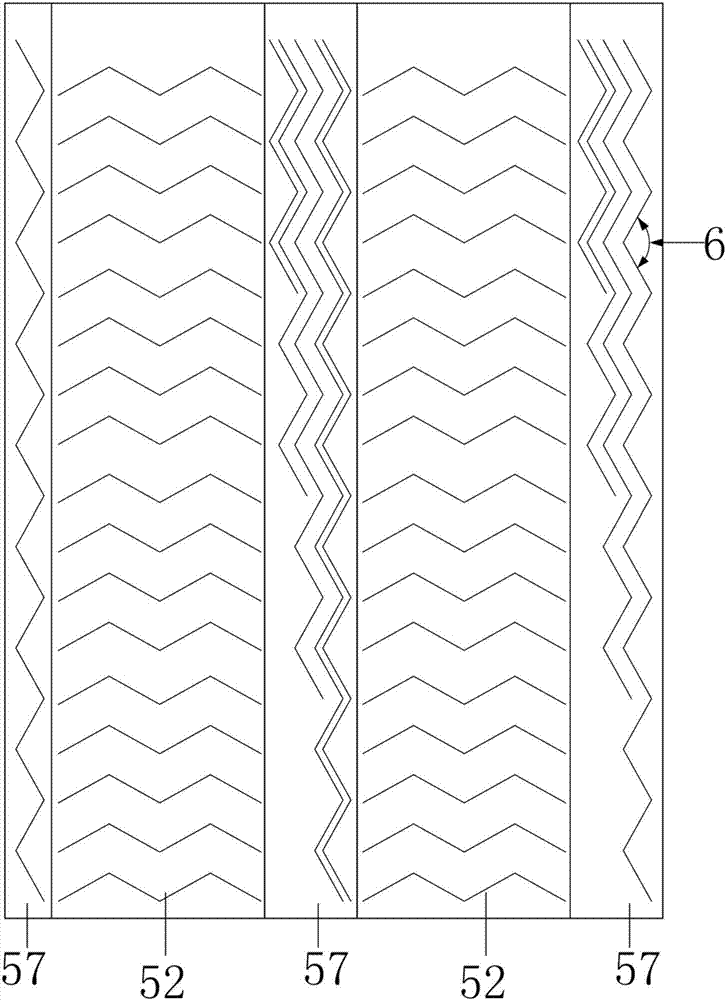

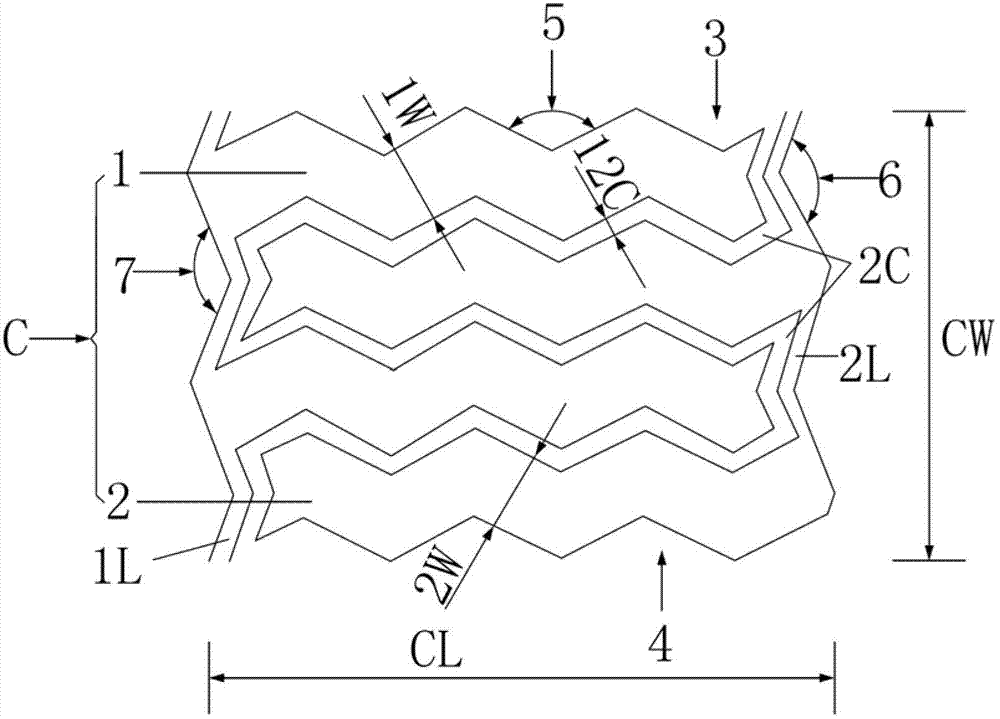

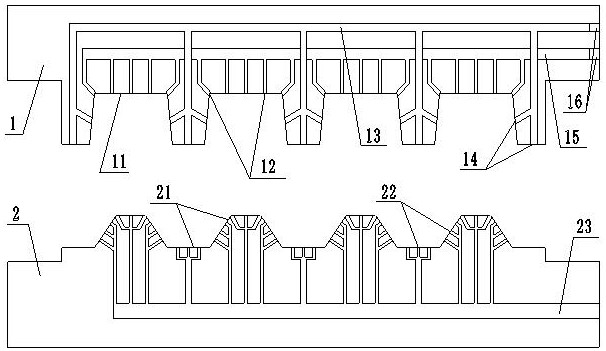

Capacitive touch screen and single-layer wiring electrode array

ActiveCN103576998AImprove the display effectEliminate StreaksDigital data processing detailsInput/output processes for data processingCapacitanceEngineering

A capacitive touch screen and a single layer wiring electrode array. The single layer wiring electrode array includes a capacitive region and a wiring region located on one plane; the wires of the wiring region are in a zigzag or a wave pattern. A capacitive touch screen comprising a single layer wiring electrode array, the capacitive touch screen including a substrate; a single layer-wiring electrode array, disposed on the substrate, the single layer wiring electrode array includes a capacitive region and a wiring region located on one plane, the wires of the wiring region are in a zigzag or a wave pattern; the wires of the wiring region connected to control ports corresponding to at least one or more integrated circuit chips respectively. The single layer wiring electrode array and capacitive touch screen makes the fabrication cost lower, the display effect better.

Owner:SILEAD

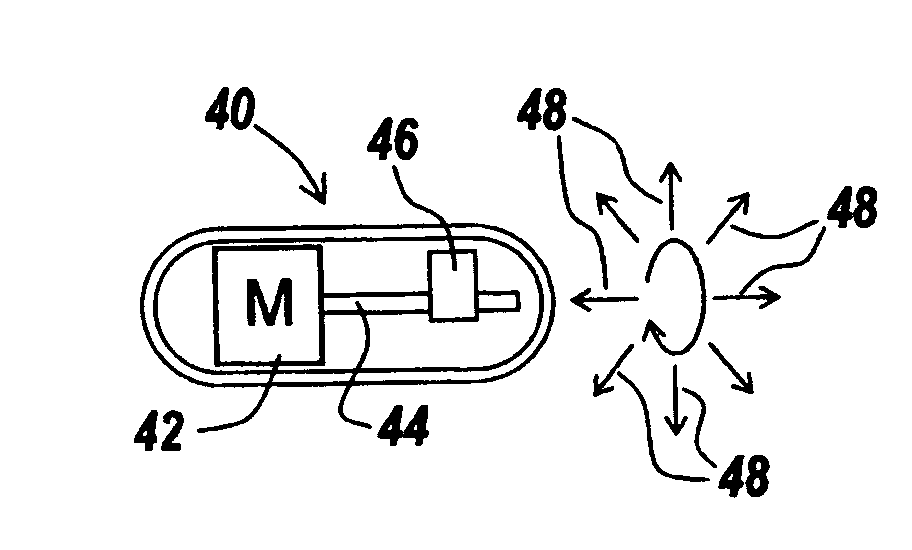

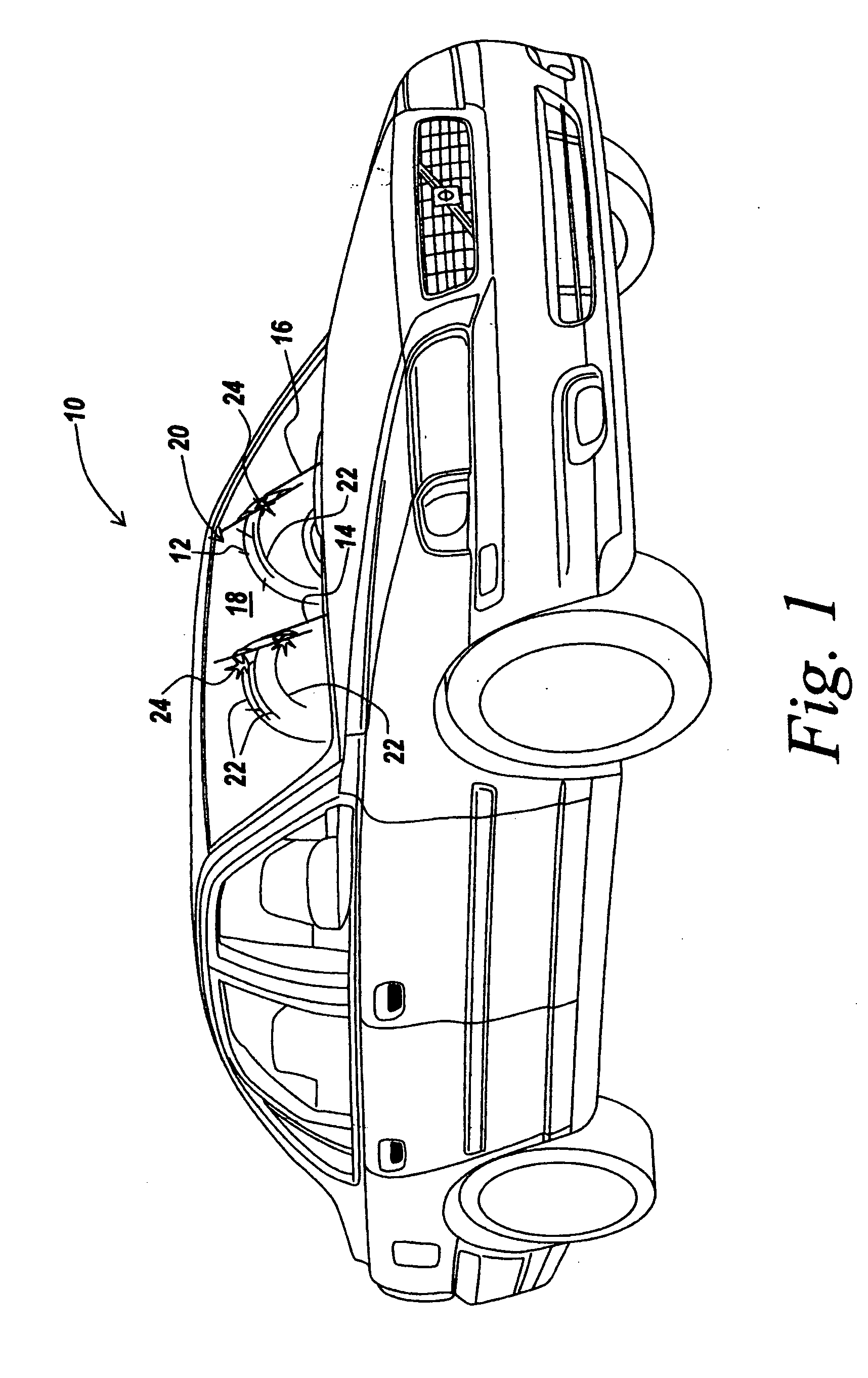

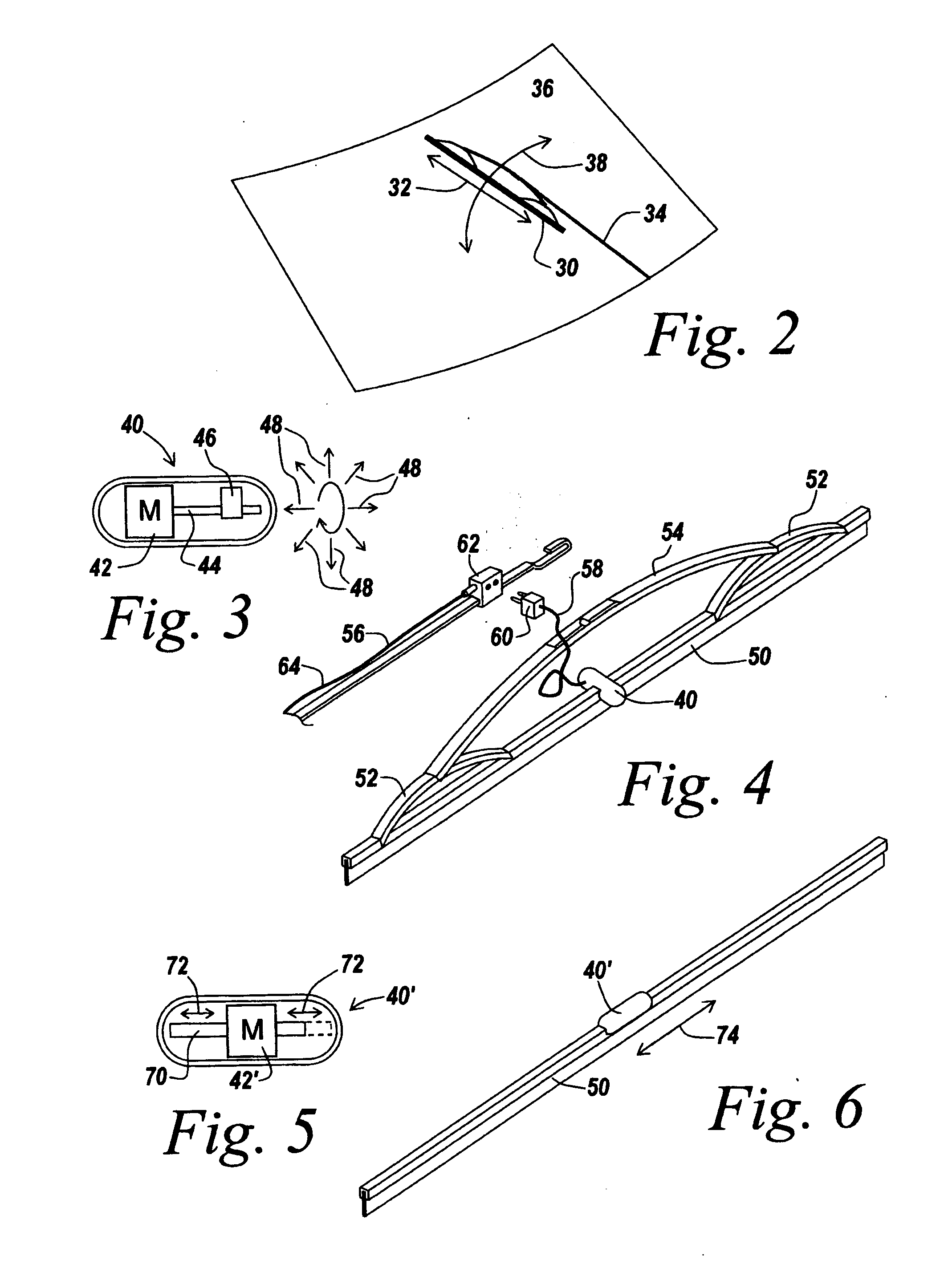

Method and apparatus for improving windshield wiper performance using a vibrating windshield wiper blade

InactiveUS20070022558A1Improve abilitiesAvoid excessive wearWindow cleanersVehicle cleaningVisibilityEngineering

A method is provided for improving the wiping capabilities of a windshield wiper by causing the windshield wiper blade to vibrate or oscillate in a direction parallel to the longitudinal centerline of the blade during a windshield wiper sweep. The vibrating mode causes less wear on the blade due to windshield abrasion since the blade edge does not contact the same eroded point on the windshield all the time. Secondly, any debris that is caught underneath the blade is quickly ejected due to the vibrating action. In one embodiment, an electromechanical vibrating unit is secured at one or more positions to the blade, with the actuator being driven by a 12-volt source and provided with a quickie disconnect at the center of the blade support structure. The vibrating actuator may be an electromechanically drive off-centered weight, a vibrating linear actuator, an ultrasonic vibrator, or a vibrator in the form of a piezoelectric crystal, with the primary mode of oscillation translating the blade along its centerline. The result is that debris underneath the blade is thrown out, including leaf stems, leaves and particulate matter, with the periodic translation of the blade providing more uniform water removal during the wiping operation to provide clearer visibility through the windshield regardless of the amount of water on the windshield, whether it be from a sporadic sprinkle or a torrential downpour. Wiper life is extended since the blade edge's position on the windshield is constantly varied during wiper sweeps.

Owner:ACOM INT

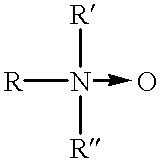

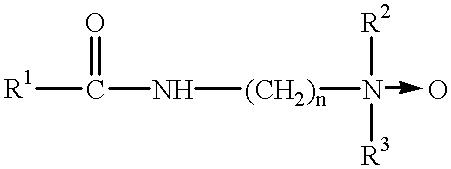

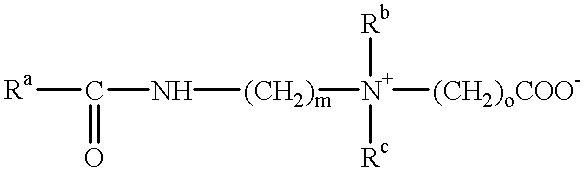

Reduced residue hard surface cleaner

InactiveUS6432897B1Film is removedEliminate StreaksNon-ionic surface-active compoundsAnionic surface-active compoundsHard-surface cleanerOrganic solvent

The invention provides an aqueous, hard surface cleaner with significantly improved residue removal and substantially reduced filming / streaking, and the cleaner comprises:(a) an effective amount of at least one organic solvent with a vapor pressure of at least 0.001 mm Hg at 25° C., and mixtures of such solvents;(b) an effective amount of either at least one anionic surfactant, or a mixture of anionic and nonionic surfactants;(c) an effective amount of a buffering system which comprises a nitrogenous buffer which will result in a pH of greater than 6.5; and(d) the remainder as substantially all water.

Owner:THE CLOROX CO

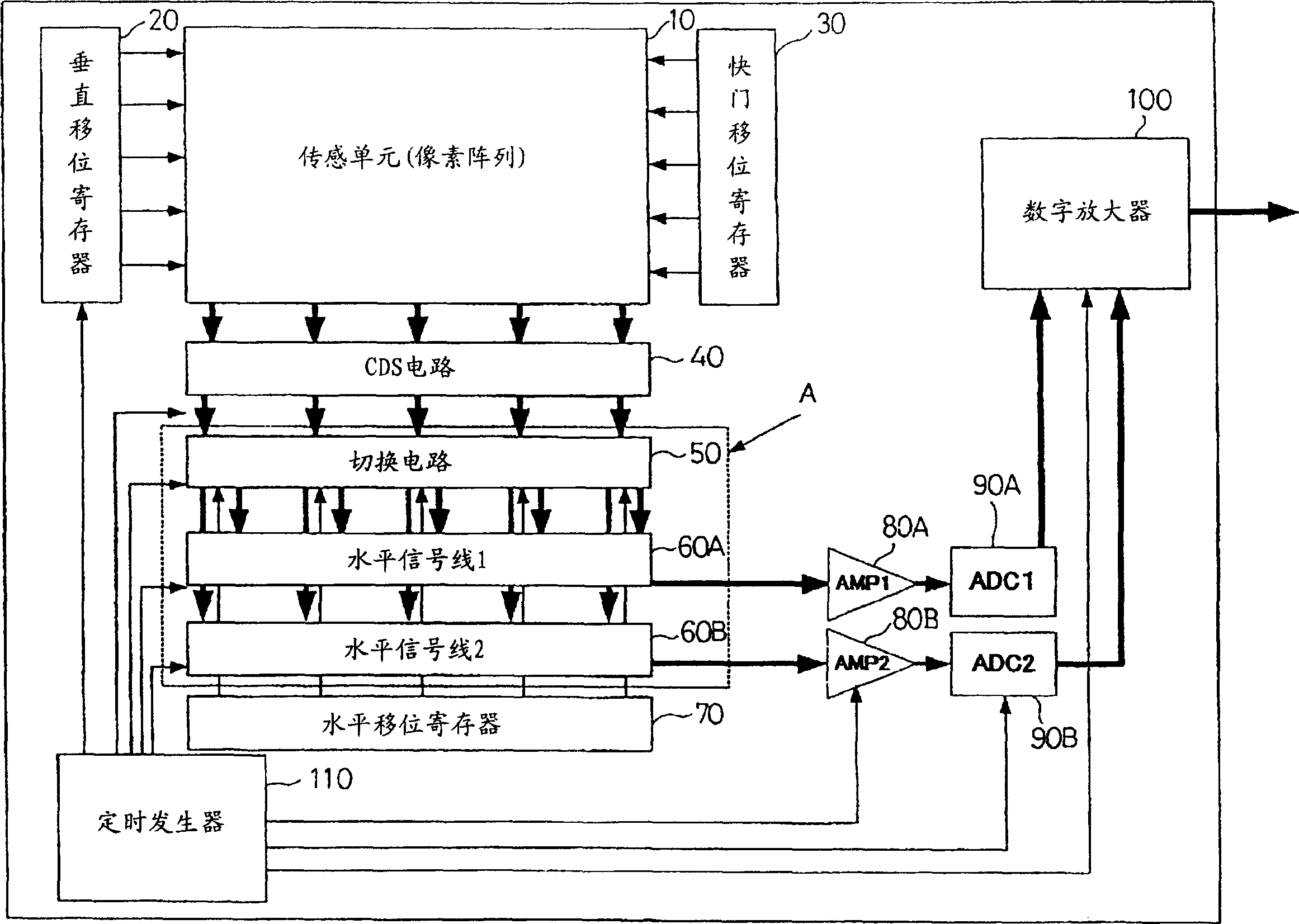

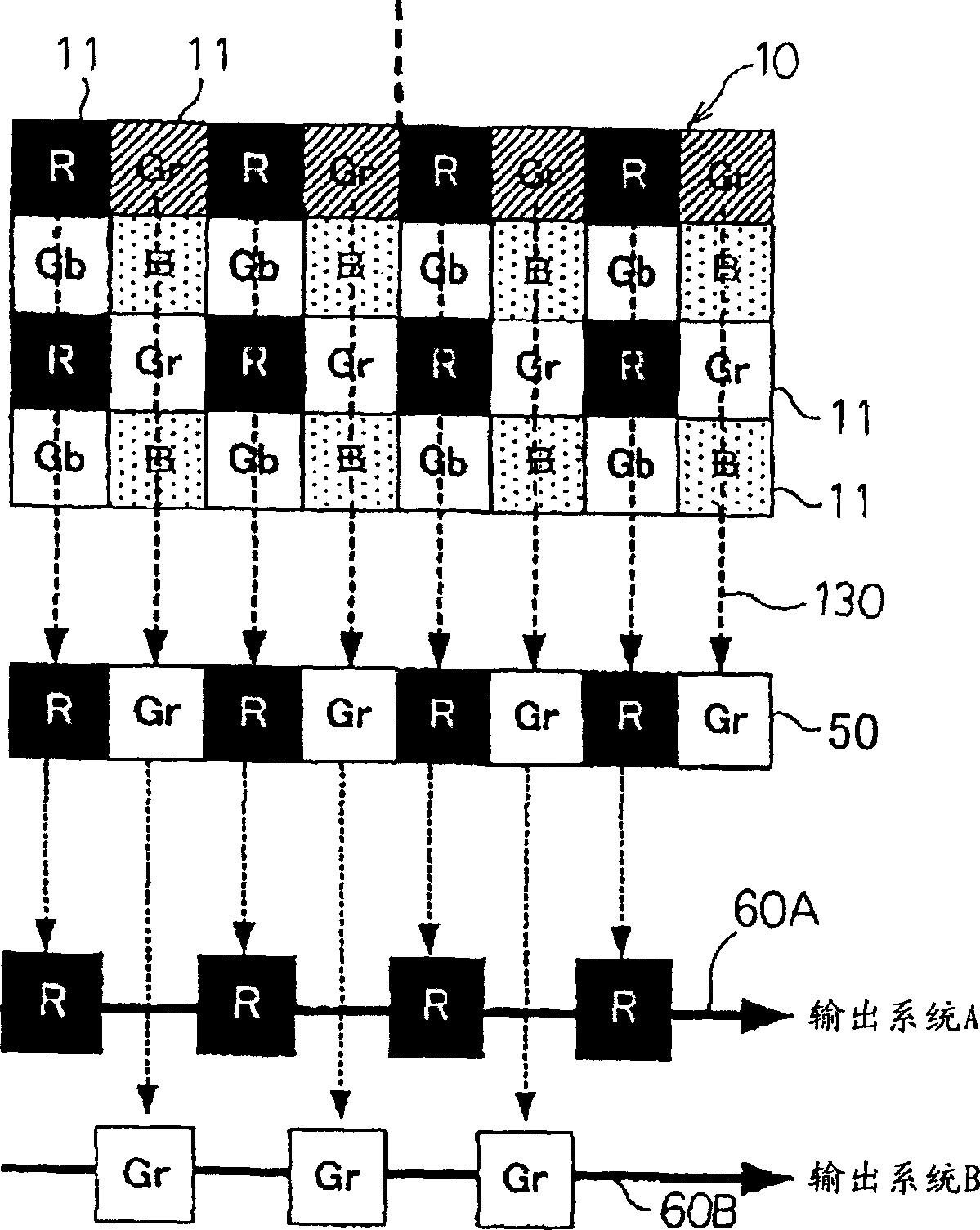

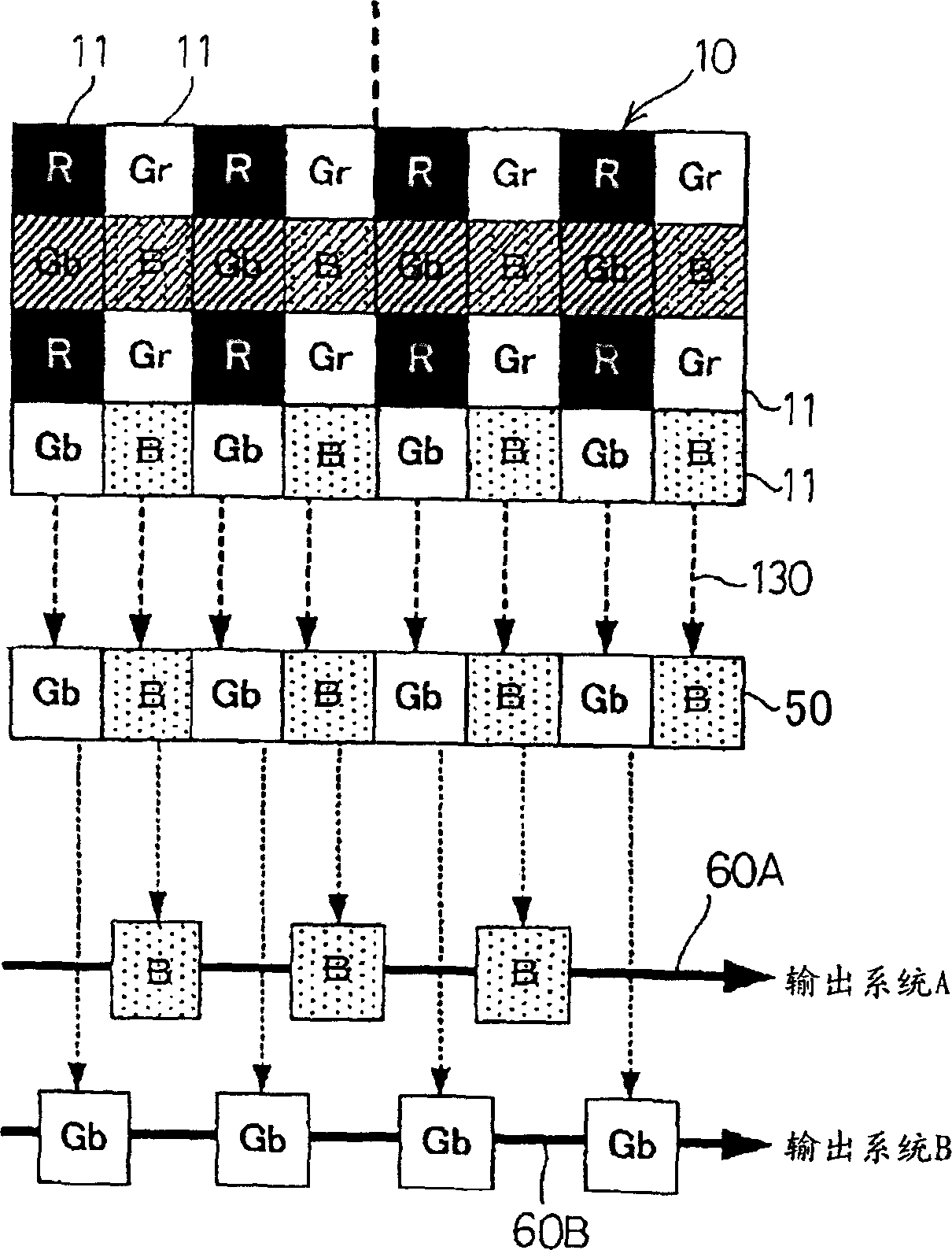

Solid-state imaging apparatus and its signal reading method

InactiveCN1717940AEliminate chromatic aberrationEliminate StreaksTelevision system detailsSignal generator with single pick-up deviceComputer scienceImage signal

In an arrangement where a plurality of horizontal signal lines are used to distribute pixel signals so as to realize a high speed operation, color differences and moire occurring in image signals are eliminated. It is shown that the pixel signals of a 2n-th row are being read out, and R pixels of the odd-numbered columns are outputted from a horizontal signal line (60A) to an output system (A). Meanwhile, Gr pixels of the even-numbered columns are outputted from a horizontal signal line (60B) to an output system (B). It is also shown that pixel signals of a 2n+1-th row are being read out, and Gb pixels of the odd-numbered columns are outputted from the horizontal signal line (60B) to the output system (B) via a switching operation of a switch circuit part (50). Similarly, the B pixels of the even-numbered columns are outputted from the horizontal signal line (60A) to the output system (A) via a switching operation of the switch circuit part (50).

Owner:SONY SEMICON SOLUTIONS CORP

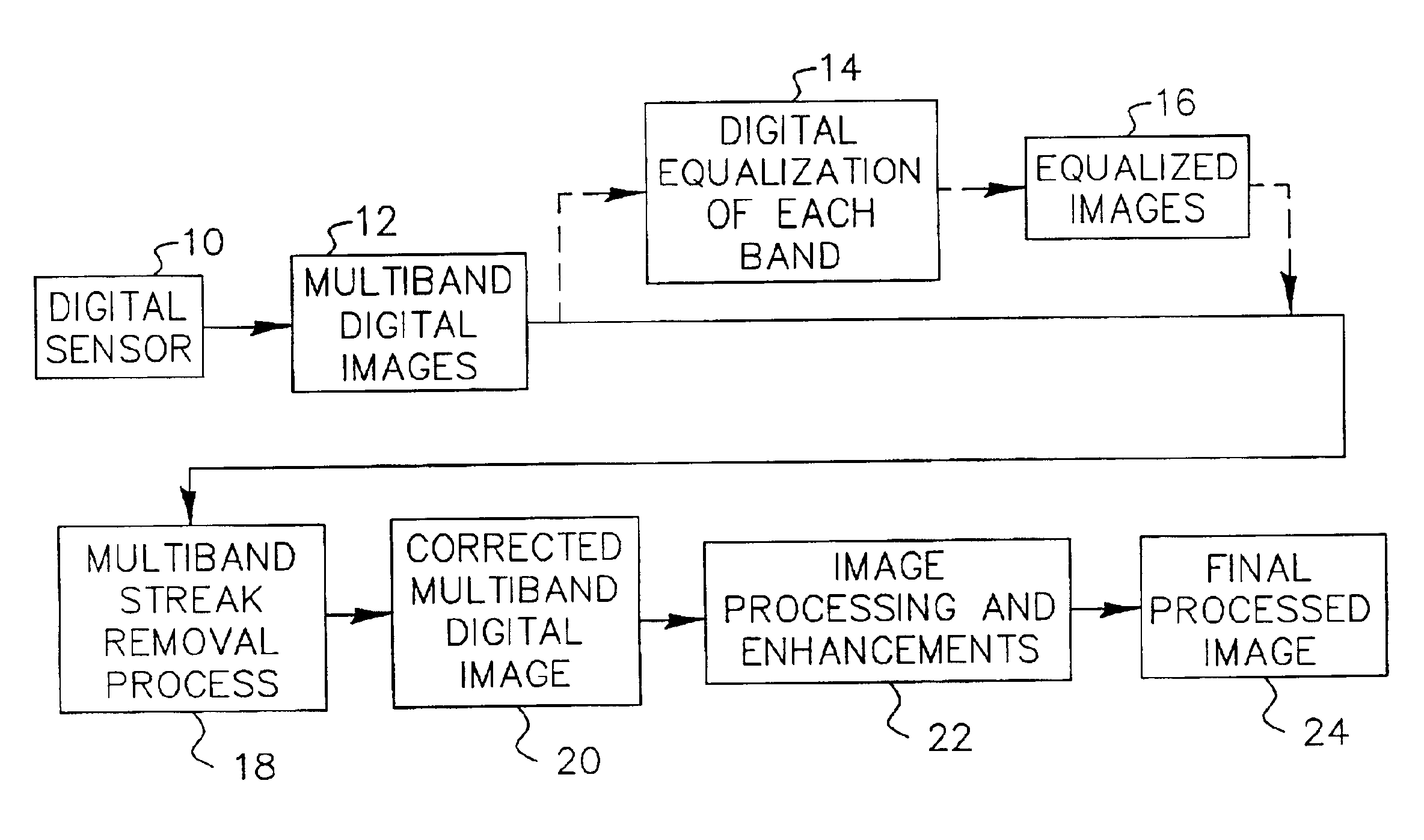

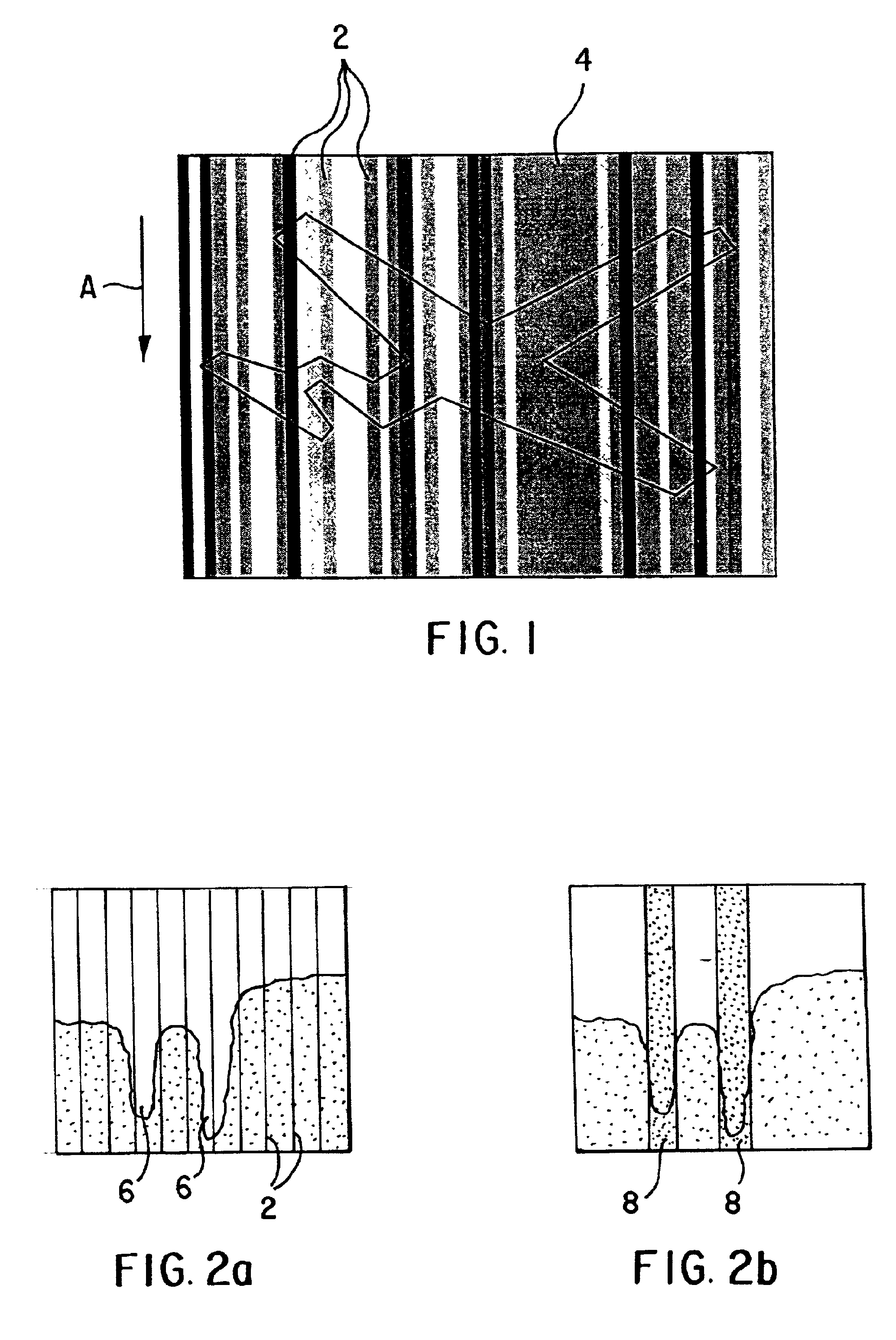

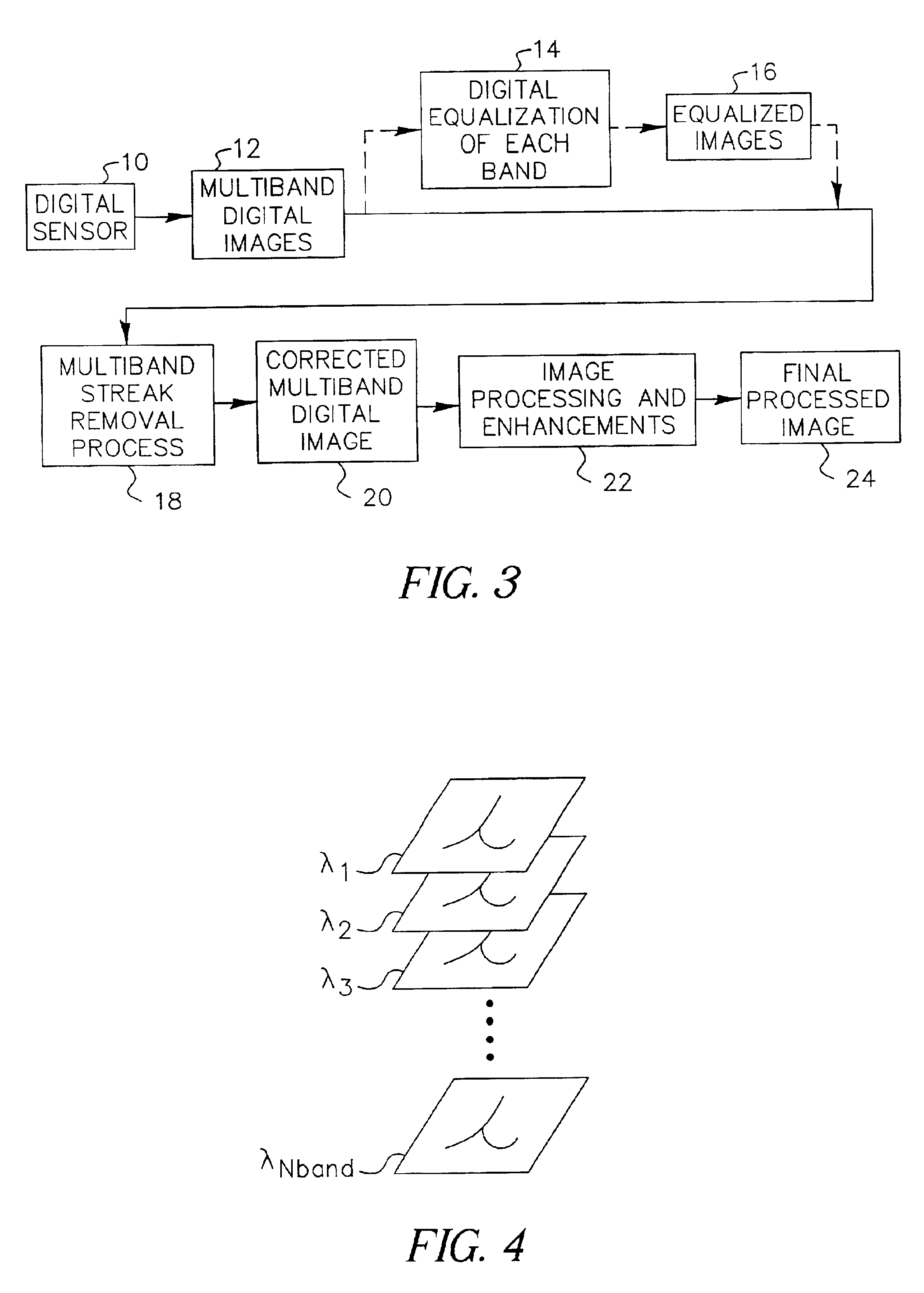

Adaptive process for removing streaks in multi-band digital images

InactiveUS6912322B2Favorable for determinationEliminate StreaksImage enhancementTelevision system detailsMulti bandDigital image

A method of removing streaks from multi-band digital images is presented in which a multi-band image is transformed to an advantageous spectral space, in which a streak removal operation is applied to the image in the advantageous spectral space. The streak removal operation is a method of removing columnar streaks from a multi-band digital image of the type in which it is assumed that pixels in a predetermined spatial and spectral region near a given pixel are strongly related to each other and employing gain and offset values to compute streak removal information, a test is performed for a strong relation between the pixels in a predetermined region spatially and spectrally near a given pixel and streak removal information is computed only if such a strong relationship exists, whereby image content that does not extend the full length of the image in the column direction will not be interpreted as a streak.

Owner:EXCELIS INC

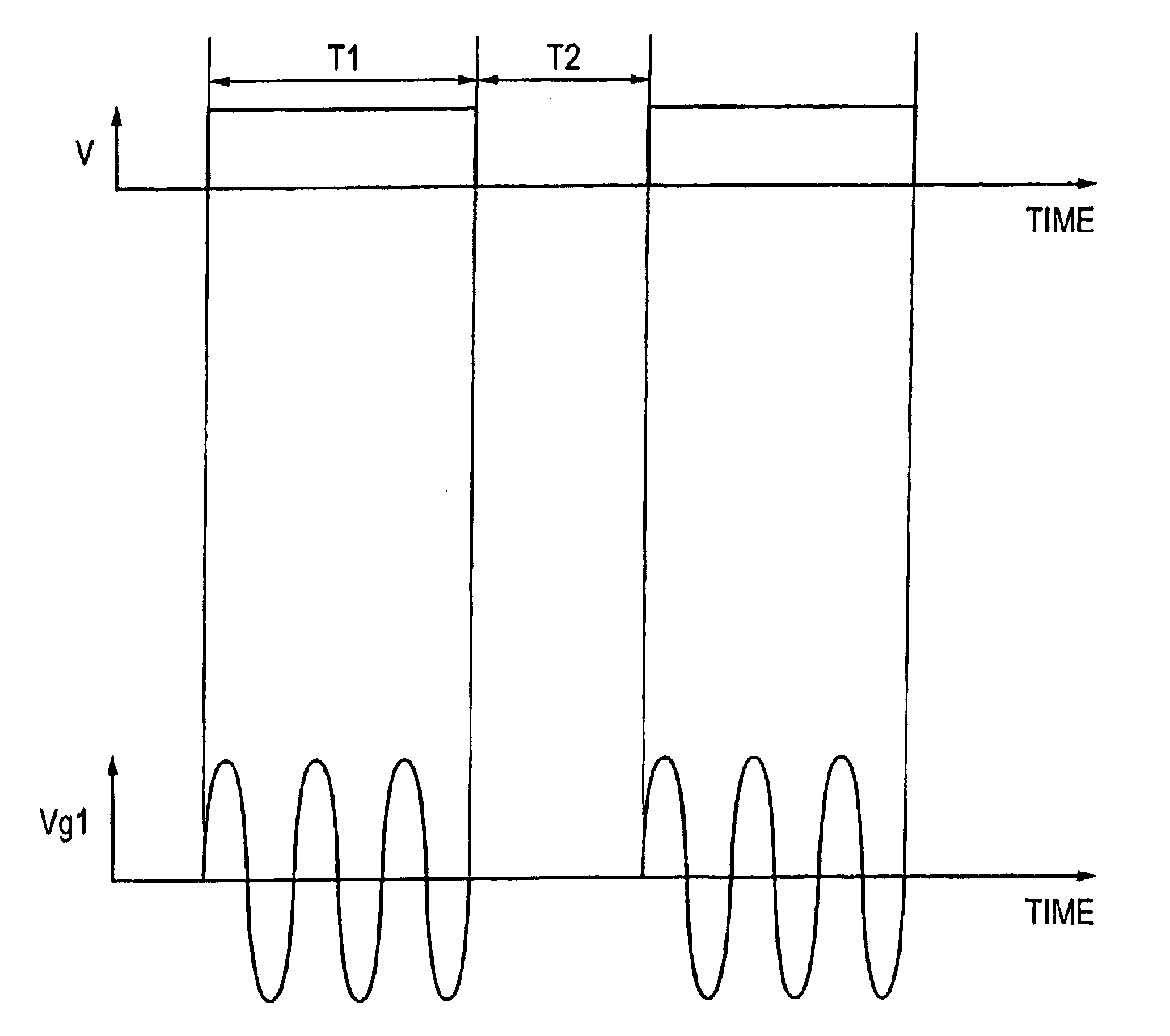

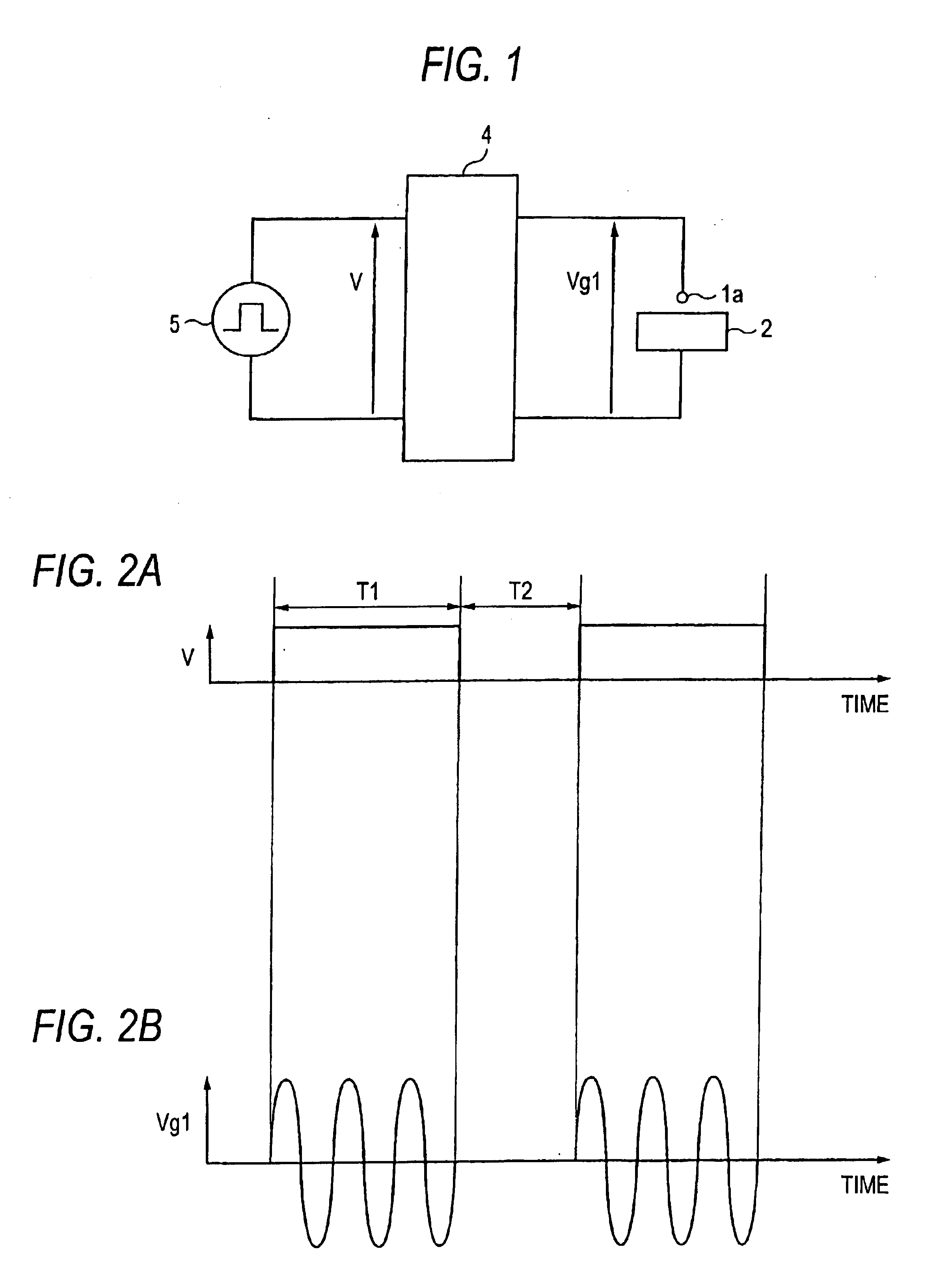

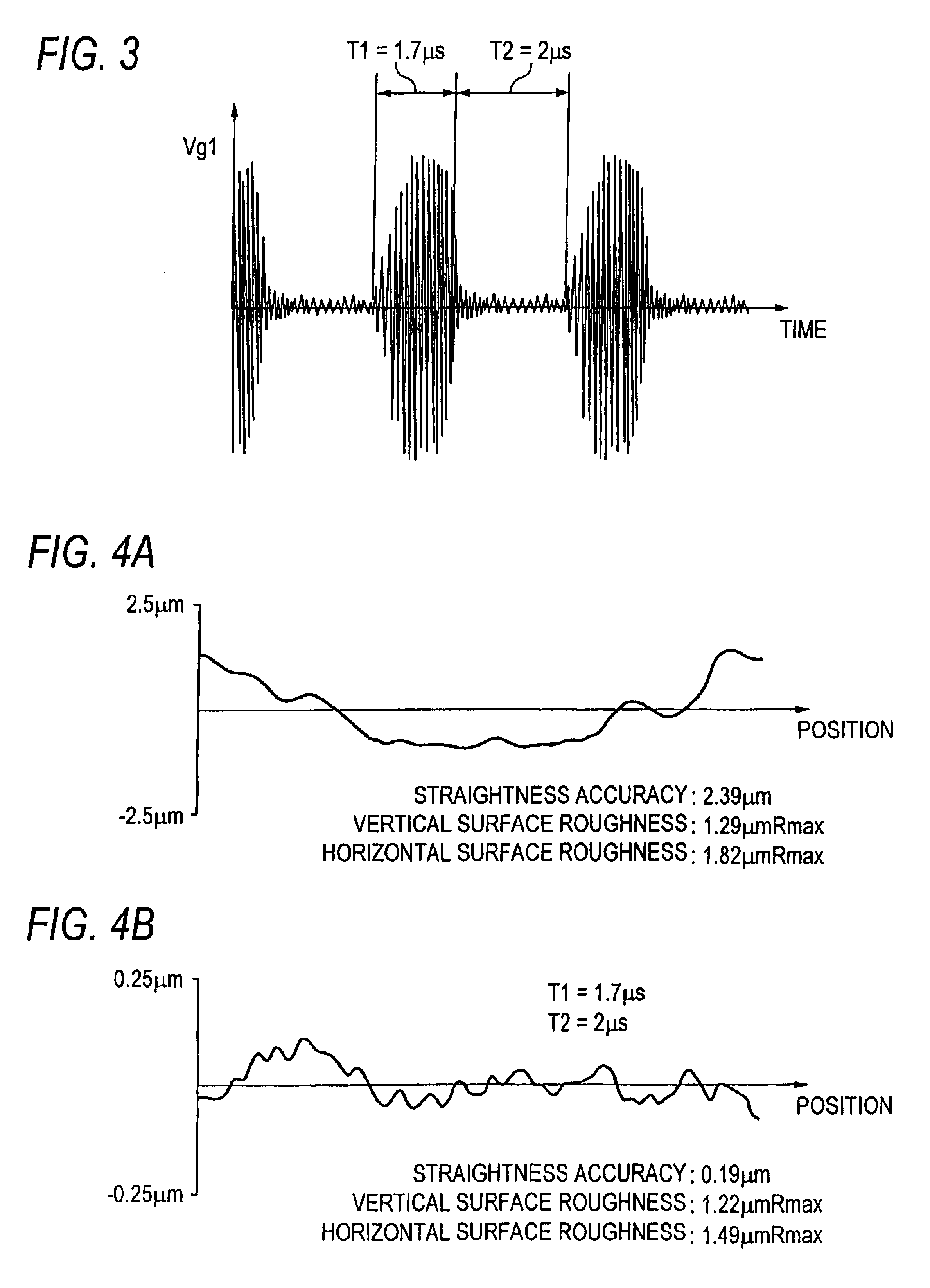

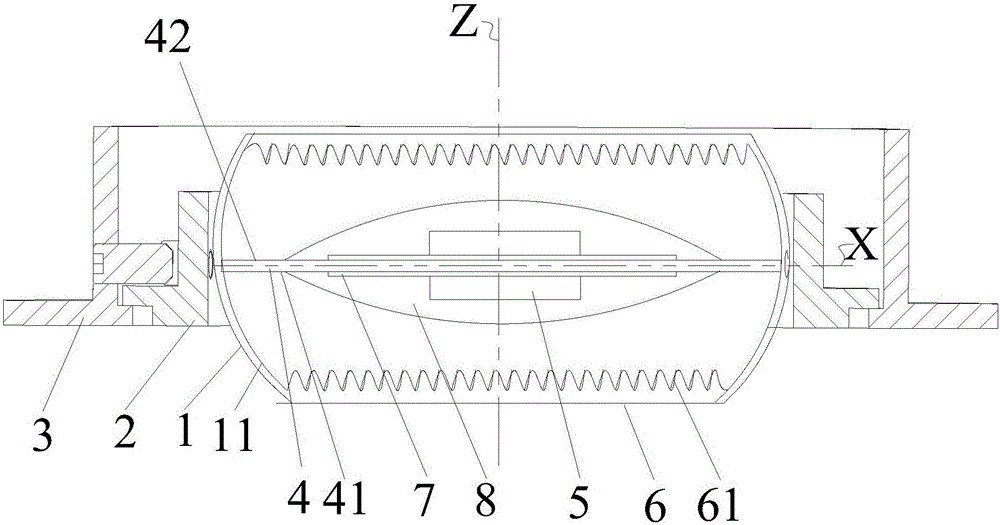

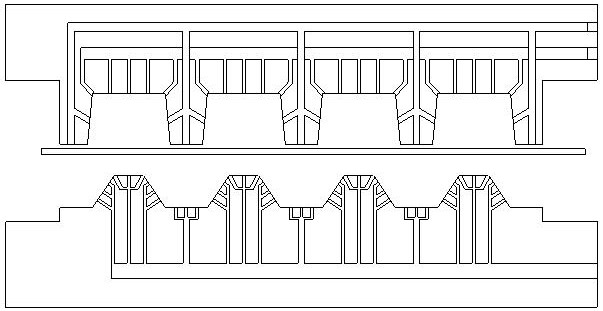

Power supply unit for wire electrical discharge machining and method of wire electrical discharge machining

InactiveUS6930273B2High straightness accuracyEliminate StreaksCalcium/strontium/barium carbonatesPigmenting treatmentHigh frequency oscillationHigh frequency

A power supply unit for wire electrical discharge machining using an ac high-frequency power supply for applying an ac high-frequency voltage between a wire electrode (1a) and a workpiece (2) includes a high-frequency oscillation and amplification circuit (4) and a pulse power supply (5) which is an ac-high-frequency-voltage intermittently supplying unit for effecting the application of the ac high-frequency voltage between the electrode and the workpiece and a pause thereof. In wire electrical discharge machining using this power supply unit for wire electrical discharge machining, it is possible to suppress the vibration of the wire electrode (1a) due tog the electrostatic force acting between the wire electrode (1a) and the workpiece (2), making it possible to improve the straightness accuracy of a machined surface of the workpiece (2) and make surface roughness small.

Owner:MITSUBISHI ELECTRIC CORP

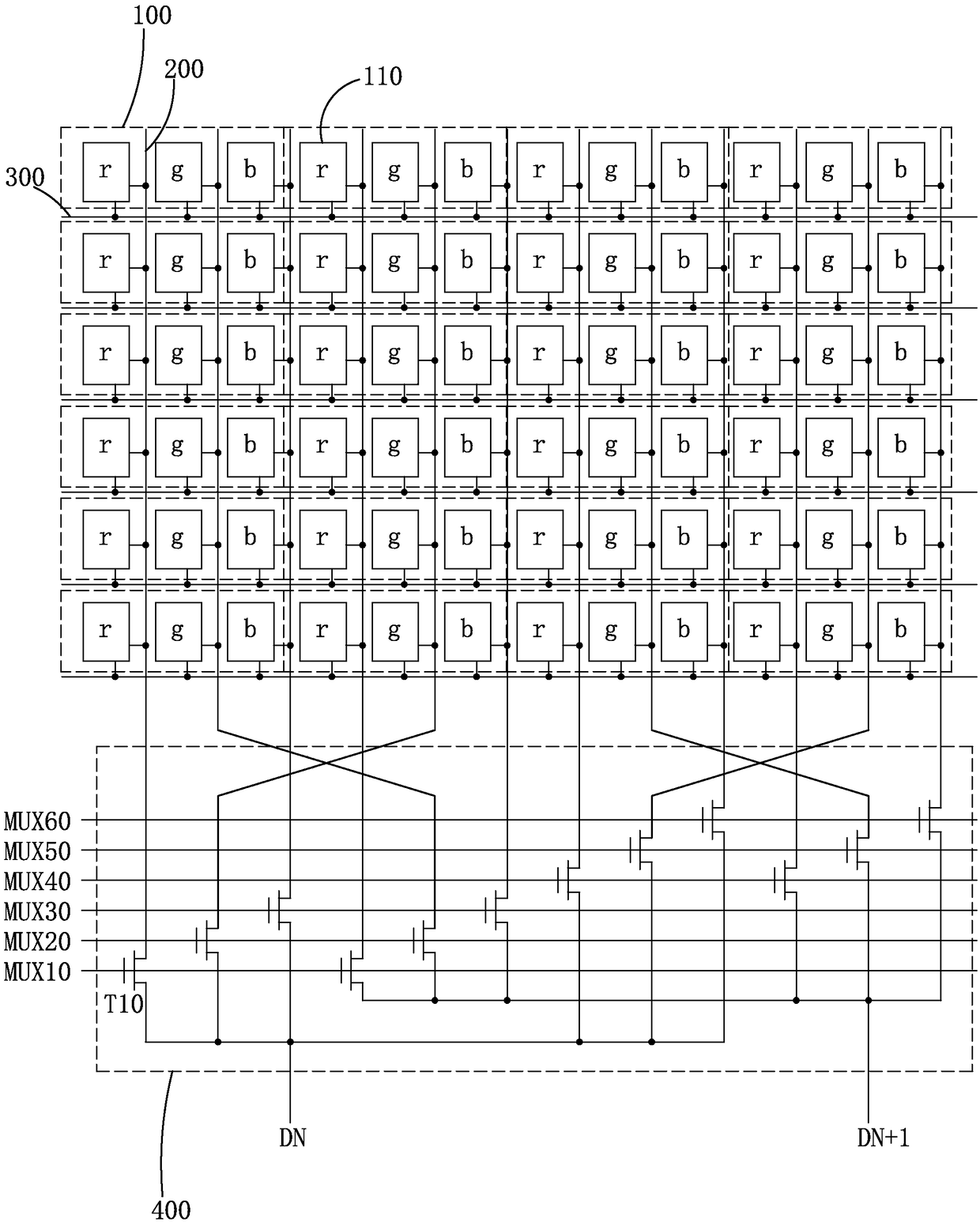

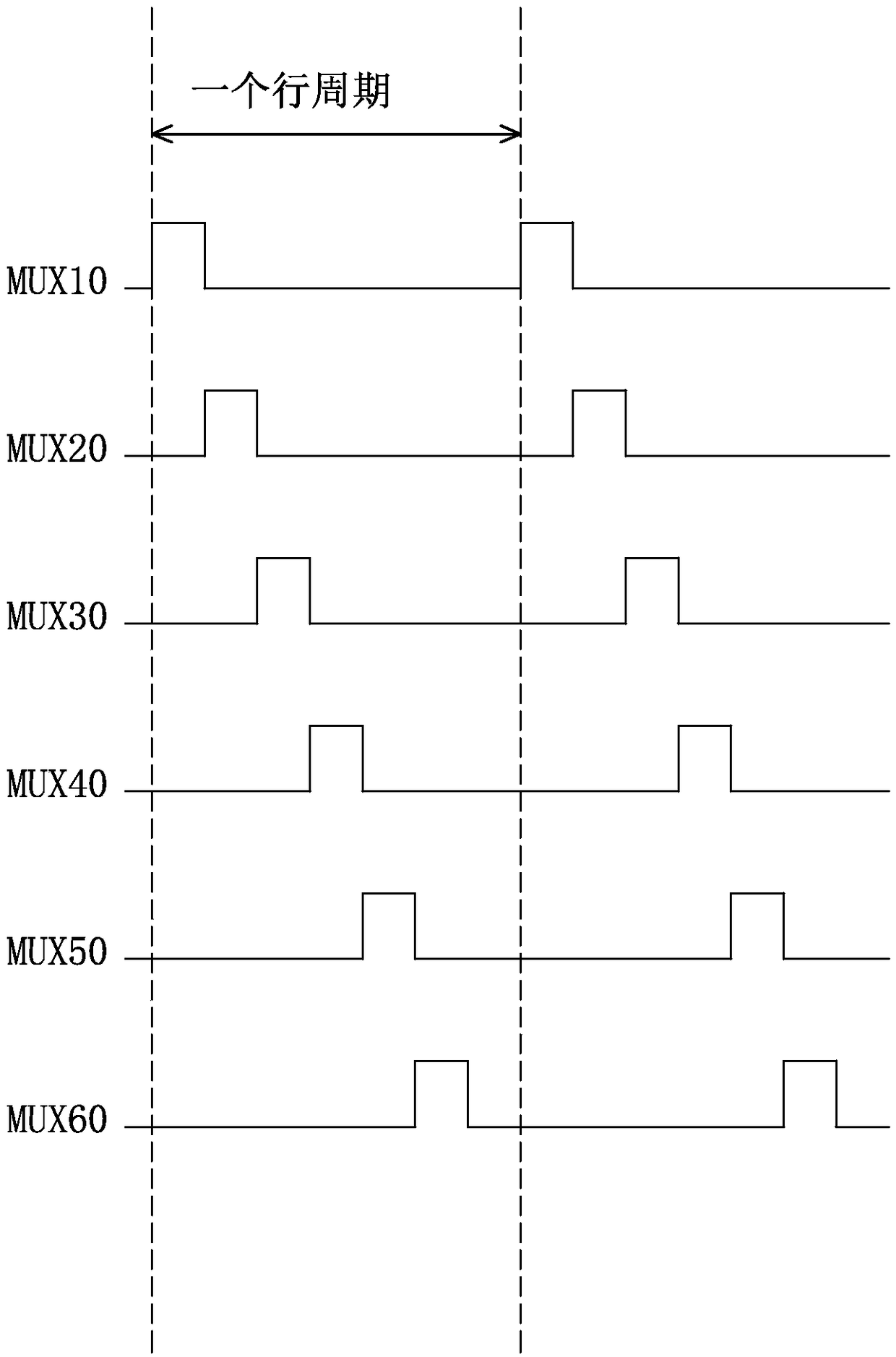

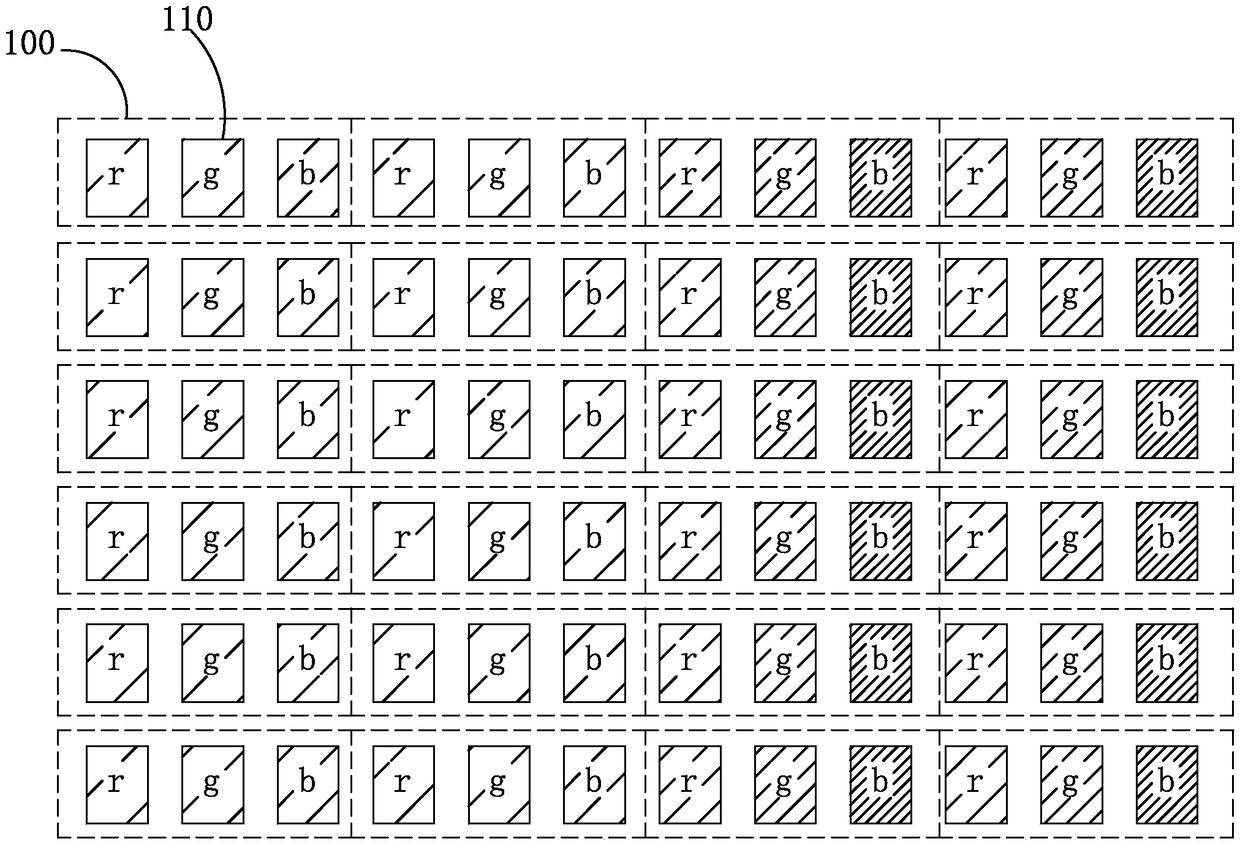

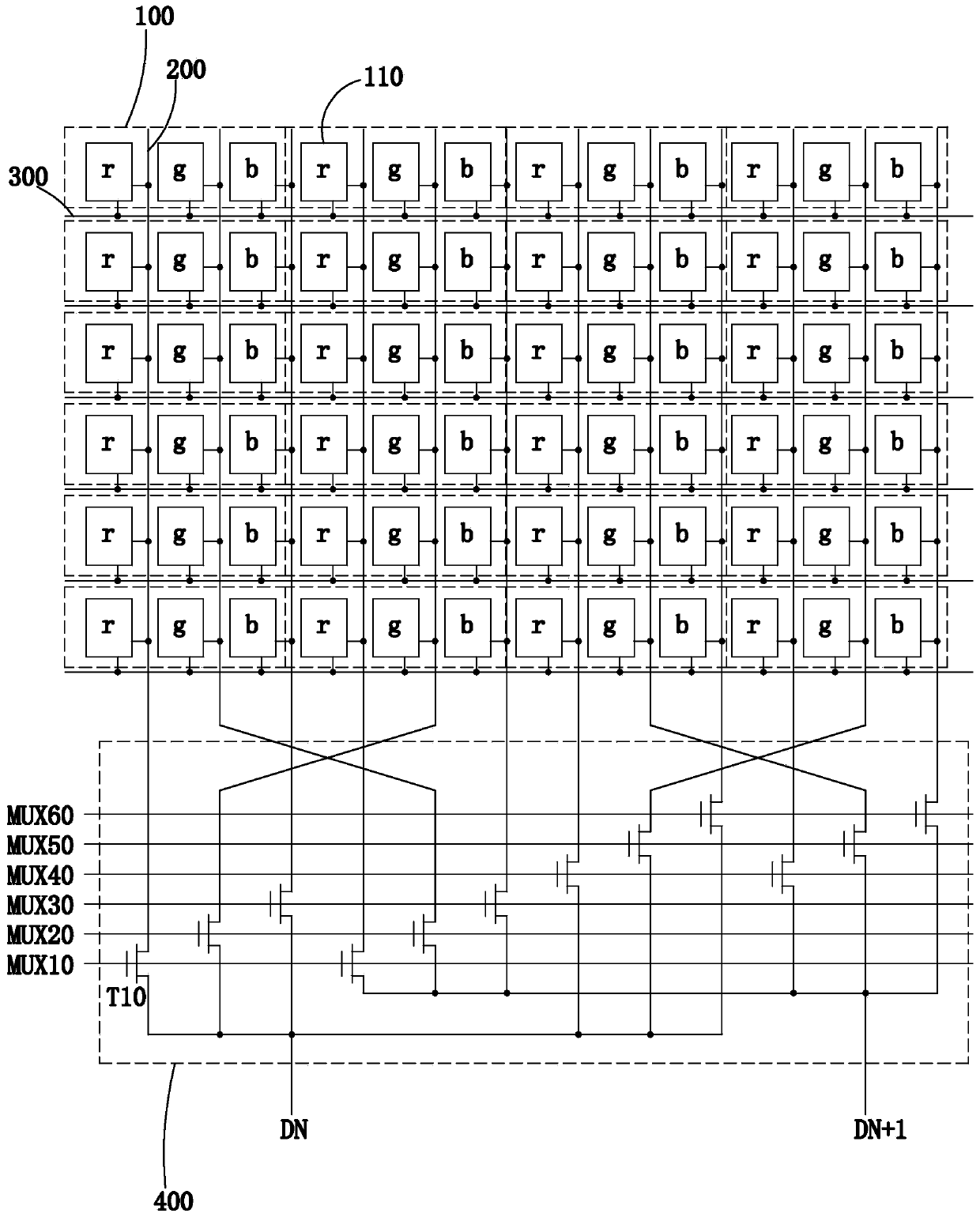

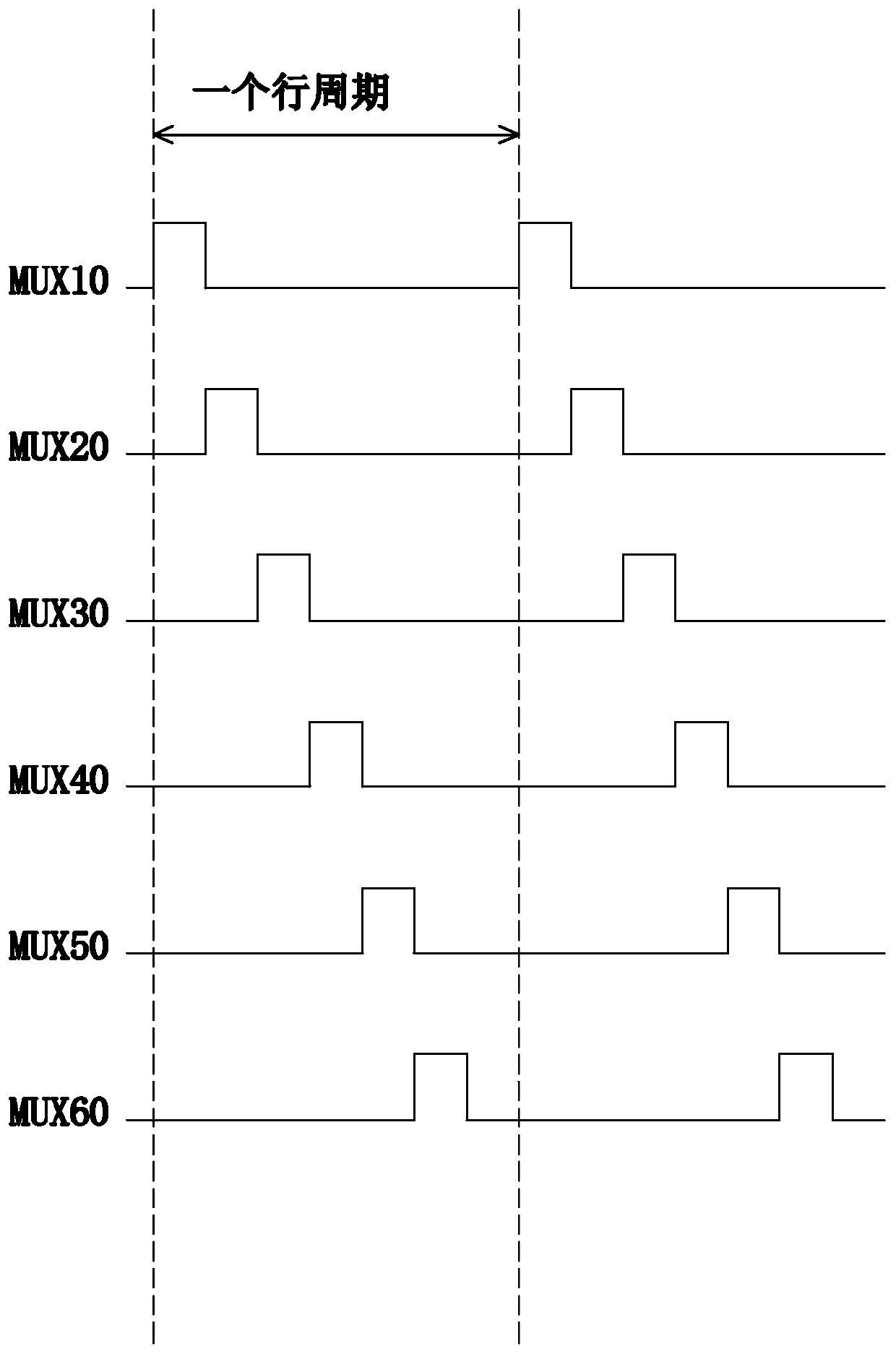

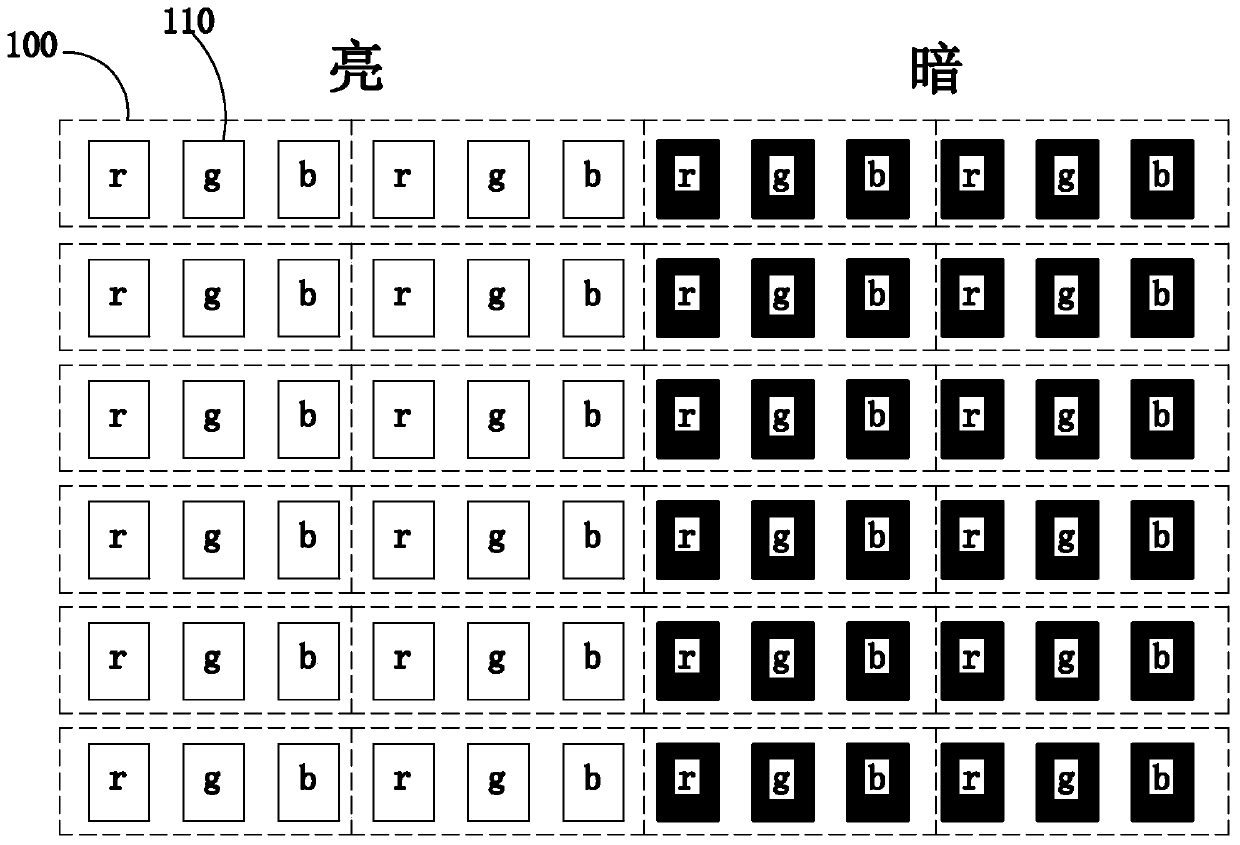

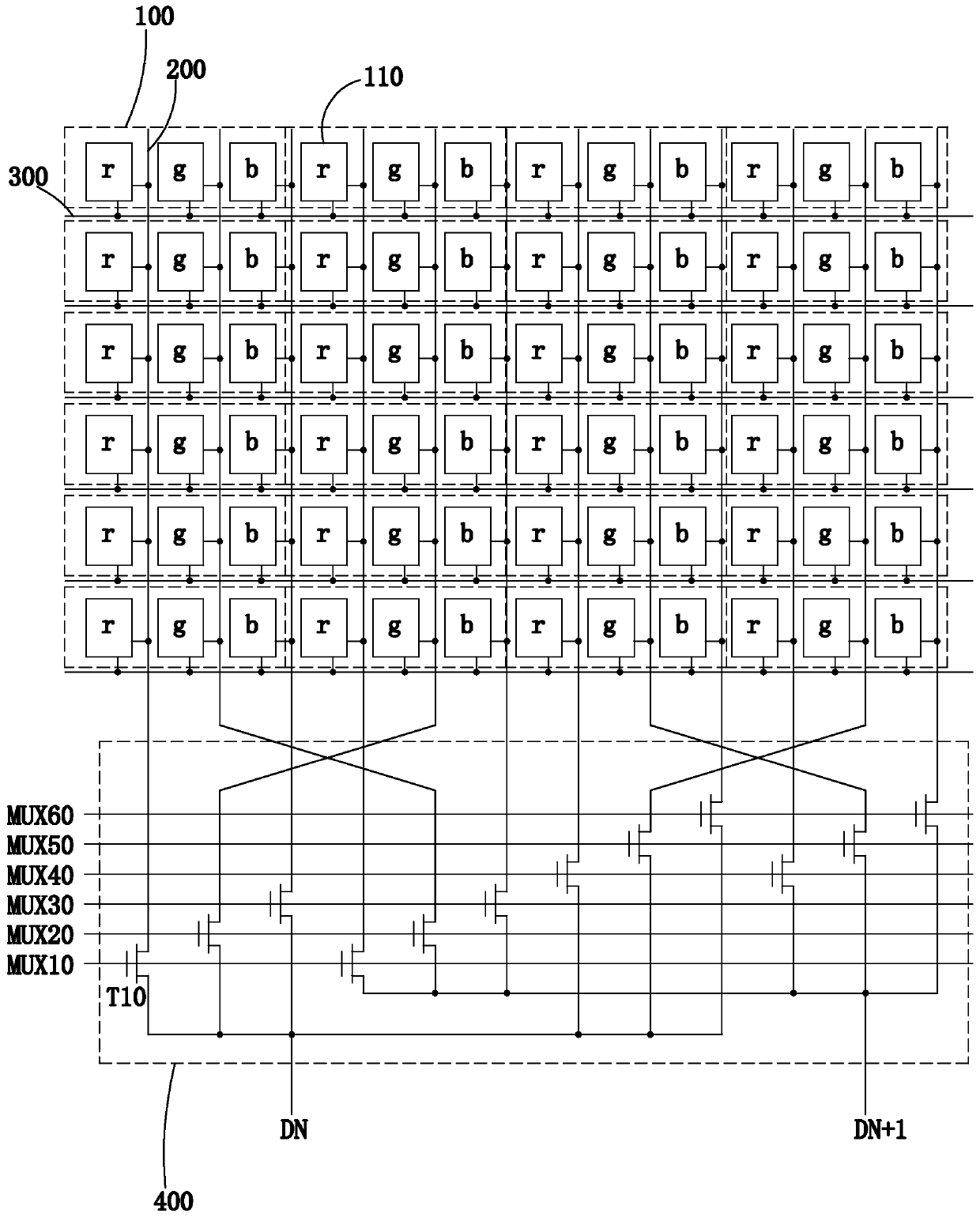

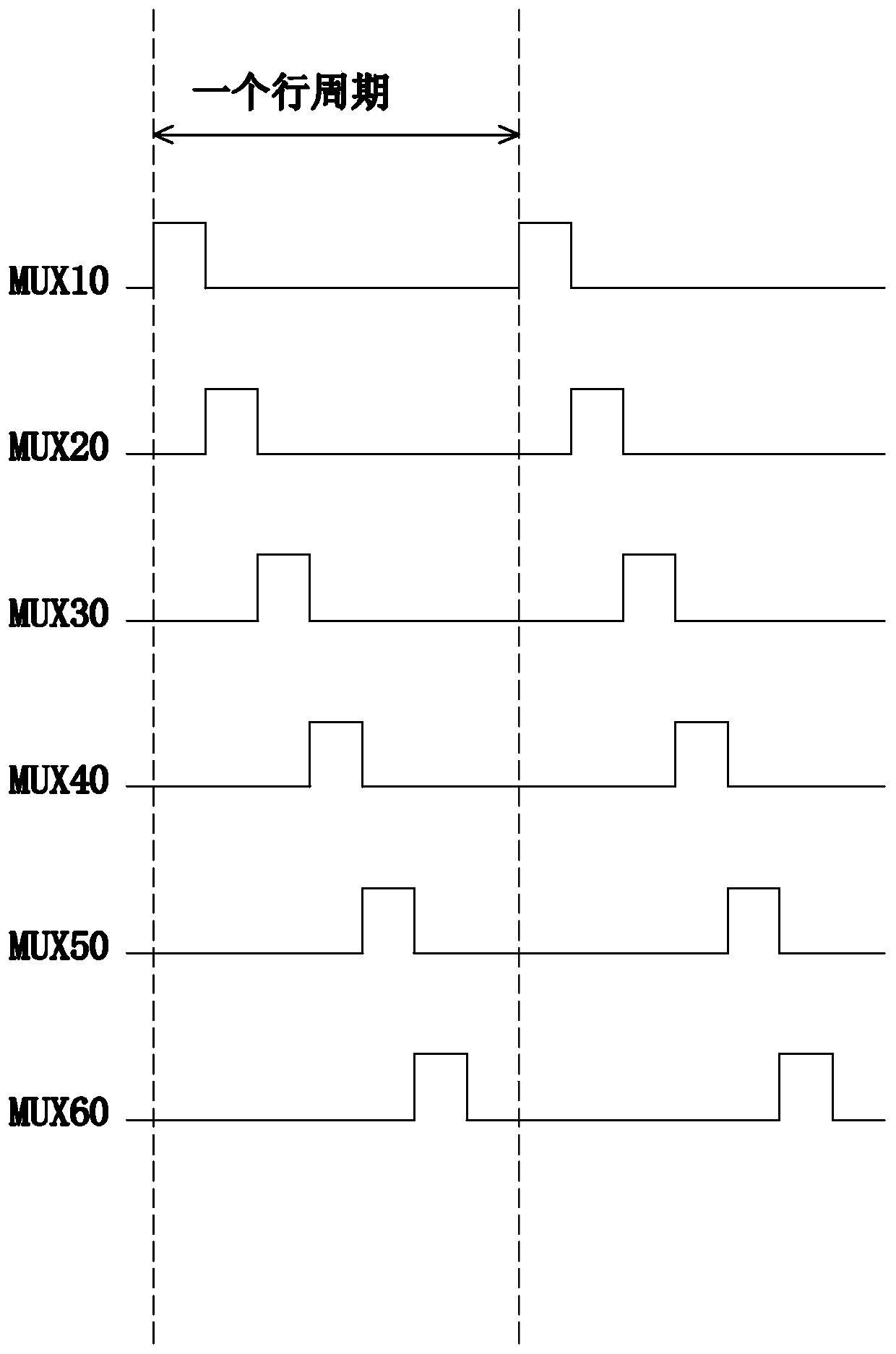

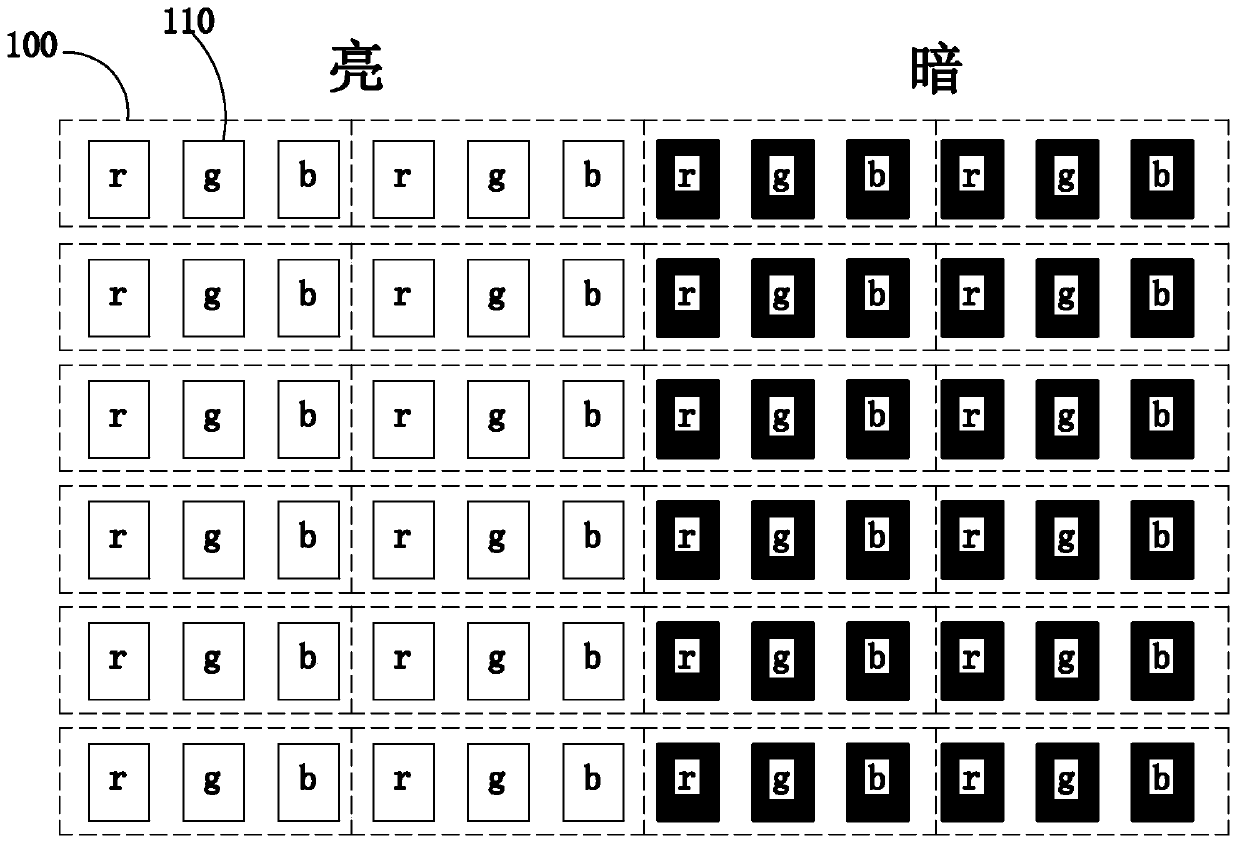

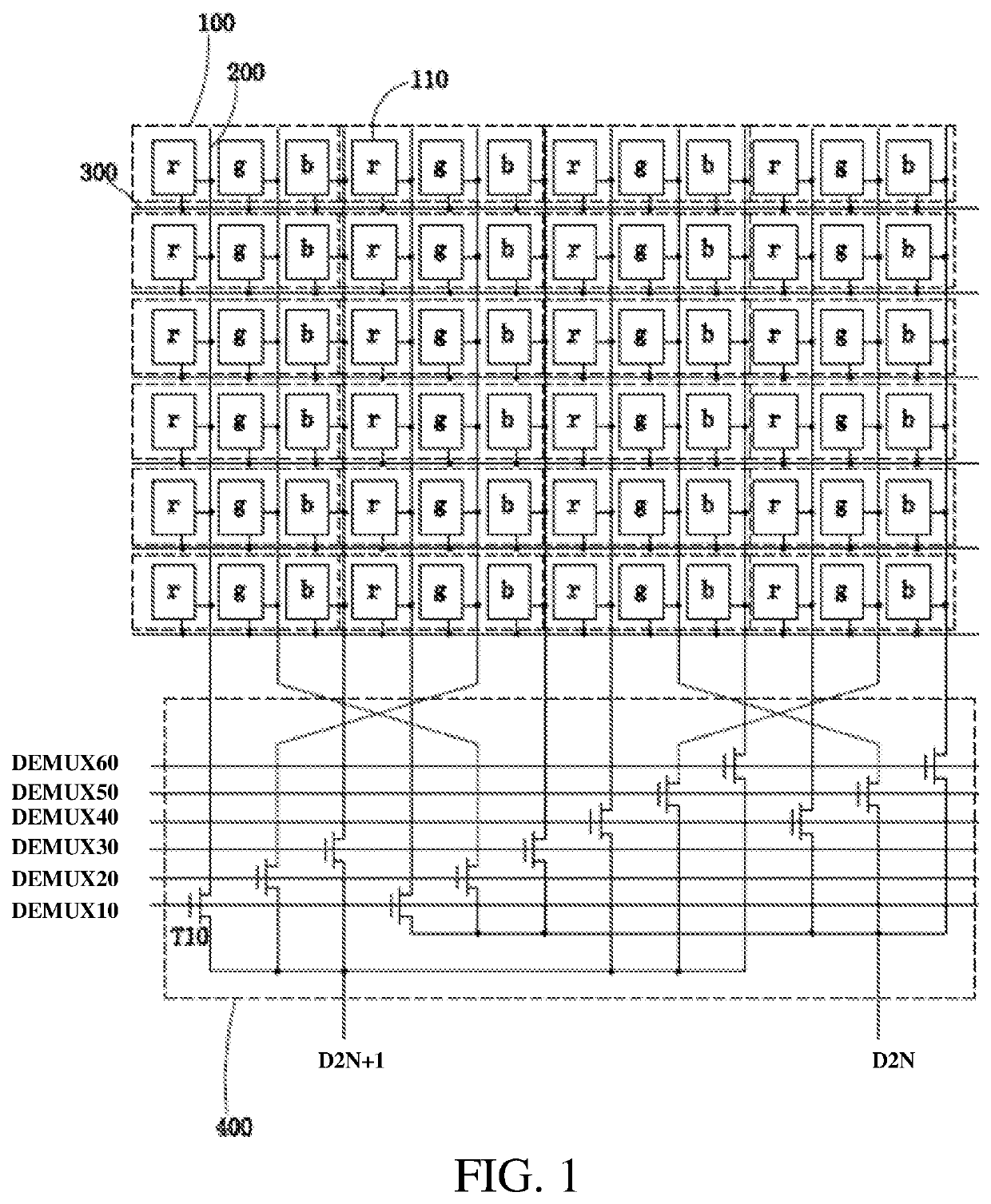

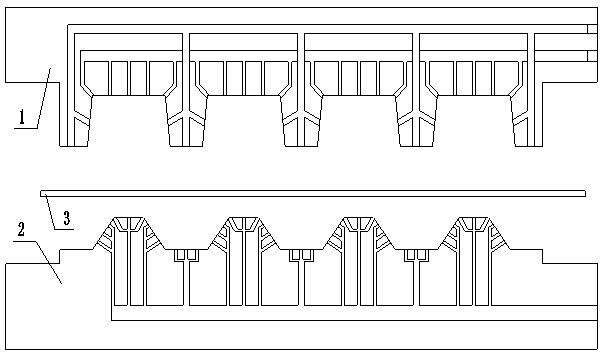

Driving method for display panels

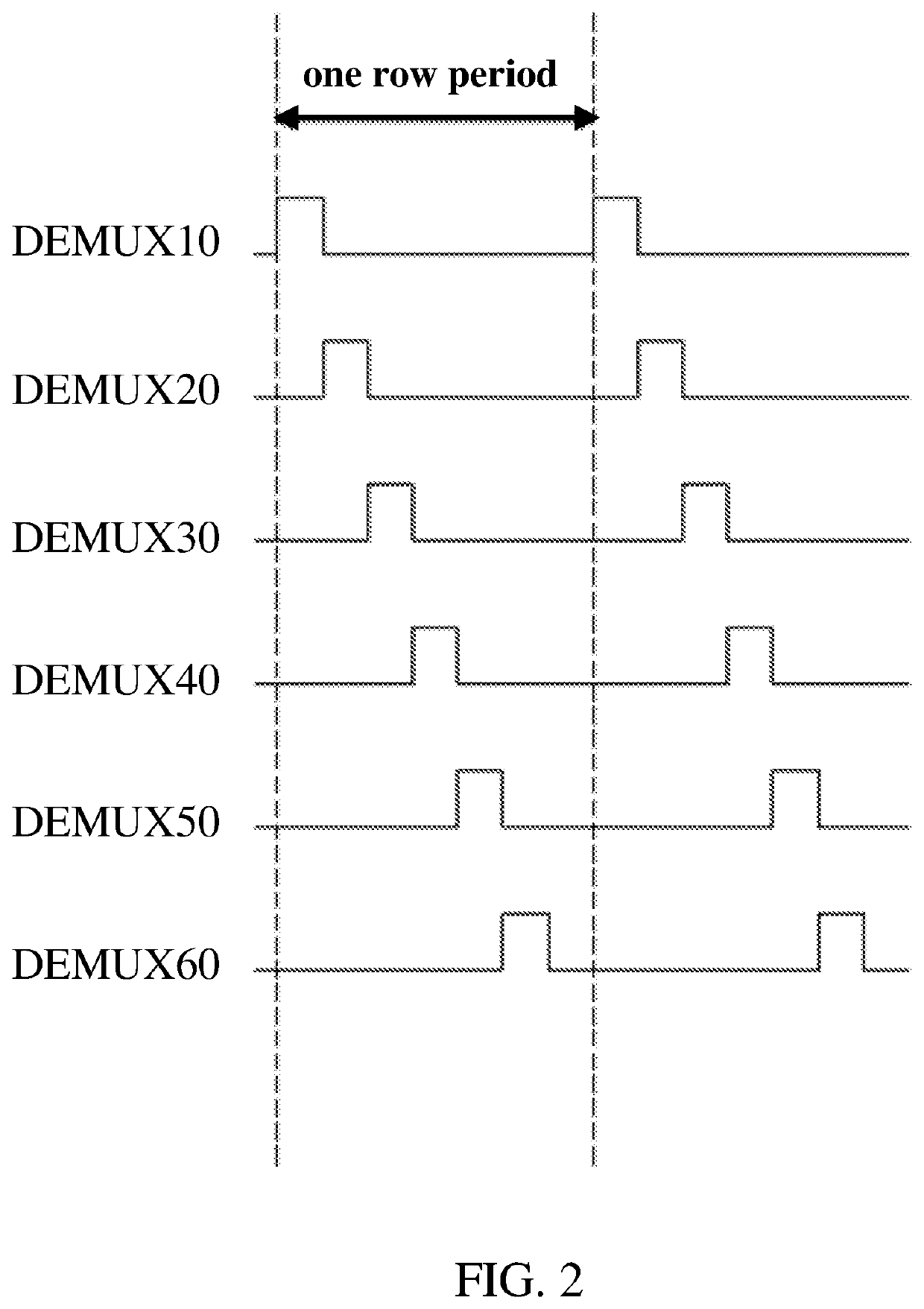

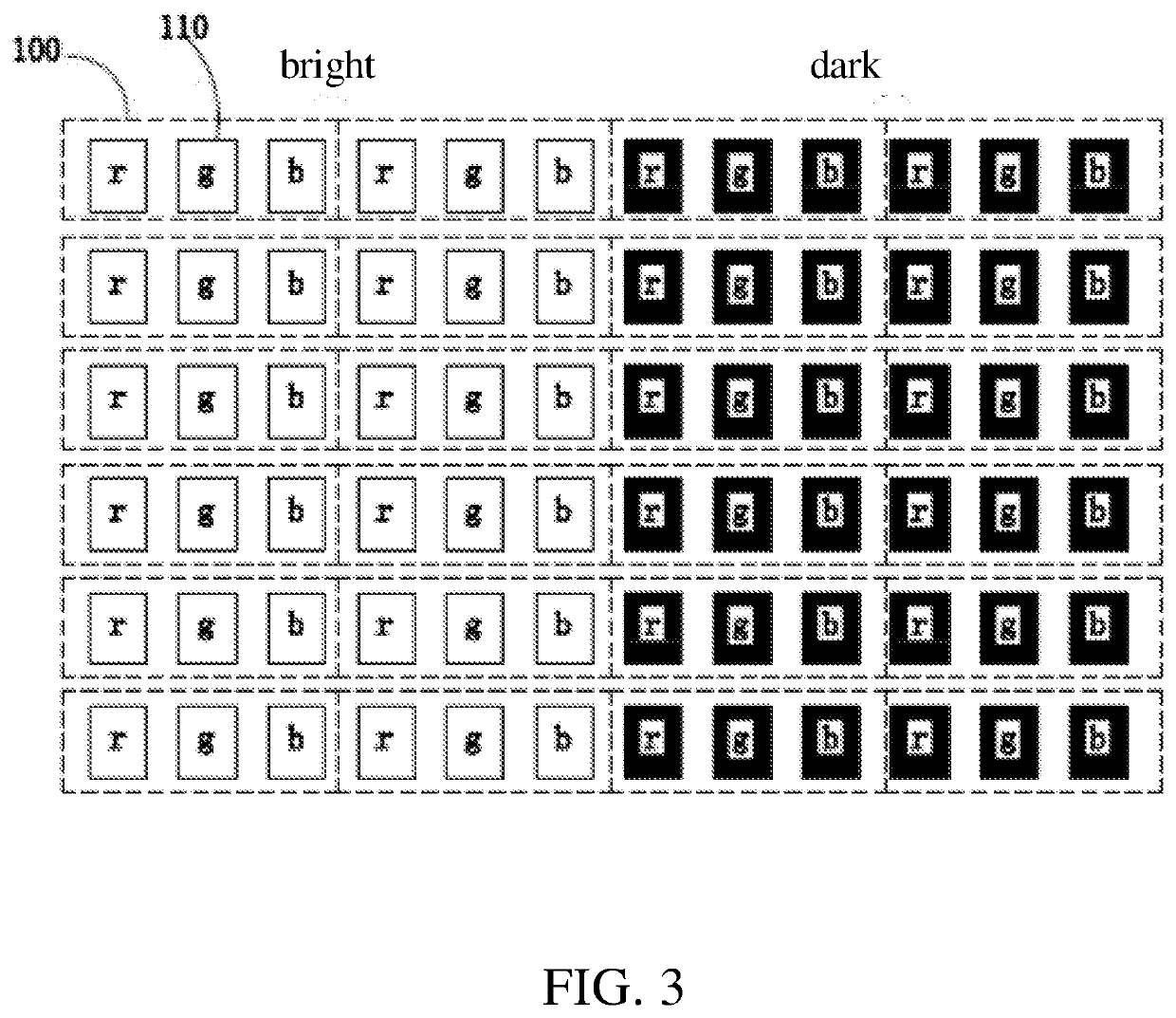

InactiveCN109346021AEliminate StreaksImprove display qualityStatic indicating devicesMultiplexingReverse order

The invention provides a driving method for display panels. According to the driving method for display panels of the invention, by making a first multiplexing signal, a second multiplexing signal, athird multiplexing signal, a fourth multiplexing signal, a fifth multiplexing signal and a sixth multiplexing signal generate a high-level pulse in a preset order in each first line period of a (2*i-1)th multiplexing period and making the first multiplexing signal, the second multiplexing signal, the third multiplexing signal, the fourth multiplexing signal, the fifth multiplexing signal and the sixth multiplexing signal generate a high-level pulse in order contrary to the preset order in each second line period of a (2*i)th multiplexing period, the fringe sense of the screen displayed on a display panel can be eliminated, and the display quality can be enhanced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

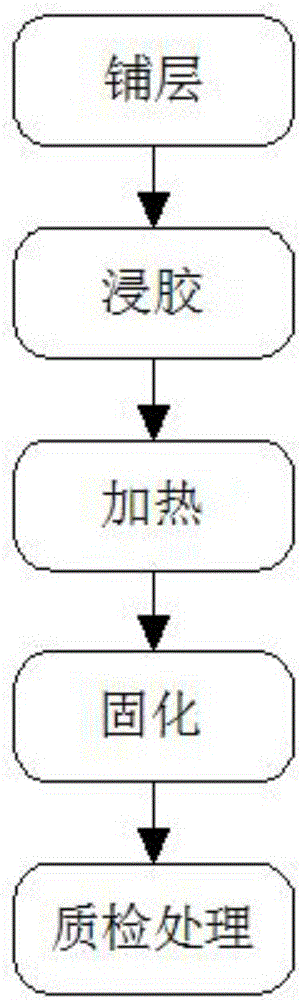

Molding process of carbon fiber composite material

The invention discloses a molding process of a carbon fiber composite material and belongs to the technical field of molding of carbon fibers. The molding process comprises the steps of laying, gumming, heating, curing and carrying out quality inspection treatment. The molding process of the carbon fiber composite material specifically comprises the following steps: S1: laying; S2: gumming; S3: heating; S4: curing; and S5: carrying out the quality inspection treatment. The molding process is simple and efficient; raw materials of the carbon fibers can be sufficiently utilized and the wastes of the materials are not caused; the production efficiency is improved and the yield of a carbon fiber product is high; and an autoclave is used for curing, so that stripes caused by the fact that a ventilation felt and other auxiliary materials are retracted can be effectively eliminated, and cured surfaces of the materials are smooth and have no folds, and furthermore, the quality of products is improved very well.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

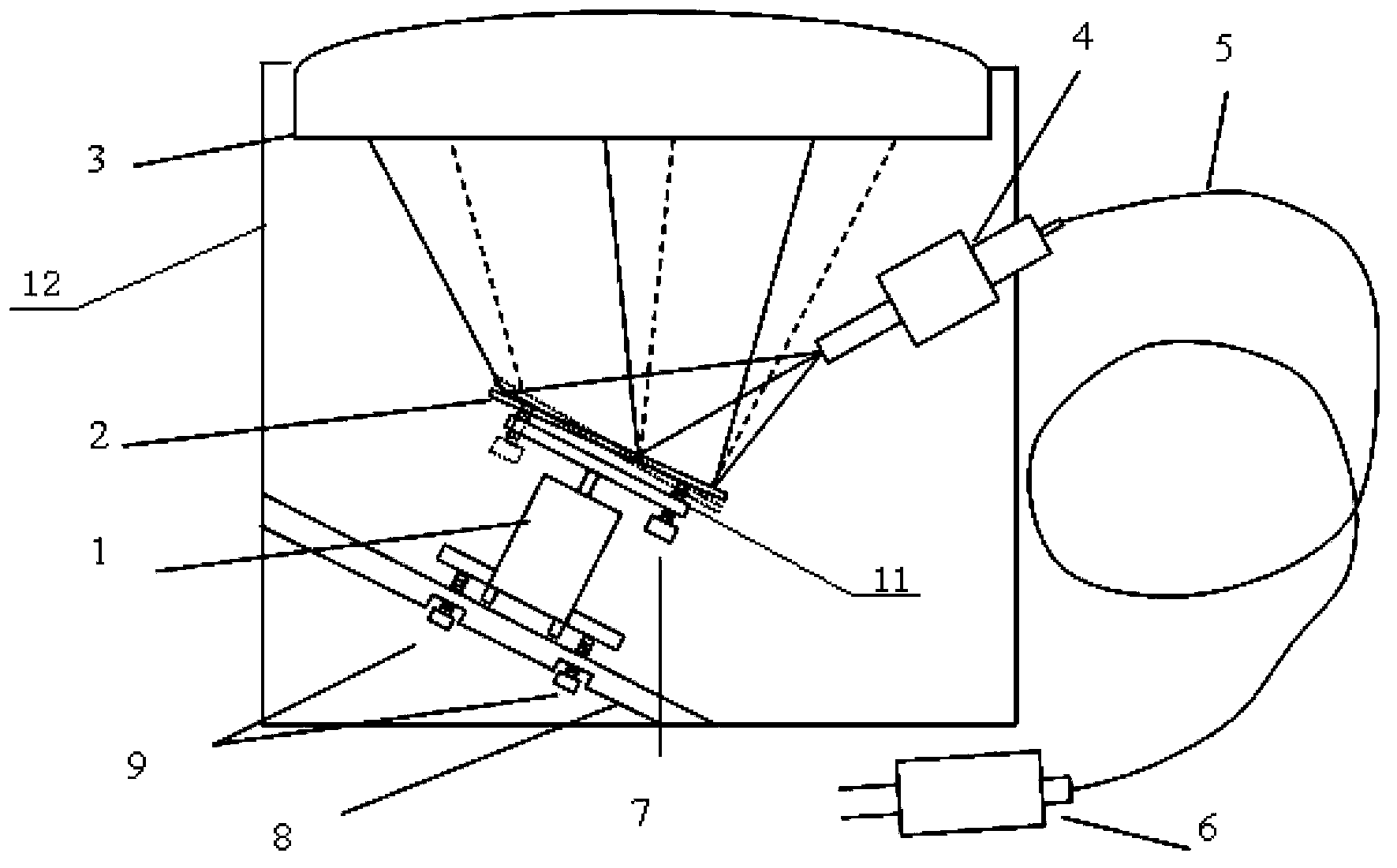

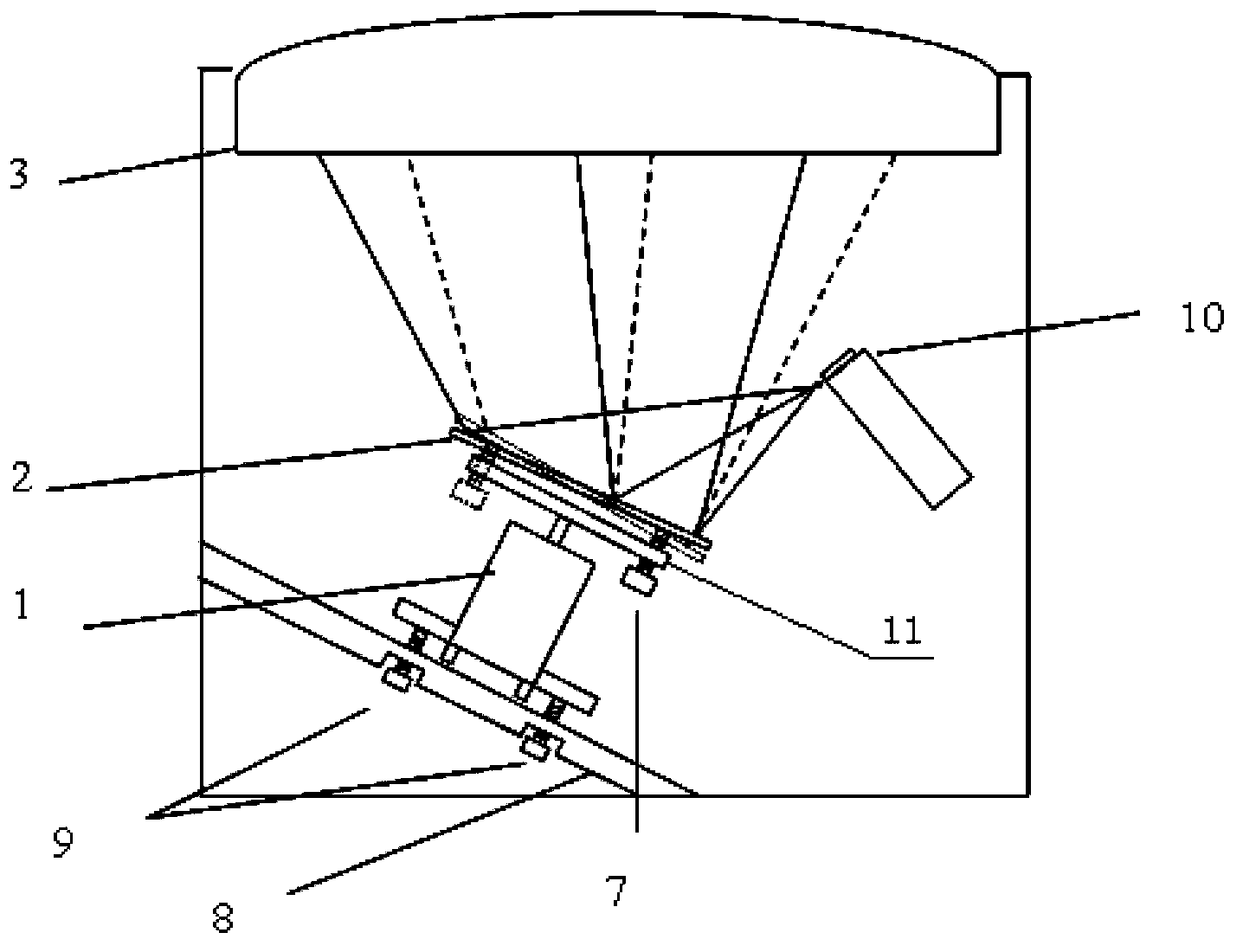

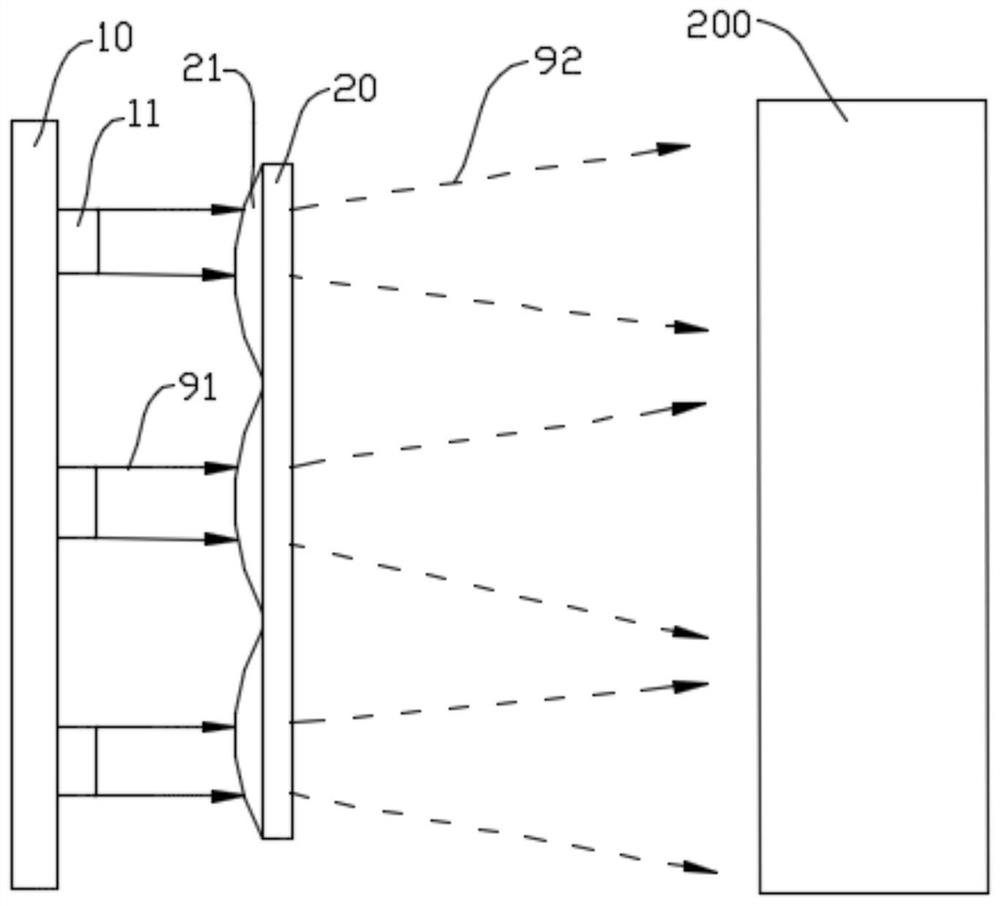

Laser rotation scanning lighting device and application thereof

The invention discloses a laser rotation scanning lighting device. The laser rotation scanning lighting device comprises a rotating device used for driving a reflecting mirror to rotate along the normal line of the reflecting mirror, the reflecting mirror and a laser light source. The emergent laser light of the laser light source is reflected by the reflecting mirror, and the reflected laser light is used as a scanning lighting source. The invention further discloses a method using the laser rotation scanning lighting device for lighting. The laser light source can be scanned by rotating the reflecting mirror, a plurality of light spots can be overlapped rapidly on a final irradiation plane, the average effect is achieved visually, and the purpose for eliminating speckles and stripes can be achieved. The laser rotation scanning lighting device is simple in structure, low in cost, high in energy utilization rate, and particularly suitable for the application field of laser night vision, security and protection, laser projection and the like in which optical fiber output laser light is used as the light source.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

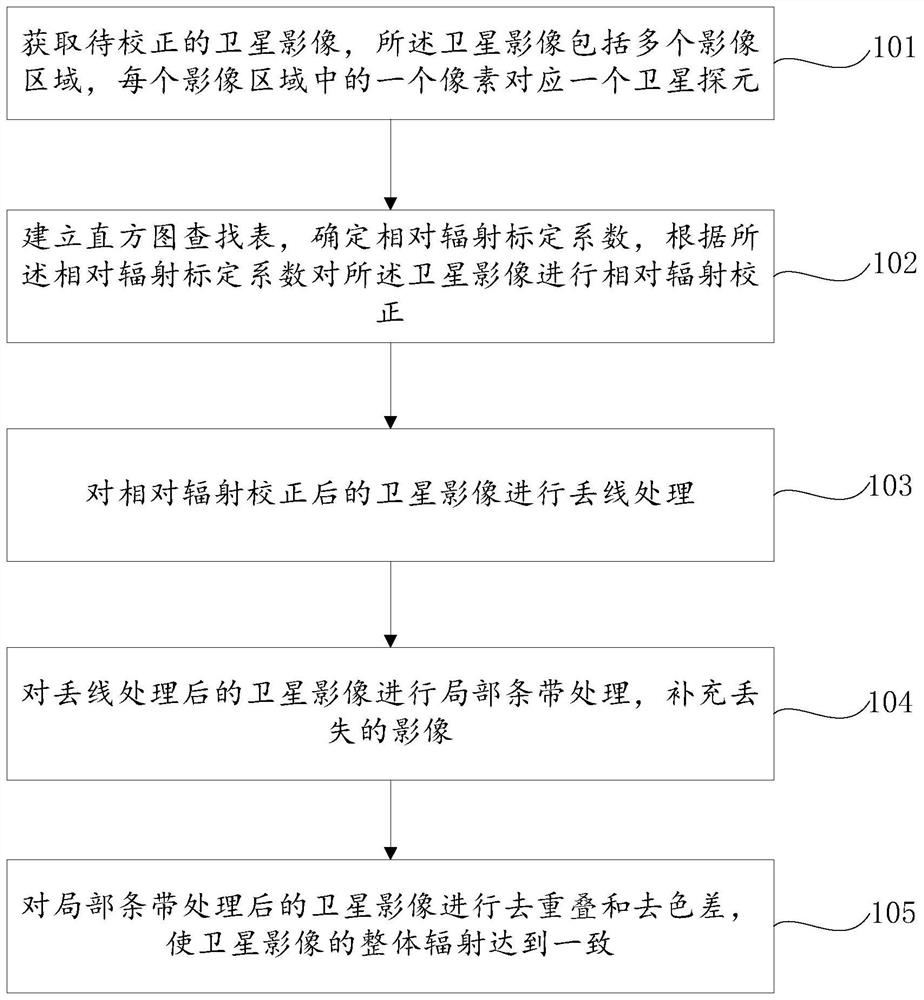

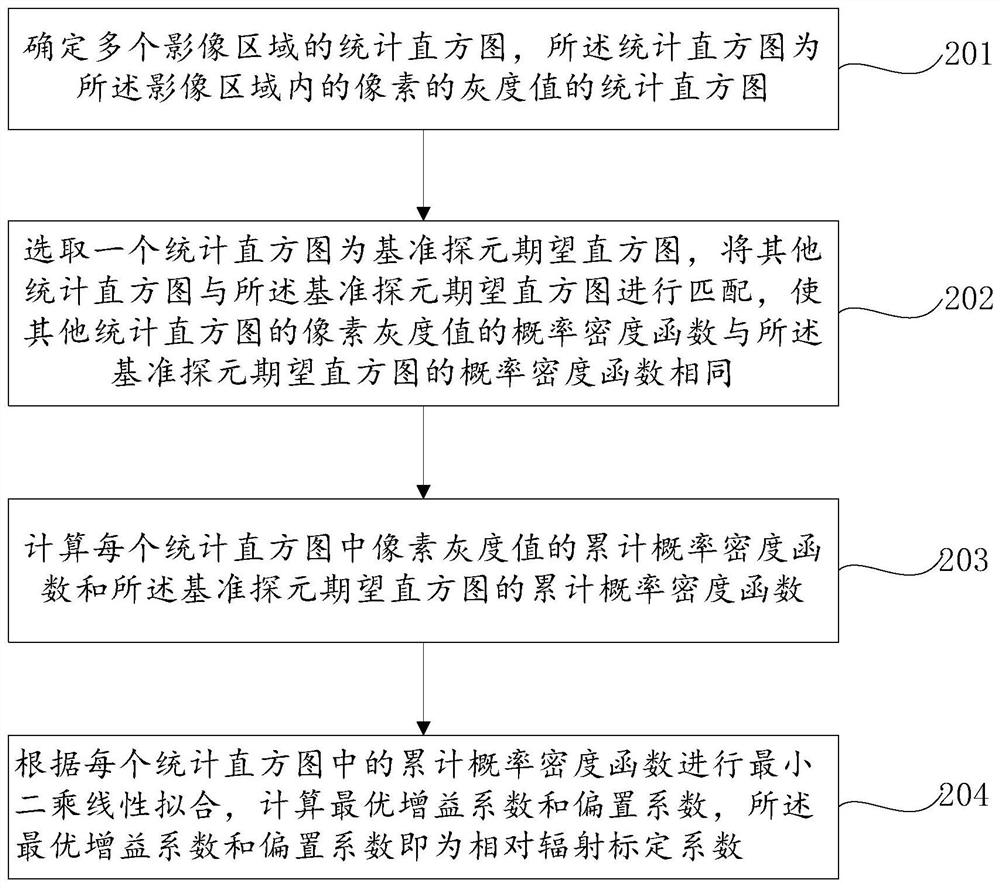

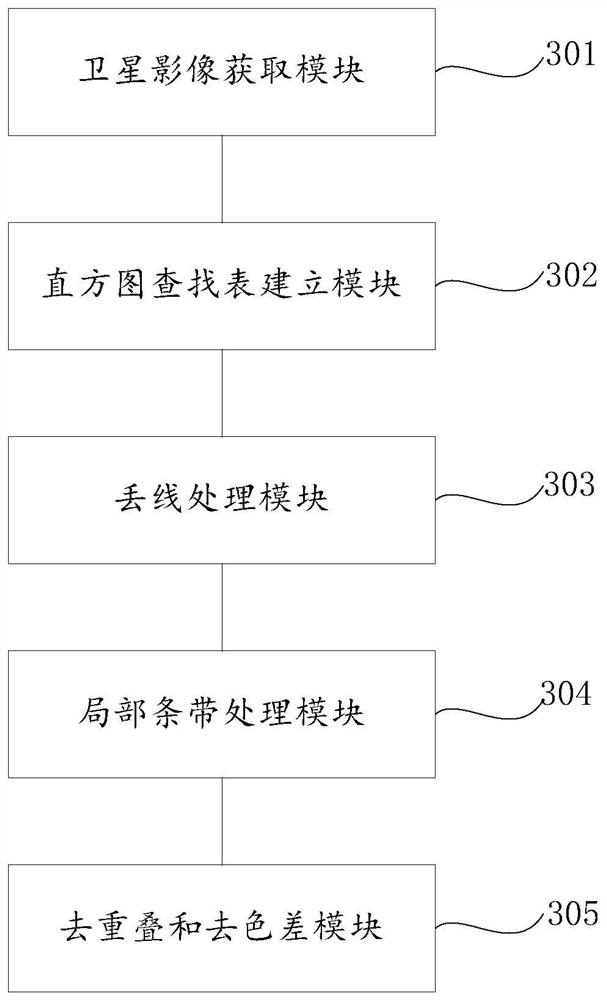

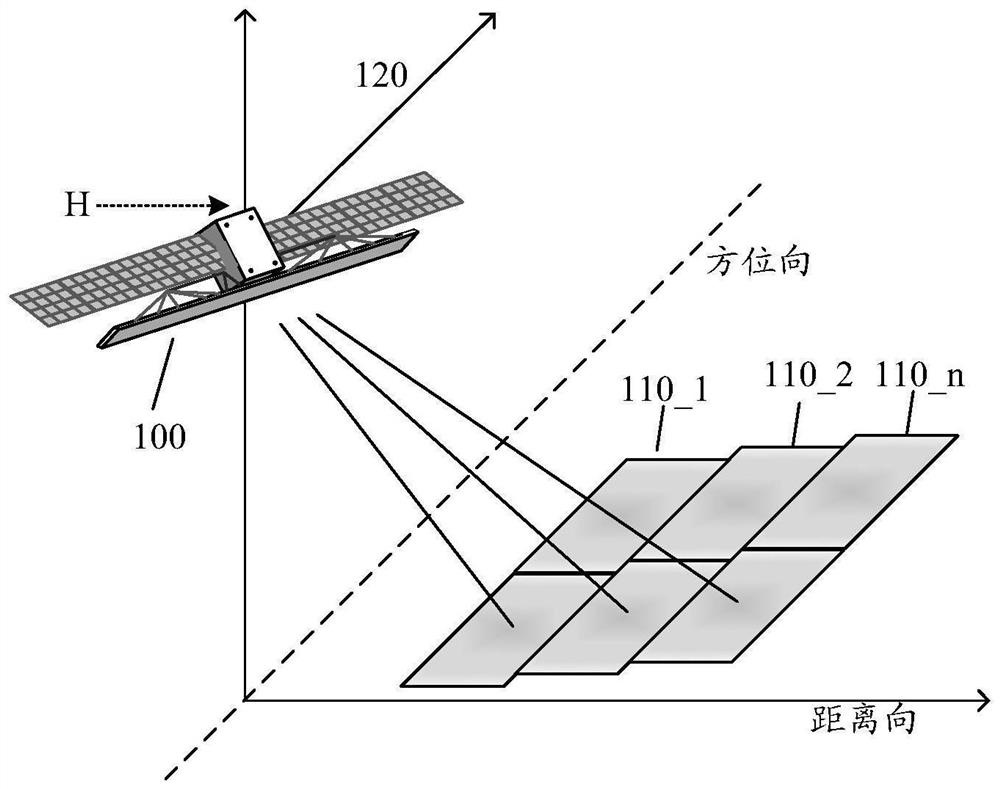

Satellite image relative radiation correction method and device

ActiveCN112529807AEliminate StreaksElimination of Ribbon Radiation DifferencesImage enhancementImage analysisSatellite imageCalibration coefficient

The invention provides a satellite image relative radiation correction method and device. The method comprises the steps: obtaining a to-be-corrected satellite image which comprises a plurality of image regions, and enabling one pixel in each image region to correspond to one satellite probe element; establishing a histogram lookup table, determining a relative radiation calibration coefficient, and performing relative radiation correction on the satellite image according to the relative radiation calibration coefficient; performing line loss processing on the satellite image after relative radiation correction; carrying out local stripe processing on the satellite image after line loss processing, and supplementing the lost image; de-overlapping and de-chromatic aberration are carried outon the satellite image after local strip processing, so that the overall radiation of the satellite image is consistent. In this way, effective relative radiation correction can be carried out on satellite images, and the stripe or strip radiation difference phenomenon of the satellite images and the chromatic aberration between the satellite images are eliminated.

Owner:DAODATIANJI SOFTWARE TECH BEIJING

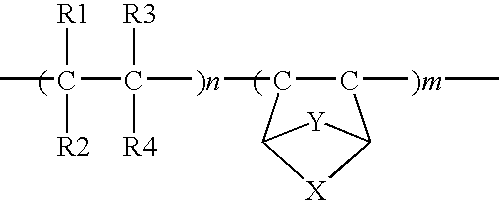

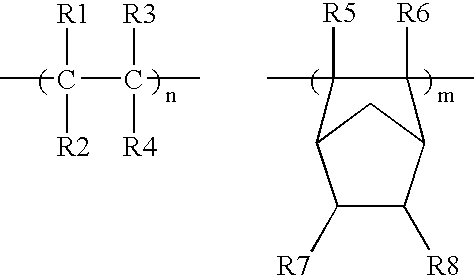

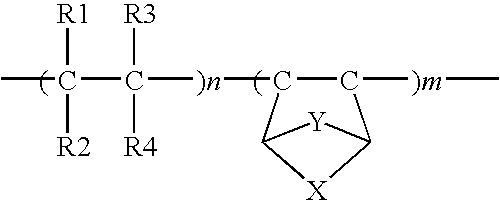

Gel Composite

InactiveUS20080128281A1Less streakingExcellent oxygen barrier propertiesSludge treatmentVolume/mass flow measurementPolymer scienceElectrophoresis

The present invention relates to electrophoresis and in particular electrophoretic gel composites used for separation of biomolecules, such as proteins and peptides. More particularly, the invention relates to gel composites with improved oxygen barrier properties. The invention provides an electrophoretic gel composite, comprising a) a polymer support; b) an electrophoretic hydrogel; and c) an oxygen barrier film between the polymer support and the hydrogel. Preferably the hydrogel is produced in the presence of an oxygen scavenger and / or under inert atmosphere. The improved oxygen barrier properties make the gel composites excellent for electrophoresis without artifacts in the gel.

Owner:GE HEALTHCARE BIO SCI CORP

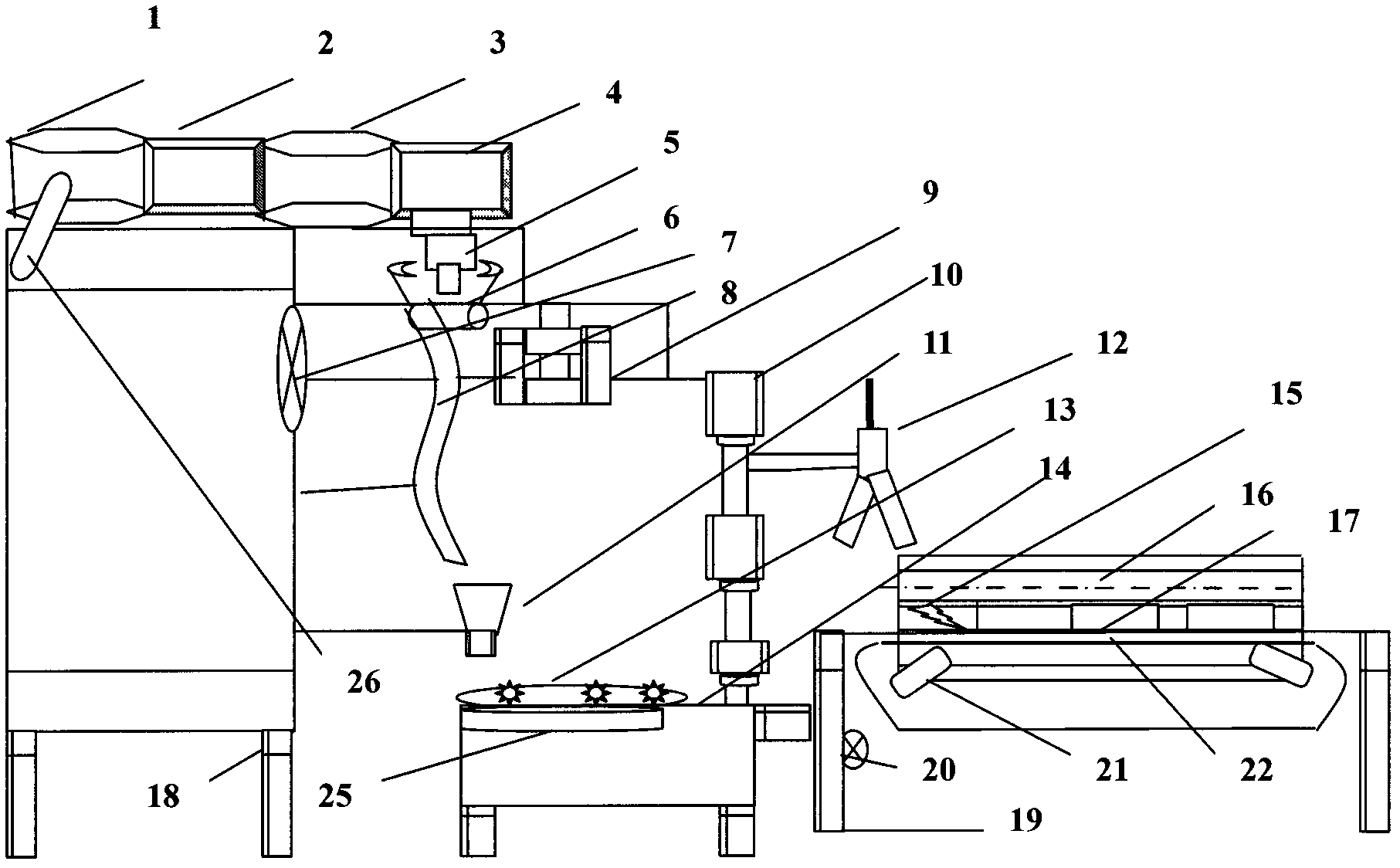

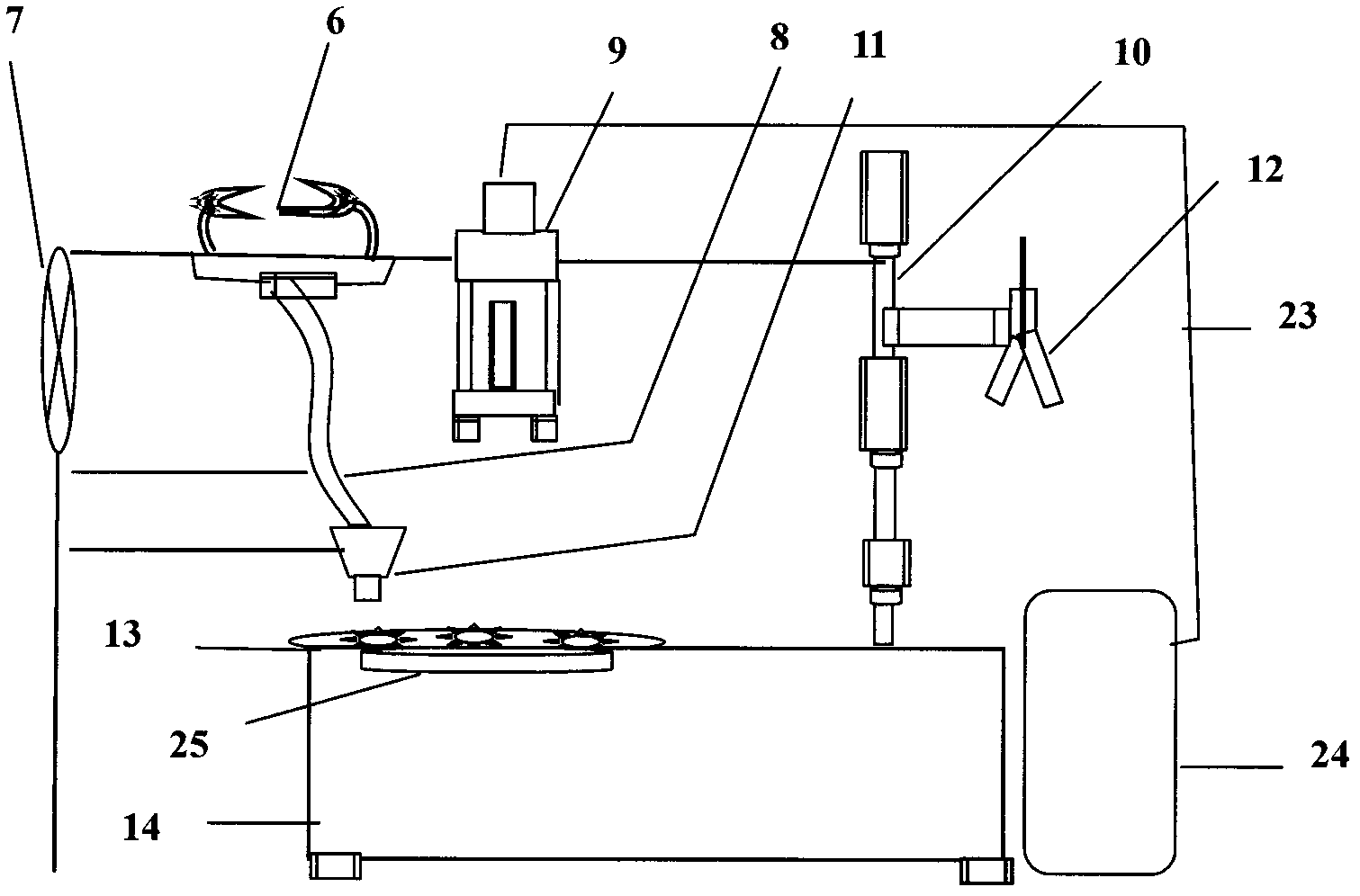

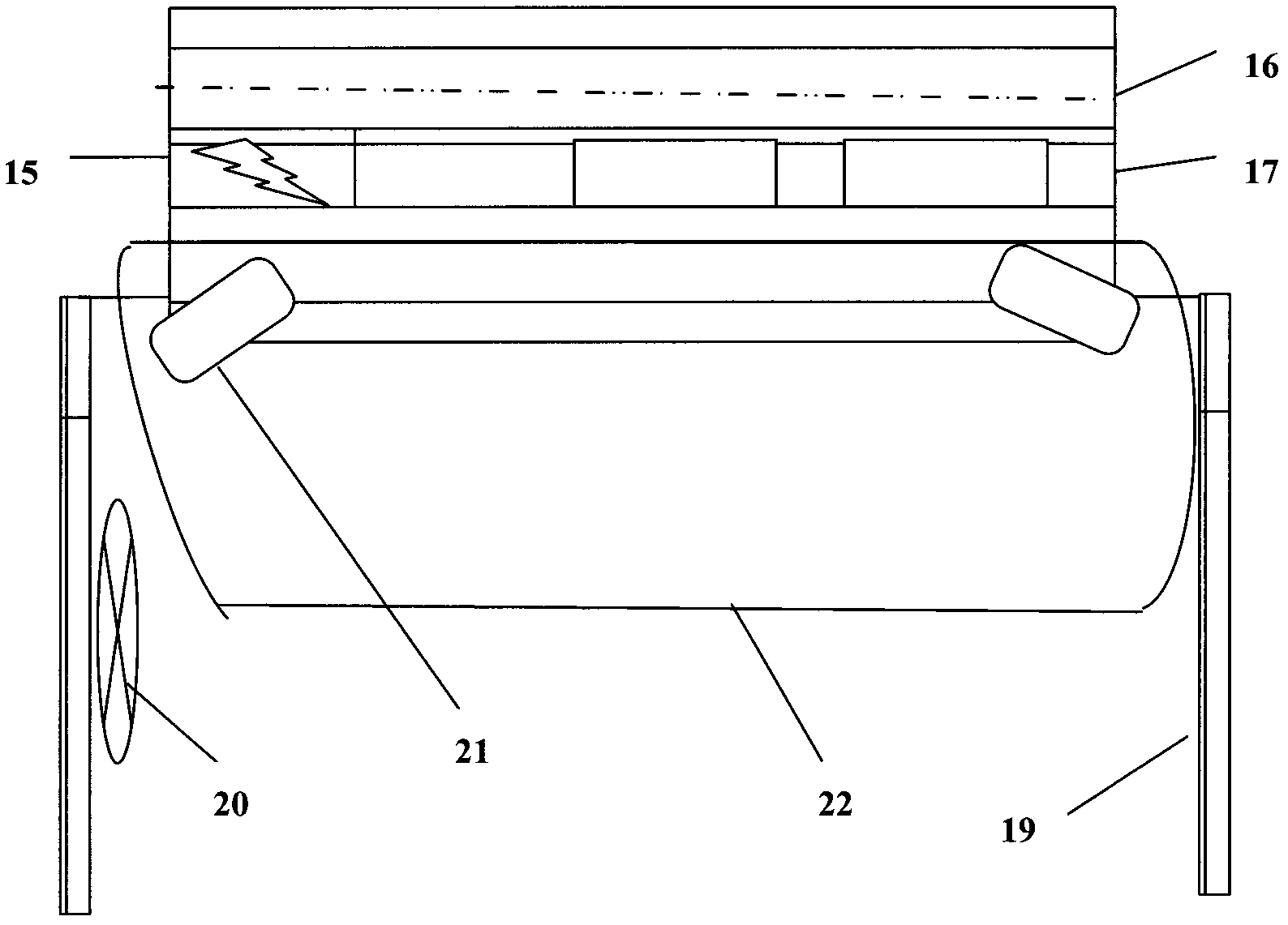

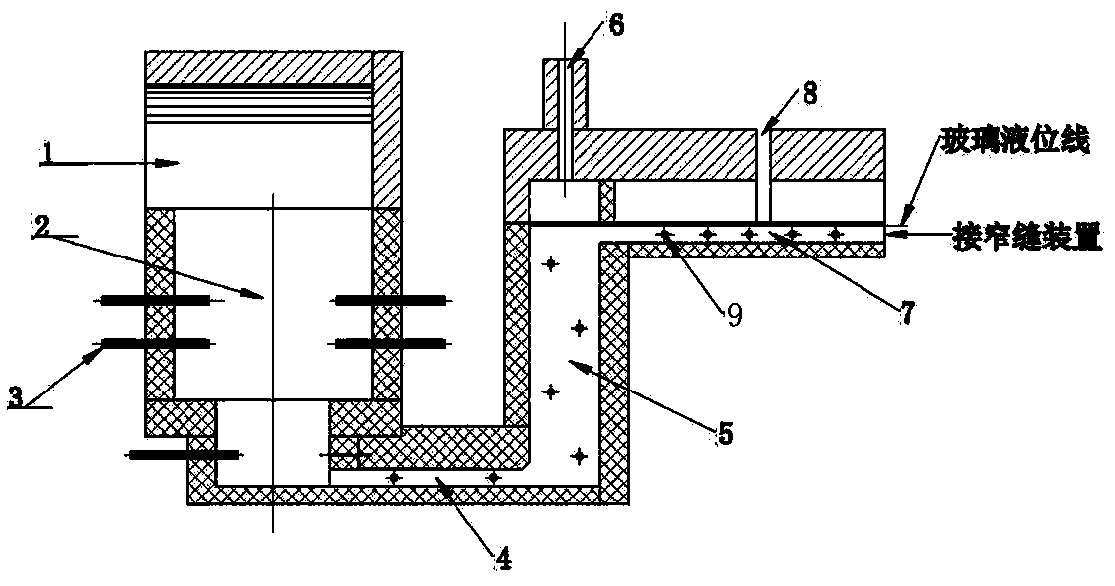

Device for producing crystal glass

InactiveCN103159396AReduce energy consumptionReduce defective rateGlass shaping apparatusGlass productionQuenchingManipulator

The invention relates to a device for producing crystal glass. The device for producing the crystal glass mainly comprises a blast furnace, a compression moulding forming device and a precision quenching device. A support rod of the compression moulding forming device is connected with a support of the blast furnace, and a forming platform of the compression moulding forming device is connected with a support of the precision quenching device. A material melting pond, a sedimentation basin, a work chamber and a discharge pond of the blast furnace are connected in sequence. A discharge port is formed at the lower end of the discharge pond. The compression moulding forming device mainly comprises a pair of scissors, a guide groove, a forming air cylinder, a mechanical arm, a forming platform, a mould, an air pump and a program control circuit controller. The upper end of the guide groove corresponds to the discharge port. The precision quenching device mainly comprises a motor, a conveyer belt, an insulating layer, a heating plate, a temperature sensor and a circuit controller. An opening at the left end of the precision quenching device corresponds to the mechanical arm of the compression moulding forming device. Compared with the prior art, the device for producing the crystal glass has the advantages that the reaction temperature of silicate can be reduced by 20-40 DEG C, energy consumption is reduced by about 10%, the production efficiency is enabled to be improved by more than 30%, and the rate of defective goods is reduced by more than 15 percent points.

Owner:宜城市大平水晶工艺品有限公司

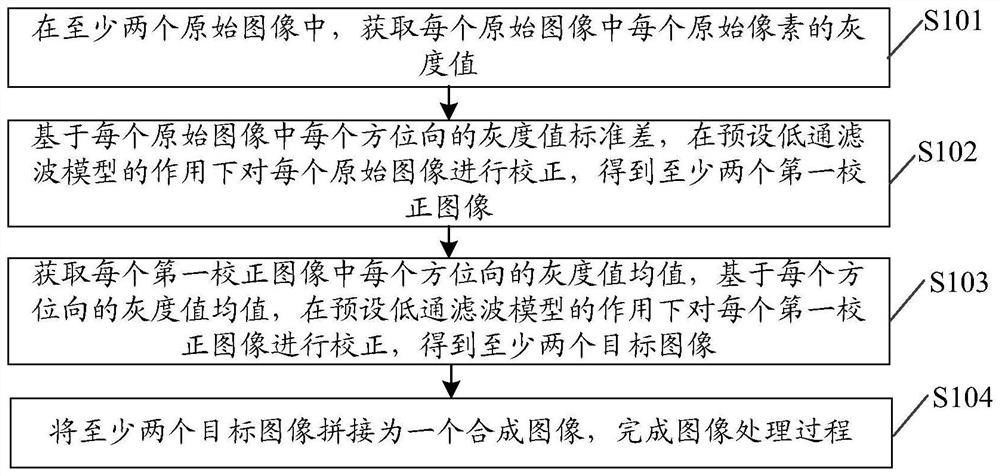

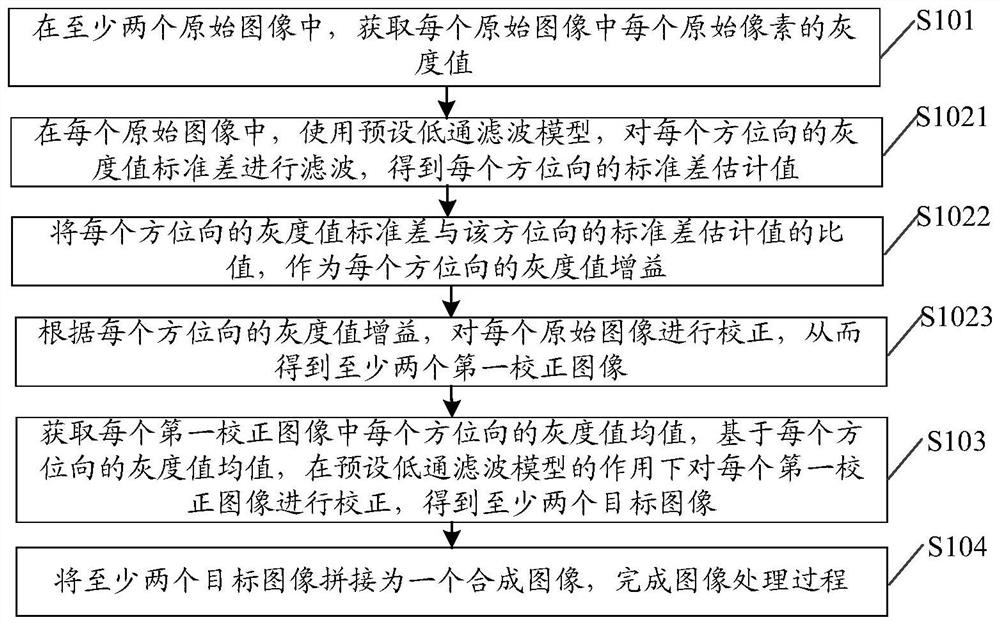

Image processing method and device, electronic equipment and storage medium

ActiveCN111738929AEliminate StreaksImprove image qualityImage enhancementICT adaptationImaging processingComputer graphics (images)

The embodiment of the invention discloses an image processing method and device, electronic equipment and a storage medium, which can improve the image quality of radar imaging. The method comprises the following steps: in at least two original images, obtaining a gray value of each original pixel in each original image; wherein each original pixel is a pixel contained in each original image; based on the gray value standard deviation of each azimuth in each original image, correcting each original image under the action of a preset low-pass filtering model to obtain at least two first corrected images; obtaining a gray value mean value of each azimuth in each first correction image, and correcting each first correction image under the action of a preset low-pass filtering model based on the gray value mean value of each azimuth to obtain at least two target images; and splicing the at least two target images into a composite image to complete an image processing process.

Owner:AEROSPACE INFORMATION RES INST CAS

Production process of PS printing base for high grade printing

ActiveCN1962178AImprove surface qualityEliminate StreaksRoll mill control devicesFurnace typesSurface patternIngot

The invention relates to a method for producing PS version base of print, wherein it comprises: 1, using 1060, 1070, 1050, or 1052 alloy as material to cast alloy cast ingot, thermally rolling it into 2.0-7.0mm; 2, first cold rolling into 2.0-4.0mm, completing 30% of cold process; 3, at 300-450Deg. C, completely annealing for 12-20h; 4, secondly cold rolling to 0.8-1.0mm, and thirdly cold rolling to 0.4-0.5mm; 5, at last, cold rolling to 0.27mm, bending, packing, obtaining the final product. The invention can significantly eliminate the surface pattern, improve the surface quality, and improve the strength.

Owner:CHINALCO RUIMIN

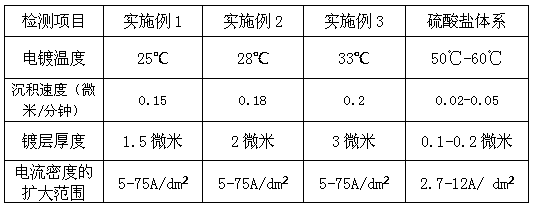

Sulphate trivalent chromium electroplating pollution as well as preparation process thereof and electroplating process thereof

The invention relates to a sulphate trivalent chromium electroplating pollution which comprises conductive salt, a preparation A, a preparation B, a preparation C, a preparation D, a wetting agent andpure water. At the normal temperature of 25-40 DEG C, an electroplated workpiece can be adopted to obtain a trivalent chromium coating with good appearance, and the thickness of the coating can be 1micron or more; the electroplated workpiece is strengthened in corrosion resistance, hardness, electrical conductivity, smoothness, heat resistance and wear resistance; a deposition rate of a chromiumlayer is 0.1-0.2 micron per minute; and electric energy can be saved, and use cost can be reduced in case of guaranteeing process quality. The Lab colour of the coating can be freely regulated withina range of L being greater than 65 and smaller than 80, a being greater than (-)1 and smaller than 1, and b being greater than 2 and smaller than 6, so that the colour of the coating can be regulatedto be brownish black from sliver, and the coating has the advantages of being good in stability, strong in covering power, good in uniform-coating ability and environmentally friendly.

Owner:陈建平

Driving method of display panel

InactiveCN109754769AImprove charging effectEliminate StreaksStatic indicating devicesMultiplexingSmall pulse

The invention provides a driving method of a display panel. The driving method of the display panel is arranged in each line scanning period. A plurality of multiplexed signals sequentially generate ahigh-potential pulse according to a preset sequence; in the same line scanning period; a plurality of high-potential pulses generated by the plurality of multiplexed signals have at least two different pulse widths; and the high-potential pulse with the large pulse width is generated after being compared with the high-potential pulse with the small pulse width, so that the charging uniformity ofthe sub-pixels is improved by increasing the pulse width of the generated high-potential pulse, the stripe feeling of a picture displayed by the display panel is eliminated, and the display quality isimproved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

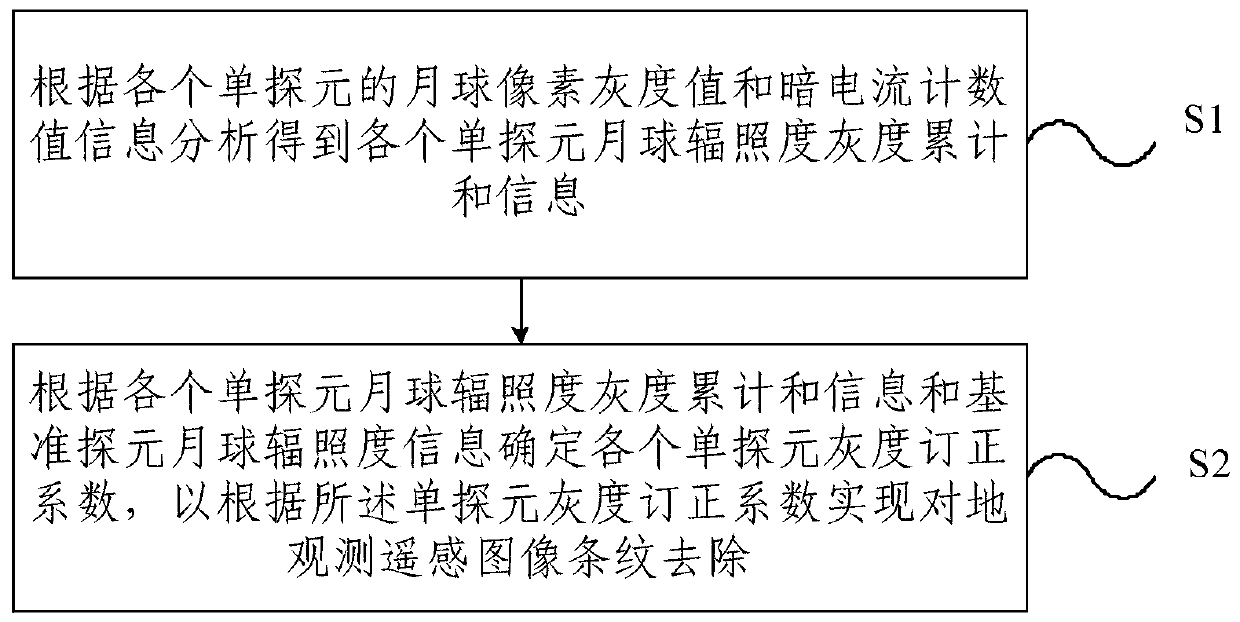

Remote sensing image stripe removing method and device

ActiveCN111145118AImprove elimination effectEliminate StreaksImage enhancementImage analysisEarth observationObservation data

The embodiment of the invention provides a remote sensing image stripe removing method and device. The remote sensing image stripe removing method comprises the steps of: analyzing moon pixel gray value and dark current count value information of each single probe element to obtain moon irradiance gray cumulative sum information of each single probe element; and determining a gray correction coefficient of each single probe element according to the irradiance gray accumulation sum information of each single probe element and the irradiance information of the reference probe element so as to remove stripes of the earth observation remote sensing image according to the gray correction coefficient of each single probe element. An on-orbit multi-probe remote sensor is used, and the lunar probeis used for observing the lunar, so that the single-probe gray value correction coefficient is calculated according to the observed full-disc observation data of the lunar multi-probe remote sensor,and the gray correction is carried out on the remote sensing image acquired by each single probe according to the single-probe gray value correction coefficient, so that the stripe phenomenon in the original earth observation image is effectively eliminated.

Owner:NAT SATELLITE METEOROLOGICAL CENT

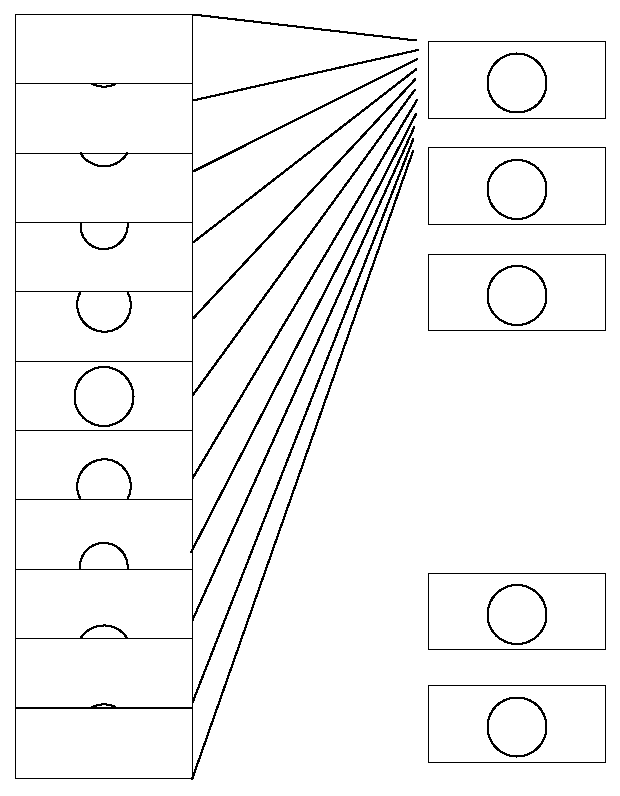

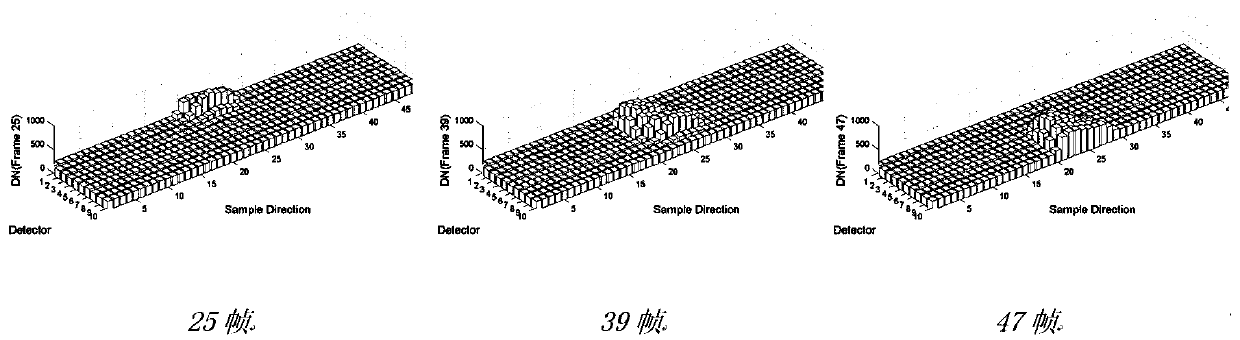

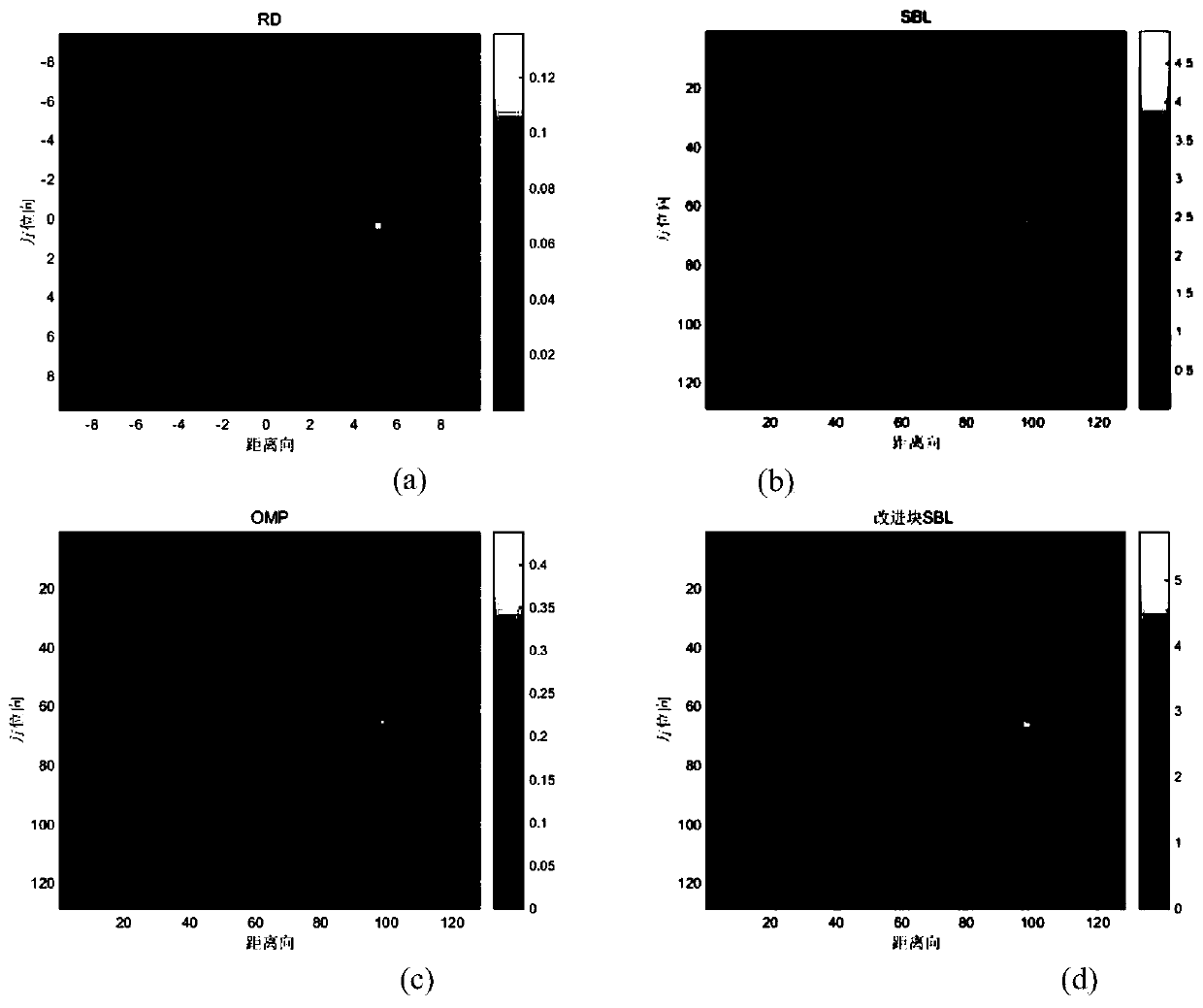

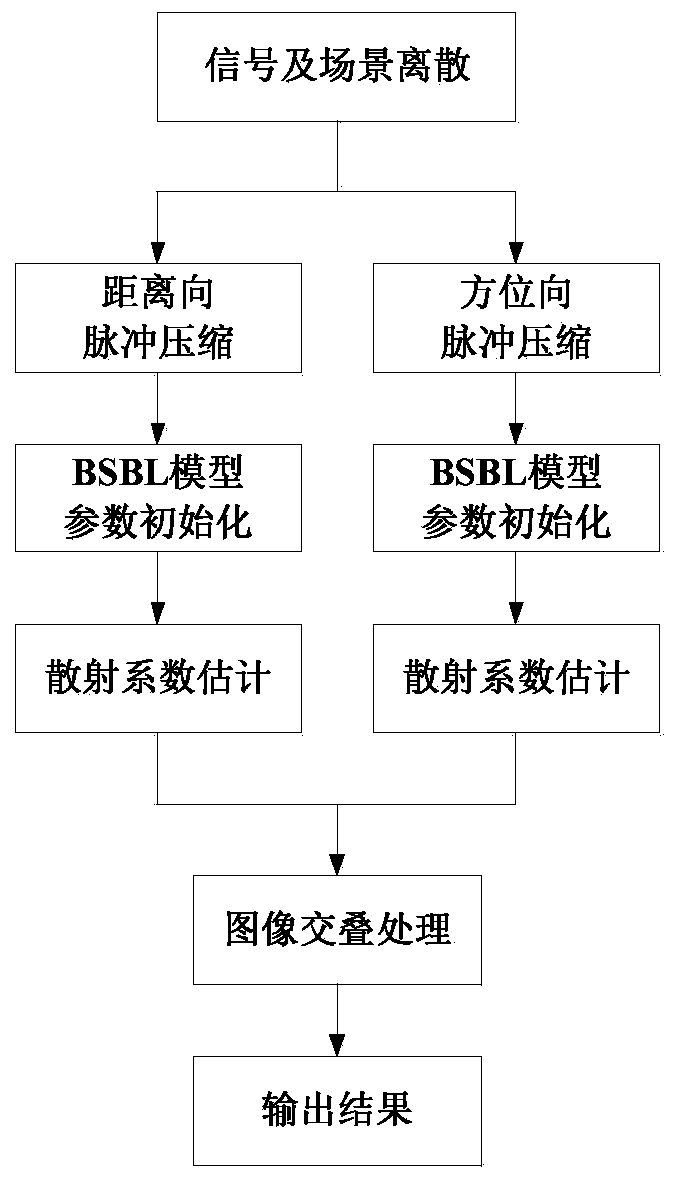

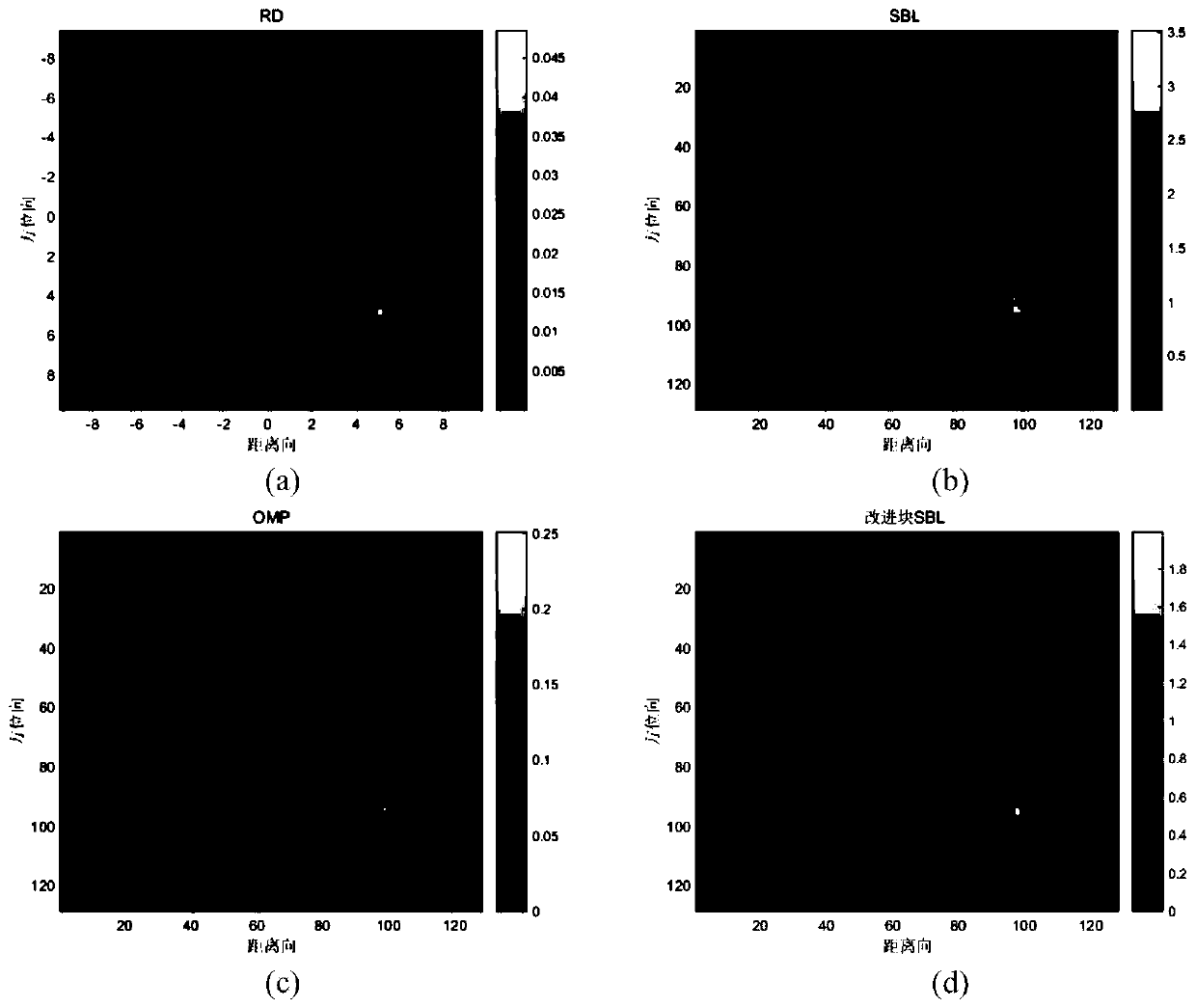

Blocked sparse Bayesian learning ISAR imaging scattering coefficient estimation method

ActiveCN110133647APoint group effect is obviousEliminate streaksRadio wave reradiation/reflectionEstimation methodsLearning methods

The invention provides a blocked sparse Bayesian learning ISAR imaging scattering coefficient estimation method. The method comprises the following steps: firstly discretizing a radar echo spectrum model and a two-dimensional imaging scene, and then performing distance-dimensional pulse compression processing on the echo spectrum; accomplishing scattering coefficient estimation by utilizing the block sparse Bayesian learning method, performing transition on an echo spectrum matrix, and performing orientation-dimensional pulse compression processing, and accomplishing the scattering coefficientestimation by utilizing the block sparse Bayesian learning method; and finally, taking intersection of two estimation results to operate, and obtaining a final two-dimensional ISAR imaging result. Through the method provided by the invention, the operation complexity is greatly reduced, the operand is reduced, the fringe interference in the image is successfully eliminated, an imaging effect is improved, and the scattering coefficient estimation precision is improved.

Owner:SOUTHEAST UNIV

Driving method of display panel

InactiveCN109859712AEliminate StreaksImprove display qualityStatic indicating devicesMultiplexingEngineering

The invention provides a driving method of a display panel. The driving method of the display panel comprises the following steps: enabling a first multiplexing signal, a second multiplexed signal, athird multiplexed signal, a fourth multiplexed signal, a fifth multiplexing signal and a sixth multiplexing signal to sequentially generate high-level pulses according to a first sequence in a first picture frame; enabling the first multiplexing signal, The second multiplexed signal, the third multiplexed signal, the fourth multiplexed signal, the fifth multiplexed signal and the sixth multiplexedsignal to sequentially generate high-level pulses according to a second order different from the first order in the second picture frame, so that the stripe feeling of a picture displayed by the display panel is eliminated through effect superposition of the first picture frame and the second picture frame, and the display quality is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

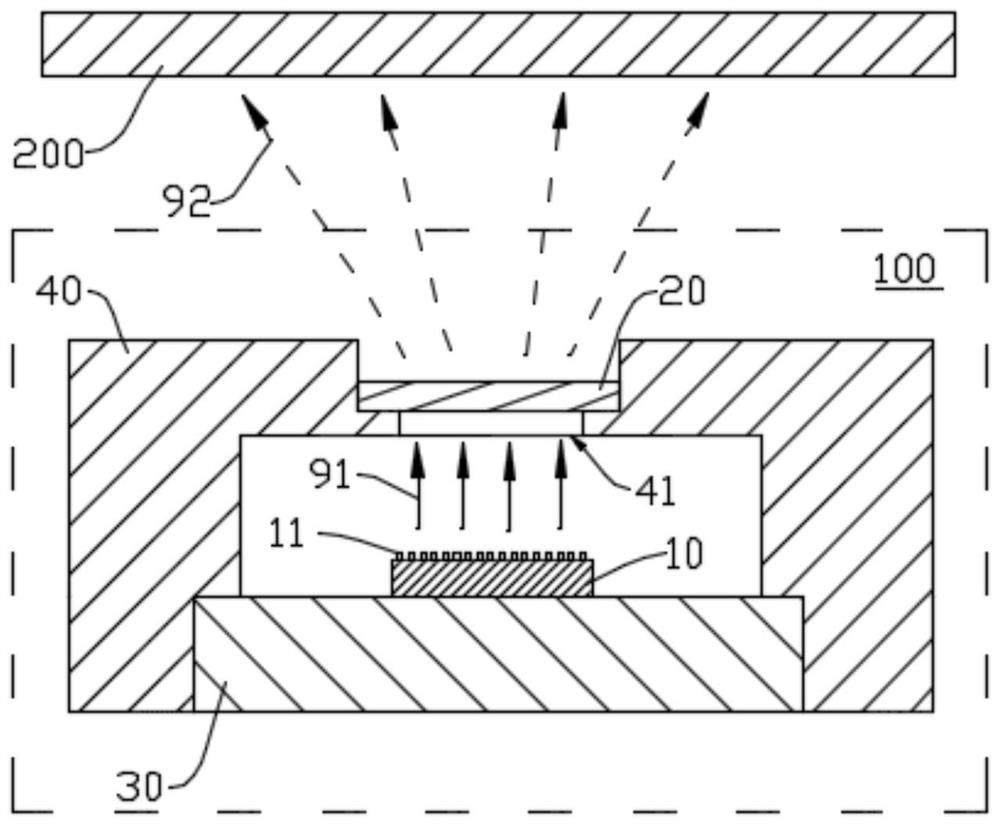

Light homogenizing structure for optical lens

The invention relates to a light homogenizing structure for a single optical lens. The structure comprises a substrate, a light source chip, an adhesive layer and a microlens layer, wherein the adhesive layer is arranged on one surface of the substrate; the microlens layer is arranged on the adhesive layer; an air layer is arranged between the microlens layer and the light source chip; the microlens layer is formed by randomly distributing a plurality of microlenses on the adhesive layer. According to the light homogenizing structure for the optical lens, the thickness of a TOF module can be controlled within 2mm as a whole, so that the light homogenizing structure can be applied to miniaturized equipment; the structure can well remove the striation phenomenon of periodic and micro-periodic microlens arrays, and maintain uniform transition of light fields; the overall filling coefficient of the surface type can reach 99%, so that the maximum utilization rate of incident light beams isensured, and the best light field effect is achieved; and the joint has no cross section, so that the processing difficulty of the mother board gray scale mask and product nano-imprinting is reduced,the possibility of residual glue on the template is reduced, and the overall processing precision and efficiency are improved.

Owner:宁波舜宇奥来技术有限公司

Driving method for display panel

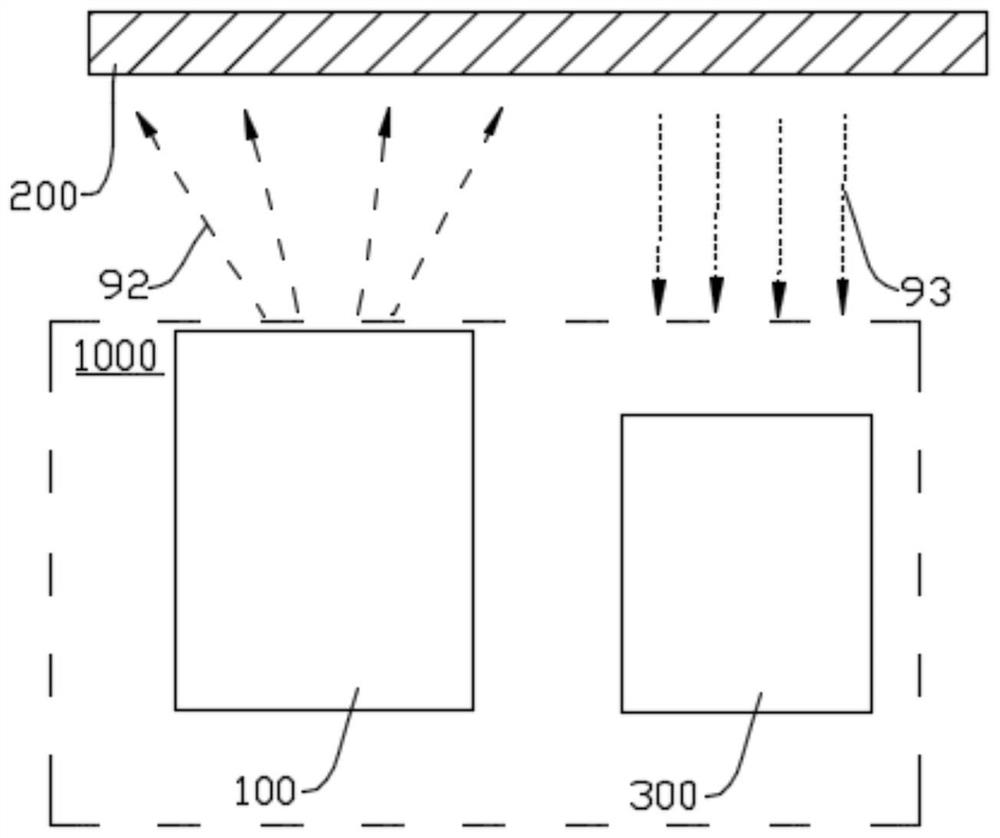

ActiveUS20200302846A1Eliminate stripesImprove display effectStatic indicating devicesEngineeringElectrical and Electronics engineering

A driving method for a display panel is through making the first demultiplexing signal, the second demultiplexing signal, the third demultiplexing signal, the fourth demultiplexing signal, the fifth demultiplexing signal and the sixth demultiplexing signal according to the first sequence generate the high-level pulse in the first image frame, and through making the first demultiplexing signal, the second demultiplexing signal, the third demultiplexing signal, the fourth demultiplexing signal, the fifth demultiplexing signal and the sixth demultiplexing signal according to the second sequence different from the first sequence generate the high-level pulse in the second image frame, thereby by adding the effect of the two image frames to eliminate stripes on the images displayed by the display panel to improve the display effect.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

Light emitting module, depth camera and electronic equipment

InactiveCN112866508AHigh precisionImprove uniformityTelevision system detailsColor television detailsVertical-cavity surface-emitting laserLight spot

The invention provides a light emitting module, a depth camera and electronic equipment. The light emitting module comprises a vertical cavity surface emitting laser and a light uniformizing sheet, the vertical cavity surface emitting laser is used for emitting first light to the light uniformizing sheet, the light uniformizing sheet is used for diffusing the first light and uniformly emitting second light to a target object, the vertical cavity surface emitting laser comprises a plurality of light emitting units, the light equalizing sheet is provided with a plurality of micro lenses, and the plurality of light emitting units and / or the plurality of micro lenses are arranged randomly. By reasonably arranging the structures of the vertical cavity surface emitting laser and the light equalizing sheet, the light emitting module emits the second light capable of collecting the information of the target object. Meanwhile, by adopting the random arrangement mode of the multiple light emitting units and / or the multiple micro lenses, resonance is avoided, so that stripes of projected light spots are improved and eliminated, and the light emitting efficiency is improved. The precision of the obtained depth information and the overall uniformity of the image are improve. The invention can be applied to a TOF high-precision application scene.

Owner:NANCHANG OUFEI BIOLOGICAL IDENTIFICATION TECH

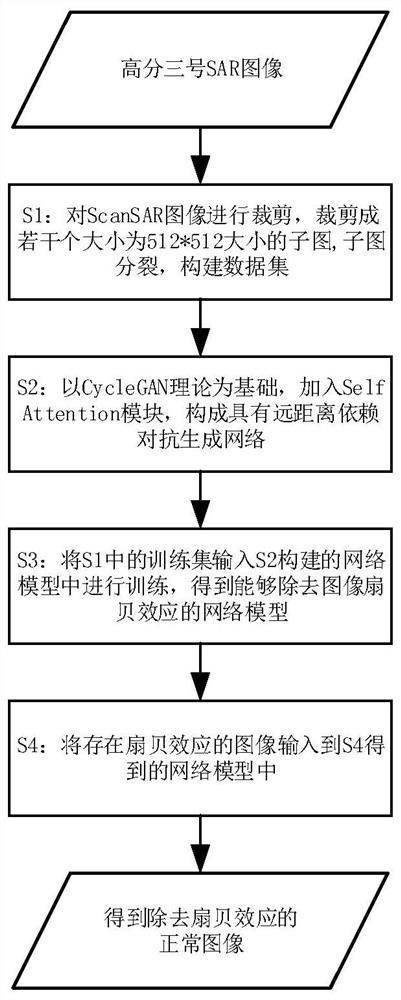

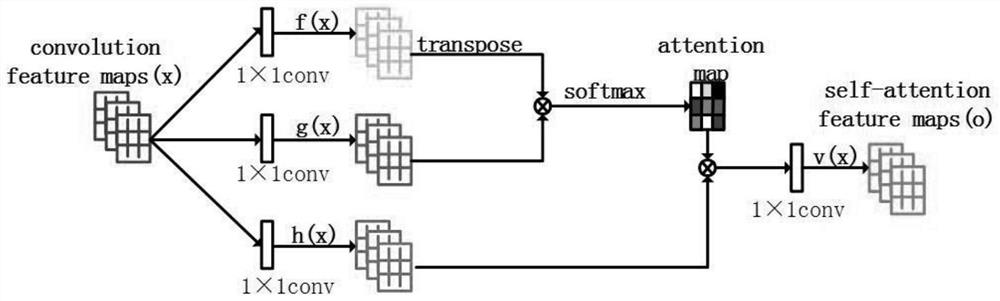

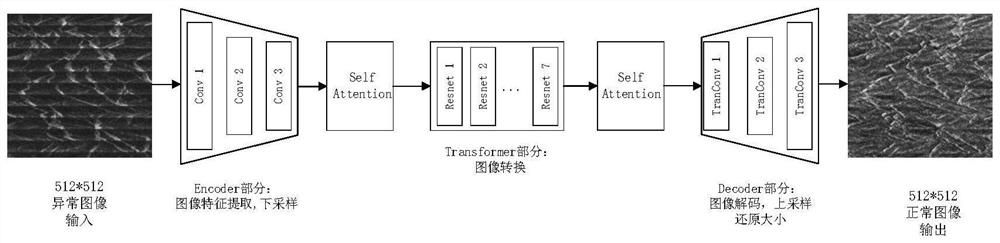

ScanSAR image scallop effect inhibition method based on self-attention mechanism and CycleGAN

PendingCN113822895AEliminate StreaksImprove image qualityImage enhancementImage analysisPattern recognitionData set

The invention provides a ScanSAR image scallop effect suppression method based on a self-attention mechanism and a CycleGAN. The method comprises the following steps: S1, constructing a ScanSAR image data set; S2, constructing an adversarial generative network model; S3, inputting the data set into the constructed neural network model for training; and S4, inputting the ScanSAR image with the scallop effect into the network model trained in the step 3. According to the ScanSAR image scallop effect suppression method based on the self-attention mechanism and the CycleGAN, the scallop effect of the ScanSAR image is processed. On the basis of the CycleGAN, a novel cyclic consistent adversarial generative network model with long-distance dependence is formed by combining a self-attention mechanism. The method has the capability of more effectively eliminating the scallop effect fringe phenomenon of the image, so that the image quality is obviously improved.

Owner:SHAANXI NORMAL UNIV

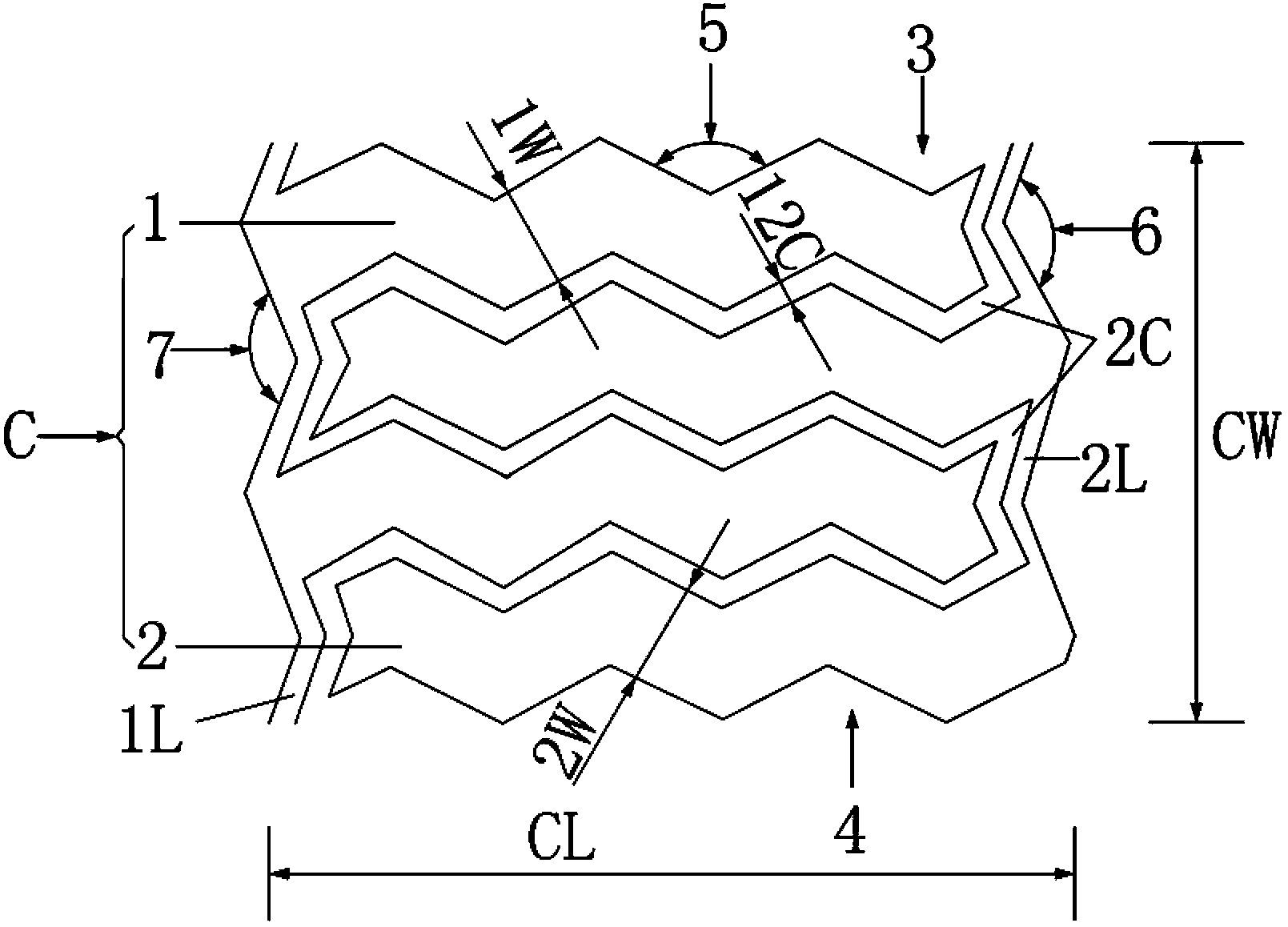

Capacitive touch screen and single-layer wiring electrode array

ActiveCN103576998BImprove the display effectEliminate StreaksDigital data processing detailsInput/output processes for data processingCapacitanceWave shape

Disclosed are a capacitive touch screen and a single layer wiring electrode array. The single layer wiring electrode array includes capacitive regions and wiring regions located on one plane. Wires in the wiring regions are zigzag-shaped or wave-shaped. The capacitive touch screen includes a substrate; a single layer wiring electrode array disposed over the substrate, wherein the single layer wiring electrode array includes capacitive regions and wiring regions located on one plane and wires in the wiring region are zigzag-shaped or wave-shaped; and control ports for connecting to one or more integrated circuits, wherein the wires in the wiring regions are connected to the control ports respectively. The single layer wiring electrode array and the capacitive touch screen lower the fabrication cost and improve the display effects.

Owner:SILEAD

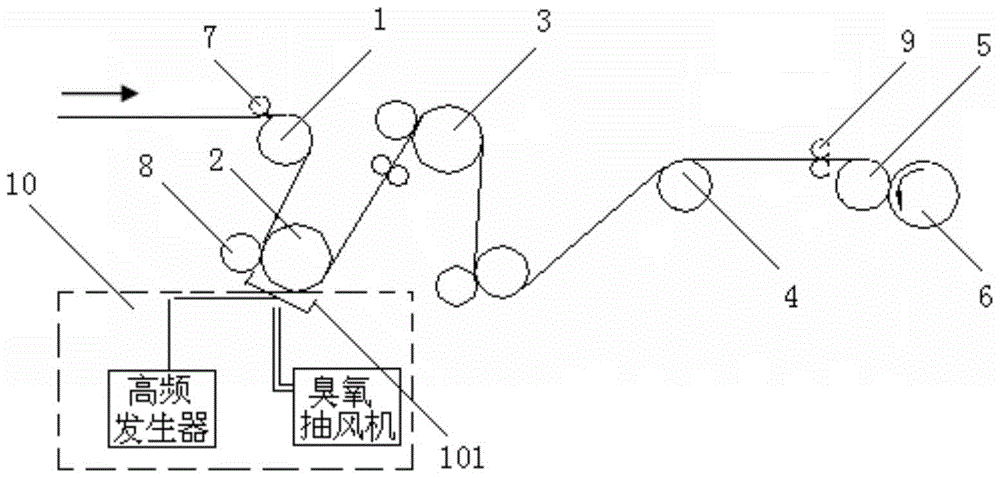

A kind of winding device and winding method for preventing bopp film from running edge

The invention provides a rewinding device and a rewinding method for preventing BOPP film from running sideways. A corona treatment device is set, including a high-frequency generator connected to the linear electrode and an ozone exhaust fan connected to the vicinity of the corona treatment roller; adjusting the distance between the linear electrode and the corona treatment roller, and setting the temperature of the cooling roller; At the beginning of double-station interchange of rolls, open the corona treatment device, let the linear electrode perform weak corona treatment on the film passing through the corona roller, and the ozone exhaust fan will suck away the ozone generated by the corona operation; Switch off the corona treatment unit at the end of the station change. The invention increases the friction between the films by applying weak corona treatment to the BOPP film, completely solves the problem of edge running between the roll core and the outer layer when changing rolls, and does not cause the problem of film discoloration and quality degradation.

Owner:ZHANJIANG PACKAGING MATERIAL ENTERPRISES

Down lamp

InactiveCN106545794AExpand the range of exposureSimple structureElectric circuit arrangementsLighting heating/cooling arrangementsEngineeringLight transmission

The invention discloses a down lamp which comprises an inner ring, a rotary ring, an outer ring, a lamp plate arranged in the inner ring, LED chips and light-transmission diffusion plates. The front and the back of the inner ring are separately connected with the diffusion plates. The front and the back of the lamp plate are separately provided with the LED chips which are located in an accommodation cavity formed by the diffusion plates, the inner ring and the lamp plate. The inner ring, the rotary ring and the outer ring are coaxially matched. The rotary ring is arranged between the inner ring and the outer ring. The inner ring and the rotary ring are movably connected to enable the inner ring to swing around the joint. The rotary ring and the outer ring are in clamped connection to enable the rotary ring to rotate around the center axis Z. According to the down lamp adopting the structure, the illumination range of LED light sources is widened by combining the rotary ring which can rotate by 360 degrees and the structure that an existing inner ring can swing in a certain angle range, and the down lamp is simple in structure and convenient and fast to manufacture and assemble.

Owner:中山市荣亮照明有限公司

A method for elimination of the stripe between the bands

ActiveCN100515086CSuitable for real-time workEliminate StreaksTelevision systemsDigital video signal modificationComputation complexityImaging quality

This invention relates to one method to remove band gap beam, which comprises the following steps: a, only adopting one band to remove band gap beam; then computing one frame of image adjacent two band boundary parameter QP values and limiting the band inside macro block QP values to remove band gap seam in B and P frames. This invention provides one method to completely remove the beam to improve subject image quality.

Owner:SHANGHAI GMT DIGITAL TECH

Glass mobile phone rear cover plate one-step pressure forming all-electric melting glass furnace and method

InactiveCN110372176AEliminate StreaksOptimize layoutGlass furnace apparatusElectric furnaceVacuum pumpingGlass furnace

The invention relates to a glass mobile phone rear cover plate one-step pressure forming all-electric melting glass furnace. An electric heating melting device is fixed to the inner wall of a glass melting device, a feeding device is installed at the top of the glass melting device, the bottom of the glass melting device is connected with a horizontally arranged feeding channel, the other end of the feeding channel is connected with a vertically upward arranged secondary homogenization and clarification device, the top of the secondary homogenization and clarification device is connected witha horizontal glass liquid conveying device, and a vacuum pumping device is arranged at the connection position between the secondary homogenization and clarification device and the glass liquid conveying device. The glass mobile phone rear cover plate one-step pressure forming all-electric melting glass furnace has the following beneficial effects that the mixture added by the feeding device is fused at high temperature under the action of the electric heating melting device, and the melting temperature can reach 1650-1680 DEG C, and the fused glass is refractory glass, mainly because the aluminum oxide content in the composition of the fused glass is up to 17%, and the melting temperature is required to be above 1650 DEG C, and the glass is kept at high temperature for a long time, fringes in the glass liquid are eliminated, and homogenized glass liquid is formed.

Owner:SHANDONG LEHE HOUSEWARES CO LTD

Plastic uptake molding method for plastic packaging box and plastic uptake mold

The invention discloses a plastic uptake molding method for a plastic packaging box and a plastic uptake mold. The molding method mainly comprises the steps of material taking, softening, feeding, vacuumizing, cooling and shaping, mold dismounting and cutting molding. The plastic uptake mold is adopted for plastic uptake molding of the plastic packaging box and can effectively eliminate stripes and reduce the situation of uneven thickness; the plastic uptake mold has the advantages that the molding speed is high, shaping is convenient, the molding efficiency can be effectively improved, the production cost is reduced, the plastic uptake mold is beneficial to subsequent auxiliary machining of the plastic packaging box, the product quality of the plastic packaging box can be guaranteed, and meanwhile the hand feeling and smoothness of products are improved; and the the plastic uptake mold has the advantages of being simple in structure, convenient to operate and use and the like.

Owner:贵州省仁怀市贵利坊塑料制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com