Capacitive touch screen and single-layer wiring electrode array

A technology of electrode array and single-layer wiring, which is applied to electrical digital data processing, instruments, digital data processing components, etc., can solve the problem of large difference in thickness of insulating layer and metal film, increase of process cost, light transmittance, Problems such as linearity and display effects, etc., to achieve high touch-sensing performance, simple preparation process, and increase the effect of display effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

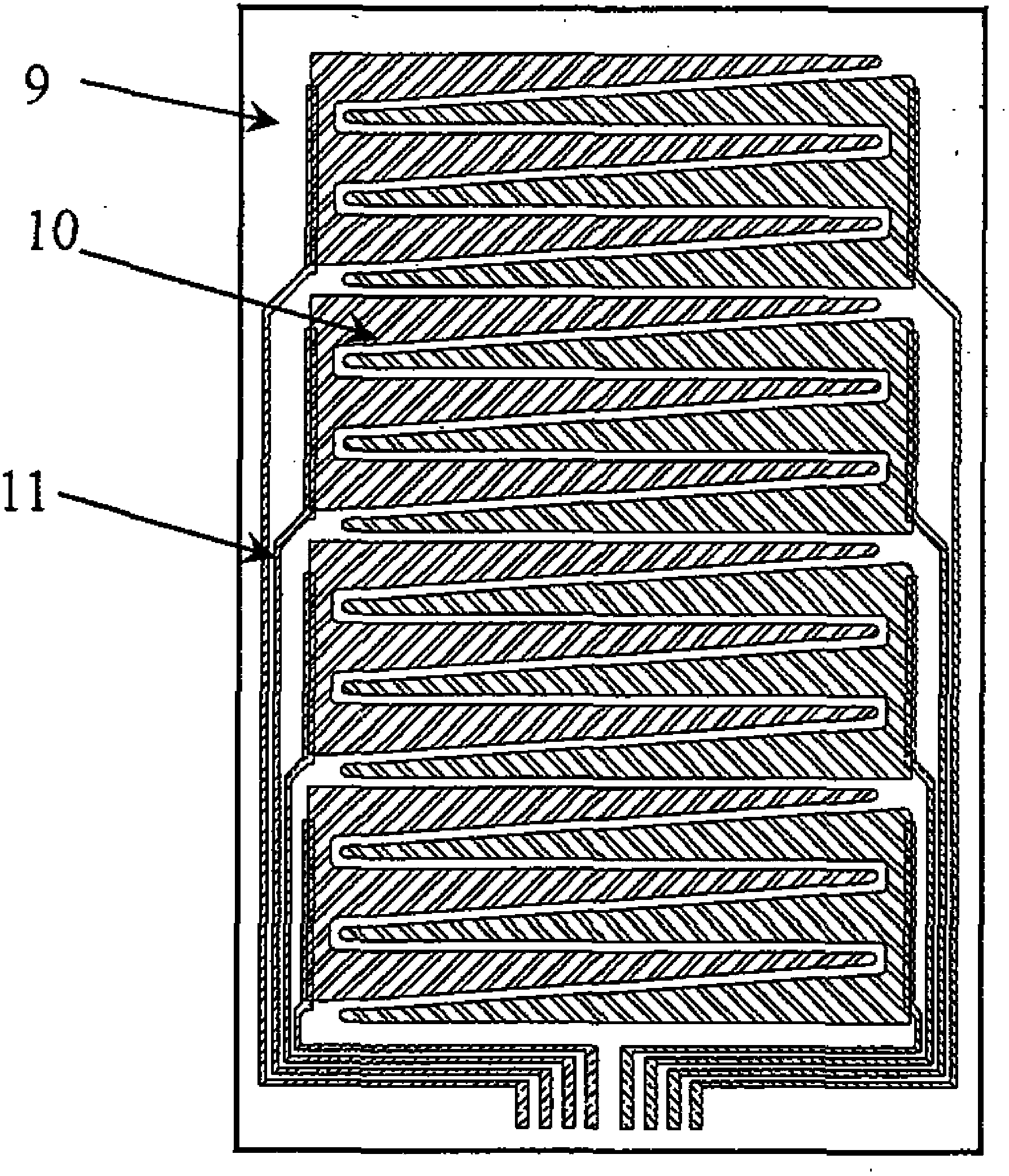

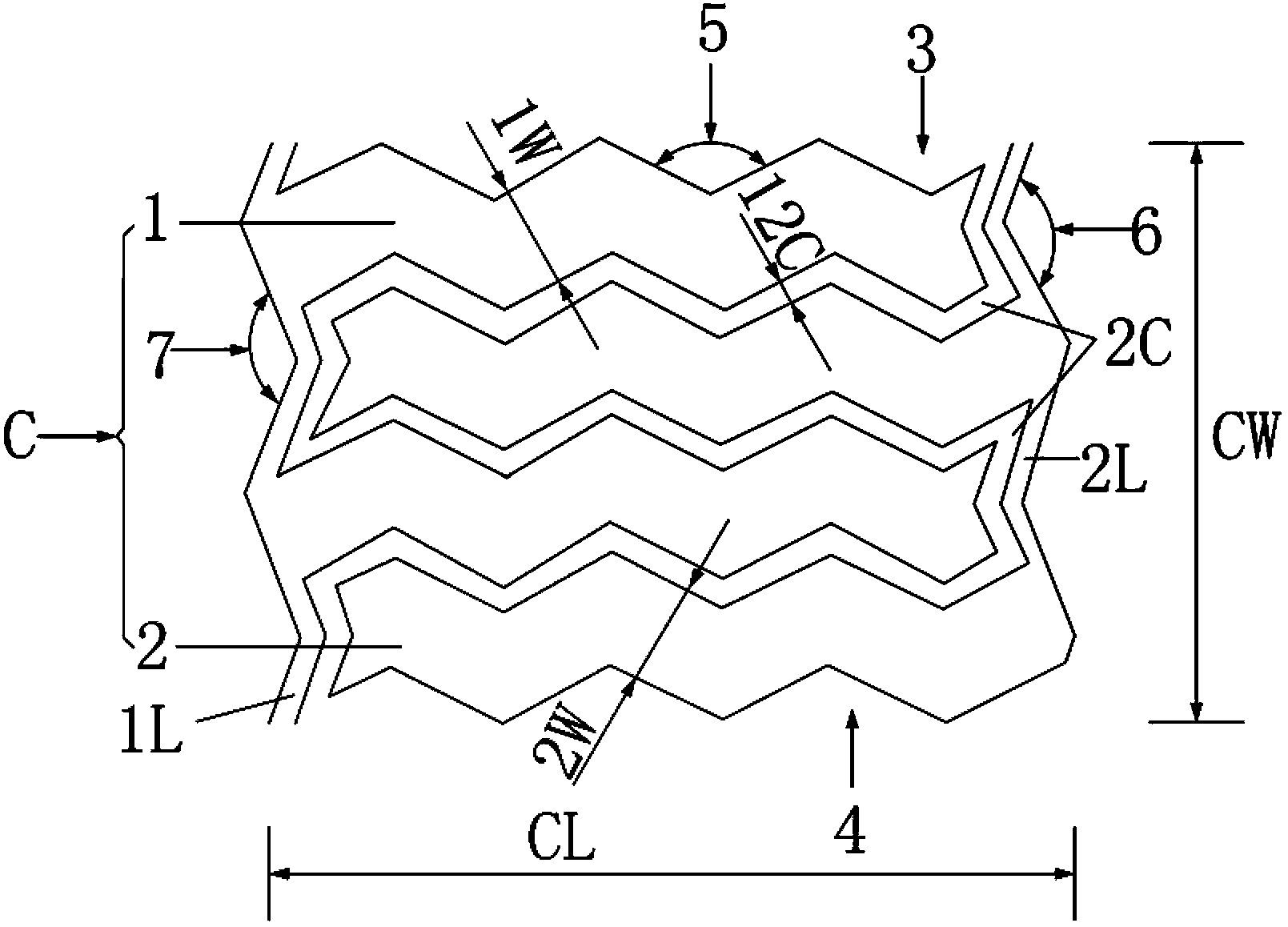

[0051] The technical solutions adopted by the present invention in order to achieve the purpose are further described below in conjunction with the accompanying drawings and the embodiments of the present invention.

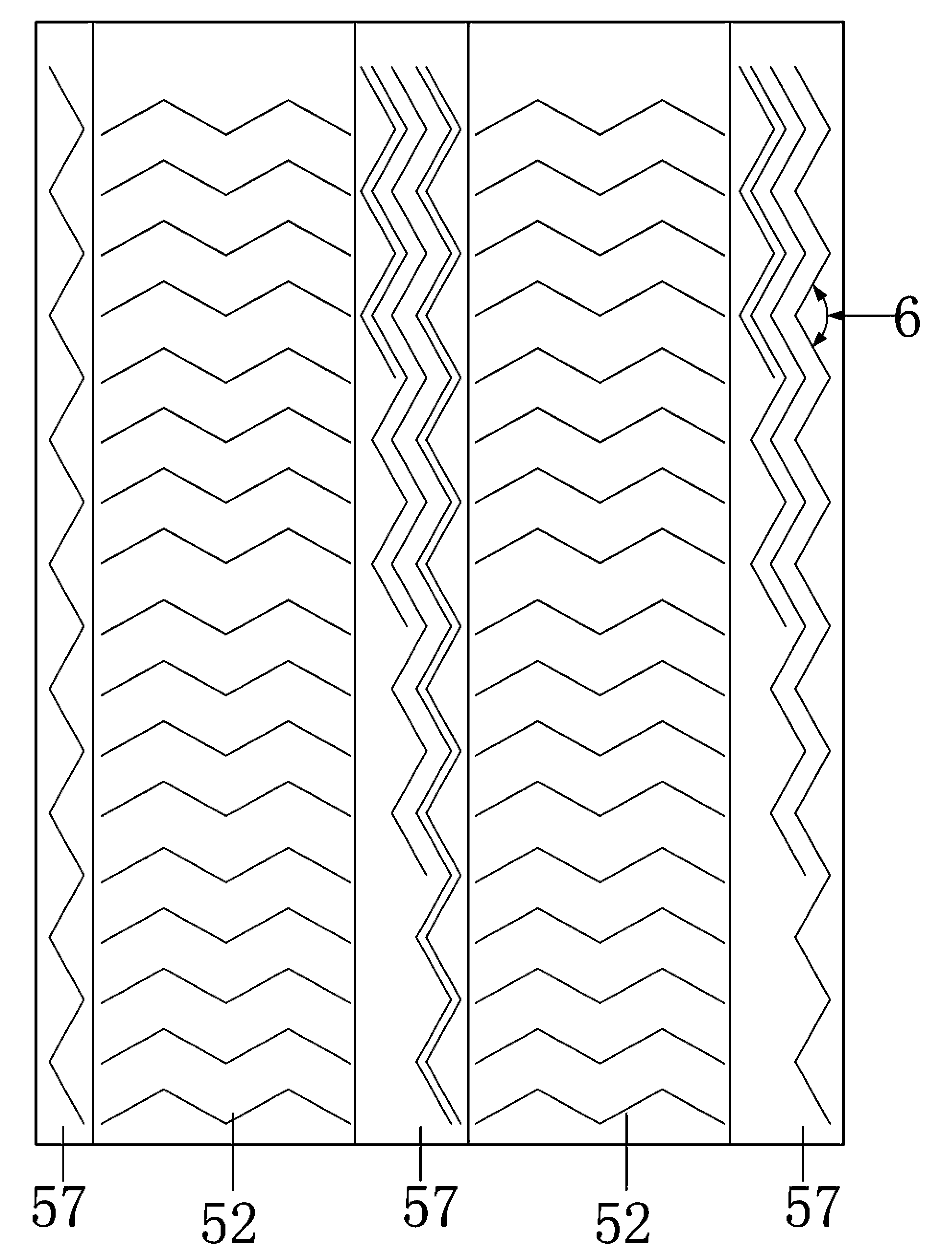

[0052] The invention provides a single-layer wiring electrode array, which includes a capacitor area and a wiring area on a plane, and the wires in the wiring area are zigzag or wavy.

[0053] In one embodiment of the present invention, the capacitor area and the wiring area are arranged at intervals. The capacitor region includes a plurality of unit capacitors arranged in sequence, wherein each unit capacitor includes at least one sensing electrode on a plane and at least one driving electrode opposite to the sensing electrode.

[0054] In a preferred embodiment of the present invention, there is a hollow hole between the sensing electrode and the driving electrode, which can reduce parasitic capacitance.

[0055] In yet another preferred embodiment of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com