A kind of winding device and winding method for preventing bopp film from running edge

A film and edge-running technology, used in thin material handling, transportation and packaging, and sending objects, etc., can solve problems such as increasing friction, and achieve the effects of increasing friction, increasing clearance, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

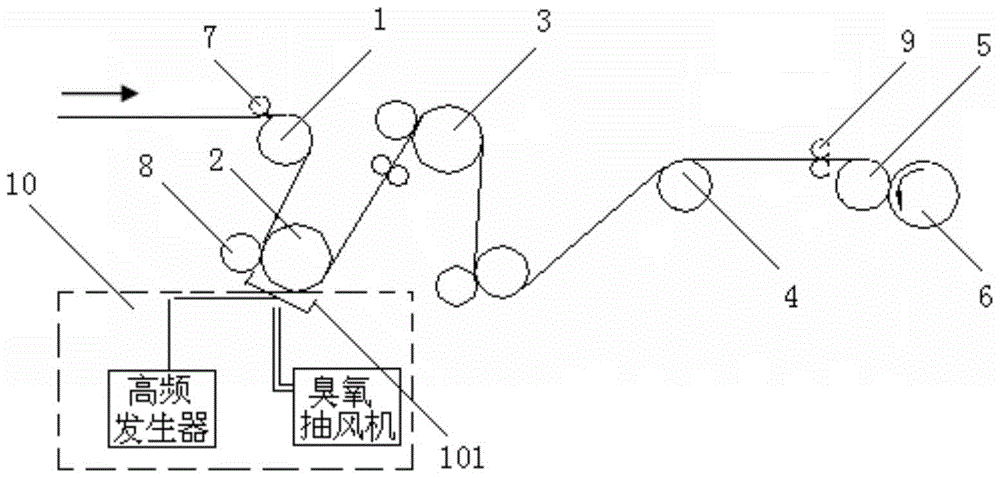

[0018] Such as figure 1 It shows an embodiment of the winding device provided by the present invention to prevent the edge run of the BOPP film, including the cooling roller 1, the lower corona treatment roller 2, the upper corona treatment roller, and the cooling roller 1 arranged in sequence from front to back according to the running direction of the film. Handling roll 3 , tension roll 4 , contact roll 5 and take-up roll 6 . After the diaphragm comes out of the horizontal stretching machine, the temperature is very high. After being cooled by the cooling roller 1, and then corona treated by the corona treatment roller, it reaches the tension roller 4 for tension detection. Take up roll on the winding roller 6. The winding device is also provided with edge flattening rollers 7, nip rollers 8, and expansion wheels 9, etc. as required. They belong to well-known means in the industry. , Floating and other defects are not marked and explained in the figure.

[0019] The coro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com