Light homogenizing structure for optical lens

An optical lens, double-sided structure technology, applied in the field of optical components, can solve the problems of not being able to match the requirements of miniaturization well, not being able to effectively remove stripes, and the volume of the homogenizing device being large, etc., to achieve the best light field effect. , Keep the light field uniform transition, the effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

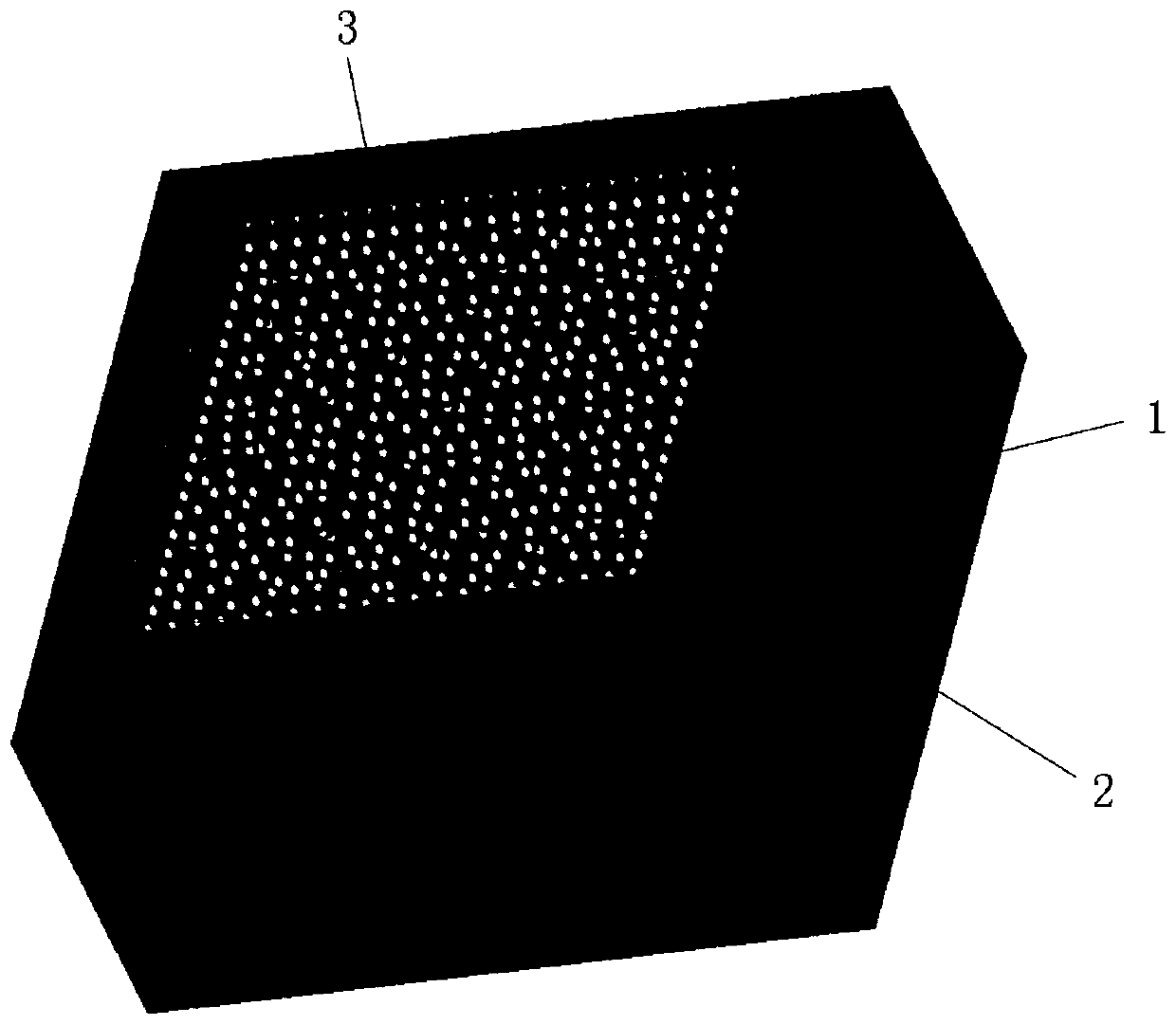

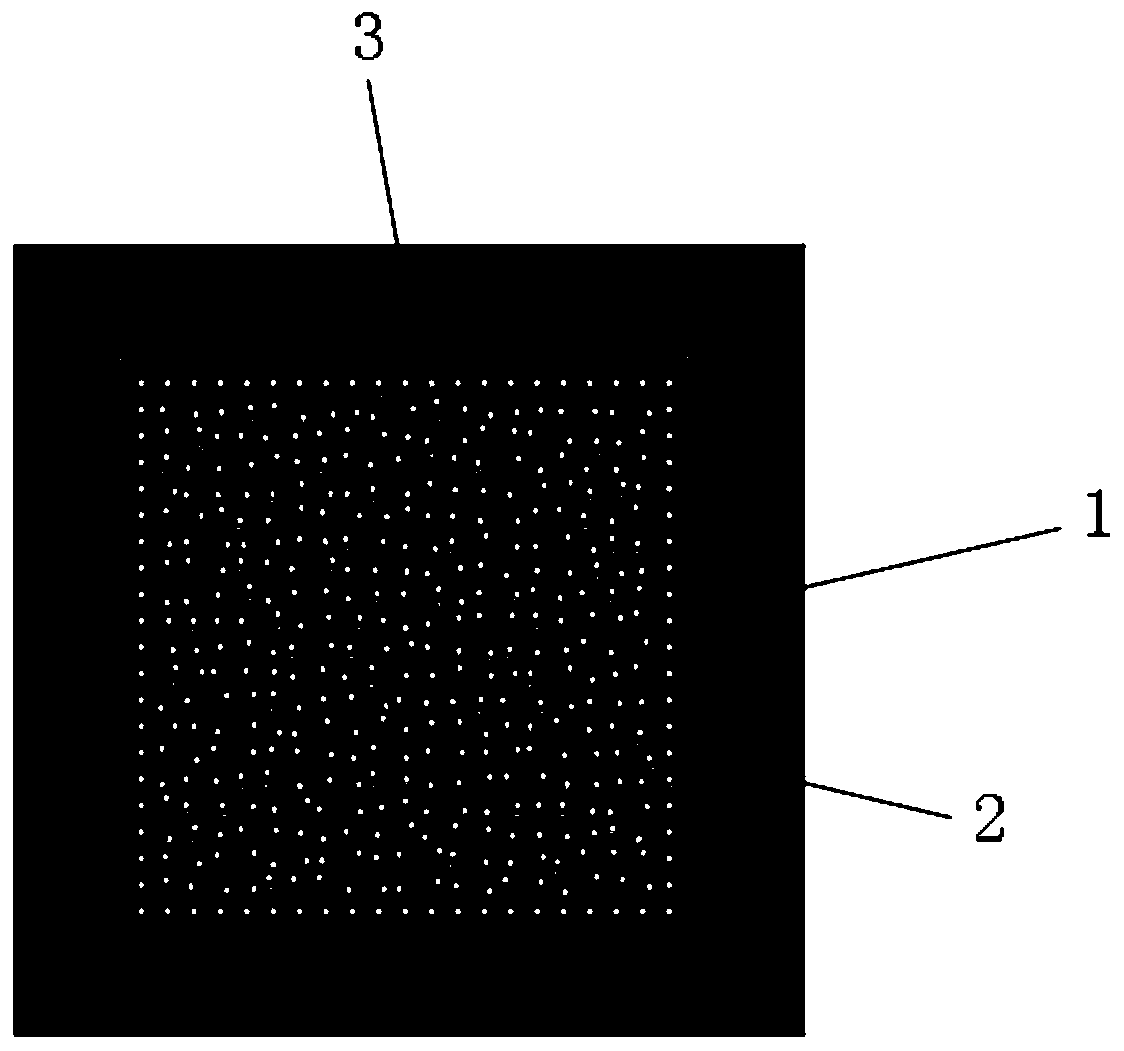

[0063] figure 1 It is a three-dimensional view of a single-sided single-layer convex microlens homogenizer; figure 2 It is the front view of the single-sided single-layer convex microlens homogenizer; image 3 It is a side view of a single-sided single-layer convex microlens homogenizer; Figure 4 An example diagram of the two-dimensional distribution of the center point and shape aperture of the single-sided single-layer convex microlens feature; Figure 5 An example graph of the 2D distribution of microlens features generated for a single-sided single-layer convex 2D center point and shape arrangement; Image 6 It is an example diagram of the three-dimensional structure of the single-sided single-layer convex microlens characteristic; Figure 7 An example diagram of the far-field outgoing light field distribution for random microlenses arranged with a dodging sheet.

[0064] combine Figure 1-Figure 7 In this embodiment, the uniform light structure is a single-sided si...

Embodiment 2

[0069] Figure 8 An example diagram of the two-dimensional distribution of the center point and shape aperture of a single-sided single-layer convex microlens; Figure 9 An example graph of the two-dimensional distribution of microlens features generated for the two-dimensional center point and shape arrangement of a single-sided single-layer convex microlens; Figure 10 It is an example diagram of the three-dimensional distribution of the single-sided single-layer convex microlens structure; Figure 11 It is an example diagram of the cross-section of the characteristic part of the single-sided single-layer convex microlens structure; Figure 12 It is an enlarged example diagram of the voronoi boundary of a part of a single-sided single-layer convex microlens area; Figure 13 An enlarged example of a single-sided single-layer convex microlens structure; Figure 14 An example diagram of the far-field exit angle distribution of the random microlens arrangement homogenizer pro...

Embodiment 3

[0075] Figure 16 It is an example diagram of the three-dimensional distribution of the single-sided single-layer concave microlens structure; Figure 17 It is an example diagram of the cross-section of the characteristic part of the single-sided single-layer concave microlens structure; Figure 18 It is a schematic diagram of the cross-section of the single-sided single-layer concave microlens structure area plus the matrix.

[0076] combine Figure 16-Figure 18 In this embodiment, the uniform light structure is a single-sided single-layer convex microlens structure, including: a substrate, a UV glue layer, a microlens layer, an air layer, a VCSEL light source chip, and a chip fixing substrate on which the light source chip is mounted. In this embodiment, the shape of the microlens is the straight boundary polygon formed by the voronoi boundary, and the center of the microlens is the definition point of the Voronoi boundary. , completely random. The distance between any t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com