Molding process of carbon fiber composite material

A molding process and composite material technology, applied in the field of carbon fiber molding, can solve problems such as wrinkles and streaks, and achieve the effects of smooth surface, improved production efficiency, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

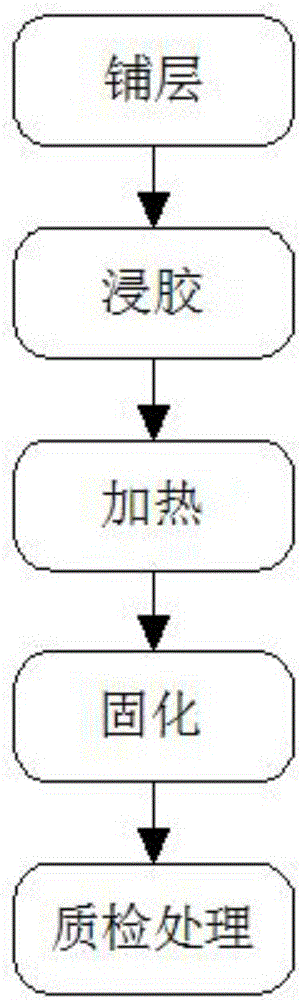

[0020] A carbon fiber composite molding process, including the steps of layer laying, dipping, heating, curing and quality inspection, the carbon fiber composite molding process specifically includes the following steps:

[0021] S1: Layup: In the preforming mold, the carbon fiber is wound and laid in two directions, axial and radial, in which the ratio of carbon fiber axial to radial layers is 3:2, and the size of the preforming mold is 4mm Wide, 0.6m long, 3mm thick, the inner cavity of the mold is provided with a wear-resistant layer, and the outer wall of the wear-resistant layer is polished smooth;

[0022] S2: Glue dipping: The carbon fiber is stretched into the dipping device through the traction mechanism. The carbon fiber is completely immersed in the epoxy resin glue in the dipping device. The roller squeezes out the excess epoxy resin glue on the surface of the carbon fiber, the temperature of the epoxy resin glue is kept at 35°C, the soaking time of the carbon fibe...

Embodiment 2

[0027] A carbon fiber composite molding process, including the steps of layer laying, dipping, heating, curing and quality inspection, the carbon fiber composite molding process specifically includes the following steps:

[0028] S1: Layup: In the preforming mold, the carbon fiber is wound and laid in two directions, axial and radial, in which the ratio of carbon fiber axial to radial layers is 3:2, and the size of the preforming mold is 5mm Wide, 0.8m long, 4mm thick, the inner cavity of the mold is provided with a wear-resistant layer, and the outer wall of the wear-resistant layer is polished smooth;

[0029] S2: Glue dipping: The carbon fiber is stretched into the dipping device through the traction mechanism. The carbon fiber is completely immersed in the epoxy resin glue in the dipping device. The roller squeezes out the excess epoxy resin glue on the surface of the carbon fiber, the temperature of the epoxy resin glue is kept at 40°C, the soaking time of the carbon fibe...

Embodiment 3

[0034] A carbon fiber composite molding process, including the steps of layer laying, dipping, heating, curing and quality inspection, the carbon fiber composite molding process specifically includes the following steps:

[0035] S1: Layup: In the preforming mold, the carbon fiber is wound and laid in two directions, axial and radial, in which the ratio of carbon fiber axial to radial layers is 3:2, and the size of the preforming mold is 8mm Width, 1.2m long, 6mm thick, the inner cavity of the mold is provided with a wear-resistant layer, and the outer wall of the wear-resistant layer is polished smooth;

[0036] S2: Glue dipping: The carbon fiber is stretched into the dipping device through the traction mechanism. The carbon fiber is completely immersed in the epoxy resin glue in the dipping device. The roller squeezes out the excess epoxy resin glue on the surface of the carbon fiber, the temperature of the epoxy resin glue is kept at 50°C, the soaking time of the carbon fib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com