Machining process of peach skin cotton fabric

A processing technology and cotton wool technology, applied in the direction of fabric surface trimming, spray/jet textile material treatment, biochemical fiber treatment, etc., can solve the problems of poor dyeing effect, wrinkling, production difficulties, etc. Delicate and clear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take the fabric C40*80 / 2+40D 275*150 42 / 3" three-layer elastic fabric as an example

[0024] 1) Seam turning: Align both sides of the seam head, encrypt both ends, tear the head, and reduce the thickness of the seam head as much as possible.

[0025] 2) singeing:

[0026] Process: speed 110 m / min

[0027] Fire mouth: two pros and one reverse

[0028] Flame temperature 950 degrees Celsius

[0029] Singeing quality: 4 grades.

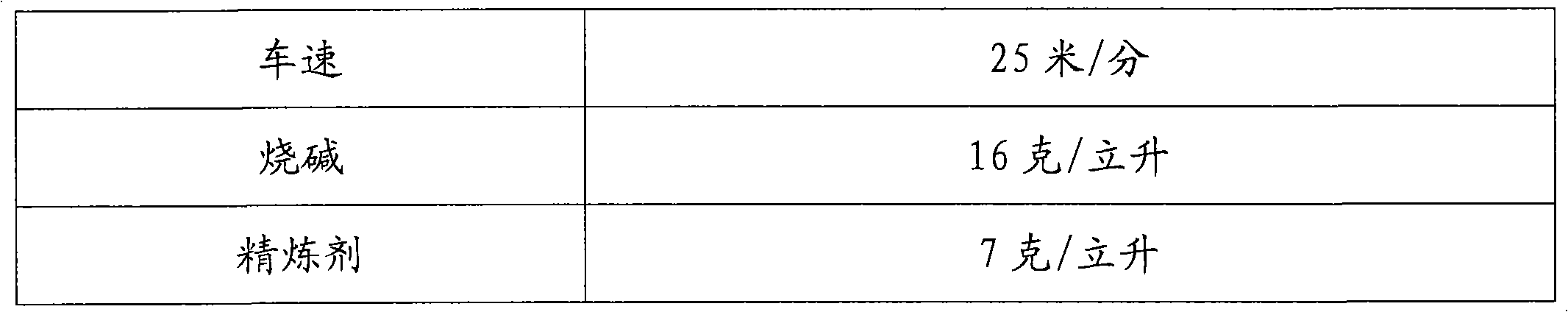

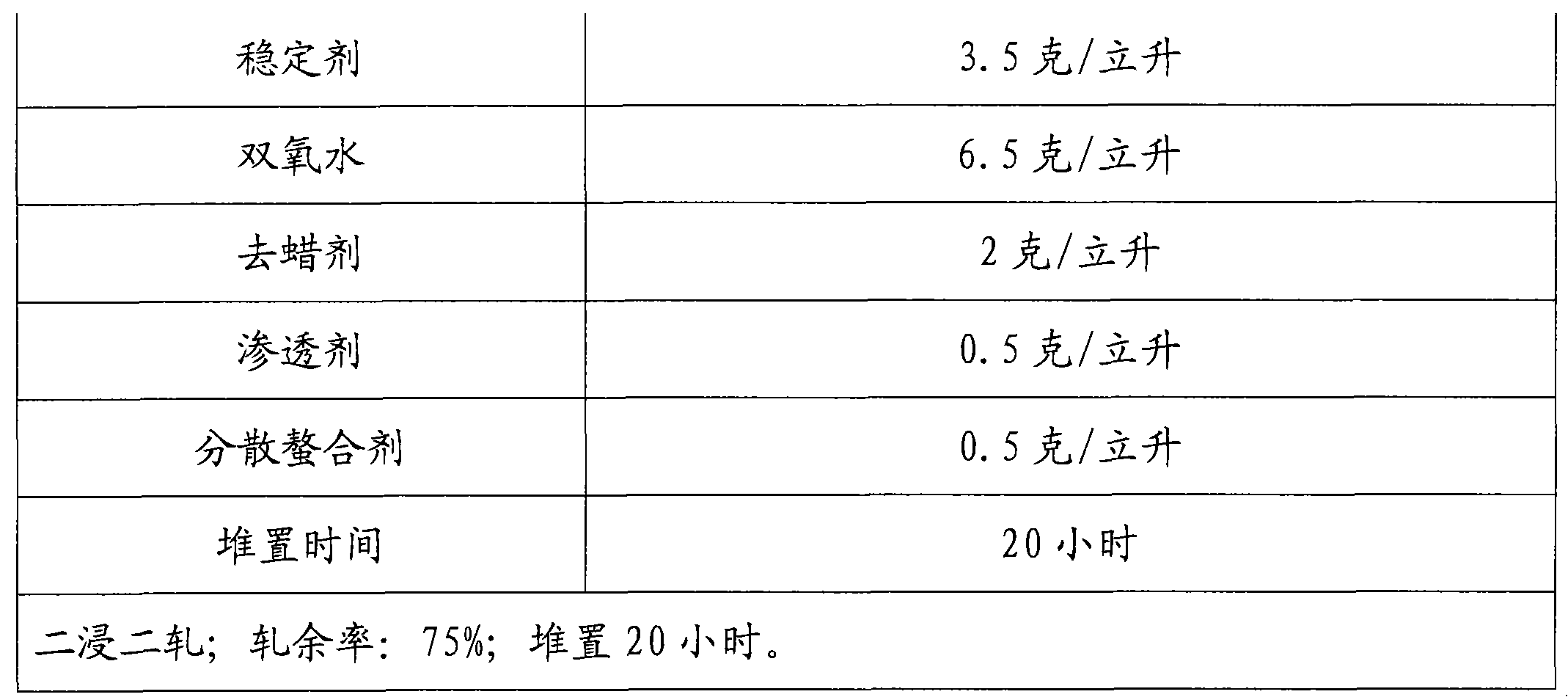

[0030] 3) Cold pile: low-alkali room temperature treatment.

[0031] Process:

[0032]

[0033]

[0034] 4) Rebleaching of jigger:

[0035] Process:

[0036] caustic soda

4.5g / liter

5g / liter

cooking agent

5g / liter

Detergent

4.5g / liter

penetrant

0.5g / liter

stabilizer

4g / liter

[0037] Dispersed Chelating Agent

0.5g / liter

time

90℃*1 hour

speed

80m / min

[0038] 5) Loose drying:

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com