Hollow capsule made of konjak

A hollow capsule, konjac technology, applied in the direction of capsule delivery, medical preparations with inactive ingredients, pharmaceutical formulas, etc., can solve the problems of hardening, unsafe hidden dangers, and not easy to disintegrate, and achieves increased viscosity, stable bonding, and strengthened bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

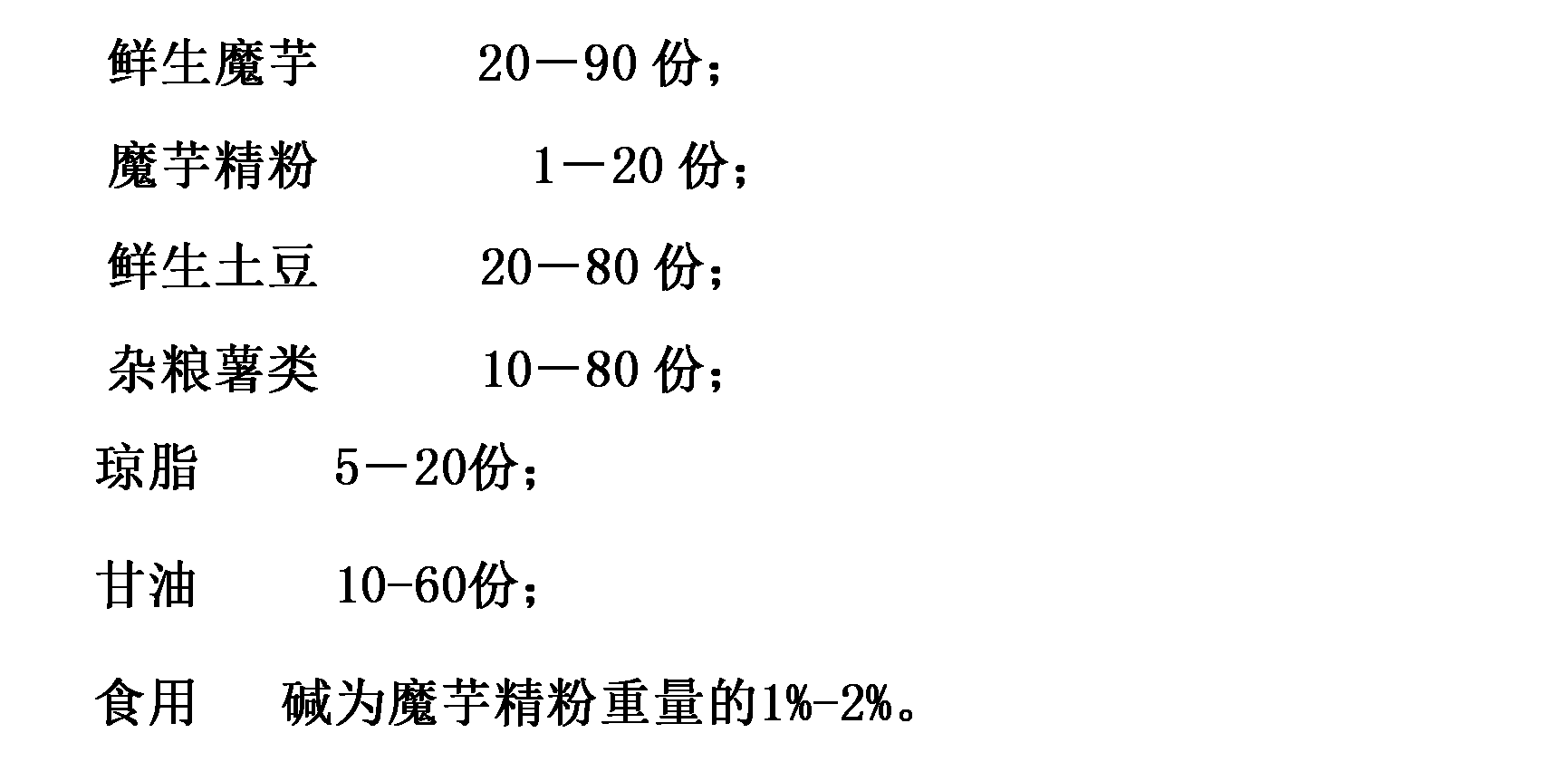

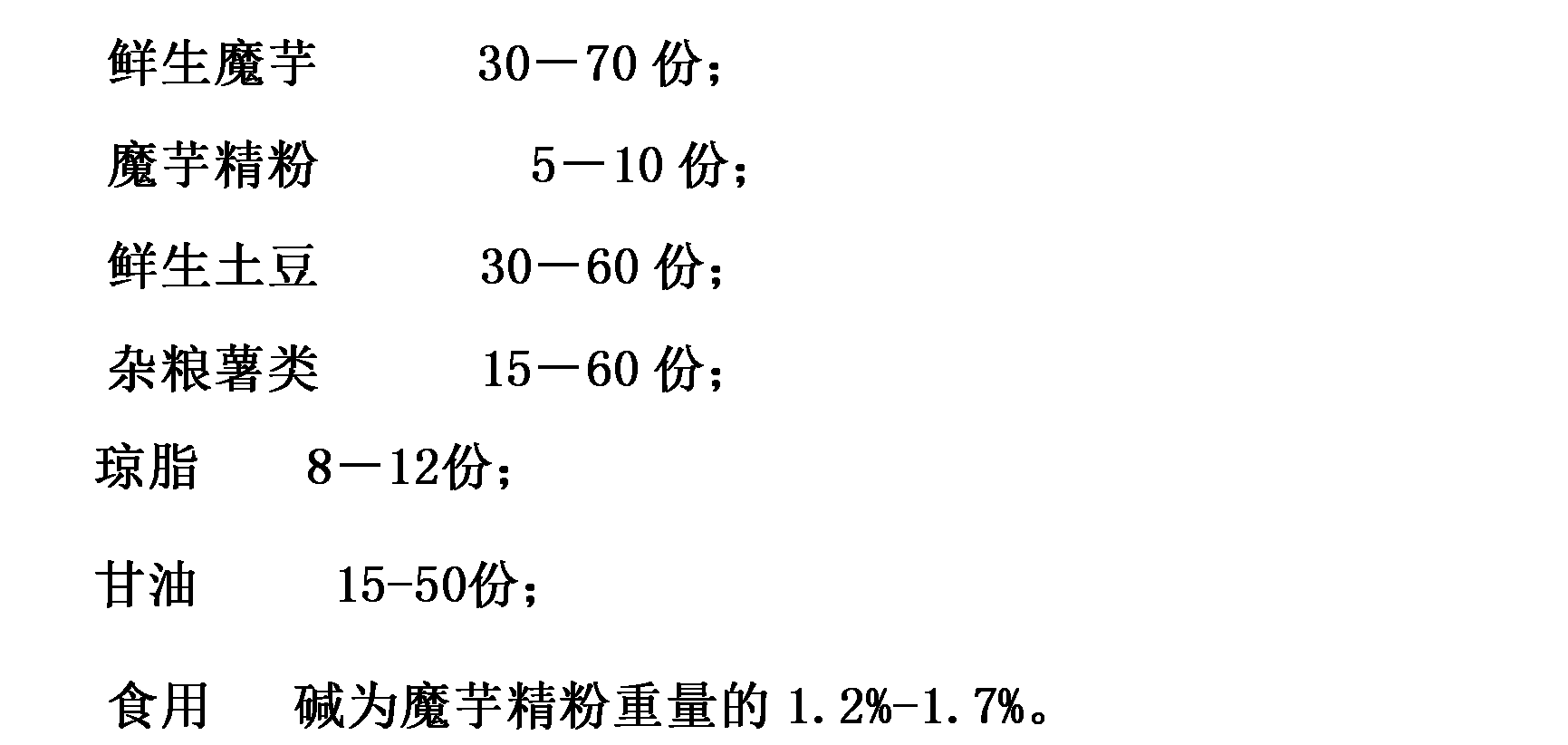

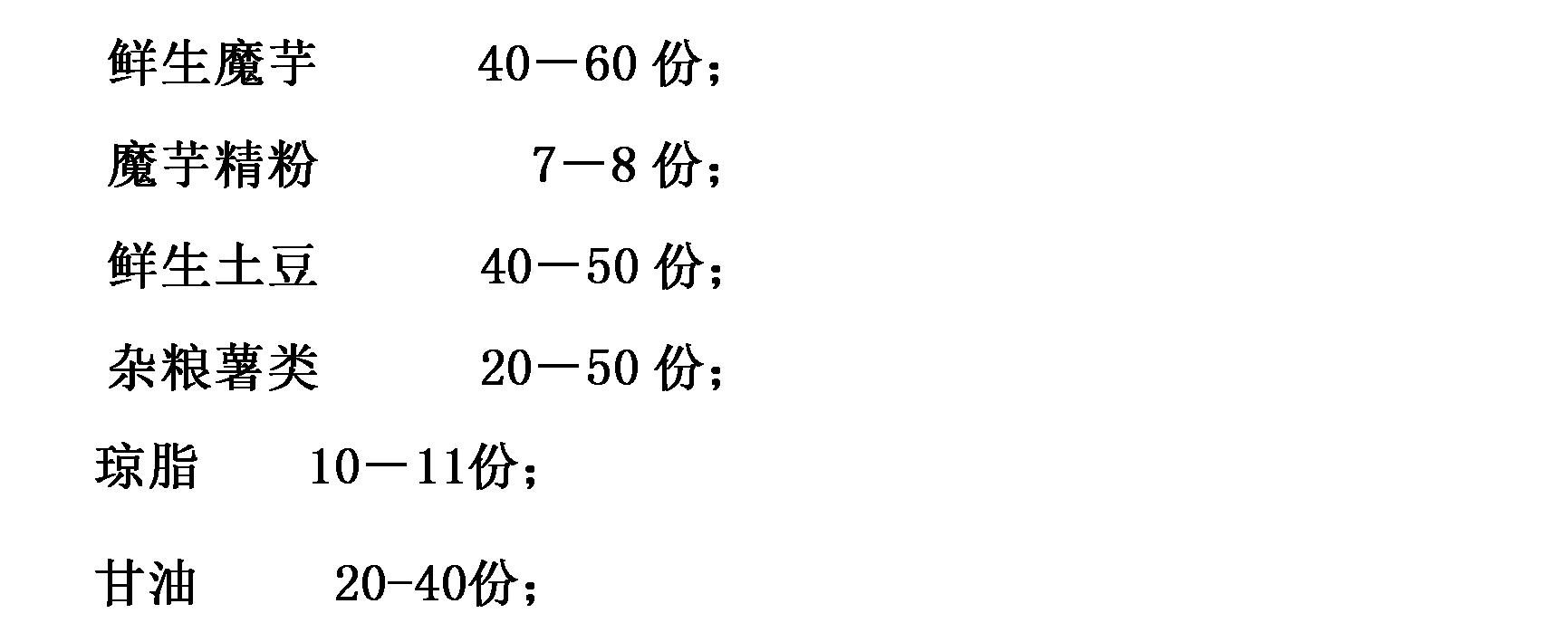

[0043] Example 1. Get 20kg fresh konjaku, 20kg konjac powder, 80kg fresh potato, 10kg miscellaneous grain potato, 20kg agar, 10kg glycerin and 0.2kg edible alkali, make hollow capsules according to the following steps:

[0044] A. Wash, peel and pulverize the fresh konjac, add water, drain and remove the slag to obtain product A for later use;

[0045] B. Add 30 times the water of konjac fine powder weight into the konjac fine powder, gelatinize and stand still to get product B for later use;

[0046] C. Wash, peel and pulverize the fresh potatoes, add water, drain and remove the slag to obtain product C for later use;

[0047] D, the sorghum is pulverized and ground into 100 mesh flour-like materials to obtain the D product for subsequent use;

[0048] E. Mix product A, product B, product C and product D, and let stand for 25 minutes to obtain product E;

[0049] F, add water 30 times of the weight of agar into the agar, heat it into porridge to get F product;

[0050] G....

Embodiment 2

[0056] Example 2. Get 90kg fresh and raw konjaku, 1kg konjac powder, 20kg fresh and raw potatoes, 80kg miscellaneous grain potato, 5kg agar, 60kg glycerin and 0.02kg edible alkali, make hollow capsules according to the following steps:

[0057] A. Wash, peel and pulverize the fresh konjac, add water, drain and remove the slag to obtain product A for later use;

[0058] B. Add 30 times the water of konjac fine powder weight into the konjac fine powder, gelatinize and stand still to get product B for later use;

[0059] C. Wash, peel and pulverize the fresh potatoes, add water, drain and remove the slag to obtain product C for later use;

[0060] D, the corn is pulverized and ground into 150 purpose flour-like materials to obtain the D product for subsequent use;

[0061] E. Mix product A, product B, product C and product D, and let stand for 30 minutes to obtain product E;

[0062] F, add water 30 times of the weight of agar into the agar, heat it into porridge to get F prod...

Embodiment 3

[0069] Example 3. Get the fresh raw konjac of 30kg, 10kg konjac fine powder, 30kg fresh raw potato, 60kg miscellaneous grain potato, 8kg agar, 50kg glycerin and 0.12kg edible alkali, make the hollow capsule that konjac is made by following steps:

[0070] A. Wash, peel and pulverize the fresh konjac, add water, drain and remove the slag to obtain product A for later use;

[0071] B. Add 30 times the water of konjac fine powder weight into the konjac fine powder, gelatinize and stand still to get product B for later use;

[0072] C. Wash, peel and pulverize the fresh potatoes, add water, drain and remove the slag to obtain product C for later use;

[0073] D, the buckwheat is pulverized and ground into 200 mesh flour-like materials to obtain the D product for subsequent use;

[0074] E. Mix product A, product B, product C and product D, and let stand for 35 minutes to obtain product E;

[0075] F, add water 30 times of the weight of agar into the agar, heat it into porridge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com