Rail web rust removal sander

A grinding machine and rail waist technology, which is applied in the direction of grinding machines, grinding/polishing equipment, metal processing equipment, etc., can solve the problems that cannot meet the requirements of high efficiency, high quality, low cost of welding operations, limited working space, and damage to equipment, etc. , to achieve the effects of easy promotion and use, flexible working space and safe work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

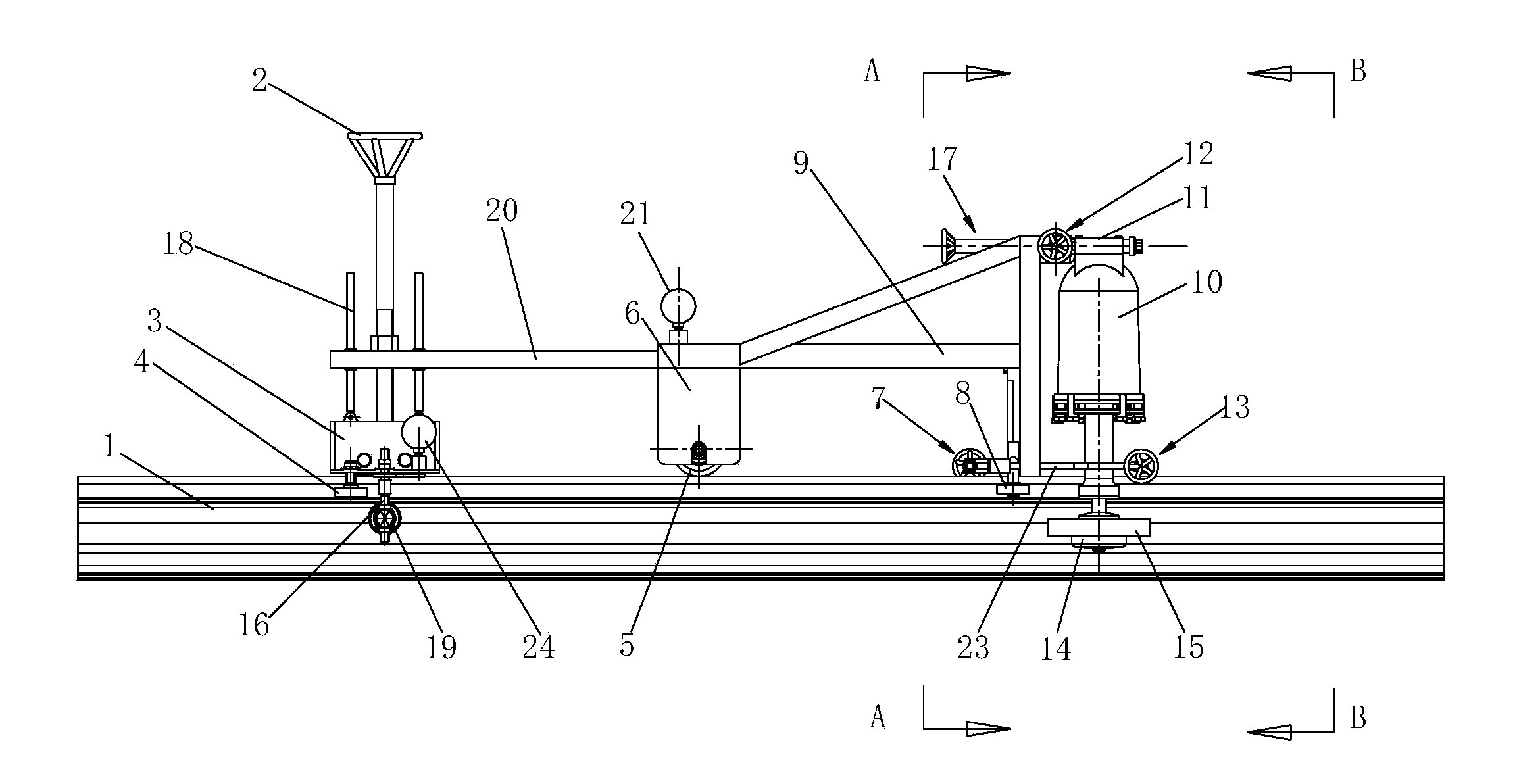

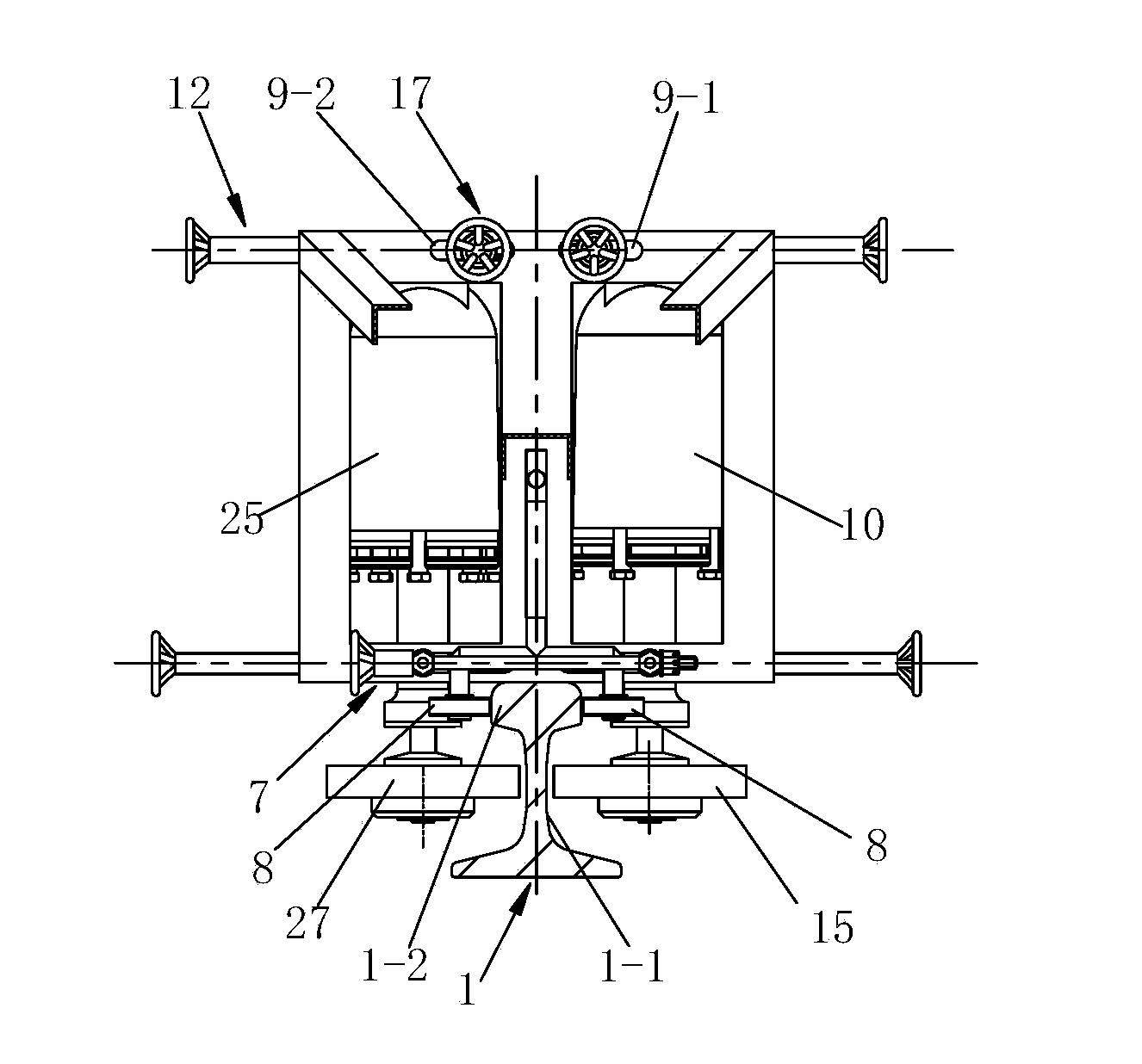

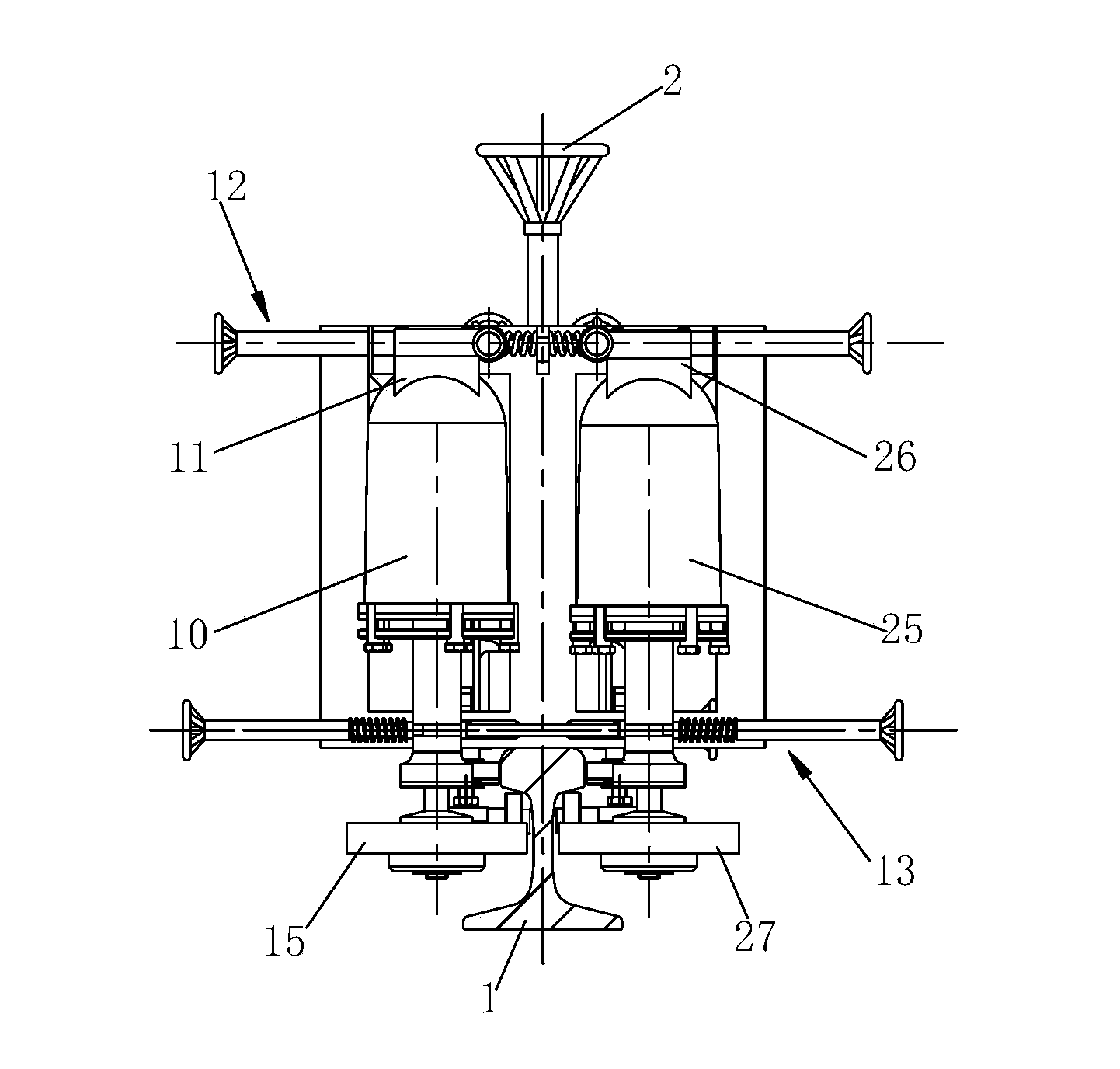

[0031] Such as figure 1 , figure 2 , image 3 and Figure 4 A rail waist derusting and grinding machine shown includes a first grinding wheel 15 for grinding the left side of the rail 1 rail waist 1-1, and a second grinding wheel 27 for grinding the right side of the rail 1 rail waist 1-1 And the main frame 9 arranged along the length direction of the rail 1, the tail frame 3 is provided at one end of the main frame 9, and the first fixed frame 11 and the second fixed frame 26 are provided at the other end of the main frame 9, the first The first working head 10 for driving the first emery wheel 15 to rotate is installed on the fixed frame 11, the second working head 25 for driving the second emery wheel 27 to rotate is installed on the second fixed frame 26, and the tail row frame 3 The left and right sides of the rail 1 rail jaw 1-2 are provided with traveling wheels 19 that walk along the bottom surface of the rail 1 rail jaw 1-2. The first guide wheel 4 that walks on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com