Header foaming frame

A foaming frame and header technology, applied in the field of solar header production equipment, can solve the problems of difficulty in controlling the density of foamed materials, poor insulation performance of the headers, and low foaming density, etc. Foaming effect, the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in further detail below:

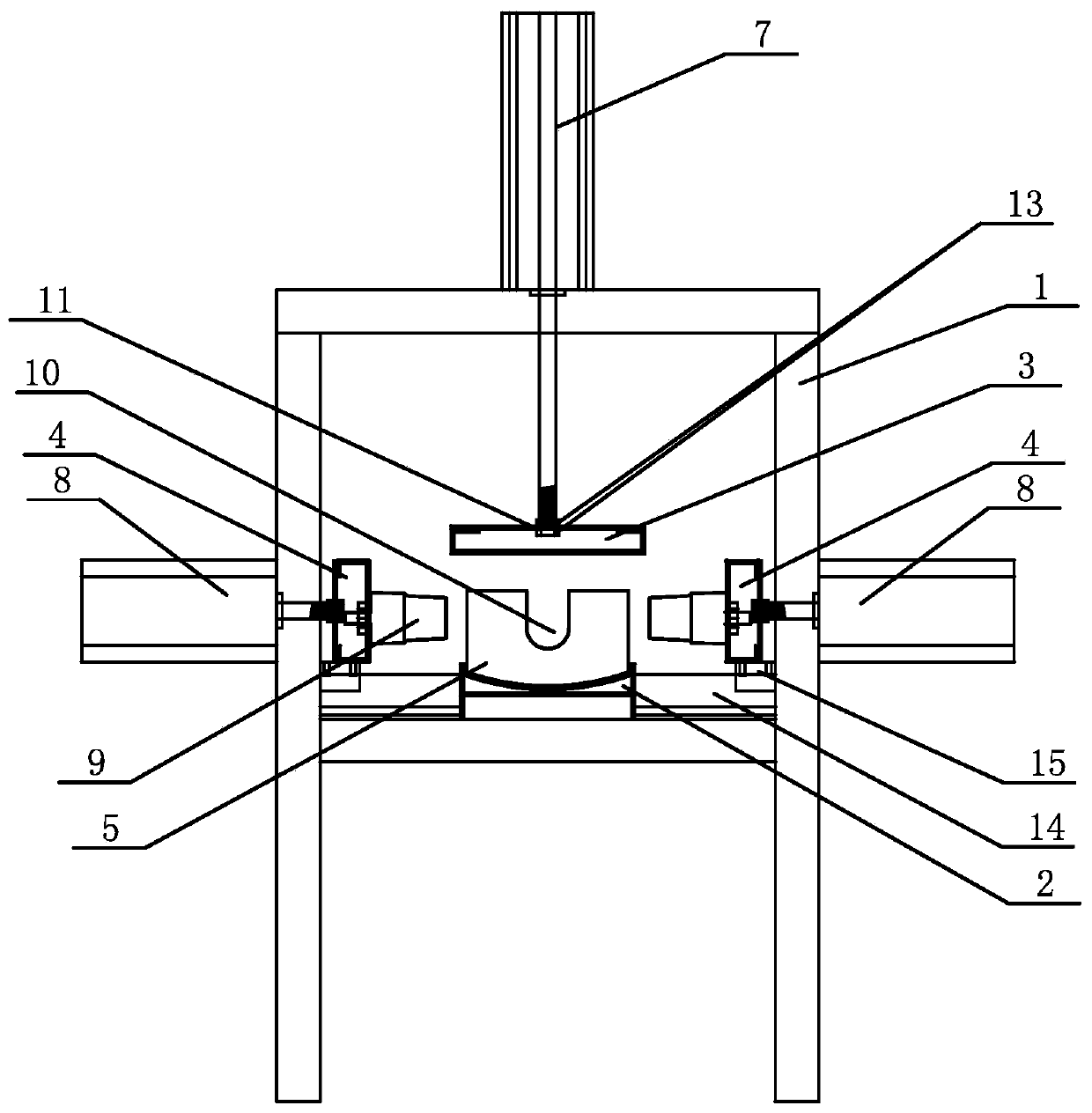

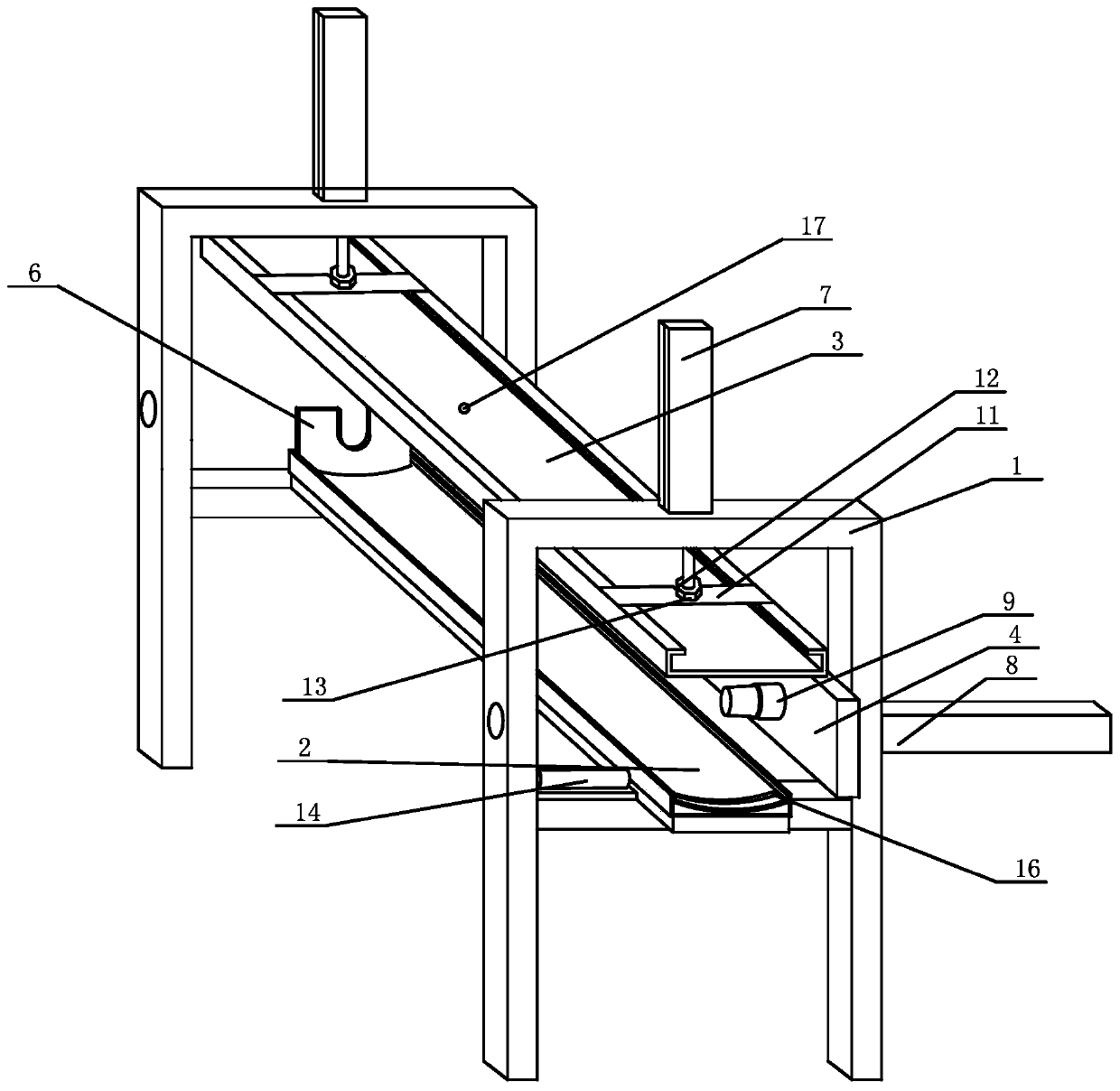

[0018] The present invention provides a header foam frame, which includes a frame 1, a base 2, an upper pressure plate 3, a side pressure plate 4, a front limiting plate 5, a rear limiting plate 6, a first cylinder 7 and a second cylinder 8, the base 2. Set horizontally on the frame 1, the upper platen 3 is located above the base 2, the first cylinder 7 is fixed on the upper end of the frame 1, the piston rod of the first cylinder 7 is connected with the upper platen 3, and the upper platen is driven by the first cylinder 7 3 can move up and down along the frame 1, and the upper pressing plate 3 is provided with a material injection hole 17 for feeding into the header, and the number of the side pressing plates 4 is two and located on the left and right sides of the base 2, The back side of the side pressure plate 4 is connected with the piston rod of the second cylinder 8, and the second cylinder 8 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com