Manual pipe bending device

A pipe bending device and manual technology, applied in the field of manual pipe bending devices, can solve the problems of pipeline deflection, inability to bend small straight pipelines, and expensive molds.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

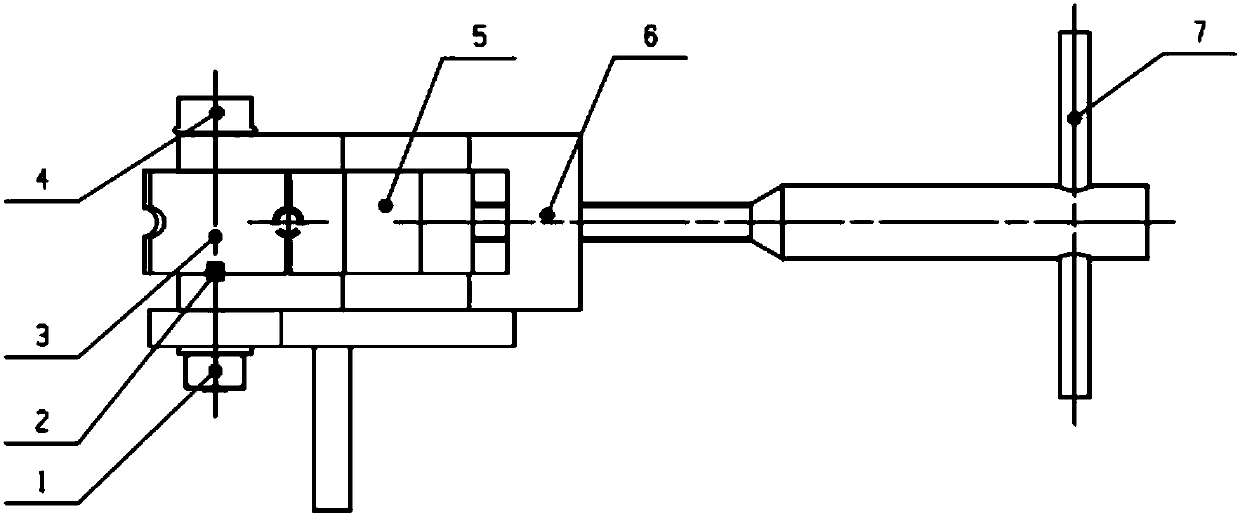

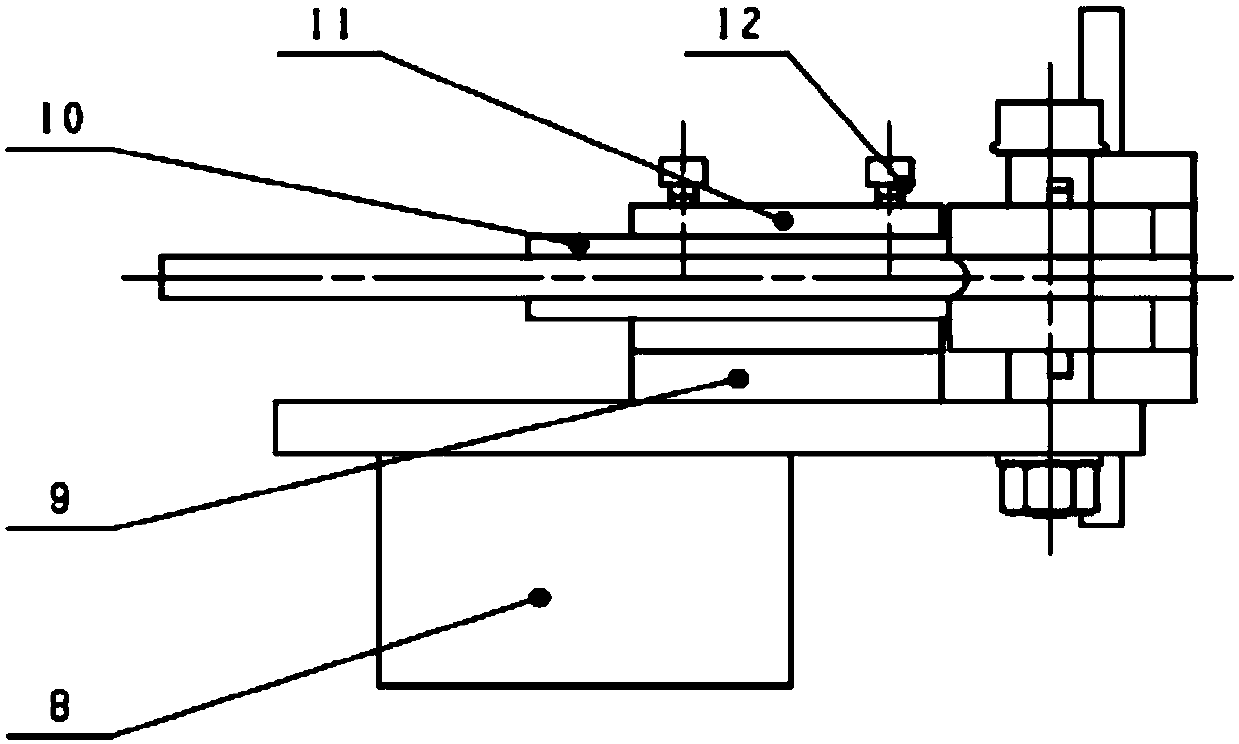

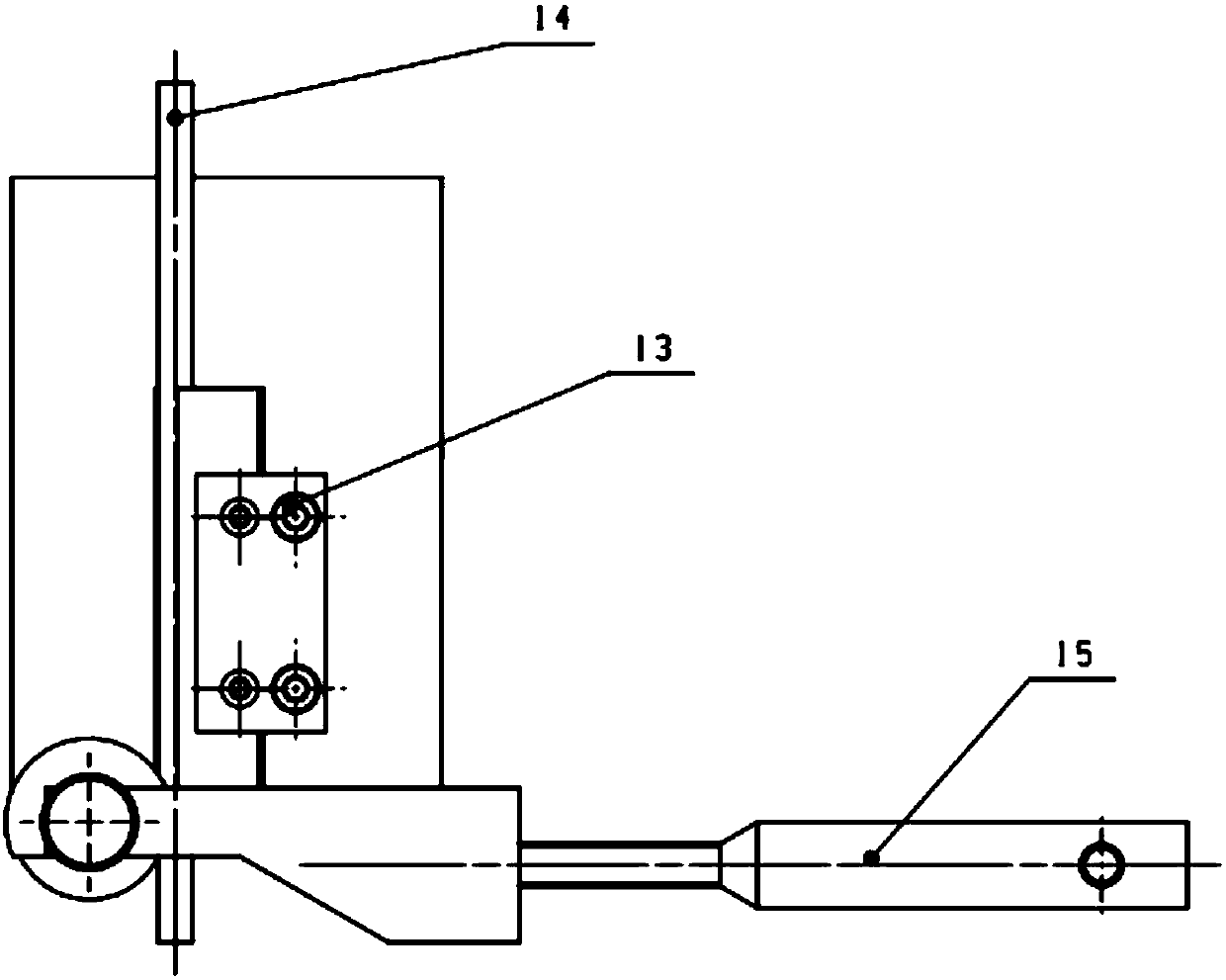

[0029] The main working parts of the manual pipe bending device include a bending die assembly, a clamping die assembly, and a compression die assembly. The bending die assembly includes the bending die 3 and the mandrel 4; the clamping die assembly includes the clamping die 5, the clamping die volume frame 6, the force arm 15 and the rod 7; Backing plate 9.

[0030] The bending die 3 is a cylinder with a side that is cut into a plane, and the central axis of the cylinder has a central through hole that cooperates with the mandrel 4 to be sleeved on the mandrel 4. On the circumference of the waist of the bending die 3 It has a groove matching the diameter of the pipeline. The clamping mold frame 6 is a fork-shaped frame. The cantilevered ends of the two fork arms have opposite through holes for being sleeved on the mandrel 4. The opposite inner sides of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com