Patents

Literature

133results about "Nailing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

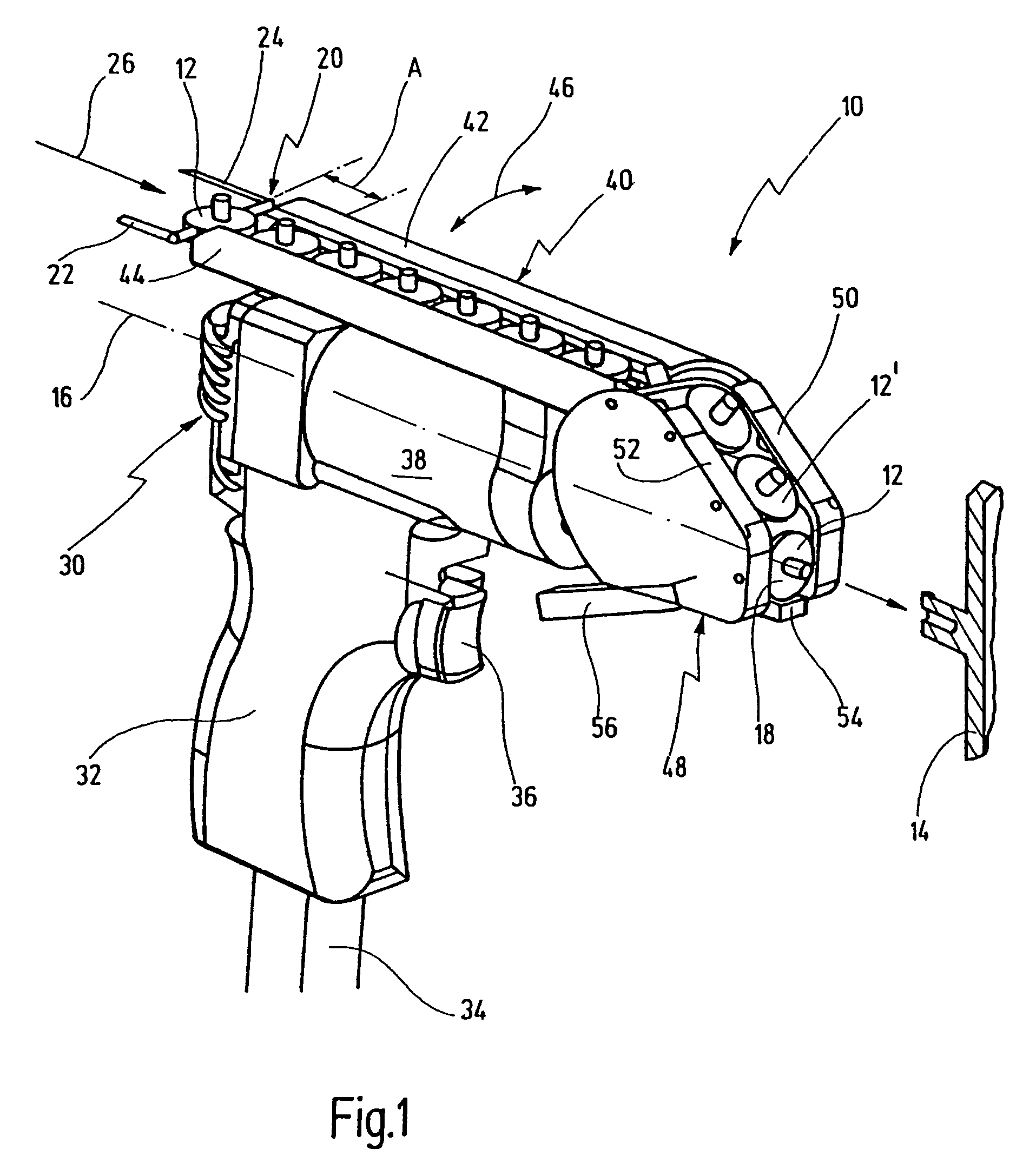

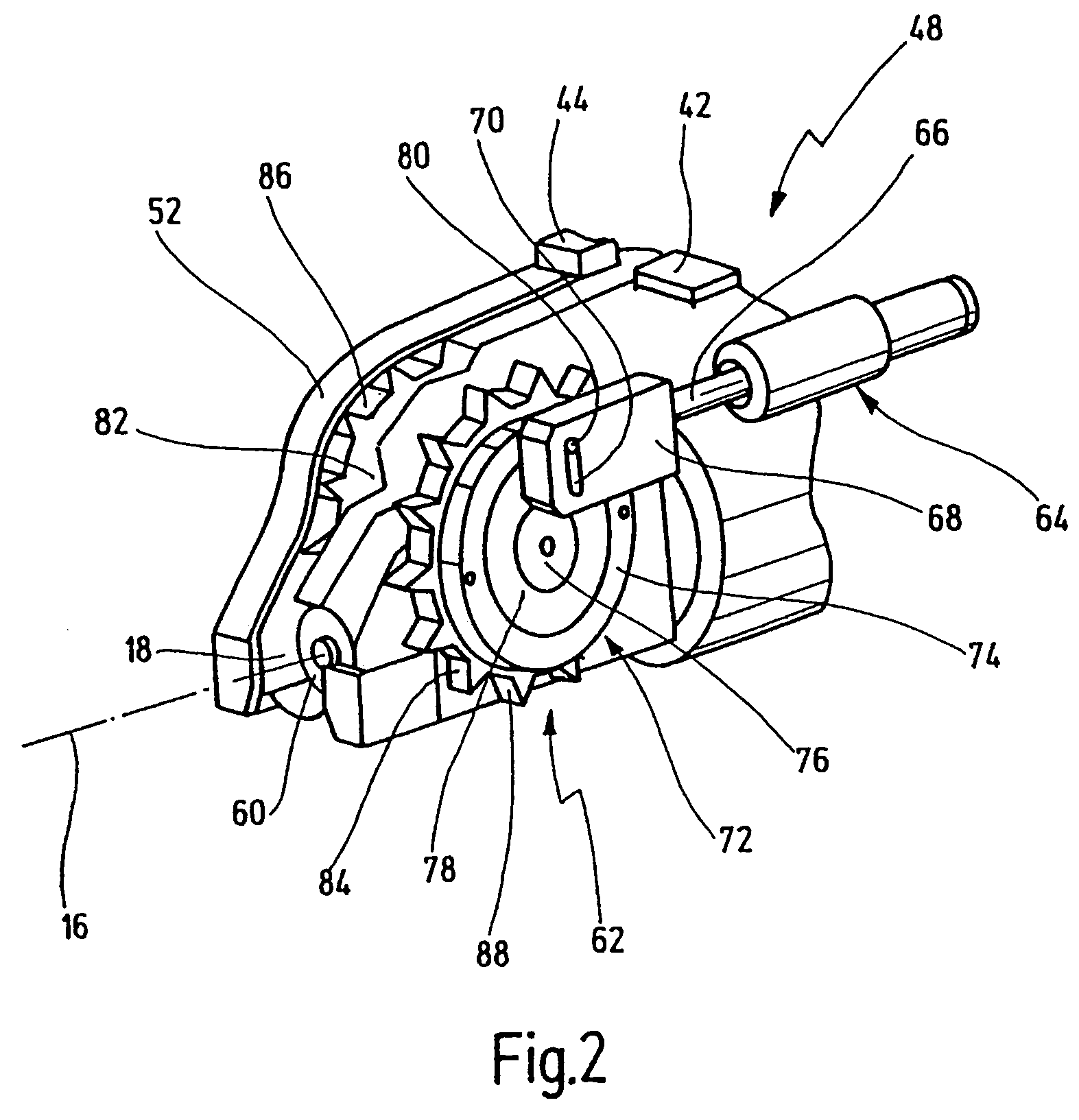

Device for dispensing plastic fasteners

ActiveUS7036680B1Easy to useReduce manufacturing costAffixing tagsCoin-freed apparatus detailsCross-linkEngineering

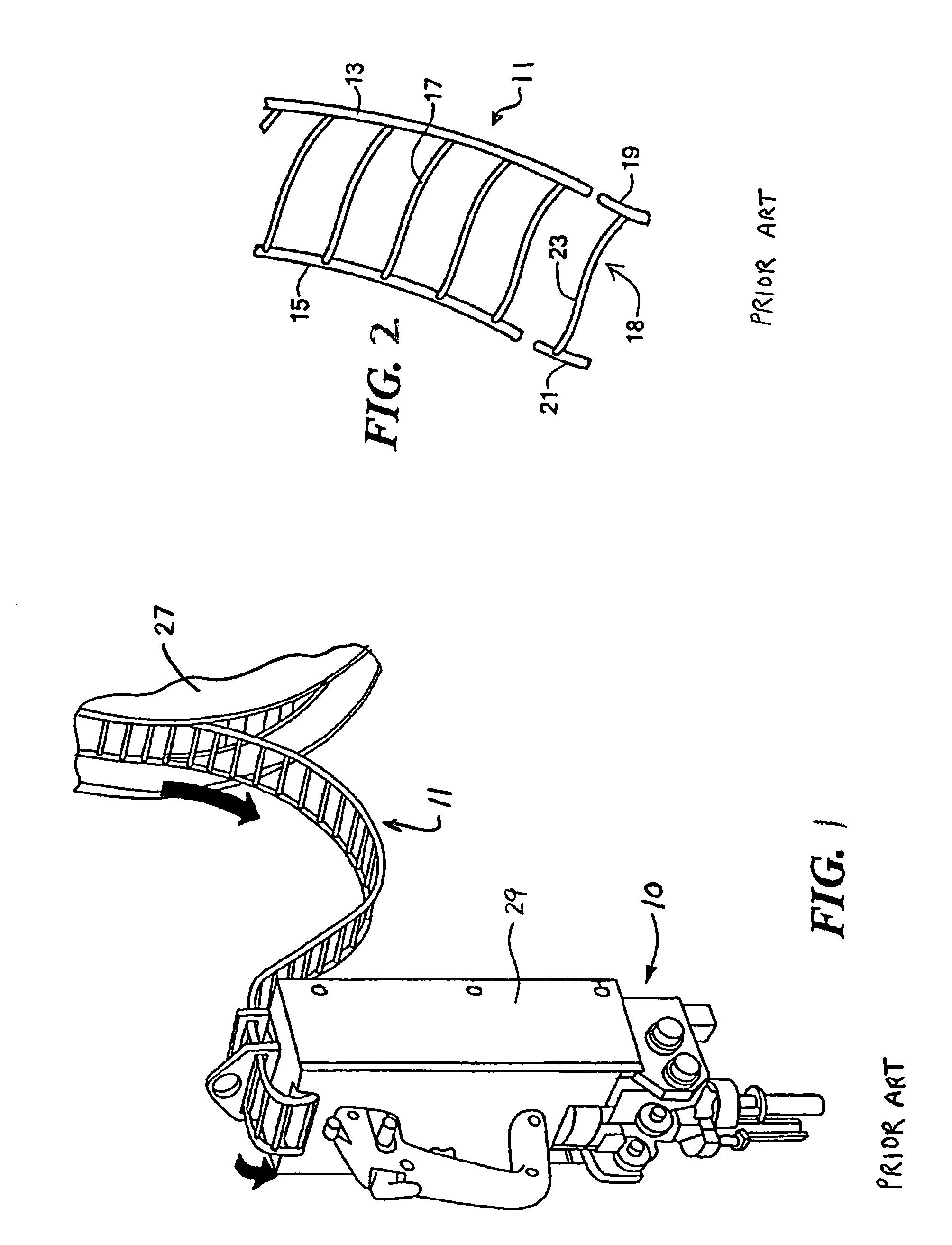

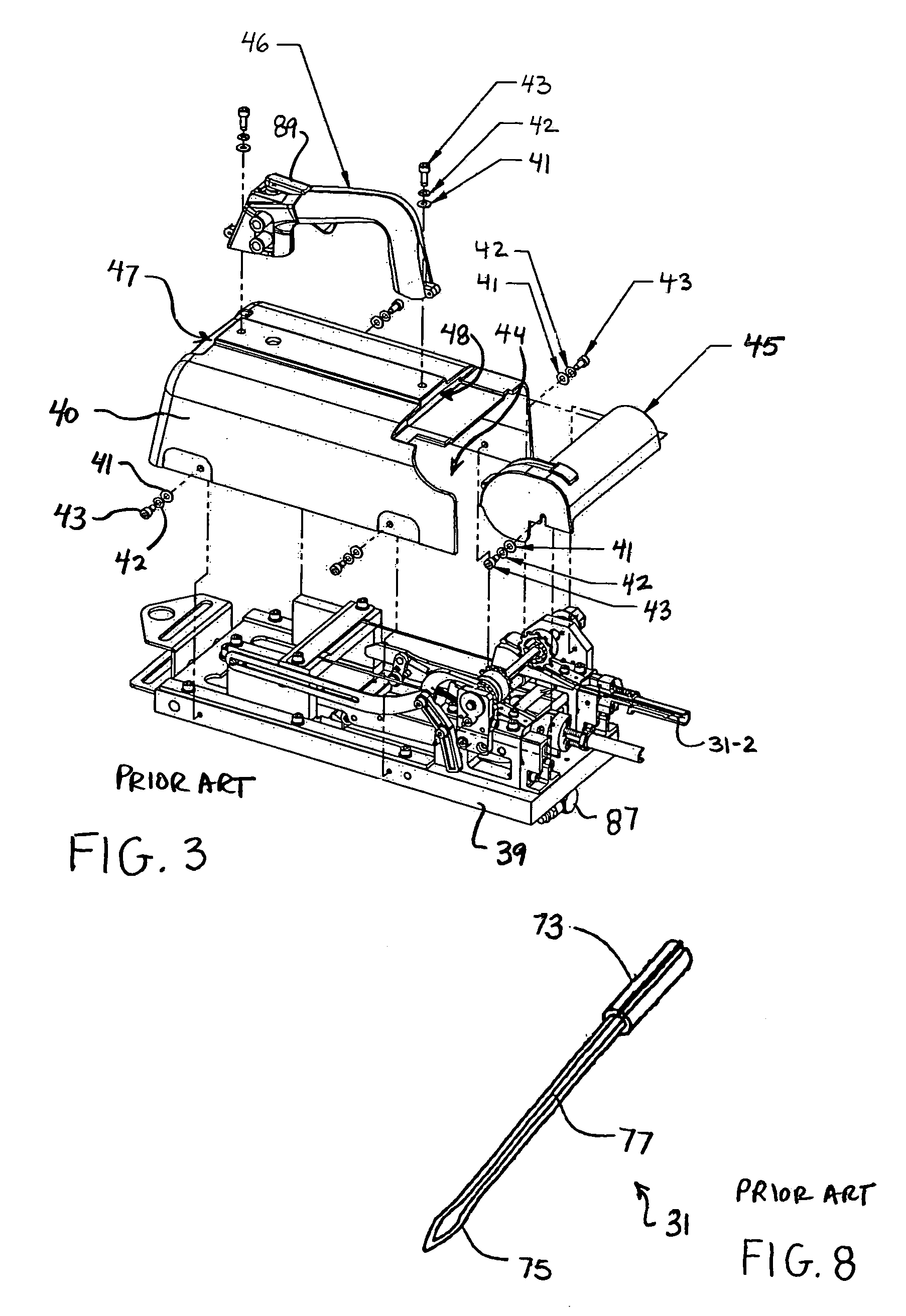

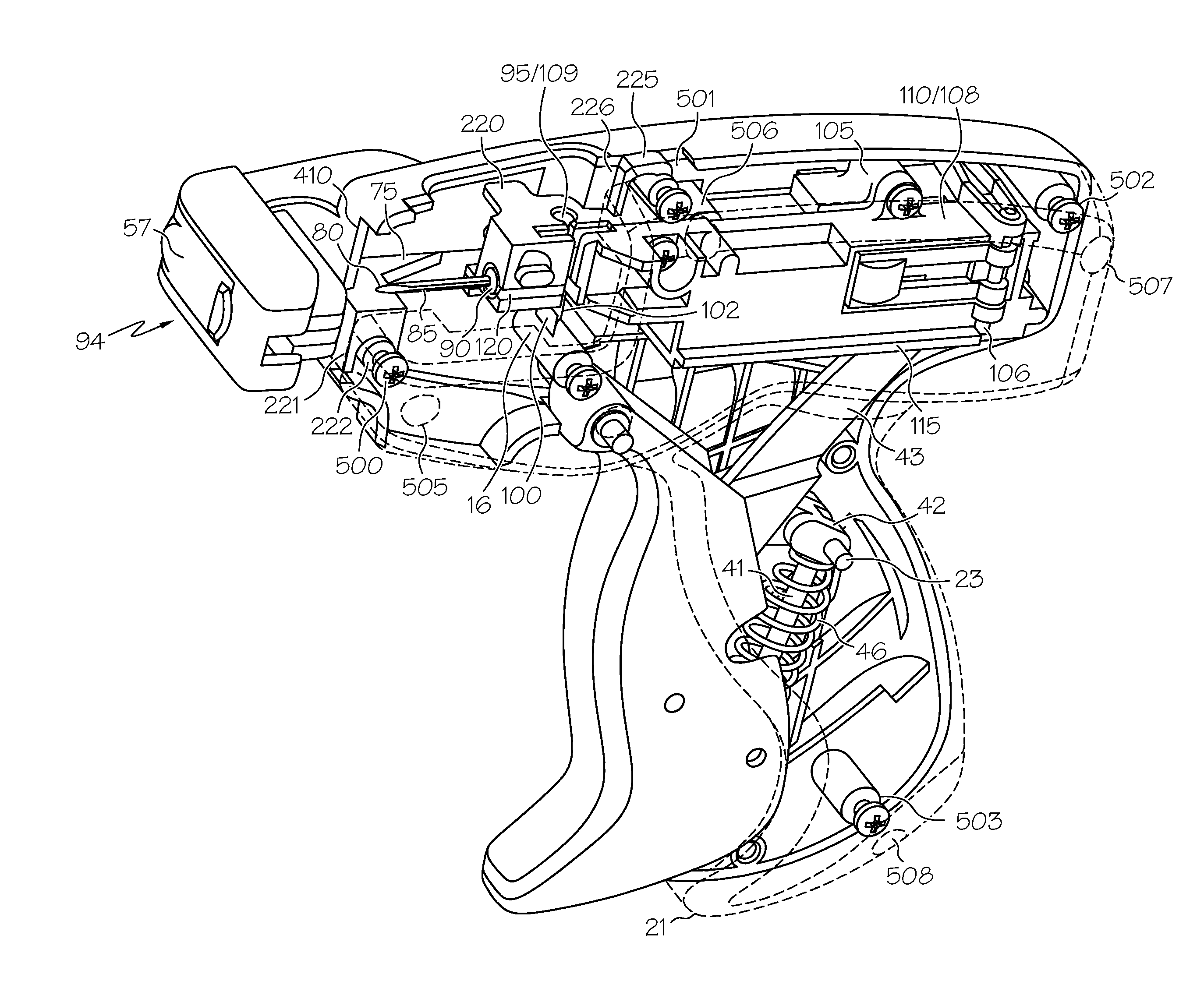

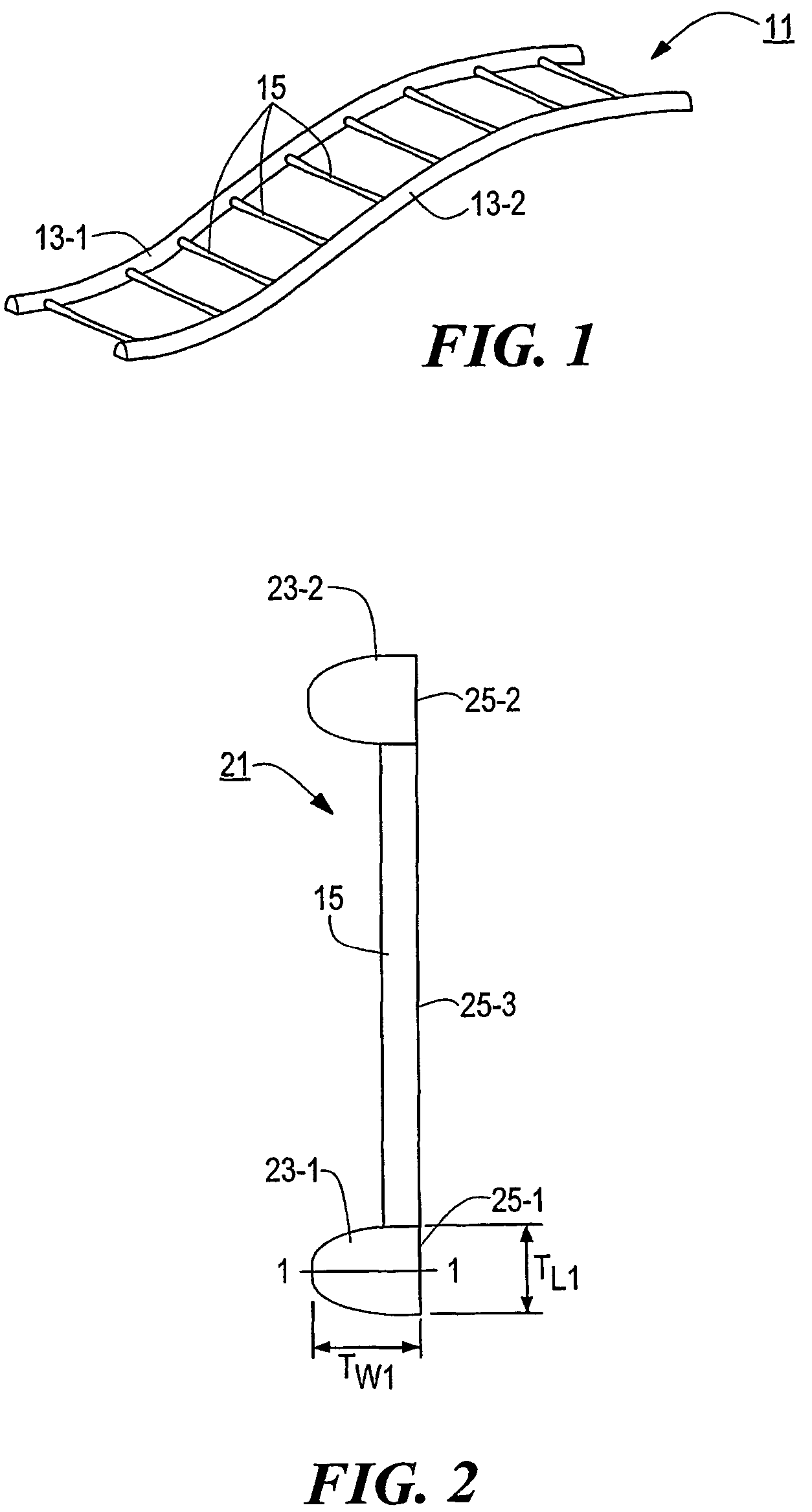

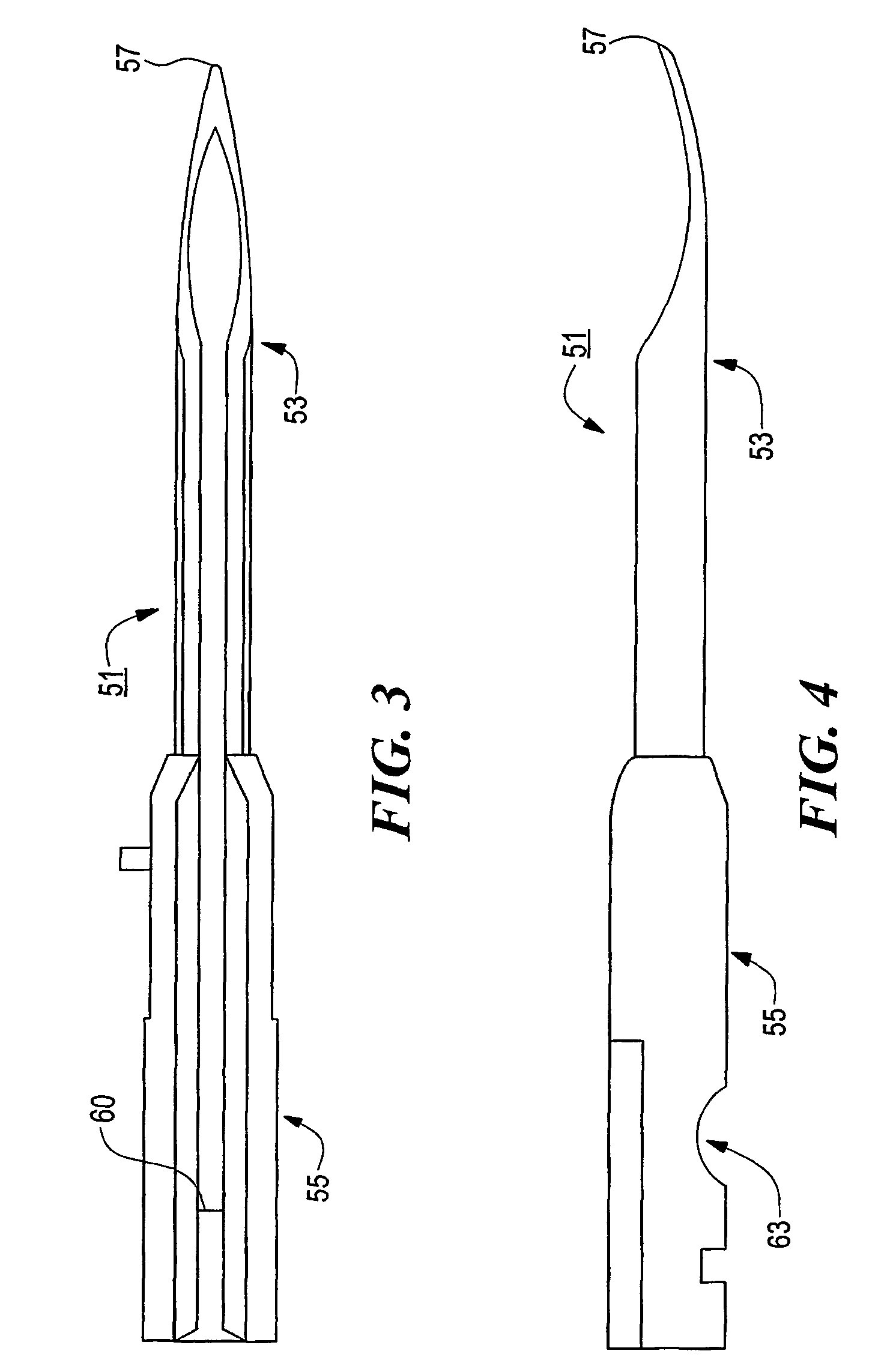

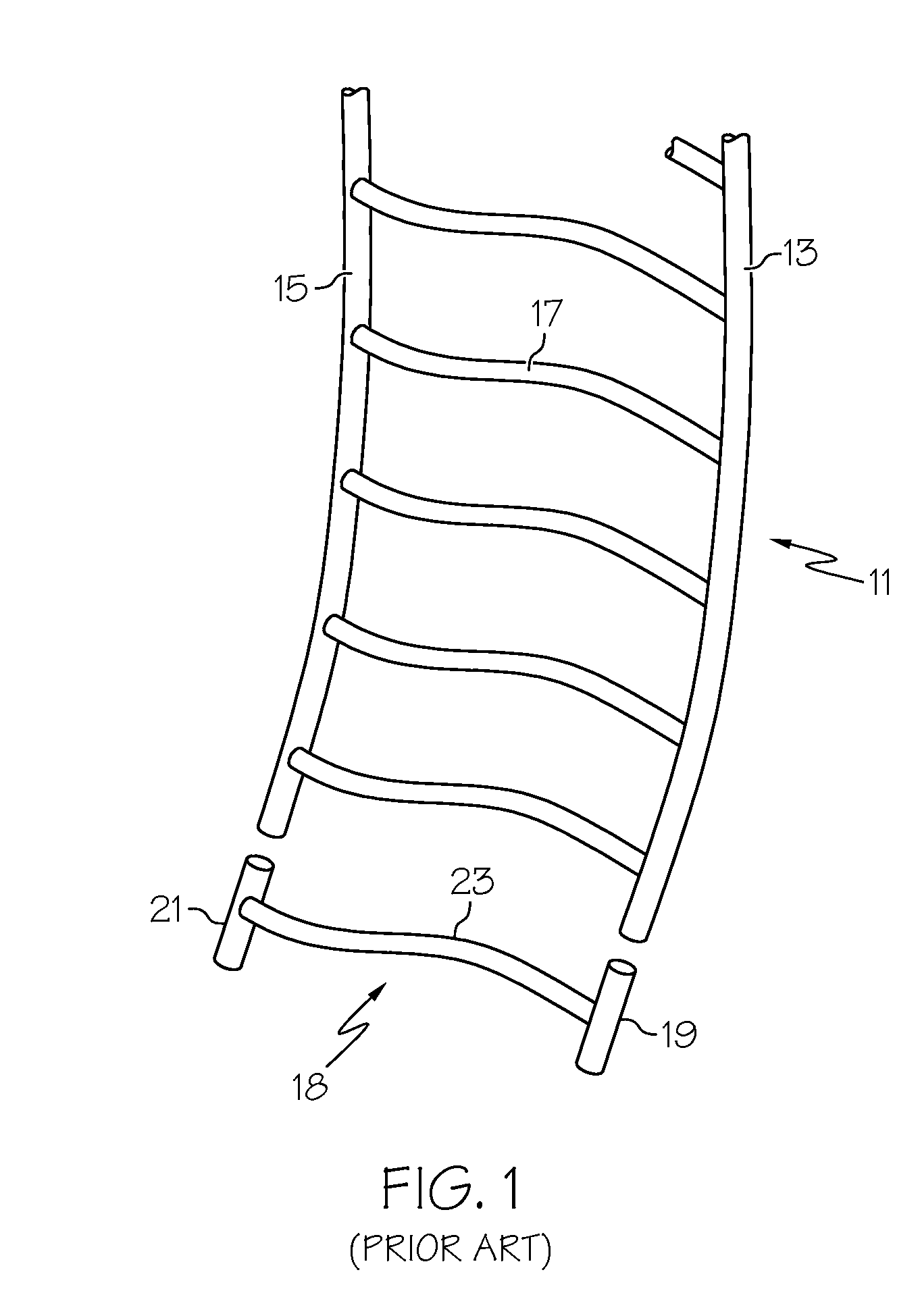

A device for dispensing an individual plastic fastener from a supply of fastener stock to couple together two or more objects. The supply of fastener stock includes a plurality of equidistantly spaced cross links which are coupled at one end to a continuous side rail. The fastener dispensing device includes a hollowed sharpened needle shaped to define a longitudinal bore and a feed mechanism for advancing the continuous side rail of the fastener stock into direct axial alignment behind the longitudinal bore of the hollowed needle. The feed mechanism includes a rotatably mounted feed shaft, a pair of feed wheels fixedly mounted on the feed shaft, each feed wheel comprising a plurality of sprockets which are sized and shaped to engage the supply of fastener stock, and first and second clutch wheels which are releasably matingly engageable with one another, the first clutch wheel being fixedly mounted on the feed shaft and the second clutch wheel being rotatably mounted on the feed shaft, each of the first and second clutch wheels including a plurality of ratchets. As a feature of the invention, the number of ratchets on each clutch wheel is at most equal to the number of sprockets on each feed wheel.

Owner:AVERY DENNISON CORP

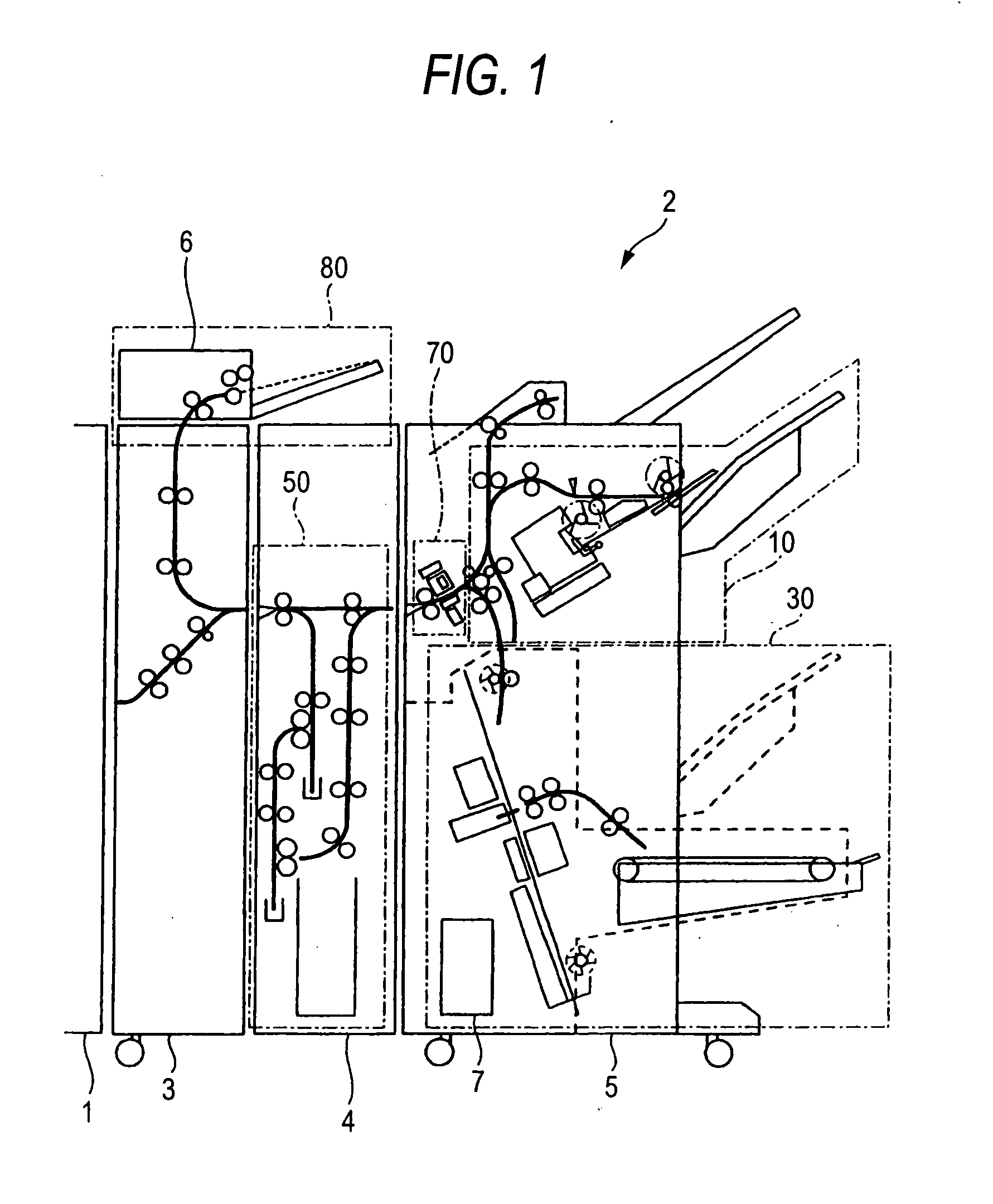

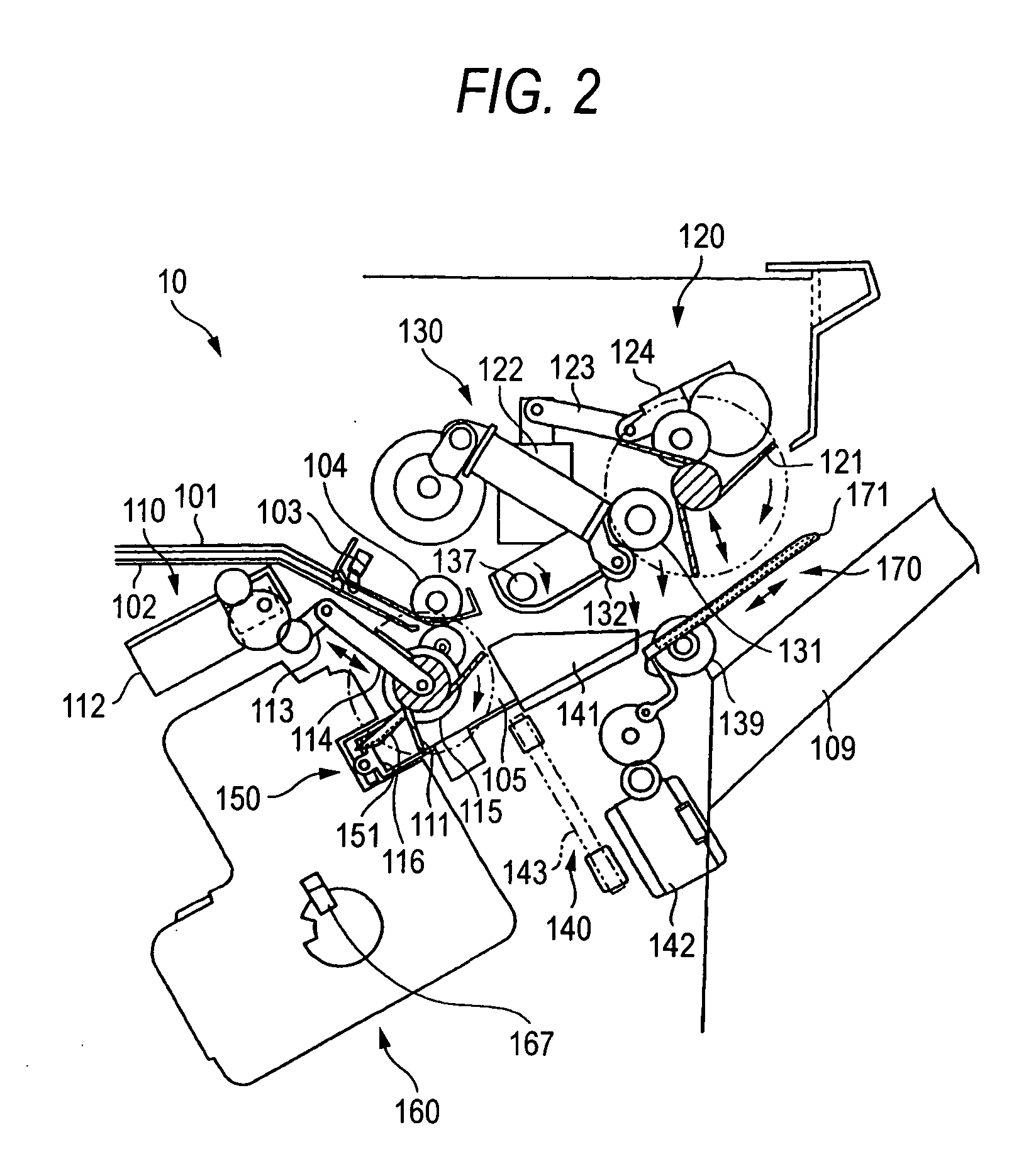

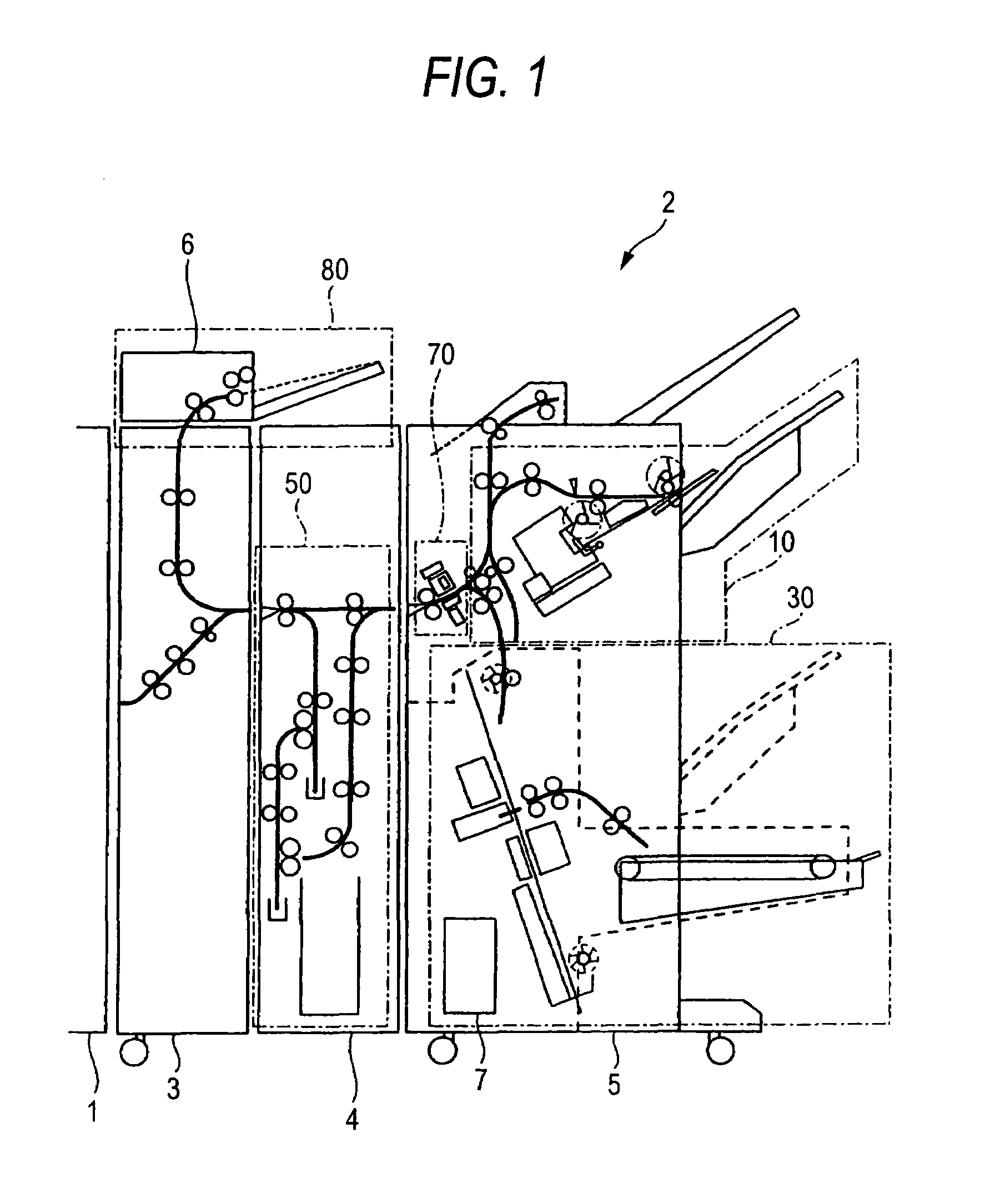

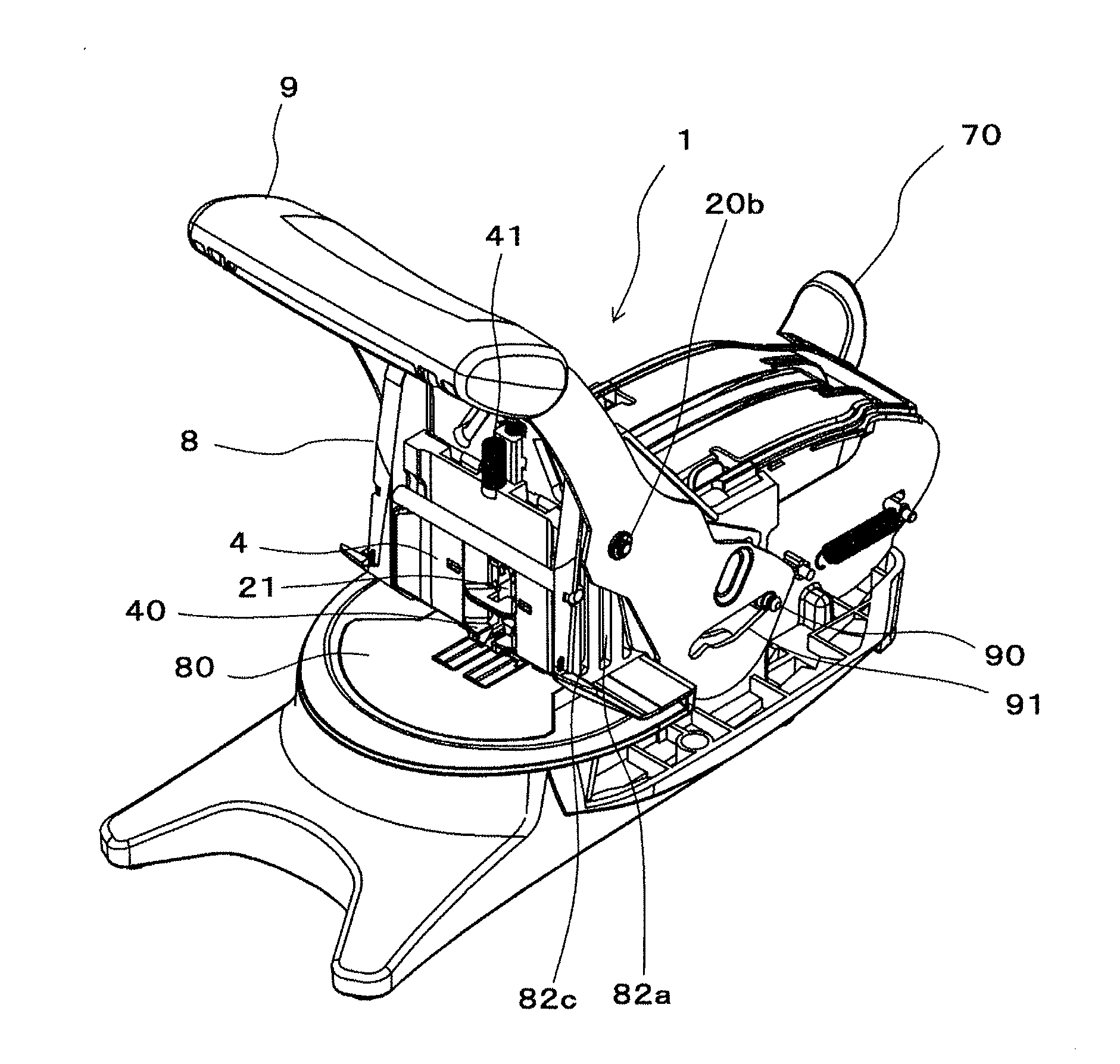

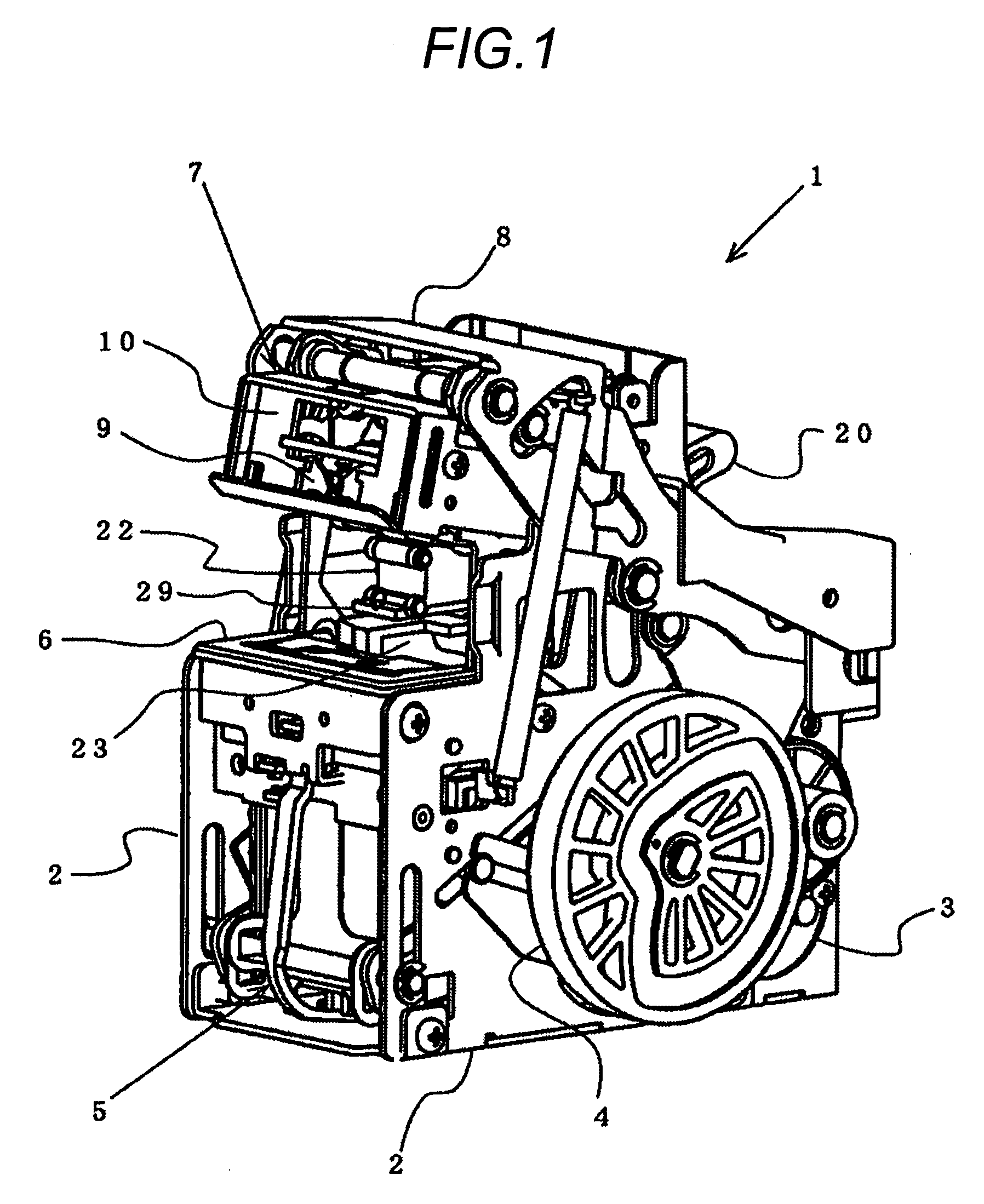

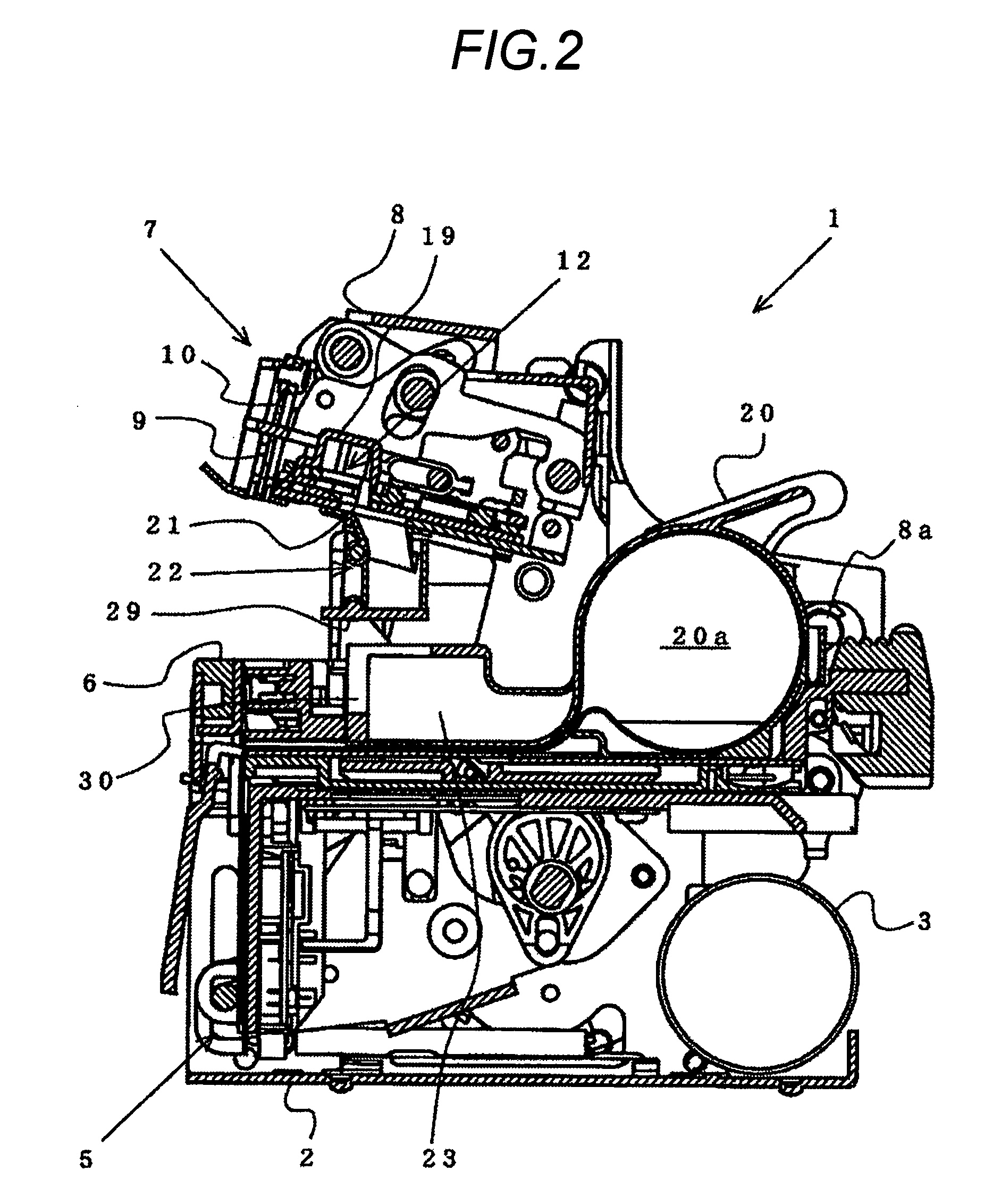

Stapling device

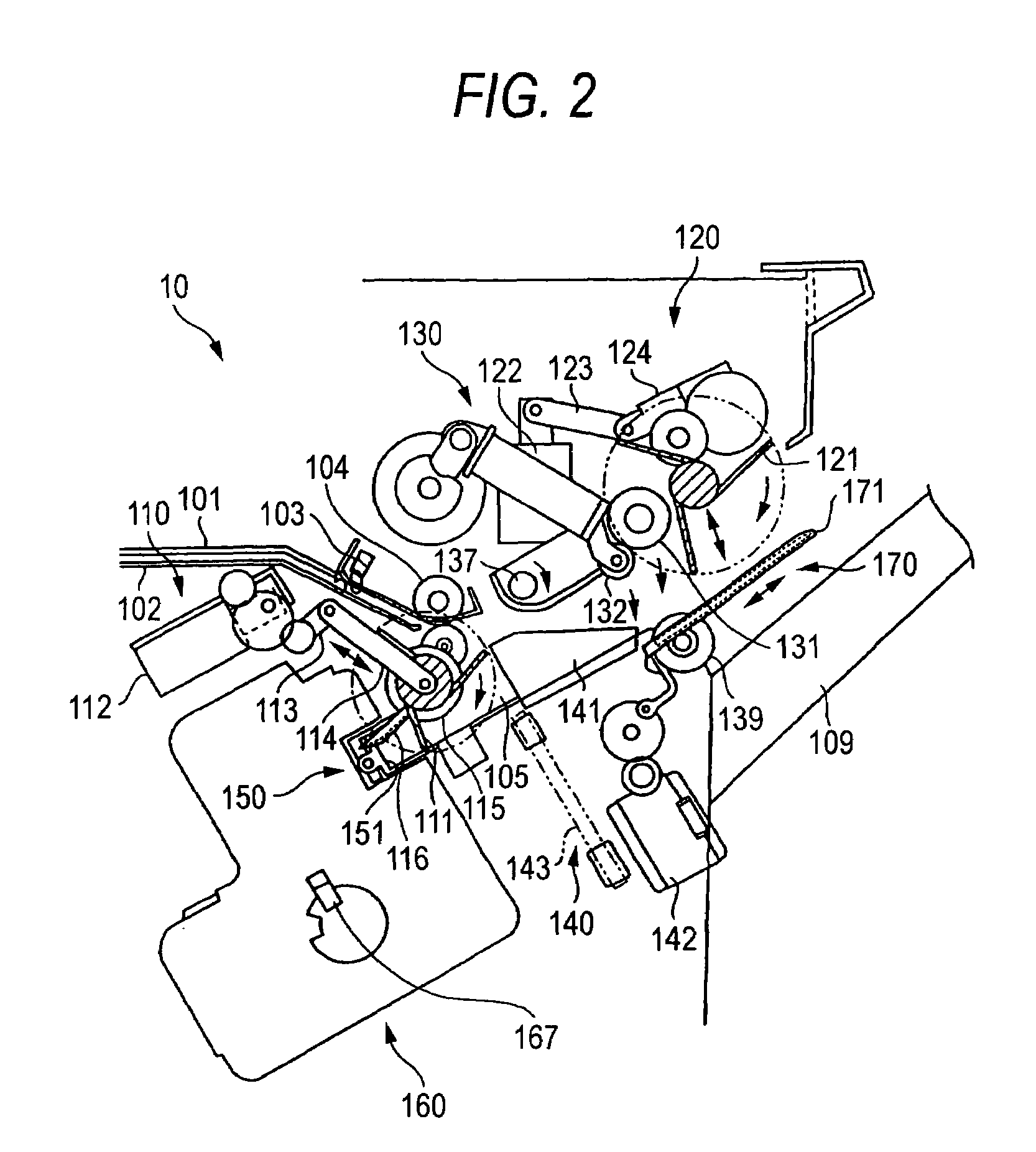

ActiveUS20060017210A1Reduce the likelihood of occurrenceProductivity is deterioratedStapling toolsNailingEngineeringElectrical and Electronics engineering

A stapler unit has a staple section, a cutter section, and a receiving section. A stapling device further includes a staple recovery box which is disposed at a staple discarding position and which recovers the tip ends to be discarded from the receiving section; and a staple discarding mechanism which delivers the tip ends received in the receiving section of the stapler unit to the staple recovery box. One of the plural stapling positions is identical with the staple discarding position.

Owner:FUJIFILM BUSINESS INNOVATION CORP

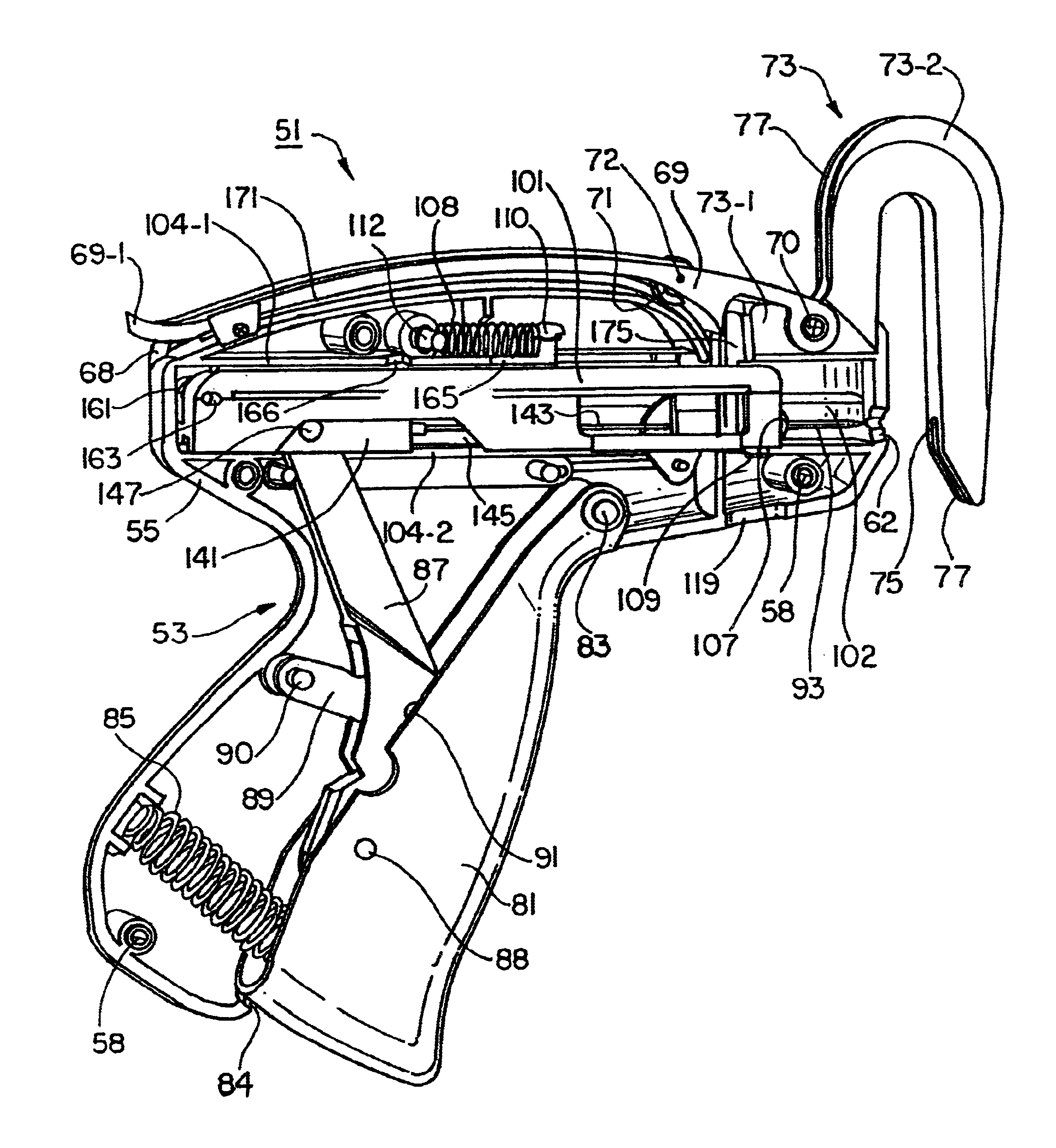

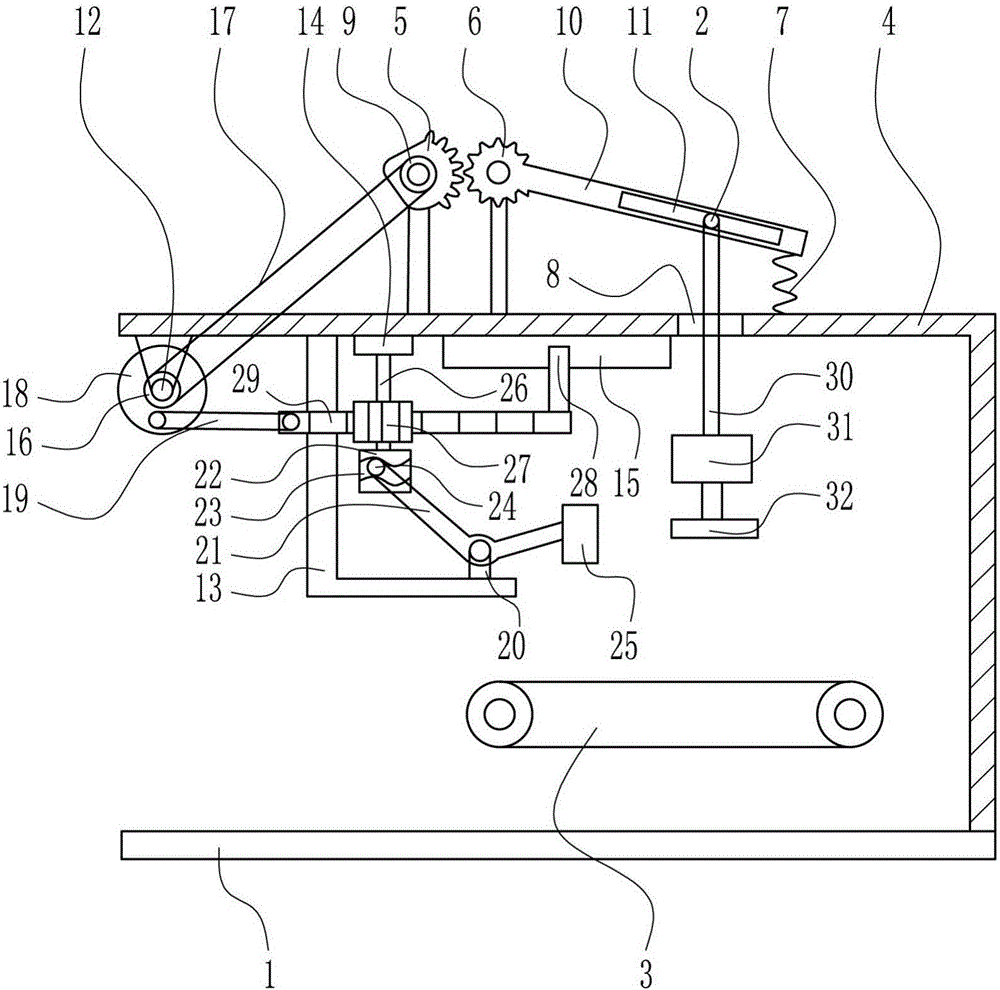

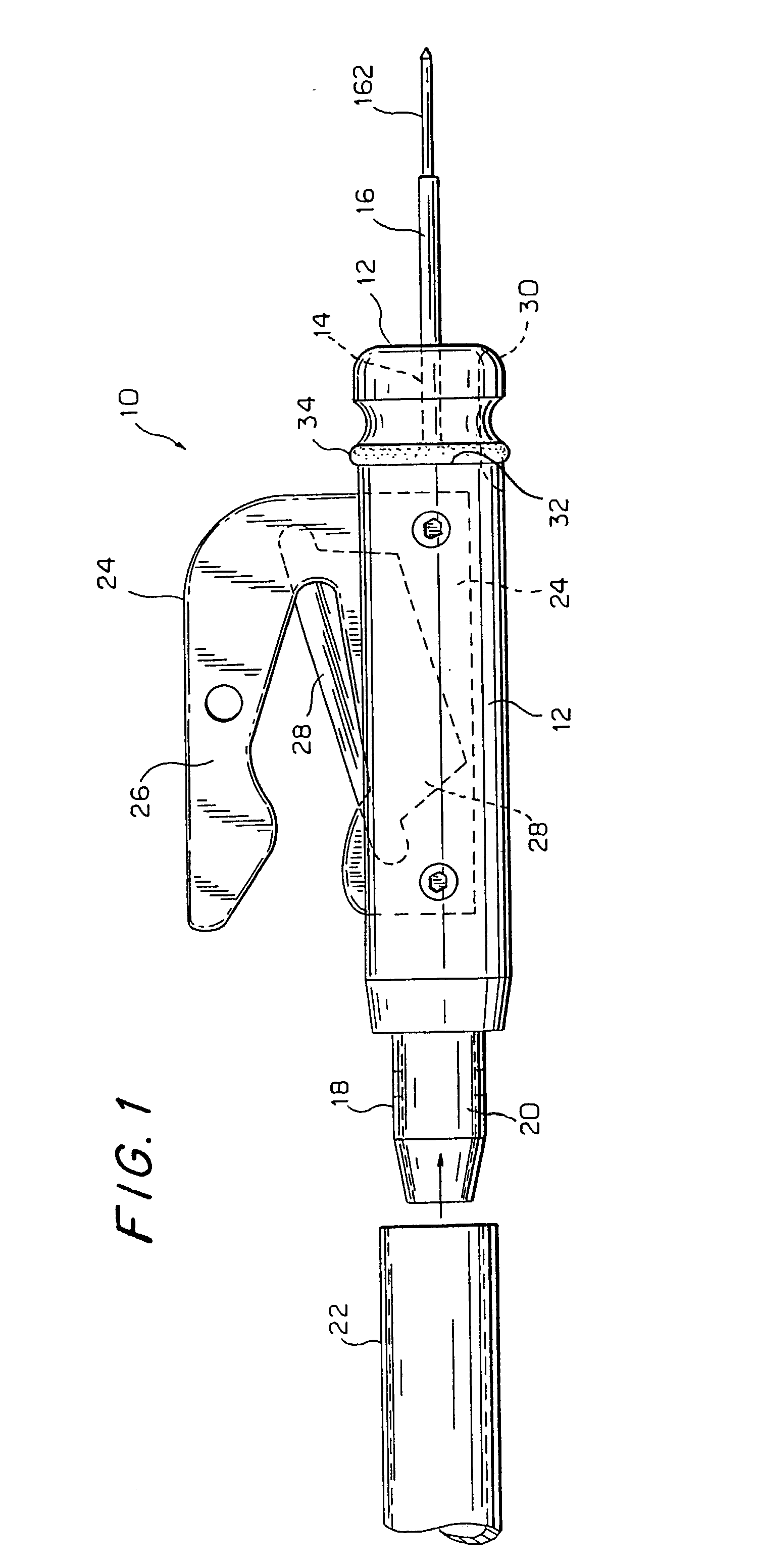

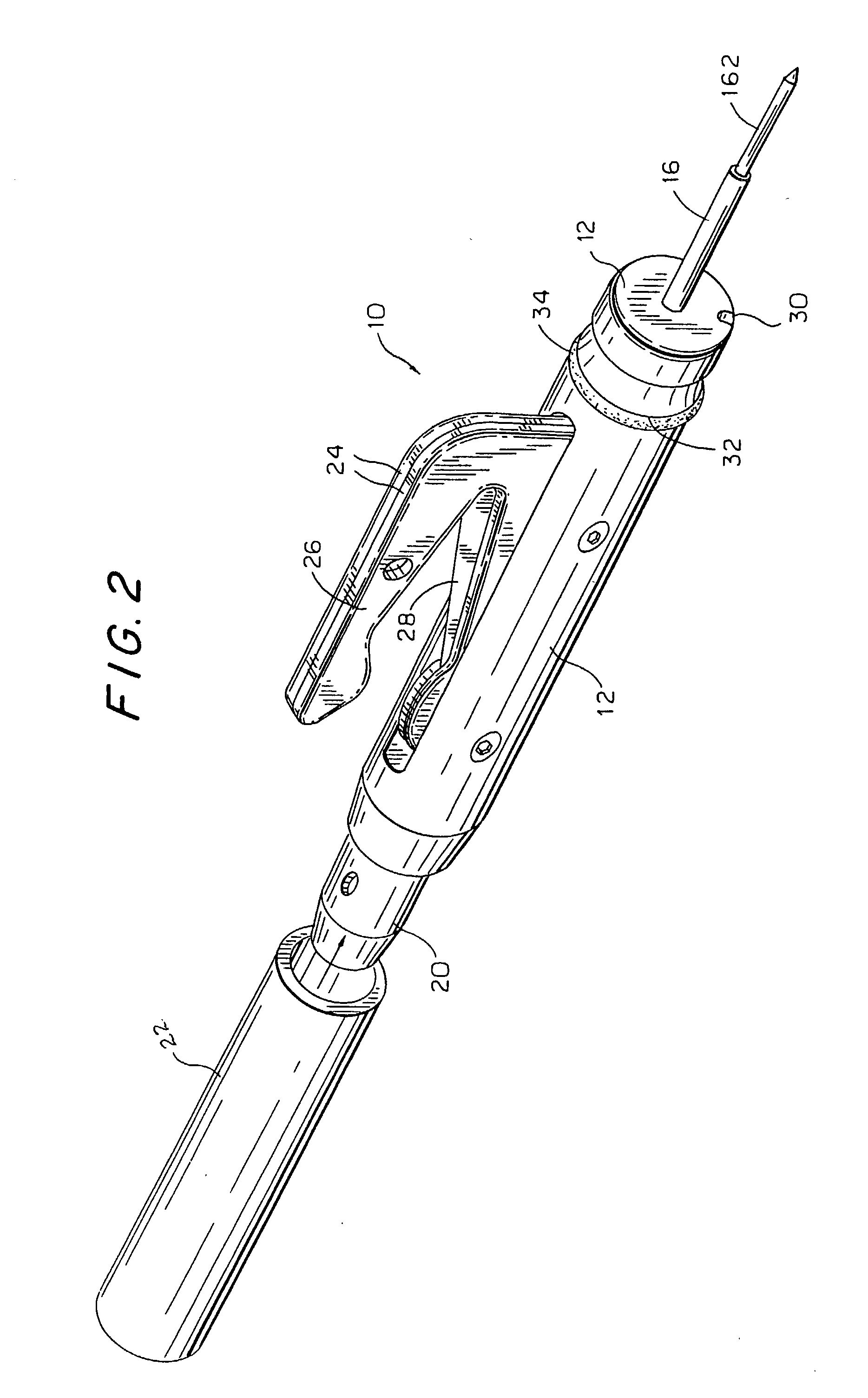

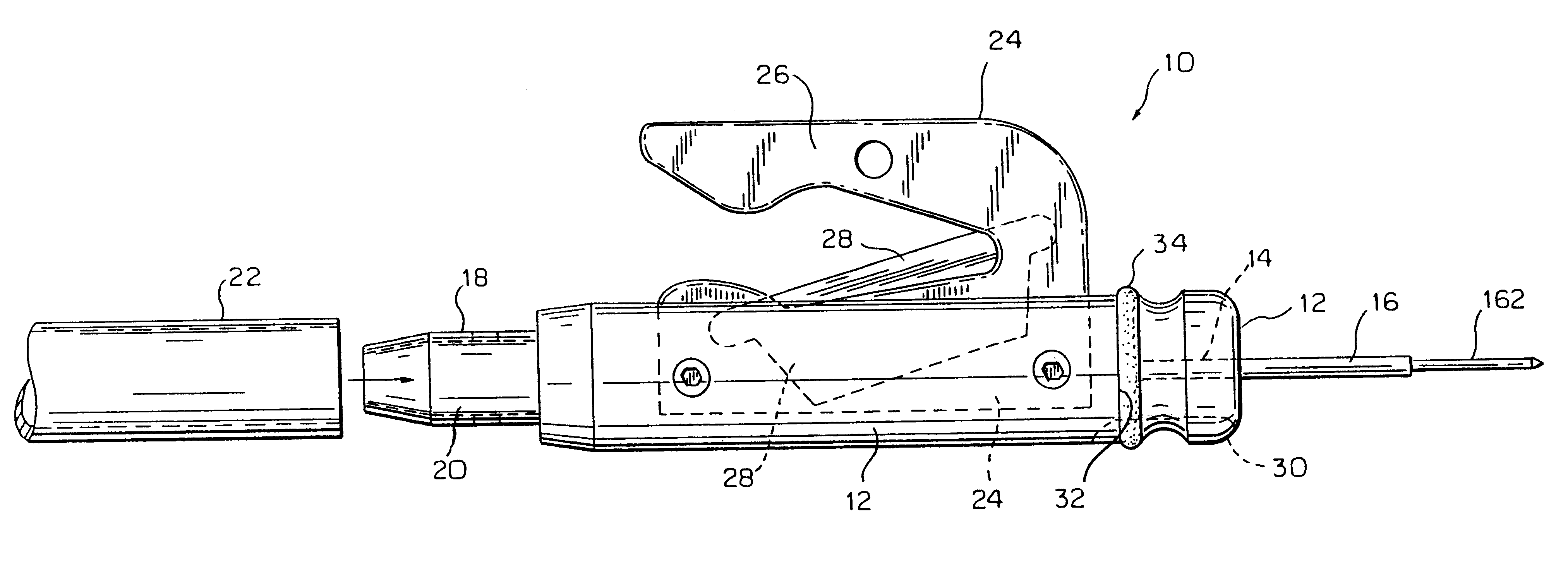

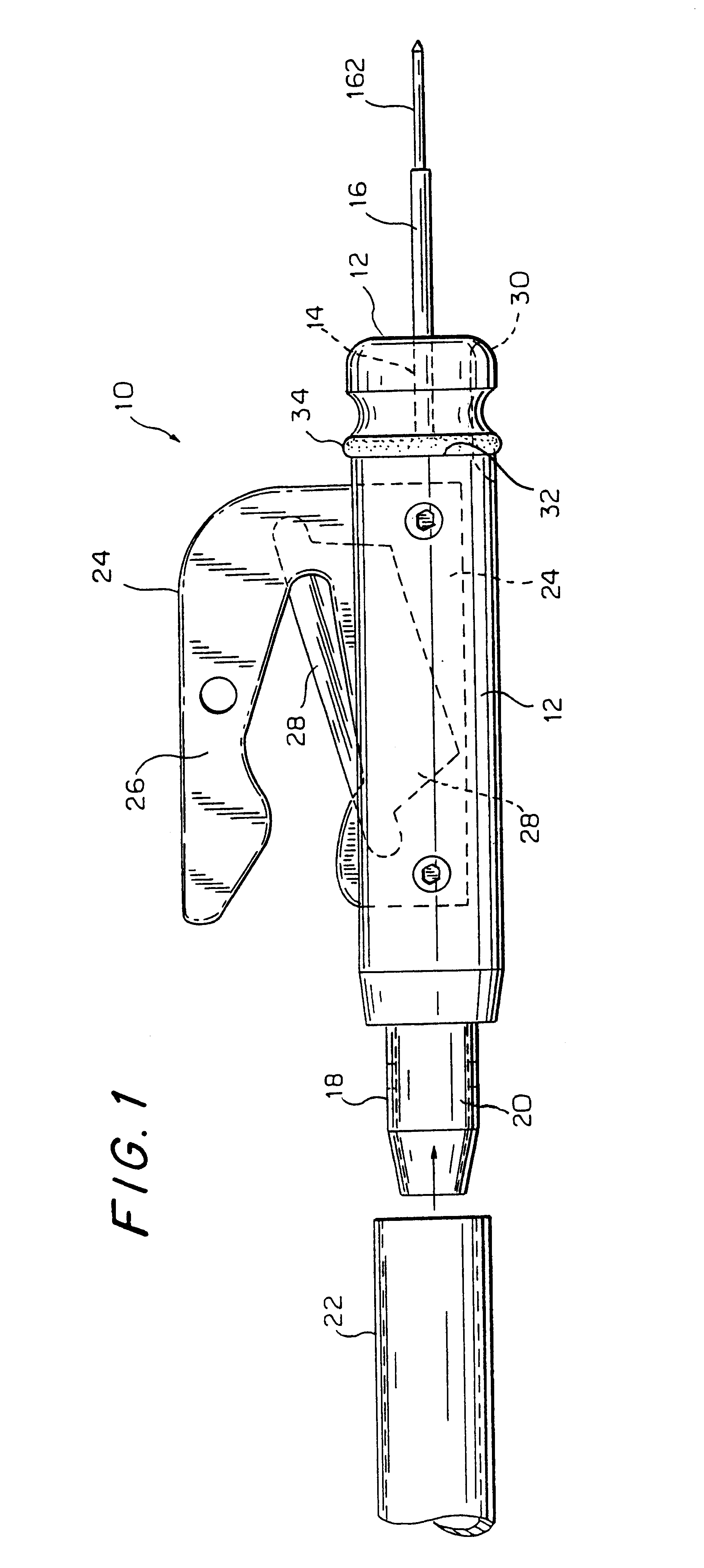

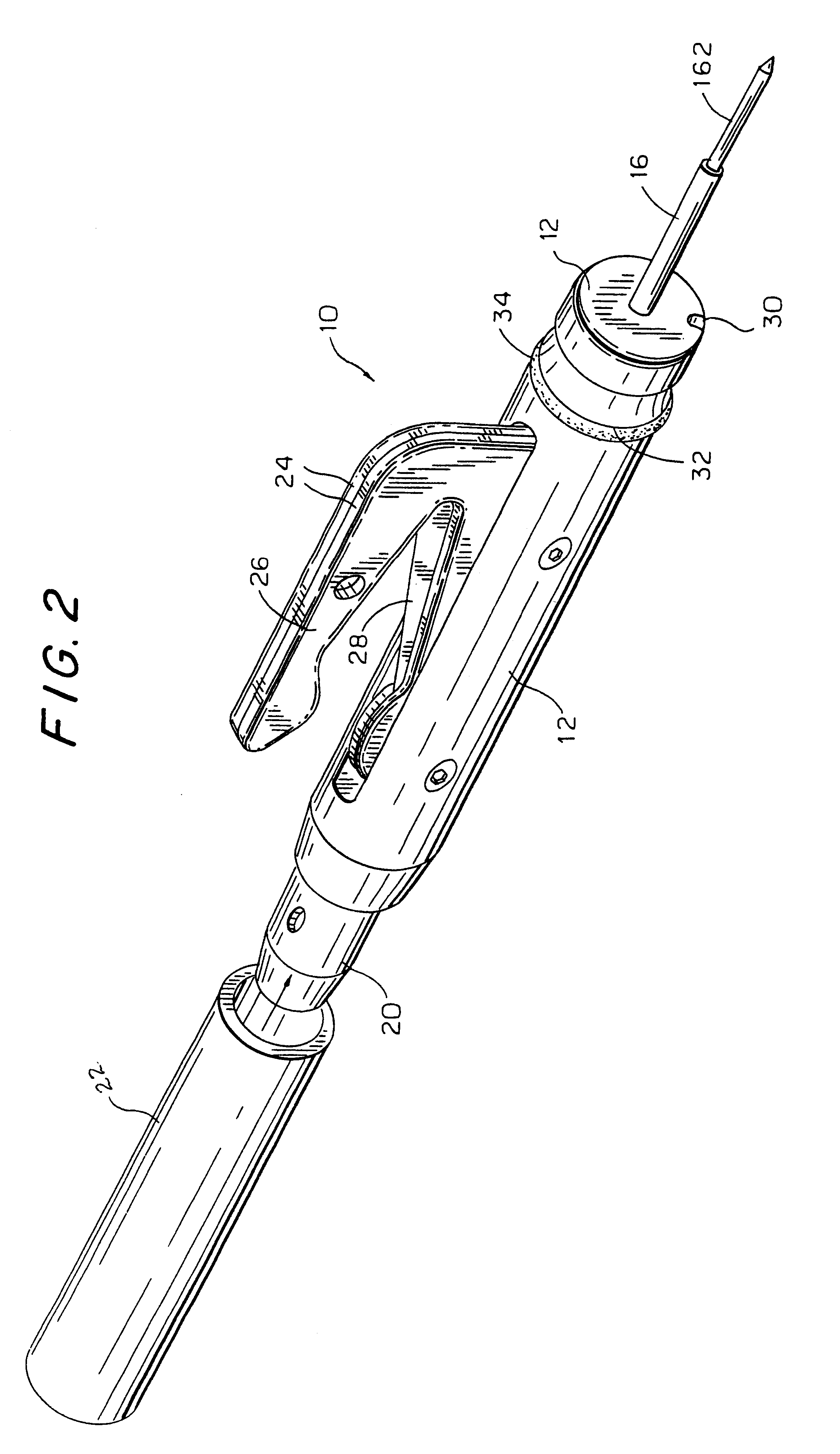

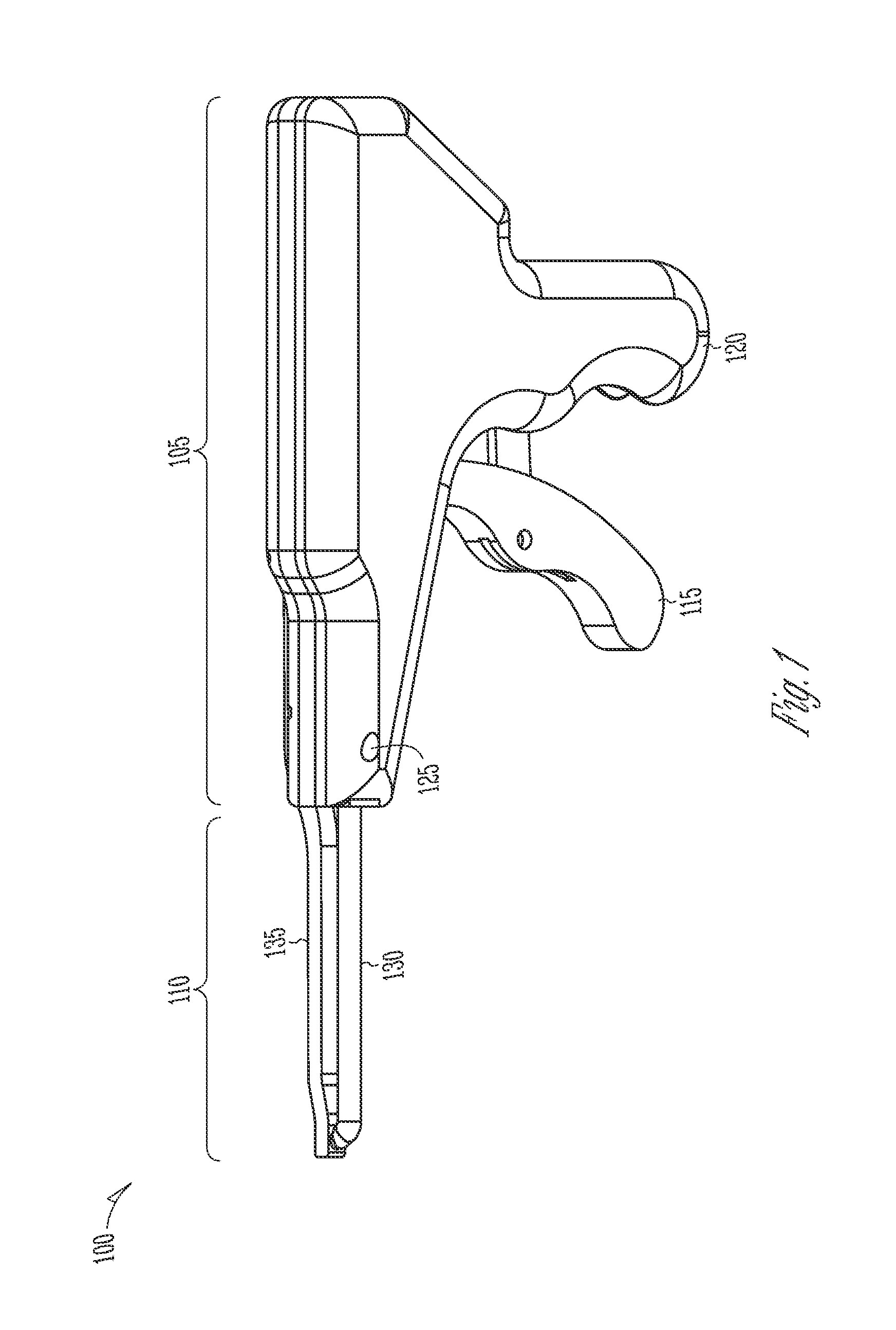

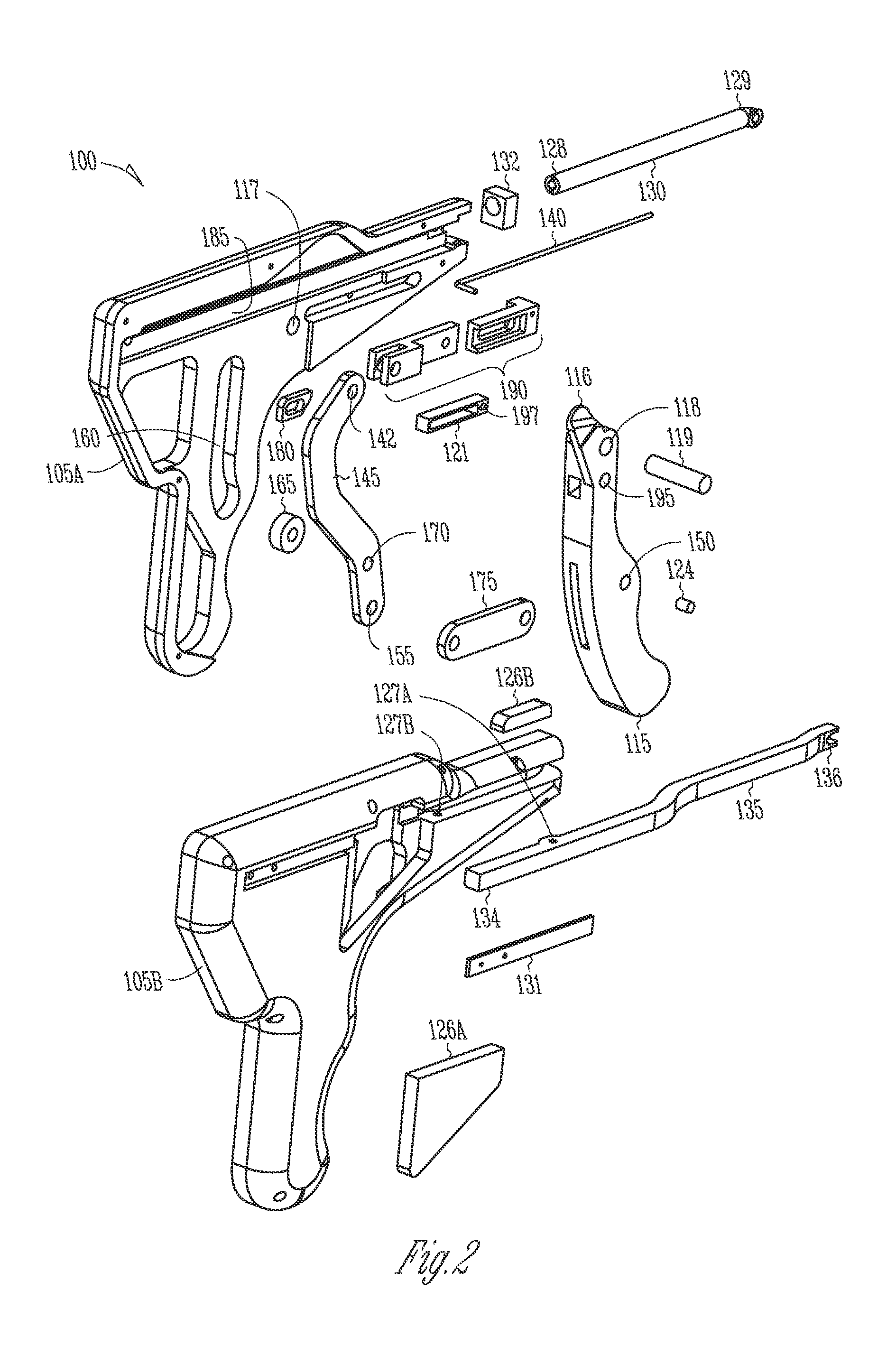

Tool for dispensing plastic fasteners

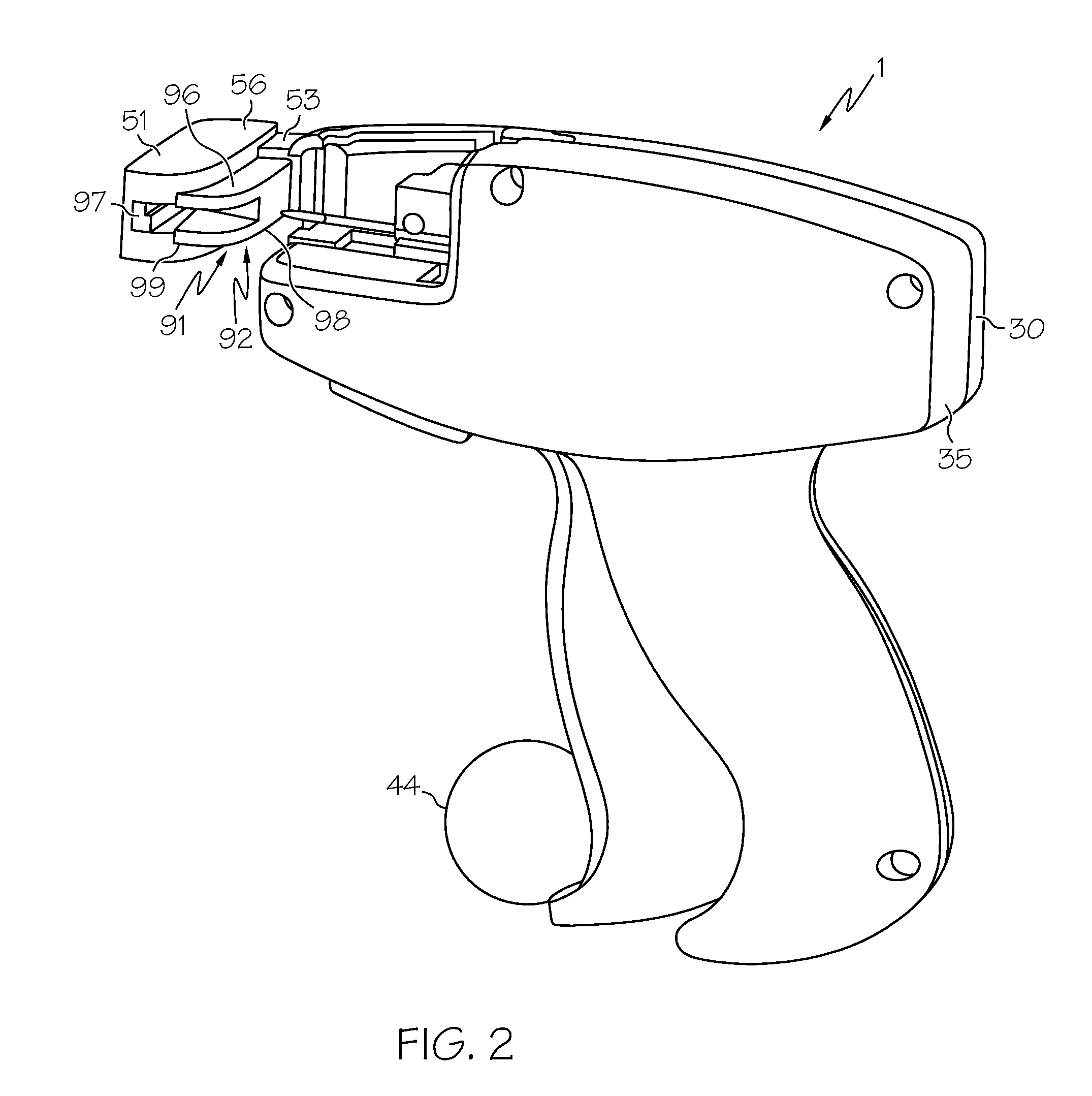

ActiveUS7331497B2Smooth trigger strokeReduce in quantityLabelling deformable materialsAffixing tagsSyringe needleBiomedical engineering

A tool for dispensing fasteners from a fastener clip having a runner bar comprises a housing shaped to include a handle portion, a barrel portion and a guide channel for receiving the used portion of the runner bar. A trigger assembly is pivotally mounted in the handle portion. The tool also includes a needle slide slidably mounted in the barrel portion, a needle coupled to the needle slide, and a needle slide link coupling the needle slide to the trigger assembly. An ejector slide is slidably mounted within the needle slide and adapted to receive an ejector rod which is insertable back and forth through the hollow needle. The needle slide and the ejector slide are independently coupled to the trigger assembly. An anvil extends out in front of the barrel portion and is adapted to receive a removable brush, the needle being aligned to selectively project into the brush.

Owner:AVERY DENNISON CORP

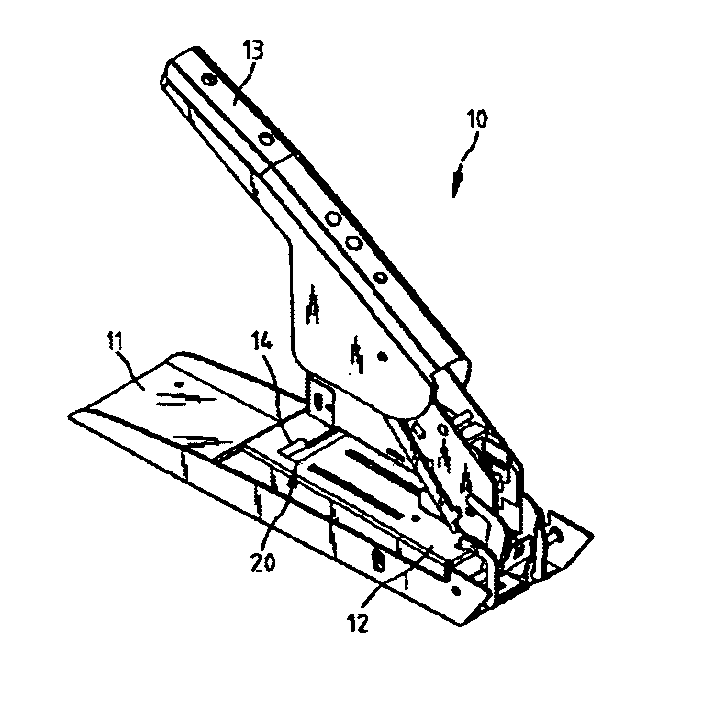

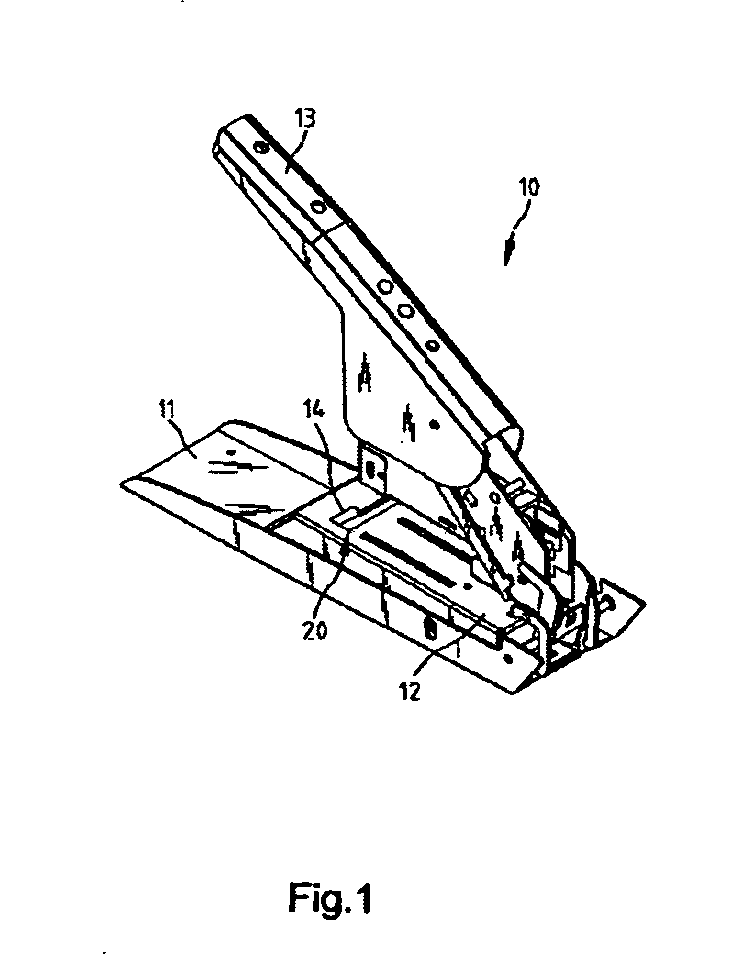

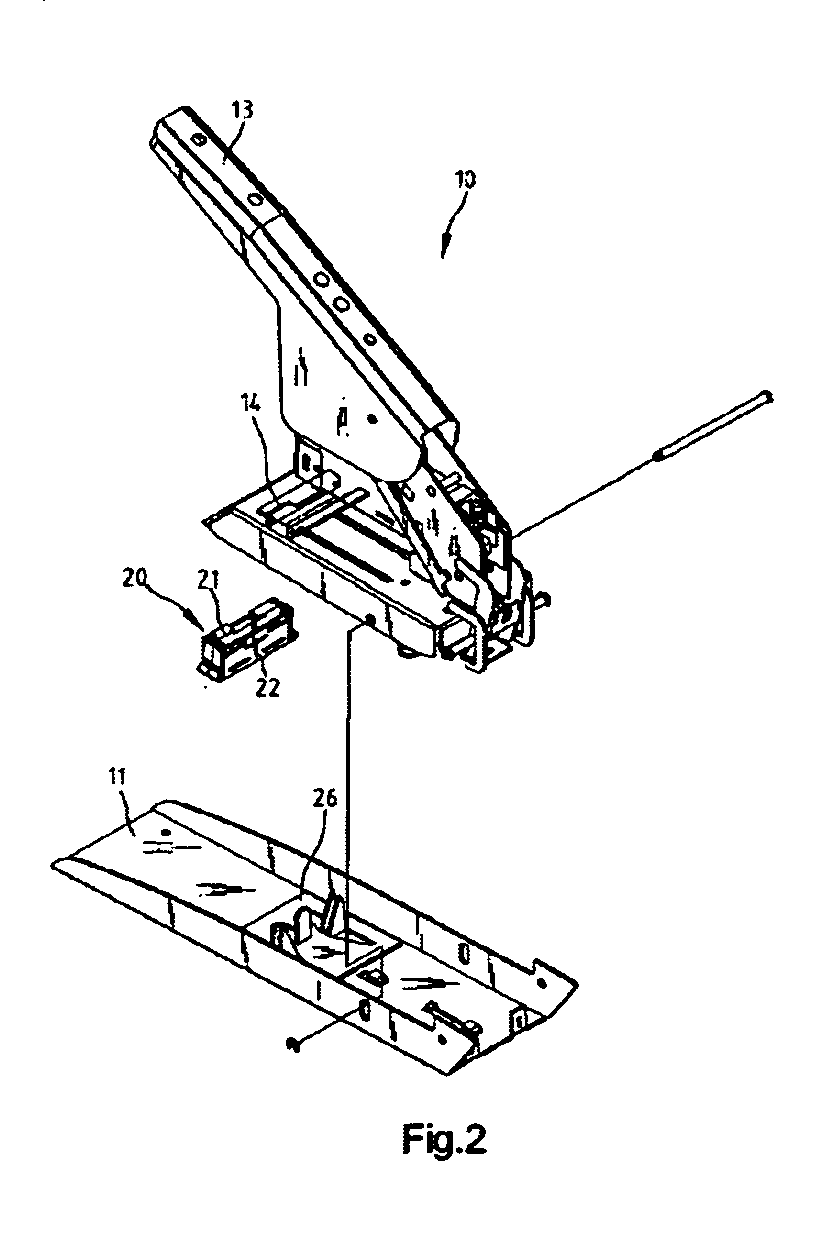

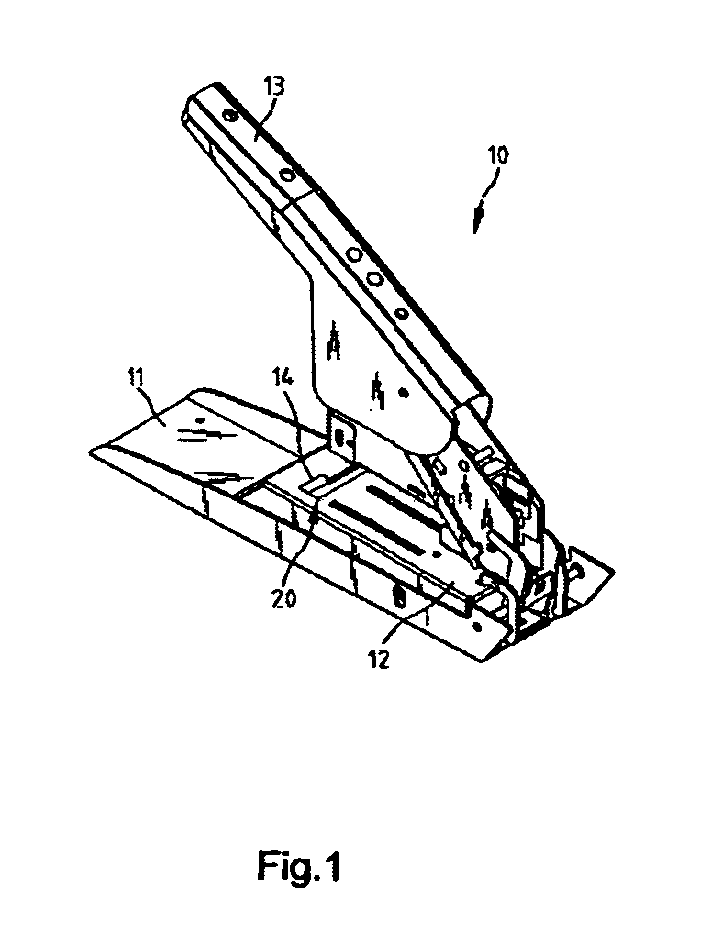

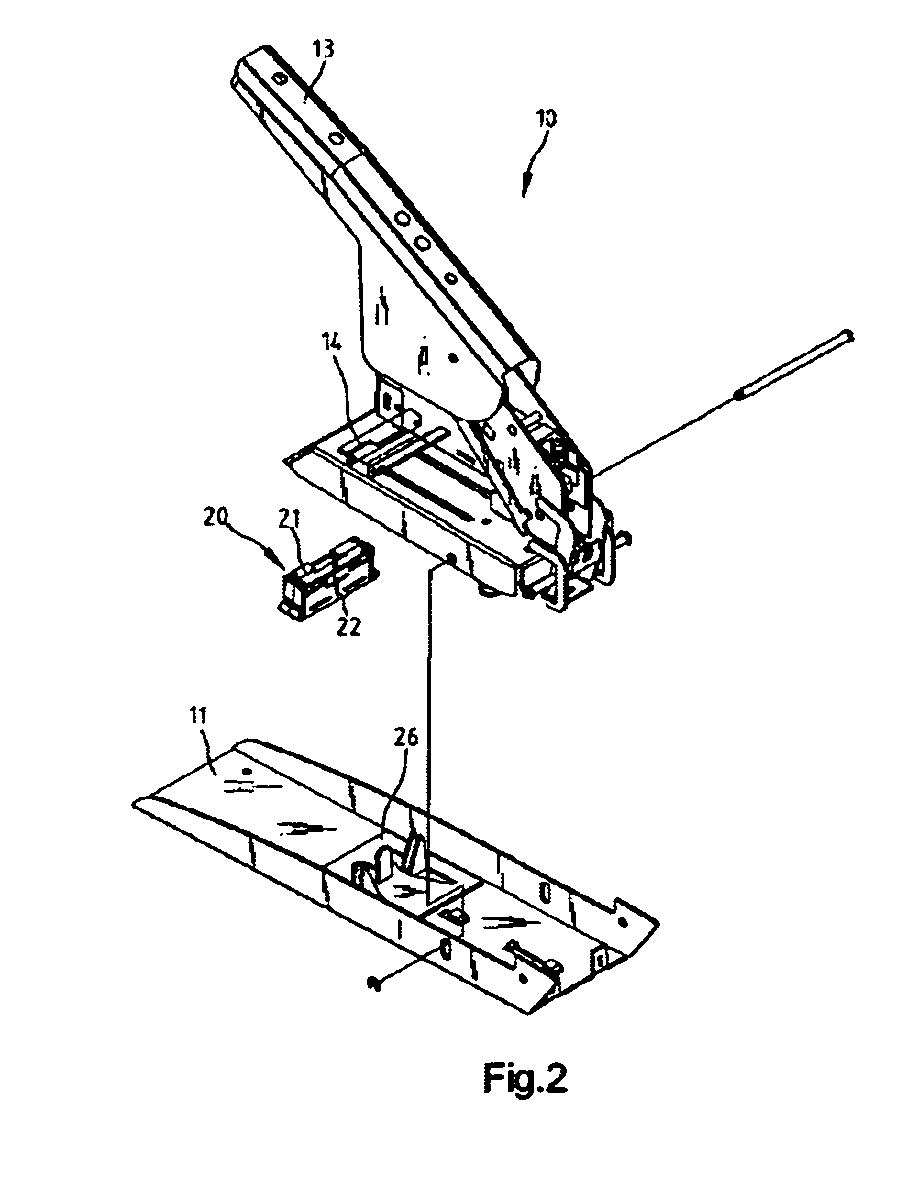

Stapler with a leg-cutting device

A stapler has a main base, a pivotal base, a recoiling device, a stapling device, a connecting device and a leg-cutting device. The leg-cutting device is mounted between the main base and the pivotal base and has an upper base, a lower base, two arm holders, two pushing arms, a cutting pad, two cutting blocks, two guiding blocks and two biasing members. The lower base has an arm-lifting top surface. The pushing arms are pivotally connected to the arm holders and each has a sliding end slidably attached to the arm-lifting top surface of the lower base and a pushing end. The cutting blocks are attached respectively to the pushing ends of the pushing arms. The guiding blocks are slidably mounted on the pivotal base and are driven by the cutting blocks.

Owner:APEX MFG

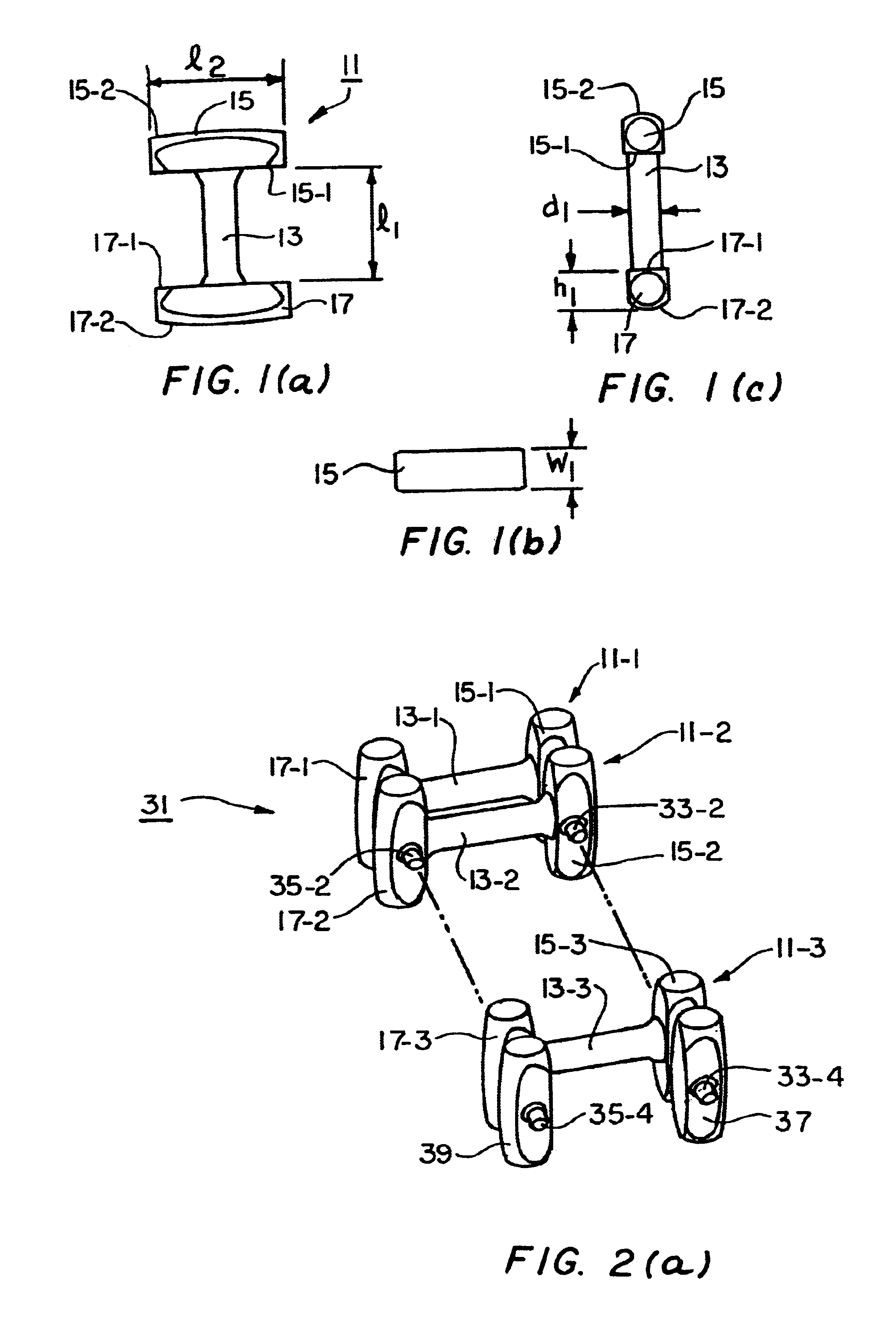

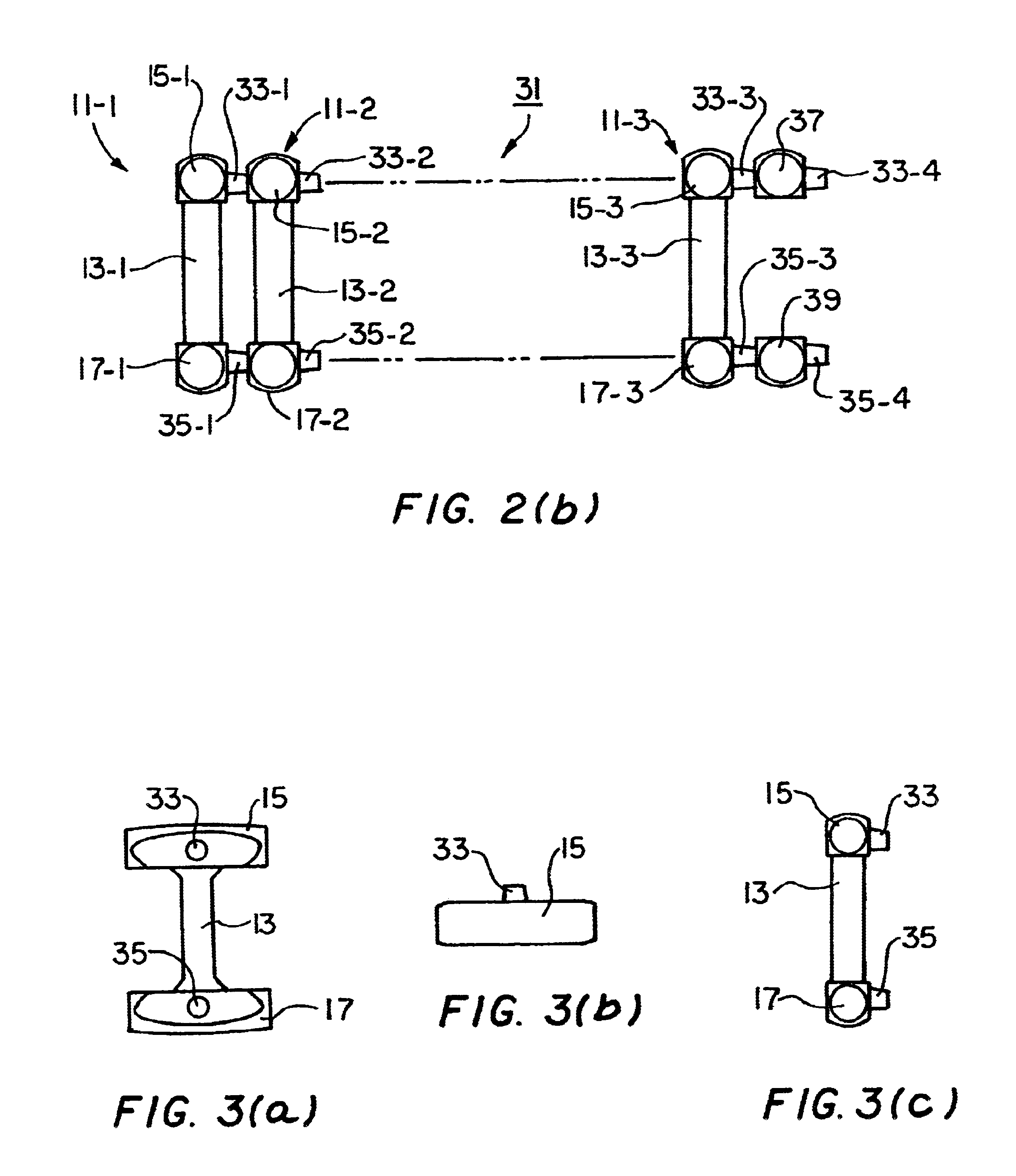

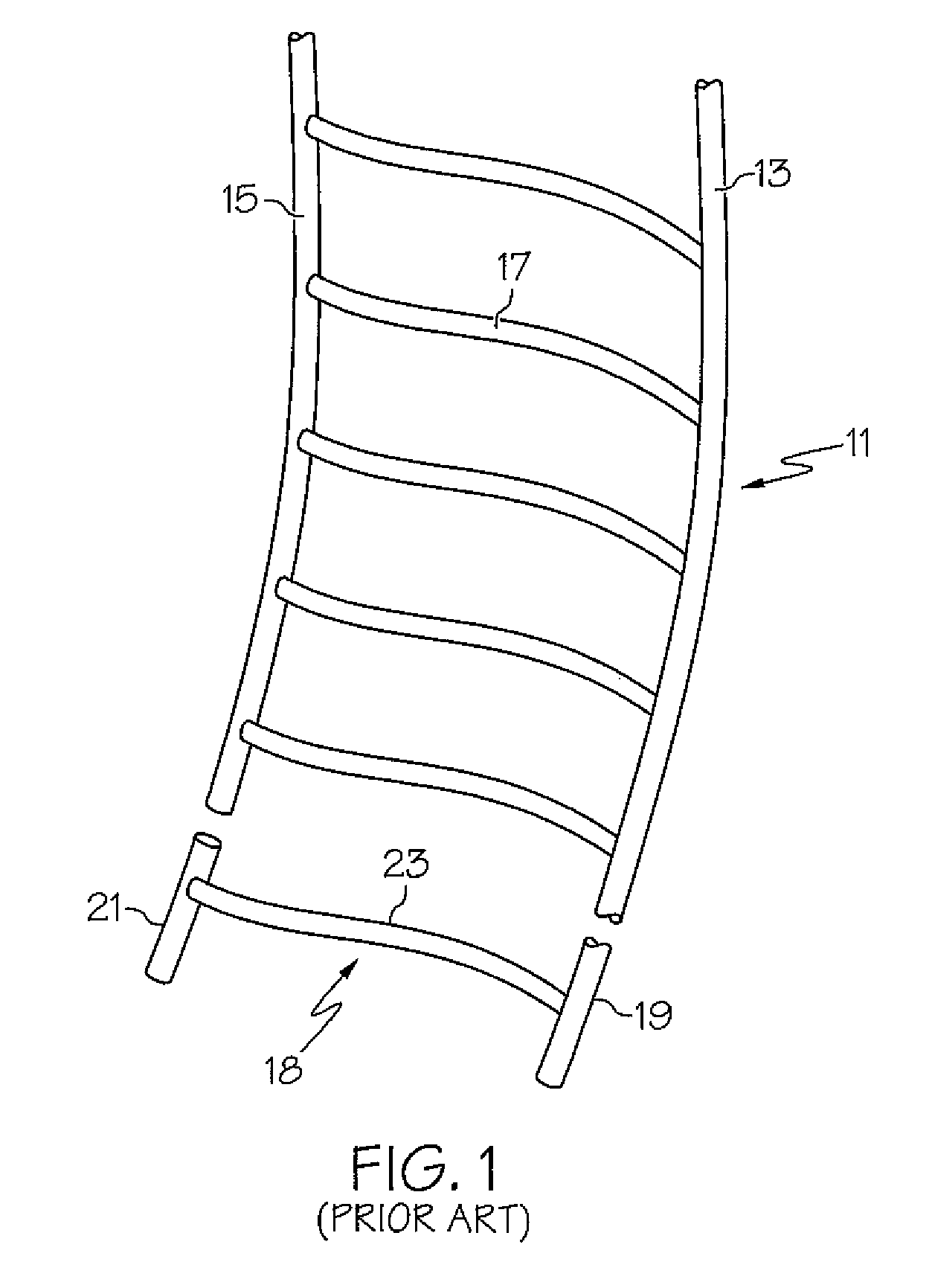

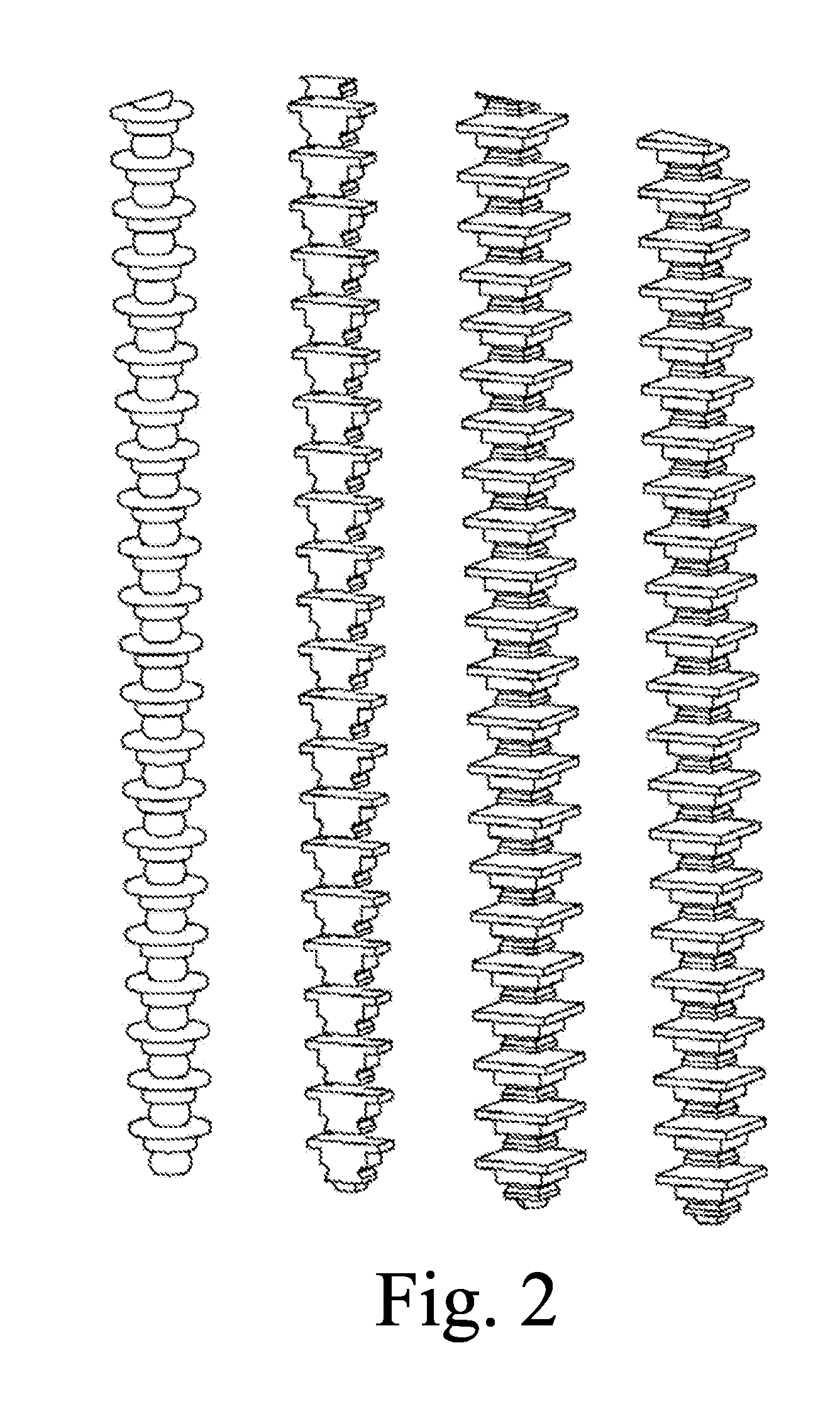

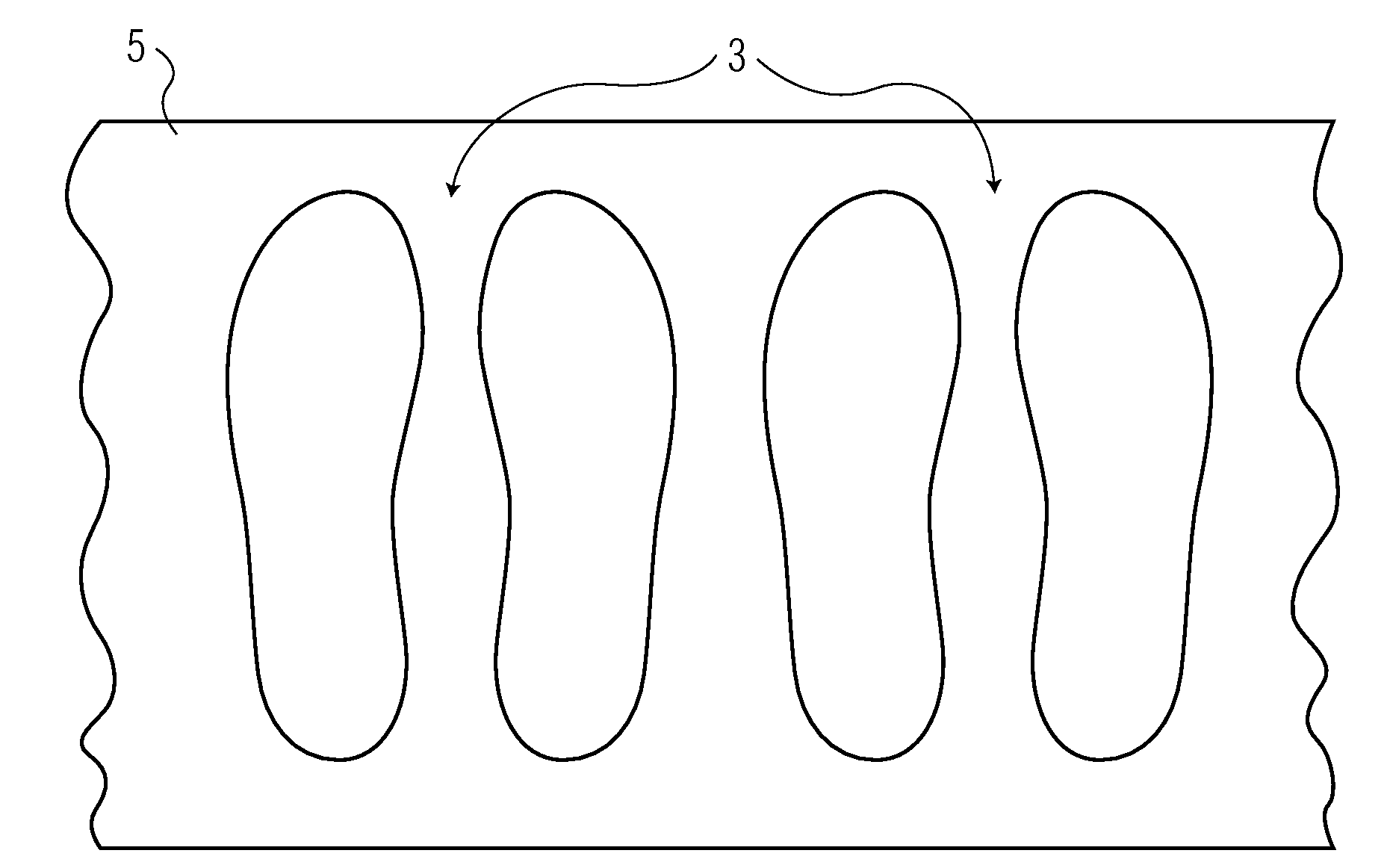

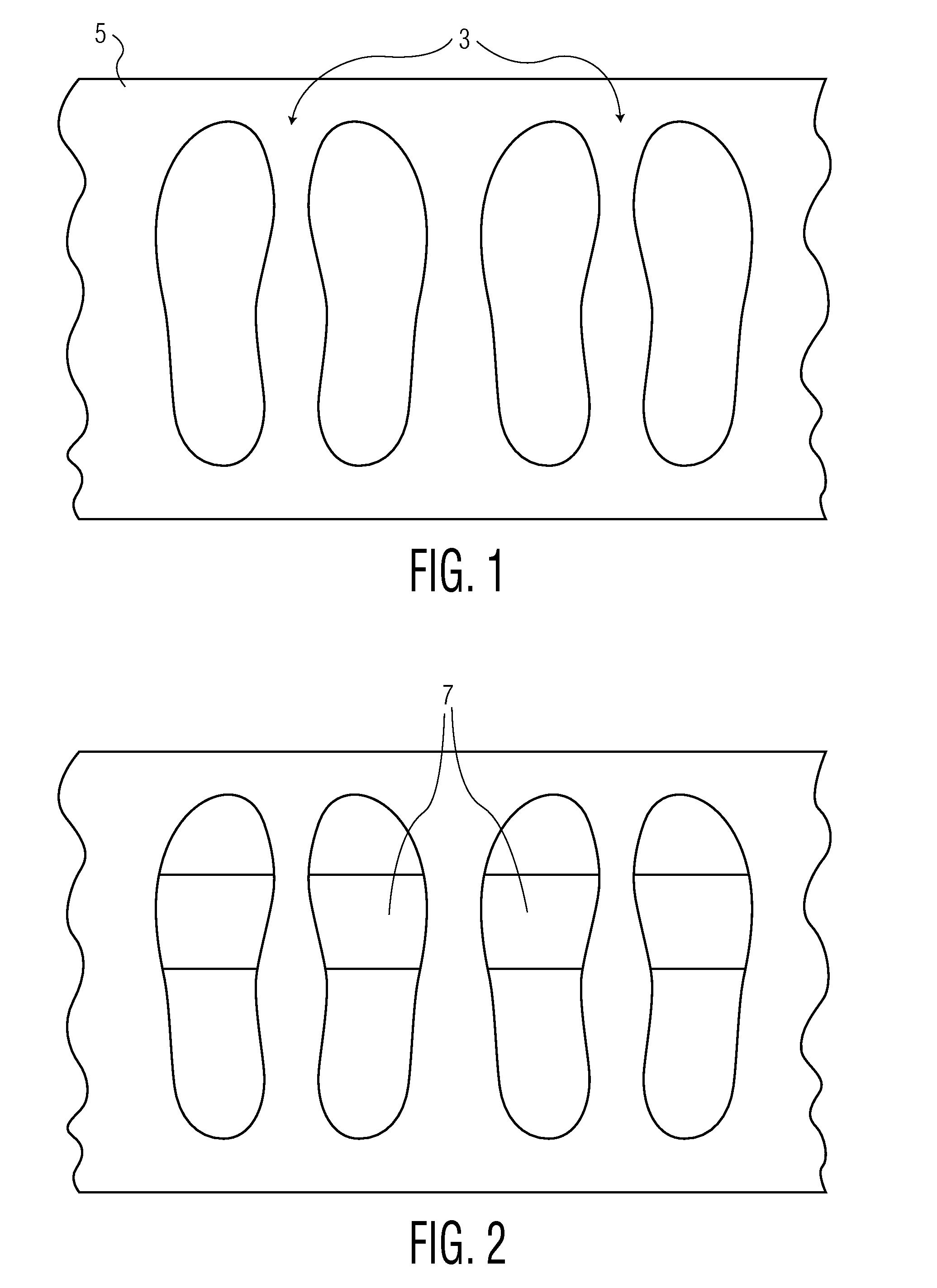

Plastic fastener, fastener clip, fastener dispensing tool and method of fastening objects

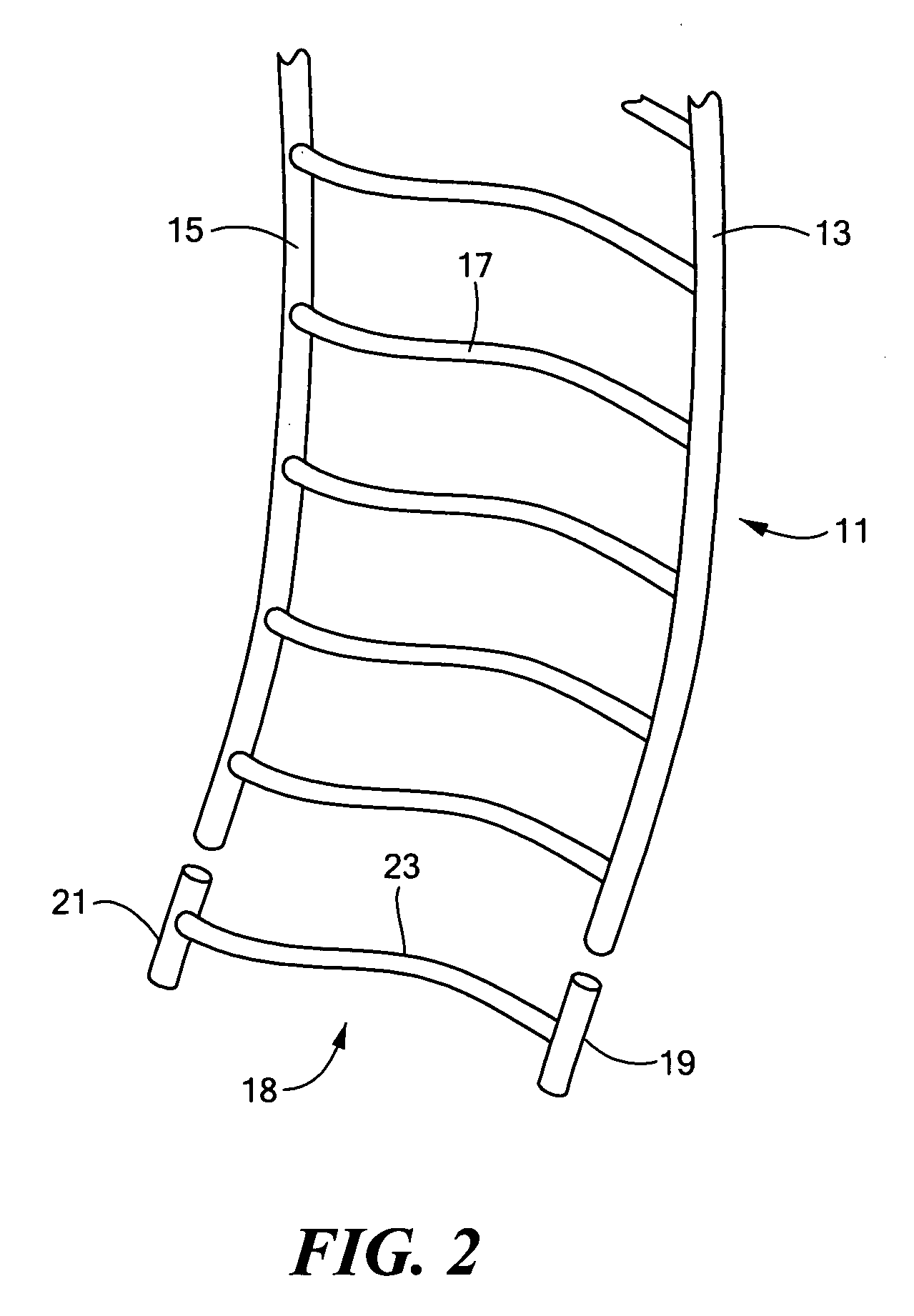

According to one embodiment, the plastic fastener comprises a flexible filament having a length of about 4.3 mm and a tensile strength of about 2 pounds, a first transverse bar located at one end of the flexible filament, and a second transverse bar located at the opposite end of the flexible filament. The fastener clip, which preferably does not contain a runner bar, comprises a plurality of identical fasteners of the aforementioned type, each of the fasteners being arranged in a parallel, side-by-side, spaced relationship. A connector post connects the first transverse bars of adjacent fasteners, and a connector post connects the second transverse bars of adjacent fasteners. An extra transverse bar is connected by a connector post to the first transverse bar of the last fastener, and another extra transverse bar is connected by a connector post to the second transverse bar of the last fastener, the extra transverse bars not being interconnected by a flexible filament.

Owner:AVERY DENNISON CORP

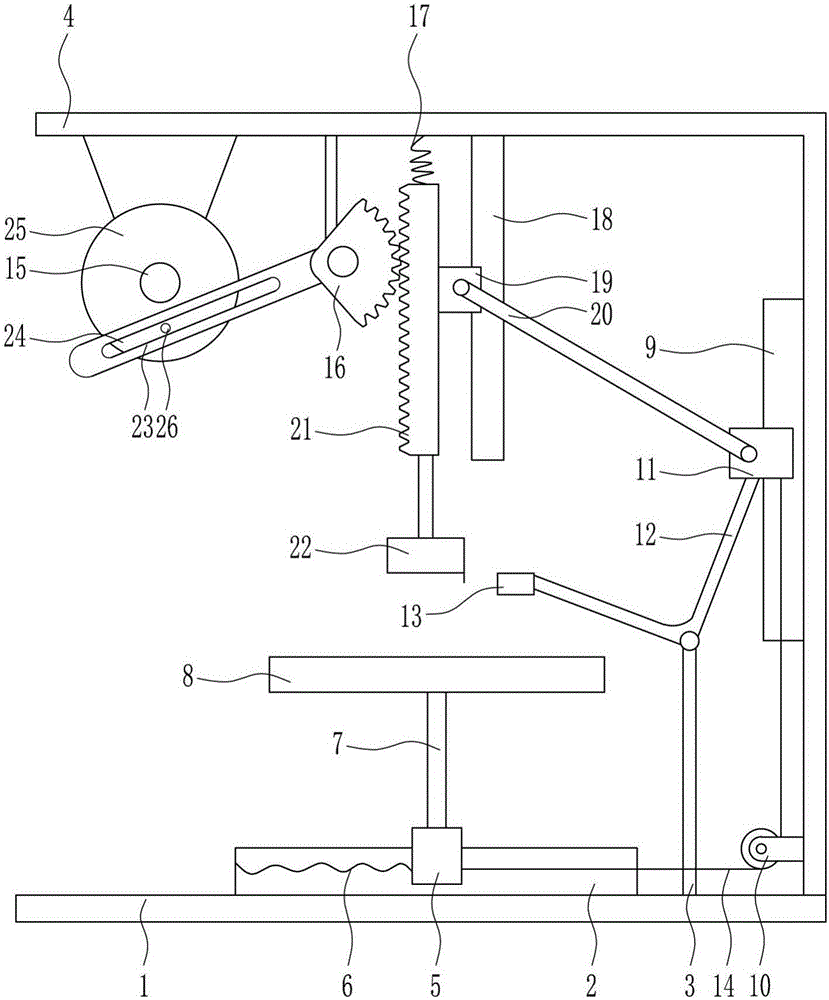

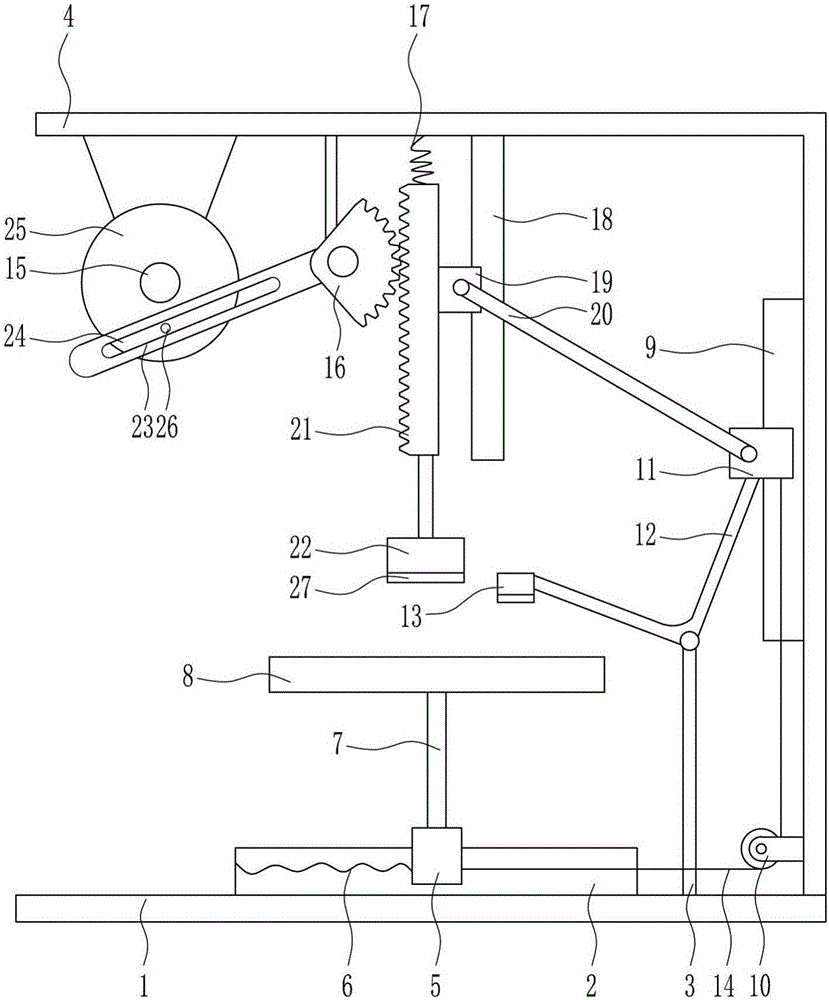

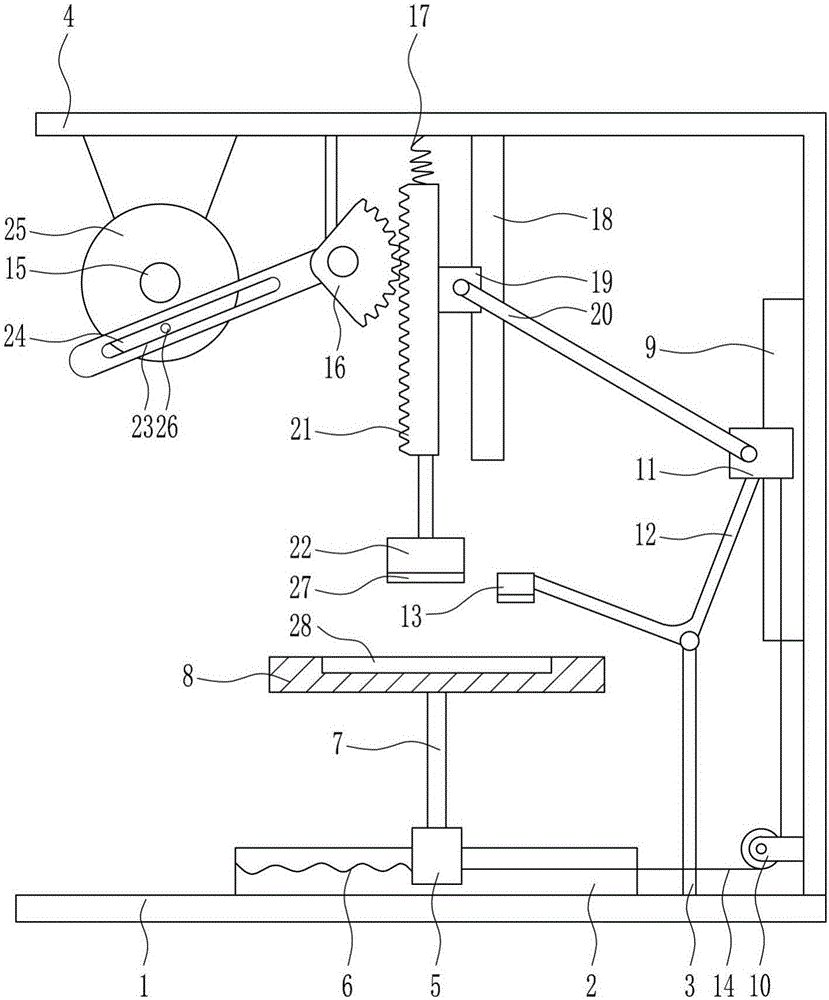

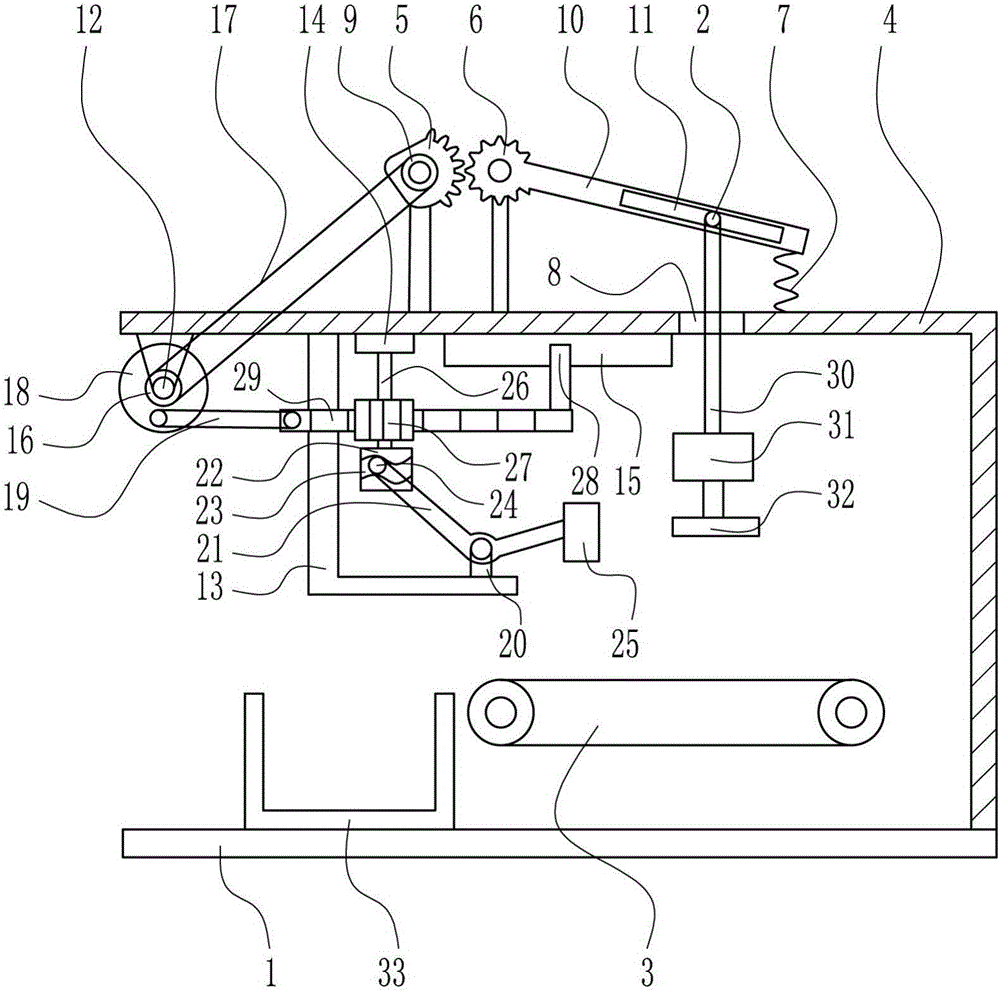

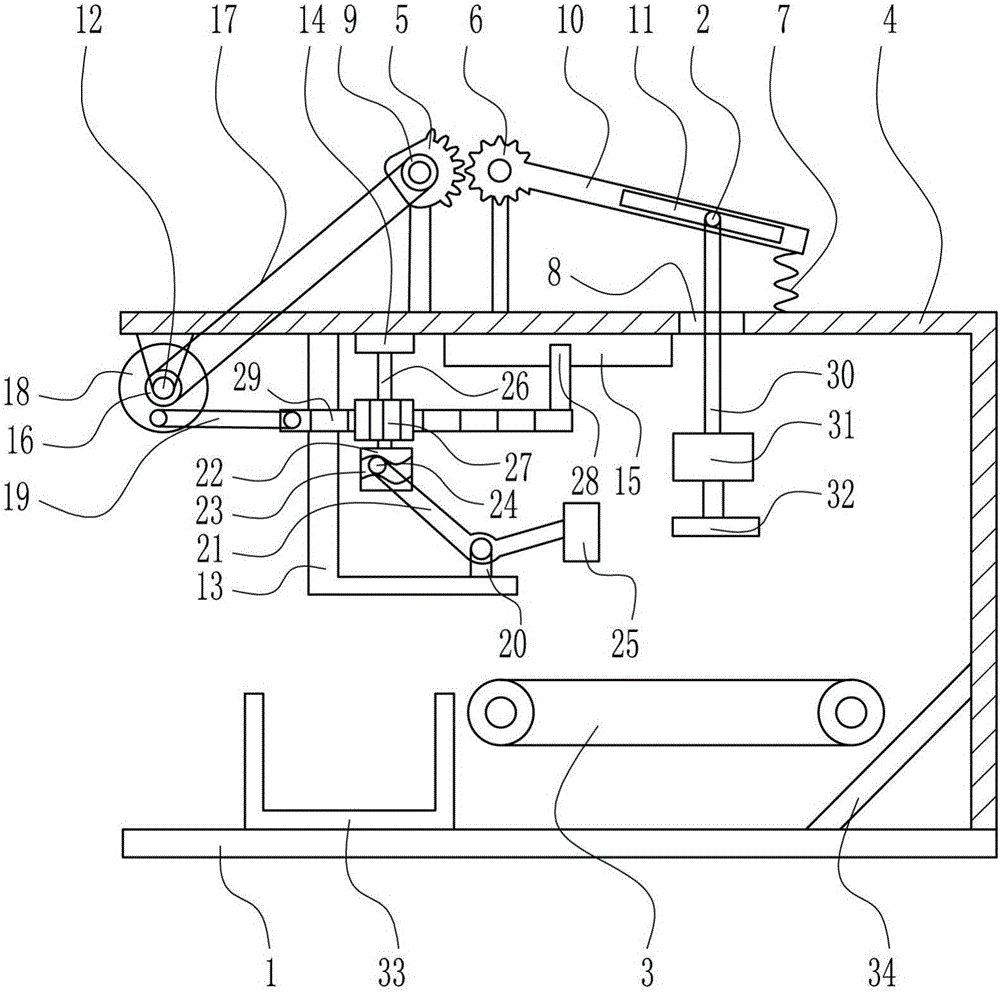

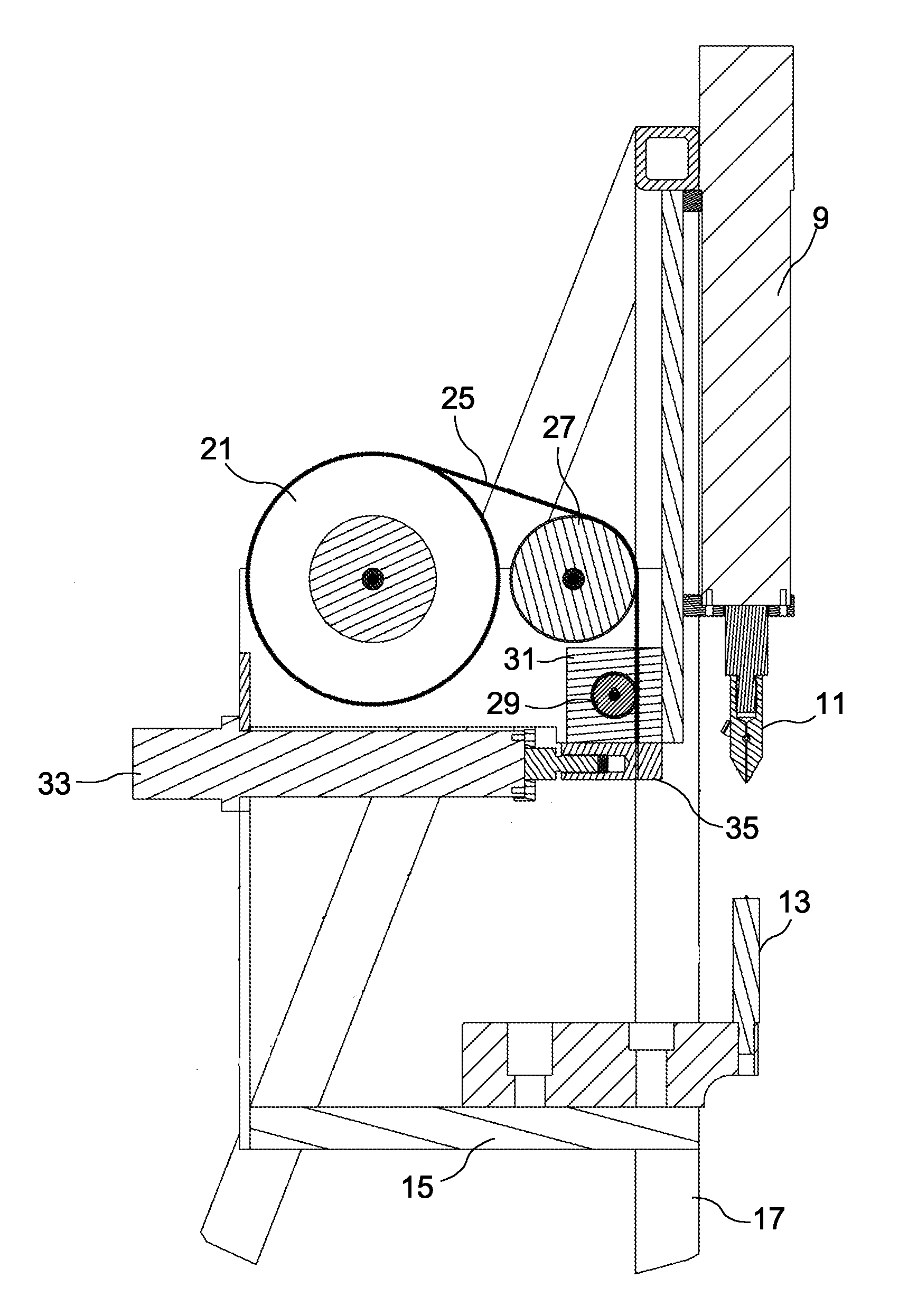

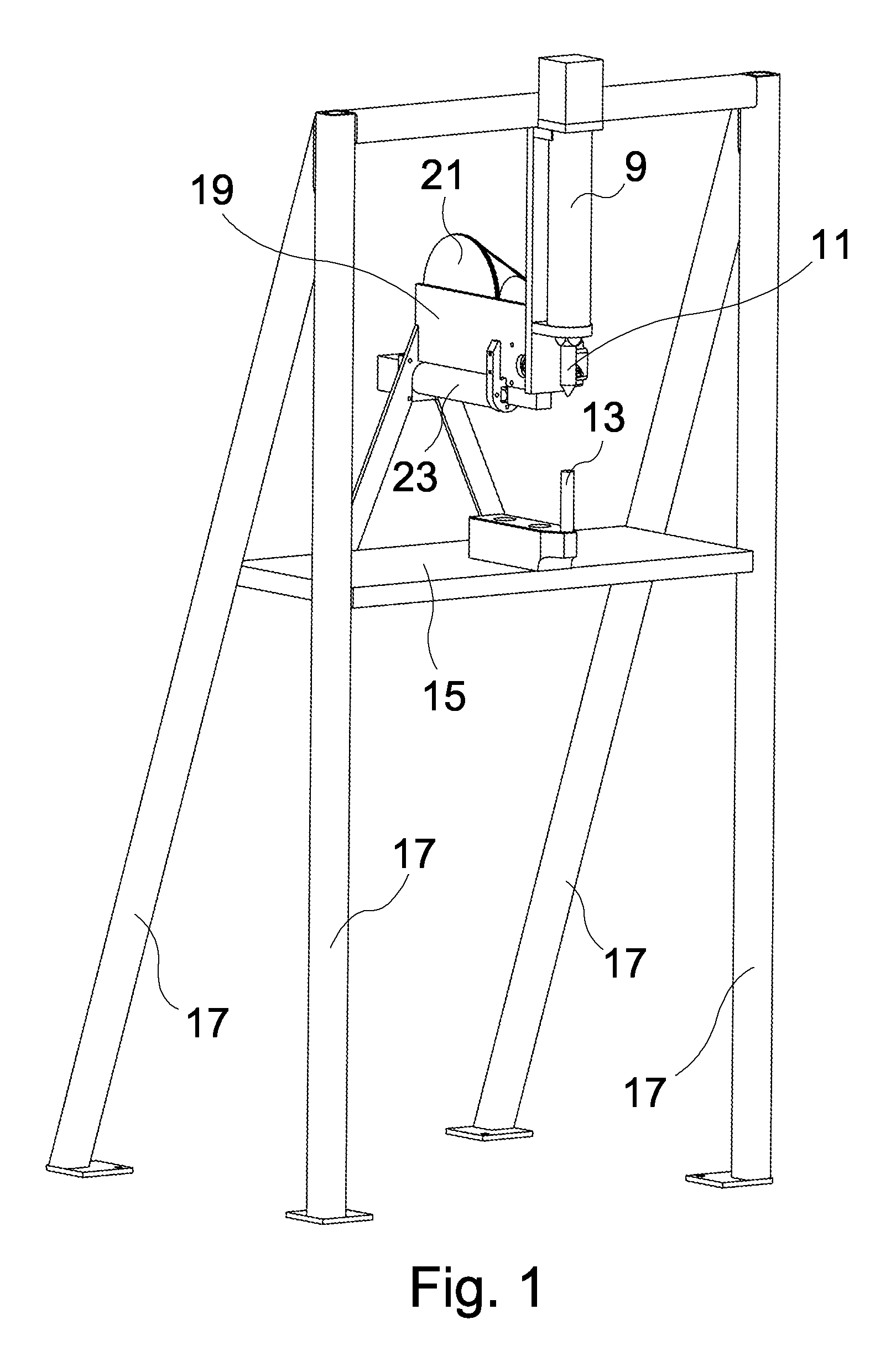

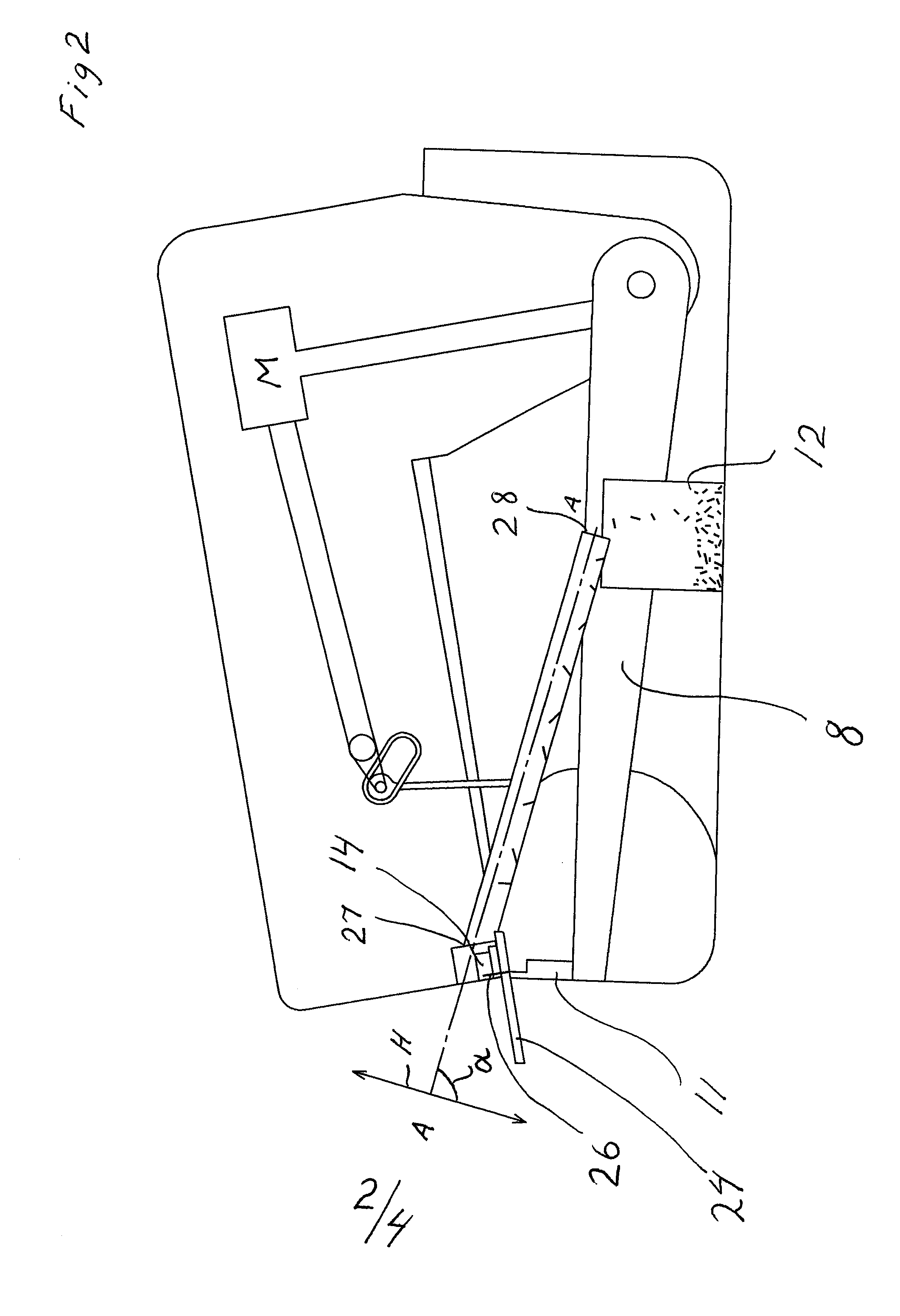

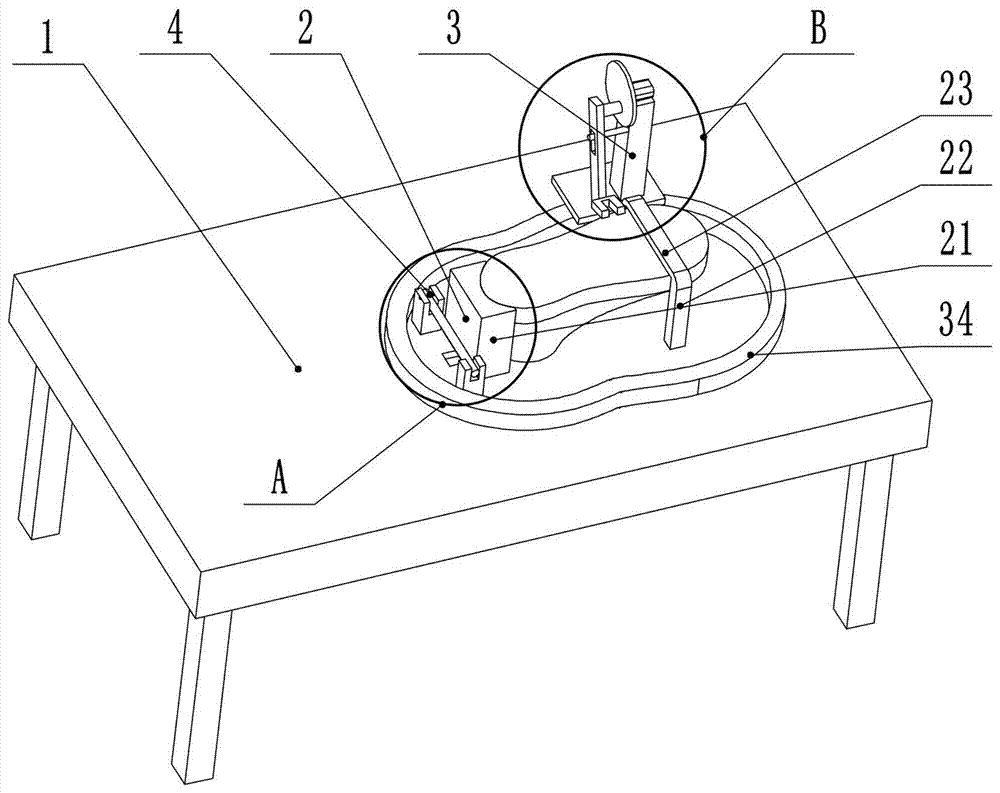

Fast insole nail striking device for shoe production

The invention relates to an insole nail striking device, in particular to a fast insole nail striking device for shoe production, and aims at solving the technical problem of providing a fast insole nail striking device which is used for shoe production and is low in manufacturing cost and easy to operate and high in working efficiency in the processing of striking a nail into an insole. For solving the technical problems, the fast insole nail striking device for shoe production comprises a bottom plate, a first sliding rail, a first support rod, a T-shaped support, a first sliding block, a first spring, a second support rod, a carrying plate, a second sliding rail, a pulley, a second sliding block, an arc-shaped connecting rod, a first striking block, a pulling rope, a motor, a fan-shaped gear, a connecting rod, a rack, a second striking block, a swing rod, a disc, a roller and the like. According to the fast insole nail striking device for shoe production, the nail more quickly enters the insole by adopting the mode of combining the first striking block with the second striking block.

Owner:张浩杰

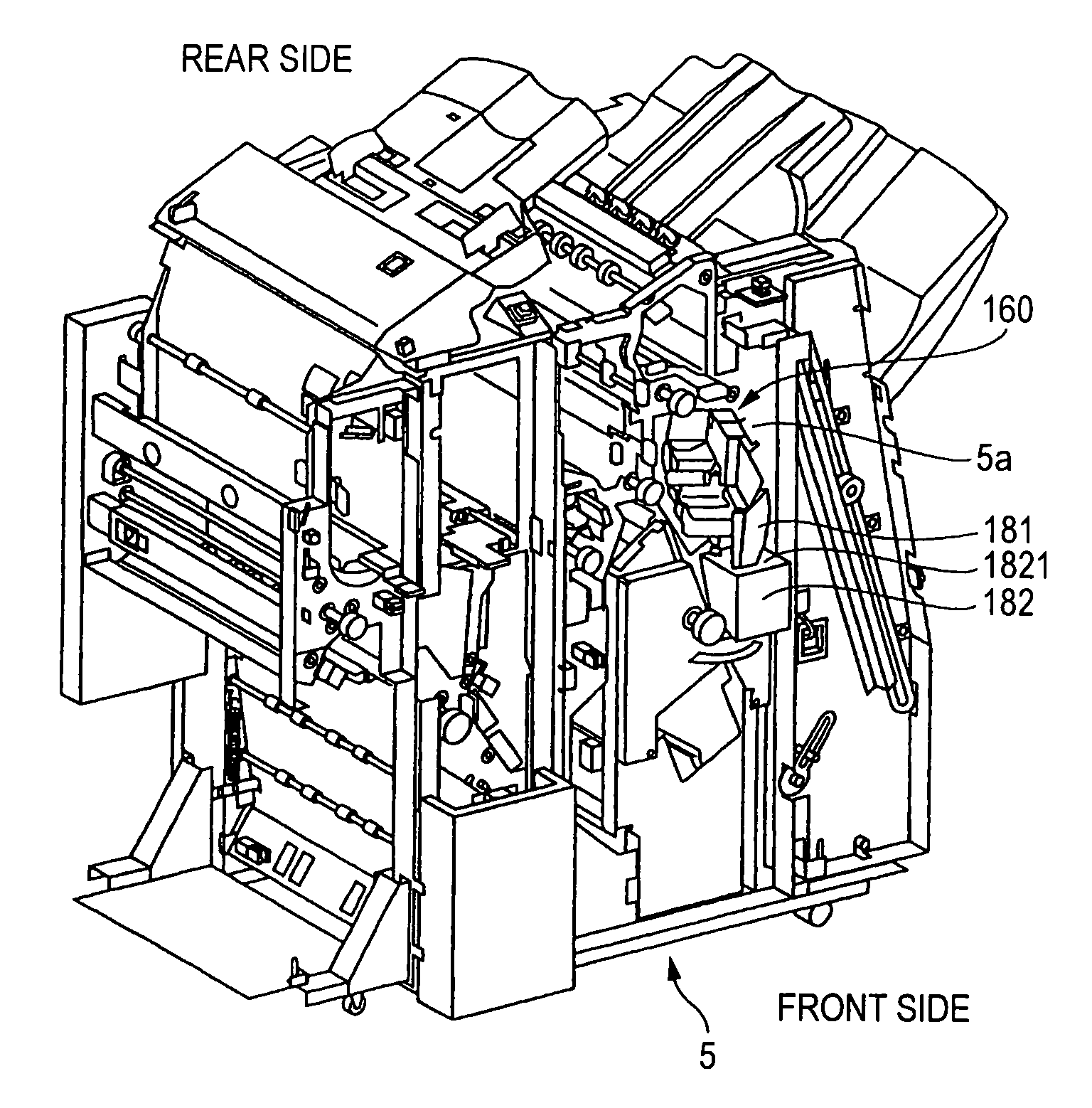

Stapling device

ActiveUS7396008B2Reduce the likelihood of occurrenceProductivity is deterioratedStapling toolsNailingElectrical and Electronics engineeringEngineering

A stapler unit has a staple section, a cutter section, and a receiving section. A stapling device further includes a staple recovery box which is disposed at a staple discarding position and which recovers the tip ends to be discarded from the receiving section; and a staple discarding mechanism which delivers the tip ends received in the receiving section of the stapler unit to the staple recovery box. One of the plural stapling positions is identical with the staple discarding position.

Owner:FUJIFILM BUSINESS INNOVATION CORP

Stapler capable of cutting staple legs

InactiveUS20060266789A1Low costAvoid High Precision RequirementsStapling toolsNailingEngineeringMechanical engineering

A stapler includes a base, a cover put movably on the base, a feeding device for feeding staples, and a bending and cutting device provided between the base and the cover for bending and cutting the legs of each staple. The cutting device includes a seat provided on the base and a housing attached to the cover. The seat includes two wedges formed thereon and a pusher formed thereon. A stationary cutting element is provided in the housing. Two movable cutting elements are provided movably in the housing and on the two wedges so that they are moved towards the stationary cutting element in order to cut the legs of each staple as they are moved towards the seat together with the housing. A spring is put between the movable cutting elements in a tendency to push the movable cutting elements from the stationary cutting element. Two bending elements are provided movably and pivotally in the housing above the movable cutting elements so that they are pushed by the pusher in order to bend the legs of each staple after the stationary cutting element and the movable cutting elements cut the legs of each staple.

Owner:APEX MFG

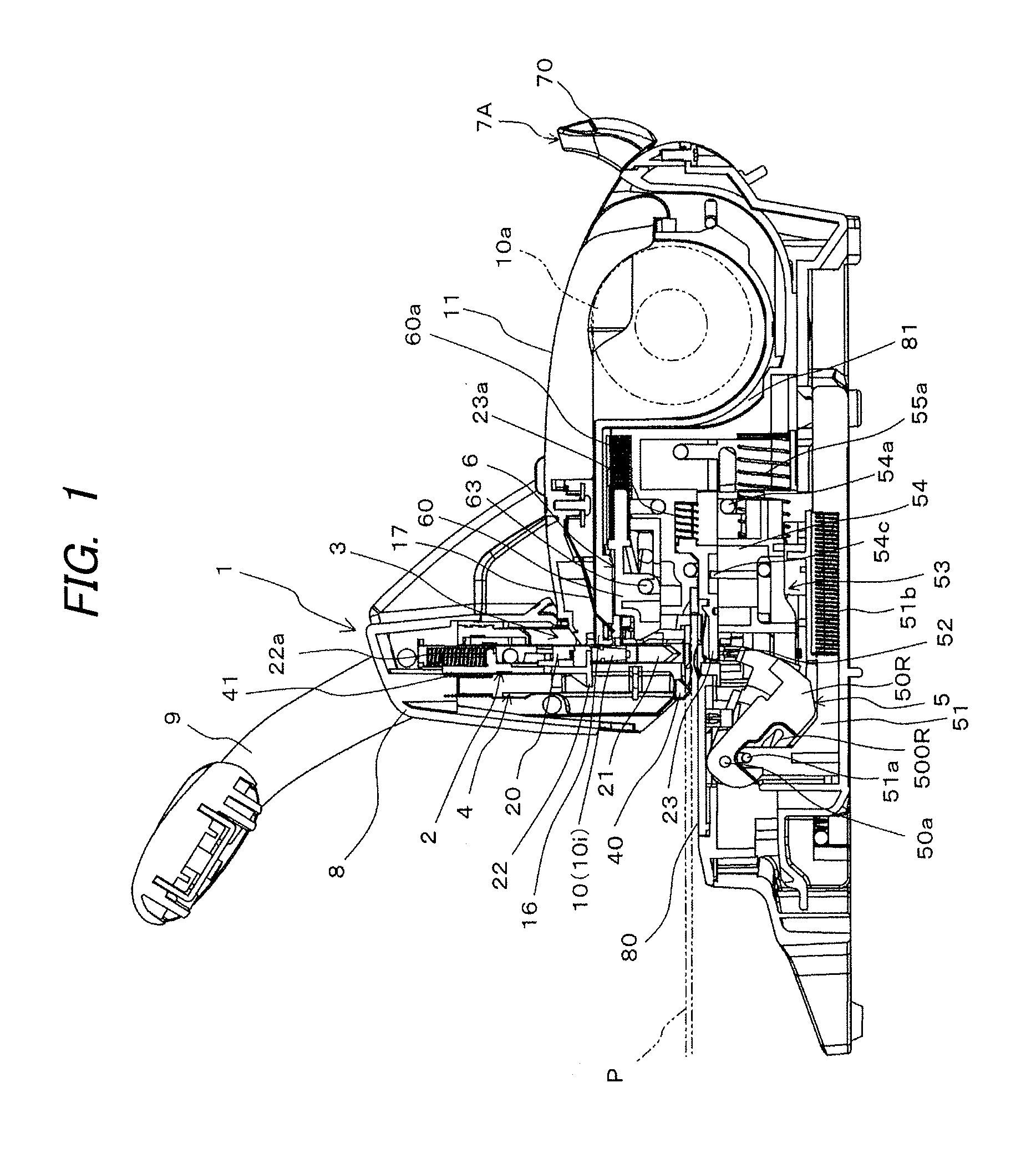

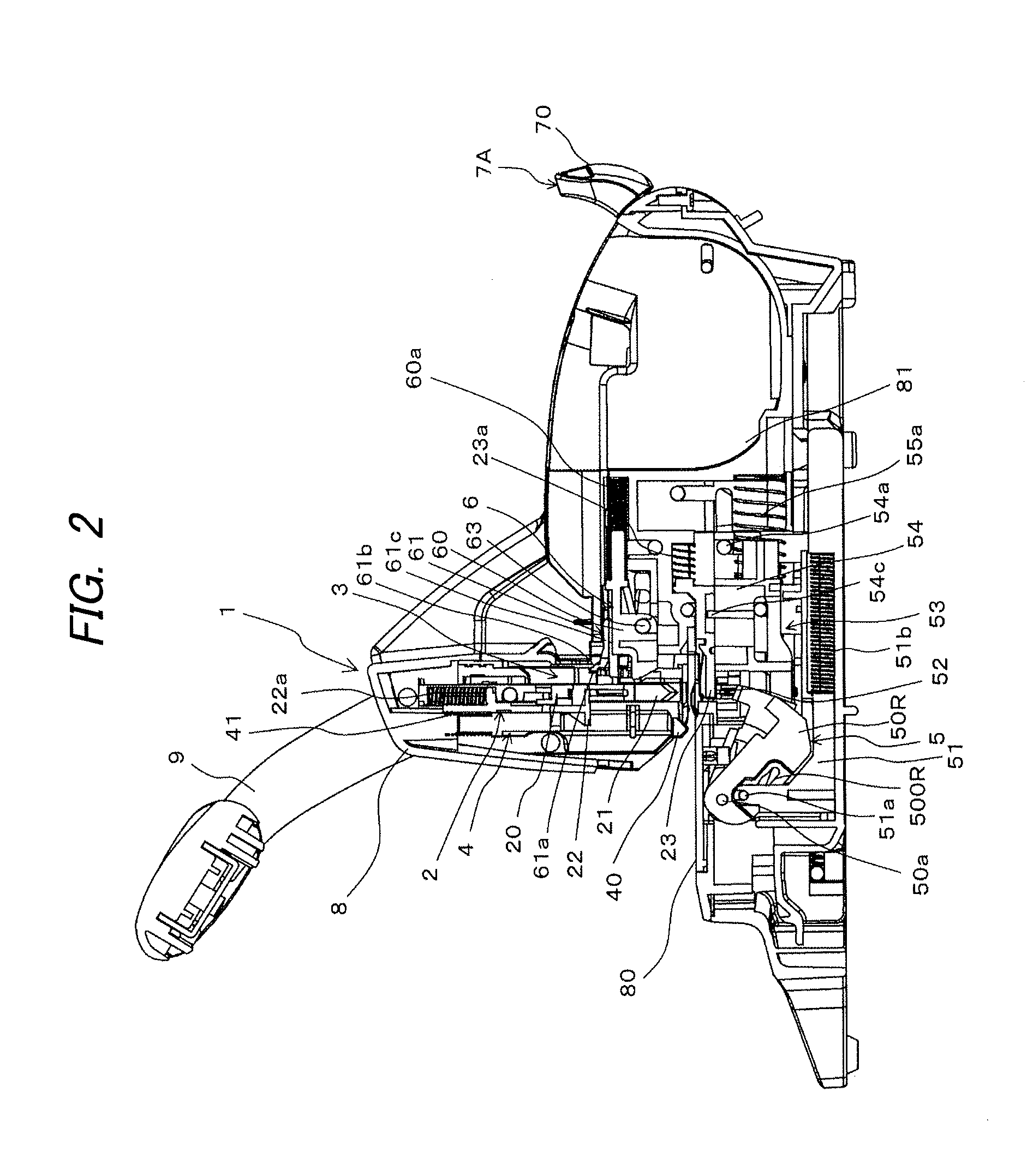

Stapler

ActiveUS20140158738A1Improve performanceGuaranteed uptimeStapling toolsNailingKnife bladesElectrical and Electronics engineering

A stapler includes a penetrating part including a pair of cutting blades to form holes in a workpiece and to cause leg portions of a staple to penetrate the workpiece, an operating member, and a bending part configured to bend the leg portions. The bending part includes a bending member configured to bend the leg portions of the staple, and a driving force transmitting section configured to transmit an operation of the operating member to the bending member.

Owner:MAX CO LTD

Stapler capable of cutting staple legs

A stapler includes a base, a cover put movably on the base, a feeding device for feeding staples, and a bending and cutting device provided between the base and the cover for bending and cutting the legs of each staple. The cutting device includes a seat provided on the base and a housing attached to the cover. The seat includes two wedges formed thereon and a pusher formed thereon. A stationary cutting element is provided in the housing. Two movable cutting elements are provided movably in the housing and on the two wedges so that they are moved towards the stationary cutting element in order to cut the legs of each staple as they are moved towards the seat together with the housing. A spring is put between the movable cutting elements in a tendency to push the movable cutting elements from the stationary cutting element. Two bending elements are provided movably and pivotally in the housing above the movable cutting elements so that they are pushed by the pusher in order to bend the legs of each staple after the stationary cutting element and the movable cutting elements cut the legs of each staple.

Owner:APEX MFG

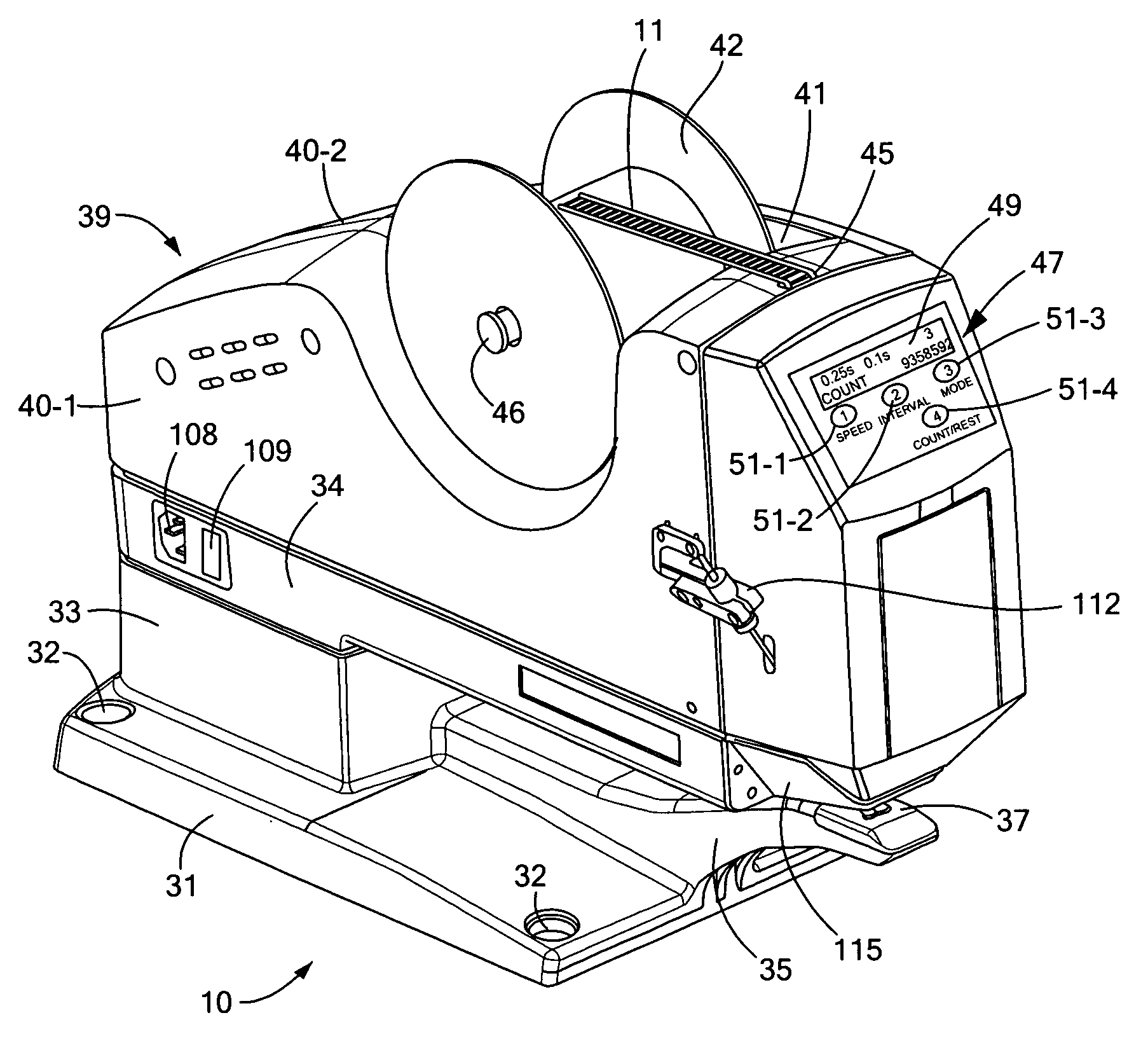

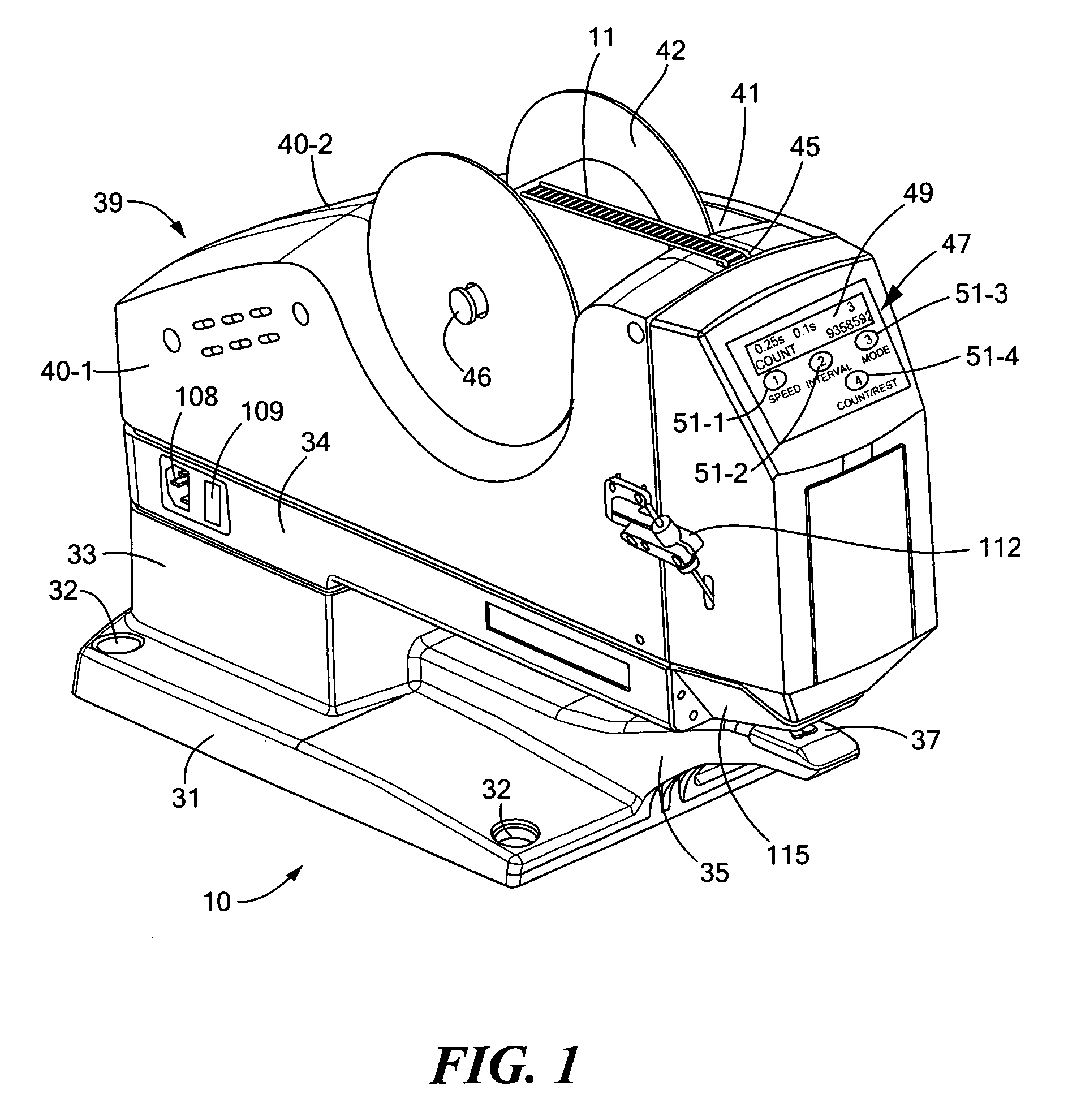

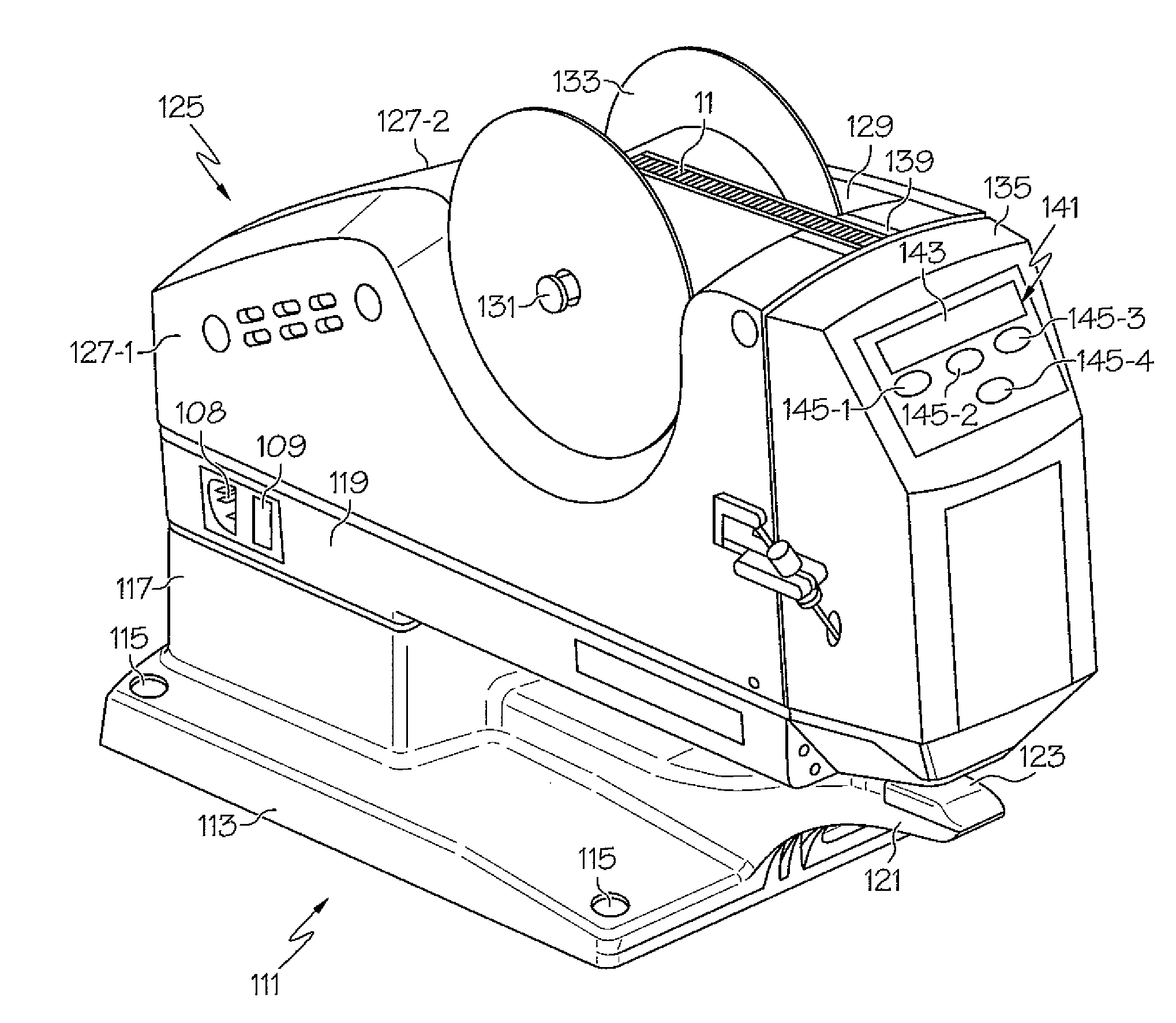

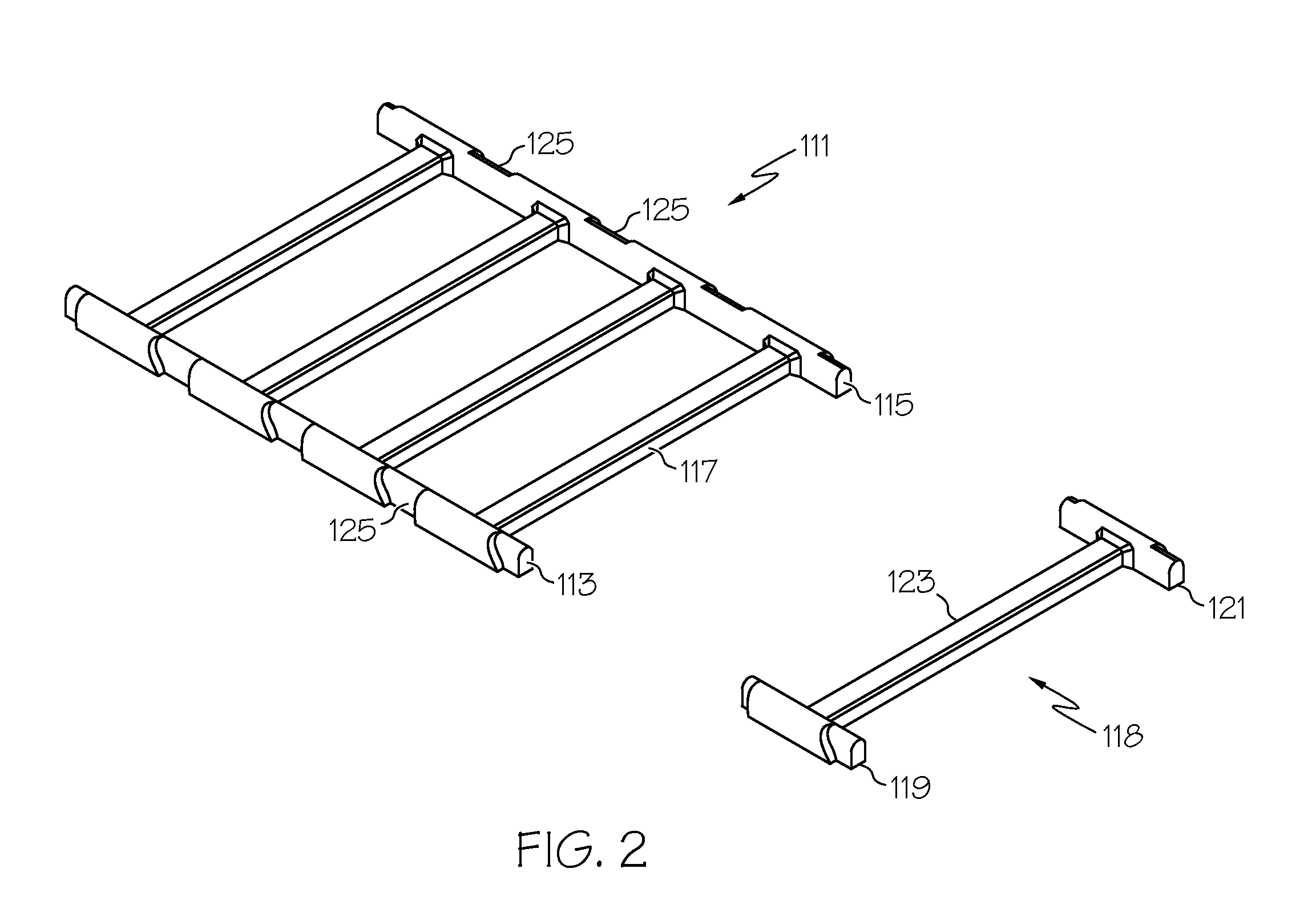

Device for dispensing plastic fasteners

ActiveUS20080164271A1Maximize productivityEnergy efficiencyStampsAffixing tagsPower switchingControl theory

A device for dispensing individual plastic fasteners from a continuous supply of 0.1875 inch pitch ladder stock includes a head assembly that is designed to receive the supply of ladder stock, sever an individual fastener from the supply ladder stock and eject the individual fastener during a single stroke of its actuation cycle. The device also includes a stepper motor for driving the head assembly through its actuation cycle, a DC power switching supply for regulating the power supplied to the stepper motor from an AC input power source, and a controller for collecting historical data relating to usage of the device and for regulating operation of the stepper motor. The controller is programmed to enable certain operational characteristics, such as stroke speed and mode, to be regulated through a user interface which includes a screen display and a plurality of control buttons.

Owner:AVERY DENNISON CORP

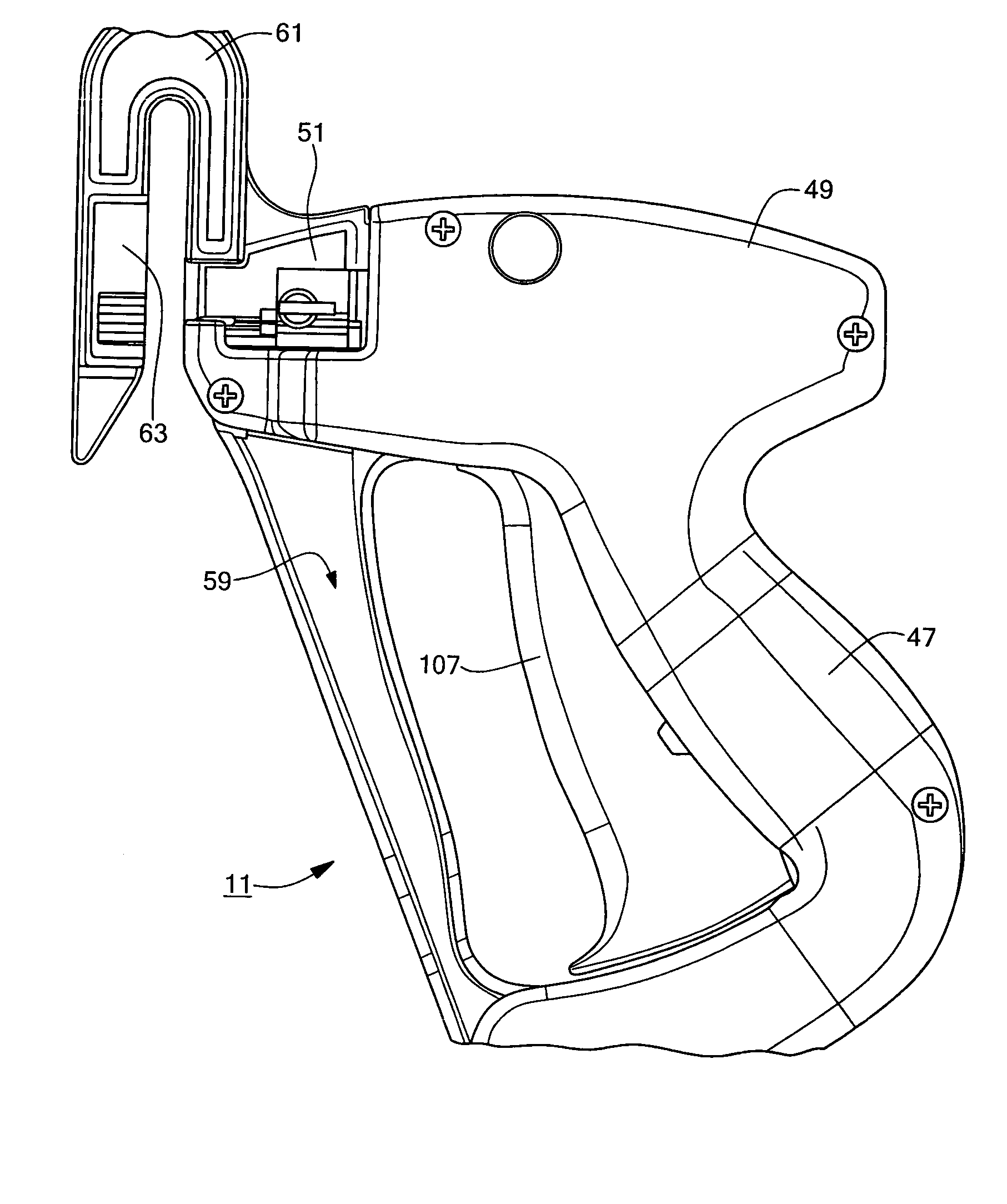

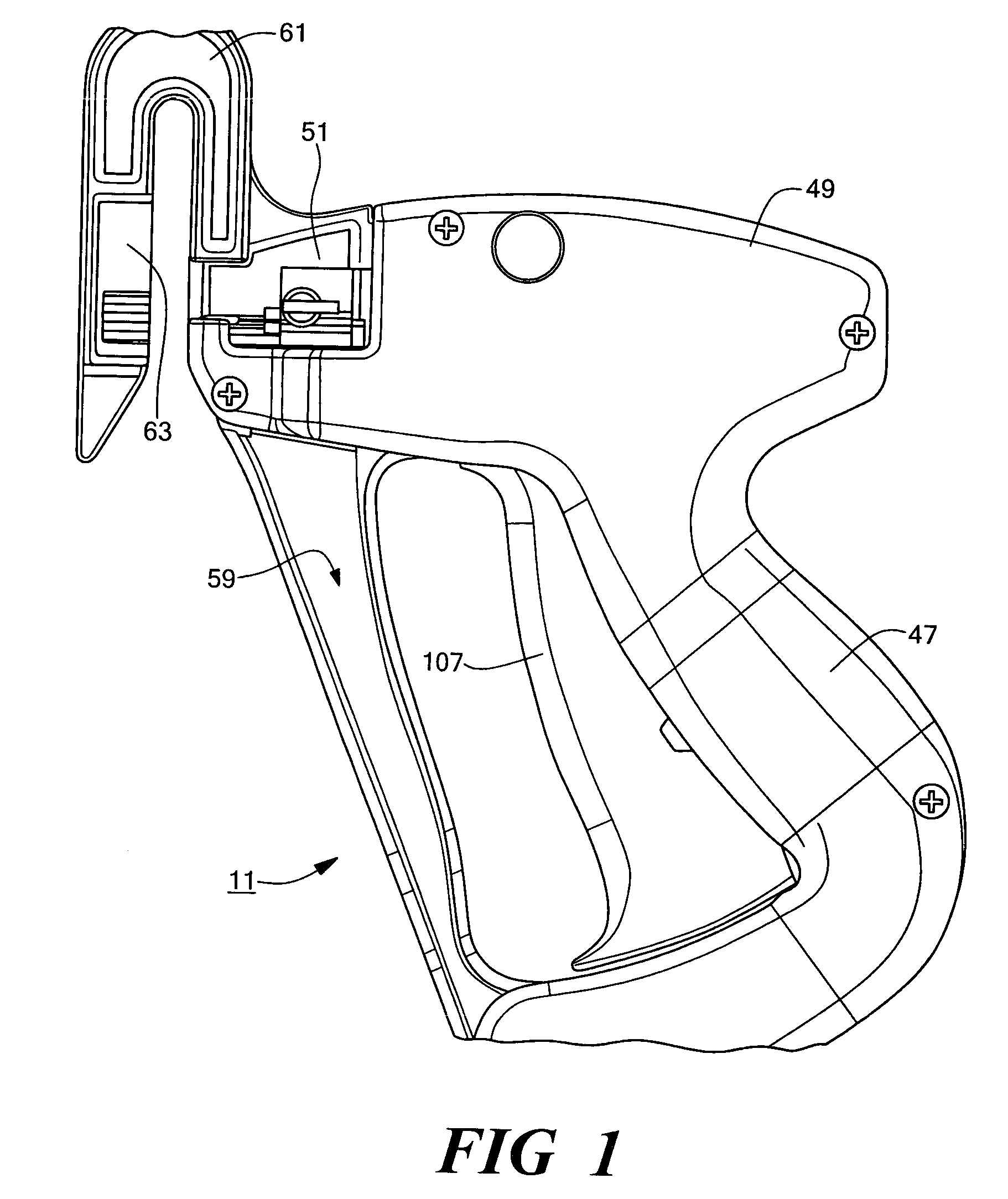

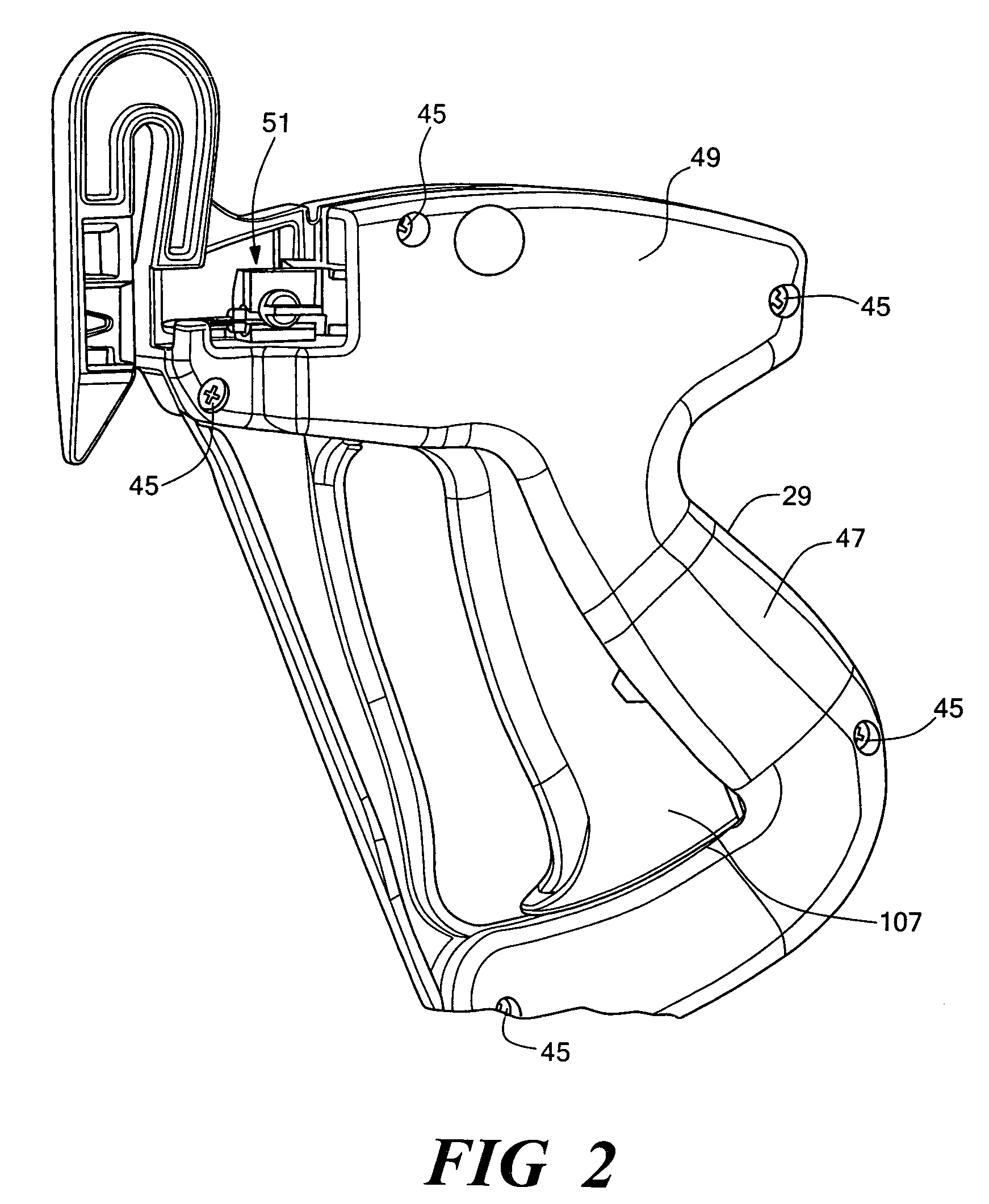

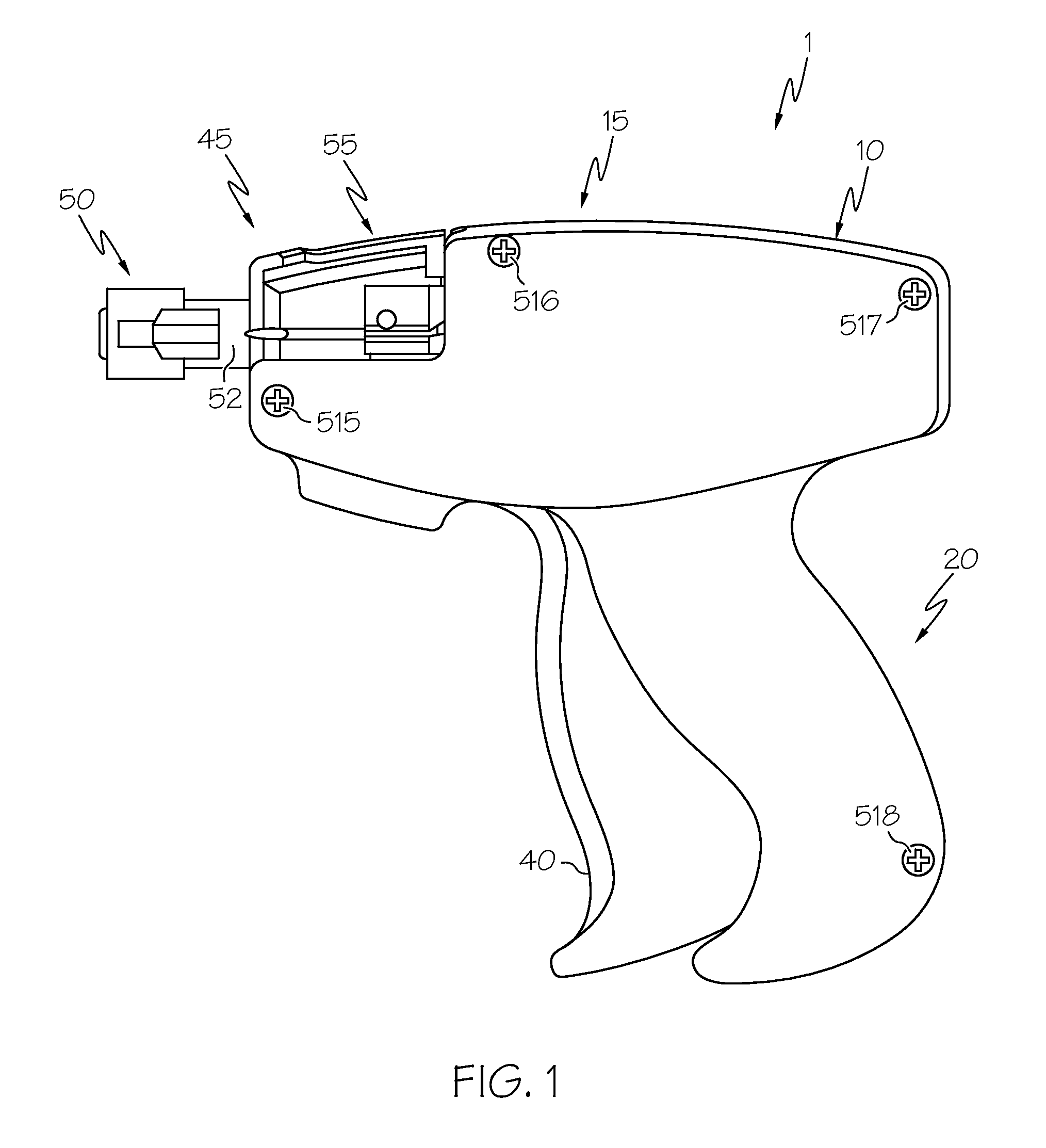

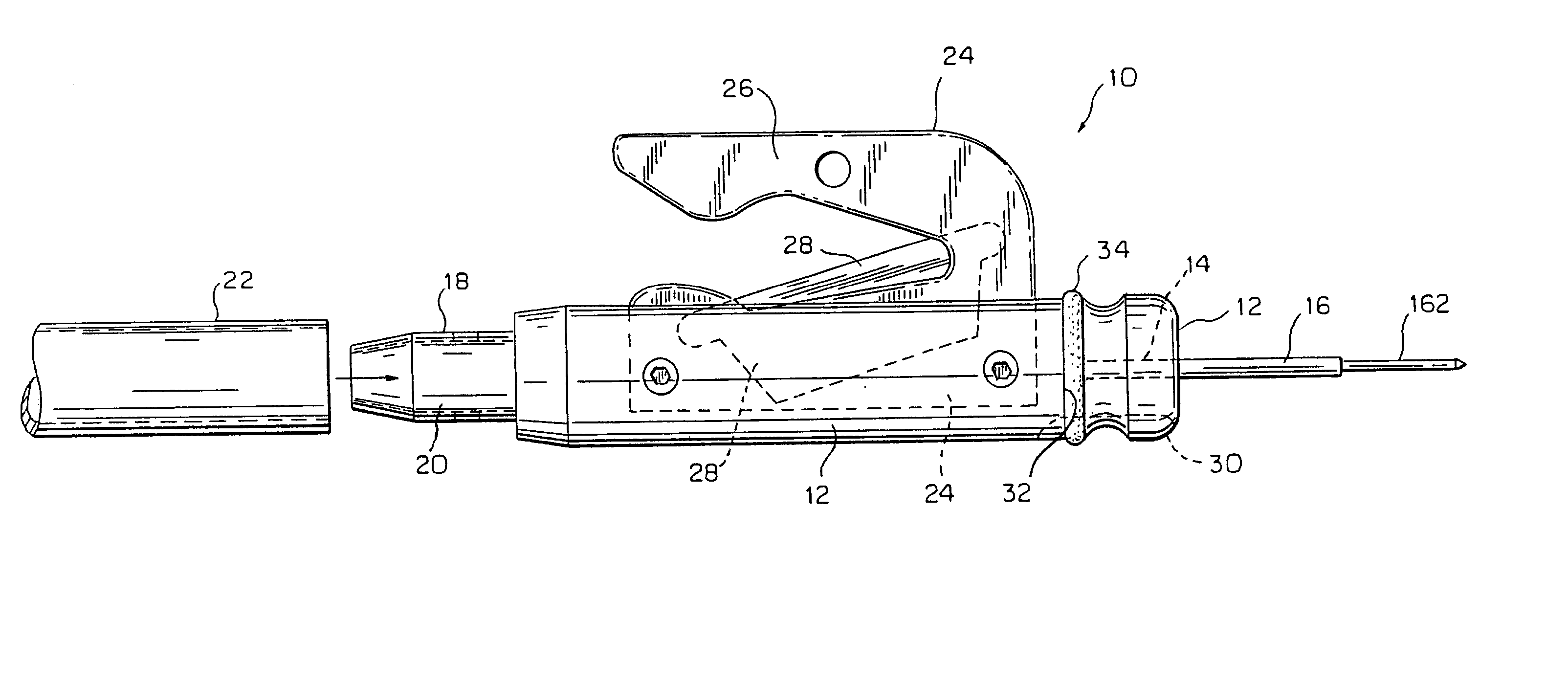

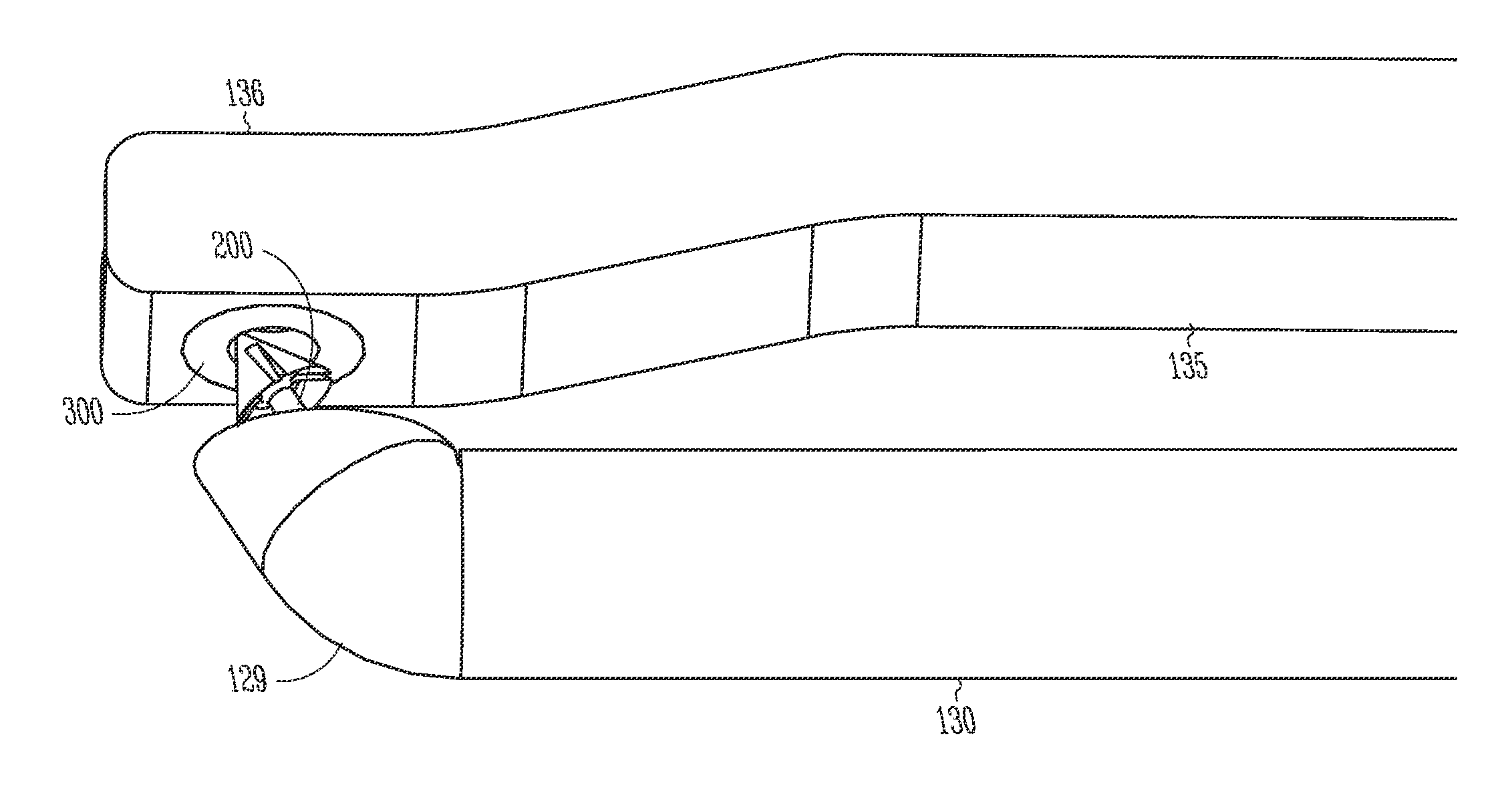

Plastic Fastener Dispensing Hand Tool Having a Novel Anvil Design to Reduce Needle Sticks

ActiveUS20110220701A1Inadvertent cutAffixing tagsPortable labelling toolsSyringe needleBiomedical engineering

An improved hand tool for dispensing plastic fasteners having a novel anvil design that reduces inadvertent user needle sticks during operation of the hand tool and a needle having a novel casing that further reduces inadvertent user needle sticks during the replacement of the hand tool needle. The hand tool has a gun shaped casing with a barrel portion and a handle portion. The casing has a needle assembly opening at the front of the barrel portion and a trigger slot at the front of the handle portion. The hand tool further has a hollow needle disposed on one end of a needle assembly. The needle assembly is slidably movable back and forth between a retracted position disposed substantially within casing and an extend position disposed substantially out of the casing through the needle assembly opening. The hand tool further has a trigger that is pivotally mounted within the casing that extends out from the trigger slot. The trigger is capable of moving the needle assembly between the retracted and extended positions. The hand tool further has an anvil. The anvil has a finger guide portion, a main portion, and a tag slot. The tag slot separates the finger guide portion from the main portion.

Owner:AVERY DENNISON CORP

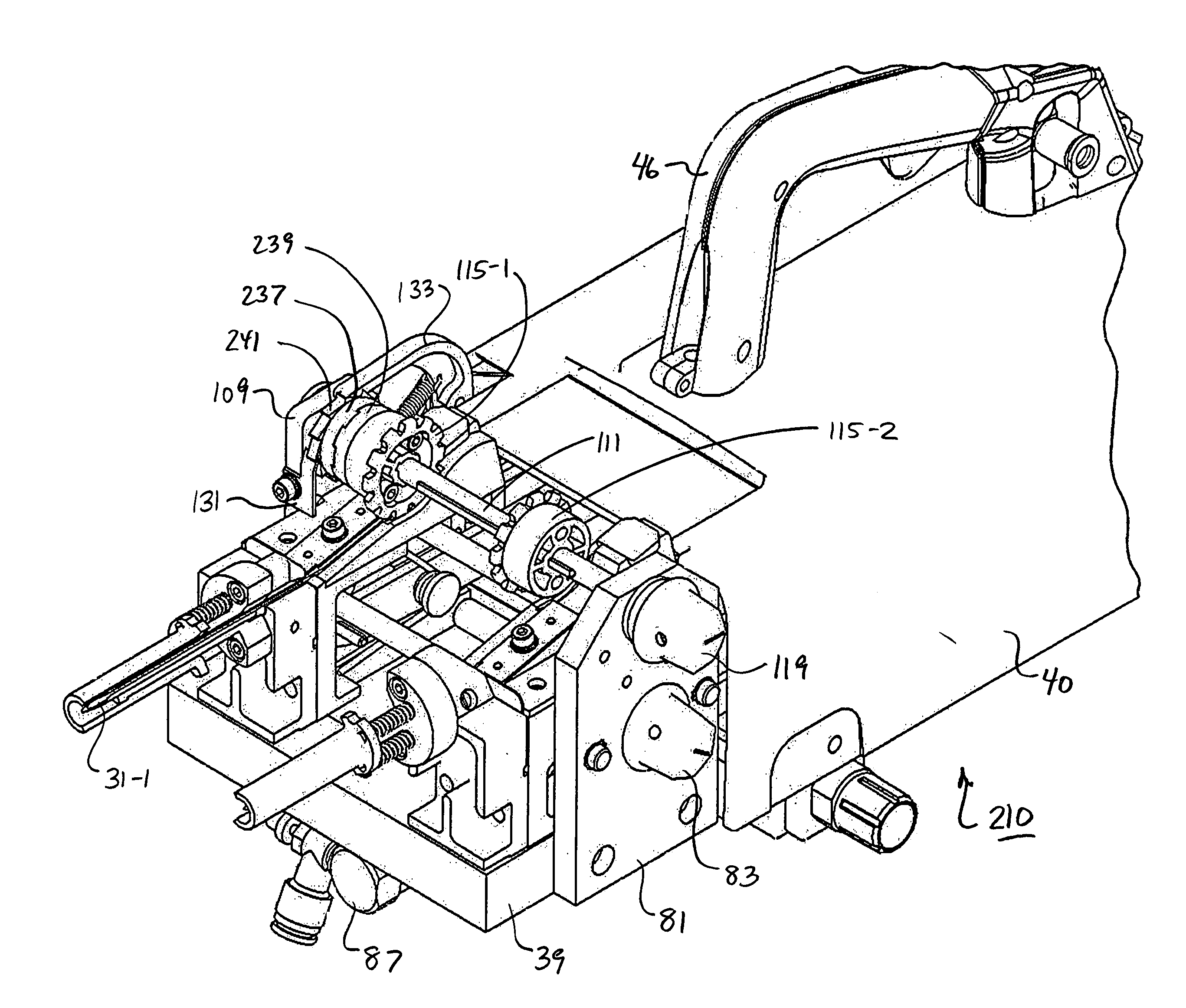

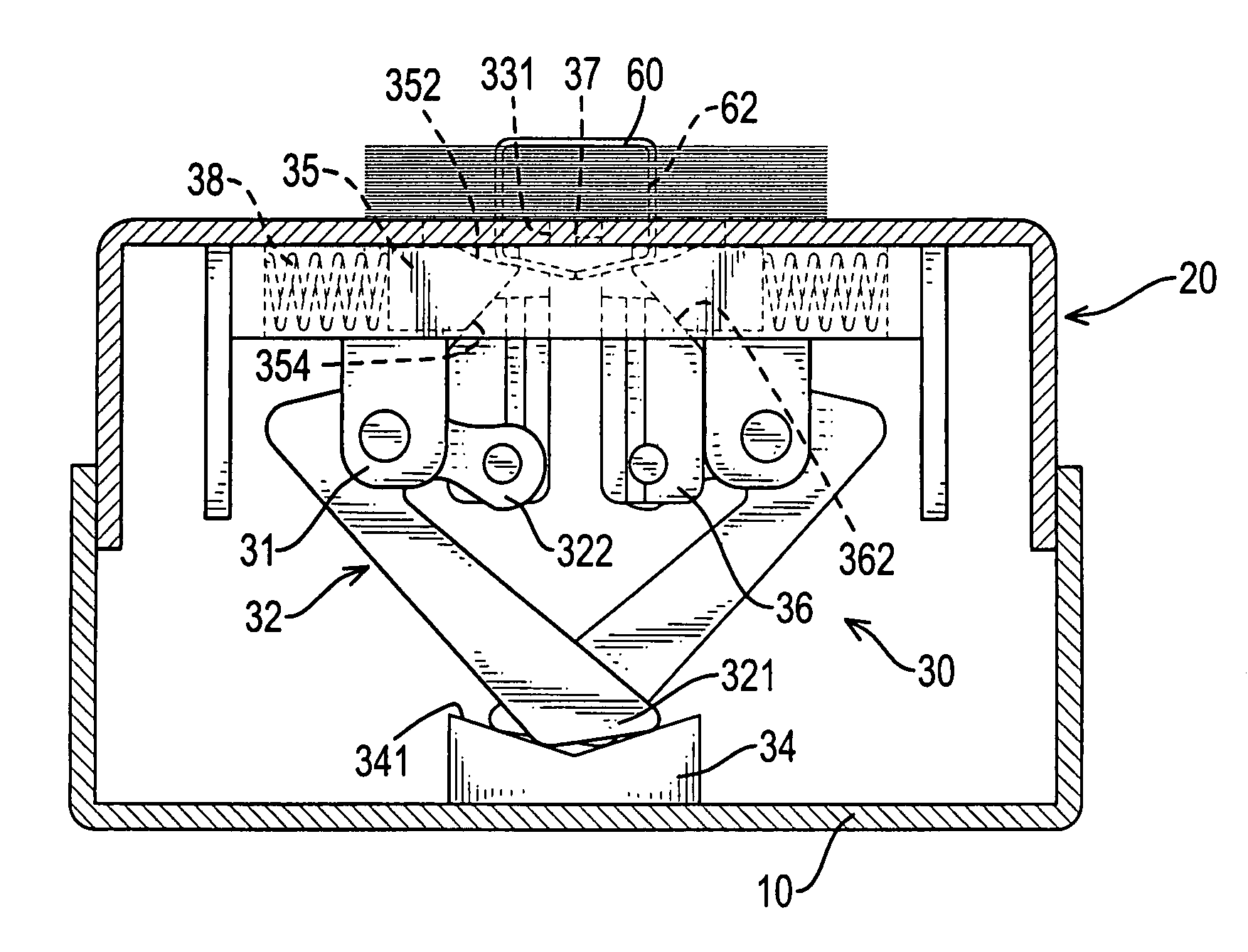

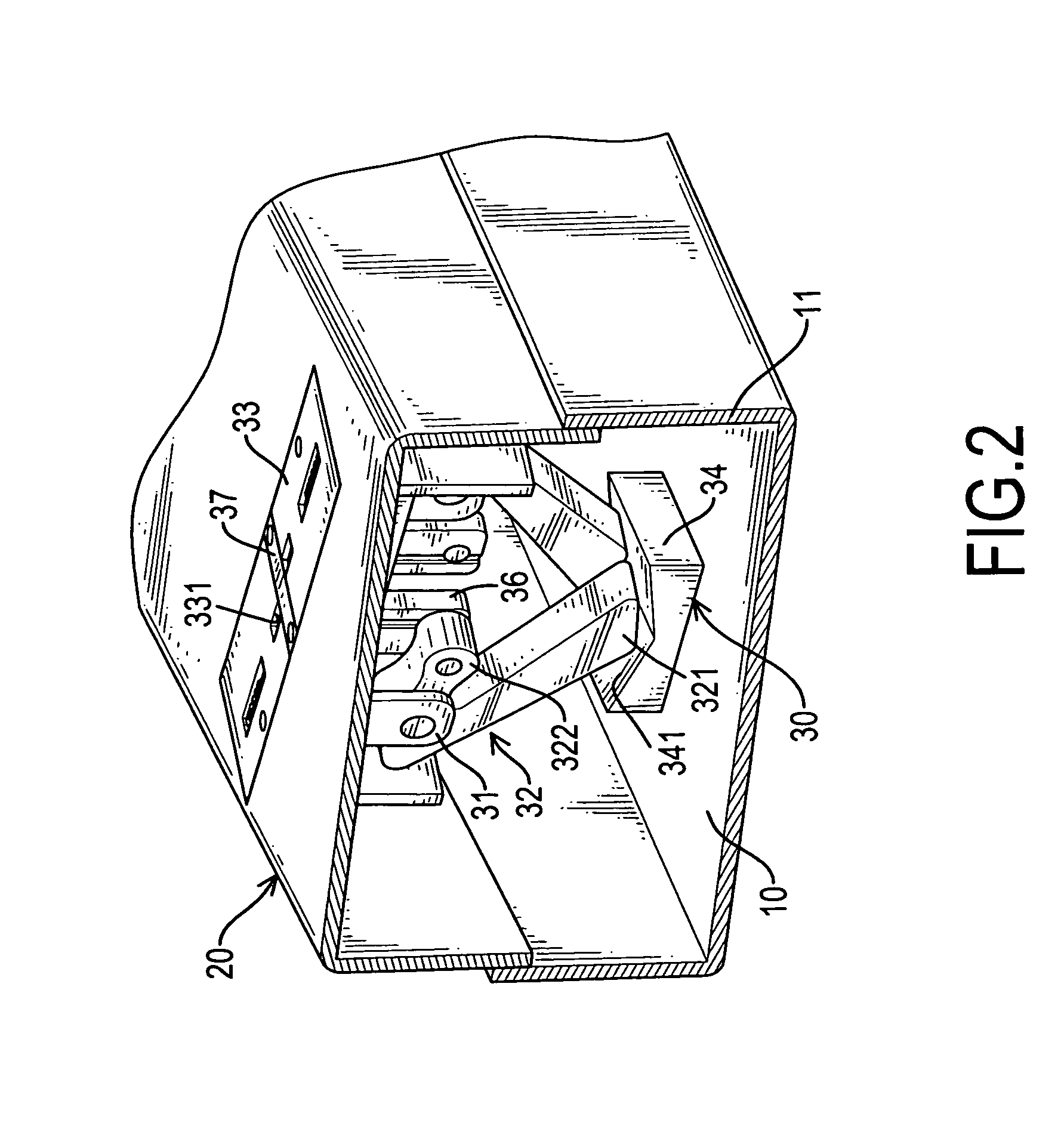

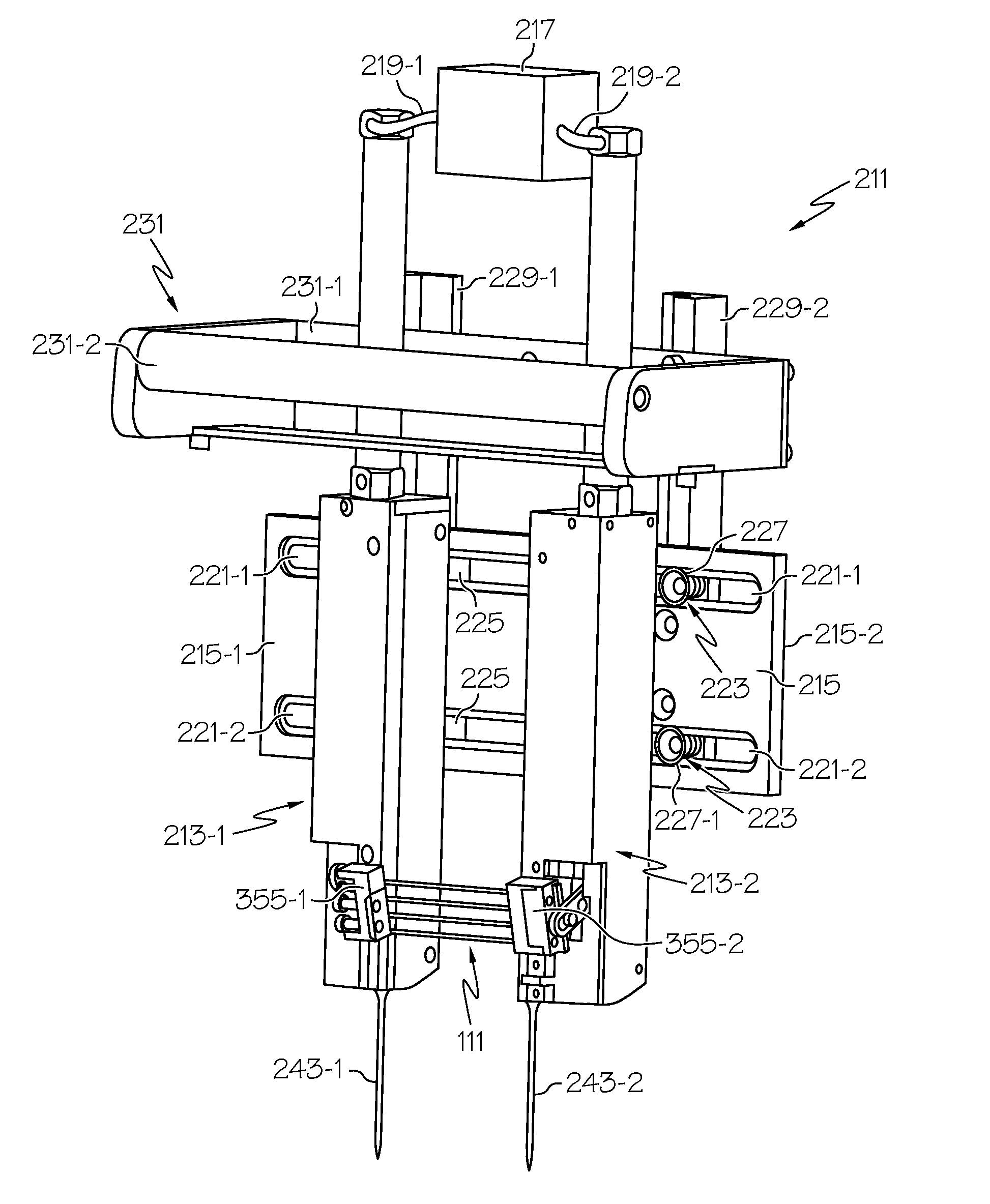

Device for dispensing plastic fasteners

A device for dispensing an individual plastic fastener from a supply of fastener stock includes a motor-driven head assembly adapted to receive the supply of fastener stock, sever an individual fastener from the supply and in turn eject the severed fastener. The head assembly includes a pair of needle block assemblies that retain corresponding hollow needles, each needle block assembly being shaped to define a feed channel that transitions a side rail for the fastener stock into axial alignment behind its corresponding needle. In addition, at least one needle block assembly includes a rearward shelf and a forward bowing plate. In use, the lowermost cross-links of the fastener stock fittingly align between the shelf and the bowing plate. In this manner, the lowermost cross-links are limited to distort uniformly upward within the single plane defined by the pair of feed channels, thereby optimizing feed reliability of the device.

Owner:AVERY DENNISON CORP

Plastic fasteners, needles for dispensing and method of manufacture

Owner:AVERY DENNISON CORP

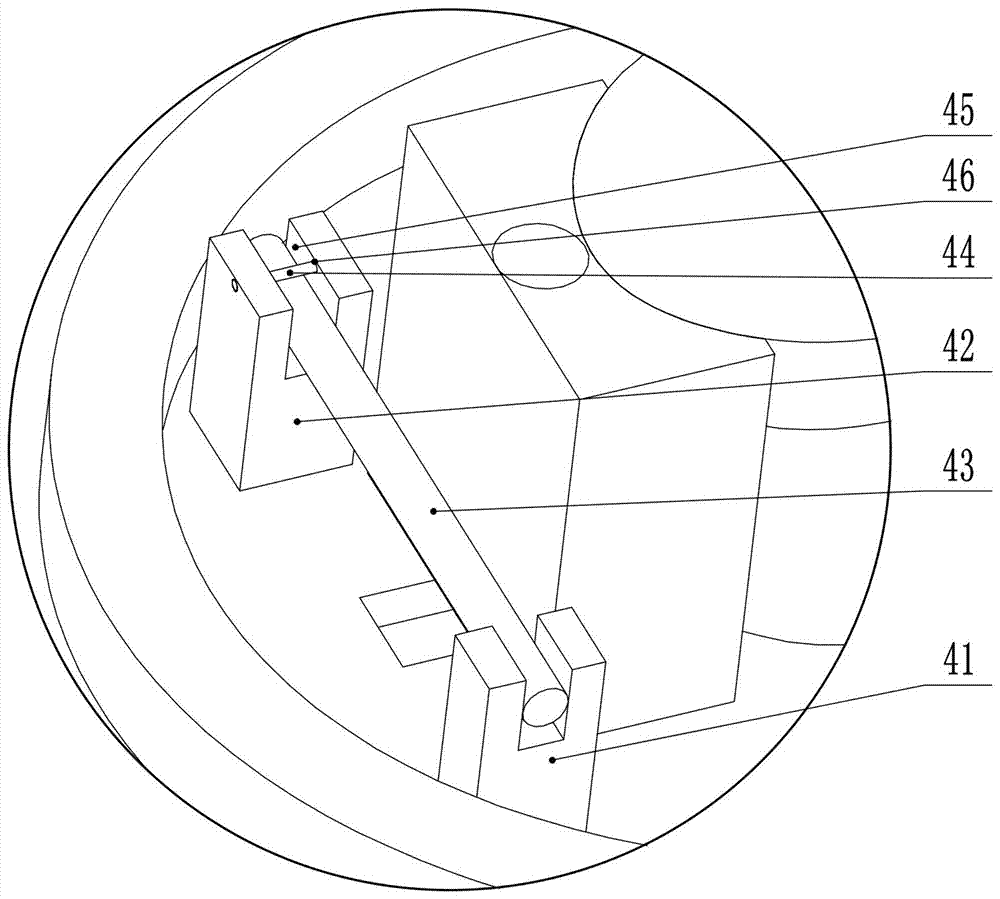

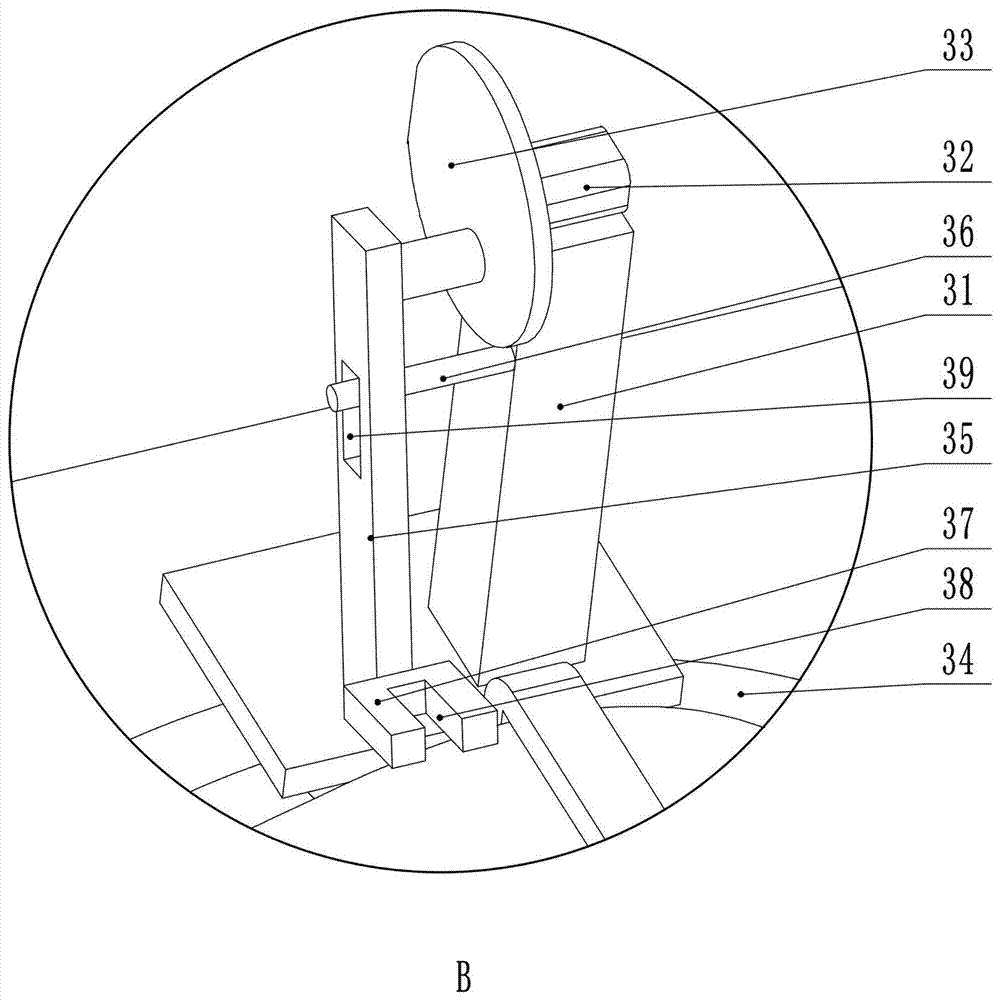

A leather shoe rapid nailing device for shoe production

The invention relates to a leather shoe nailing device, in particular to a leather shoe rapid nailing device for shoe production. The leather shoe rapid nailing device for shoe production has the advantages of good fixing effect, high nailing efficiency and simple operation. The leather shoe rapid nailing device for shoe production comprises a bottom plate, a rolling shaft, a conveying device, a 7-shaped support, a sector gear, a first gear, a spring, a first belt wheel, a cross plate, a first motor, an L-shaped rod, a bearing base, a slide rail, a second belt wheel, a flat belt, a disc, a first connecting rod, a strut, an arc-shaped connecting rod, a cylindrical cam, a ball, a hammer, a rotating shaft, a slider, a rack, a lifting rod, a second motor and an electromagnet. The leather shoe rapid nailing device for shoe production employs an inclined plate located on the bottom plate and the lower portion of the 7-shaped support; the top end of the inclined plate is fixedly connected with the lower portion of the 7-shaped support.

Owner:益阳中康鞋业有限公司

Tack Pin Installation Press

An automated press feeds a string of tack pins loaded on a reel. The press shears the part from the string of fasteners and delivers each part individually to a punch for installation. The string of fasteners is pulled from the reel by a sprocket which includes peripheral teeth for engaging the fasteners and for feeding them in a vertical column to a shear station. A horizontally reciprocal shear block severs individual fasteners one-at-a-time from the end of the fastener string at the shear station, each fastener being indexed to the next shear position by incremental rotation of the sprocket. The punch includes vacuum retaining means for lifting each fastener from the shear block.

Owner:PEM MANAGEMENT INC

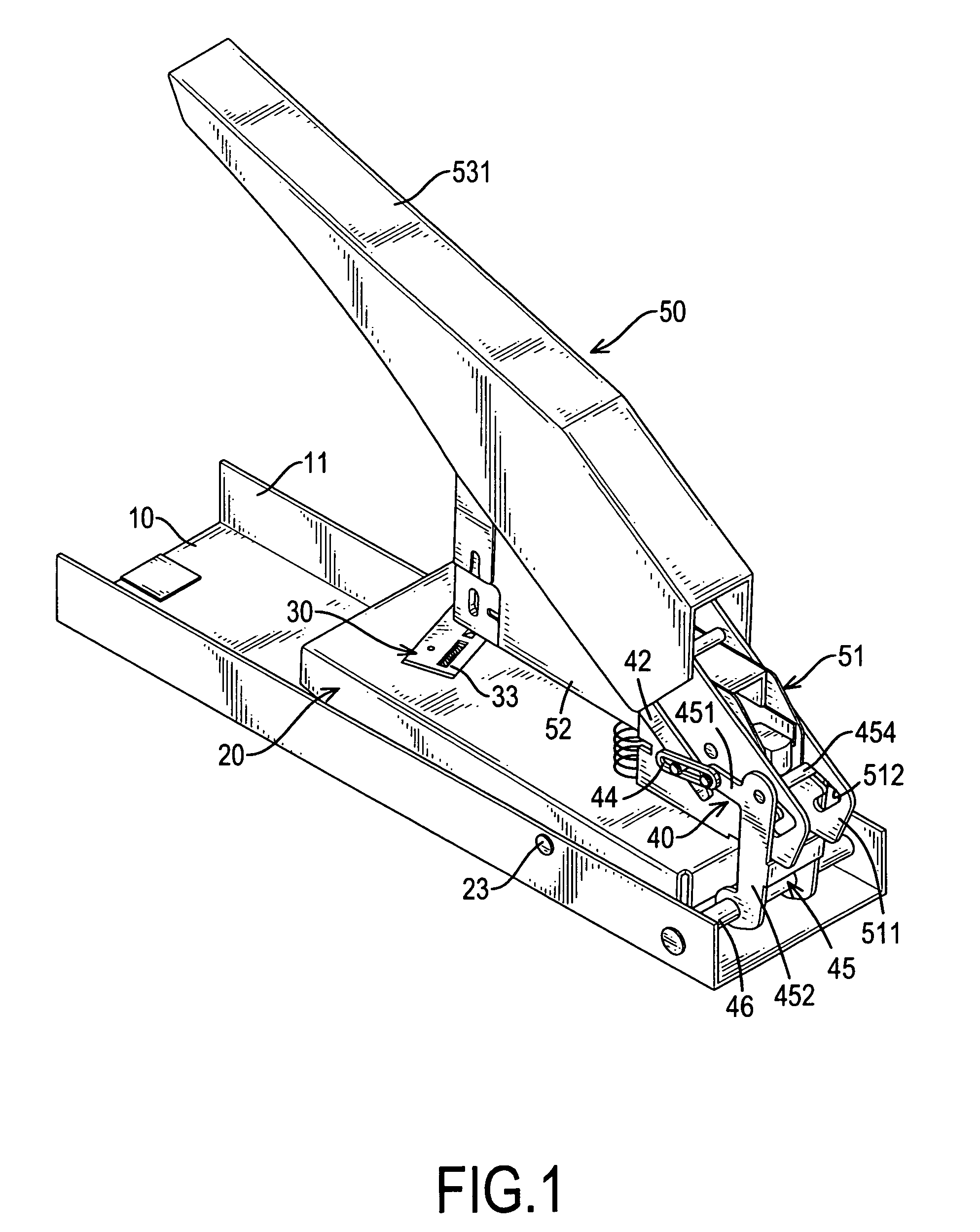

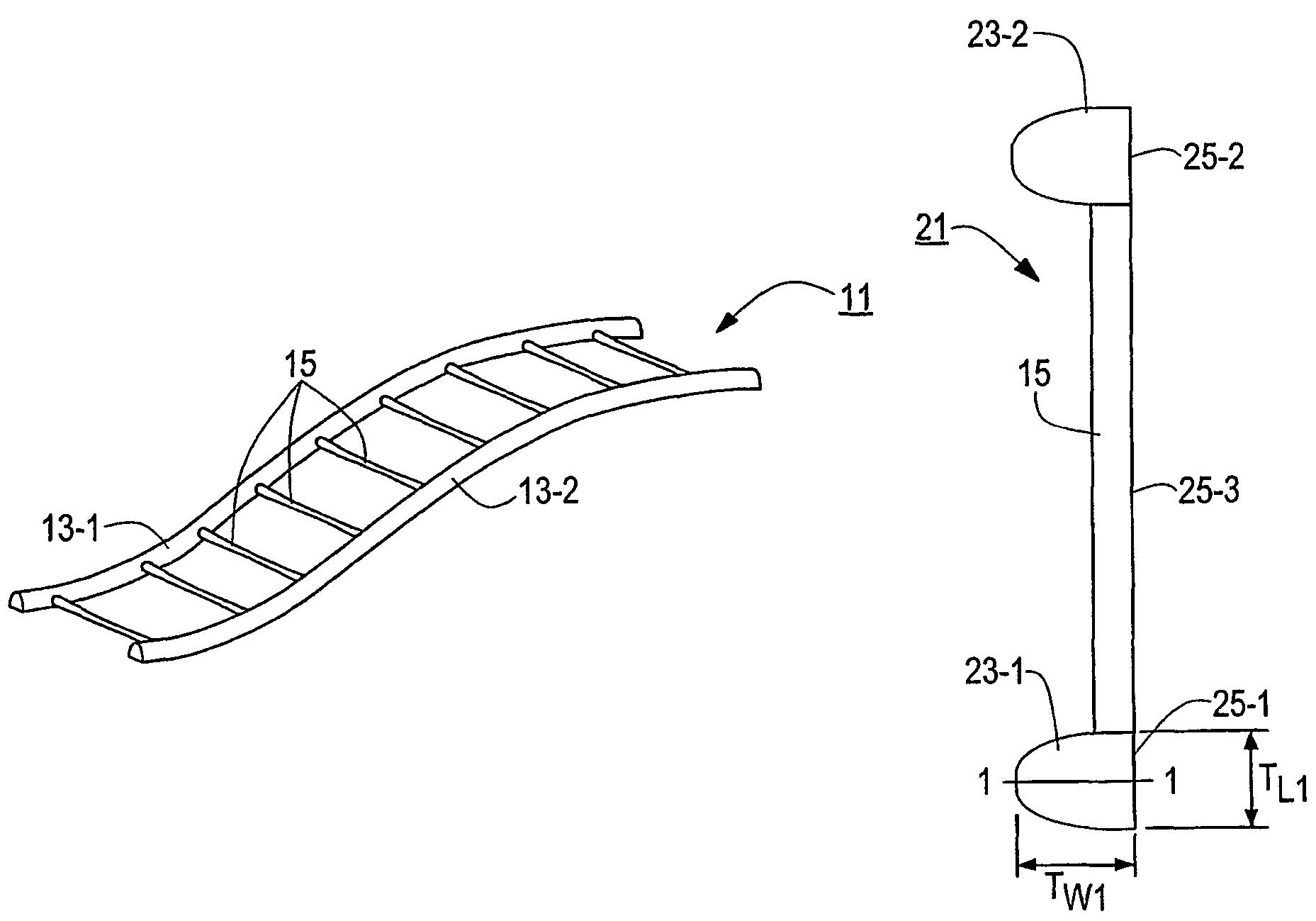

Fastener stock and device for use in dispensing plastic fasteners therefrom

ActiveUS20130134205A1Limited amountIncrease flexibilityStampsDispensing apparatusComputer moduleAngular orientation

A device for dispensing a plastic fastener from a supply of ladder-type fastener stock includes a pair of separate modules that are independently pneumatically powered by a common air source. Each module is adapted to receive and index a corresponding side rail of the fastener stock, separate a cross-bar therefrom and eject the separated cross-bar out through a sharpened needle. As a feature of the invention, the pair of modules ejects the cross-bars of the dispensed fastener in an offset relationship to minimize fastener stress. As another feature of the invention, the pair of modules is independently slidably coupled to a common mounting plate. In this manner, the spacing and angular orientation between the modules are adjustable. As another feature of the invention, the feed mechanism includes a feed pawl that selectively engages outwardly facing notches formed in the side rail to ensure accurate alignment prior to the severing process.

Owner:AVERY DENNISON CORP

Tag and release device

InactiveUS20030079696A1Improve securityQuick changeStampsAnimal huntingEngineeringBiomedical engineering

A device for safely tagging and releasing large fish includes a long pole to which is attached at its distal end a holder body for retaining therewithin an axially extending cutting blade and, at its tip portion, a tag applicator.

Owner:BANKSTON PARKER

Tag and release device

InactiveUS6679199B2Improve securityImproved, quicker and safer tagging and subsequent release of the fishStampsAnimal huntingBiomedical engineering

A device for safely tagging and releasing large fish includes a long pole to which is attached at its distal end a holder body for retaining therewithin an axially extending cutting blade and, at its tip portion, a tag applicator.

Owner:BANKSTON PARKER

Button attachment kit

ActiveUS8381958B2Reduce manufacturing costEasy loadingStapling toolsReciprocating drilling machinesEngineeringBiomedical engineering

A self-contained button attachment kit includes a pair of buttons, fastener clips and a tool for dispensing a fastener from a fastener clip to reattach a button to an article of clothing. The tool includes a single, hollow needle, a holder adapted to retain the needle and buttons, a handle telescopingly mounted on the holder, a spring-biased ejection mechanism connected to the handle, a front cap removably coupled to the handle over the needle and a rear cap removably coupled to the handle for storing fastener clips. In operation, the front cap serves as an anvil that supports the article and button to be attached. With a fastener clip loaded into the holder, the needle is then inserted through the pair of items. Displacement of the handle relative to the holder causes an ejection rod to dispense the cross-bar of a fastener through the needle, thereby completing the attachment process.

Owner:AVERY DENNISON CORP

Fastener deployment system and method

This document discloses, among other things, a long reach, side ejecting fastener placement apparatus suitable for use in nasal septal surgery. A first linear member carries a fastener body and a second linear member delivers a fastener retainer or provides support for placement of the fastener body. In various examples, the fastener includes a single stud rivet or includes a two legged staple. A mechanical linkage coupled to the handle provides a linear force for placement and deployment of a fastener.

Owner:ERDMAN ARTHUR G +2

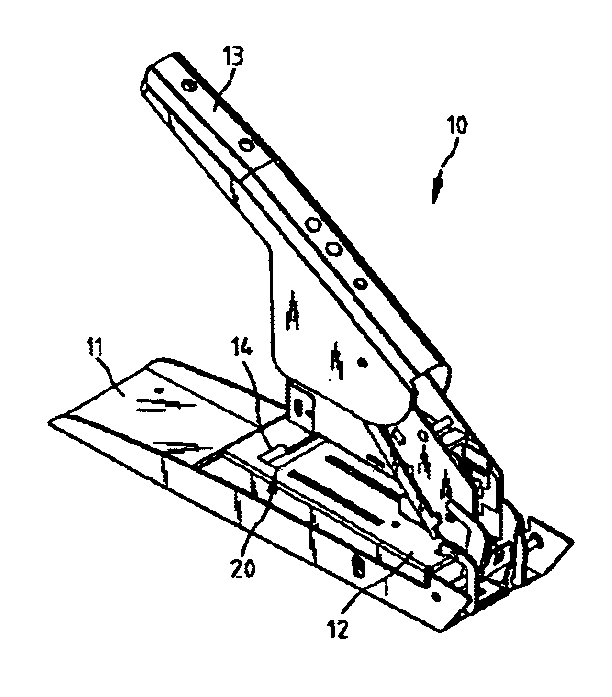

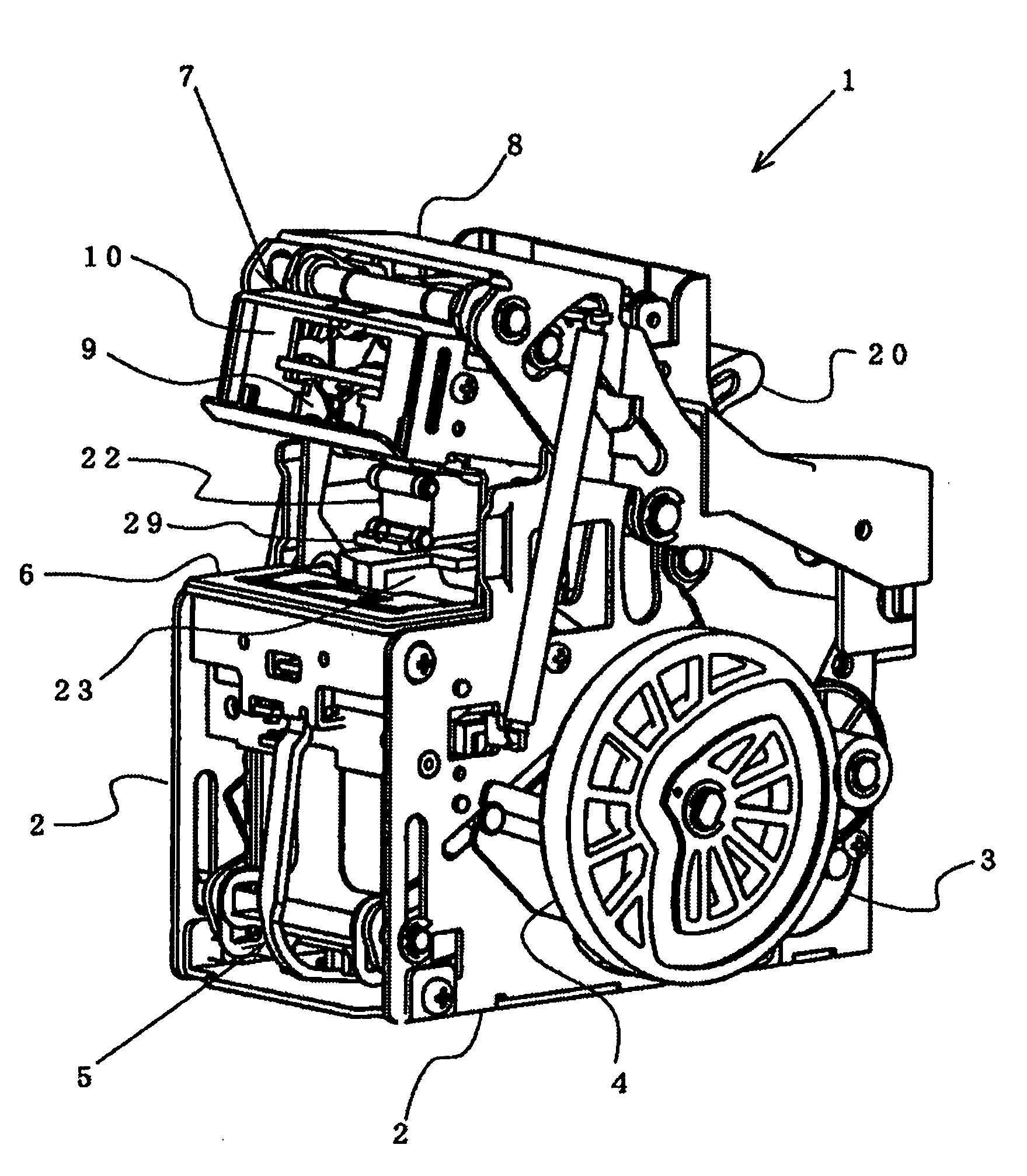

Staple Cartridge and Staple Leg Chip Processing Apparatus

A stapler 1 is provided with a cutter unit 12 for cutting a leading end portion of a staple leg projected to a back face side of sheets. A staple cartridge 20 containing a number of staples is formed with a chip containing portion 23 for containing a chip of the staple leg. The chip of the staple leg cut by the cutter unit 12 is guided into the chip containing portion 23 of the staple cartridge 20 by a chute 22 formed on the cutter unit 12. The chip of the staple leg is collected in the staple cartridge 20.

Owner:MAX CO LTD

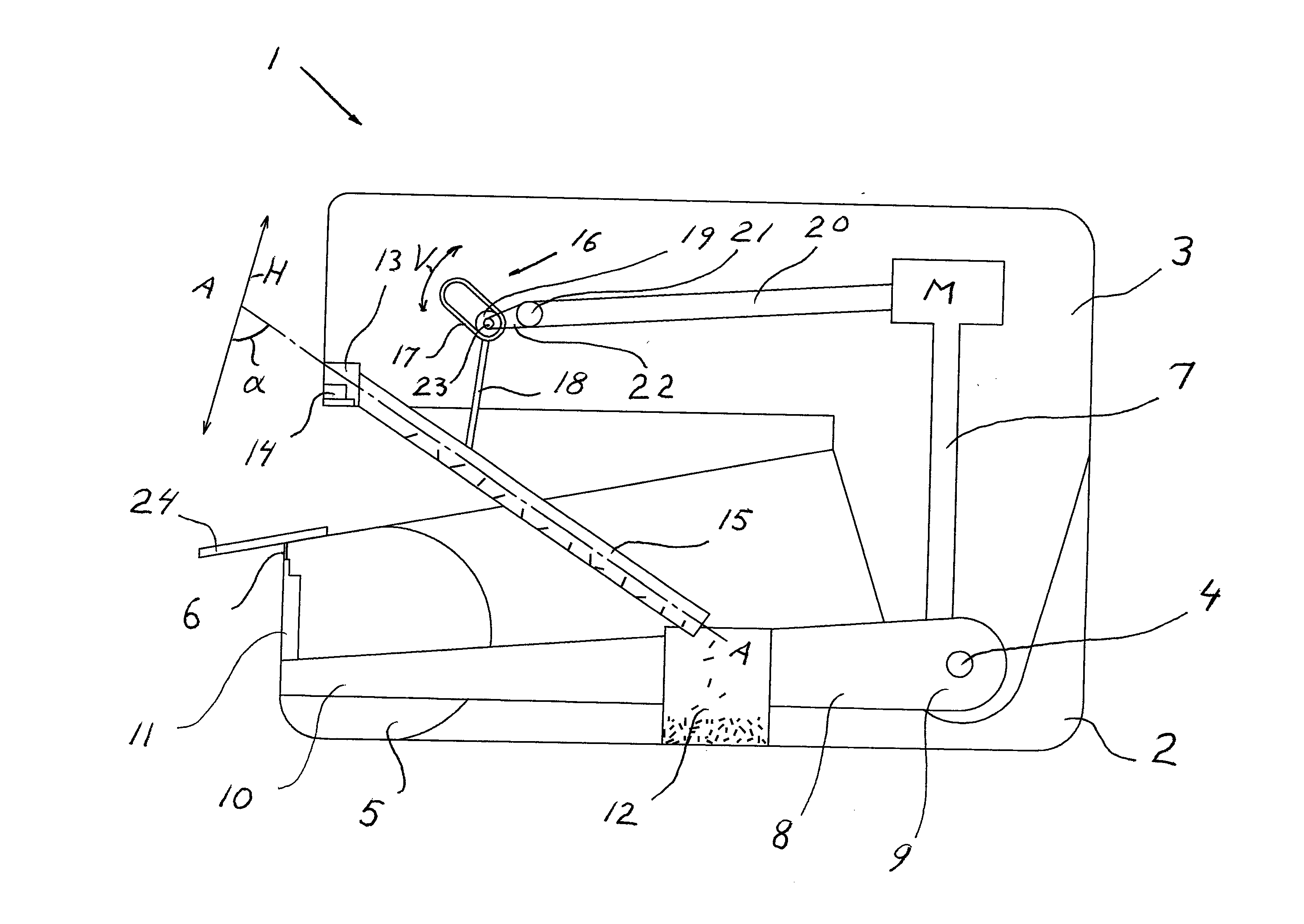

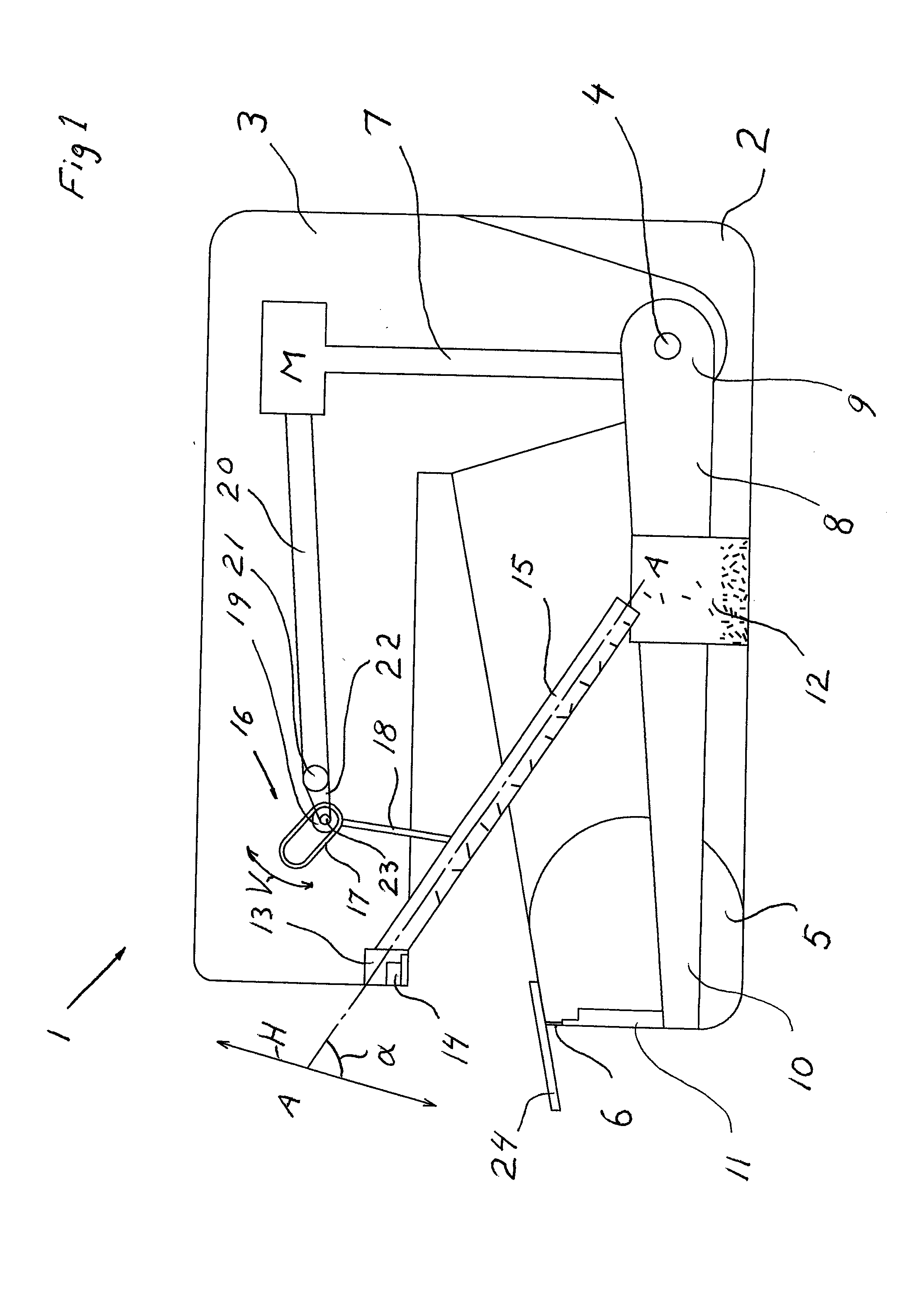

Stapler

Stapler (1) for using a staple (6) to staple together a workpiece (24), e.g. a sheaf of papers, by the staple being driven through the workpiece, by a driver (11) fitted in the stapler, from a staple magazine (5) to a position in which the staple legs penetrate the workpiece, which stapler comprises also a clipping arrangement (14), which moves reciprocatingly relative to the staple magazine in a defined direction (H) between a working position and a position of rest so that the clipping arrangement in the working position clips off surplus lengths of the staple legs when they have penetrated the workpiece, and a container (12) for gathering the staple leg clippings by their being conveyed via a channel (15) which runs in a defined longitudinal direction (A-A) between the clipping arrangement and the container, which channel (15) is attached pivotably to the stapler by means of a connecting device (16).

Owner:ISABERG RAPID

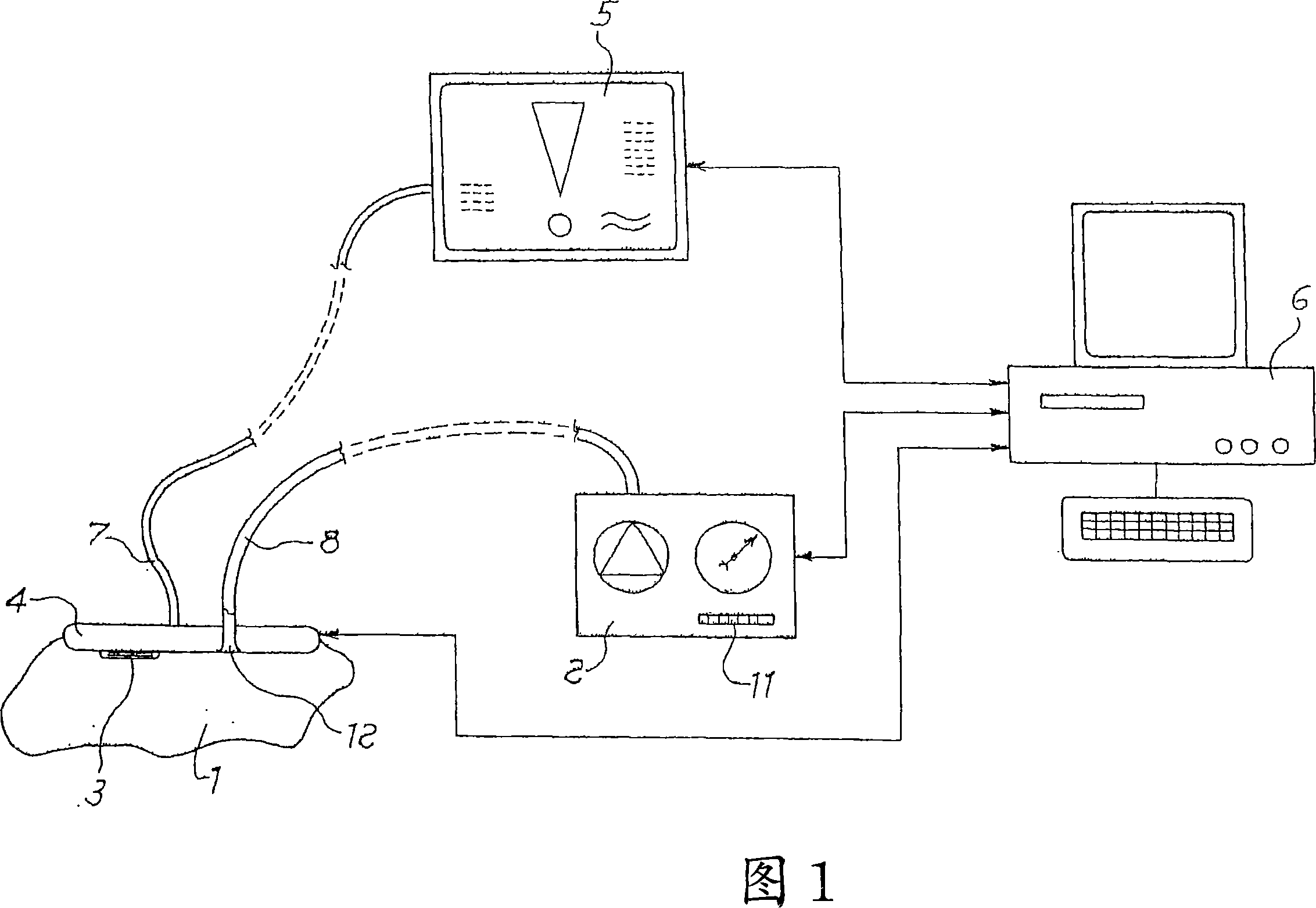

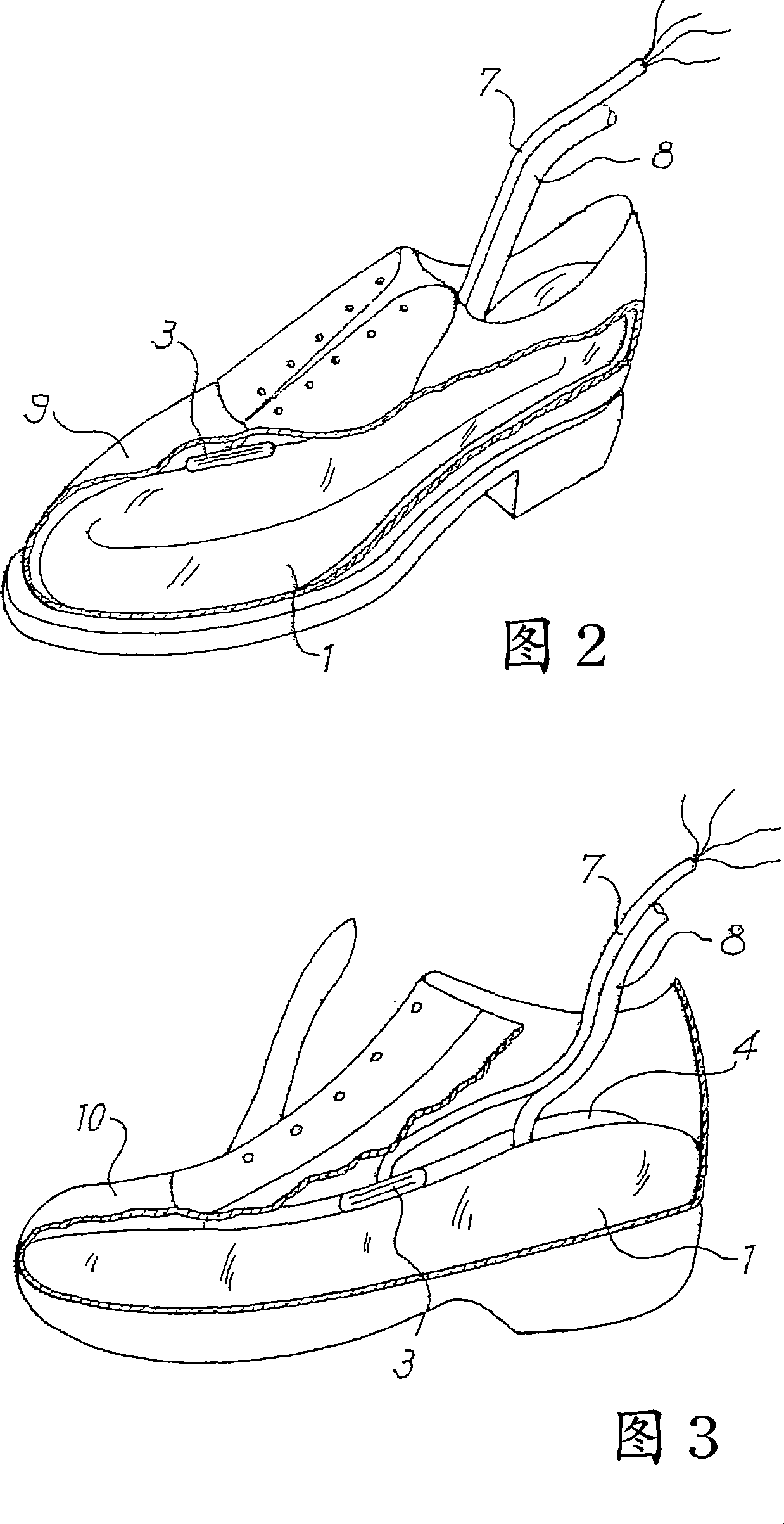

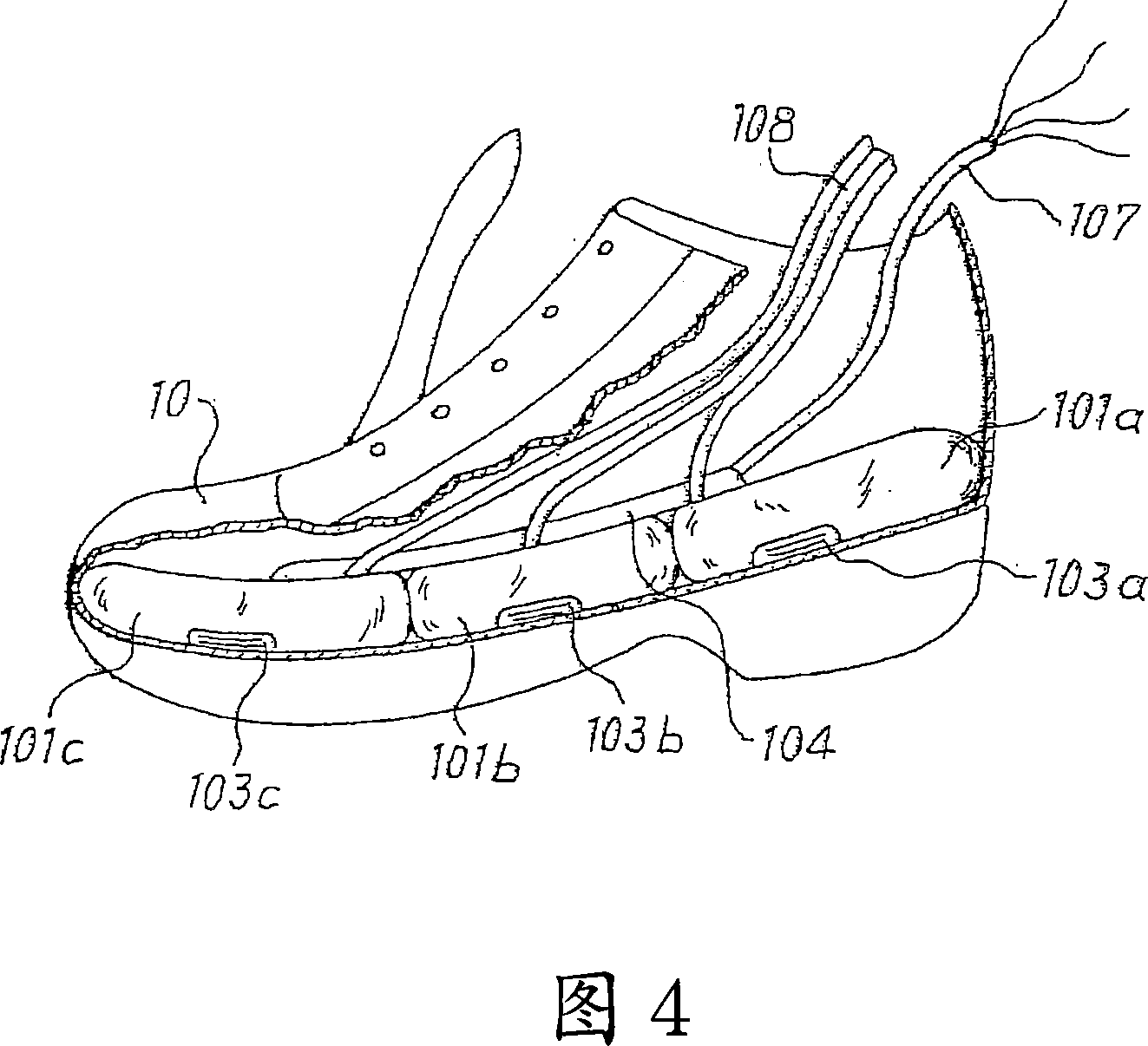

A method and device for inspecting the interior of a footwear

A method for inspecting the inside of a shoe, comprising the following steps: a. arranging at least one inflatable body within the shoe (1,4,101a,101b,101c,104); b. inflating, by means of a controlled amount of fluid, said inflatable body within the shoe (9,10) until the inflatable body, or a part thereof, is substantially rested on at least a portion of an inner wall of the shoe; c. after inflation, measuring and / or evaluating the internal pressure of the inflatable body and / or the force applied by said portion of an inner wall of the shoe against said inflatable body, or vice versa.

Owner:ELETTROTECNICA B C SPA

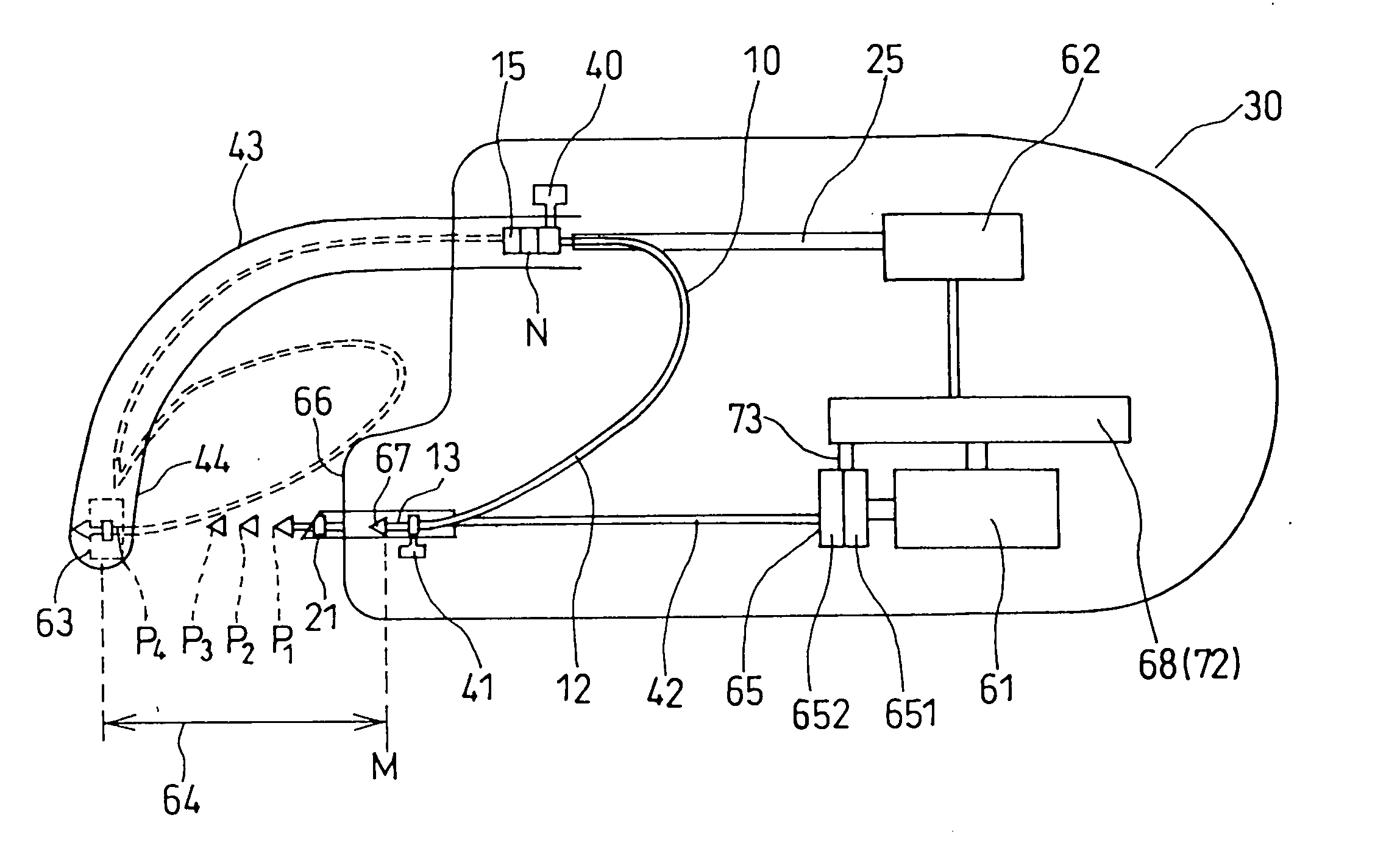

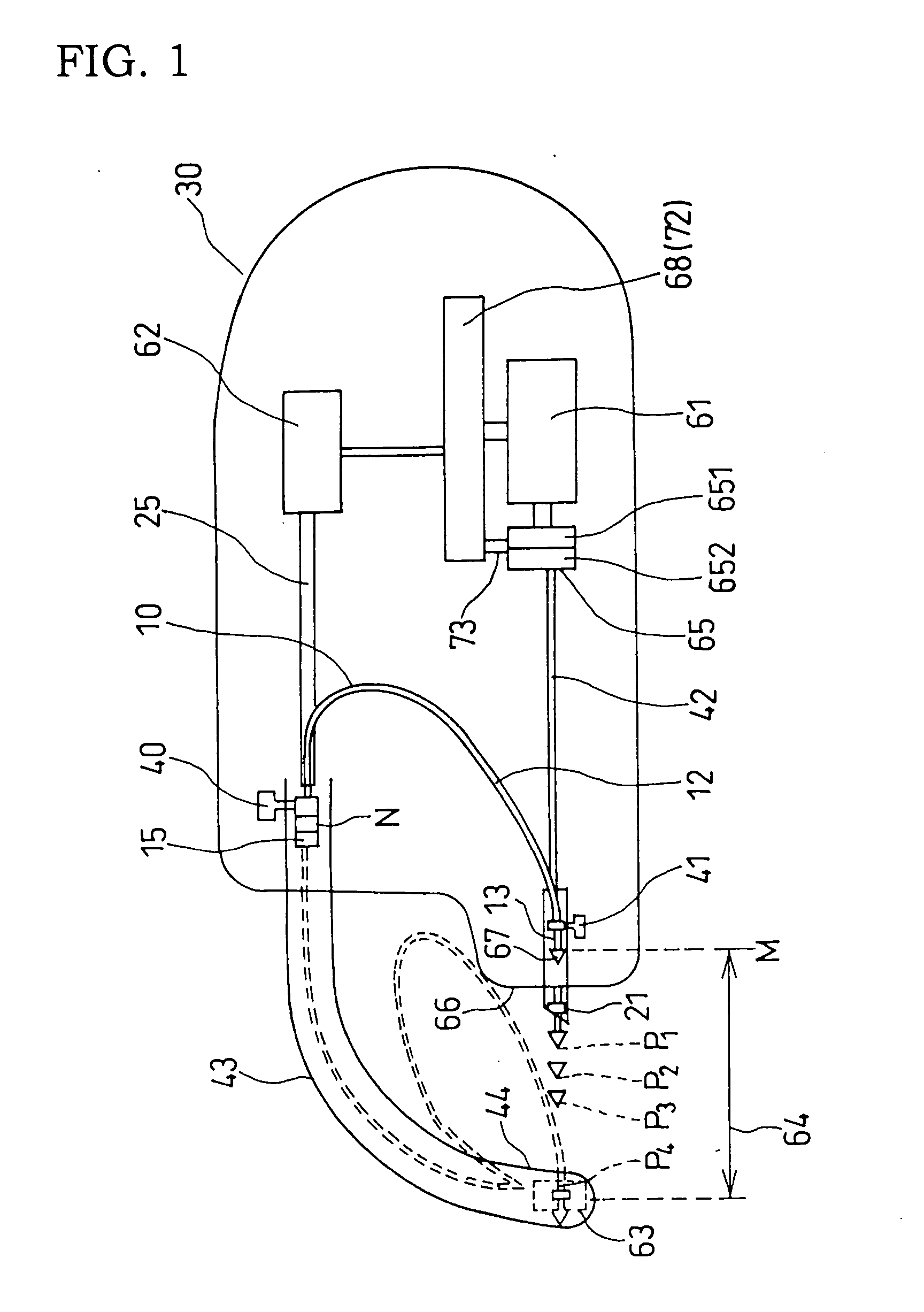

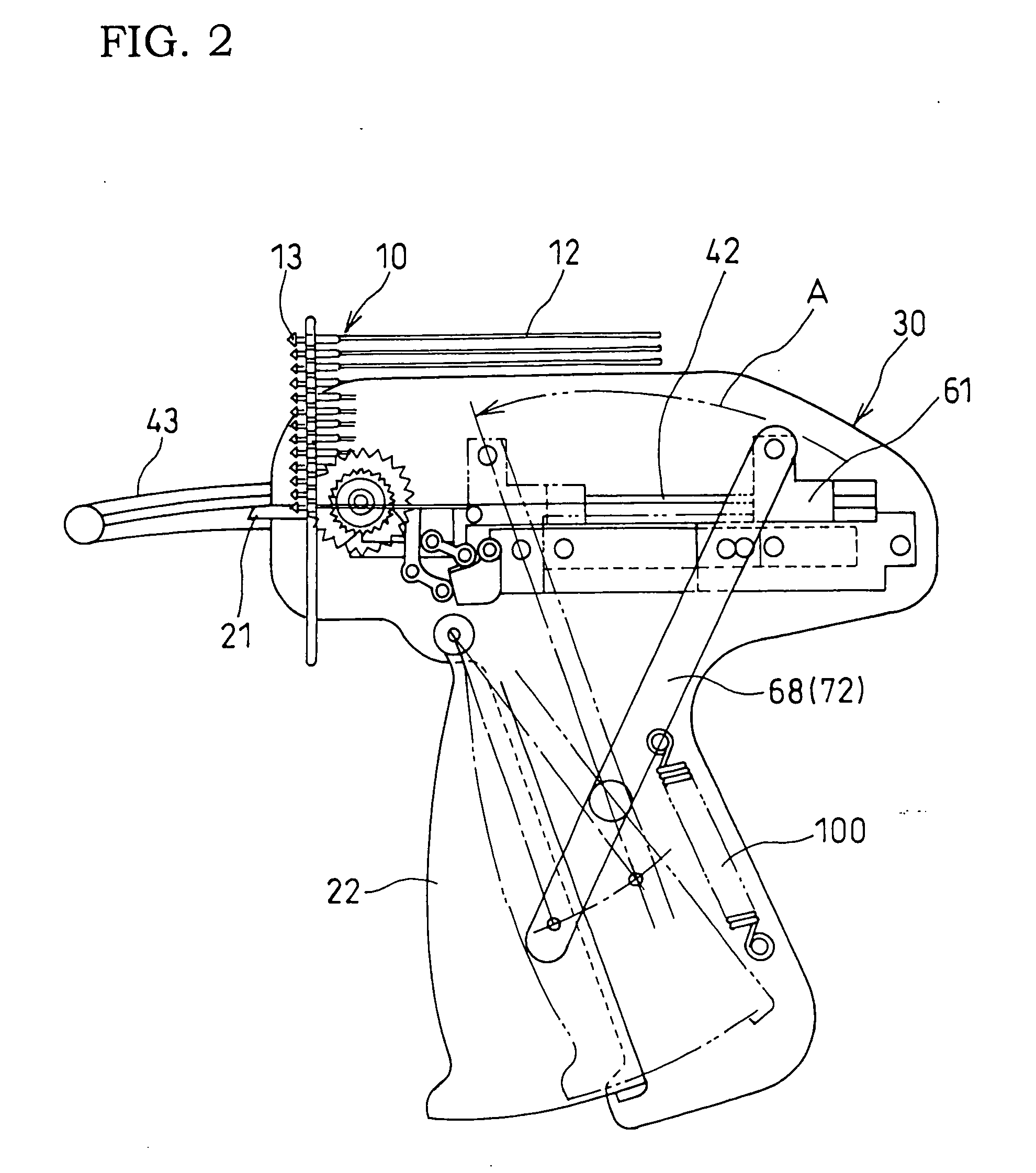

Loop pin connecting device

InactiveUS20050001006A1Easily and efficiently passing insertion head portionImprove work efficiencyLabelling deformable materialsStapling toolsHead partsEngineering

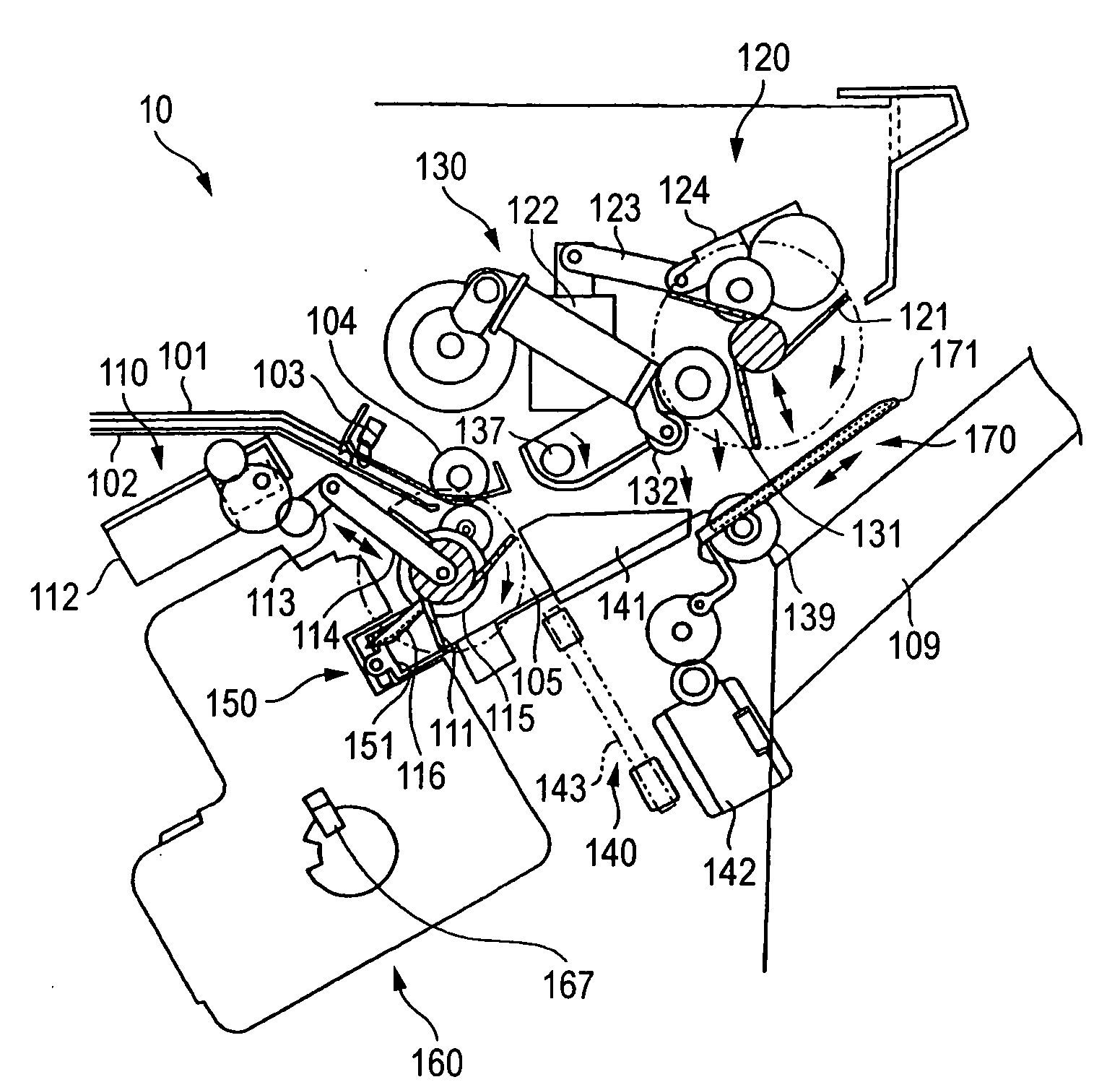

A loop pin connecting device for causing mutual mating between a insertion head portion and a socket portion of a filament has a first feeding means, which feeds out the insertion head portion in front of the loop pin connecting device, and a second feeding means, which feeds out the socket portion in front of the loop pin connecting device, wherein along one stroke from a position at which the insertion head portion and the socket portion of the individual loop pins are set into the device such that the insertion head portion and socket portion are moved up to a position at which there is mutual mating therebetween, at least the first feeding means has a operation interruption mechanism capable of temporarily stopping the feeding operation at an arbitrary position during the stroke.

Owner:M I T INT

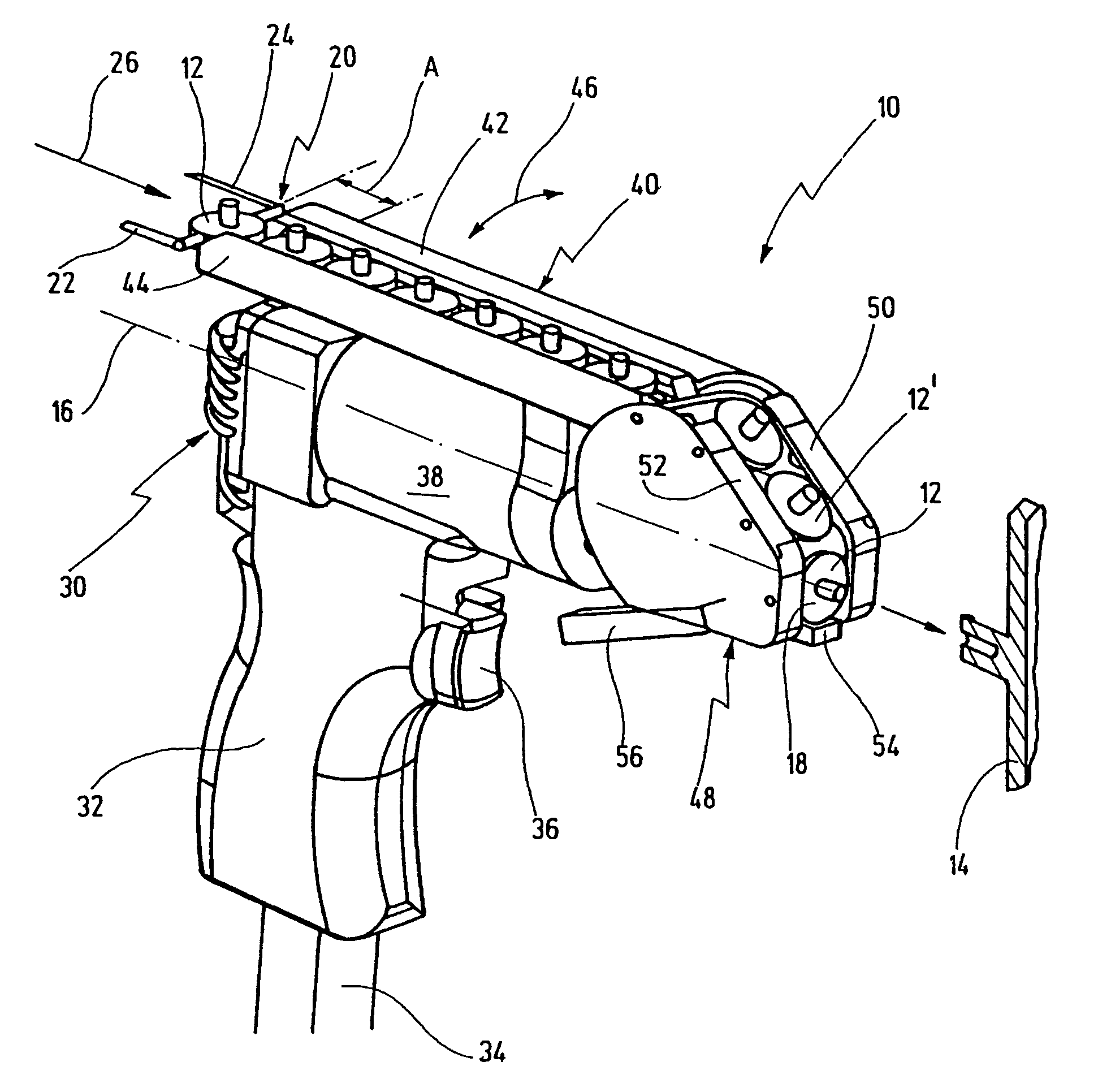

Fastening tool

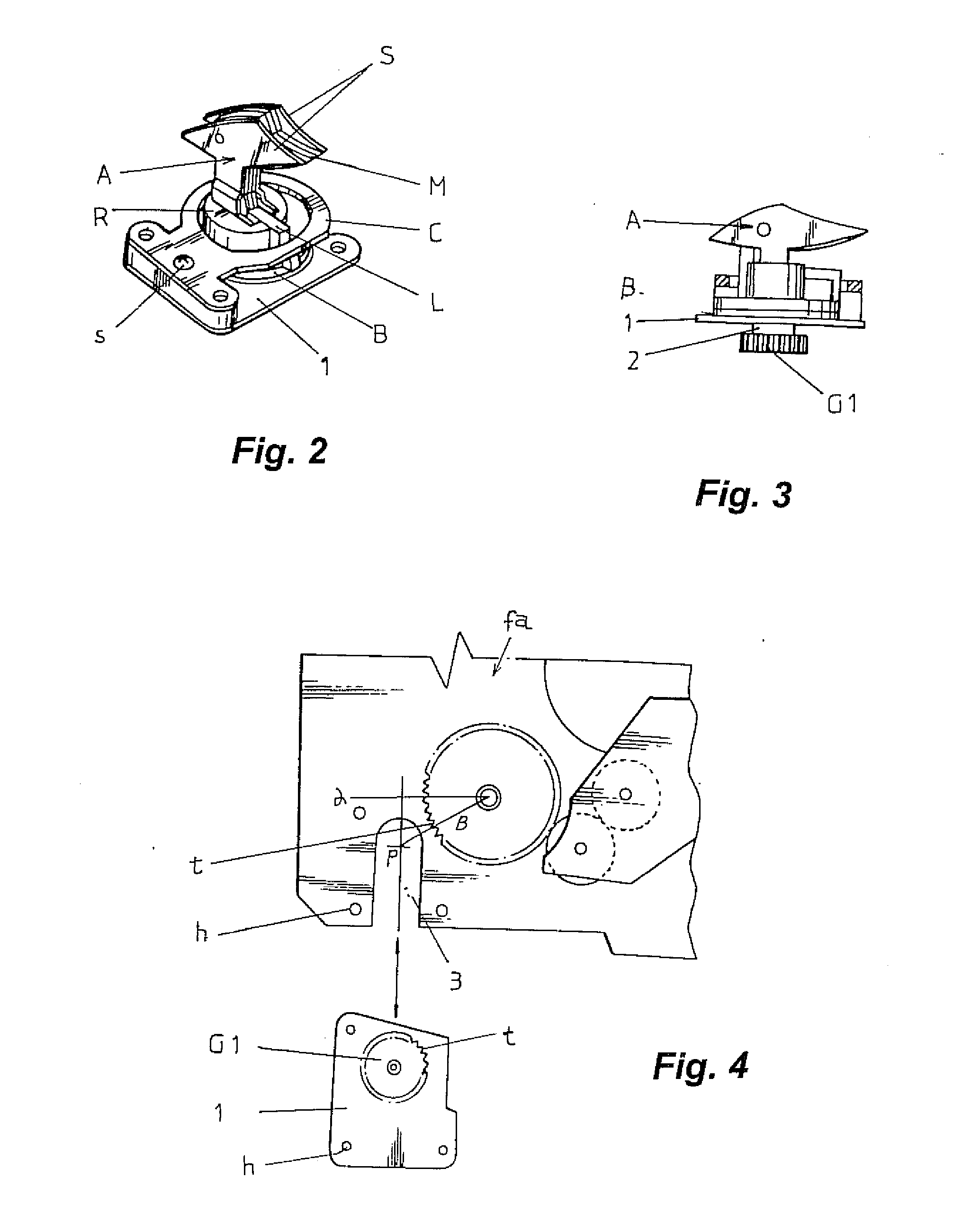

A fastening tool applies parts, in particular plastic parts, to objects. The plastic parts are supplied in the form of a belt in which the plastic parts are linked together by at least one flexible web. The fastening tool transports the belt by a feed mechanism such that one plastic part at a time is delivered to a fastening position. The feed mechanism has a fluid drive that is coupled by a translation-rotation converter to a transport gear rotatably mounted on the fastening tool and designed to positively or nonpositively engage the belt in order to transport it. The translation-rotation converter has an overrunning clutch whose driving gear is kinematically coupled to the fluid drive and whose driven gear is coupled to the transport gear in a rotationally fixed manner.

Owner:NEWFREY

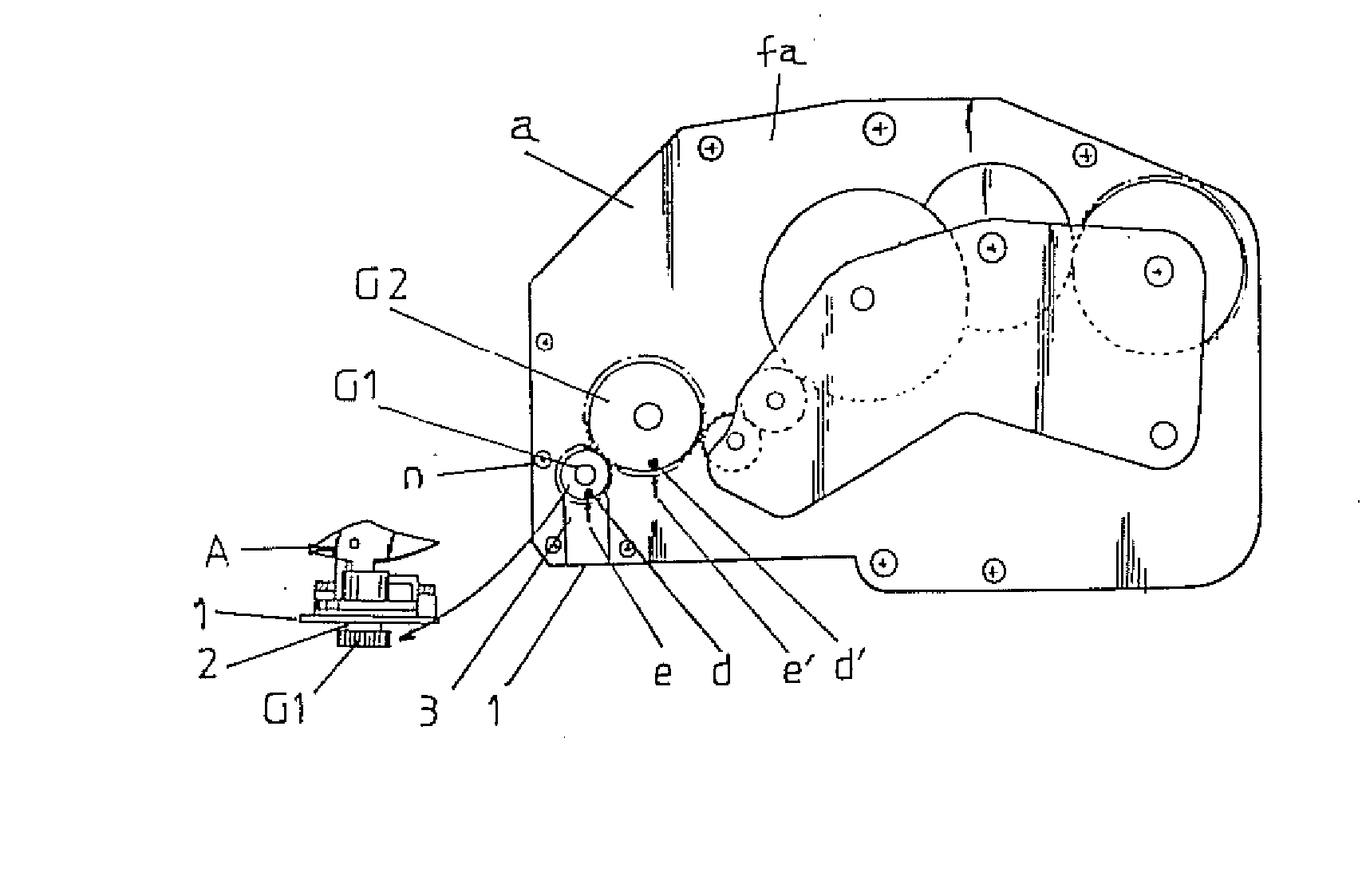

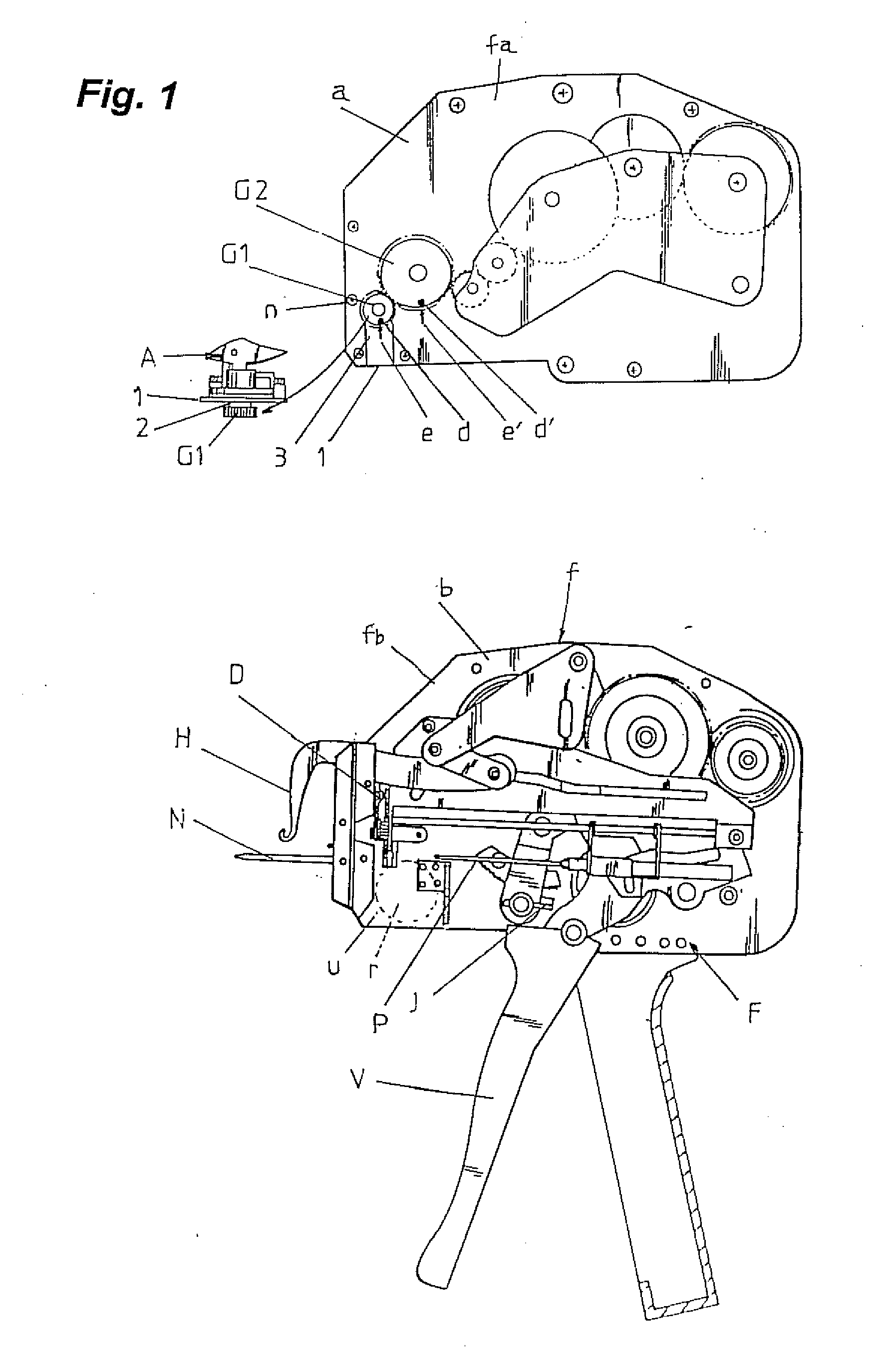

Apparatus for replacing a knotter in a tag fastener

InactiveUS20080237292A1Easy to disassembleImprove practicalityStapling toolsAffixing tagsEngineeringPinion

The present invention relates to an apparatus for replacing a knotter in a tag fastener, wherein the knotter is mounted on a separate base plate and the hub of the pinion of the knotter is inserted vertically from the bottom of a side plate of the tag fastener body. The pinion protruding onto the outside of the base plate is mounted onto a side of the body by the base plate and engaged with the driving gear arranged on the outside of the body of the tag fastener. A tag is fastened by the tag fastener while the knotter, working in conjunction with the mechanism in the body, knots a looped thread and cuts the knotted loop. The knotter can be separated easily from the body of the tag fastener for repair or replacement without disassembling the body of the tag fastener.

Owner:LEE DUK HEE

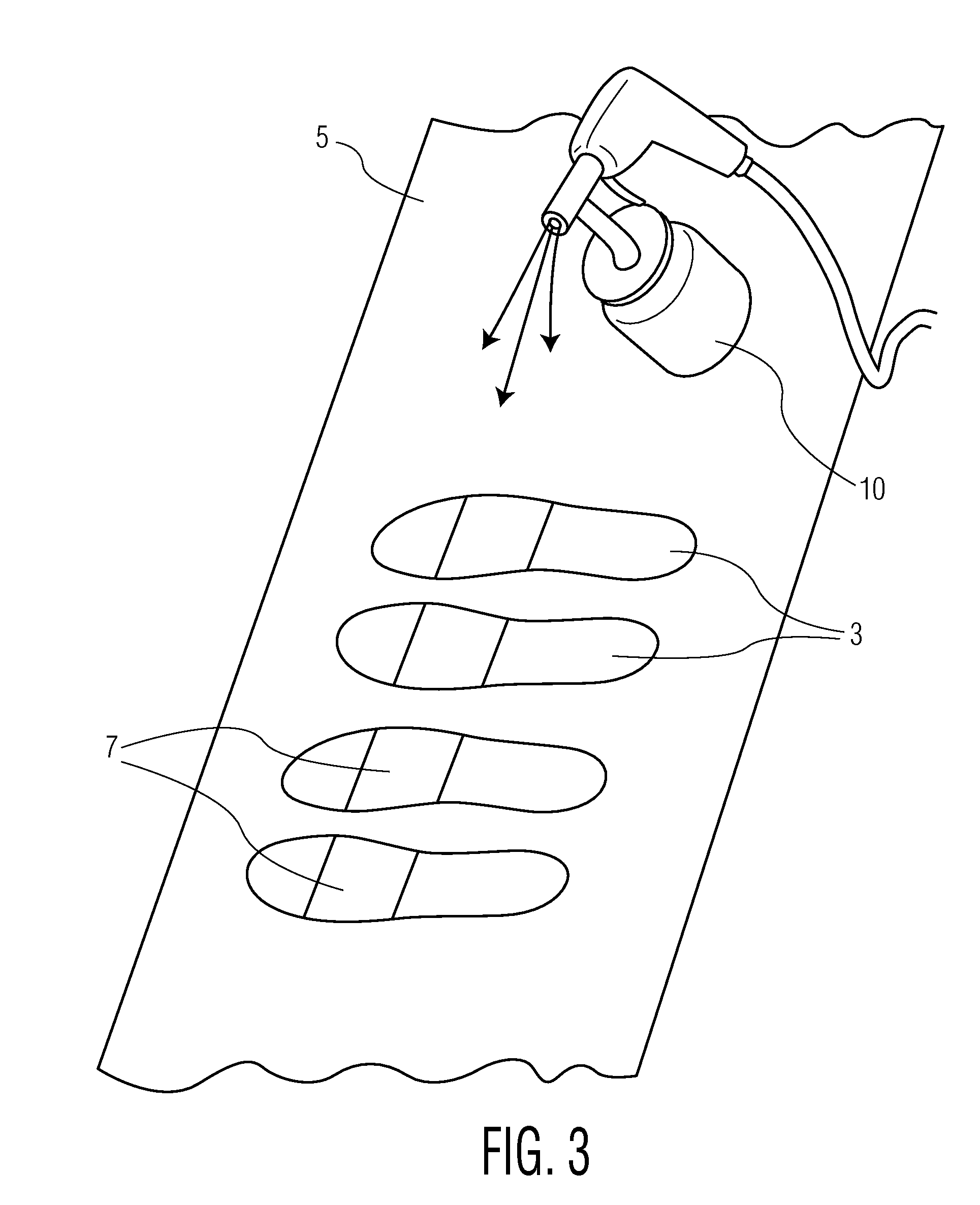

Method and Apparatus for Applying Flocking to the Outsole of Shoe Under Pressure

Flocking fibers are applied to the outsole of a shoe by placing the fibers in a chamber within a housing and placing the outsole over an opening in the housing after applying an adhesive to a surface of the outsole which is to receive the flocking. A pressurized gas jet is activated to increase the pressure in the housing thereby causing the fibers to exit the chamber and collide with the adhesive surface of the outsole. The outsoles may be supported on screens within openings in a tray which is removably mountable on the housing over the opening therein.

Owner:VIDA SHOES INT

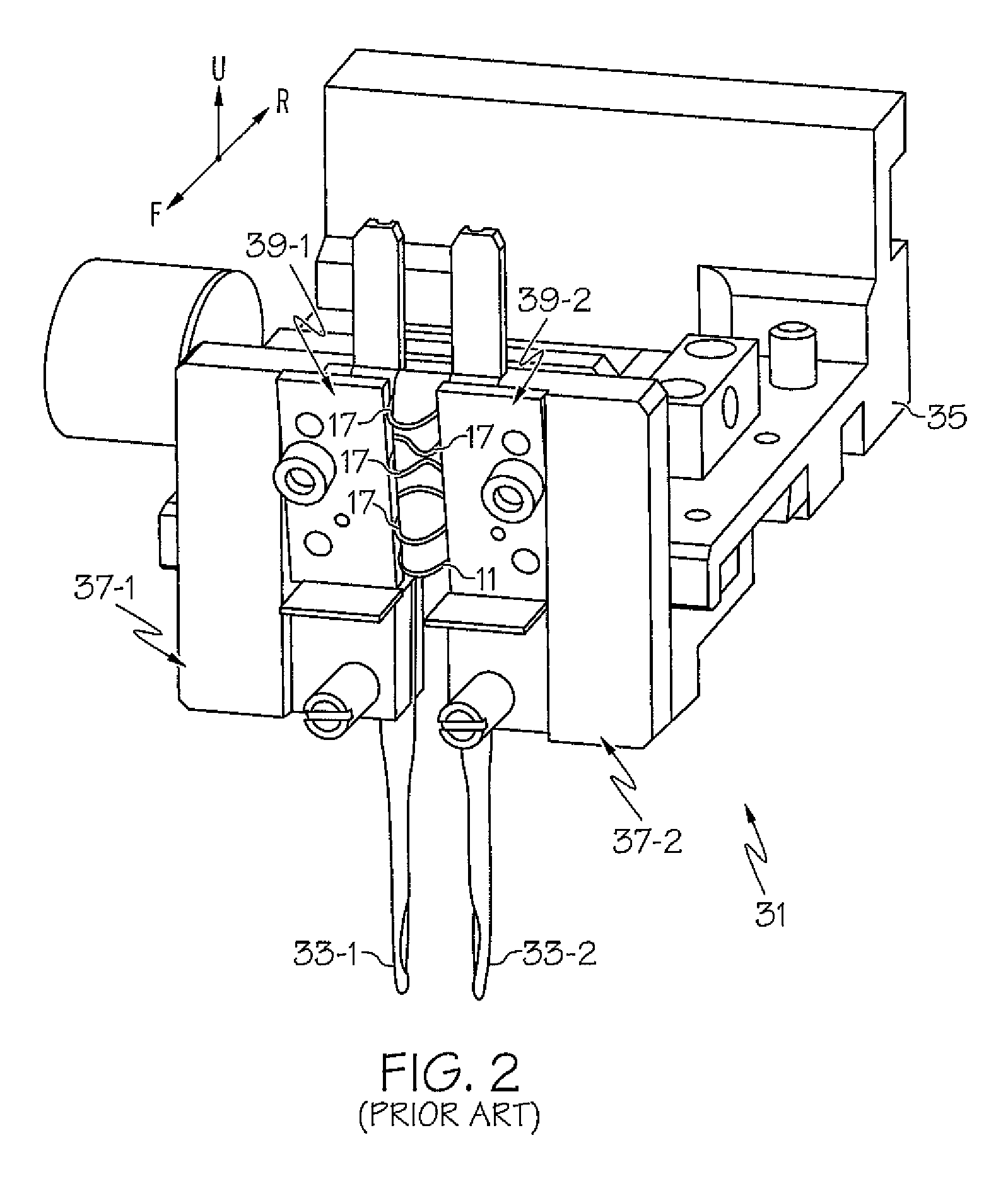

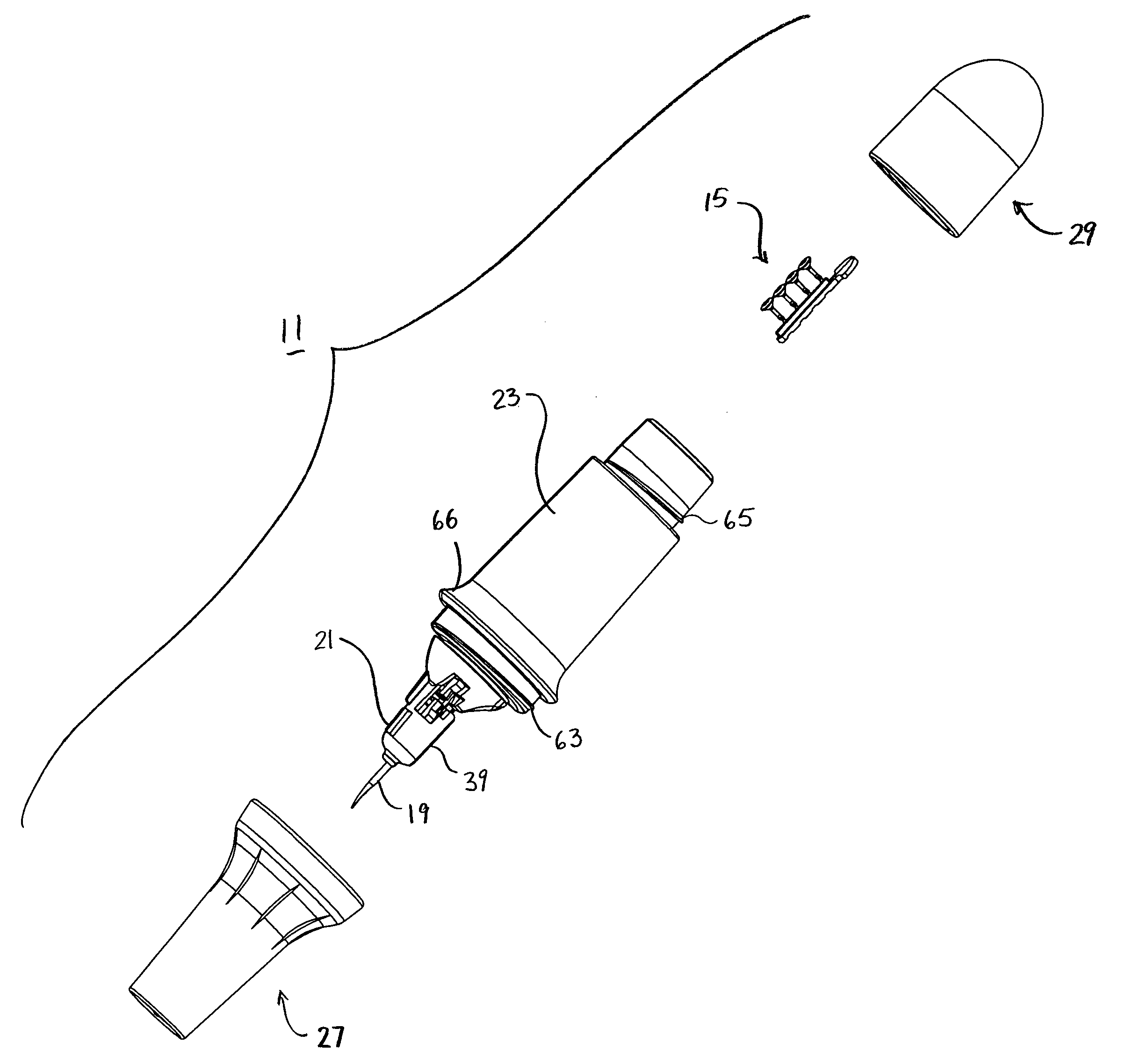

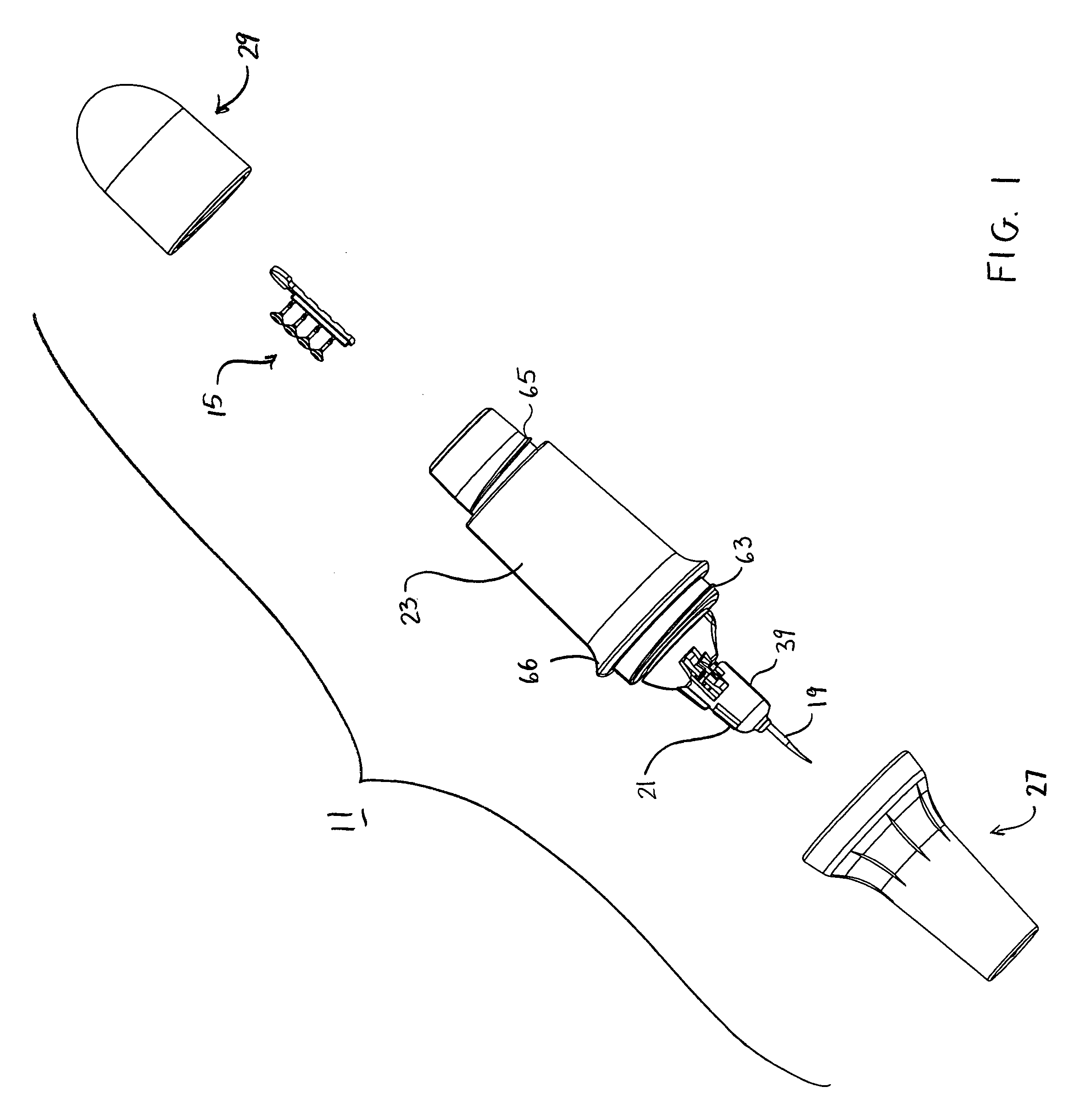

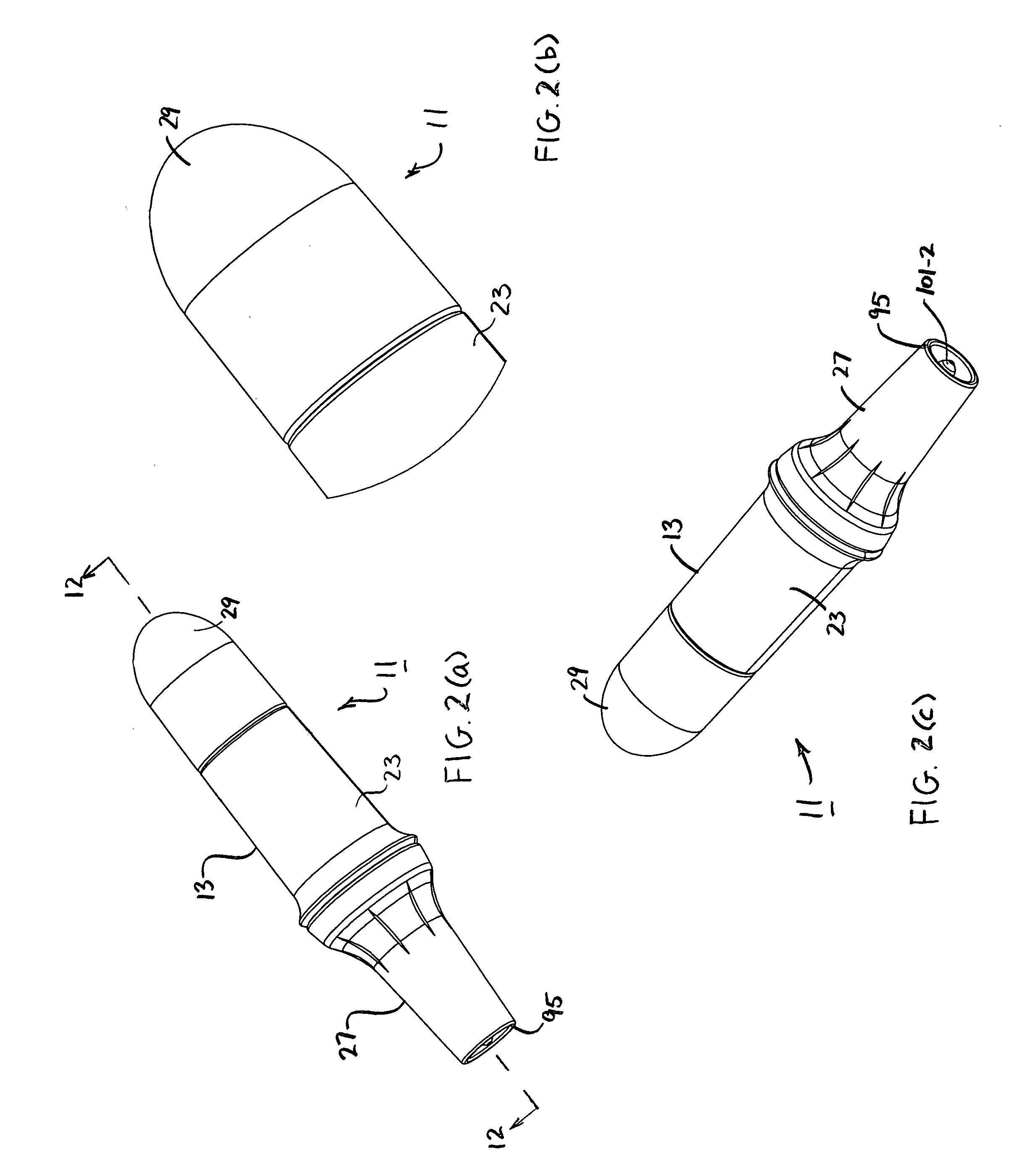

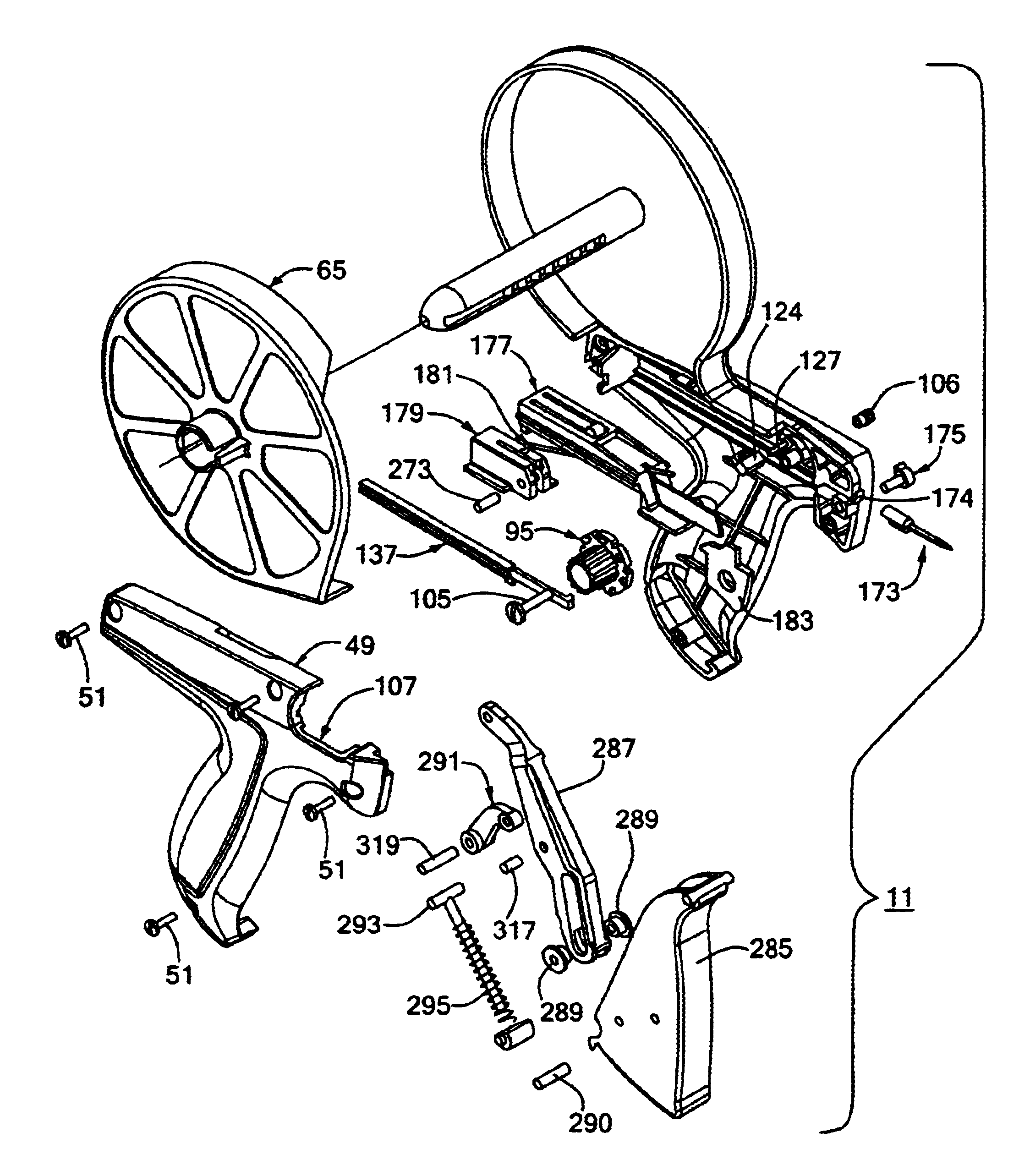

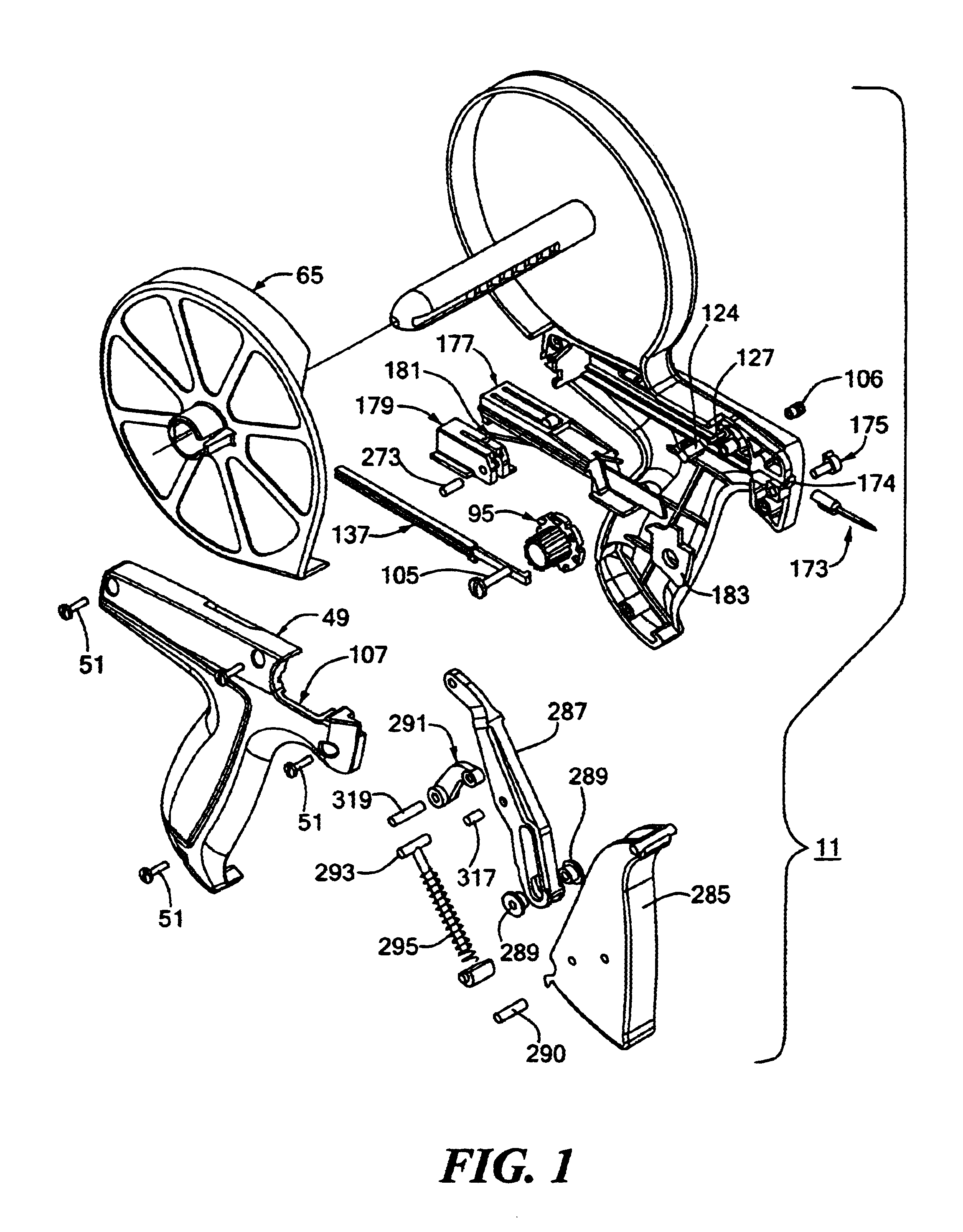

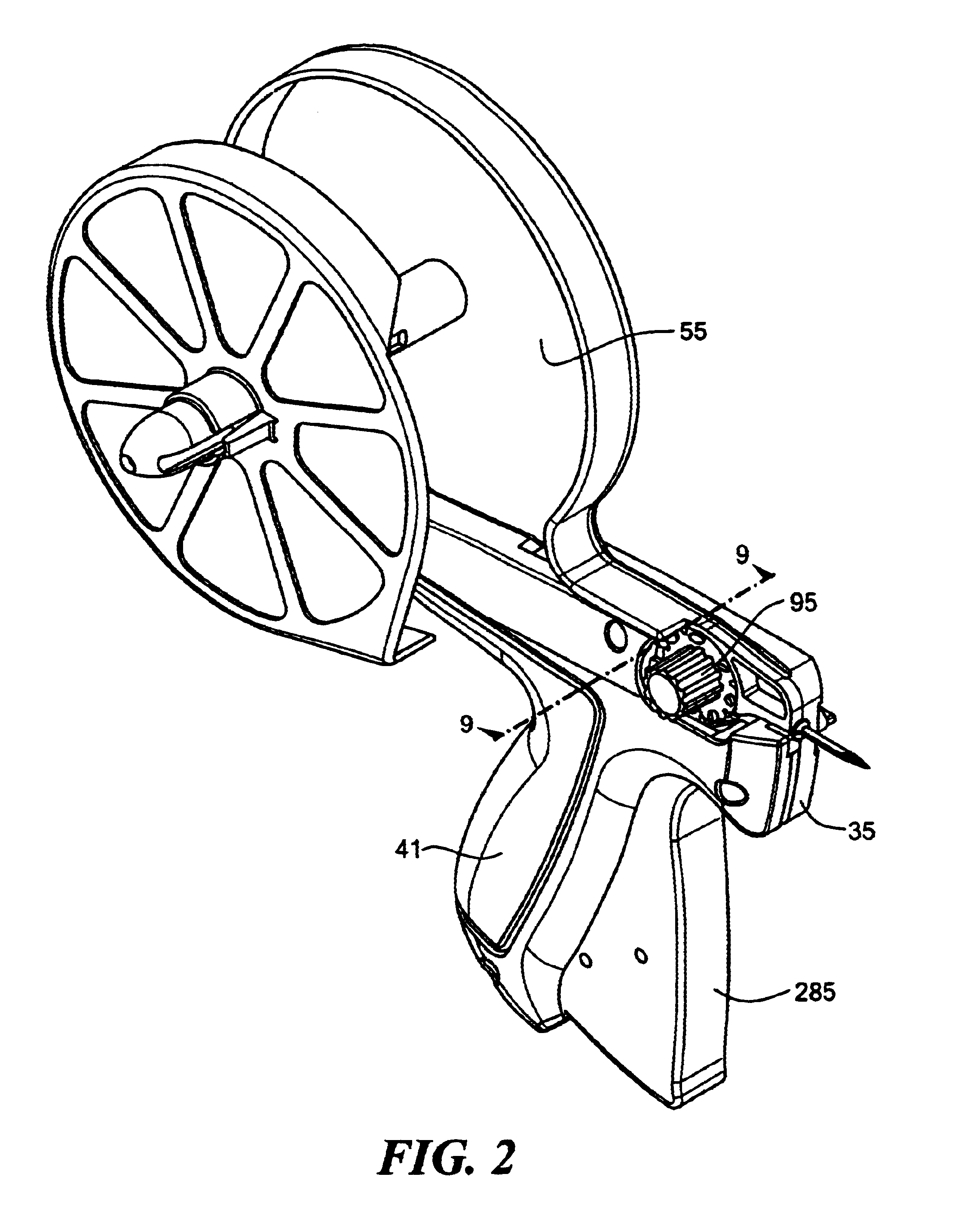

Apparatus for dispensing individual plastic fasteners from fastener stock

InactiveUS6848606B2Less susceptible to interferenceReduce manufacturing costAffixing tagsNailingBiomedical engineeringPlunger

An apparatus (11) for dispensing individual plastic fasteners from fastener stock (13), includes a housing (27) and a hollow slotted needle (173) mounted onto said housing (27). An indexing wheel (95) is rotatably disposed within the housing (27) and advances a fastener to the rear end of the needle (173). A rocker (177) is slidably disposed within the housing and serves to move the cross-bar of the fastener in parallel with the needle bore. A plunger (179) is disposed within the housing (27) and is capable of being slidably displaced by a trigger assembly. An ejector rod (181) is fixedly mounted onto the plunger (179) and serves to push the cross-bar of the fastener out of the front of the needle (173). An indexing slide (137) separate from the rocker (177) is slidably disposed within the housing (27) and serves to rotatably advance the indexing wheel (95) after the ejector rod (181) pushes the cross-bar of the fastener out the front end of the needle (173).

Owner:AVERY DENNISON CORP

Automatic nail pulling equipment for shoemaking

ActiveCN107334221AEasy to pull nailsReduce manual operationsNailingLocking mechanismIndustrial engineering

The invention discloses automatic nail pulling equipment for shoemaking. The automatic nail pulling equipment for shoemaking comprises a machine frame, a fixed mechanism and a nail pulling mechanism; the fixed mechanism comprises a fixed block and a fixed strip; a fixed ring is fixed on the fixed strip; a locking mechanism is arranged on the machine frame; and after the head of a shoe tree is inserted into the fixed ring, the locking mechanism locks the fixed strip on the tail part of the shoe tree and the fixed strip presses against the tail part of the shoe tree, so that the shoe tree is fixed on the machine frame. When a nail is pulled, an operator inserts the head of the shoe tree fixed with a vamp into the fixed ring and then moves the fixed block to enable the fixed block to press against the tail part of the shoe tree, and the operator uses the locking mechanism to fix the fixed block on the machine frame so as to fix the shoe tree with the vamp on the machine frame, and then the nail pulling mechanism pulls out the shoe nail from the shoe tree to complete the nail pulling operation. Compared with the existing operation of pulling out the shoe nail through manual operation, the automatic nail pulling equipment for shoemaking realizes the function of automatically pulling the shoe nail, reduces manual operation and improves nail pulling efficiency.

Owner:温州鞋革职业中等专业学校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com