Patents

Literature

72results about How to "Improve nailing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Energy-storage stapler

InactiveCN1948022ACompact structureEasy to useStapling toolsSheet bindingStorage energyEngineering management

An energy accumulated stapler is composed of base, upper cover, staple slot, staple driving plate, elastic staple pusher in said staple slot, the staple plate and bottom spring on said base, a box hinged on base, and such unit in said box as lever, energy-accumulating spring unit and open-close plate. Its advantage is to save labor.

Owner:廖金志

High-speed intelligent automatic screw fastening assembly machine

InactiveCN102922273AGuaranteed reliabilitySimple structureMetal working apparatusStructural engineeringMaterial supply

Owner:DALIAN YUN MING AUTOMATION TECH

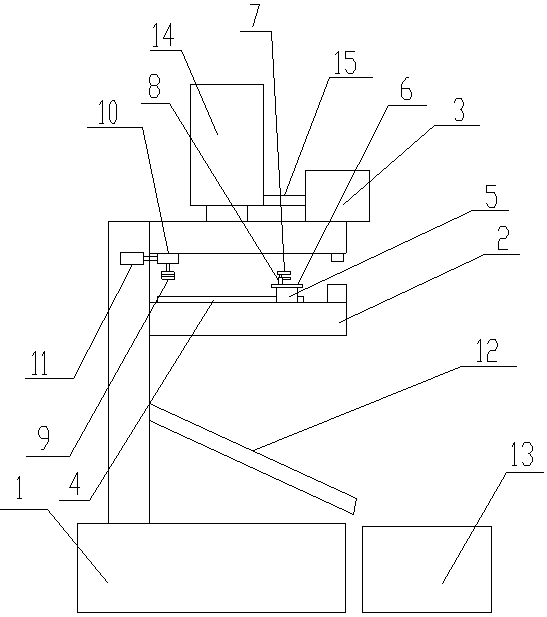

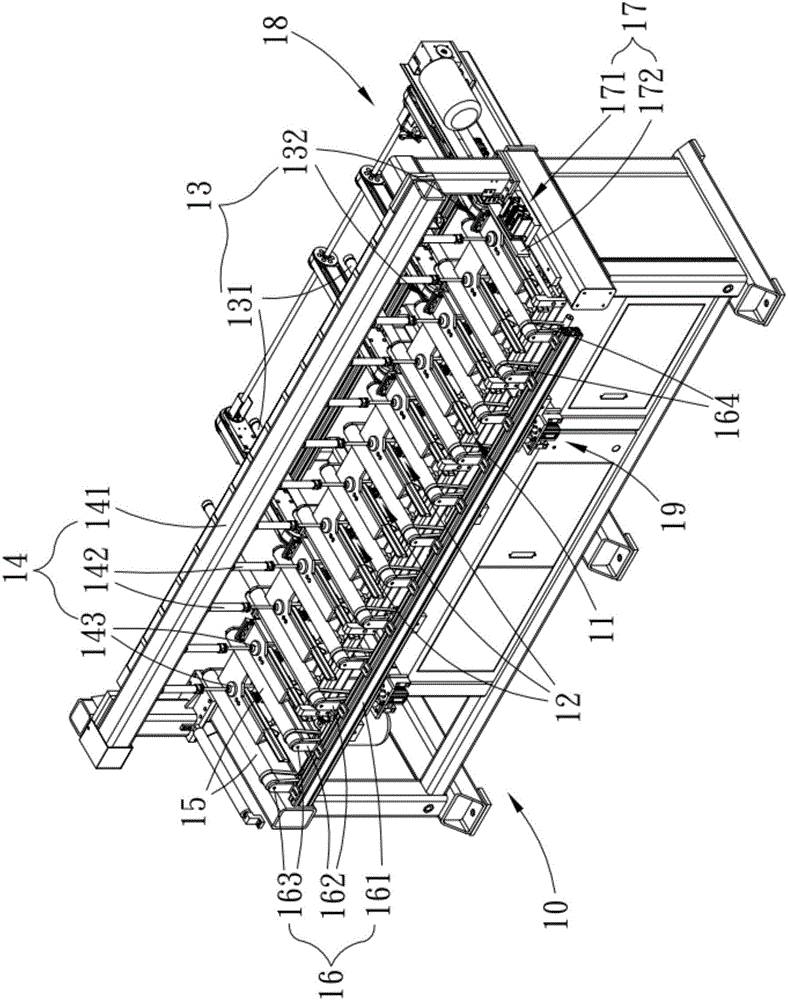

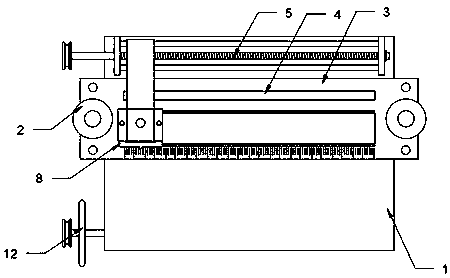

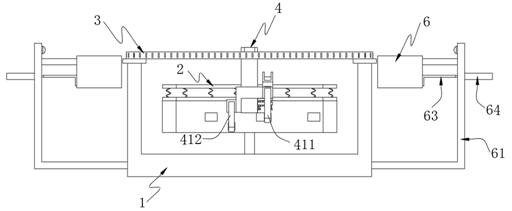

Full-automatic nailing machine for boards

ActiveCN104149144AImprove reliabilityPrecise positioningStapling toolsNailing toolsEngineeringControl unit

The invention discloses a full-automatic nailing machine for boards. The full-automatic nailing machine comprises an operating platform, a transmission device rack, a transmission device, nailing devices, a cutting mechanism, a squeezing cylinder, positioning wheels, a pressing plate wheel and a control unit. The transmission device rack is welded on the upper portion of the operating platform, the transmission device is arranged on the upper portion of the transmission device, the nailing devices are symmetrically arranged on the front and rear sides of the operating platform, the cutting mechanism is arranged on the lower portion of the operating platform, the squeezing cylinder is arranged on the upper left of the cutting device, the positioning wheels are arranged on the upper plane of the operating platform, the pressing wheel device is arranged on the right side of the transmission device, and the control unit is connected with the transmission device, the squeezing device, the cutting mechanism and the nailing mechanism. By the means, the full-automatic nailing machine has the advantages of high reliability, positioning accuracy, compact structure, high nailing efficiency, convenience in use and the like, completely substitutes for labor to nail the boards, and has good application prospect in the board processing industry.

Owner:沭阳县成基实业有限公司

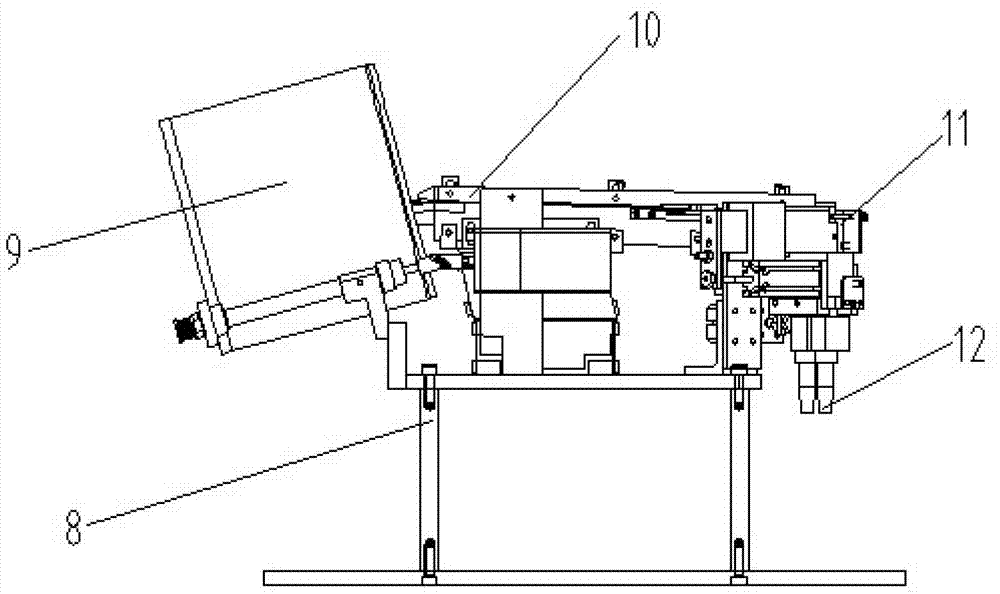

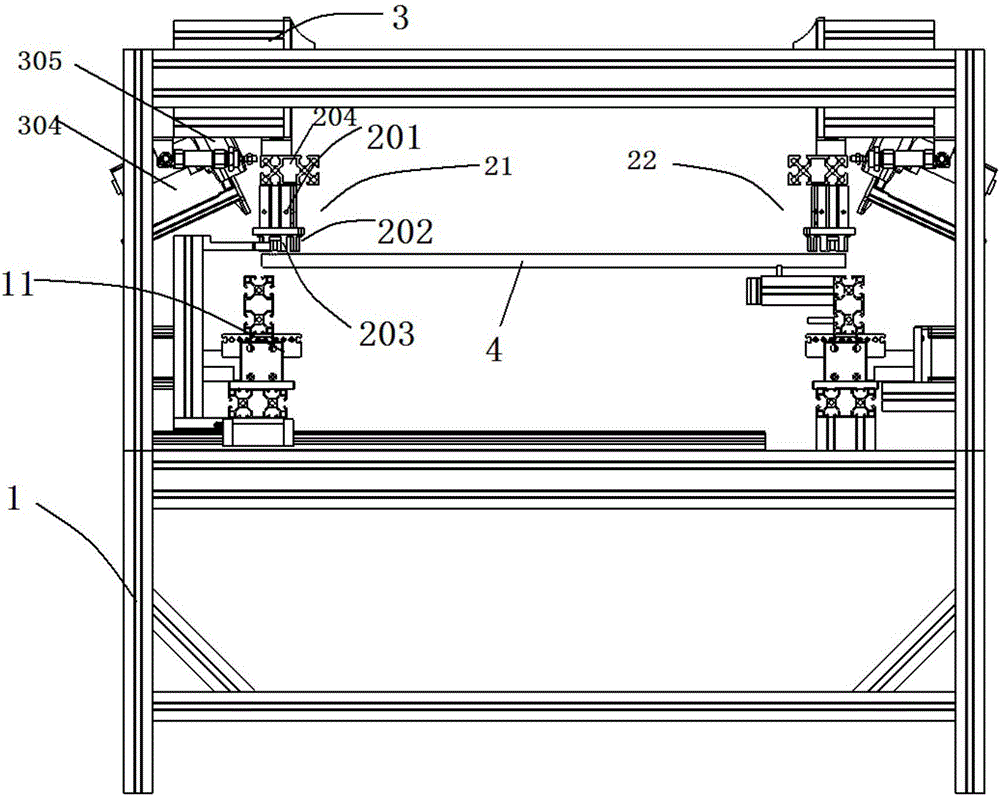

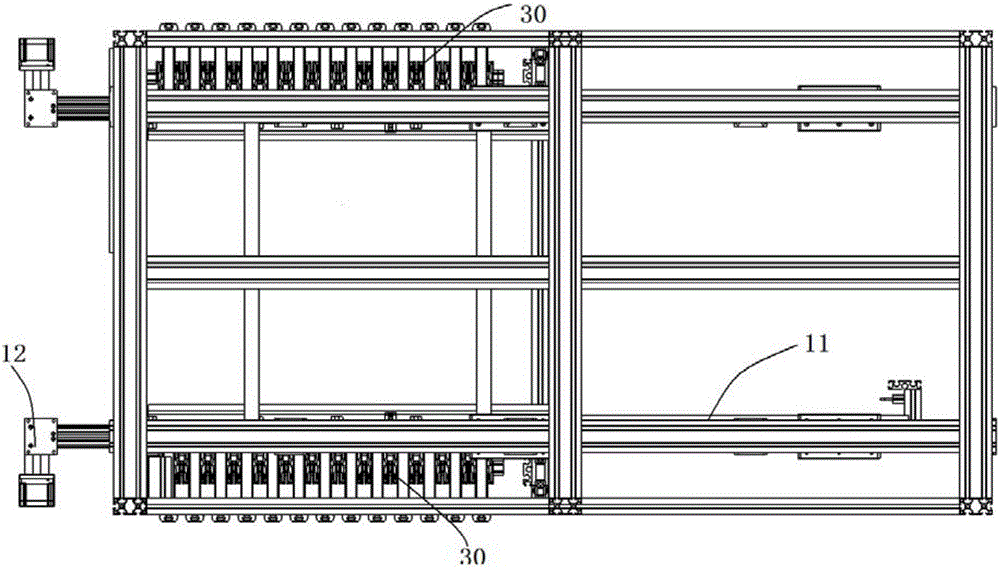

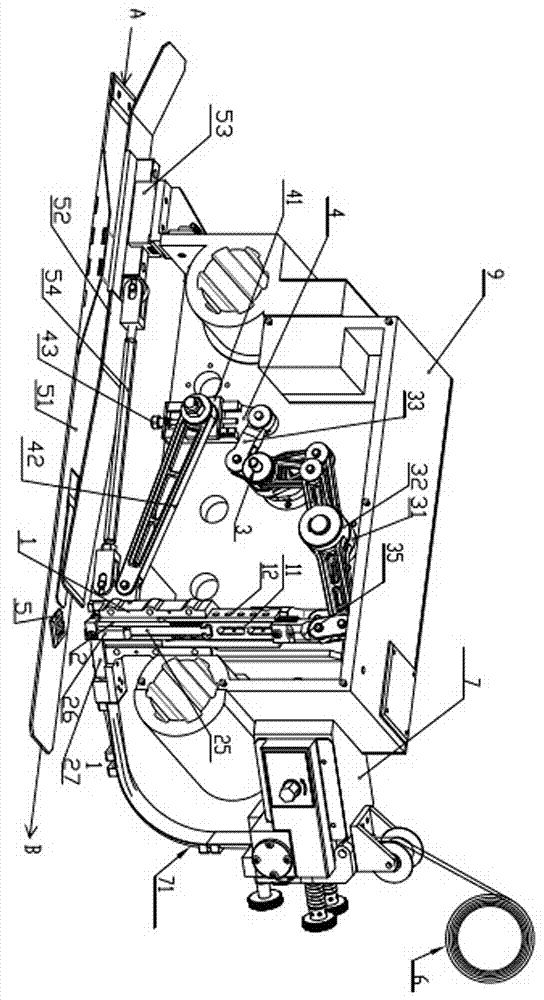

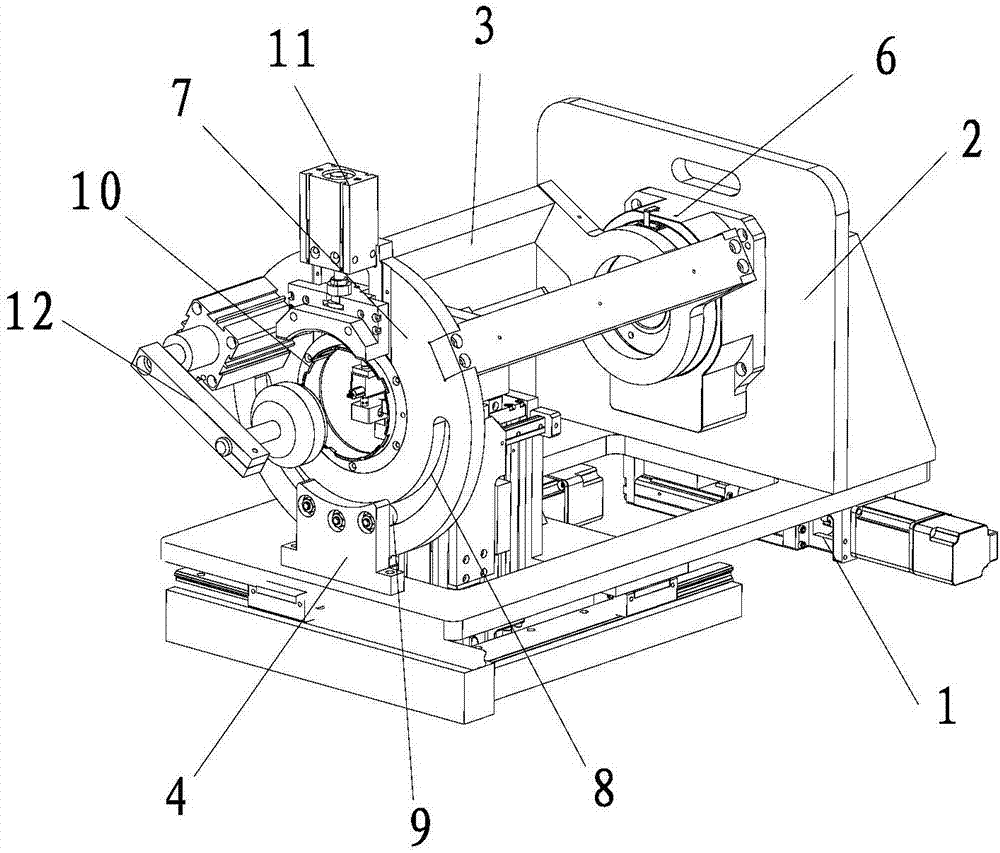

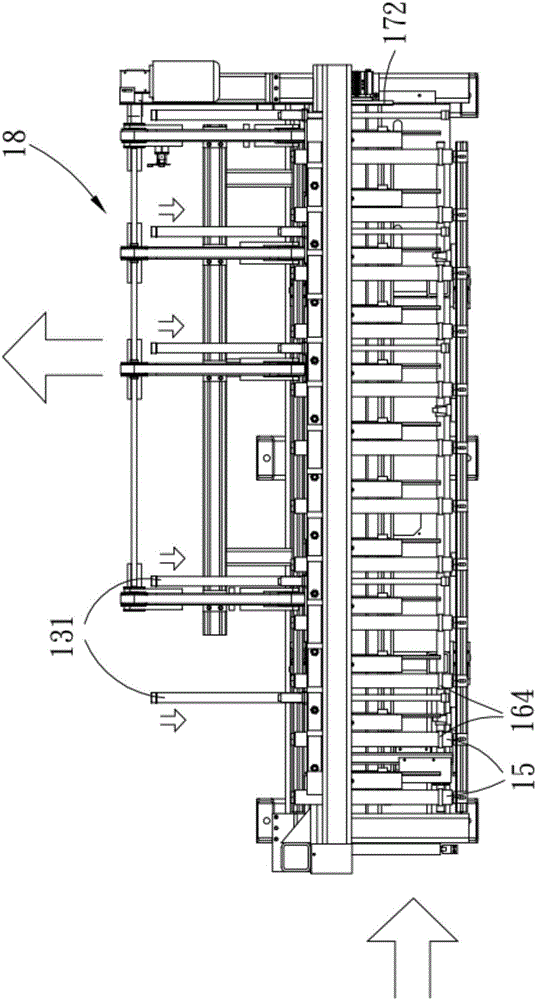

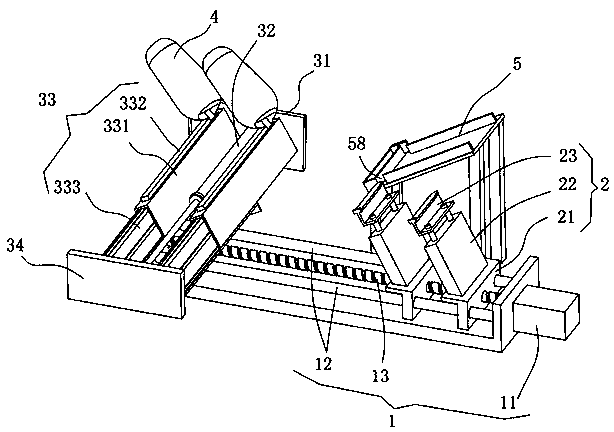

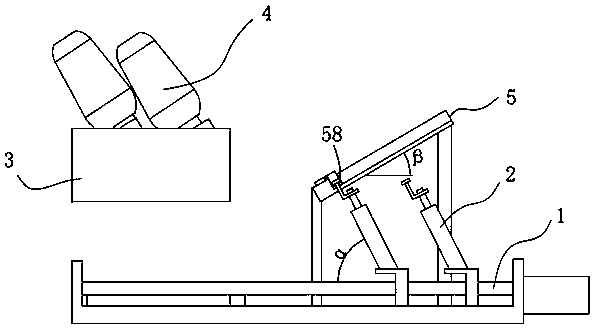

Canvas stretching and nailing device

InactiveCN106347013AConsistent tightnessGuaranteed smoothSpecial ornamental structuresEngineeringNail gun

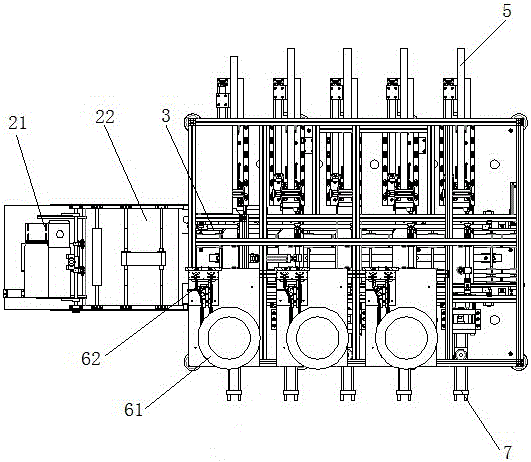

The invention discloses a canvas stretching and nailing device which comprises a bottom moving track, a clamping and pushing device and a stretching and nailing device, wherein the moving track pushes a canvas and a frame to the bottom of the clamping and pushing device, the canvas is delivered to an accommodating space between clamping jaws, a clamping cylinder drives the clamping jaws to clamp the edge of the canvas, a pushing cylinder pushes a pushing plate profile, the clamping cylinder moves along with the pushing plate profile, the clamping jaws wrap the edge of the canvas on the frame; a cylinder drives a heavy sliding block to drive an aluminium profile to move downwards, and a nail gun falls to the stretching and nailing position along with the aluminium profile, and stretches and nails the canvas on the frame. The device disclosed by the invention can automatically complete the process flows of wrapping the frame and stretching and nailing, realize uniform tightness of stretching and nailing, and ensure the levelness of stretching and nailing, thus improving the stretching and nailing efficiency and reducing investment of labor force.

Owner:ALLIO ROBOT TECH (CHANGSHU) CO LTD

Automatic packing box nailing equipment

ActiveCN106742320AQuality improvementQuality assuranceWrapper twisting/gatheringHigh volume manufacturingLow vacuum

The invention provides automatic packing box nailing equipment. The automatic packing box nailing equipment comprises a rack, a discharge conveying mechanism, a servo positioning mechanism, an automatic box opening module, a profile modeling positioning module and an automatic nailing module. The discharge conveying mechanism is located on one side of the rack. The servo positioning mechanism comprises a synchronous conveyor belt located on the rack and a servo motor used for driving the synchronous conveyor belt. The automatic box opening module comprises a lower vacuum sucker and a jacking cylinder. The automatic box opening module further comprises an upper vacuum sucker and a box opening cylinder. The profile modeling positioning module is located on one side of the synchronous conveyor belt. The automatic nailing module is located on the other side of the synchronous conveyor belt and is opposite to the profile modeling positioning module. The automatic packing box nailing equipment can conduct centralized production of multiple nailing procedures, and can automatically complete the whole nailing process of anti-fake rivets of packing boxes. The quality of packing boxes is guaranteed. The requirements for mass production are met. The cost is saved.

Owner:武汉世豪同创自动化设备有限公司

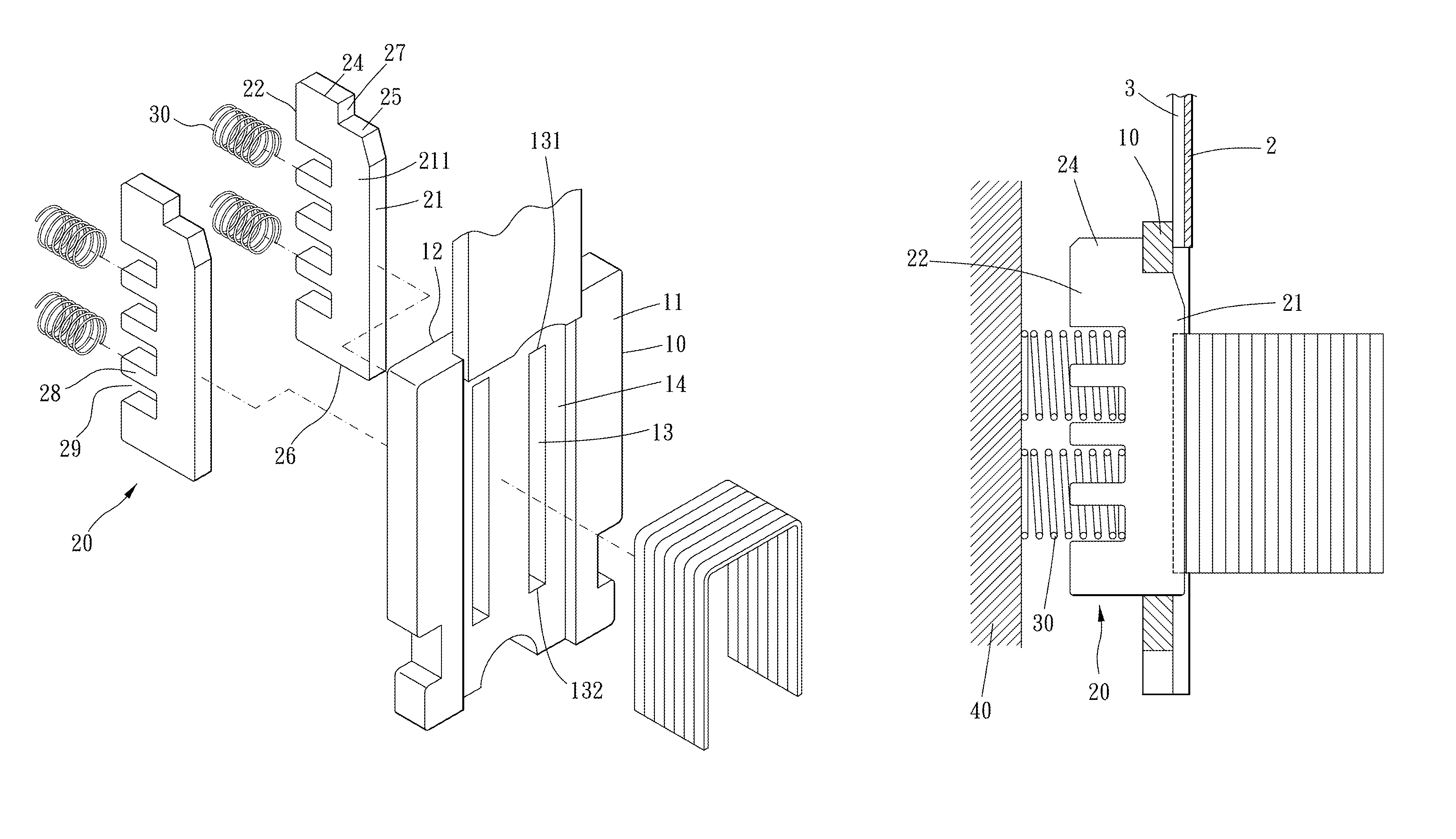

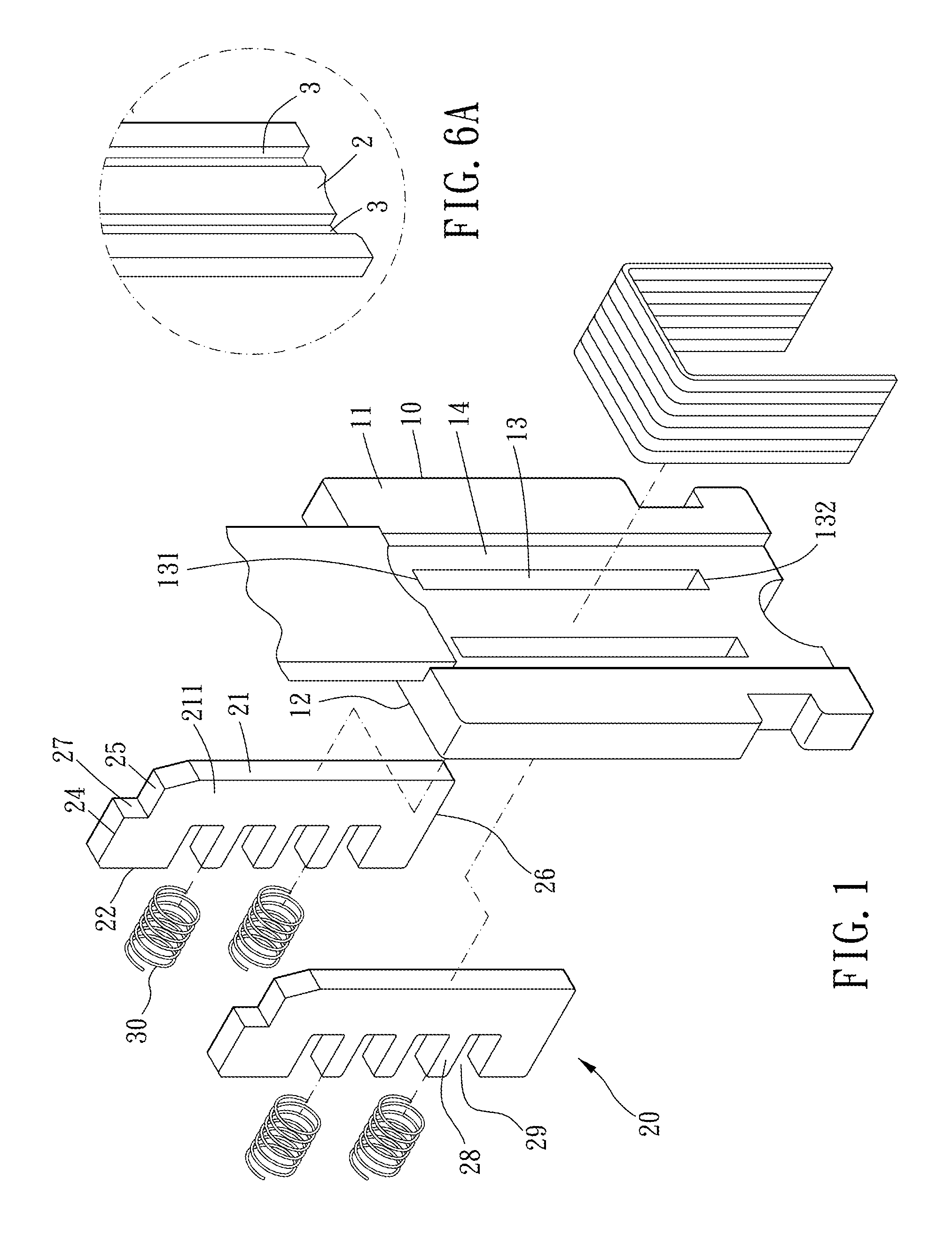

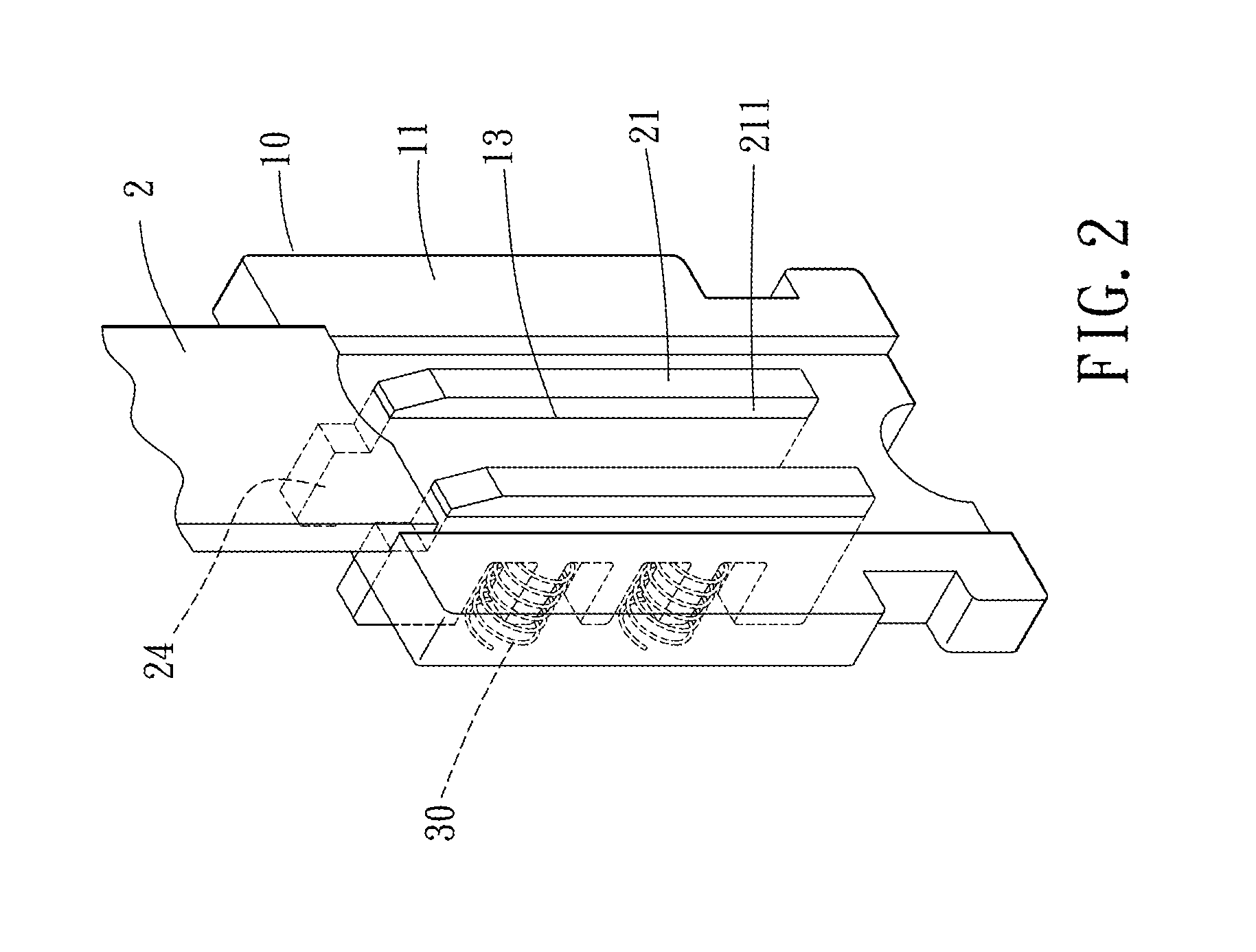

Nail guider and nailing device having the same

Owner:APEX MFG

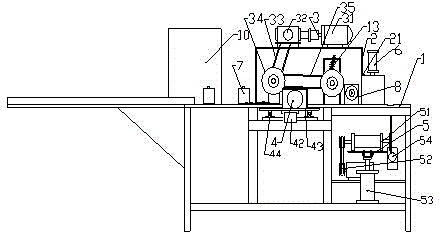

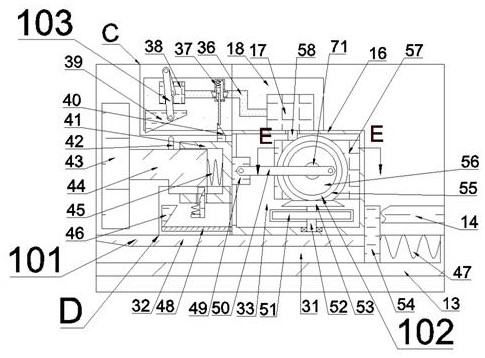

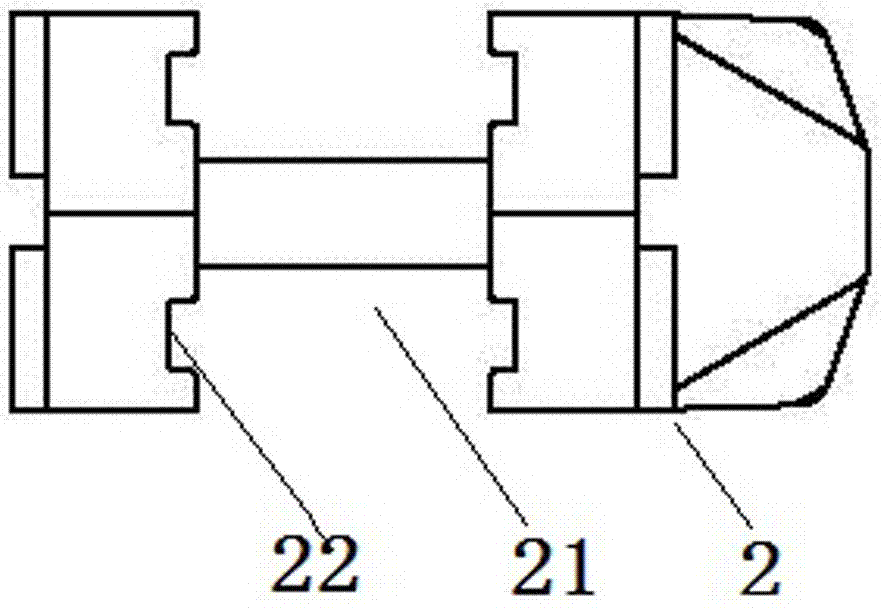

Nail head device for nailing corrugated board and box nailing machine

InactiveCN104742412AAchieve horizontal swingAvoid the bad phenomenon of scratchingBox making operationsPaper-makingMechanical engineeringEnergy consumption

The invention provides a box Nailing machine for nailing a corrugated board. The machine comprises a base, a driving device, a line conveying device, a bottom die and a nail head device; the nail head device comprises a cutter device and a medium punch, wherein the cutter device is arranged on a nail head device and can linearly displace up and down; chutes are respectively formed in two opposite side surfaces of the cutter device; nail line grooves are formed in two opposite side surfaces of the chutes; the medium punch is the chutes; a movable bending die is mounted on the nail head rack and can be used for positioning the nail line into the nail line grooves after forming the nail line; when the medium punch downwards displaces, the bending die can be extruded to be separated from a binding line; the driving device is movably connected with the cutter device and the medium punch through connecting rods; a nail head oscillating device is respectively connected with the driving device, the nail head rack and a linear bearing mounted on the base through the connecting rods. The machine is compact in structure, small in energy consumption, high in nailing efficiency, and free of special U-shaped nails, and a binding line coil is only mounted.

Owner:苏州市富祥润通机电科技有限公司

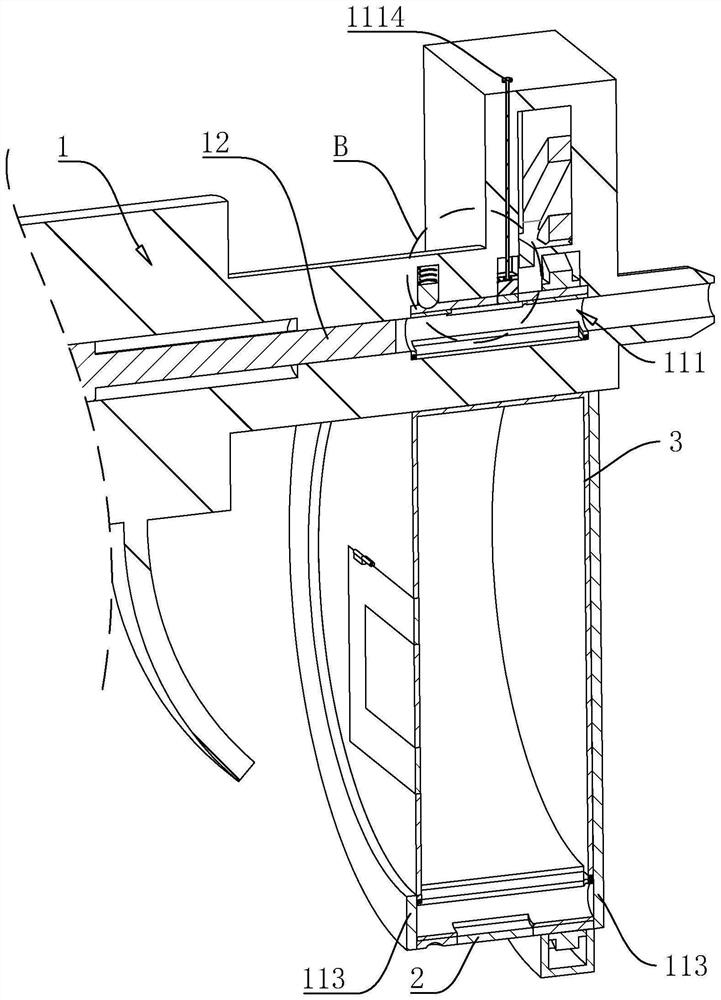

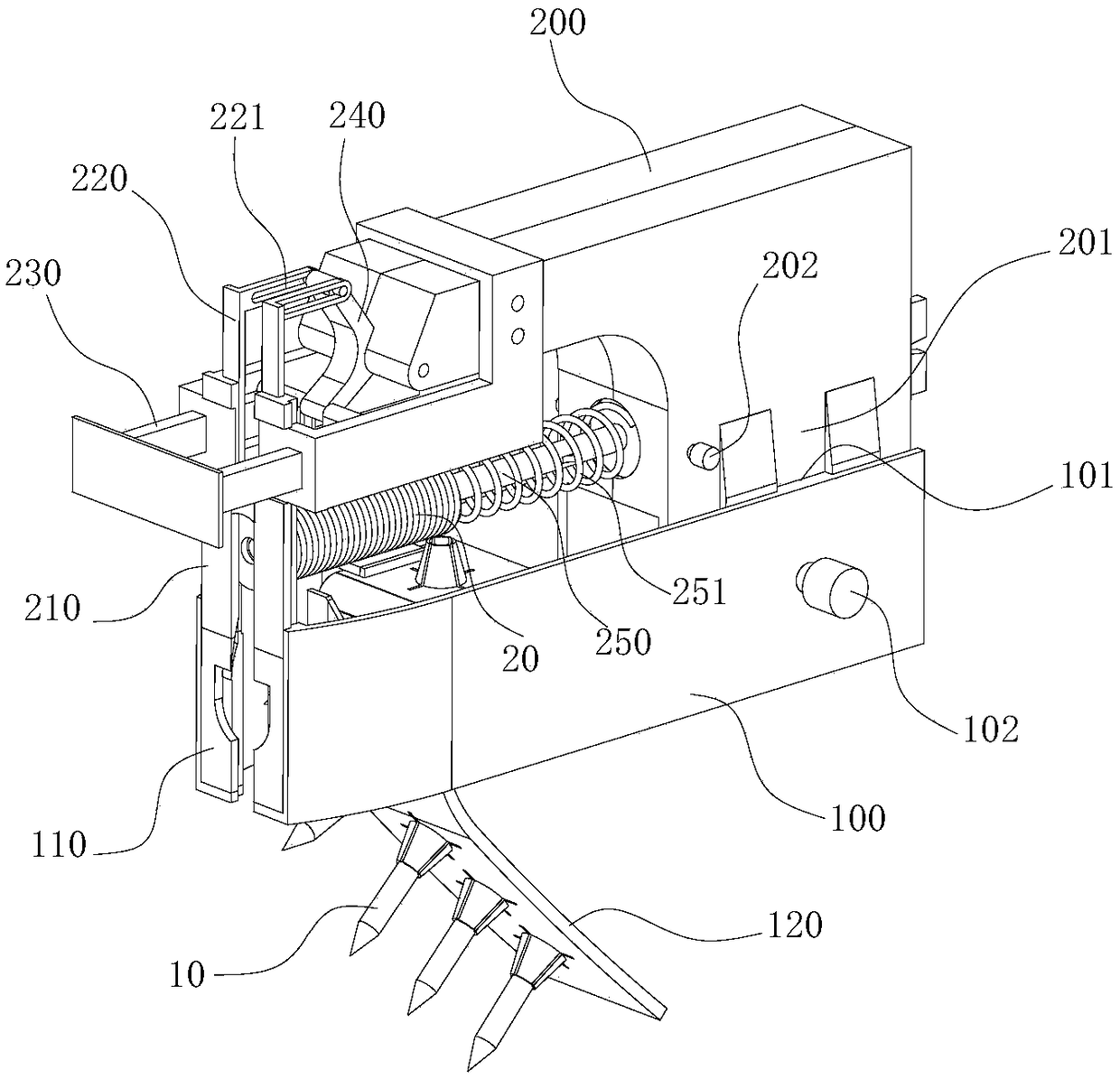

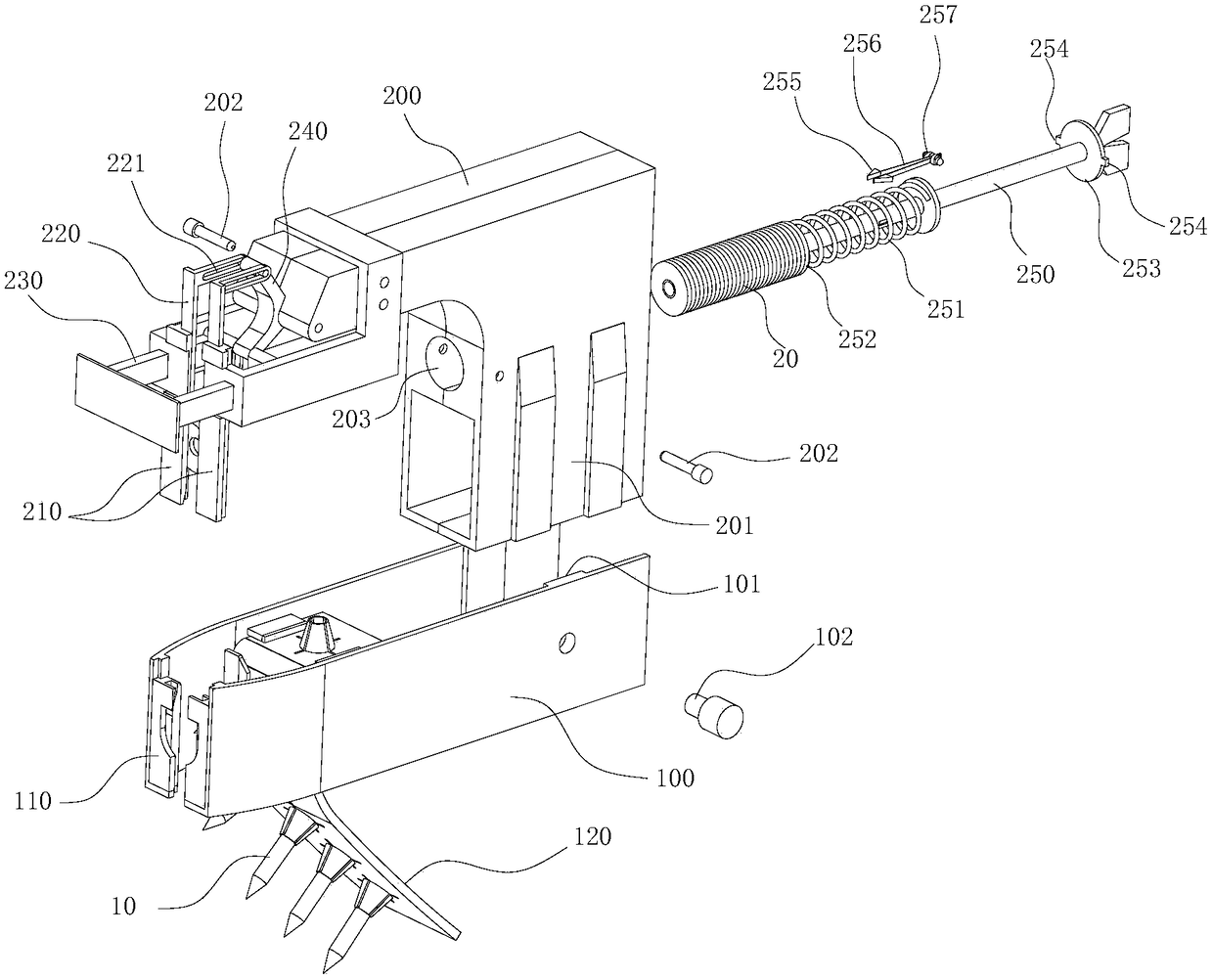

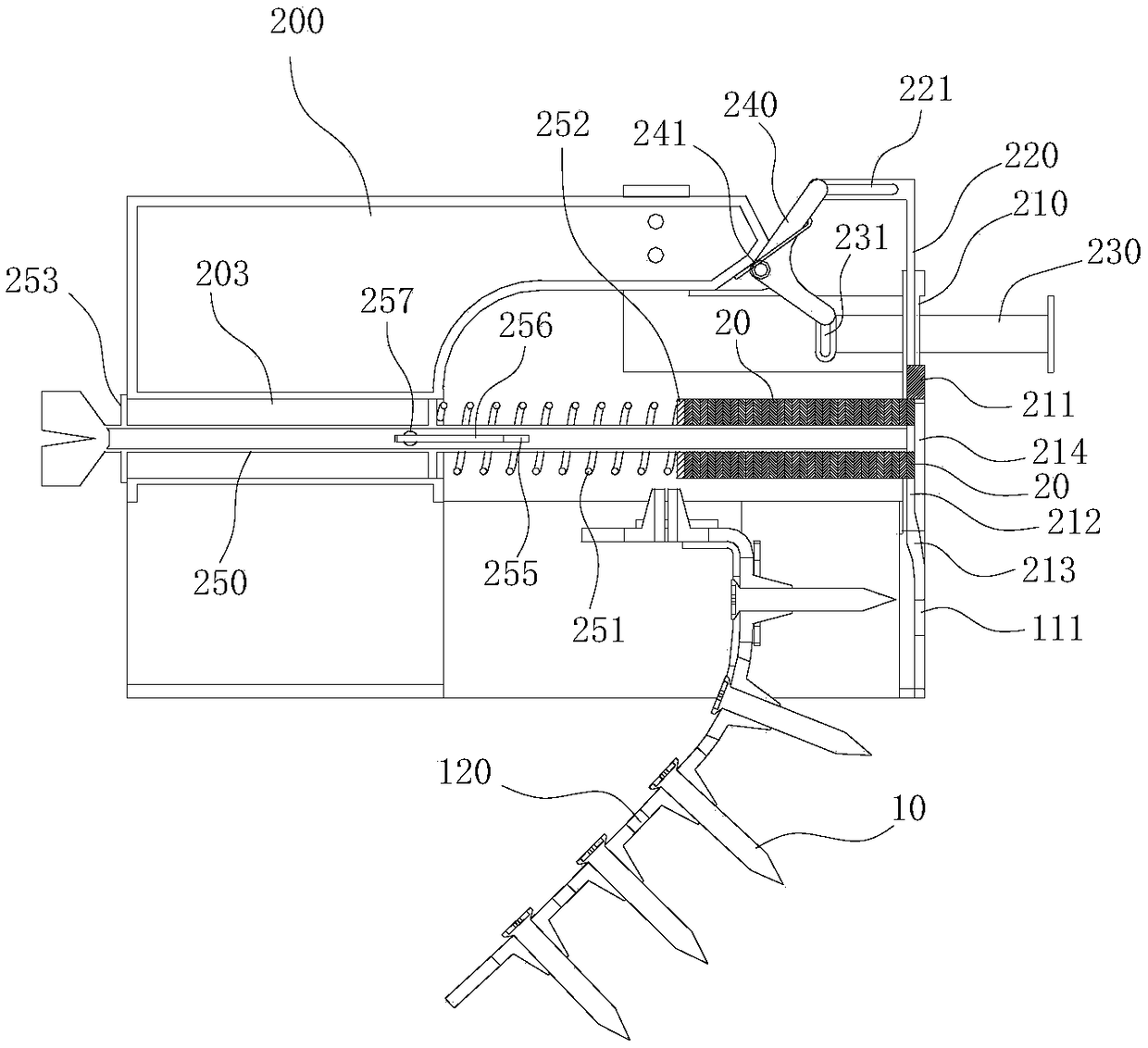

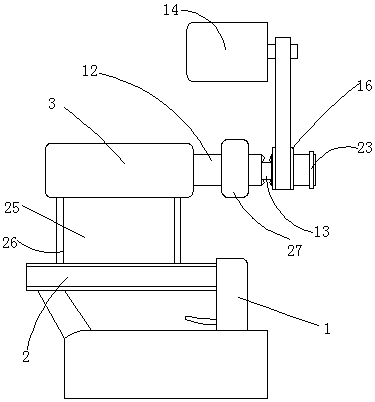

Board nailing machine for wood packaging

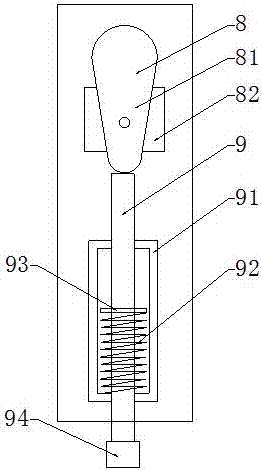

InactiveCN107398964AAvoid security risksImprove nailing efficiencyStapling toolsNailing toolsMagnetCam

The invention relates to a wooden board nailing machine for wooden packaging, which belongs to the field of wooden packaging processing. It includes a frame and a workbench arranged under the frame. An automatic unloading device and a nailing device are connected to the frame. The automatic unloading device has a box body fixed on the frame. One side of the box body is provided with a slide nail channel connected to the vibrating plate, a guide magnet is arranged above the slide nail channel, a vertical channel is provided below the guide magnet, and a pushing mechanism is arranged at the bottom of the vertical channel. The invention is beneficial in that it can realize the automatic feeding of iron nails, avoiding the safety risk caused by manual nail arranging; the nailing efficiency is high, and the nailing is performed by using the cam mechanism, the equipment structure is simple, and the volume is small; The rotation speed can realize the adjustment of the nailing frequency.

Owner:苏州卫刚木包装制品有限公司

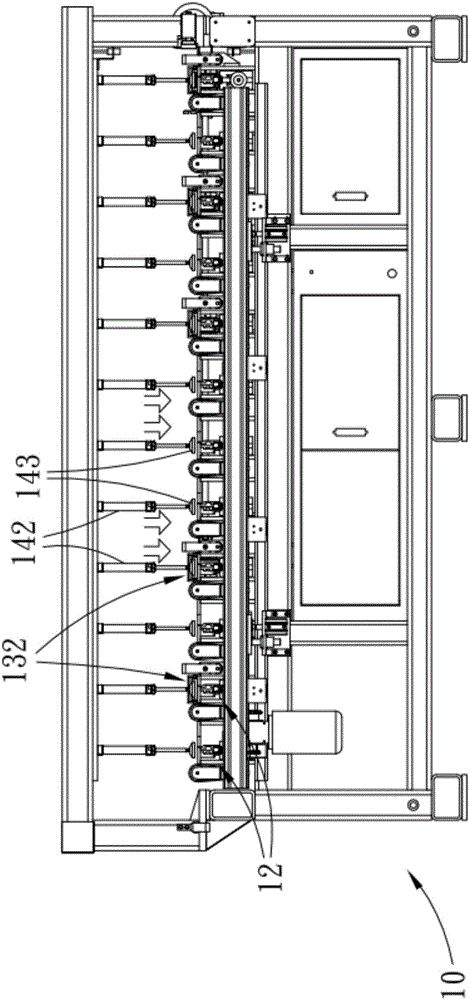

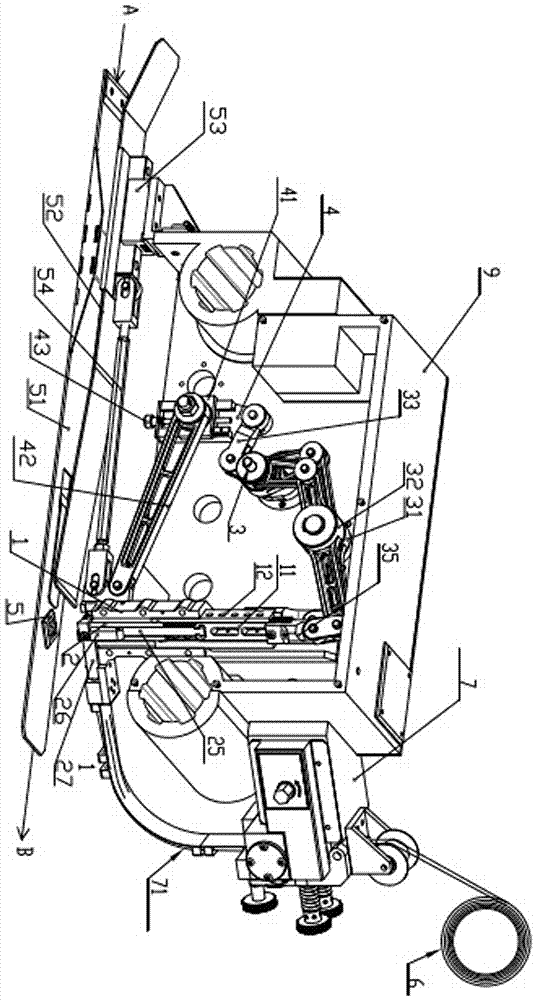

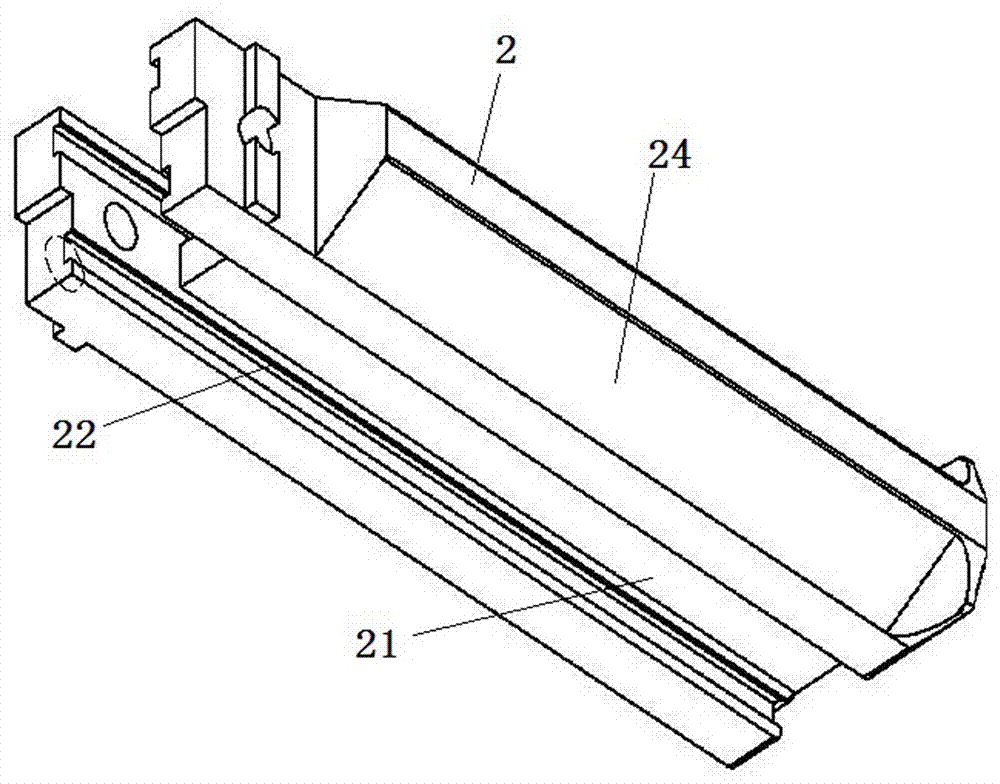

Automatic nail loading equipment and automatic nail loading type nail gun system

PendingCN111267188ARealize integrated intelligent productionAvoid stickingStapling toolsNailing toolsNail gun

The invention provides automatic nail loading equipment. The automatic nail loading equipment is used for pushing nail rows into an automatic nail loading type nail gun. The automatic nail loading equipment is characterized in that the automatic nail loading equipment comprises a bottom plate, a nail stacking sliding chute, a plurality of pushing pins, a plurality of pushing pin cylinders, a nailloading rail, a nail pushing rod, a nail pushing cylinder, a joint groove, a displacement detection element and a control module; the nail stacking sliding chute is provided with a first passage stretching in the vertical direction; the plurality of pushing pins are used for controlling the sliding of the nail rows in the first channel; the plurality of pushing pin cylinders are correspondingly connected with the plurality of pushing pins; the nail loading rail is provided with a second channel perpendicular to the first channel; the nail pushing rod is used for pushing the nail rows to move in the length direction of the second channel; The nail pushing cylinder is connected with the nail pushing rod correspondingly through a connecting block; the joint groove is used for being connectedwith the automatic nail loading type nail gun; the displacement detection element is used for detecting the approaching and leaving of the connecting block and outputting corresponding detection electric signals; and the control module is used for control only one nail row to slide into the second channel from the first channel and be pushed into the automatic nail loading type nail gun through the second channel.

Owner:SHANGHAI BAOYE ELECTROMECHANICAL TECH CO LTD

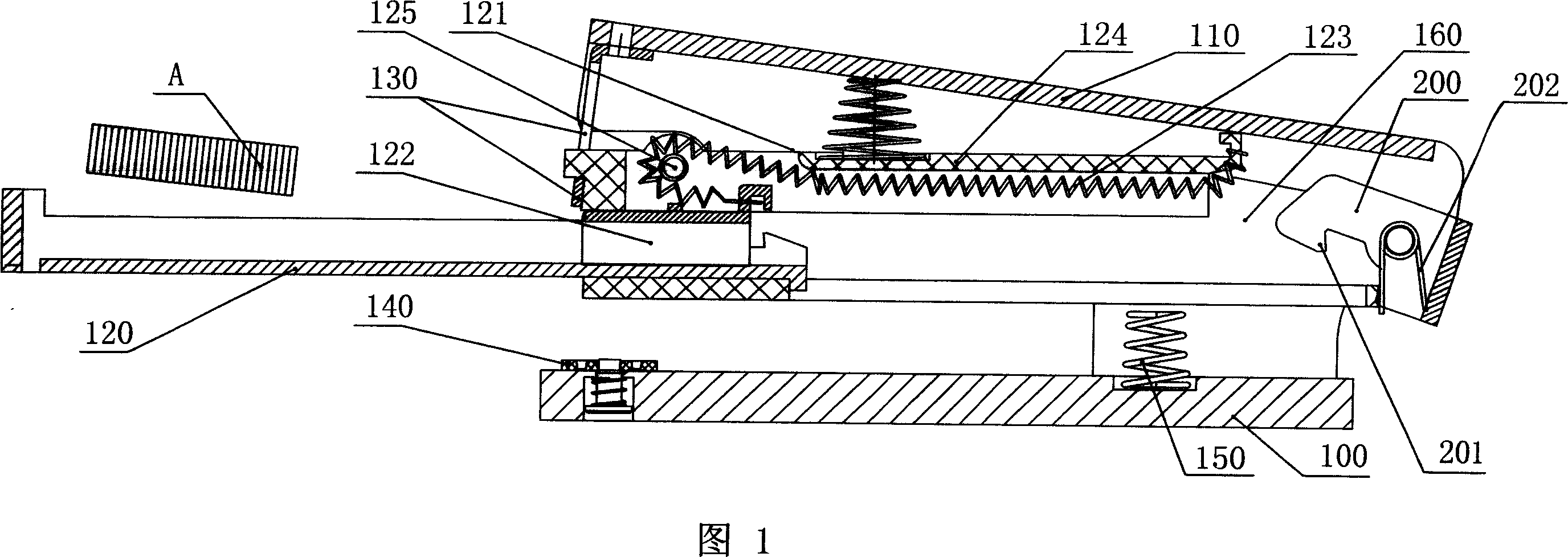

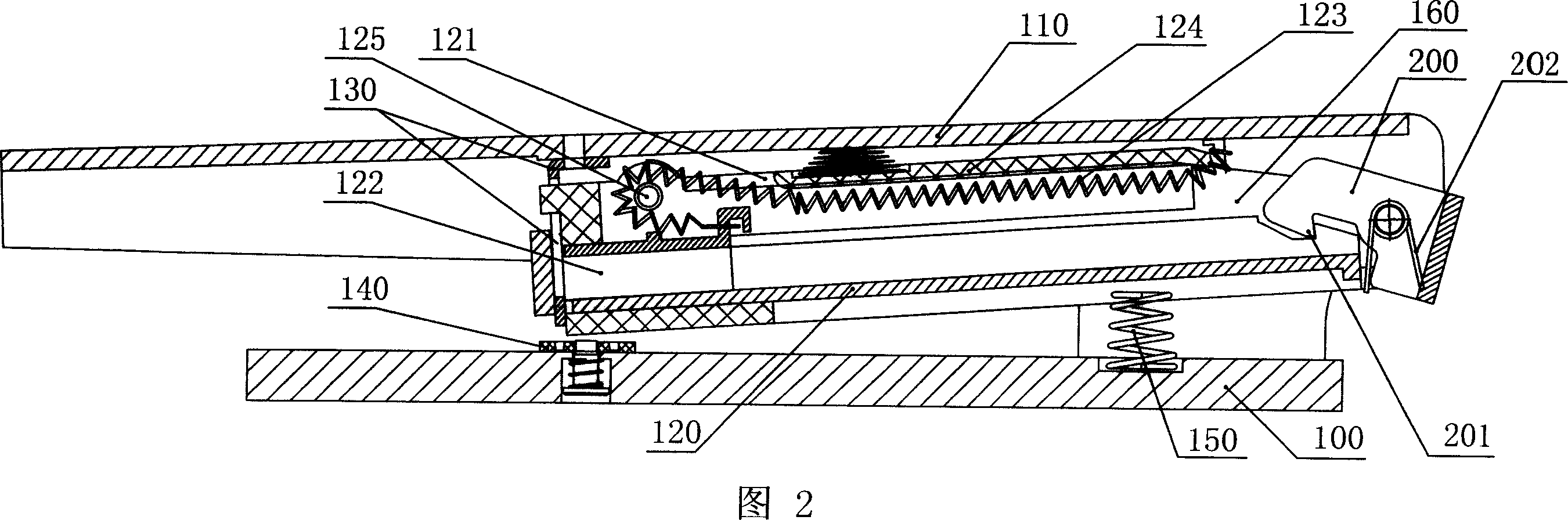

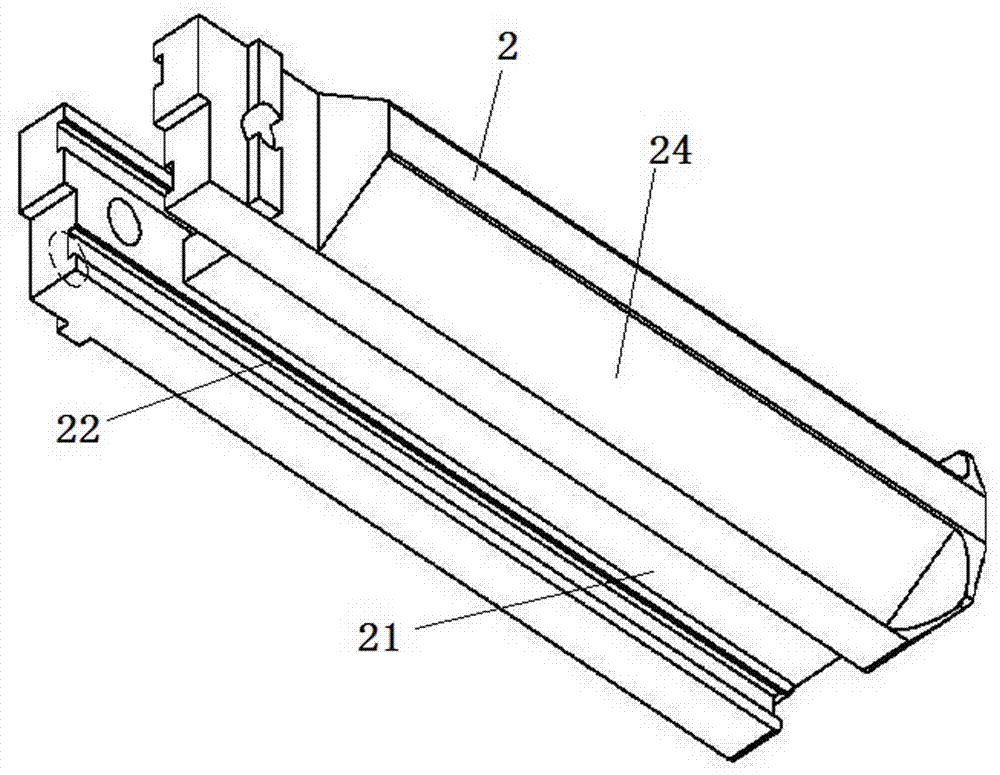

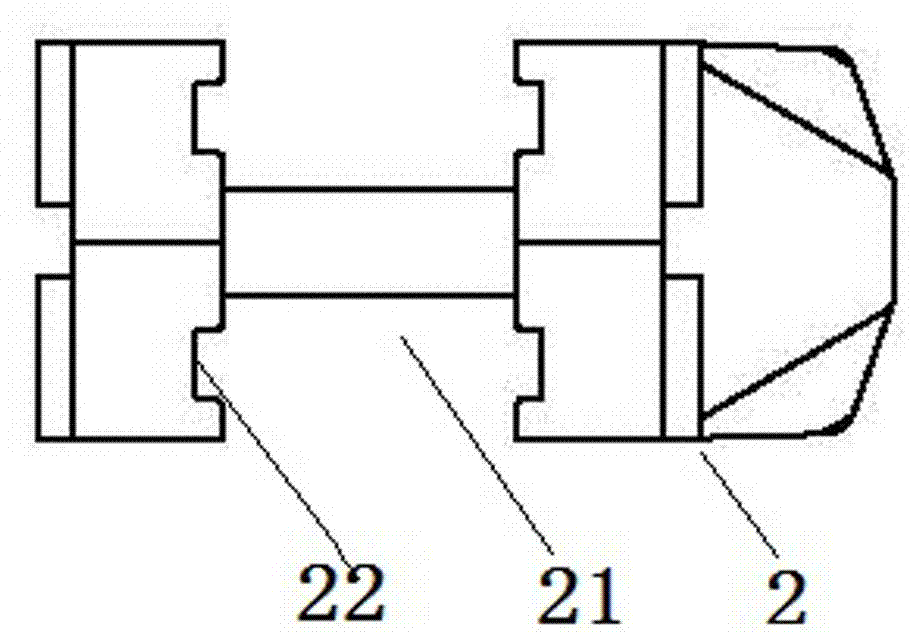

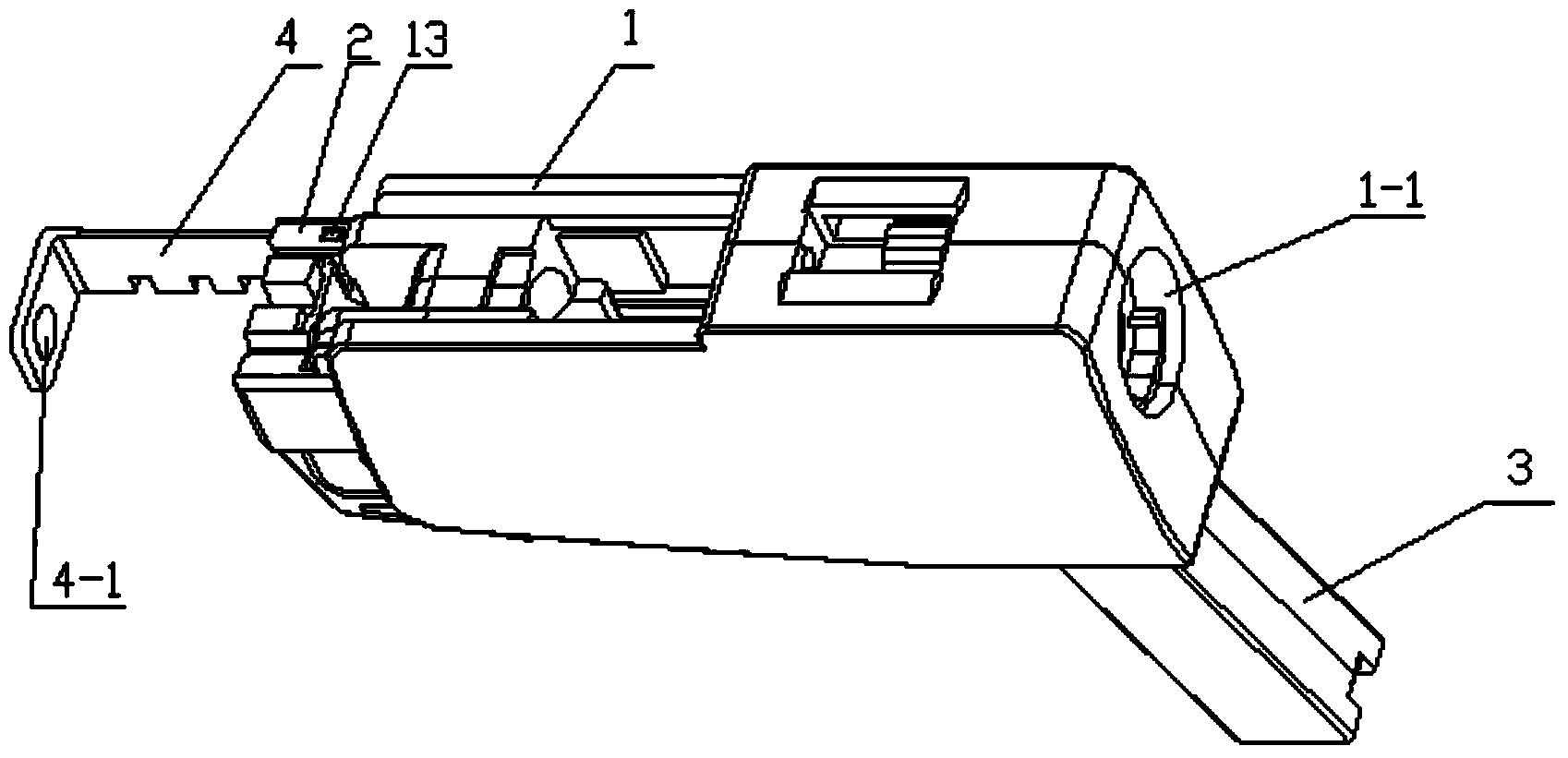

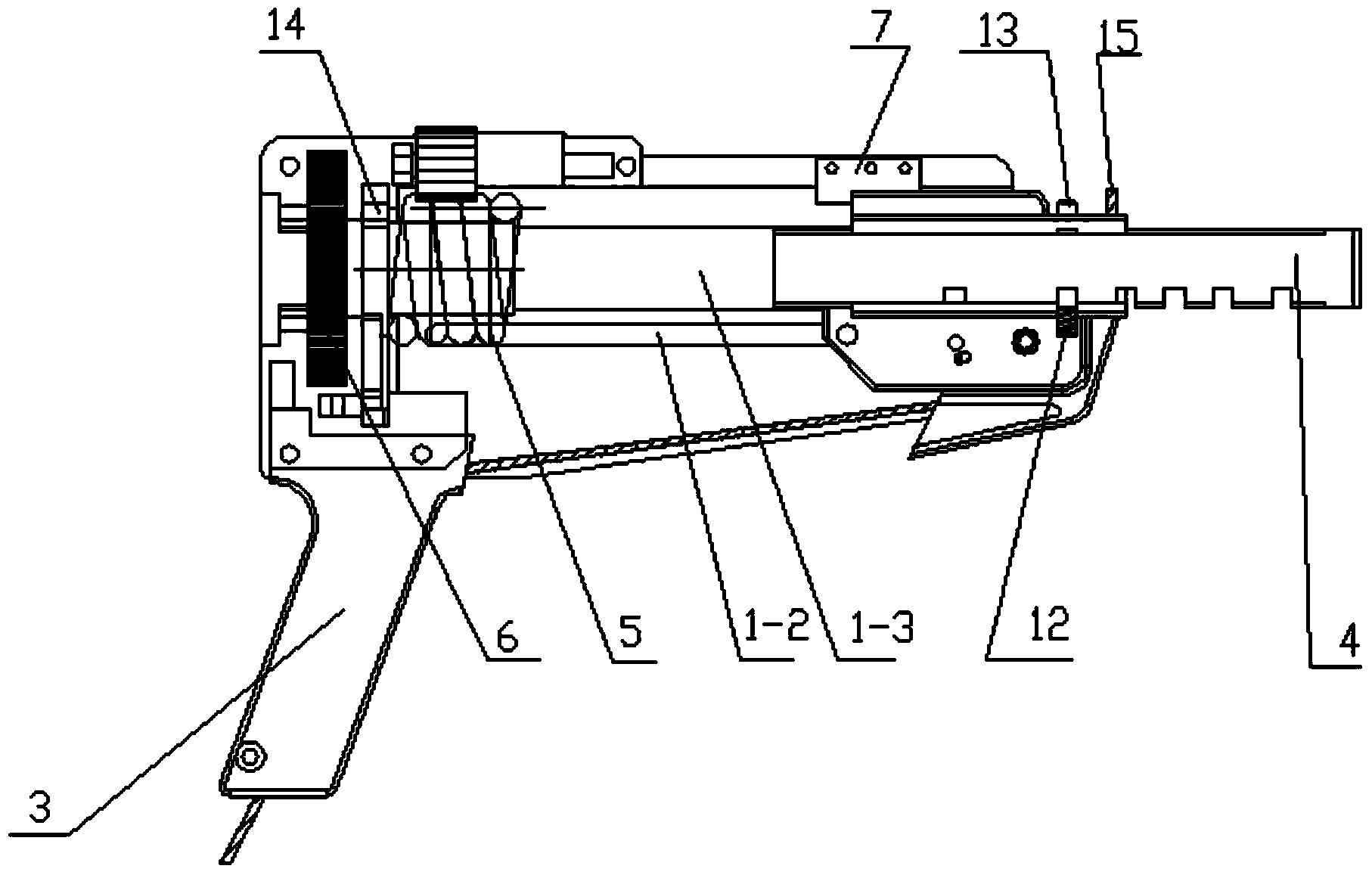

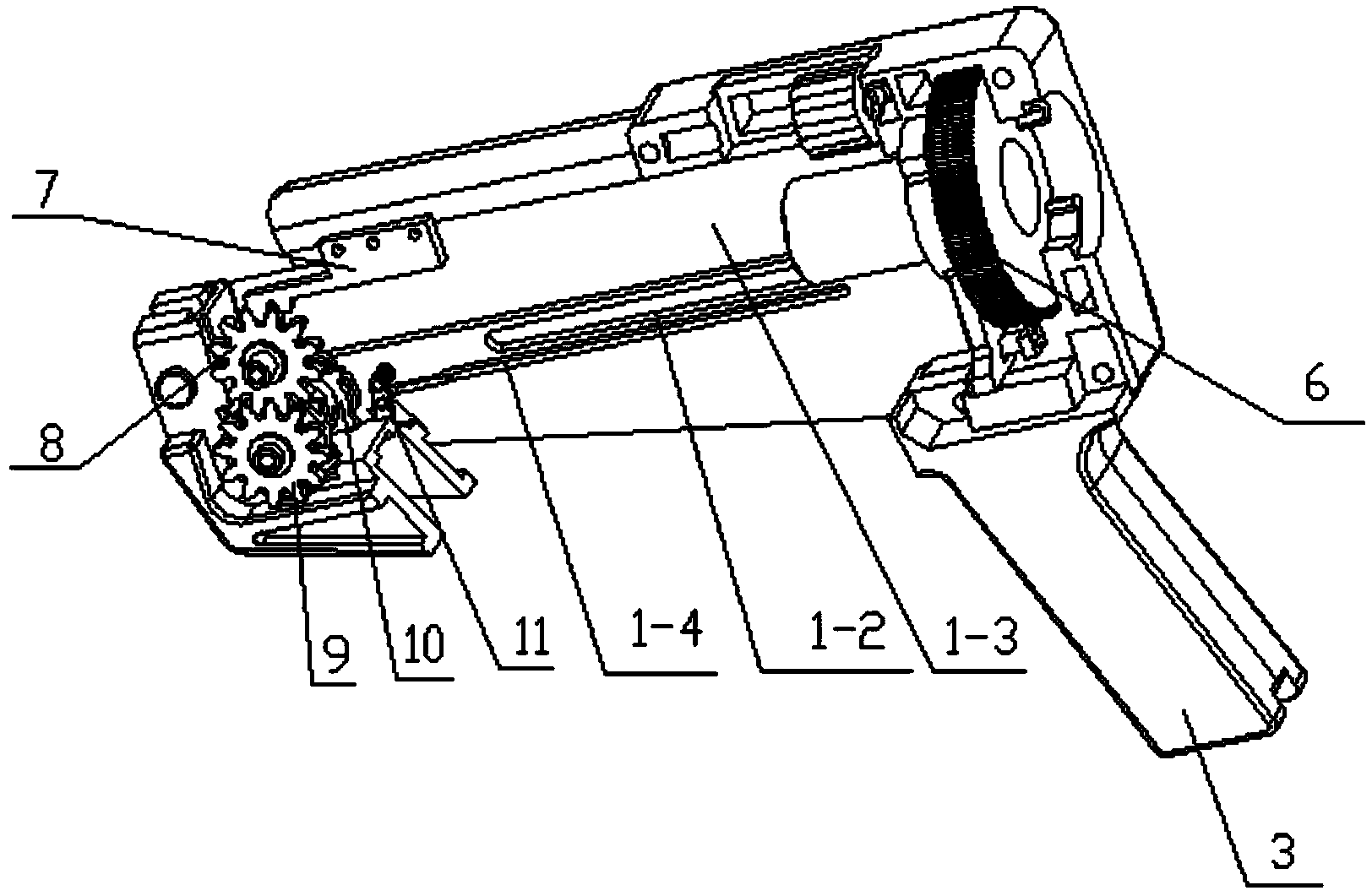

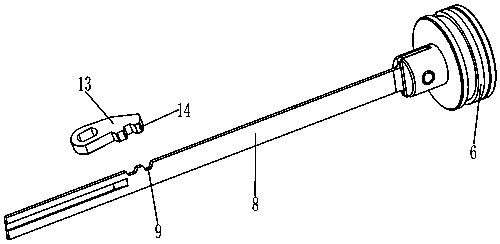

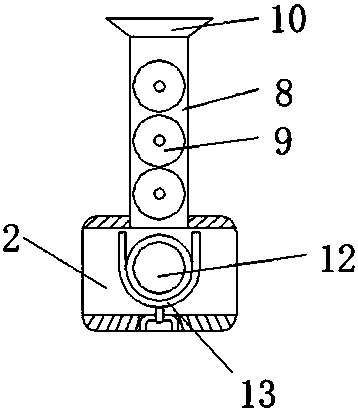

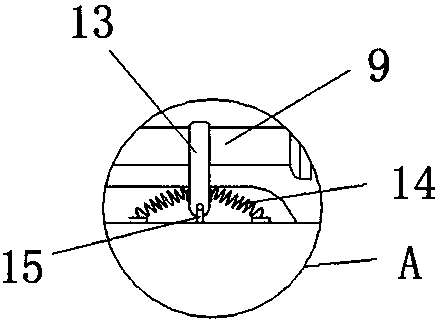

Nail case for mechanical type automatic nailing machine capable of vertically nailing

InactiveCN103770078AFirmly connectedSimple structureStapling toolsNailing toolsGear wheelEngineering

The invention discloses a nail case for a mechanical type automatic nailing machine capable of vertically nailing. A nail conveying mechanism of a conventional nail case for an automatic nailing machine has a complicated structure, is convenient to maintain and cannot automatically and continuously convey nails due to adoption of a four-bar mechanism. According to nail case for the mechanical type automatic nailing machine, a nailing machine stretching hole is formed in the tail part of an enclosure; a nail case main body is in sliding connection with the enclosure; one end of a resetting spring is fixedly connected with the enclosure; a nailing machine connection nut is embedded into a nut mounting groove opening of the enclosure; one side of an outer wall is exposed out of the enclosure; a nail filling case is fixed at the bottom of the enclosure; one arm of a nailing positioning plate is fixedly connected with the nail case main body and the other arm of the nailing positioning plate is provided with a nailing hole; a rack is fixed in the enclosure; a ratchet wheel and a driven gear are connected by a spline; a driving gear is engaged with the rack and the driven gear at the same time; one end of a ratchet wheel limiting piece is hinged with the nail case main body and the middle part of the ratchet wheel limiting piece is connected with the enclosure by a movable cam pair; and a hook needle is arranged at the other end of the ratchet wheel limiting piece. The nail case can be used for continuously and automatically conveying the nails and shooting the nails with different lengths; and the nail case can be in reliable connection with a machine body of the nailing machine.

Owner:ZHEJIANG SCI-TECH UNIV

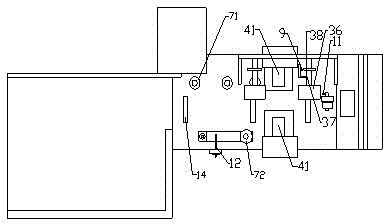

Automatic carton nailing device for paper cartons

InactiveCN109109376AImprove consistencyImprove work efficiencyBox making operationsPaper-makingCardboardCarton

An automatic carton nailing device for paper cartons includes a base. A machine body is arranged on the base, a carton nailing table is arranged on the machine body, the carton nailing table is provided with a carton nailing machine at one end, a slide rail is arranged on the carton nailing table, a sliding motor is arranged on the slide rail, the sliding motor moves on the slide rail, a platformis arranged on the sliding motor, a clamping clamp is arranged on the platform, a clamping cylinder is arranged at the lower end of the clamping clamp, and the clamping cylinder drives the clamping clamp to clamp a paperboard, and drives the paperboard to move through the sliding motor. The paperboard is nailed by the carton nailing machine, and one end of a paper carton is fixed by the clamping clamp, during nailing, the paperboard is driven to move by the sliding motor, automatic movement of the paperboard is realized, the consistency of the product is improved, no manual movement of the paperboard is required, and the working efficiency is improved, moreover, a rotating roller is driven to rotate by a rotating motor, so that the paperboard close to the rotating roller is rotated, and the nailing efficiency is improved.

Owner:WUHU MEIWEI PACKAGING PROD

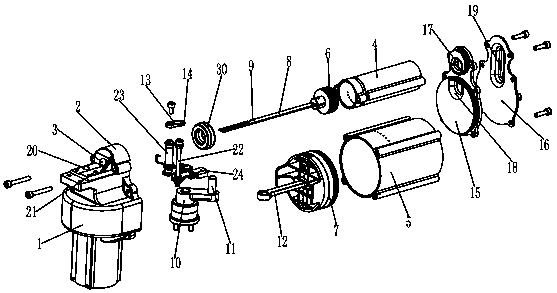

Locking device on firing pin of double-air-cylinder electric nail gun

ActiveCN109571373ARealize the effect of automatic nailingAvoid complicated nailing processStapling toolsNailing toolsAtmospheric pressurePiston

The invention discloses a locking device on a firing pin of a double-air-cylinder electric nail gun. The locking device comprises a gear case, wherein a connector is arranged on the upper right of thegear case; a moving hole which communicates with the internal space of the connector is formed in the left side wall of the connector; a first air cylinder is connected with the connector; a second air cylinder which communicates with the internal space of the gear case is arranged on the right side wall of the gear case and positioned right below the first air cylinder; a first piston matched with the first air cylinder is arranged in the first air cylinder; a second piston matched with the second air cylinder is arranged in the second air cylinder; the firing pin is connected with the firstpiston; the front part of the firing pin penetrates to the outside world through the moving hole; a plurality of clamping grooves are formed in the front part, which penetrates to the outside world,of the firing pin; an eccentric shaft seat is arranged in the gear case; and an eccentric shaft is arranged on one side of the eccentric shaft seat. The locking device on the firing pin of the double-air-cylinder electric nail gun has the beneficial effect that under the circumstance that the internal air pressure of the double-air-cylinder electric nail gun is enough, a positioning sheet can be automatically opened and the automatic nailing effect can be achieved.

Owner:ZHEJIANG RONGPENG AIR TOOLS

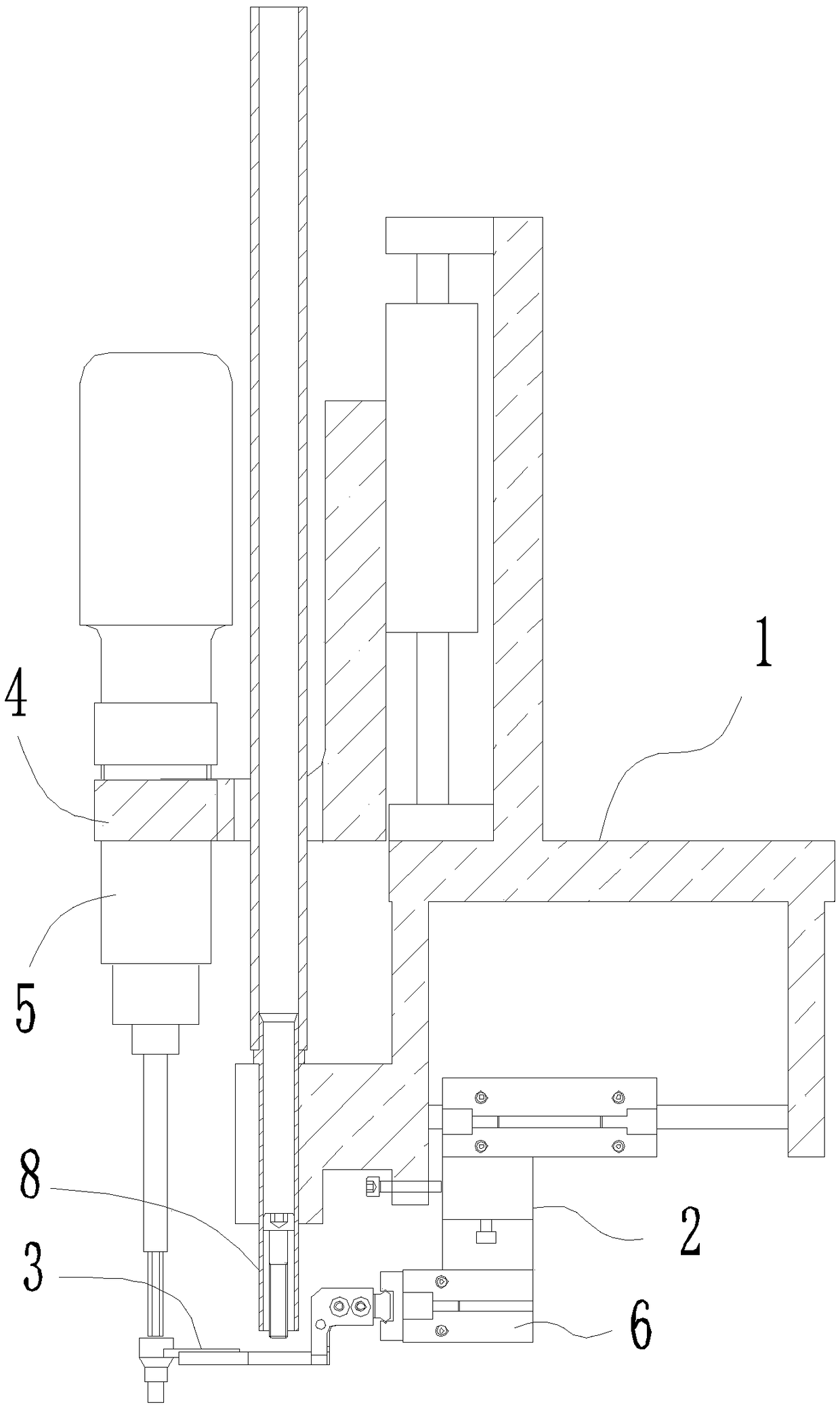

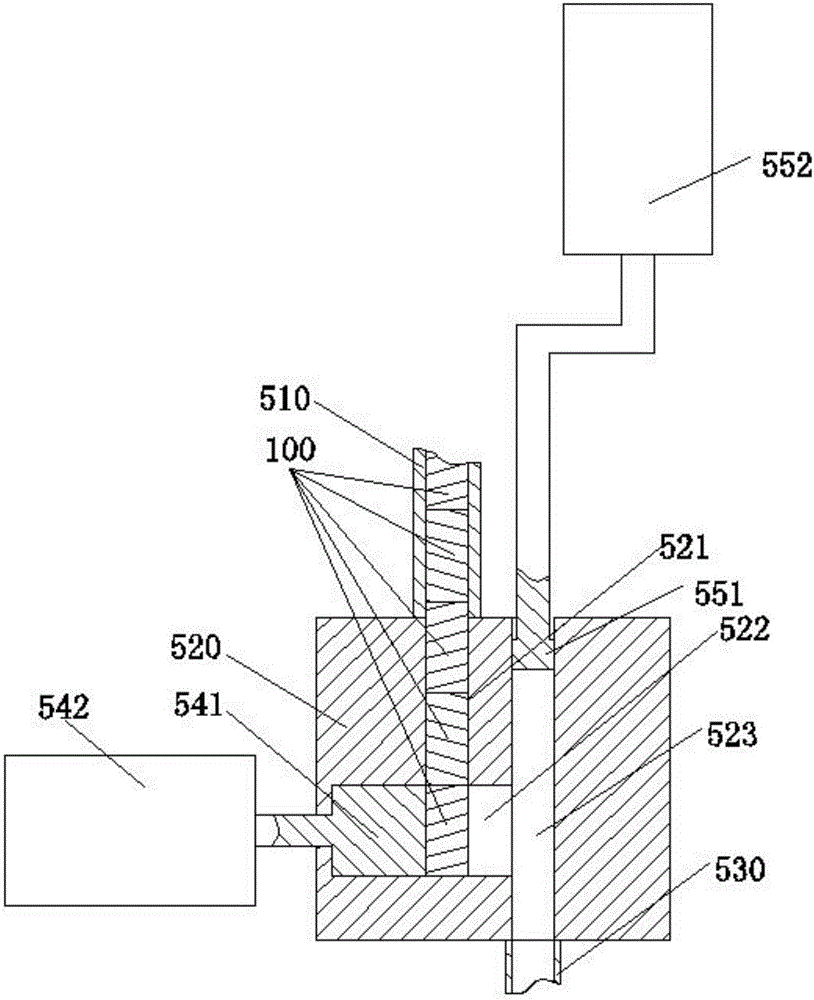

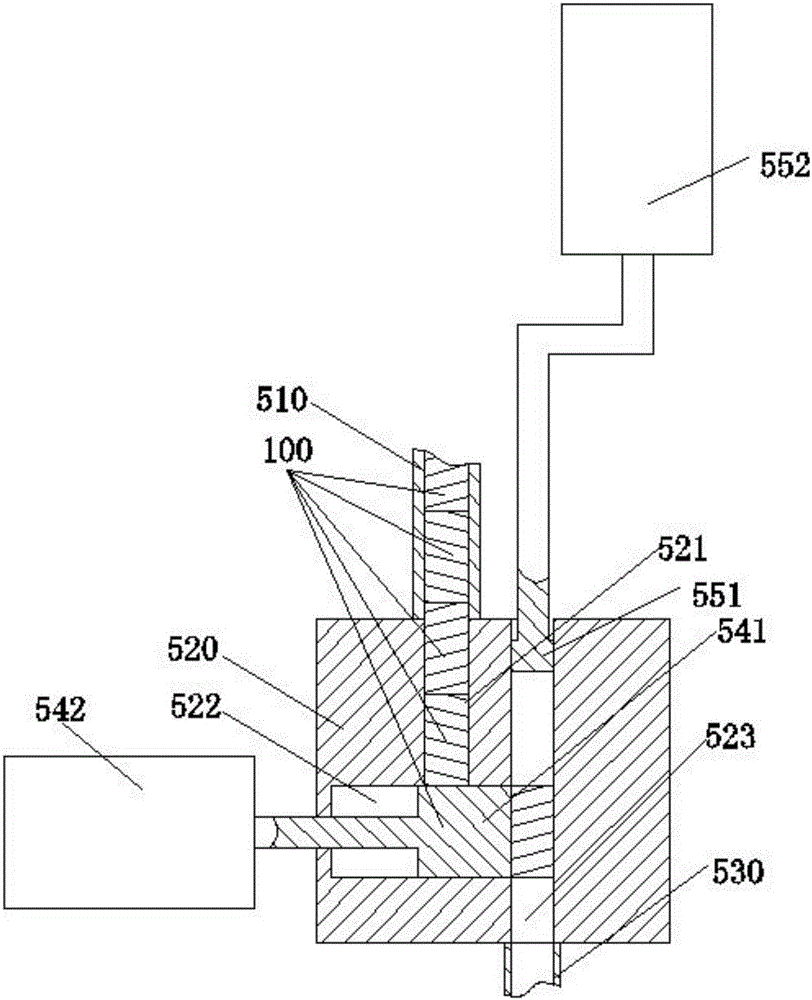

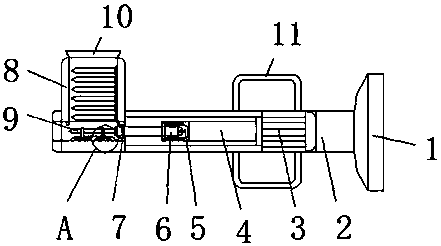

Full-automatic copper nail implantation machine with adjustable angle

The invention discloses an angle-adjustable fully automatic copper nail implanting machine, which includes a vibration plate and a nail embedding module. The nail embedding module is composed of an X-axis rotary positioning module and a YZ-axis automatic melting nail module. The vibration plate is oriented to the YZ axis. The automatic welding nail module supplies nails; the X-axis rotary positioning module includes the X-axis linear guide rail, the rotary seat, the rotary arm, the clamp and the cam seat. The rotary seat is vertically installed on the X-axis linear guide rail through a bottom plate, and the rotary arm passes through the A rotating table is fixed on one side of the rotating seat; the front end of the rotating arm has a disc, the disc surface has an arc groove, the fixture is installed in the center of the disc; the cam seat is fixed on the bottom plate, and the cam seat The top is provided with two cams stuck in arc grooves. The above-mentioned nail planting machine realizes multi-angle nail planting of one machine by adjusting the angle of the product, which not only reduces the equipment cost of the enterprise, but also improves the efficiency of nail planting.

Owner:昆山汇之胜电子科技有限公司

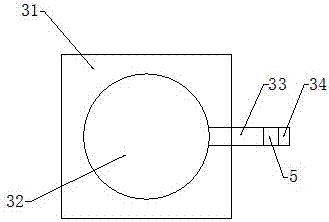

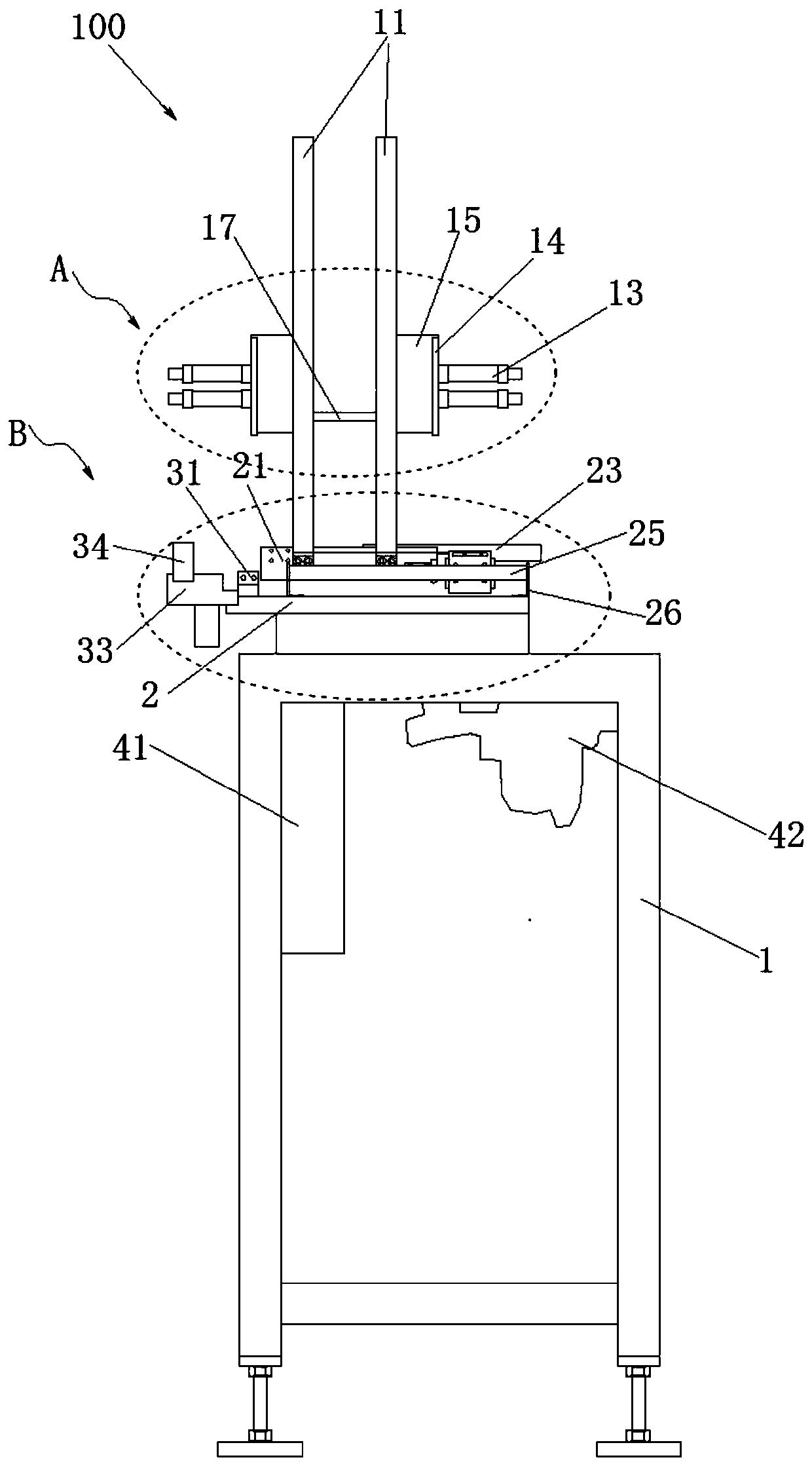

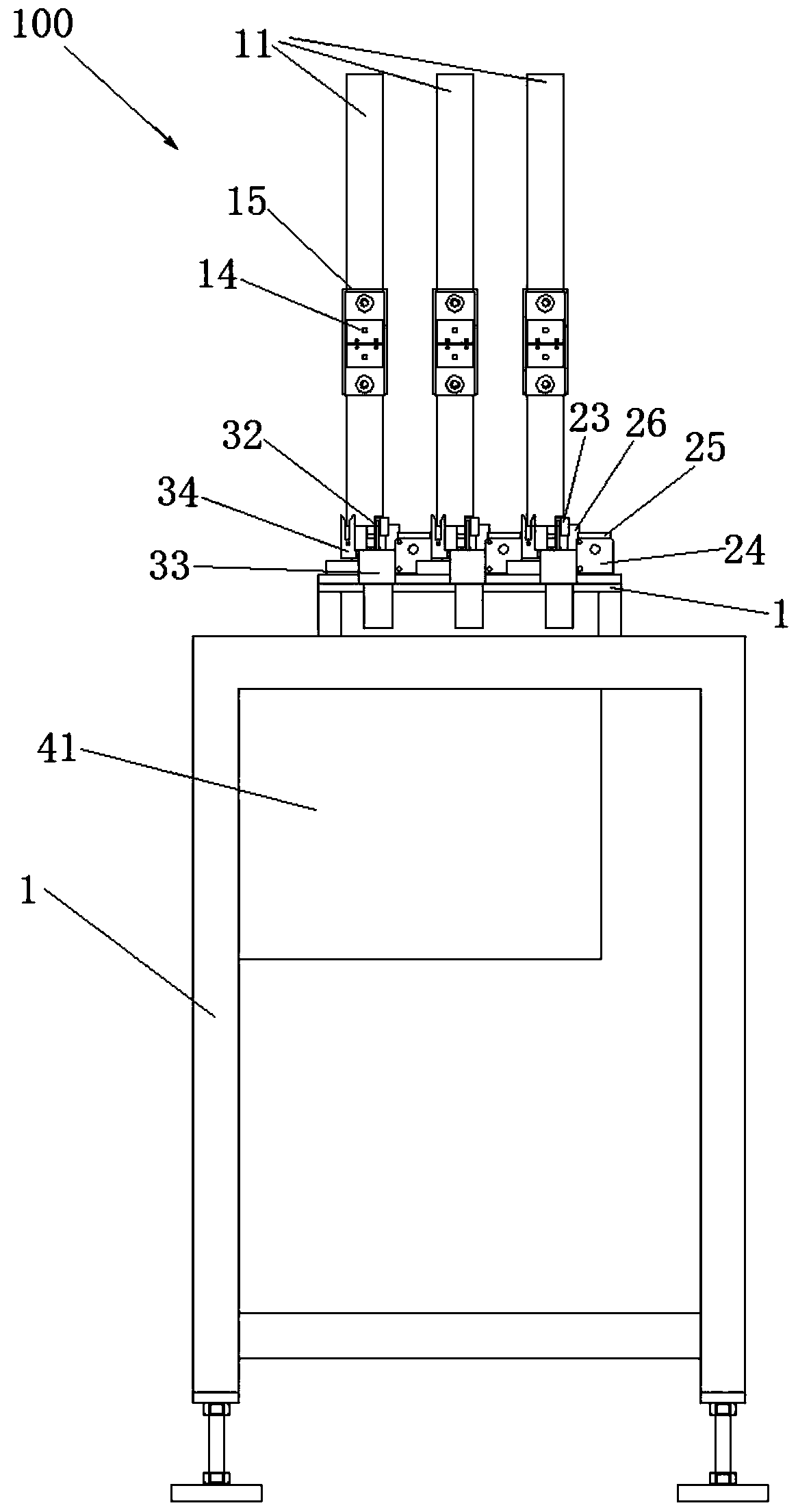

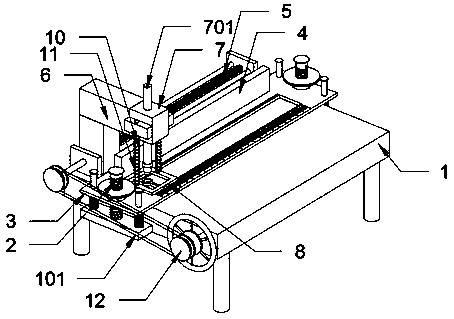

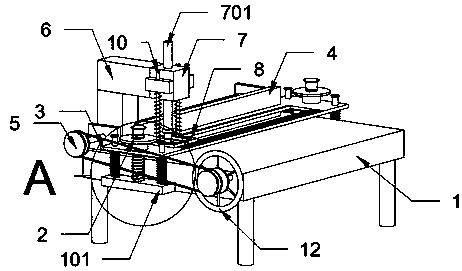

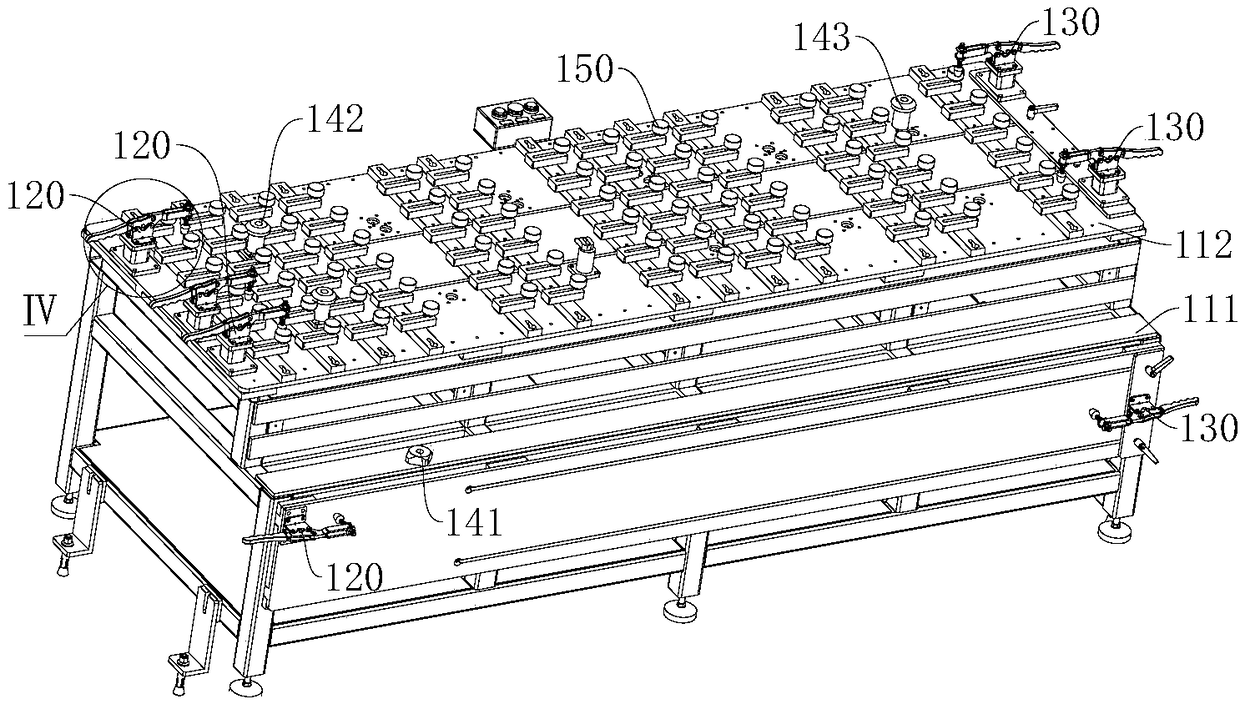

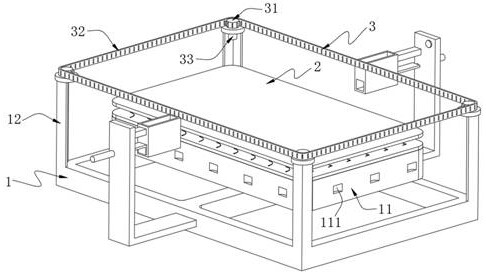

Nailing device

The invention discloses a nailing device. The nailing device comprises a machine table; a worktable is arranged above the machine table; a plurality of nailing machines are arranged below the worktable; a side fixed anchor is arranged on one side of the worktable; and an upper compressing device is arranged above the worktable and corresponds to the nailing machines. Through the nailing device, a retaining strip and a door pocket plate can be nailed and fixed quickly, so that the labour cost can be reduced, the nailing efficiency can be improved, and accidents can be reduced.

Owner:NANTONG YUETONG CNC EQUIP CO LTD

Garment nailing device realizing integral compacting and realizing rapidness and high precision

The invention provides a garment nailing device realizing integral compacting and realizing rapidness and high precision. The garment nailing device comprises a table, springs B and an adjusting wheel, wherein a nailing machine main body is fixedly connected to a main body fixing arm, and a nailing shaft is arranged on the nailing machine main body. For the nailing device realizing integral compacting, the edges of a garment needing nailing are subjected to correcting and clamping through a track board, then the garment needing nailing is subjected to integral compacting through a pressing plate, during nailing, on one hand, the fixing is firmer than the method realizing locating adopting a plurality of pressing blocks, and therefore, the phenomenon of deviation due to the relatively softmaterial of the garment during nailing is prevented; and on the other hand, compared with the one-by-one locating and nailing method, the method is more rapid and has higher accuracy, the integral compacting can realize continuous nailing, the nailing efficiency is higher, time is saved, meanwhile, the phenomenon that during one-by-one locating, due to the fact that the material of the garment issoft, deviation occurs on two adjacent nailing positions during compacting, then inclining occurs between rivets, consequently, the quality and attractiveness of the garment are influenced is avoided.

Owner:赵瑞霞

Full-automatic screwing machine

The invention relates to a full-automatic screwing machine. The full-automatic screwing machine comprises a nailing mechanism, wherein the nailing mechanism comprises a seat, wherein a nail receivingstation and a nailing station are arranged on the seat; a nail pushing slider is movably arranged at the lower end of the seat, and moves on the nail receiving station and the nailing station in a reciprocating manner; an electric screwdriver mounting seat capable of moving vertically is arranged on the seat and positioned above the nailing station; an electric screwdriver is vertically mounted onthe electric screwdriver mounting seat; two nail clamping forceps capable of carrying out opening and closing clamping movement are arranged at the front end of the nail pushing slider; and a clamping opening for placement of to-be-operated screws is formed between the two nail clamping forceps. The screws can be rapidly and stably conveyed and pushed, finally, the screws can be beaten by the electric screwdriver, and the whole machine runs stably and reliably, and is high in nailing efficiency.

Owner:遨博(江苏)机器人有限公司

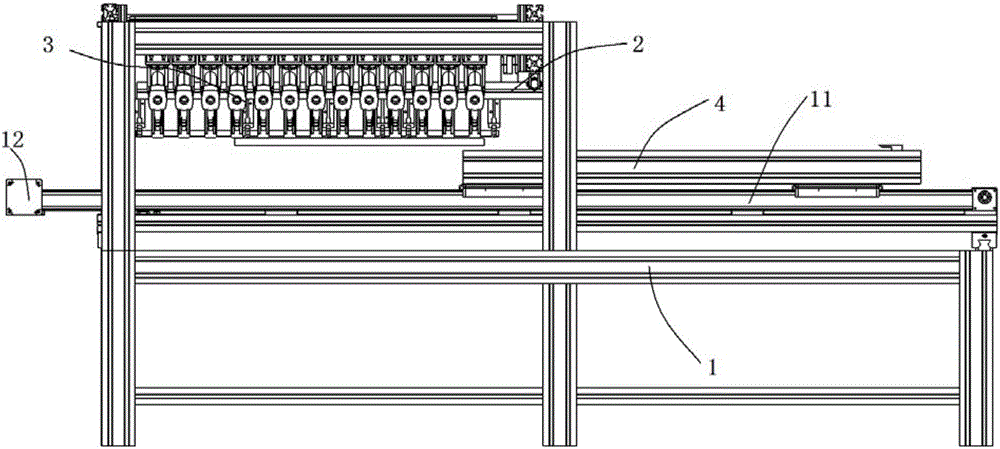

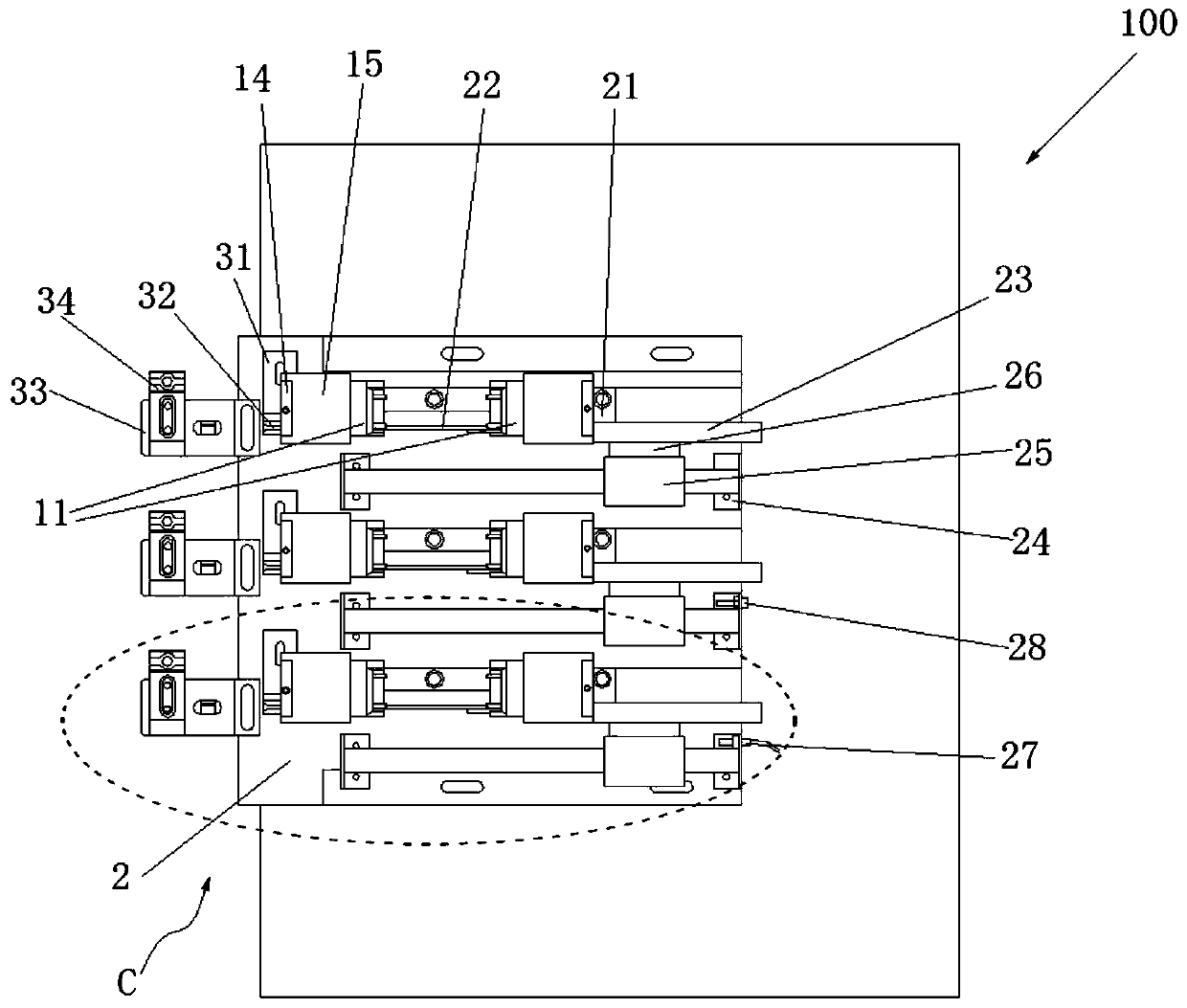

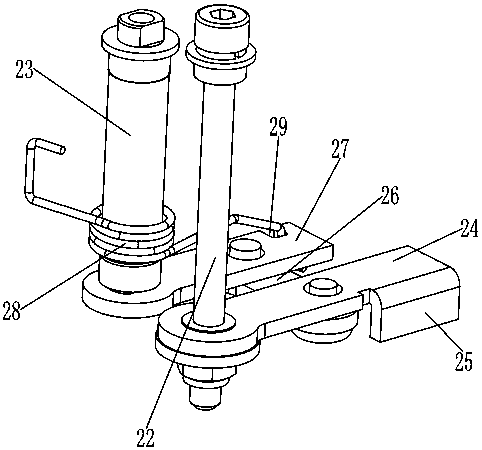

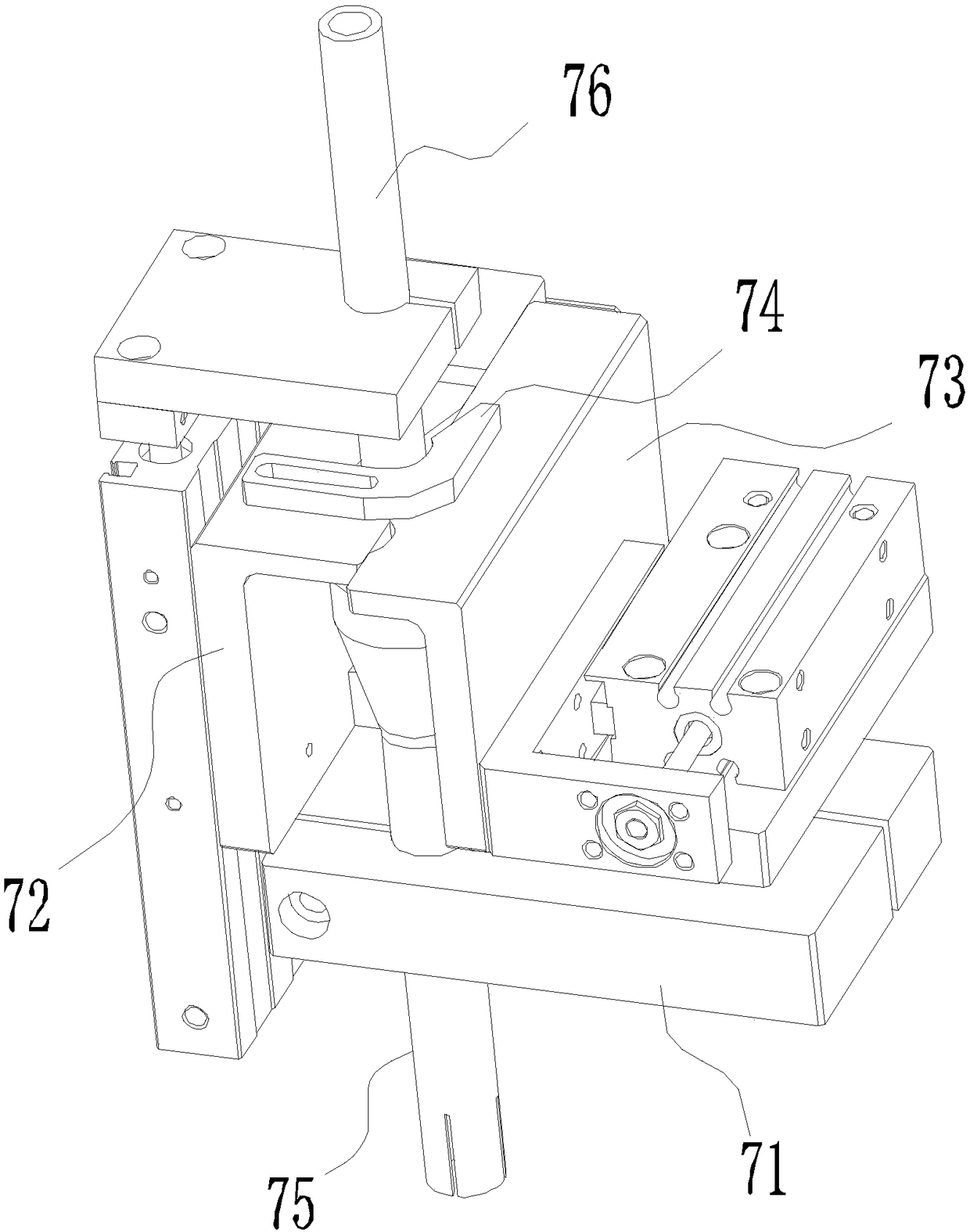

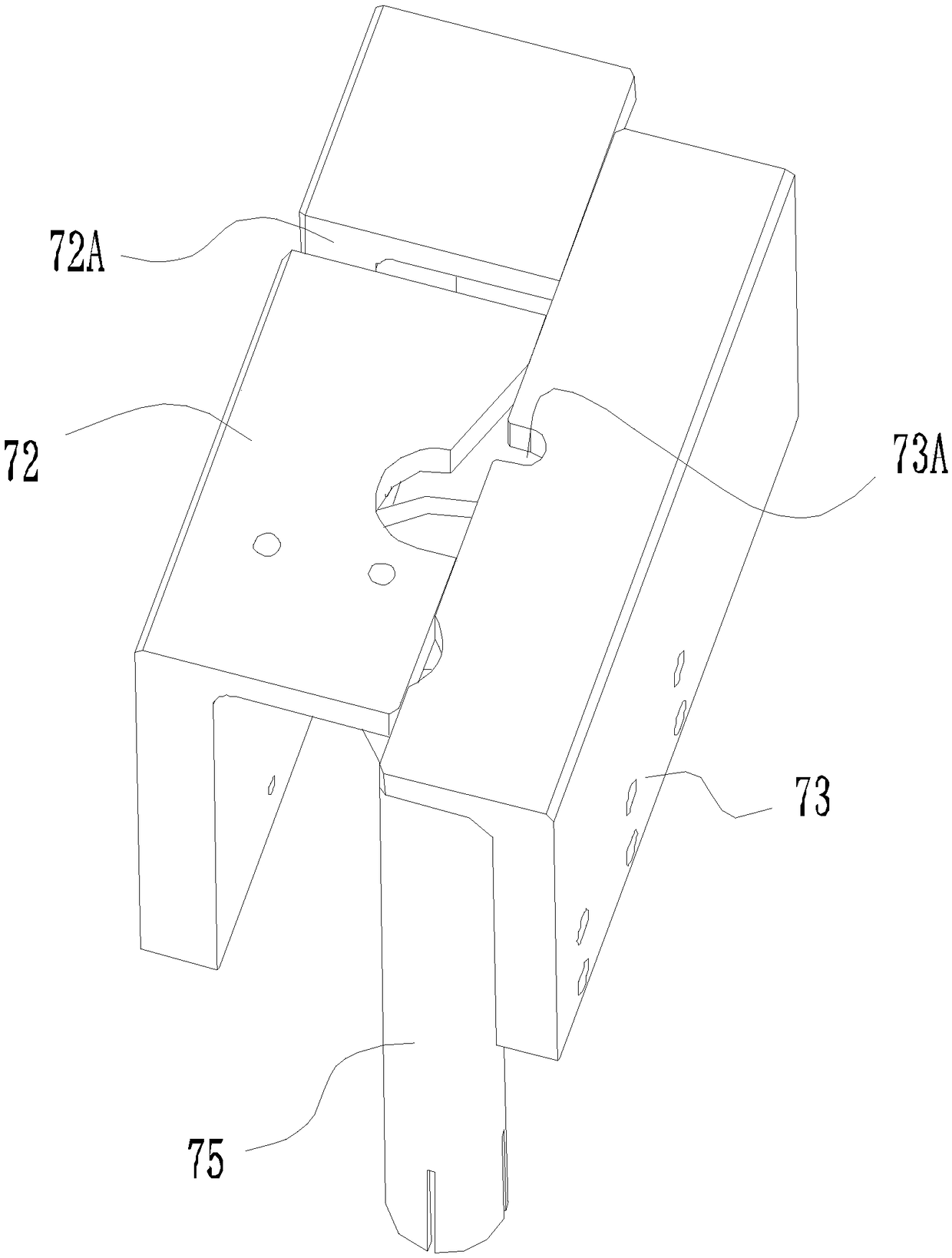

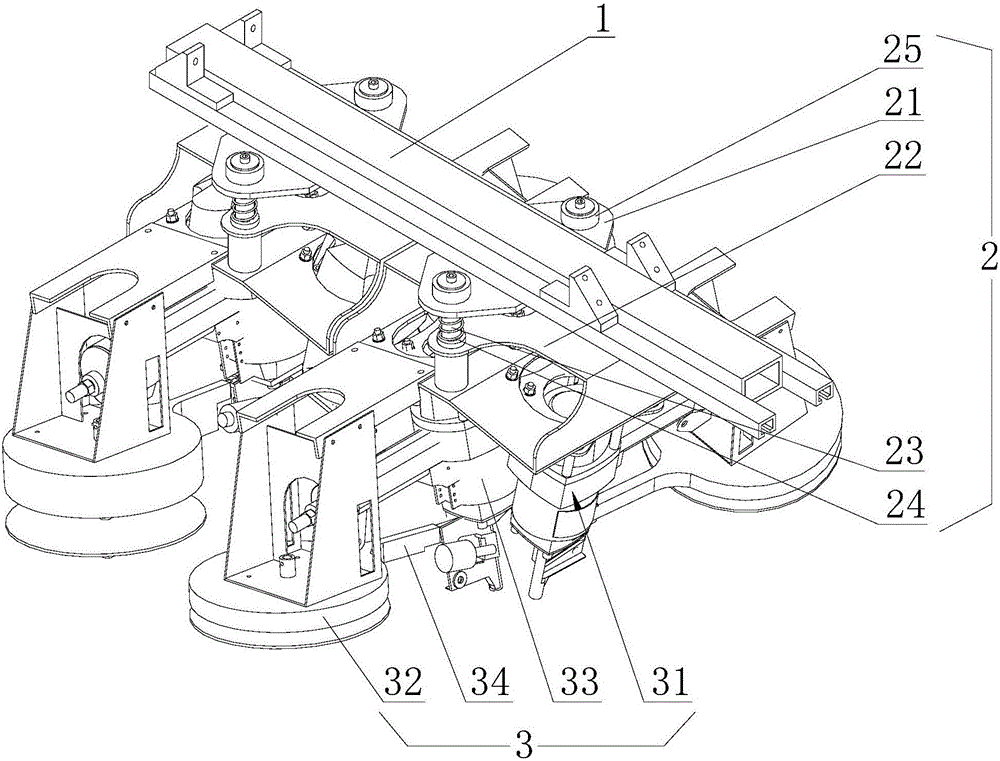

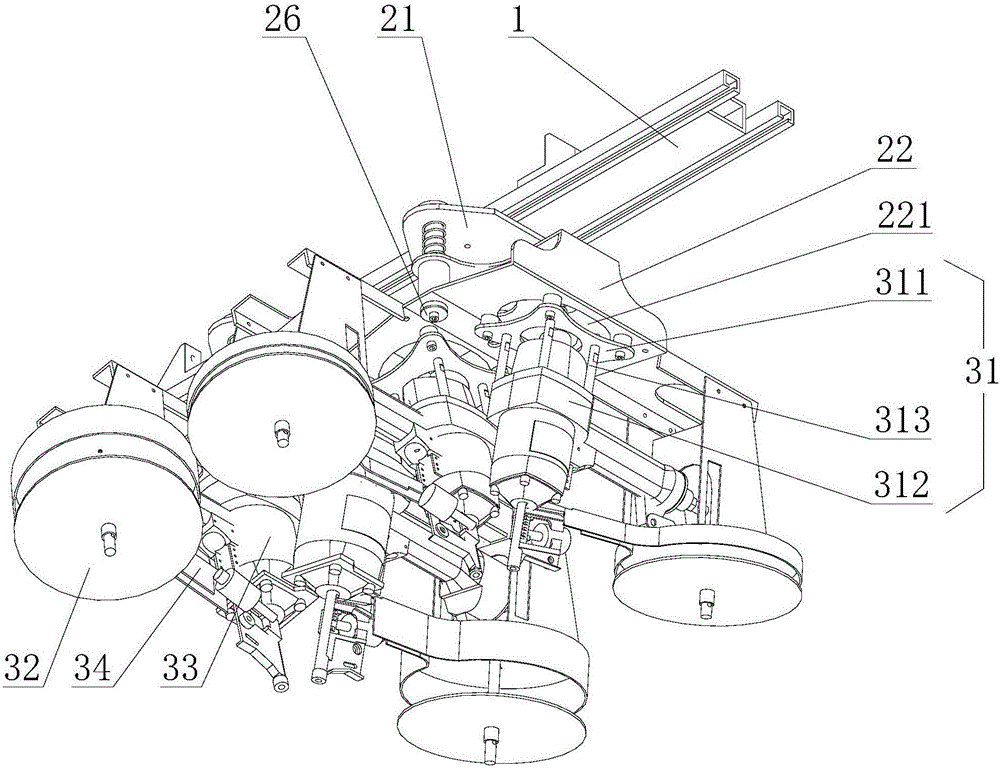

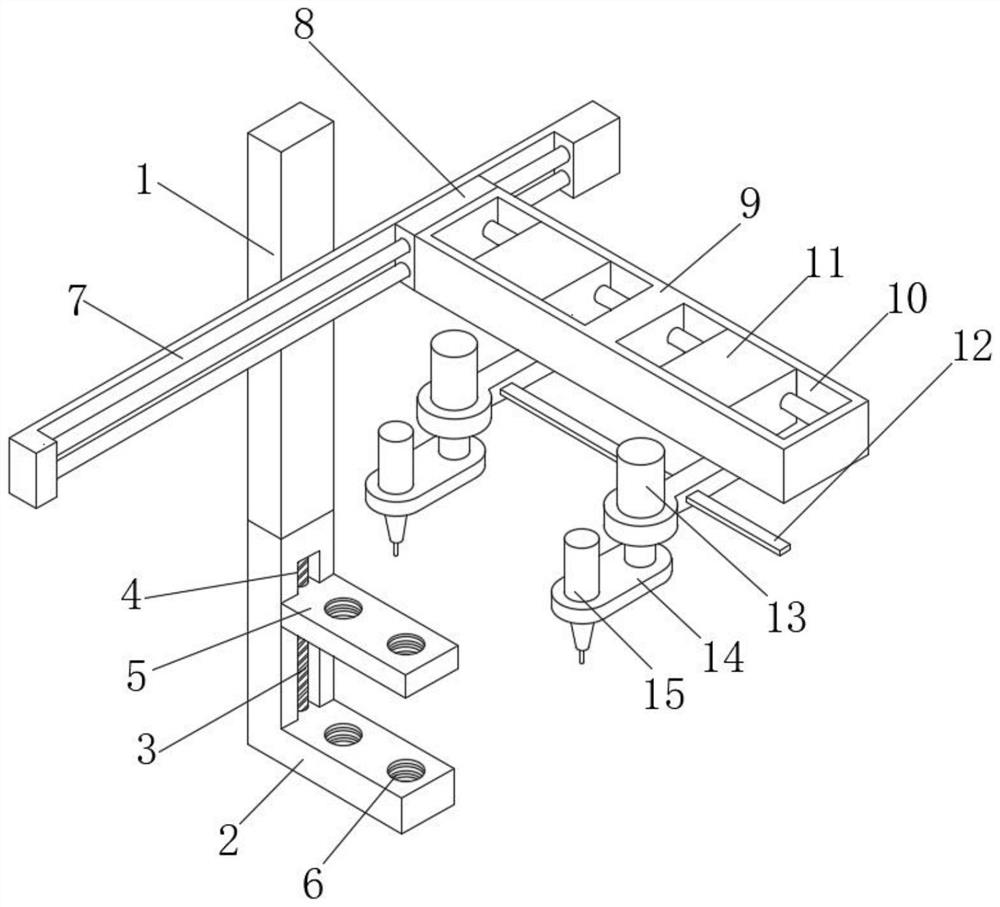

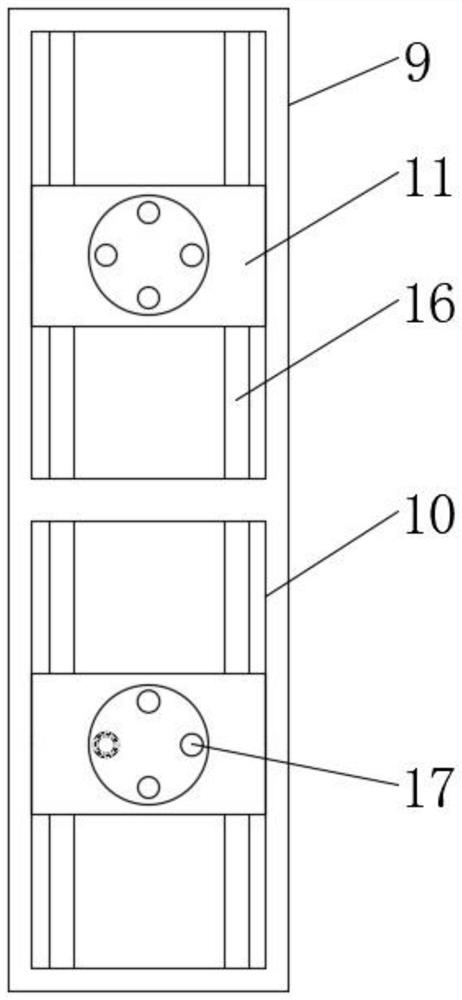

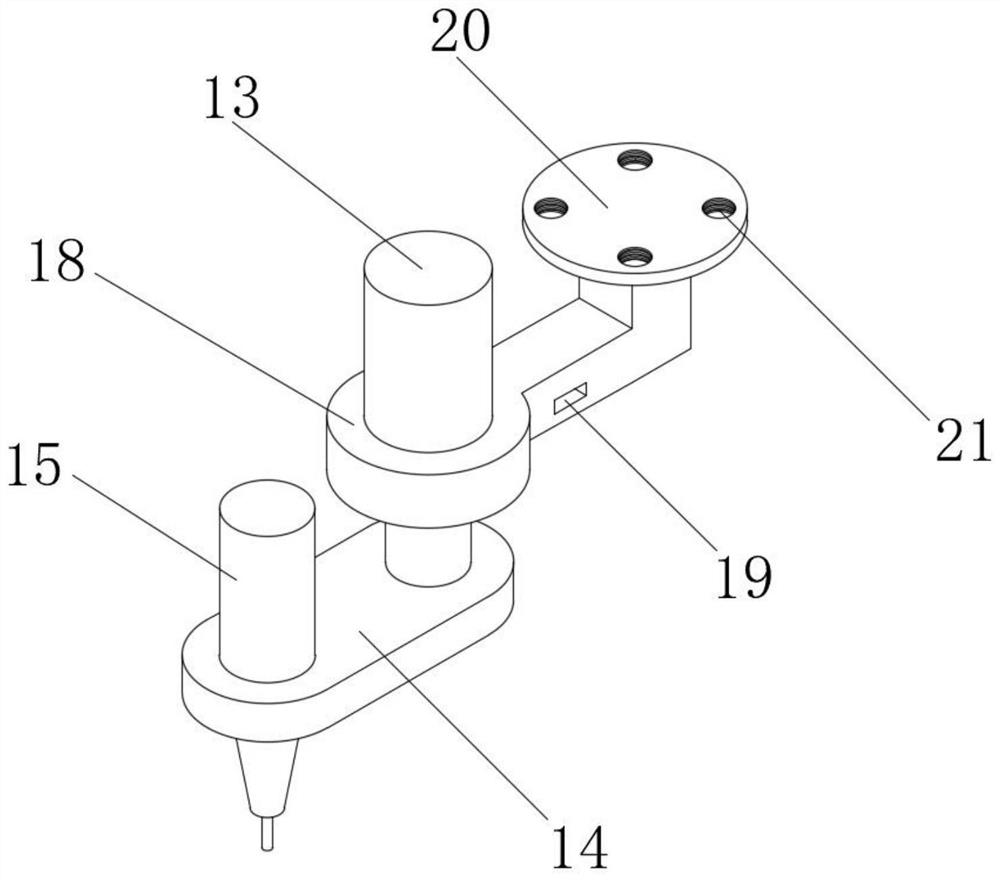

Multiple-gun nailing device

InactiveCN106564106AImprove nailing efficiencyEasy to nailStapling toolsNailing toolsEngineeringNail device

The invention discloses a multiple-gun nailing device. The multiple-gun nailing device comprises a sliding rail, a mounting base mechanism slidably arranged under the sliding rail, and a nail gun mechanism arranged under the mounting base mechanism in a suspended mode. The mounting base mechanism comprises sliding blocks, connecting parts arranged under the sliding blocks and used for arranging the nail gun mechanism in a suspended mode, connecting columns penetrating through the sliding blocks and the connecting parts, elastic parts arranged between the sliding parts and the connecting parts, first fixing parts arranged on the upper portions of the sliding blocks and arranged on the connecting columns in a sleeving mode, and second fixing parts arranged under the connecting parts and arranged on the connecting columns in a sleeving mode. The nail gun mechanism comprises gun bases arranged on the connecting parts in a suspended mode, nail boxes arranged on the connecting parts in a suspended mode, nail guns fixedly arranged in the gun bases, and nail feeding channels formed between the nail guns and the nail boxes. By arranging the two nail guns under the connecting parts at a certain angle, the two nail guns can conduct nailing in the same position of a plank simultaneously, and the nailing efficiency of the nail guns is improved; and by arranging mounting bases which can be detached and replaced on the gun bases, and muzzles of the two nail guns with different lengths can be adjusted to be aligned.

Owner:SUZHOU COV PACKAGING ENG CO LTD

Automatic nail feed nailing machine

ActiveCN110253695AAvoid affecting the slurry effectImprove nailing efficiencyStapling toolsNailing toolsEngineeringElectromagnet

The invention discloses an automatic nail feed nailing machine which comprises a control component, nail delivery components, a chamber component and a plurality of gun heads, wherein the nail delivery components comprise first push rods and nail racks; the nail racks are fixed at the end parts of the first push rods; the nail racks are made from nonferrous materials; the chamber component comprises a fixing rack, a second push rod, a plurality of chambers and a connecting plate; the chambers comprise nail frames, electromagnets mounted on the nail frames and elastic push plates mounted in the nail frames; the nail frames are located above the nail racks and connected with the fixing rack; the gun heads are mounted at the end parts of the nail frames; nail outlet grooves are formed at the end parts of the gun heads; the electromagnets are located above the nail frames; the elastic push plates are fixed on the connecting plate; one end of the second push rod is connected with the fixing rack; the other end of the second push rod is connected with the connecting plate; and the second push rod controls the connecting plate to move to drive the elastic push plates to move in the nail frames. Automatic massive nail feed is achieved in a magnetic adsorption manner; the automatic nail feed and nailing are achieved; the efficiency is improved; and the waste due to breaking of strip nails in a manual nail feed process is avoided.

Owner:HUAWAY IOT TECH

Code nail driving device

ActiveCN112518922AImprove nailing efficiencyHigh degree of automationStapling toolsNailing toolsEngineeringStructural engineering

The invention relates to a code nail driving device. The code nail driving device comprises a mounting base, a first push-pull mechanism, a nail driving assembly, a mounting plate and an adjusting rod; the mounting base is provided with a conveying groove used for conveying a code nail row; a nail driving window is formed in the bottom wall of one end of the conveying groove; the first push-pull mechanism is arranged at the other end of the conveying groove and is used for driving the code nail row in the conveying groove to move to the nail driving window along the conveying groove; the naildriving assembly comprises a nail driving head; the nail driving head is arranged opposite to the nail driving window and is used for driving code nails located at the nail driving window into presetparts; the mounting plate is fixedly mounted on a supporting structure; and the adjusting rod is adjustably arranged on the mounting plate and is connected with the mounting base. According to the code nail driving device, the code nails can be automatically mounted in the preset parts in batches, the working efficiency is relatively high, the automation degree is relatively high, and the labor cost is saved.

Owner:GUANGZHOU HUAXINKE ENTERPRISE

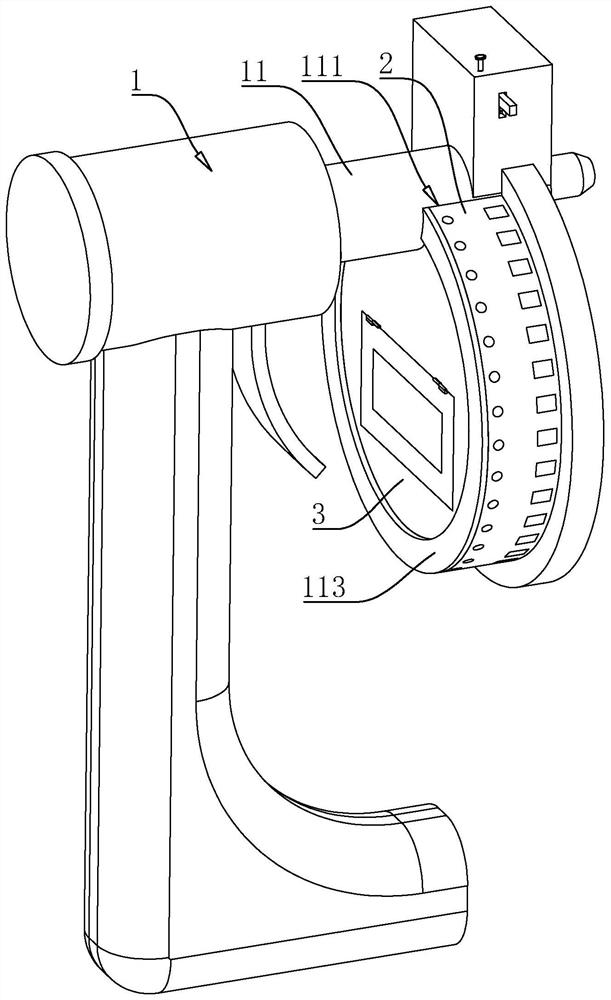

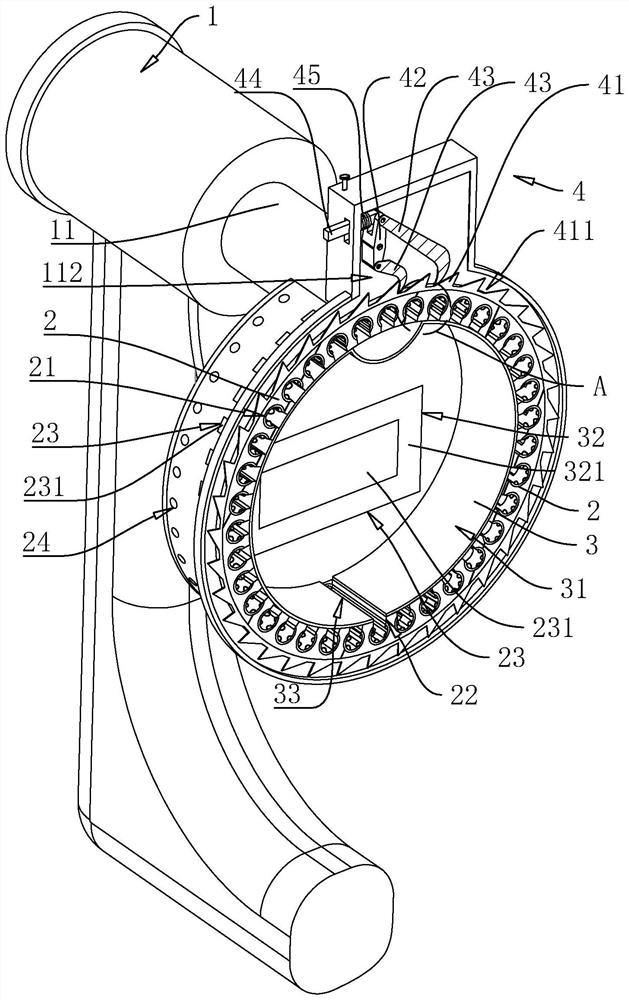

Efficient nailing gun

PendingCN114523451ARealize automatic nailingImprove nailing efficiencyNailing toolsMechanicsNail gun

The invention relates to an efficient nailing gun, and relates to the technical field of nailing. The nail gun comprises a nail gun body, and the nail gun body comprises a nail outlet pipeline arranged at the end and a firing pin used for ejecting nails in the nail outlet pipeline out of the nail outlet pipeline. The device further comprises an annular nail box, a communicating hole allowing the annular nail box to penetrate and be inserted is formed in the side wall of the nail outlet pipeline, placing holes allowing single nails to be placed are formed in the end wall of the annular nail box in a penetrating mode, the placing holes are evenly formed in the circumferential direction of the annular nail box, and the placing holes communicate with the nail outlet pipeline. Baffles are detachably connected to the positions, located at the two ends of the annular nail box, of the side wall of the nail outlet pipeline correspondingly, and the annular baffles are attached to the end wall of the nail box. The driving assembly is used for driving the annular nail box to rotate in the circumferential direction with the center point of the annular nail box as the center; the nailing device has the effects of achieving rapid supply of nails and improving the nailing efficiency.

Owner:JIANGSU HEHUI POWER TOOLS CO LTD

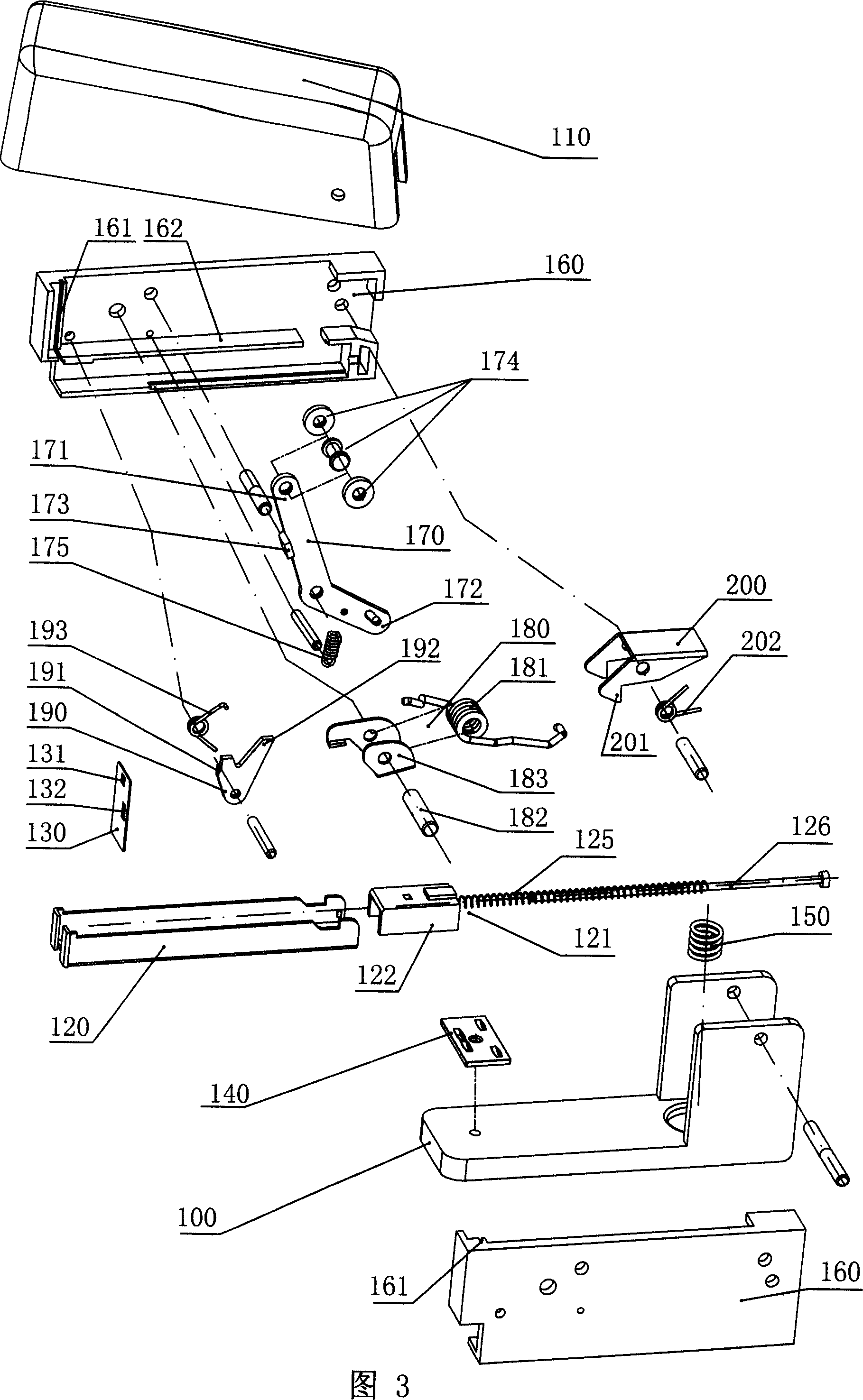

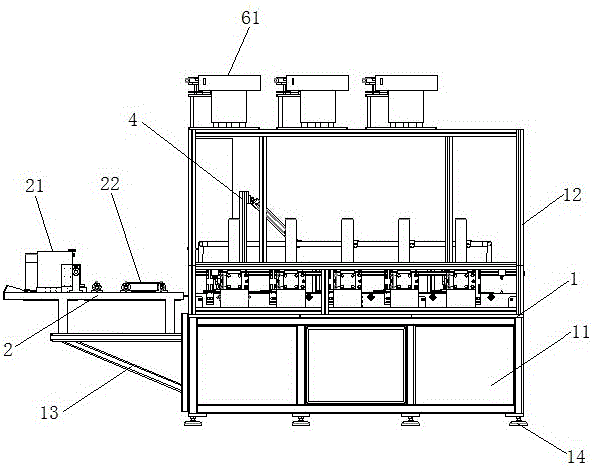

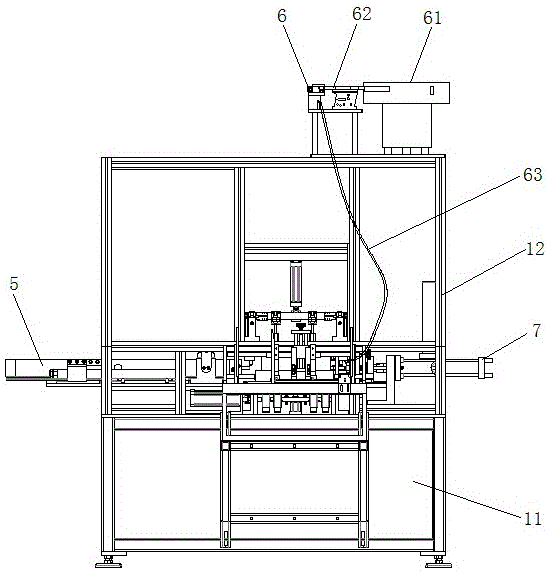

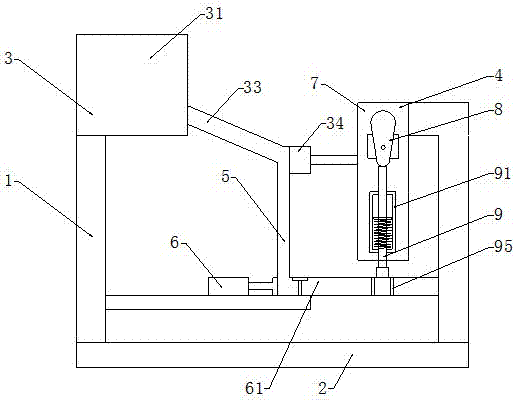

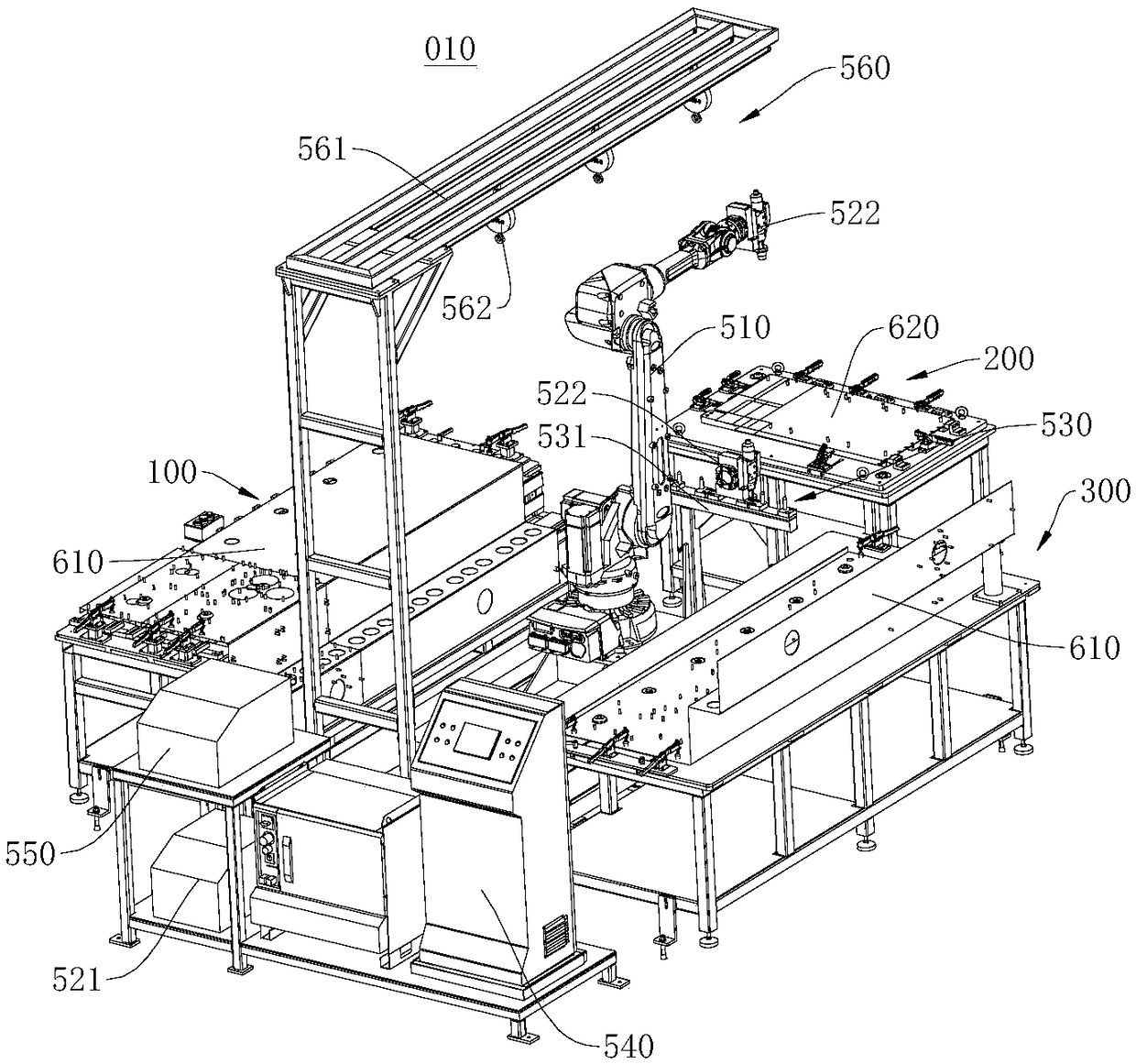

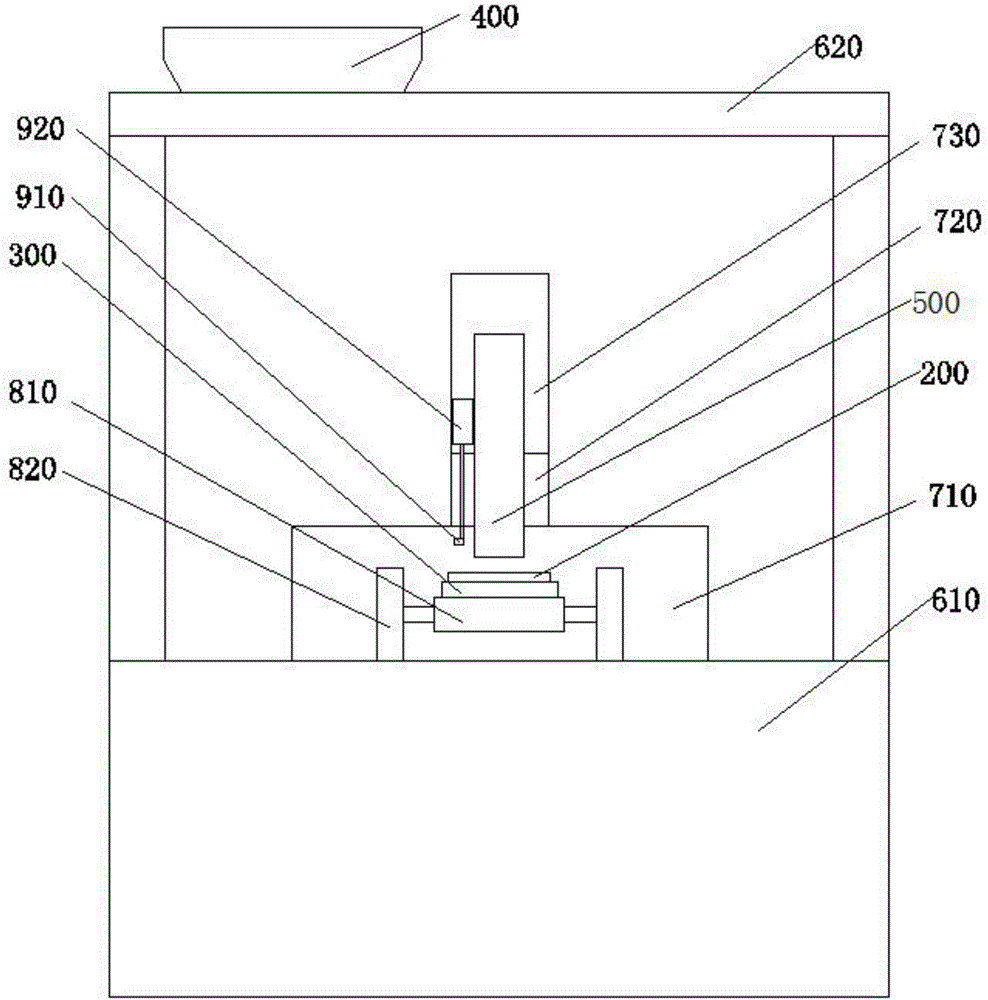

Automatic nailing device

ActiveCN109048132AReduce labor intensityImprove nailing efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringOperating table

The invention relates to the technical field of mechanical processing, and aims to provide an automatic nailing device. The automatic nailing device provided by the invention comprises an operating table, a nail feeding machine, a nailing robot, a first clamping mechanism, and a second clamping mechanism. The first clamping mechanism is used for fixing a first workpiece to be nailed, and the second clamping mechanism is used for fixing a second workpiece to be nailed. The nailing robot is fixedly connected with a nailing mechanism. The nail feeding machine is used for feeding screws to the nailing mechanism. The nailing mechanism moves under the driving of the nailing robot, and can perform nailing operations at different positions on the first workpiece and the second workpiece. In addition, the nail feeding machine, the nailing robot, and the nailing mechanism are all connected with the operating table, and under the control of the operating table, the nailing operations are automatically performed, the nailing efficiency is high, the labor intensity of workers is low, and the nailing quality can be guaranteed.

Owner:广州创研智能科技有限公司

Automatic screw gun

ActiveCN108747325AImprove nailing efficiencyImplement automatic installationMetal working apparatusDrive motorEngineering

The invention belongs to the technical field screw installing and particularly relates to an automatic screw gun. The automatic screw gun comprises a gun body shell composed of a gun handle, a gun body and a gun holder, a driving motor arranged in the gun body and a screwdriver rod arranged in the gun holder; the driving motor is used for driving the screwdriver rod to rotate; the front end of thegun holder is provided with a slider which is further provided with a gasket supplying mechanism; and the gasket supplying mechanism can be used for conveying one gasket into a through hole before ascrew penetrates into the through hole. According to the automatic screw gun, the gasket supplying mechanism is used for automatically conveying one gasket to the front end of the screw each time before the screw is jet out, and therefore automatic installing of the gasket is achieved, the nailing efficiency of the automatic screw gun is greatly improved, and meanwhile potential safety hazards existing during manual releasing of the gaskets are avoided.

Owner:李翠平

Automatic nailing machine

The invention discloses an automatic nailing machine, comprising a positioning jig, a vibrating disc and a nailing mechanism; the nailing mechanism comprises a feed pipe, a heat conductor, a discharge pipe, a pull component and a nailing component; the heat conductor is provided with a preheating passage, a pull passage and a nailing passage, the preheating passage is vertically extended with an upper port communicated with a lower port of the feed pipe, the pull component is horizontally extended, the sidewall of the pull component is communicated with the lower port of the preheating passage, the nailing passage is vertically extended, the sidewall of the nailing passage is communicated with one horizontal port of the pull passage, a pull head of the pull component is horizontally and slidably connected into the pull passage, and a nailing head of the nailing component is vertically and slidably connected into the nailing passage. One copper nail is discharged at a time, basic conditions are provided for automatic nailing, and the copper nail is heated during conveying such that nailing efficiency is improved.

Owner:FISCHER SCI & TECH SUZHOU CO LTD

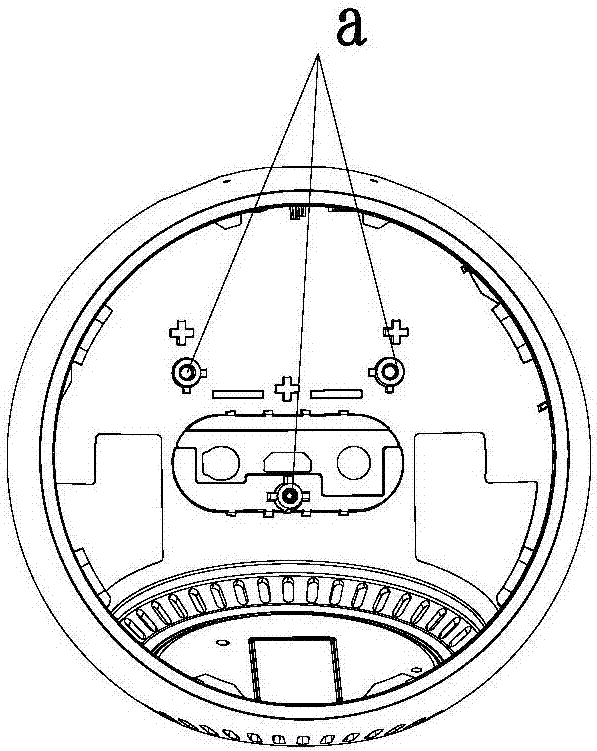

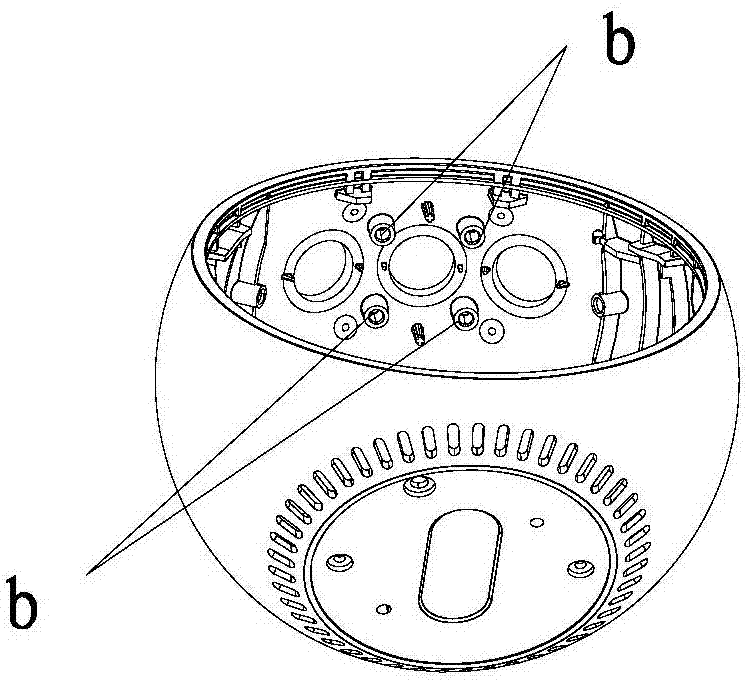

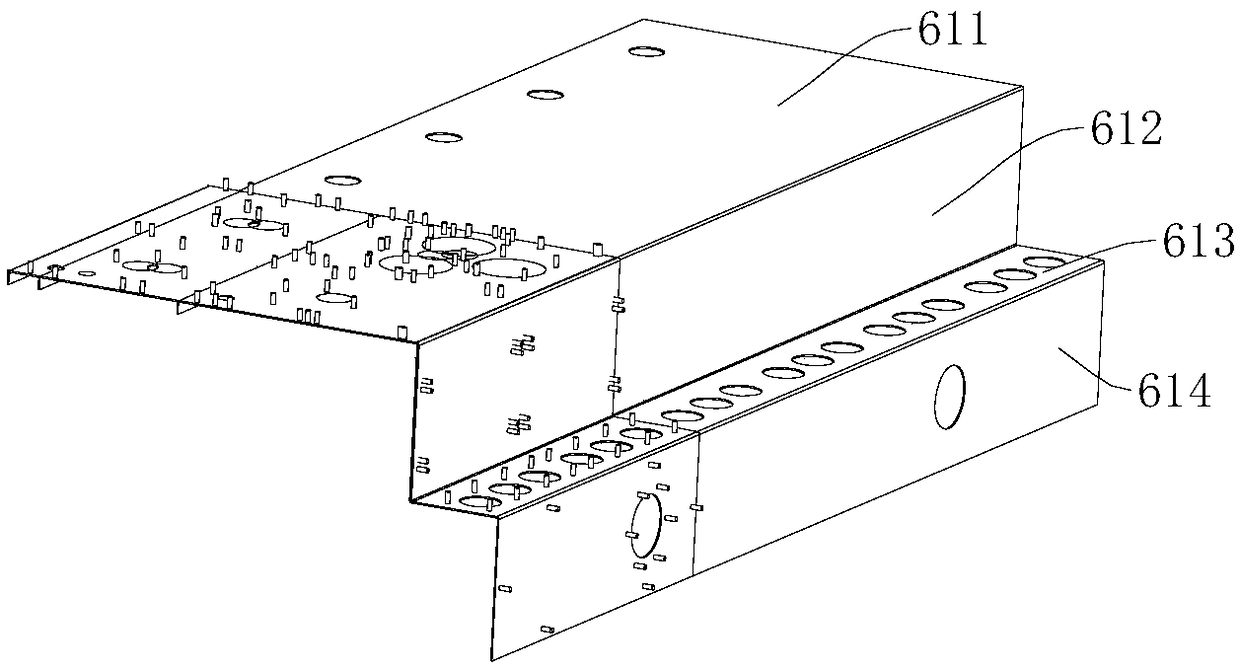

Intermittent reinforcing and frame connecting equipment for mattress springs

PendingCN114766862AInfluence stuffedAffect elasticitySpring mattressesClassical mechanicsStructural engineering

The invention relates to mattress spring intermittent reinforcing and frame connecting equipment which comprises a rack, a carrying mechanism, an operating mechanism, a flanging mechanism and a material supplementing mechanism. The working assembly comprises a feeding unit used for intermittently feeding an elastic piece a into an elastic piece b at the edge of a bed frame and a connecting unit used for intermittently connecting the elastic piece a pushed into the edge of the bed frame with the elastic piece b, and the flanging mechanism comprises a clamping assembly used for clamping cotton and an edge pulling assembly arranged in the clamping assembly. The material supplementing mechanisms are symmetrically arranged on the side face of the machine frame and used for feeding materials to the feeding unit. The device solves the problems that in the prior art, cotton is prone to wrinkling, so that plugging of a new spring and work of a code clamping gun are affected, plugging of the new spring cannot be linked with the code clamping gun, the operation requirement is high, and the nailing efficiency is low.

Owner:安徽情暖家具有限公司

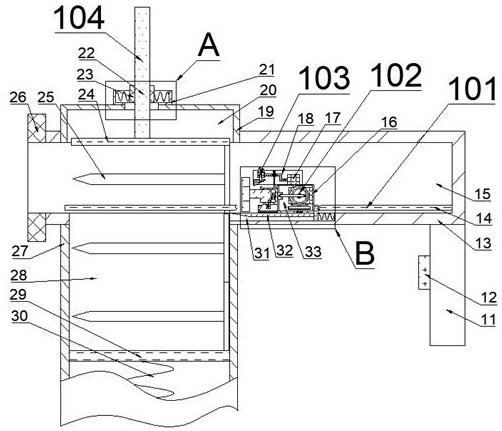

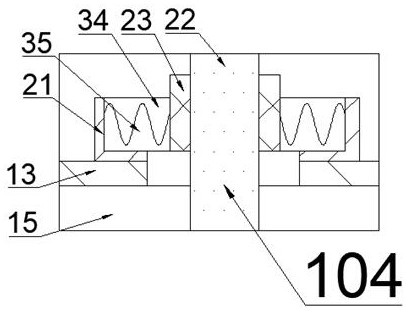

Nailing gun with high safety coefficient

InactiveCN111716294AImprove the efficiency of nailing into the working surfaceImprove nailing efficiencyNailing toolsNail gunNail device

The invention discloses a nailing gun with a high safety coefficient. The nailing gun comprises a nailing gun body, wherein a nailing gun cavity with a leftward opening is formed in the nailing gun body; a nailing gun body device is arranged in the nailing gun cavity; a secondary knocking device is arranged on a vibration nailing device; the secondary knocking device is used for carrying out secondary knocking on nails; the secondary knocking device comprises a sliding cylinder fixedly connected to the end face of the left side of an auxiliary sliding block; the opening of the sliding cylinderfaces leftwards; a sliding block is connected in the sliding cylinder in a sliding mode; a second compression spring is connected between the sliding block and the inner wall of the right side of thesliding cylinder; a nail supply device located on the left side of the vibration nailing device is arranged on a grip; and the nail supply device is used for supplying the nails. According to the nailing gun, the problem that the safety coefficient is low due to the fact that the kinetic energy of the nail ejection of a traditional nailing gun is large can be solved, and the nailing efficiency ofthe nails is guaranteed through secondary acceleration knocking and high-frequency knocking.

Owner:东阳鸿松机械科技有限公司

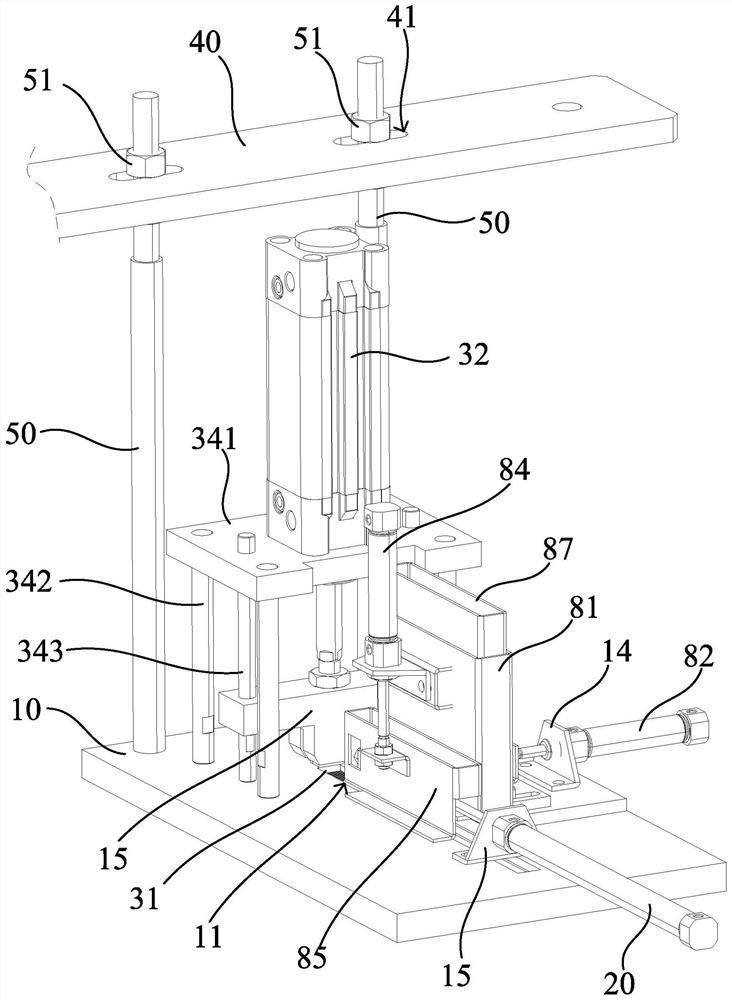

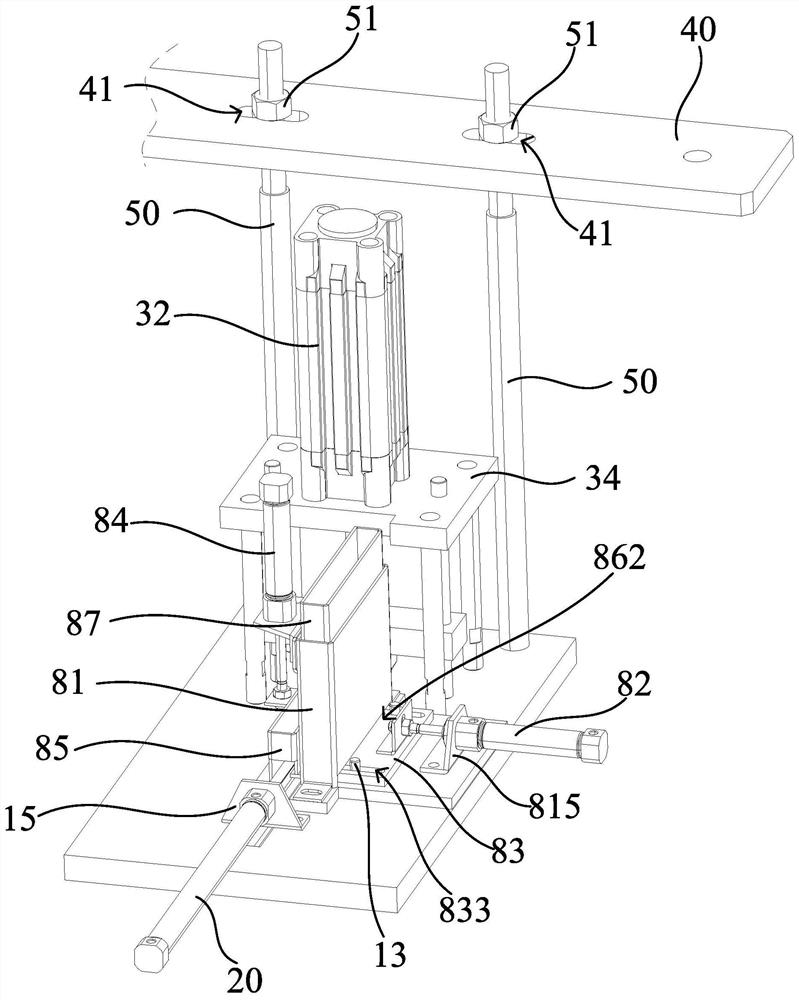

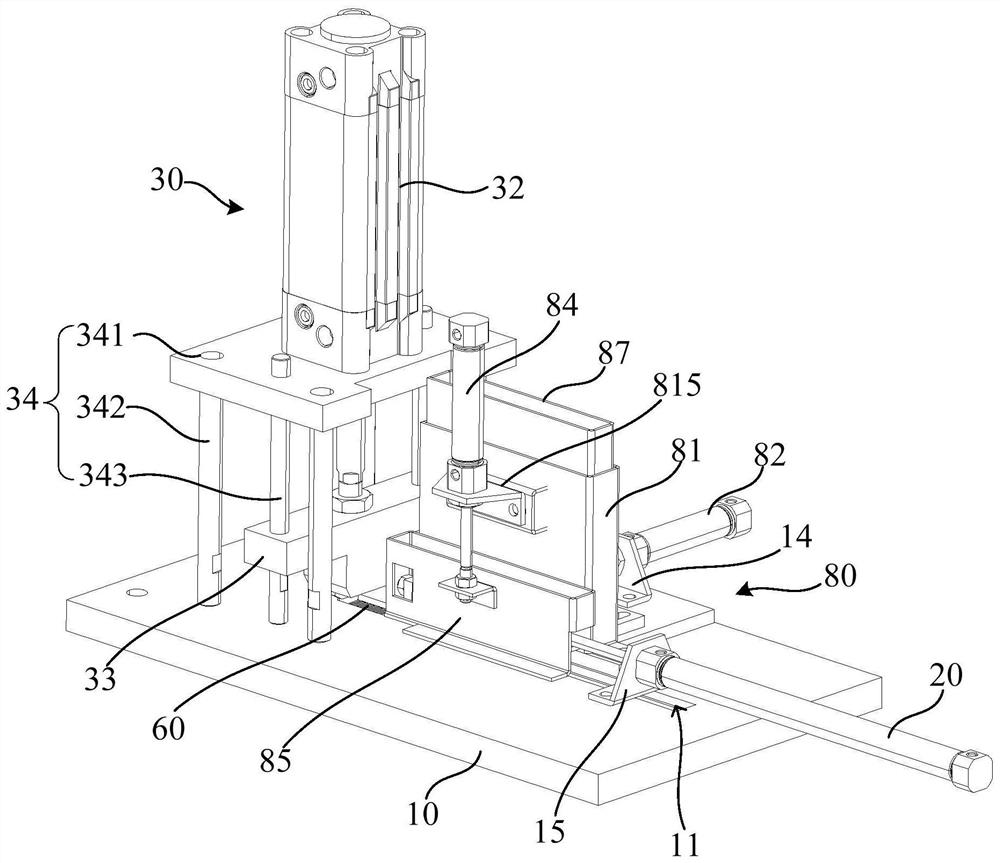

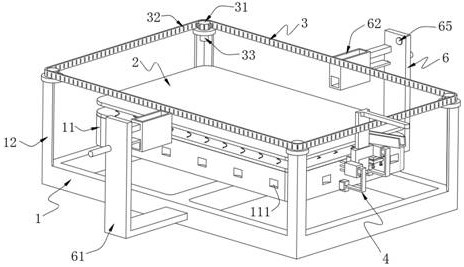

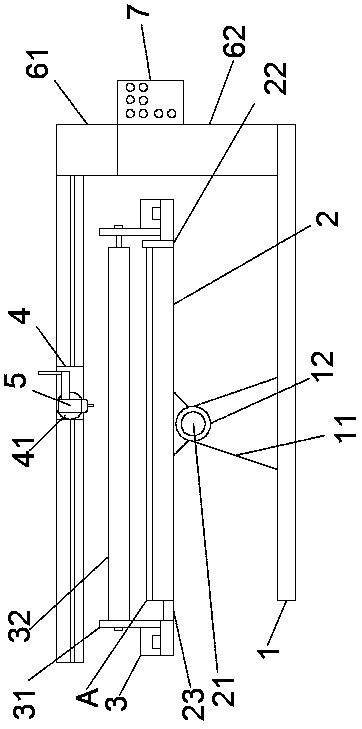

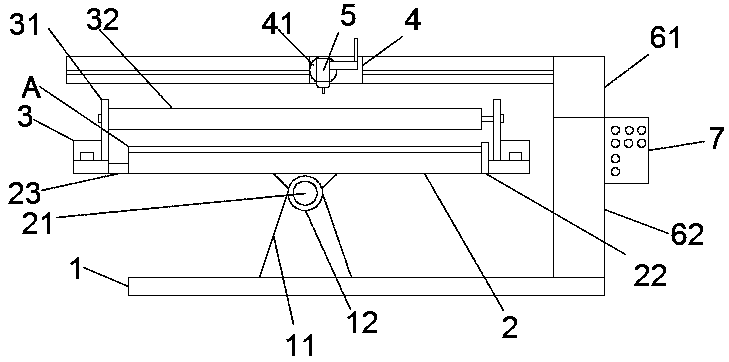

Automatic nailing device for wood boards

InactiveCN111152314AImprove nailing efficiencyStapling toolsNailing toolsElectric machineryWood plank

The invention belongs to the technical field of wood board machining equipment, and particularly relates to an automatic nailing device for wood boards. The automatic nailing device comprises a machine table, a machine arm and a nailing gun, wherein a control box is arranged on one side of the machine table, the machine arm stretches across the machine table, and the two ends of the machine arm are slidably connected with the two sides of the machine table; an electric sliding table is arranged on a machine arm cross beam, and the nailing gun is fixedly arranged on the electric sliding table;the upper portion of the machine arm is connected with the lower portion of the machine arm in a rotating mode, and a rotating motor is arranged on the lower portion of the machine arm; and a wood board fixing device is arranged on the machine table, and movable sliding rails are arranged on the two sides of the fixing device. The automatic nailing device for the wood boards moves and rotates through the machine arm, moves through the electric sliding table, nailing is carried out on the wood boards on the machine table in a horizontal, longitudinal and circular arc-shaped mode, and manual nailing is not needed, so that the wood board nailing efficiency improved.

Owner:惠州市天锦门业有限公司

Mechanically automatic nail driving device

InactiveCN108356762AEffective launchAchieve the effect of automatic nailingDispensing apparatusNail dispensersFixed frameEngineering

The invention discloses a mechanically automatic nail driving device comprising a tail seat and a nail placing opening. The left side of the tail seat is connected with a supporting column, and a motor is mounted inside the supporting column; brackets are arranged on the upper side and the lower side of the supporting column correspondingly, a nail outlet is formed in the leftmost side of the supporting column, the left side of the motor is connected with a rotating shaft, and a connecting seat is connected into the left side of the rotating shaft; and an air cylinder is arranged in the connecting seat, the left side of the air cylinder is provided with a nail pushing head, nails are arranged in a nail storing cavity, the nail placing opening is formed in the upper portion of the nail storing cavity, nail fixing frames are arranged on the lower portions of the nails, springs are mounted on the two sides of the nail fixing frames, and the lower portions of the nail fixing frame are connected with connecting rods. According to the mechanically automatic nail driving device, the nails in the device can be effectively pushed out, the nails are pushed back and forth through the air cylinder, thus the automatic nail driving effect is achieved, the nail driving time of the device is saved, and the nail driving efficiency of the device is improved.

Owner:王芳

Nail head device and box nailer for corrugated cardboard stapling

InactiveCN104742412BAchieve horizontal swingAvoid the bad phenomenon of scratchingPaper-makingBox making operationsLinear displacementMechanical engineering

Owner:苏州市富祥润通机电科技有限公司

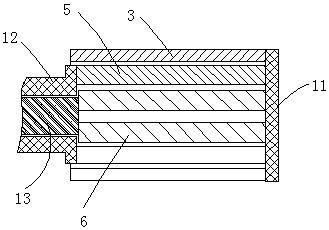

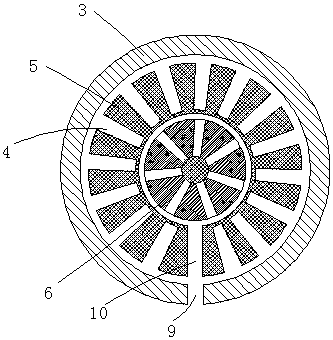

Nail gun with automatic nail supply device

PendingCN107825360ASimple structureEasy to manufacture and installStapling toolsNailing toolsNail plateNail gun

The invention discloses a nail gun with an automatic nail supply device. The nail gun comprises a nail gun body, a clip feeding device, a conveying device and a transmission device. The nail gun bodycomprises a gun body and a main nail bin for containing nail plates. The clip feeding device comprises a plurality of clip barrels and a fixed shell, and the multiple clip barrels are each arranged tobe of a hollow barrel-shaped structure, are sequentially fixed to each other in a sleeved mode from inside to outside and are coaxially arranged; each clip barrel is internally provided with a plurality of branched nail bins for containing the nail plates; the multiple clip barrels are driven by the transmission device and freely rotate relatively; the clip barrels are arranged in the fixed shell, the lower portion of the shell is provided with a first discharging outlet, and the clip barrels are provided with second discharging outlets matched with the first discharging outlet; and the nailplates flow out from the discharging outlets and are conveyed into the main nail bin through the conveying device. Through the nail gun with the automatic nail supply device, the storage quantity of the nail plates is increased to a great extent, the continuous nailing sustainability of the nail gun is improved, the nailing efficiency is improved, and the practicality is high.

Owner:彭方

Rapid screw driving device for plate product packaging

PendingCN112497382AAdjustable distanceReduce manual operationsStapling toolsWood working apparatusSlide plateBar pressing

Owner:FOSHAN CHUANGLIBAO PACKAGING MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com