Patents

Literature

37results about How to "Improve nailing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

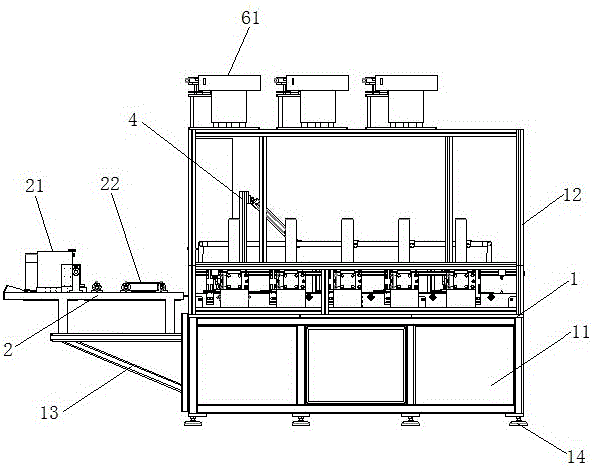

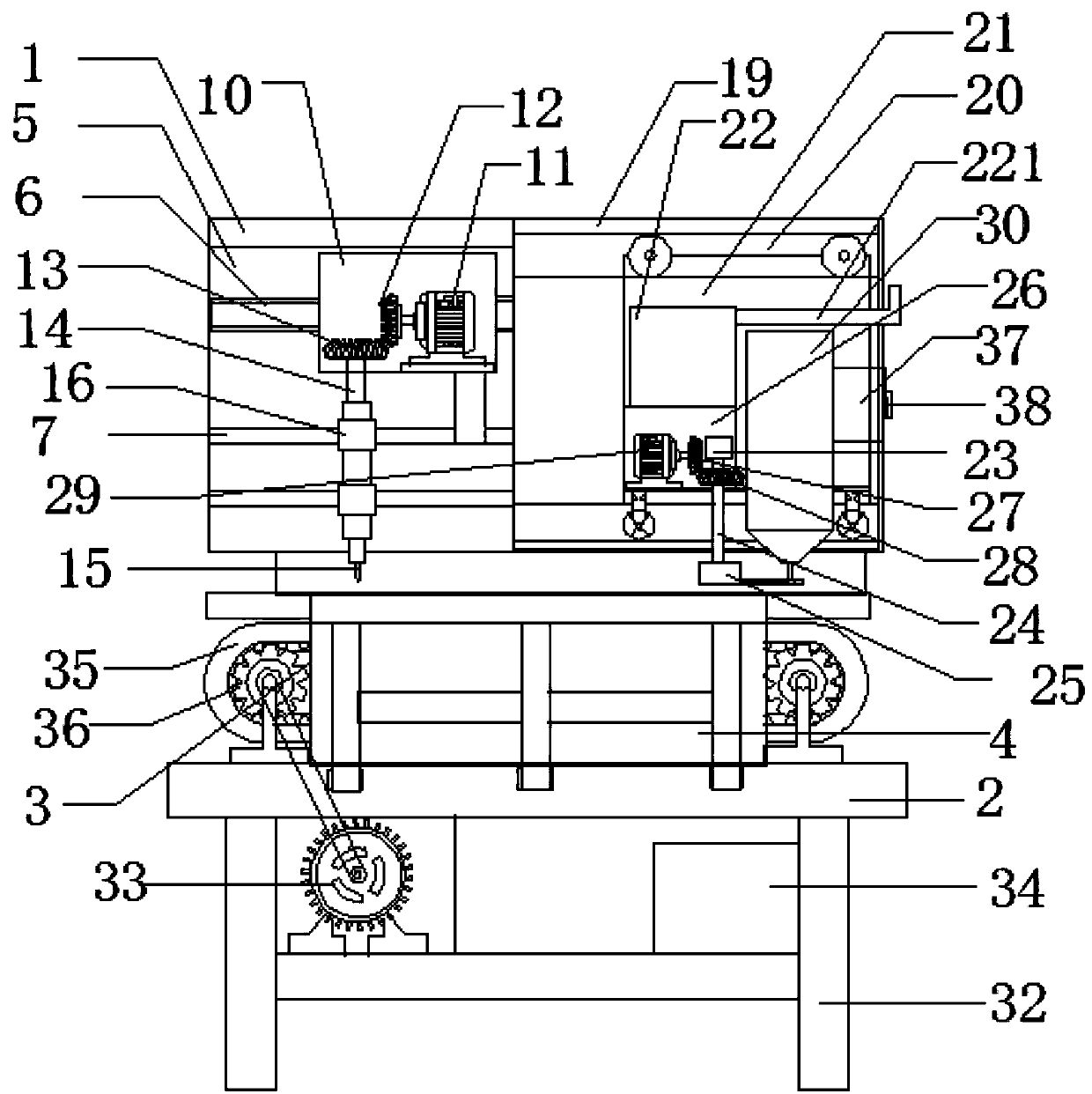

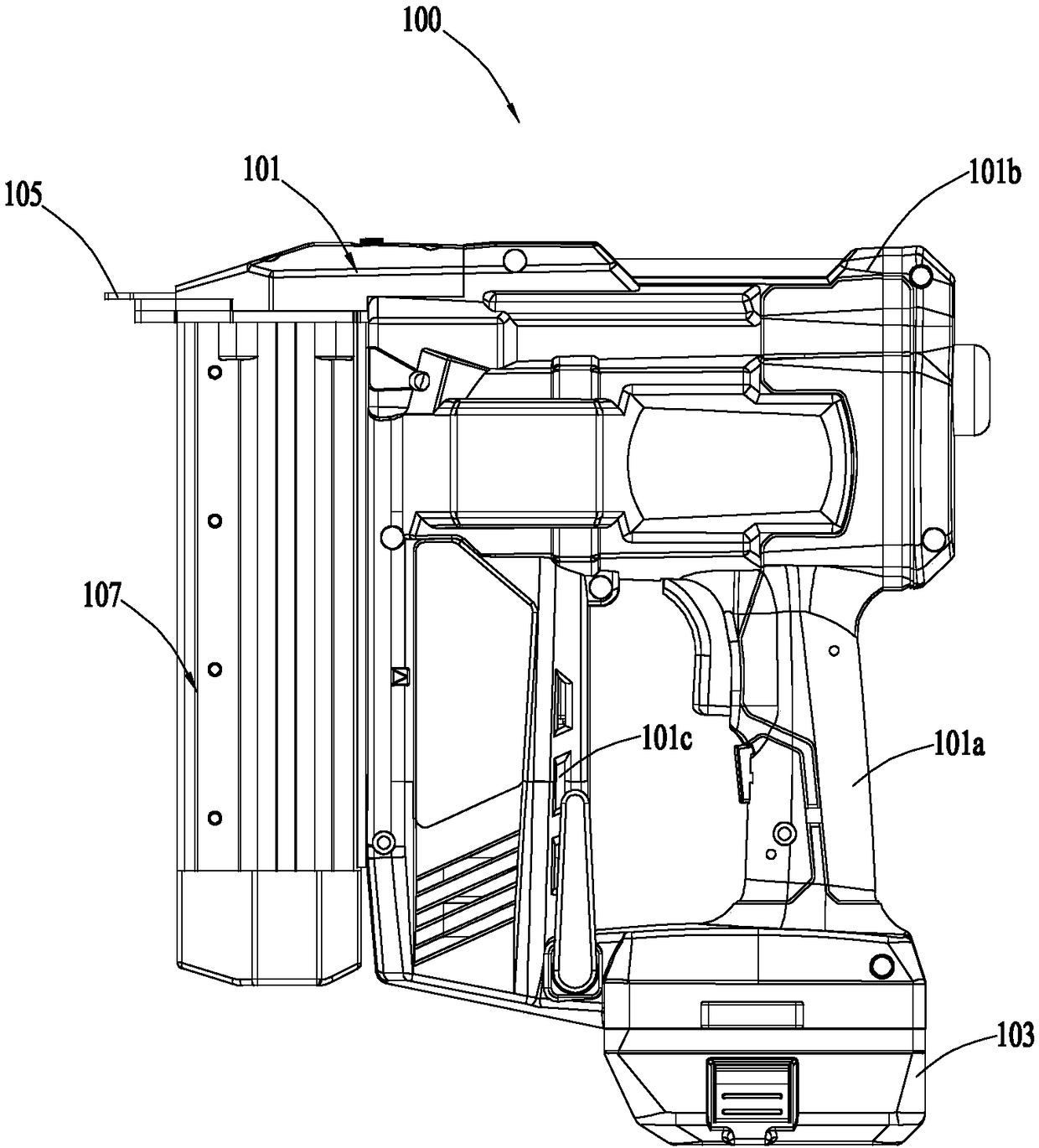

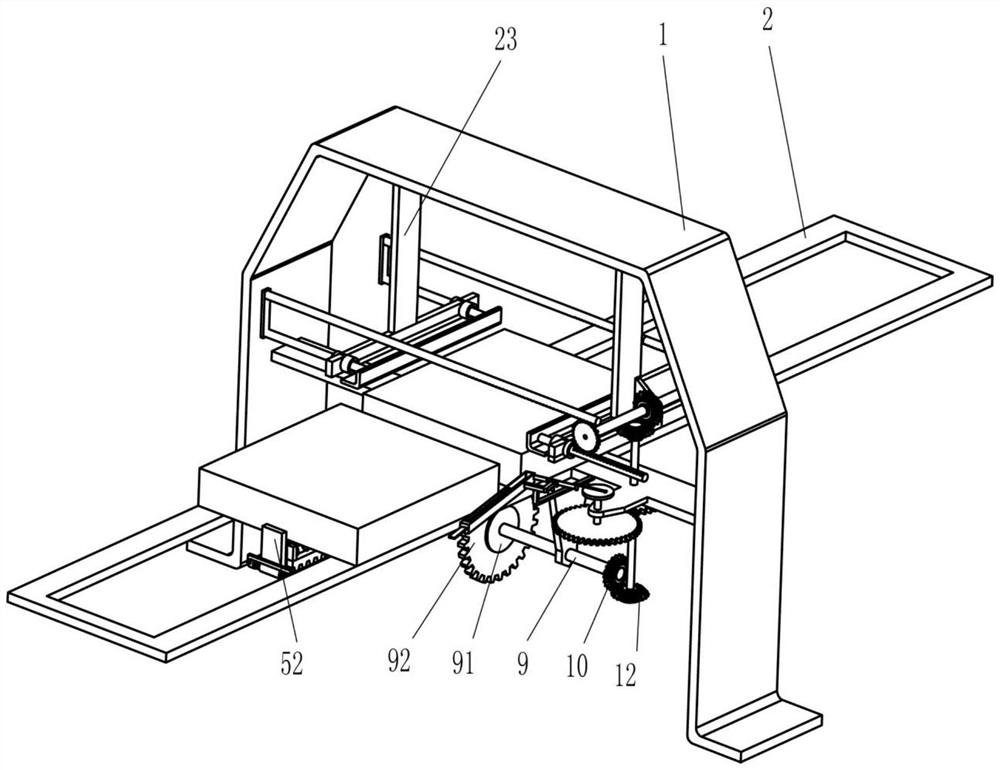

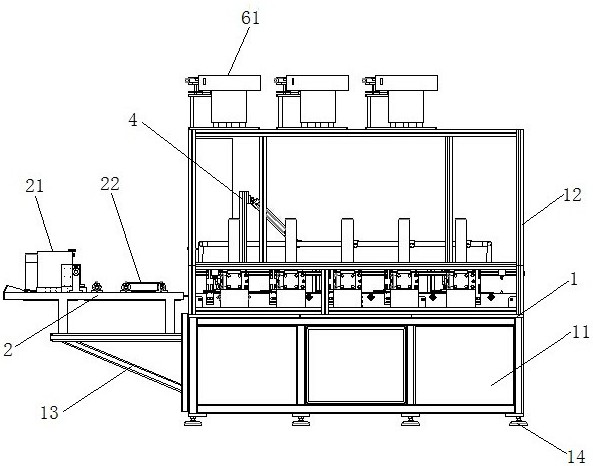

Automatic packing box nailing equipment

ActiveCN106742320AQuality improvementQuality assuranceWrapper twisting/gatheringHigh volume manufacturingLow vacuum

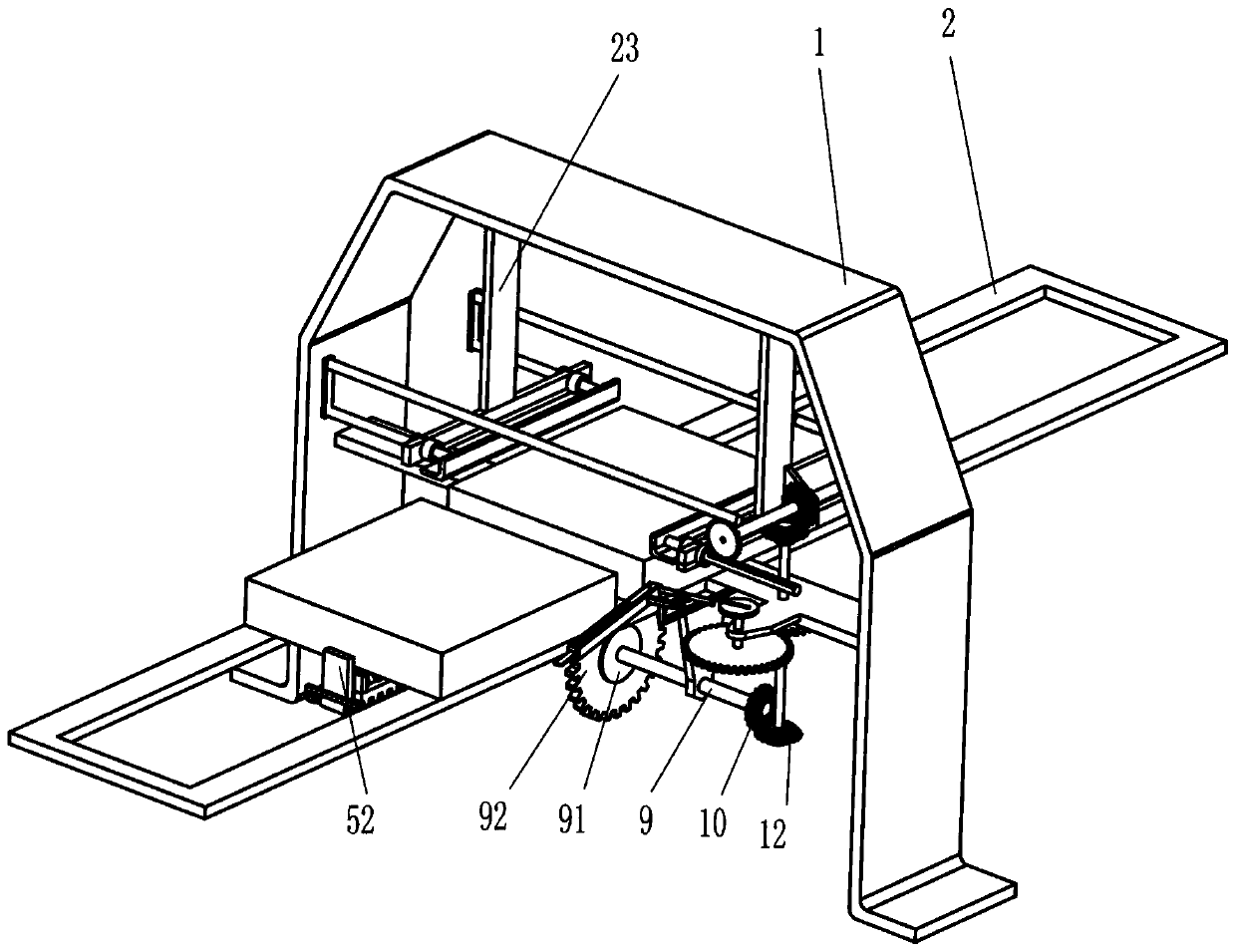

The invention provides automatic packing box nailing equipment. The automatic packing box nailing equipment comprises a rack, a discharge conveying mechanism, a servo positioning mechanism, an automatic box opening module, a profile modeling positioning module and an automatic nailing module. The discharge conveying mechanism is located on one side of the rack. The servo positioning mechanism comprises a synchronous conveyor belt located on the rack and a servo motor used for driving the synchronous conveyor belt. The automatic box opening module comprises a lower vacuum sucker and a jacking cylinder. The automatic box opening module further comprises an upper vacuum sucker and a box opening cylinder. The profile modeling positioning module is located on one side of the synchronous conveyor belt. The automatic nailing module is located on the other side of the synchronous conveyor belt and is opposite to the profile modeling positioning module. The automatic packing box nailing equipment can conduct centralized production of multiple nailing procedures, and can automatically complete the whole nailing process of anti-fake rivets of packing boxes. The quality of packing boxes is guaranteed. The requirements for mass production are met. The cost is saved.

Owner:武汉世豪同创自动化设备有限公司

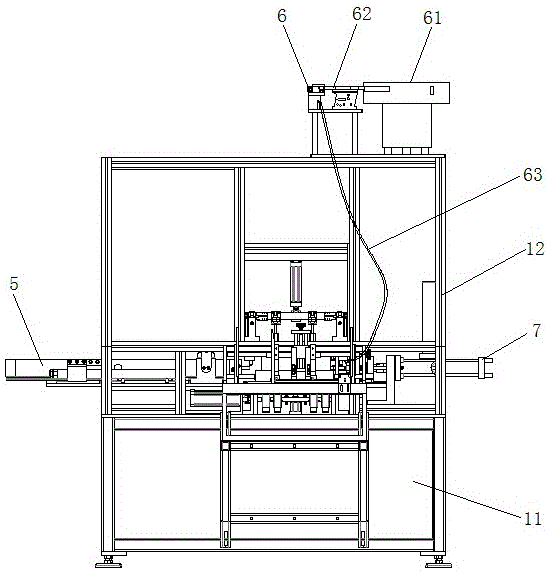

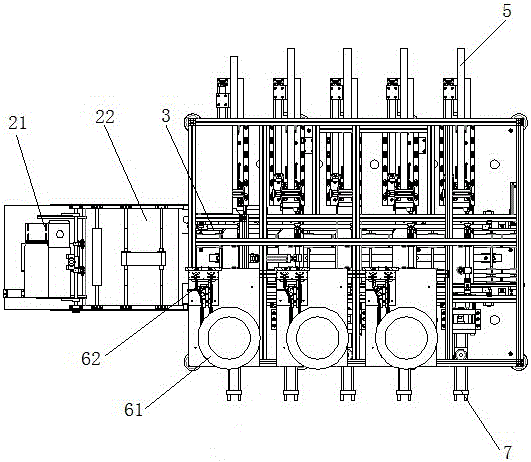

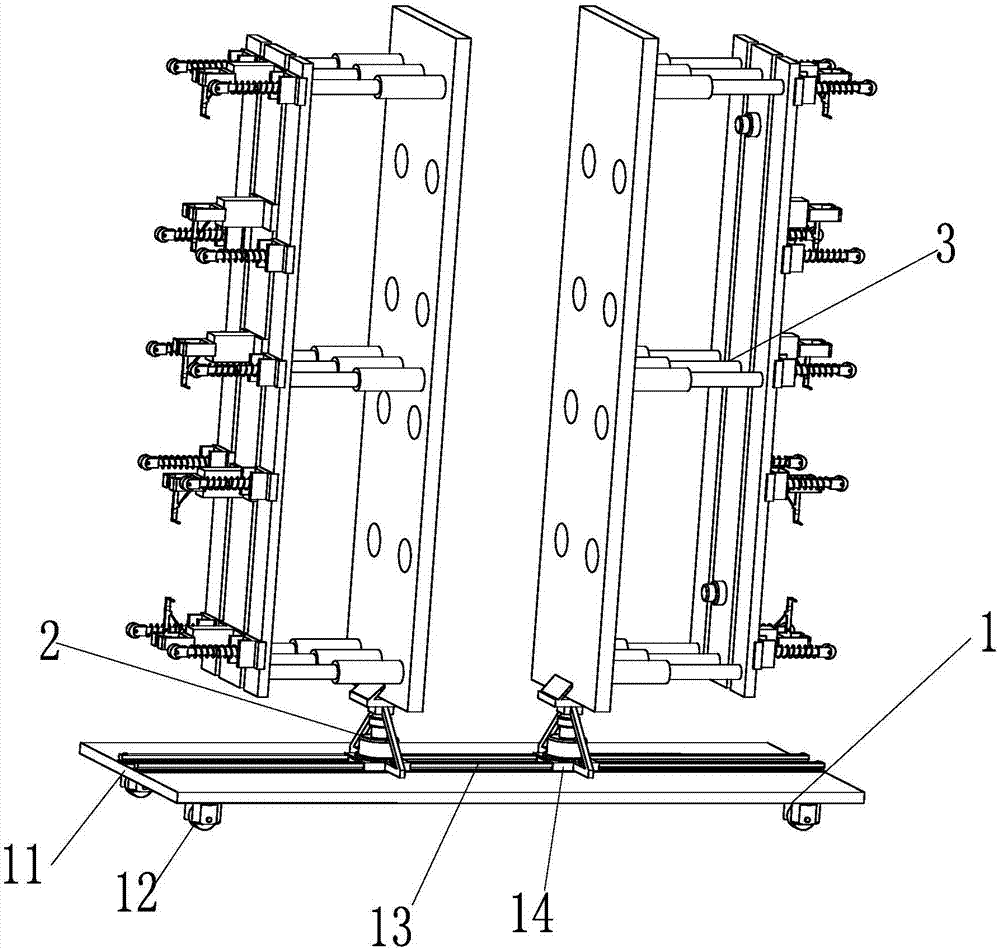

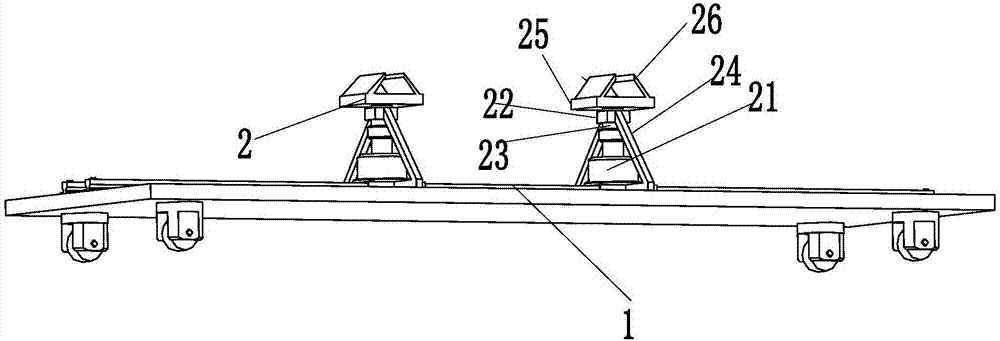

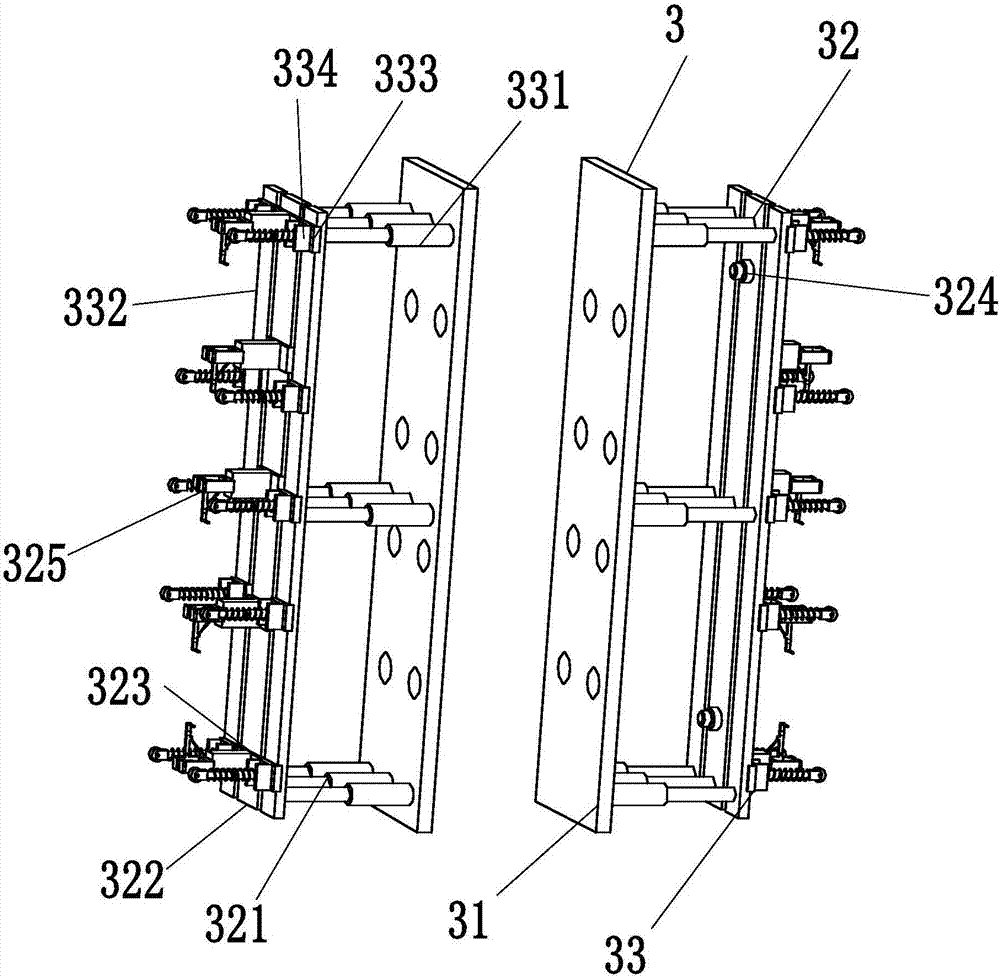

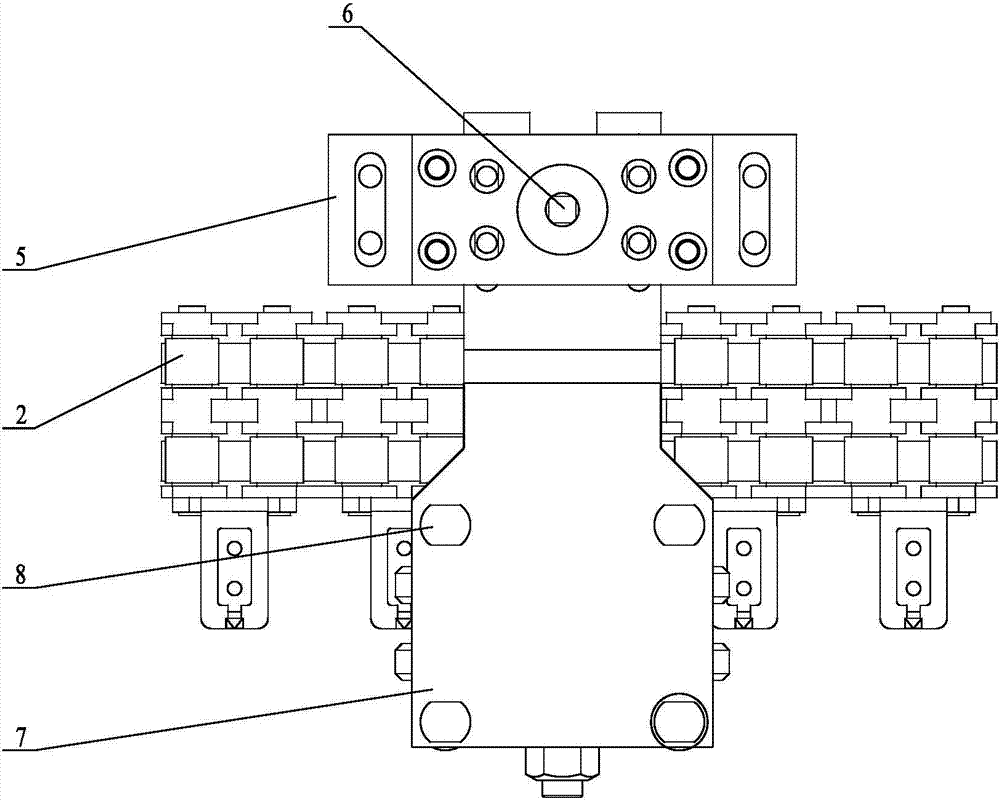

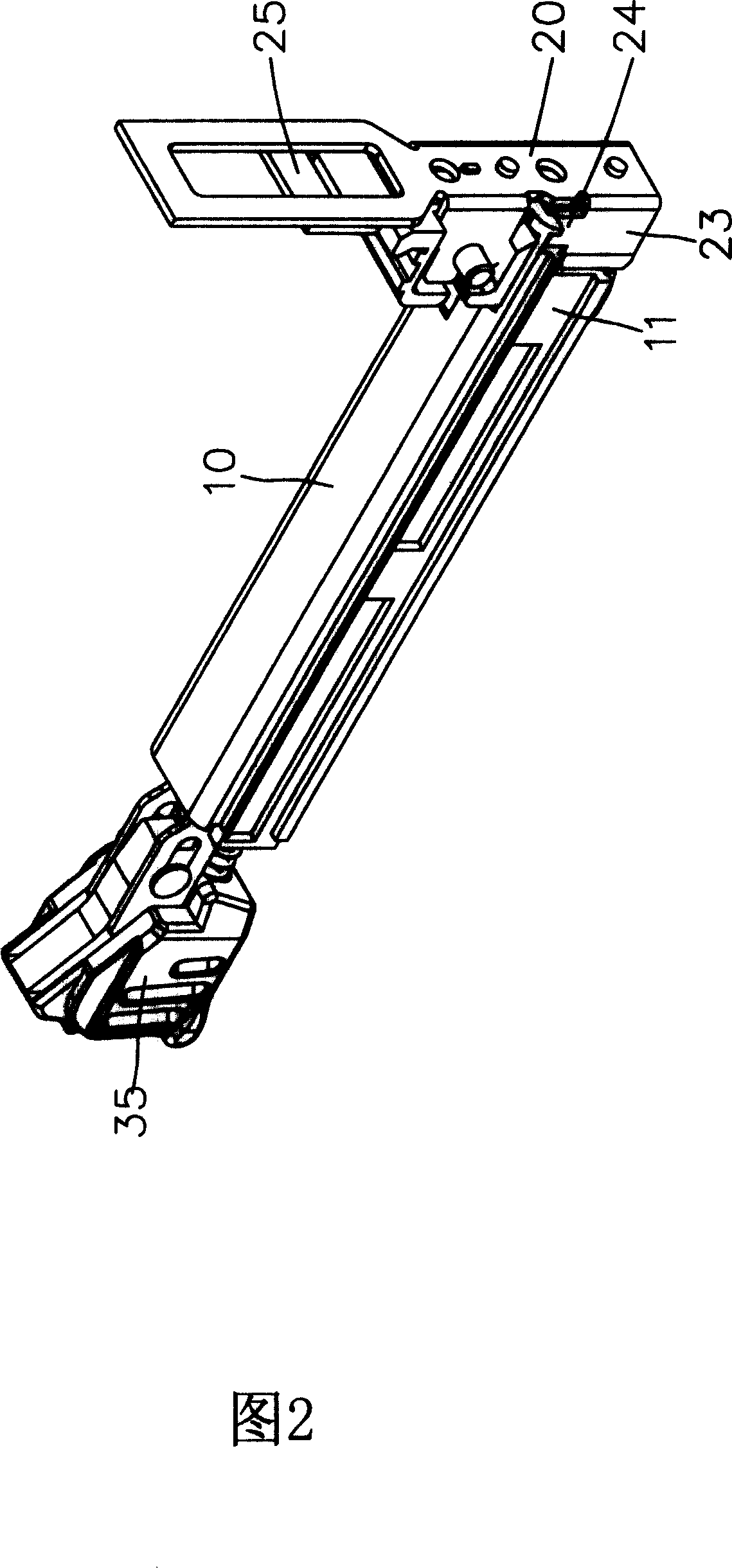

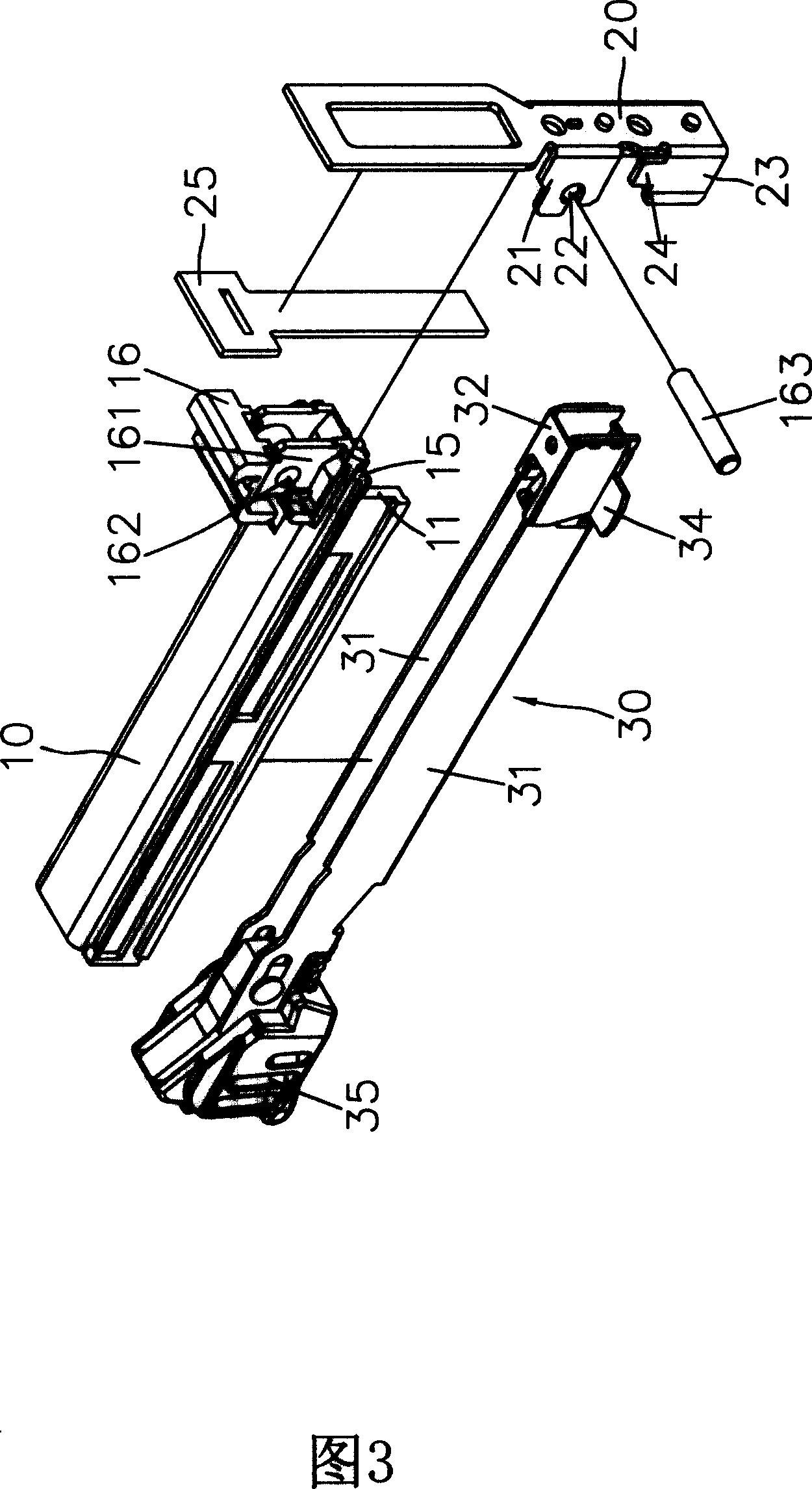

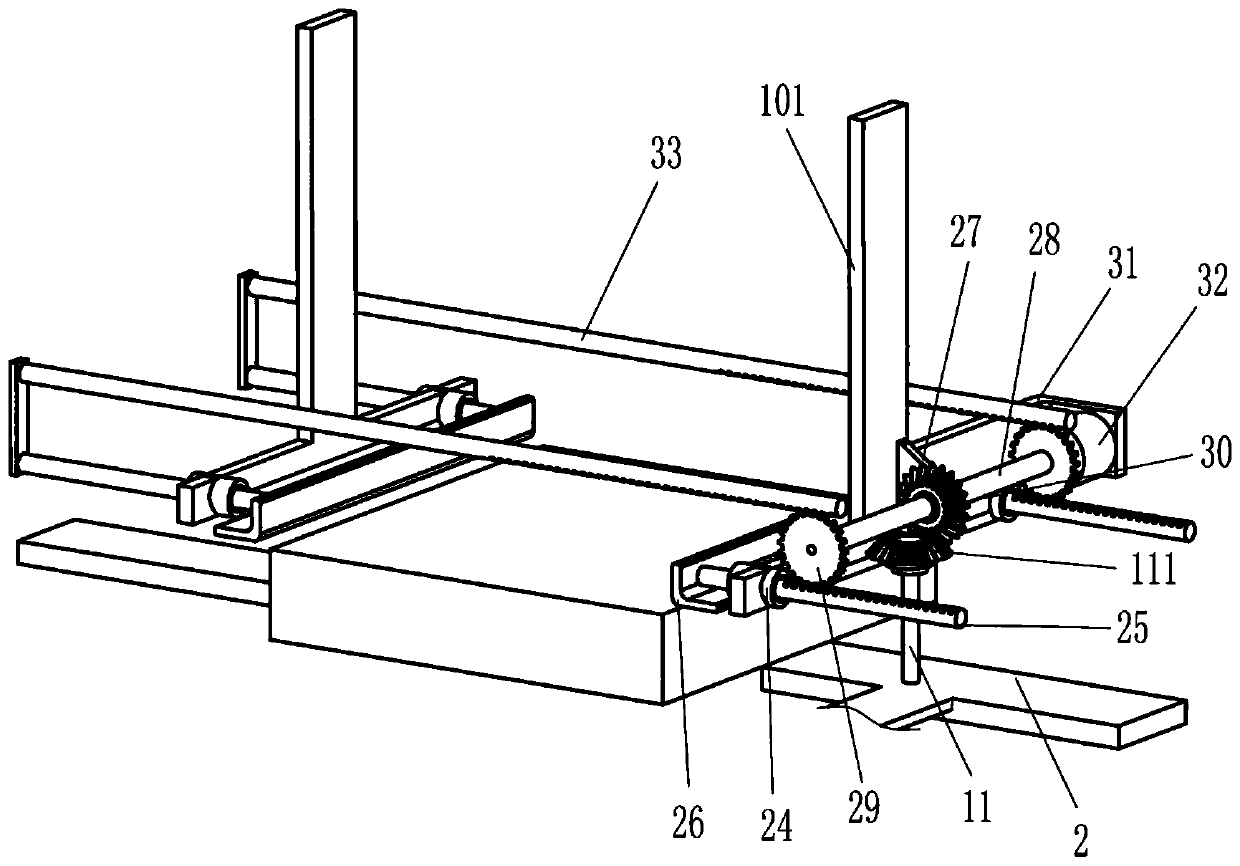

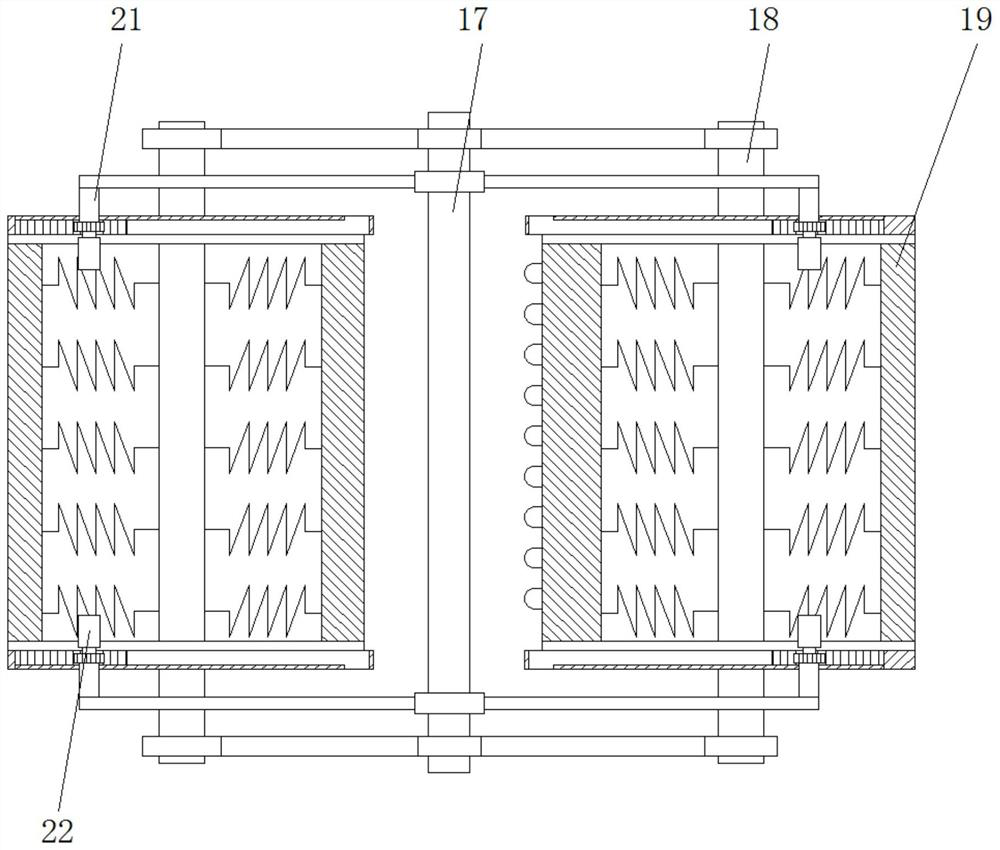

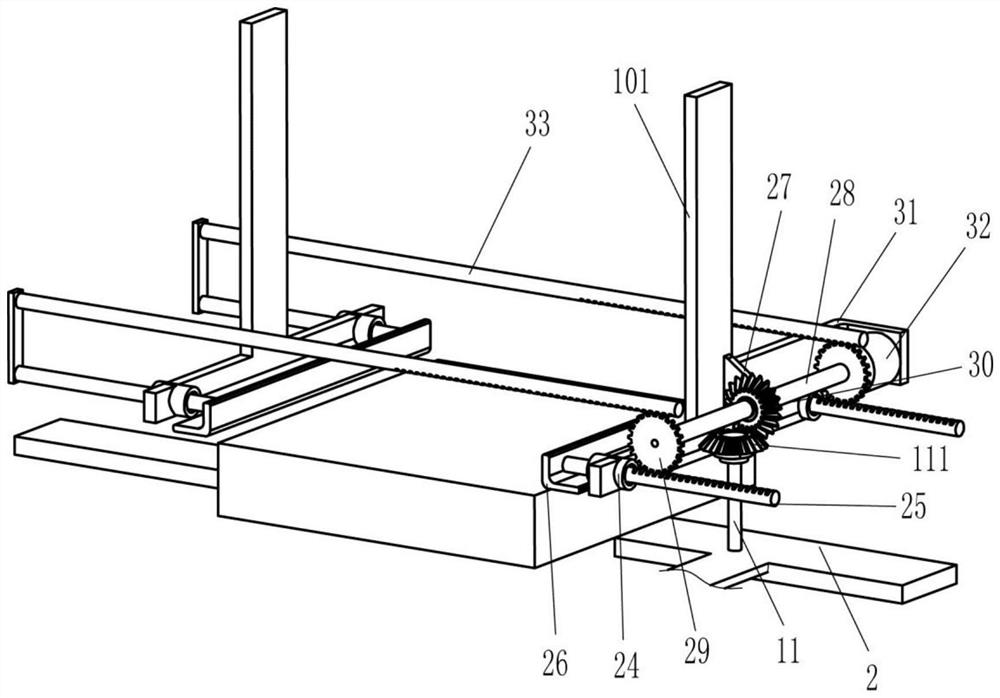

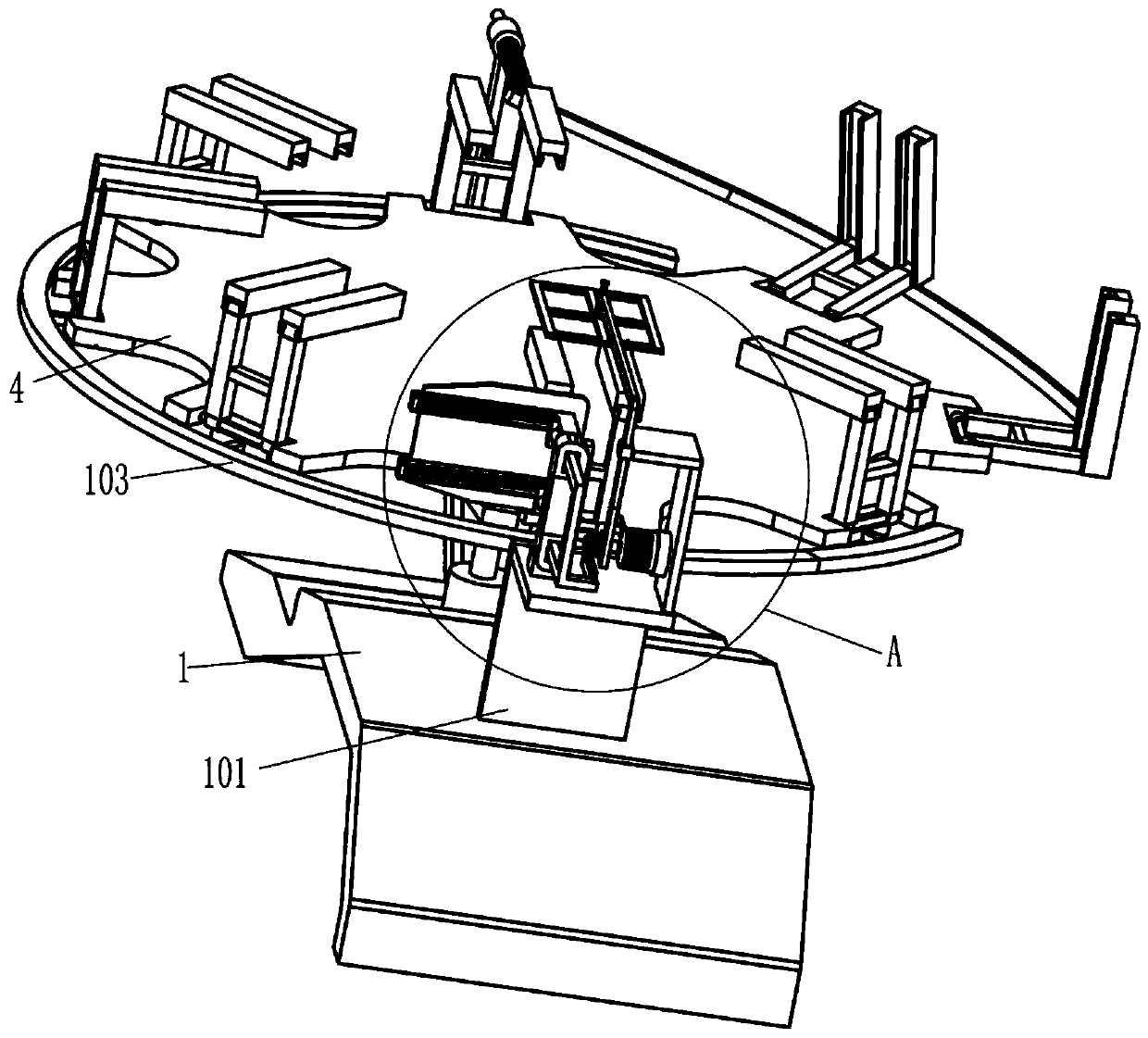

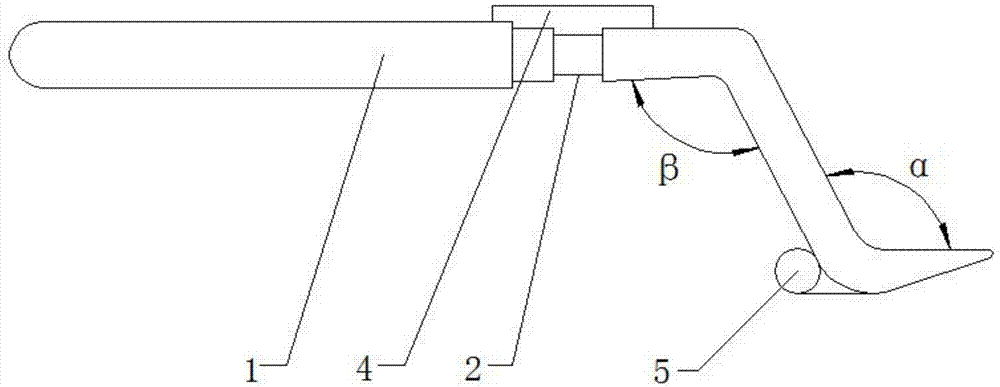

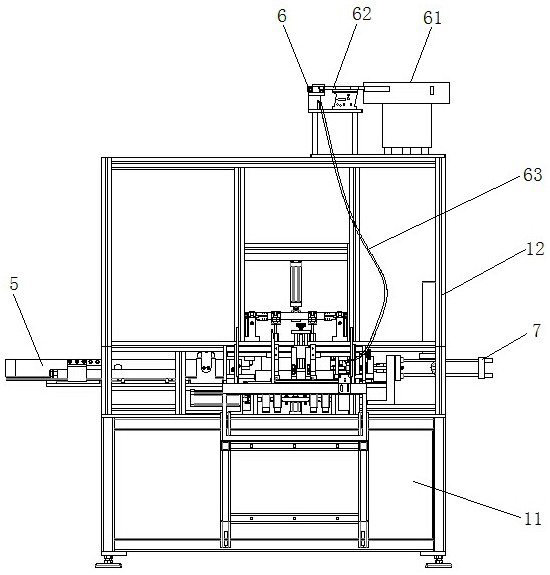

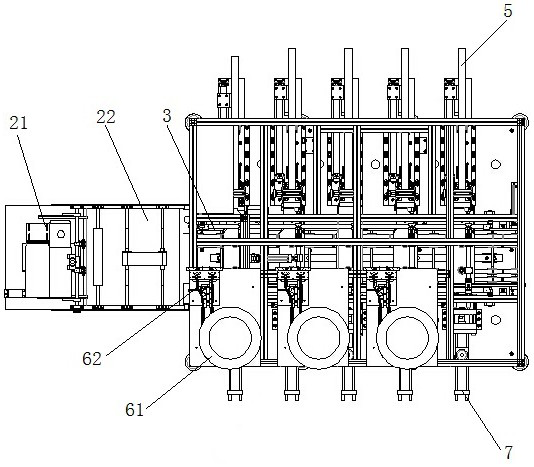

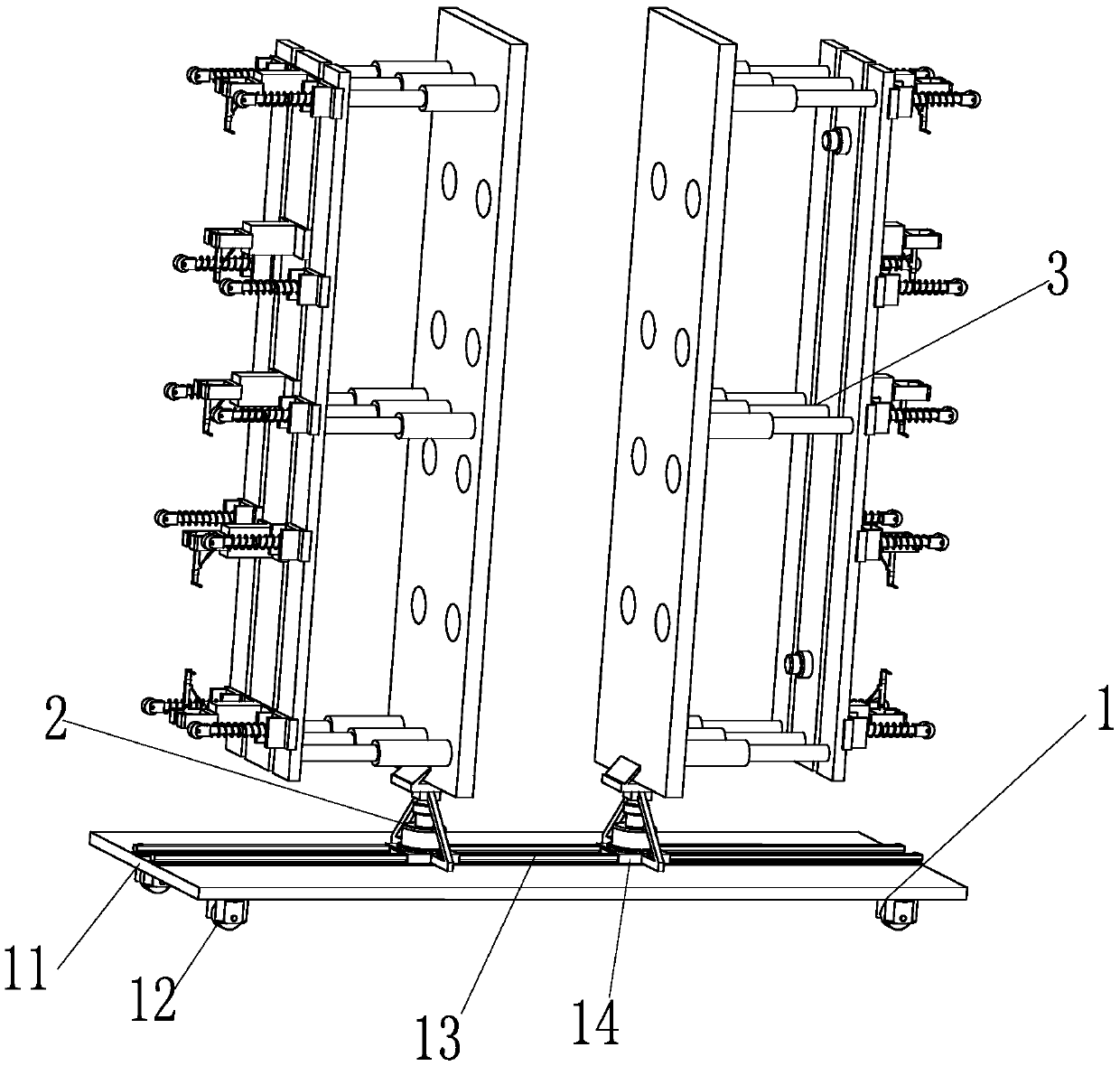

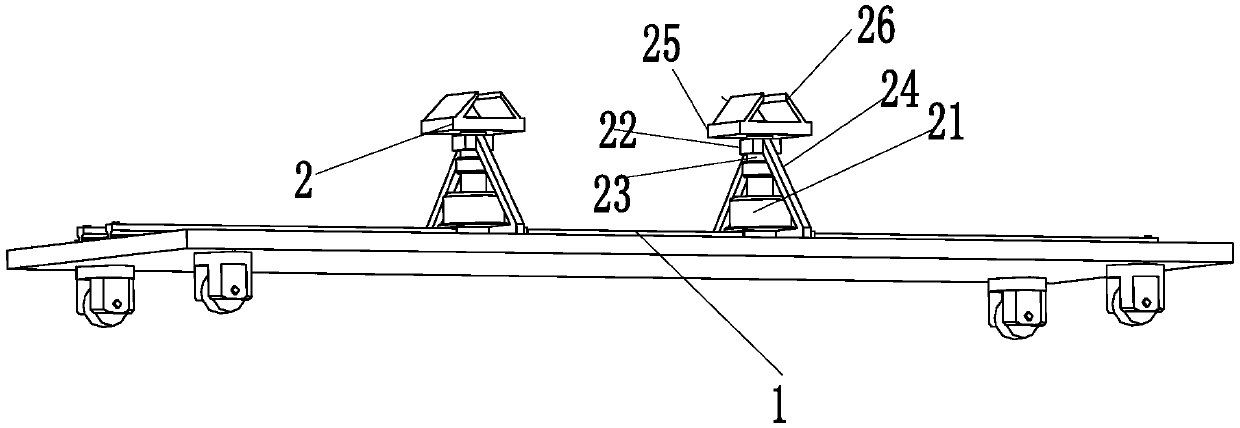

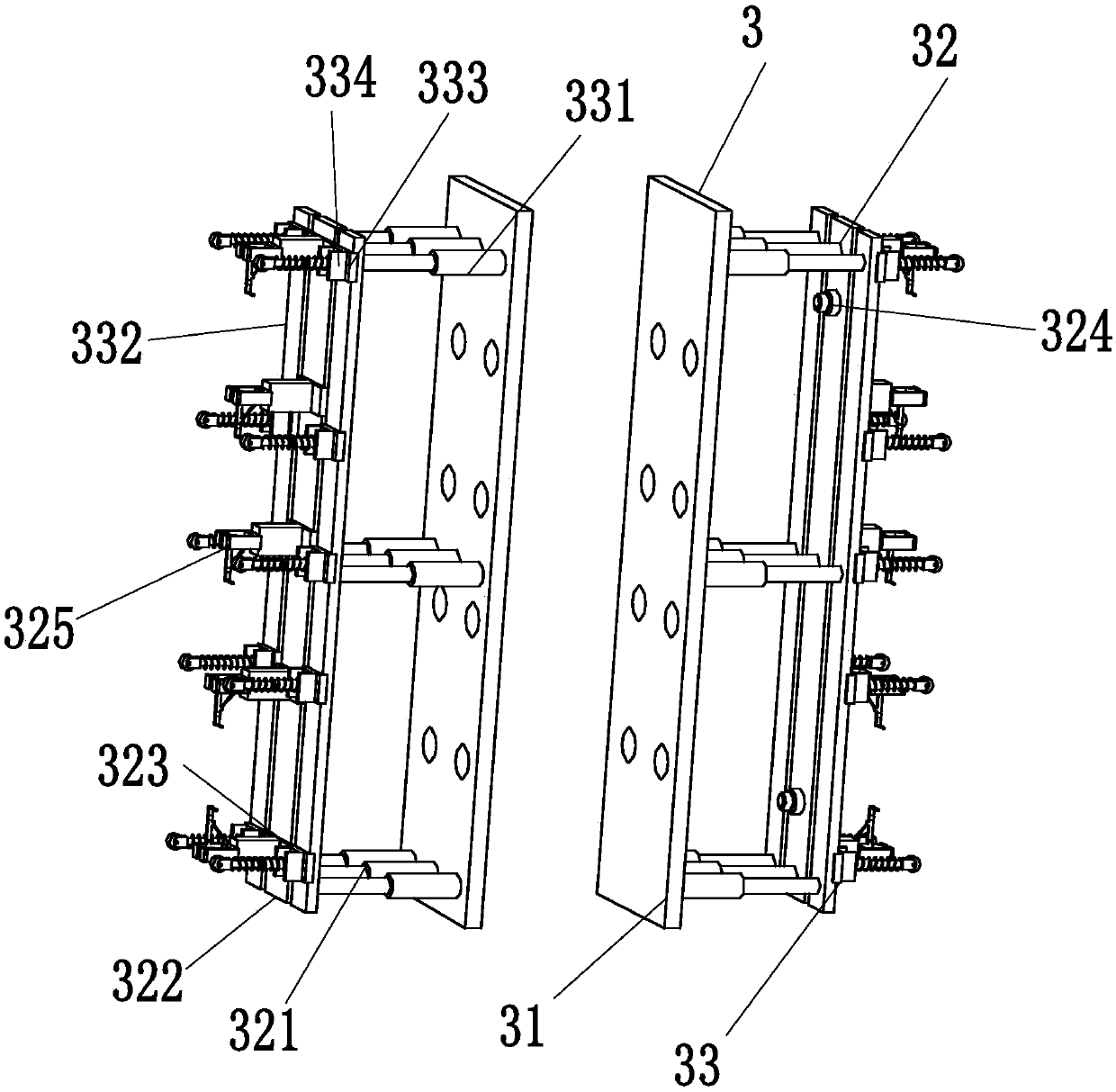

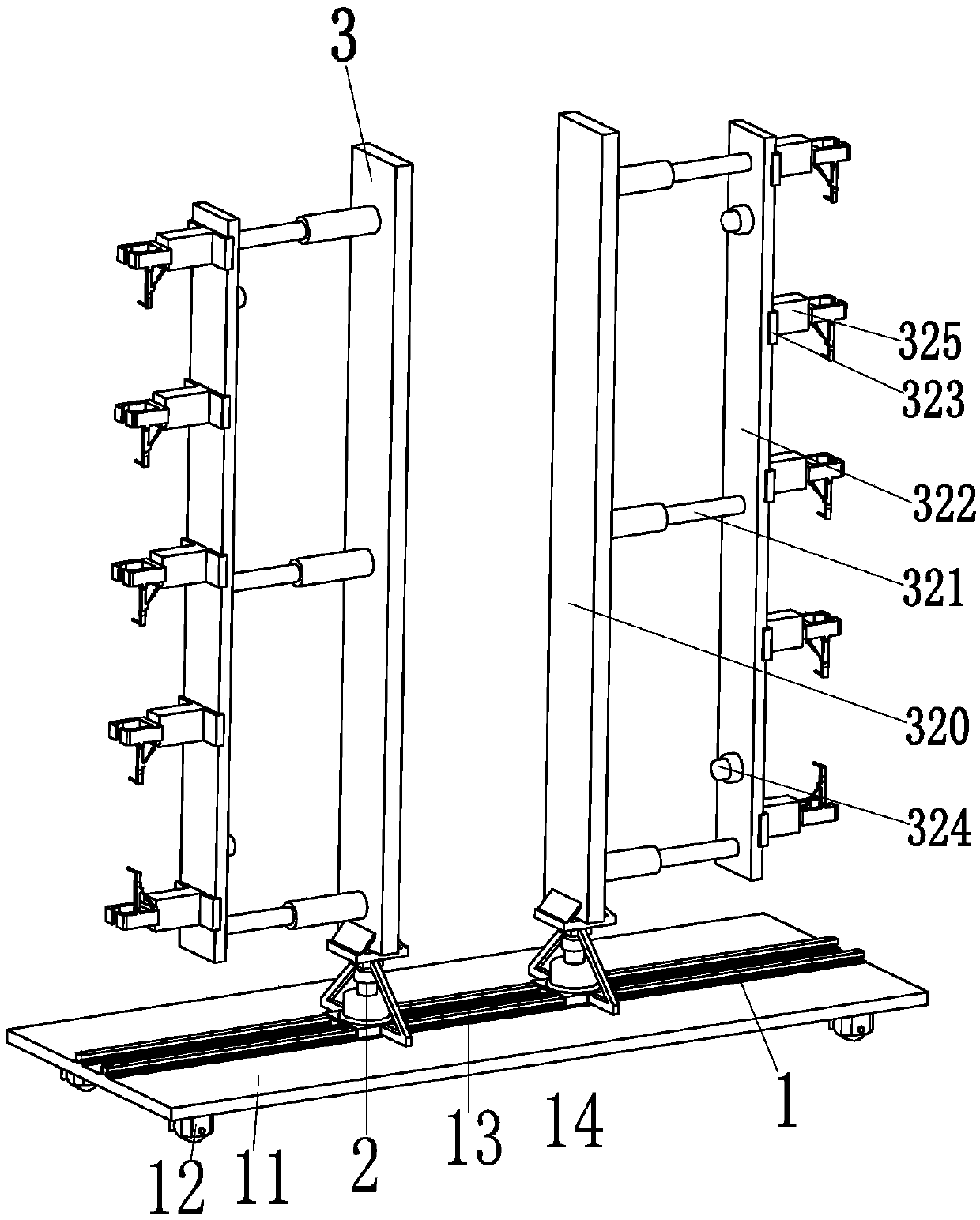

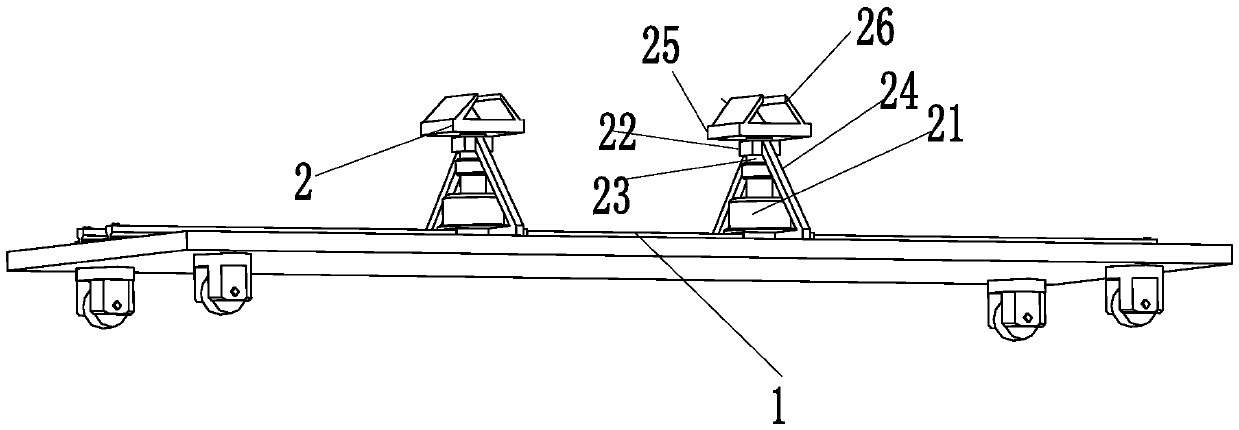

Automatic pressing and nailing machine for aluminum alloy door frame sleeve

ActiveCN107243960AImprove work efficiencyReduce labor intensityStapling toolsNailing toolsEngineeringUltimate tensile strength

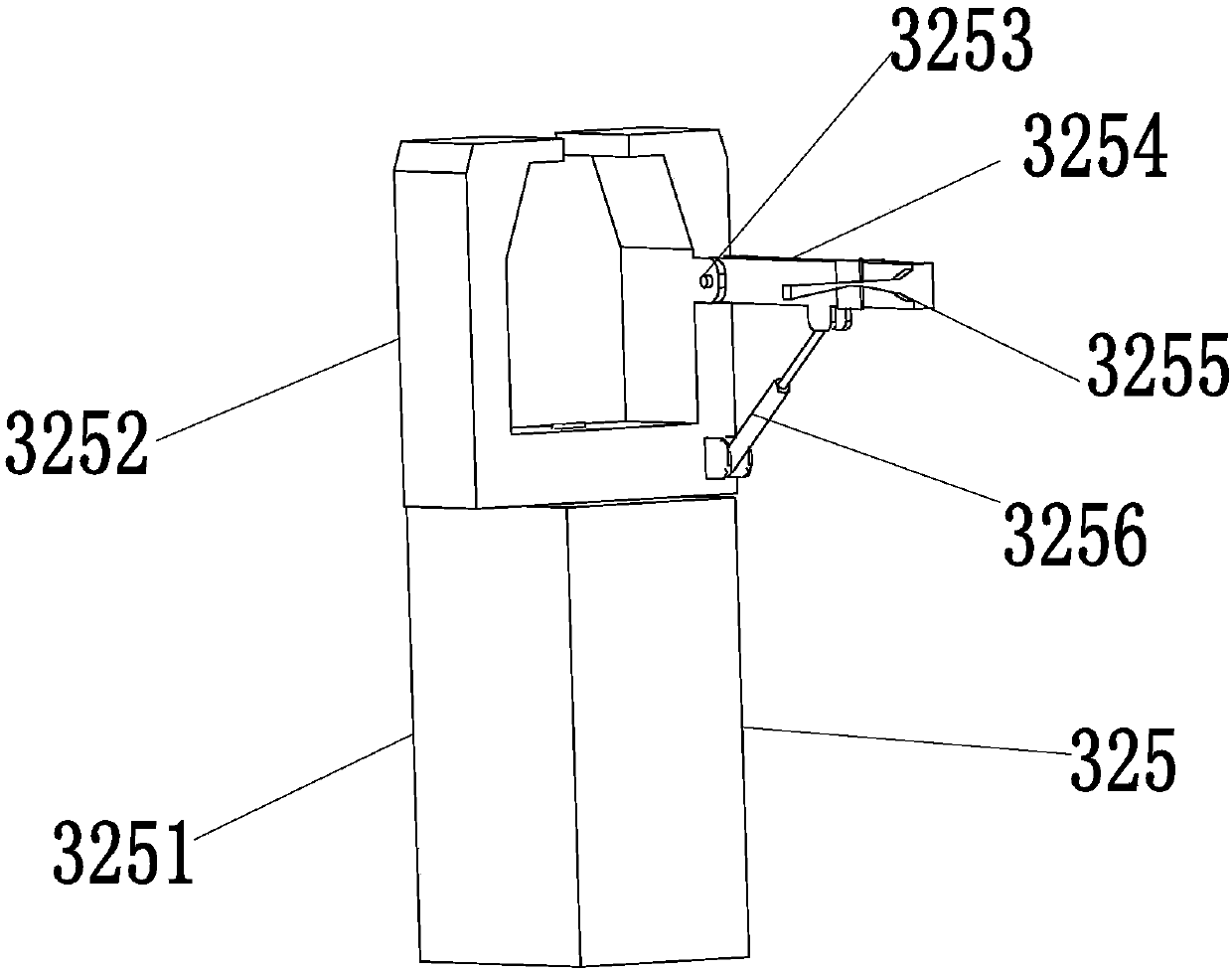

The invention relates to an automatic pressing and nailing machine for an aluminum alloy door frame sleeve. The automatic pressing and nailing machine comprises a walking device, two rotating devices and pressing and nailing devices. The two rotating devices are symmetrically mounted above the walking device. The two rotating devices are oppositely arranged. The pressing and nailing device is mounted above each rotating device. By the adoption of the automatic pressing and nailing machine for the aluminum alloy door frame sleeve, the problems that by means of existing manual pressing and nailing of the door frame sleeve, the working efficiency is low, the labor intensity is large, the pressing and nailing cannot be conducted conveniently at the same time, risks exist in manual nailing and nailing is inconvenient in some higher or lower positions are solved, the full-mechanical pressing and nailing functions of the aluminum alloy door frame sleeve are achieved, and the automatic pressing and nailing machine has the beneficial effects that the work efficiency is high, the labor intensity is small, pressing and nailing can be conducted at the same time, the nailing work can be conducted fully mechanically, and the automatic nailing work can be conducted on different angles and positions of the door frame sleeve.

Owner:GUANGDONG GOLDEN ALUMINUM

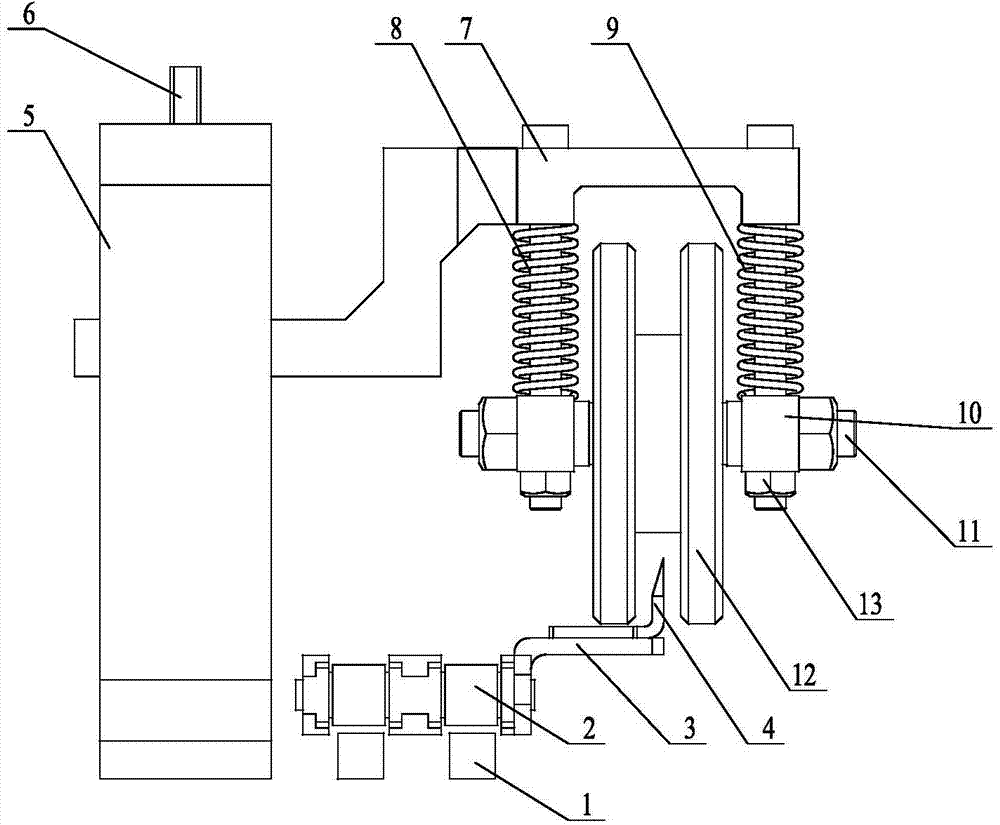

Optimized bamboo wood automatic nailing device

ActiveCN107856143AQuality improvementAvoid crackingStapling toolsNailing toolsEngineeringPre treatment

The invention discloses an optimized bamboo wood automatic nailing device and relates to the technical field of wood product processing and production. The optimized bamboo wood automatic nailing device comprises a main work box. The bottom end of the main work box is fixedly connected with a supporting worktable through a supporting frame, and the two sides of the top end of the supporting worktable are fixedly connected with transferring devices through supporting frames. The two sides of the middle of the supporting worktable are fixedly connected with wood fixing clamp supporting devices,and one side of the interior of the main work box is fixedly connected with a pretreatment box. The inner walls of the two sides of the pretreatment box are fixedly connected with first sliding rails,second sliding rails and third sliding rails correspondingly, and the first sliding rails are slidably connected with a pretreatment rotary power box through first sliding wheels. According to the optimized bamboo wood automatic nailing device, the nailing process is pretreated, the existing situation of cracking during nailing of a bamboo wood material is greatly reduced, meanwhile the automation degree in the production and processing processes is increased, and manpower resource waste is reduced.

Owner:河源盛宴竹业科技有限公司

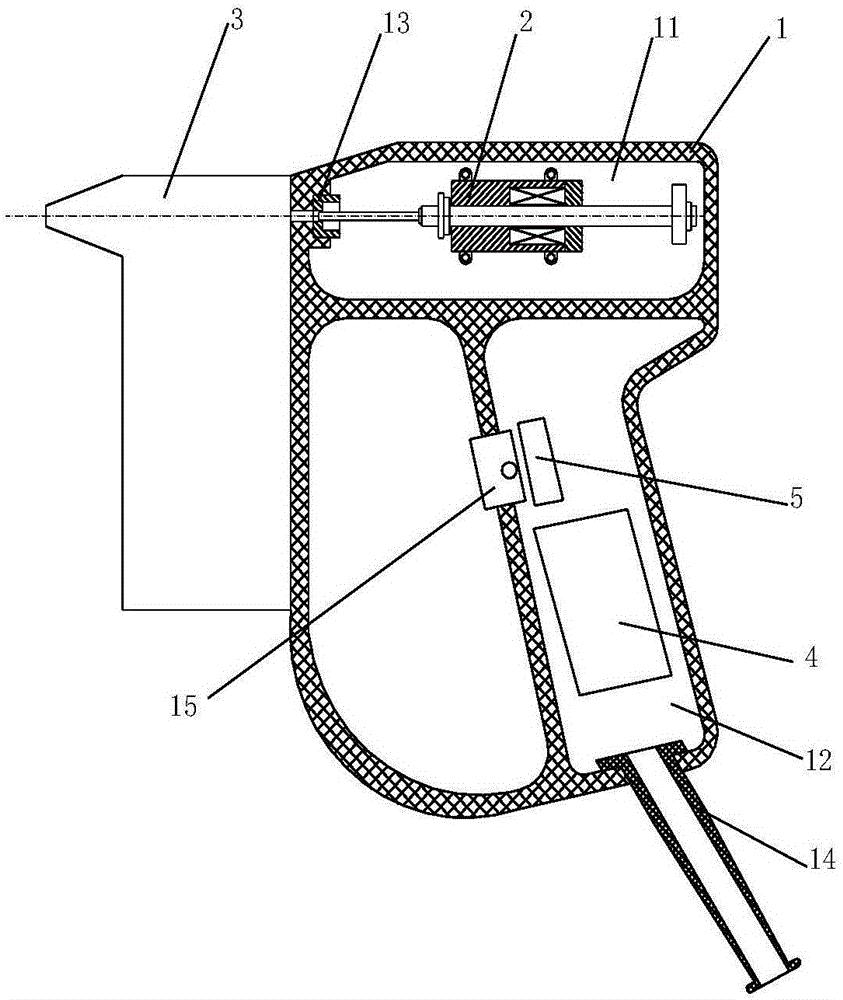

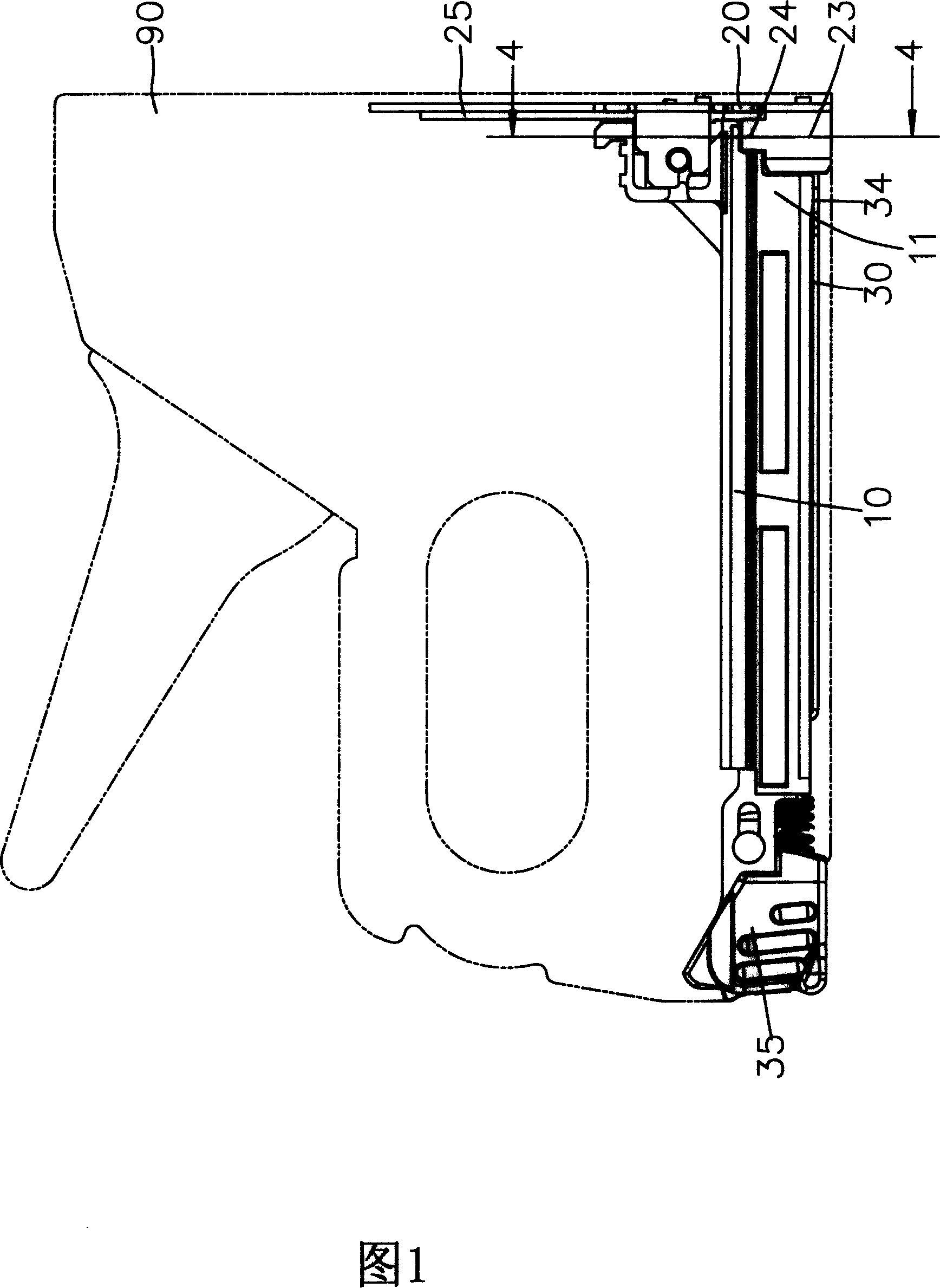

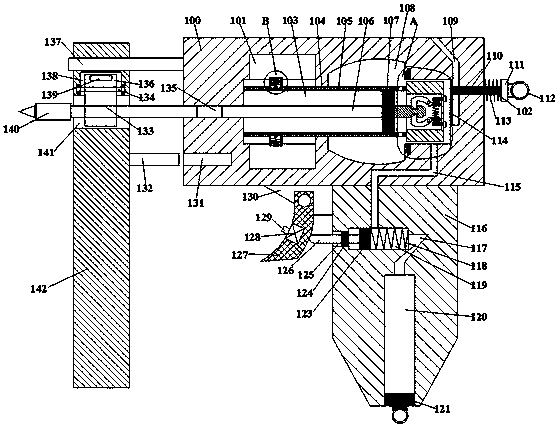

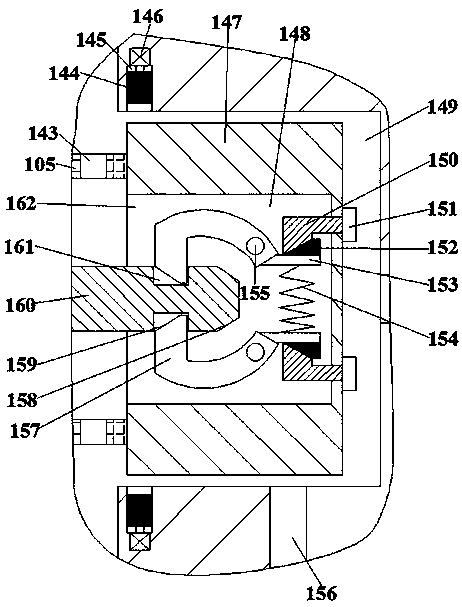

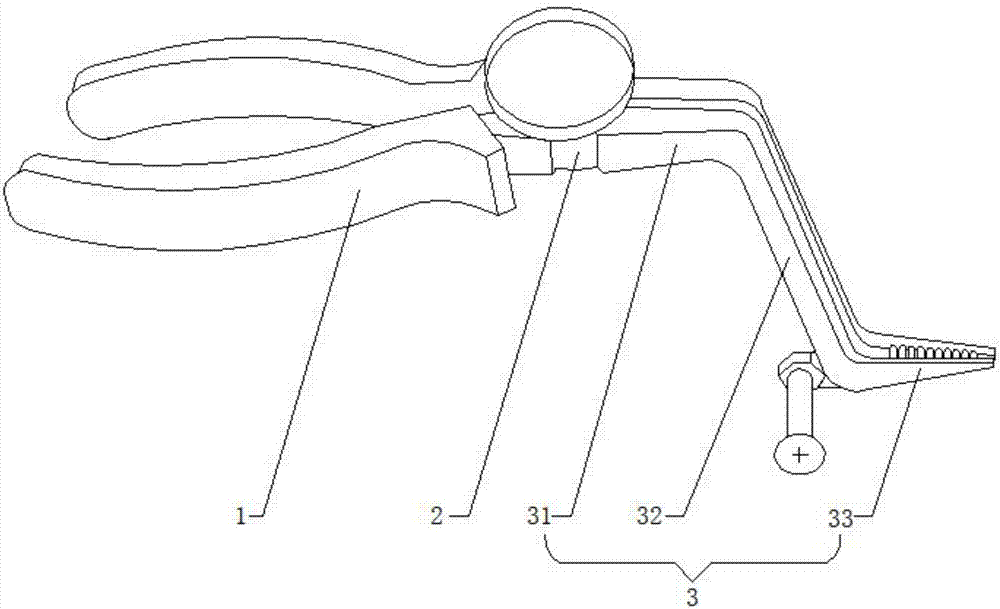

Electromagnetic nail gun

InactiveCN106625425ASimple structureLow processing and manufacturing costsNailing toolsEngineeringElectromagnet

The invention specifically relates to an electromagnetic nail gun, and belongs to the technical field of handheld tools. The electromagnetic nail gun comprises a gun body, and a nail clamping module arranged on the gun body; and the gun body includes a main body part and a handle part integrally arranged. The electromagnetic nail gun further comprises a power device arranged on the main body part; the power device includes a cylinder connected with the main body part, a collision pin slidingly sleeved on the cylinder, an electromagnet arranged on the cylinder for reciprocating driving of the collision pin, and an axial magnet arranged on the collision pin to bring convenience to the electromagnet for reciprocating driving of the collision pin; the electromagnet includes a skeleton connected with the cylinder, and a coil wound on the skeleton; and the coil is provided with a back wiring end, a front wiring end and a middle wiring end. The invention aims to slidingly arrange the collision pin on the electromagnet, directly performs reciprocating driving for the collision pin by the electromagnet, is simple in structure and reliable in operation, and meanwhile, solves the problem of higher wear of the collision pin and a slide way.

Owner:重庆福特来动力科技有限公司 +1

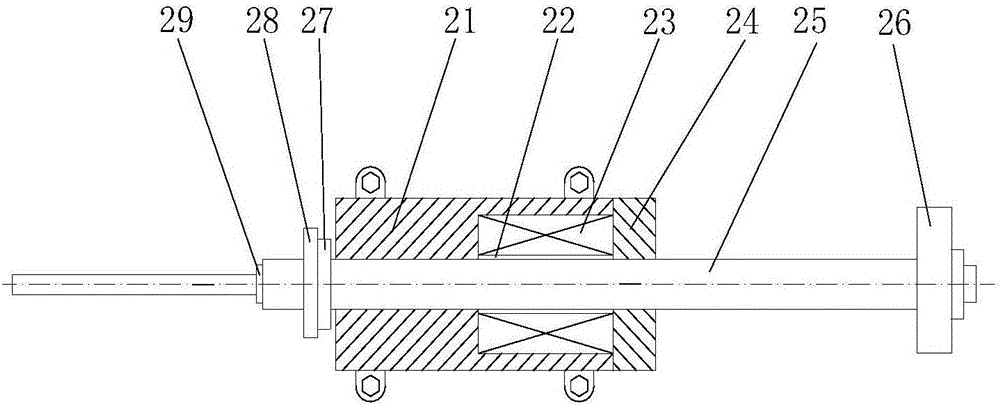

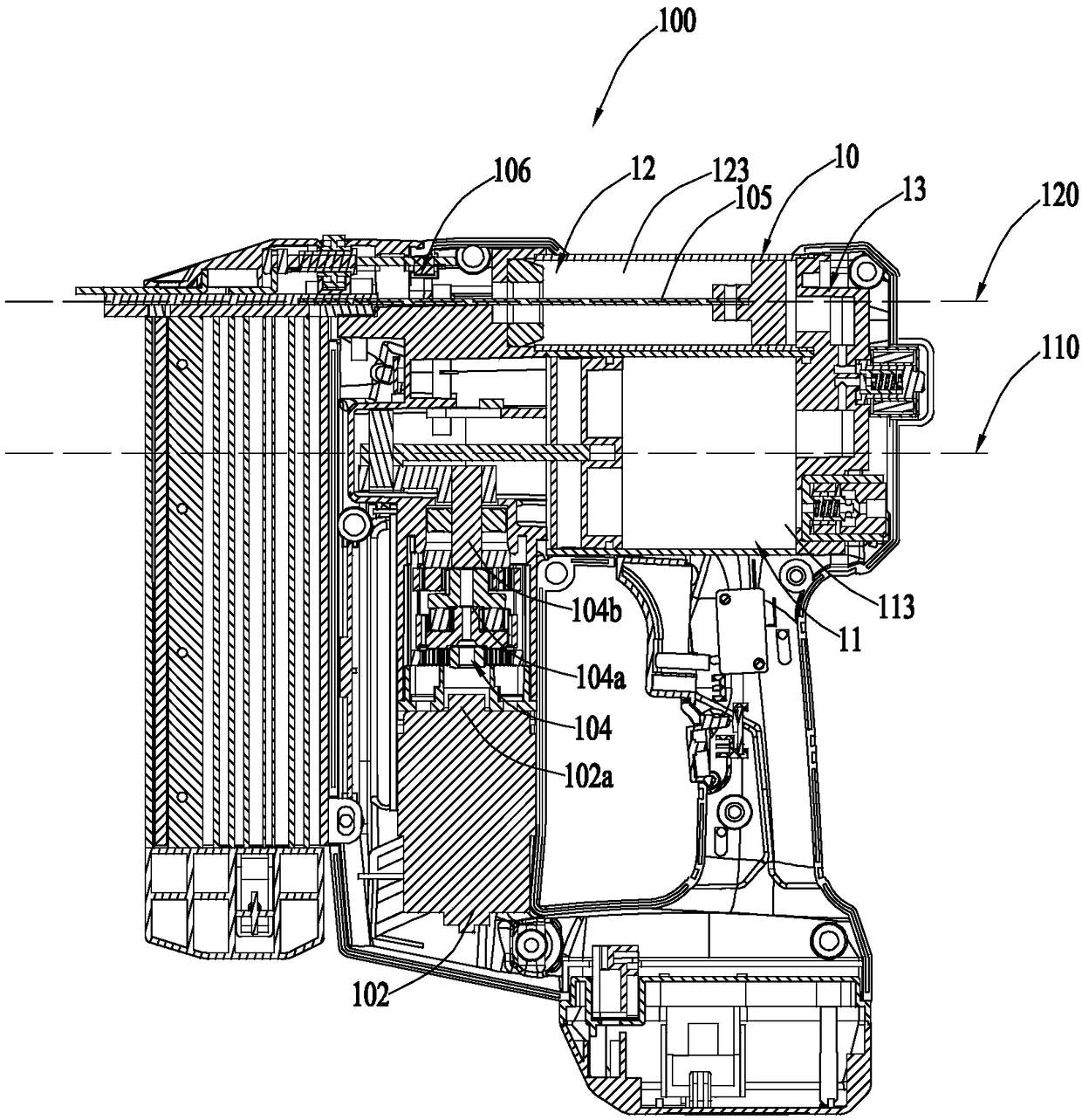

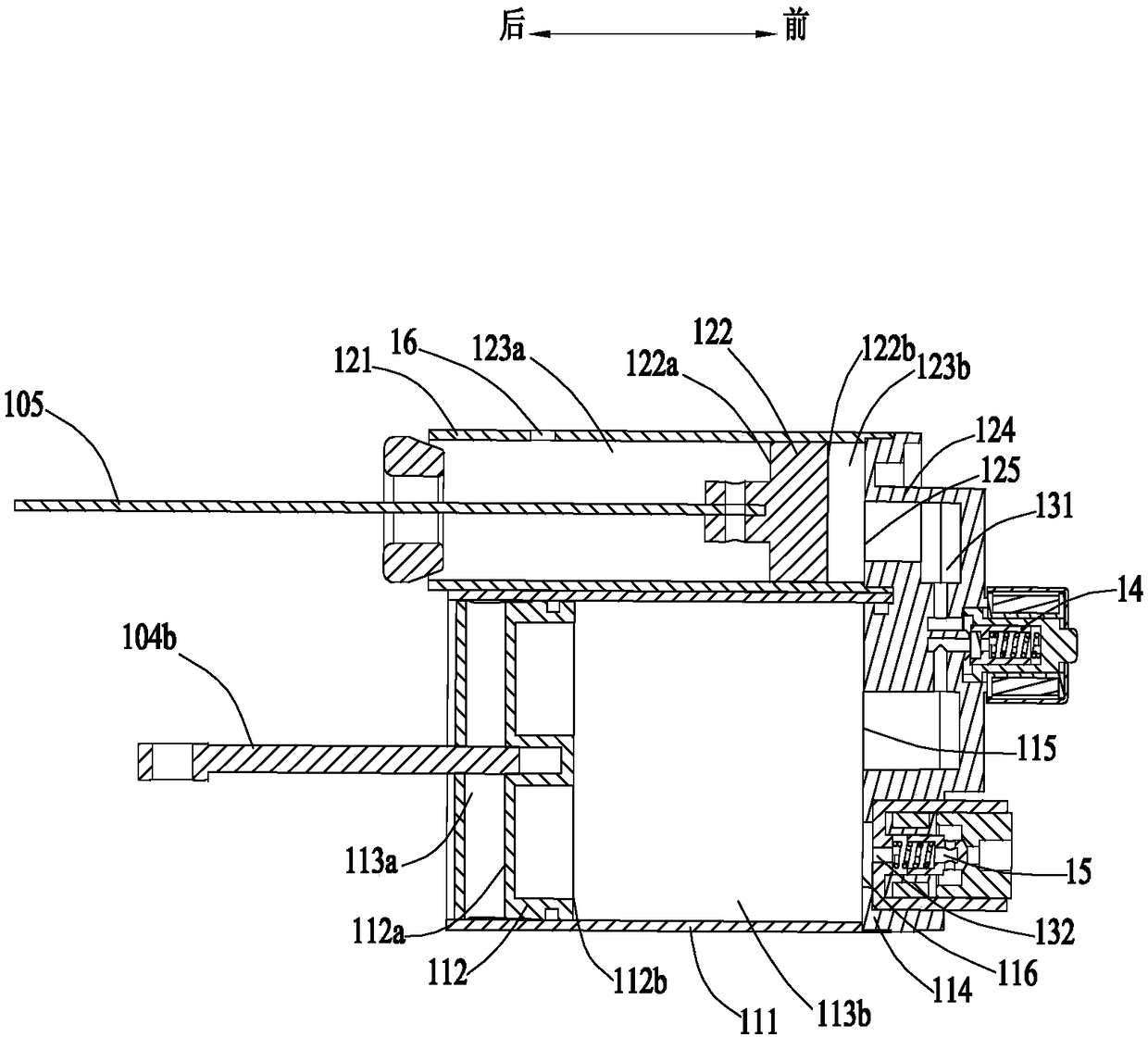

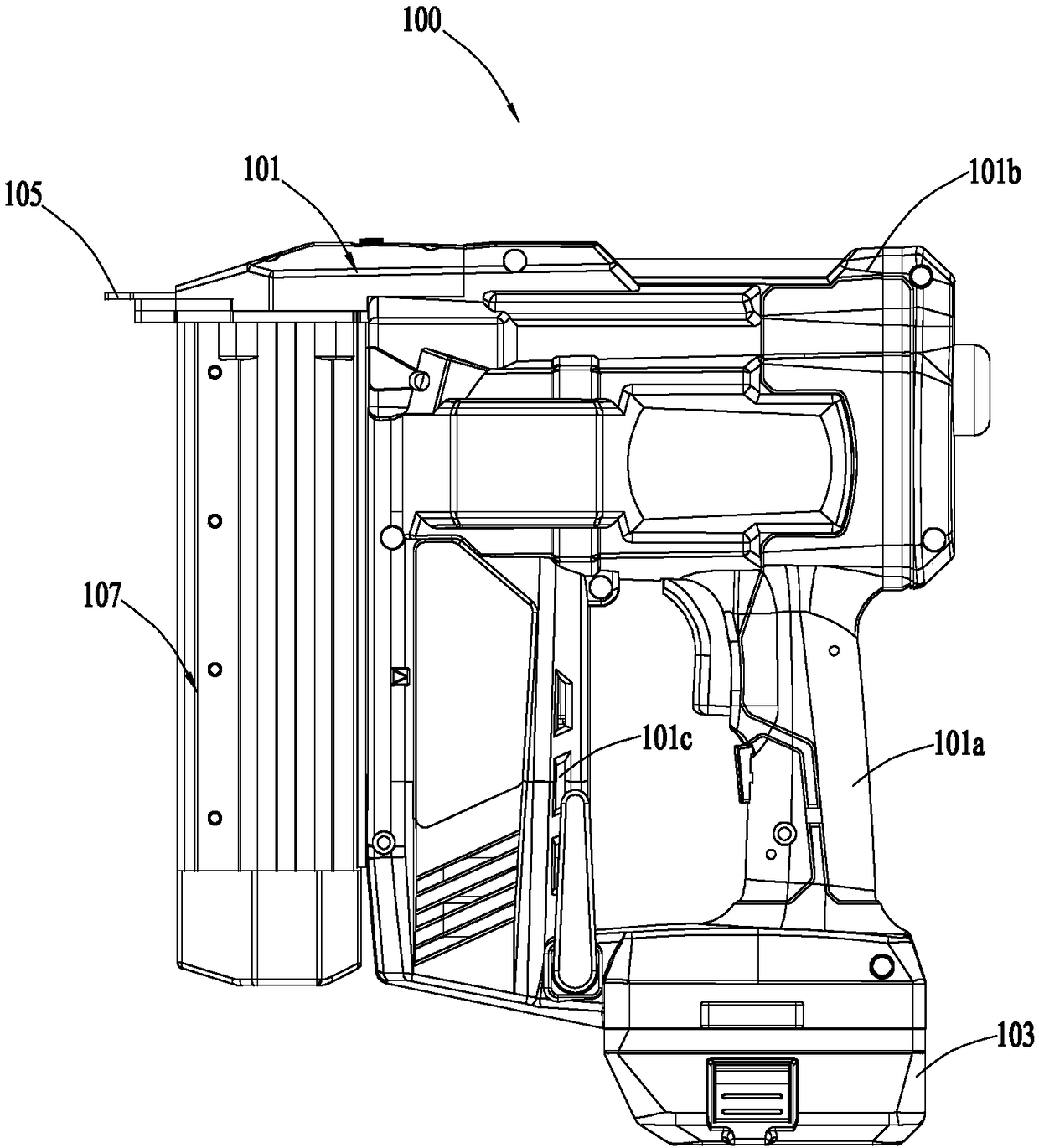

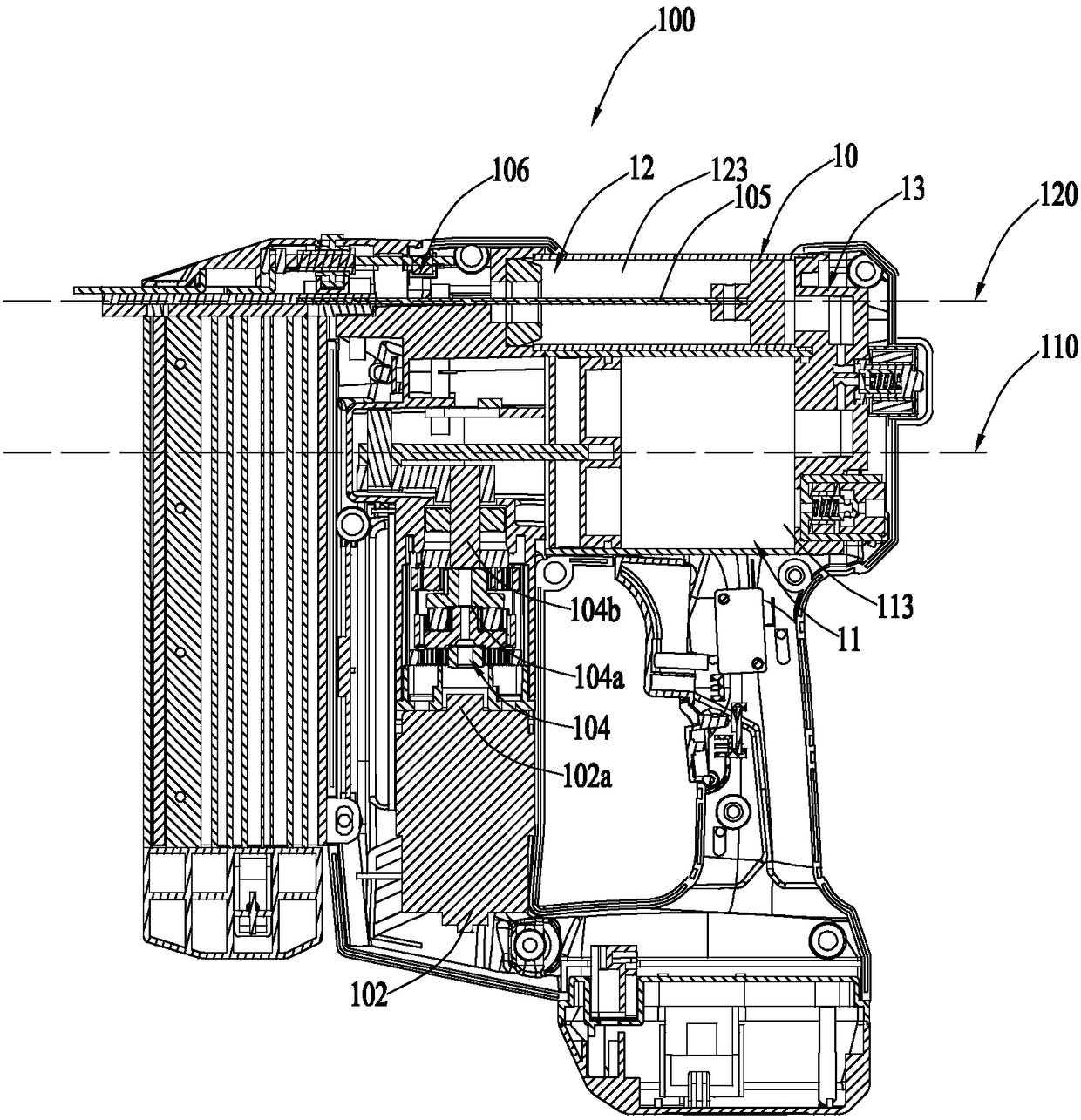

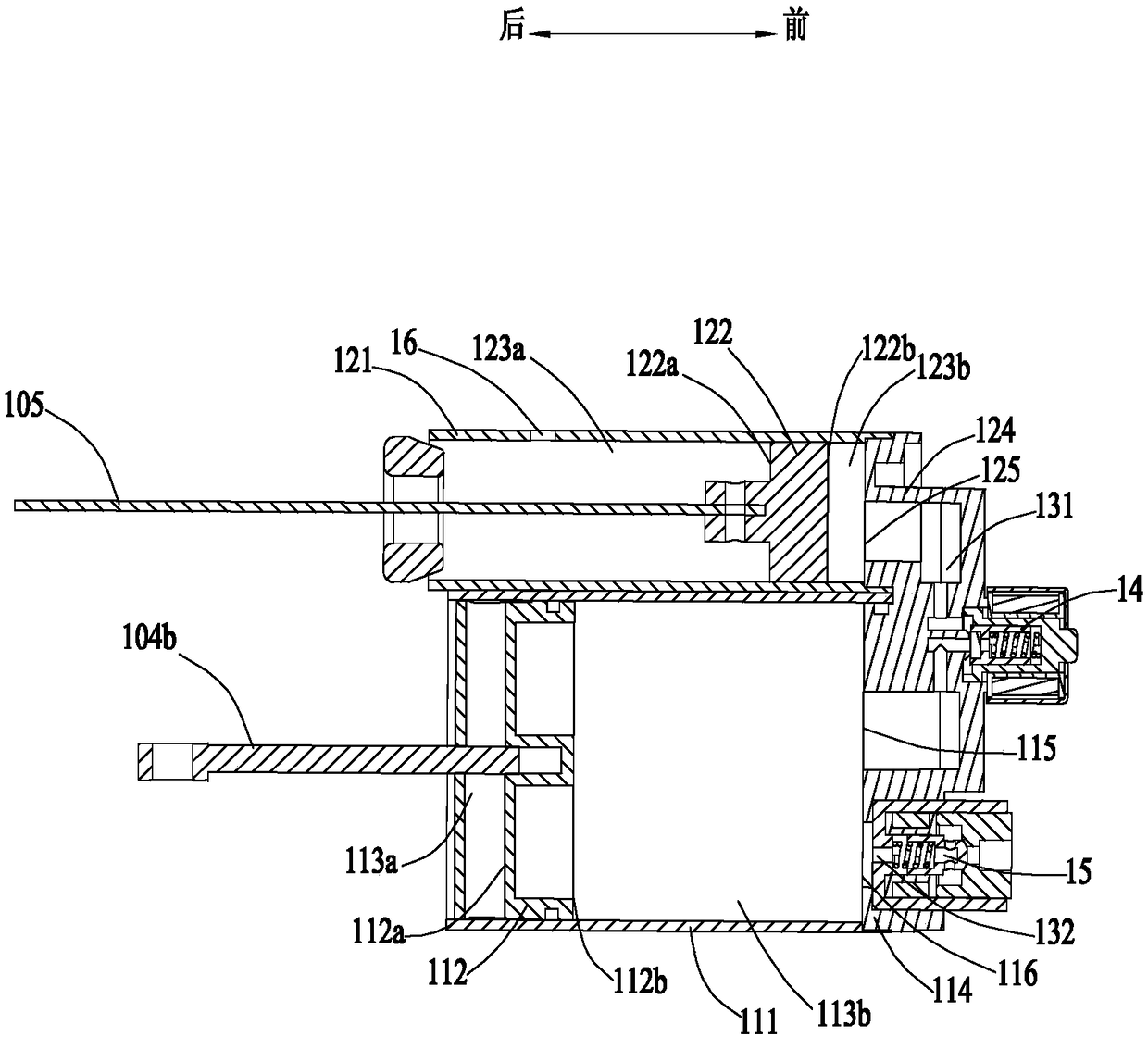

Air nailer

The invention discloses an air nailer, comprising a first cylinder, a second cylinder, a striker and a driving device, wherein the first cylinder comprises a first cylinder wall with a formed first chamber and a first piston; the second cylinder comprises a second cylinder wall with a formed second chamber and a second piston; the driving device comprises a driving member for driving the first piston; the first piston comprises a first surface connected with the driving member and a second surface; the second piston comprises a third surface connected with the striker and a fourth surface; thefirst chamber is divided by the first piston into a first chamber portion located on the side, where the first surface is arranged, of the first piston, and a second chamber portion located on the other side of the first piston; and the second chamber is divided by the second piston into a third chamber portion on the side, where the third surface is arranged, of the second piston, and a fourth chamber portion located on the other side of the second piston. The air nailer is further provided with a first air flow passage allowing the second chamber portion to communicate with the fourth chamber portion, and a second air flow passage allowing the first chamber portion to communicate with the third chamber portion. The air nailer provided by the invention has good nailing effect.

Owner:NANJING CHERVON IND

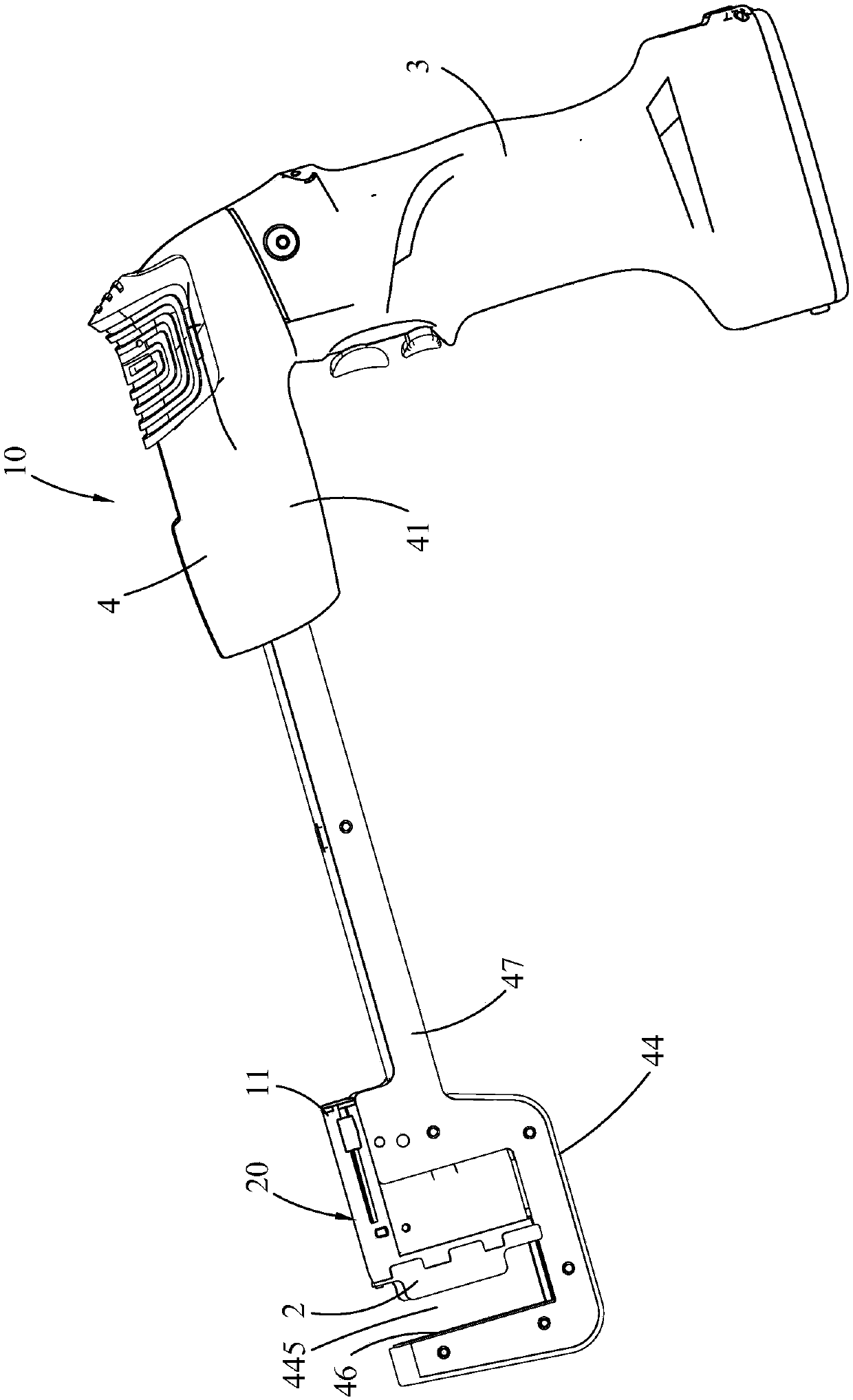

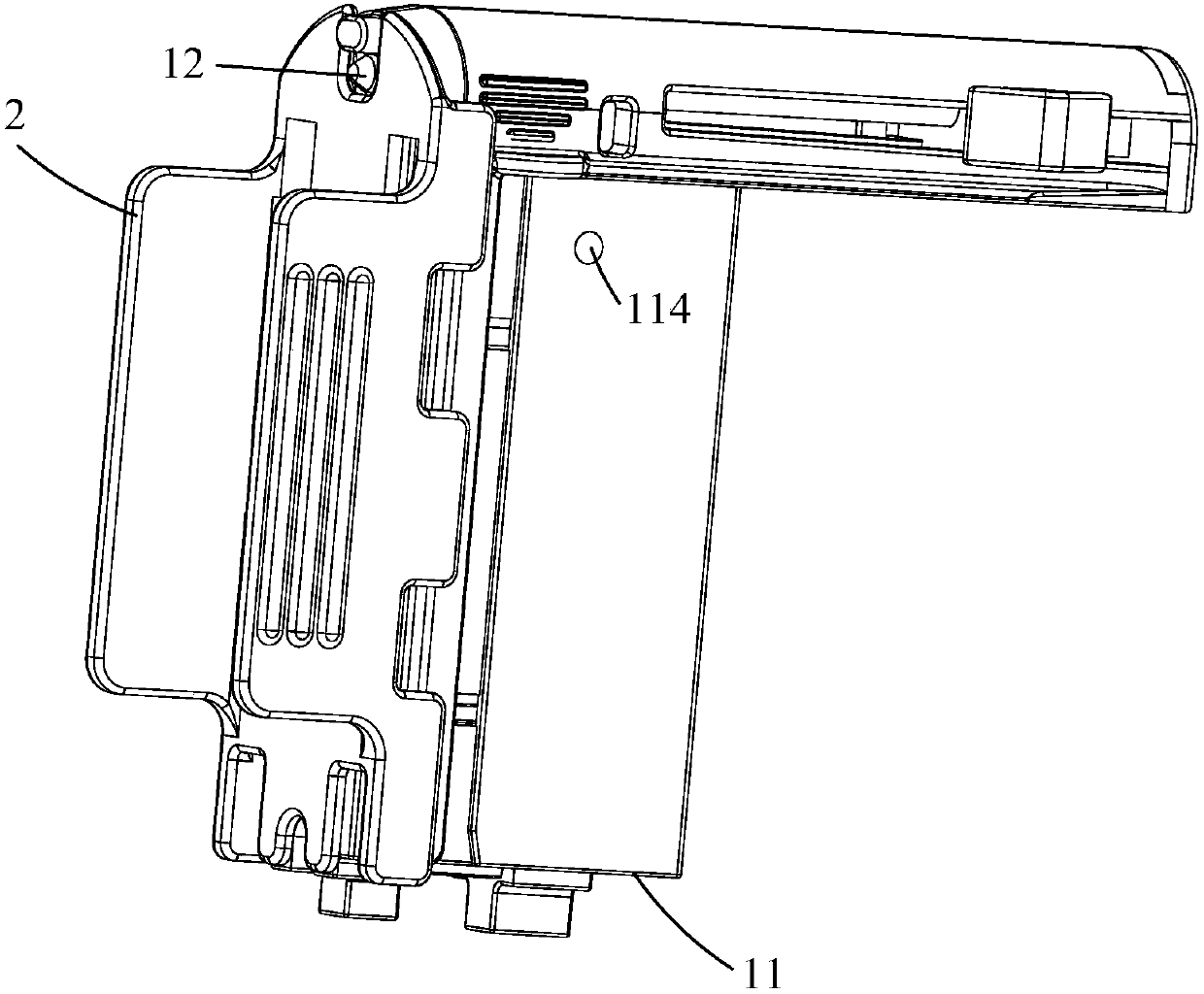

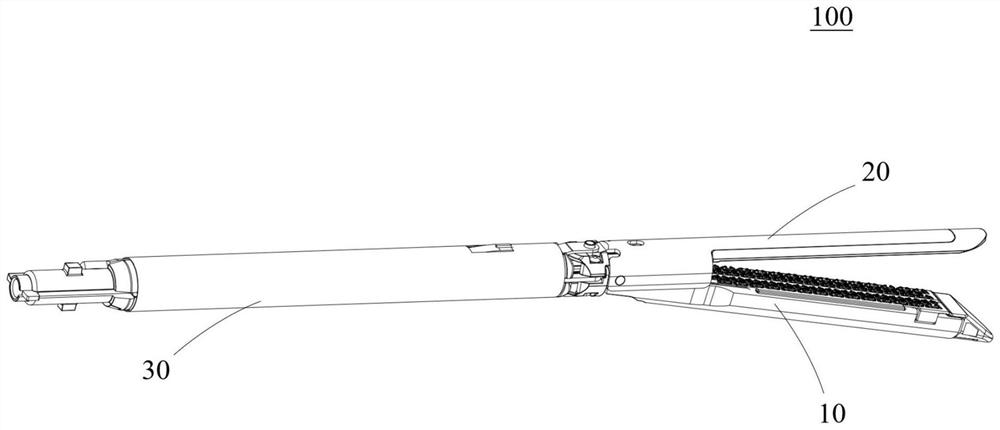

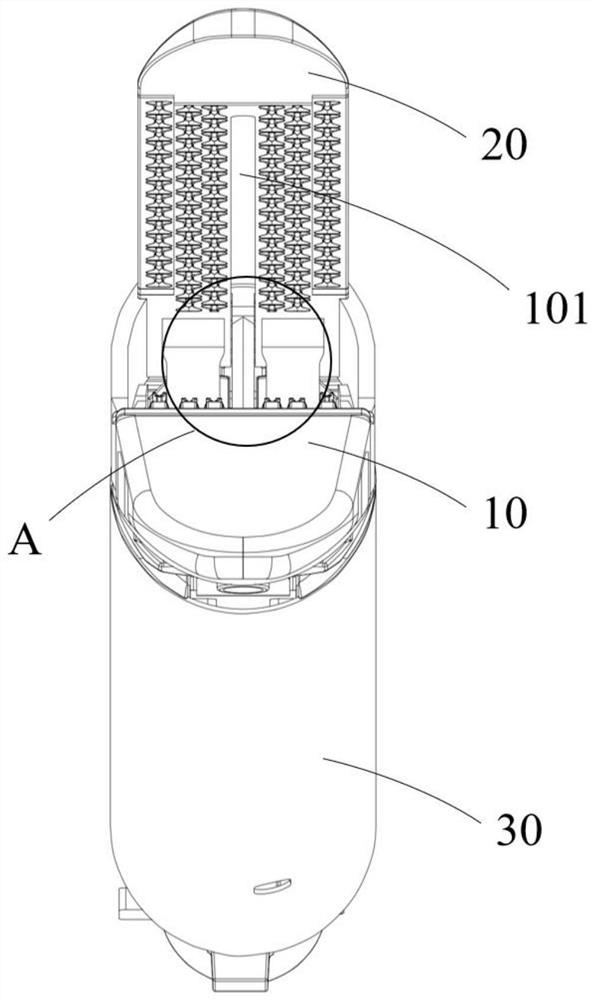

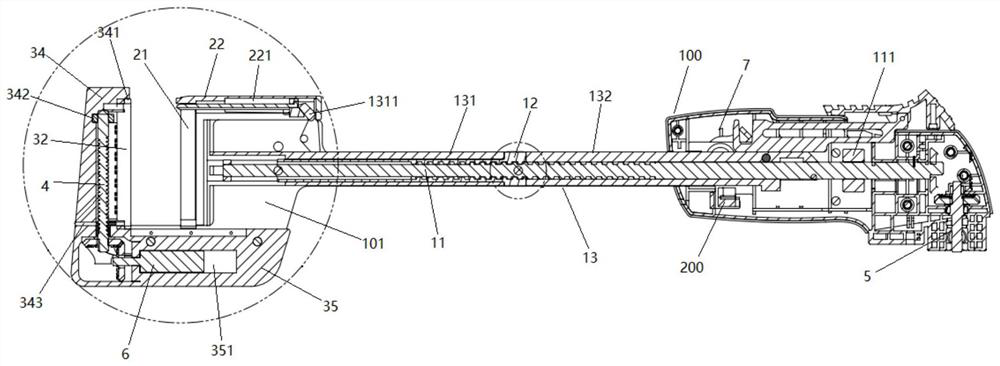

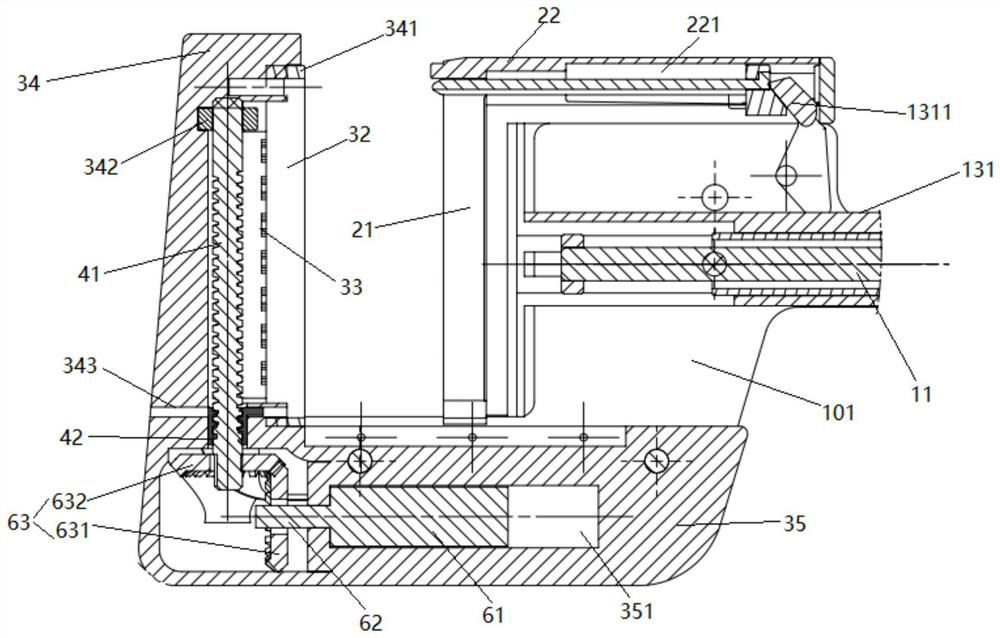

Surgical instrument

The invention relates to a surgical instrument which is used for suturing and cutting tissue. The surgical instrument comprises a gun body and a nail bin component arranged on the gun body, the gun body comprises a closing rod, a triggering rod, a nail anvil support and a nail anvil, the nail bin component is connected with the triggering rod and the closing rod and comprises a bin body, a suturing nail mounted in the bin body, a nail pushing plate for pushing the suturing nail out of the bin body and a cutting component capable of moving relative to the bin body, the cutting component is abutted against the nail pushing plate to enable the suturing nail to move out of the bin body, the triggering rod has a front end face abutted against the cutting component, and the front end face is arc-shaped or conical. The surgical instrument can improve nail forming effect of the suturing nail; after the front end face is arranged to be arc-shaped or conical, the nail anvil support does not needto be pre-bent, so that the surgical instrument is simpler to design and manufacture.

Owner:SUZHOU YINGTUKANG MEDICAL TECH CO LTD

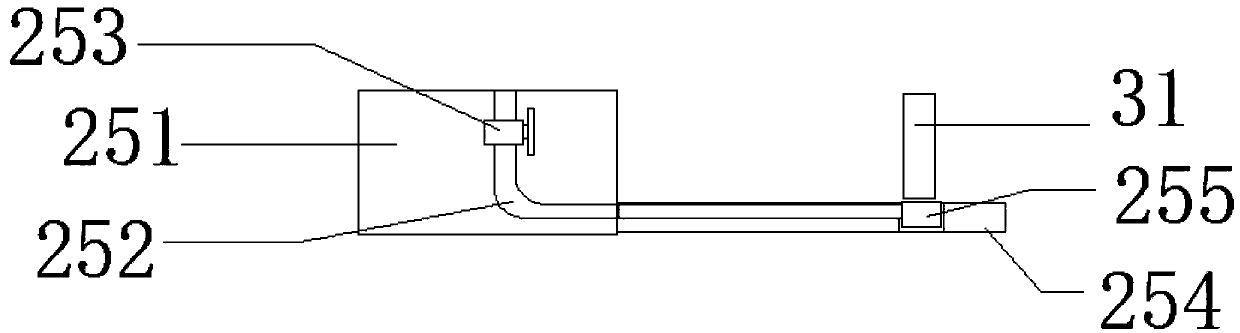

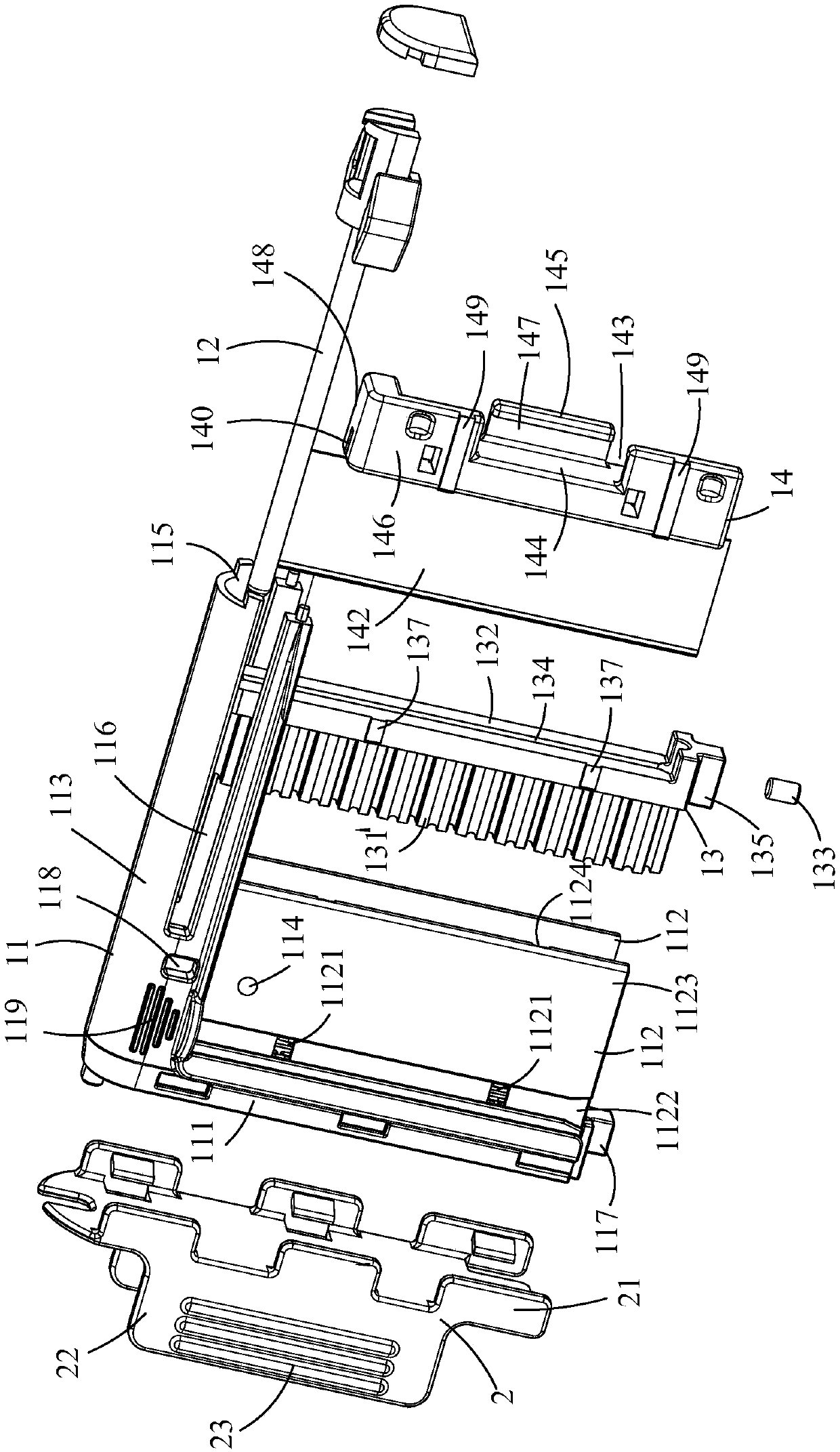

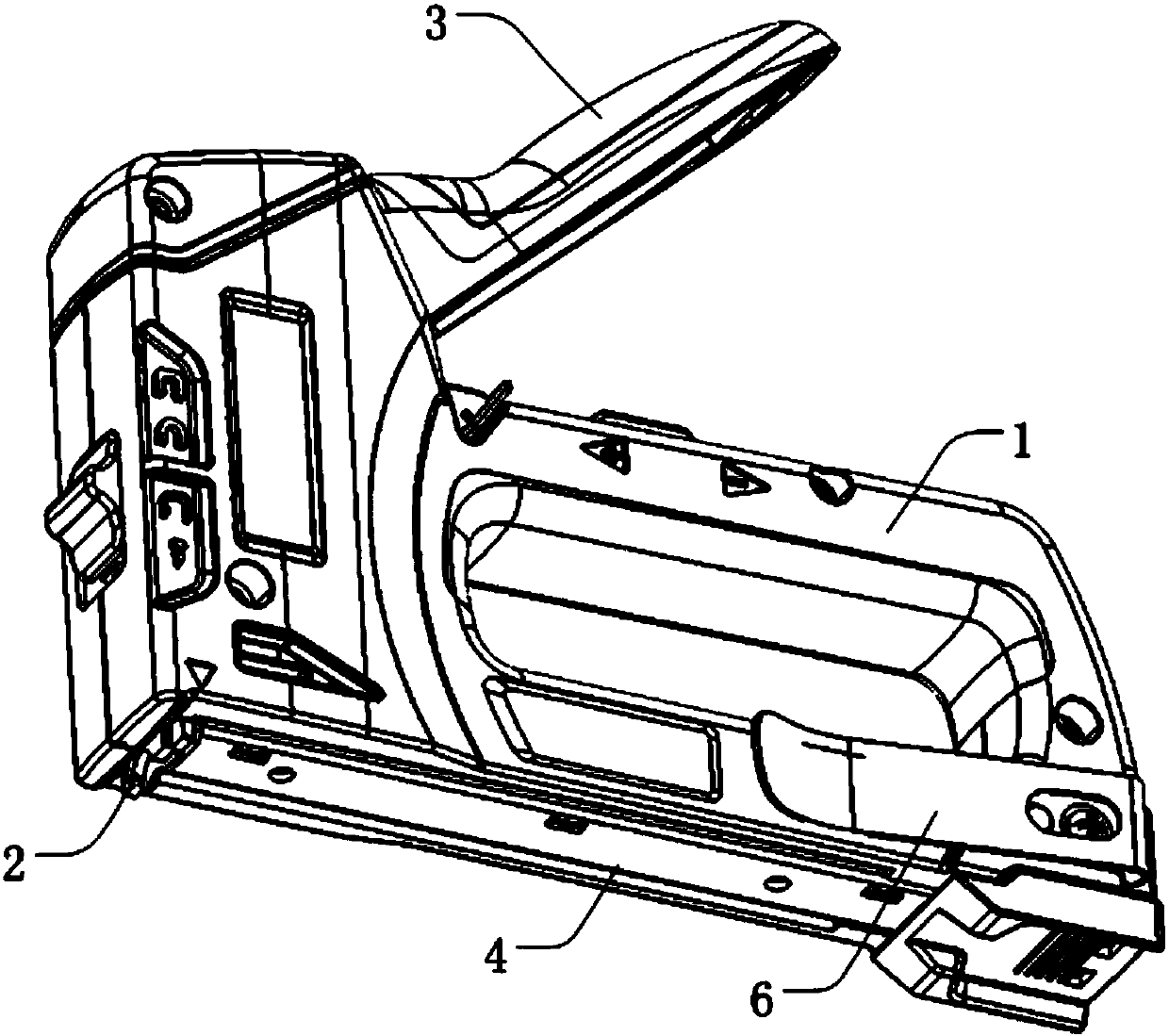

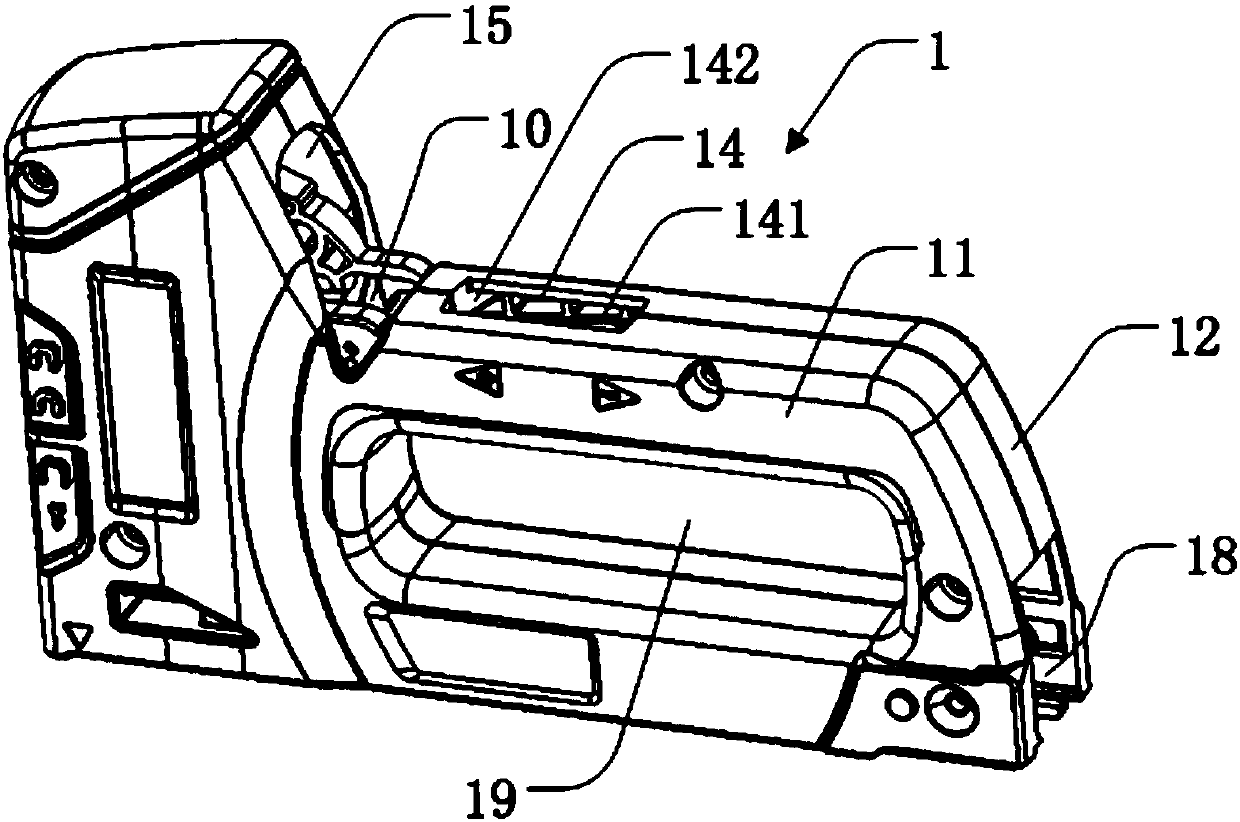

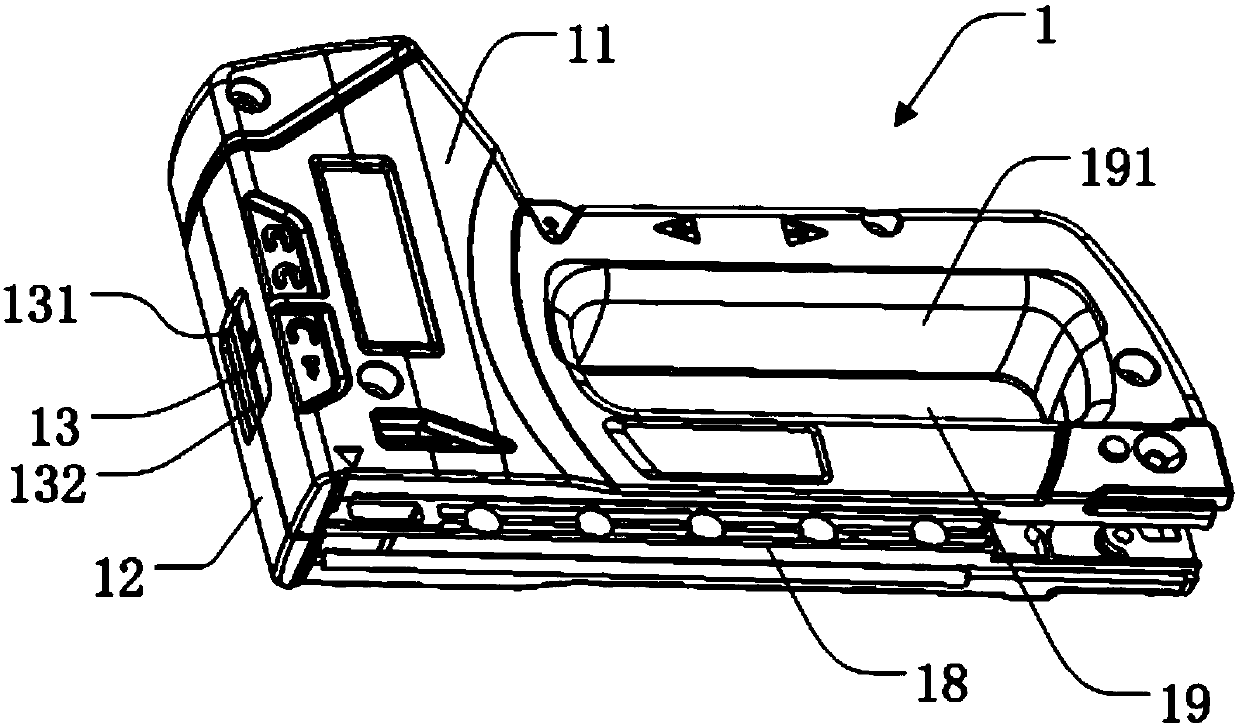

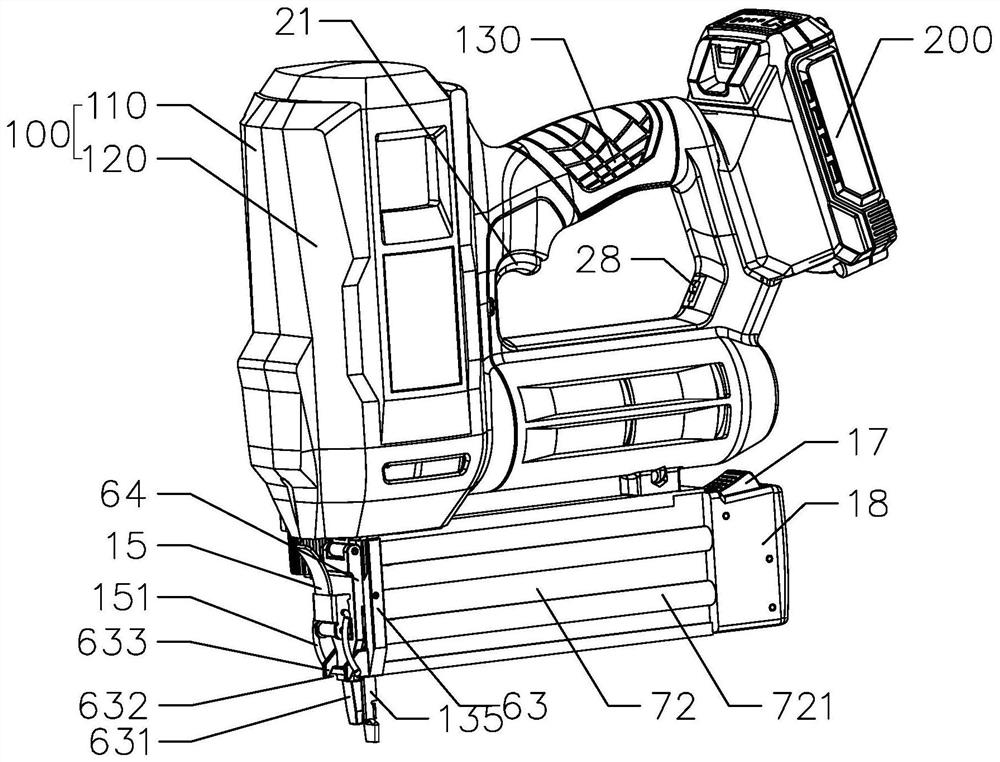

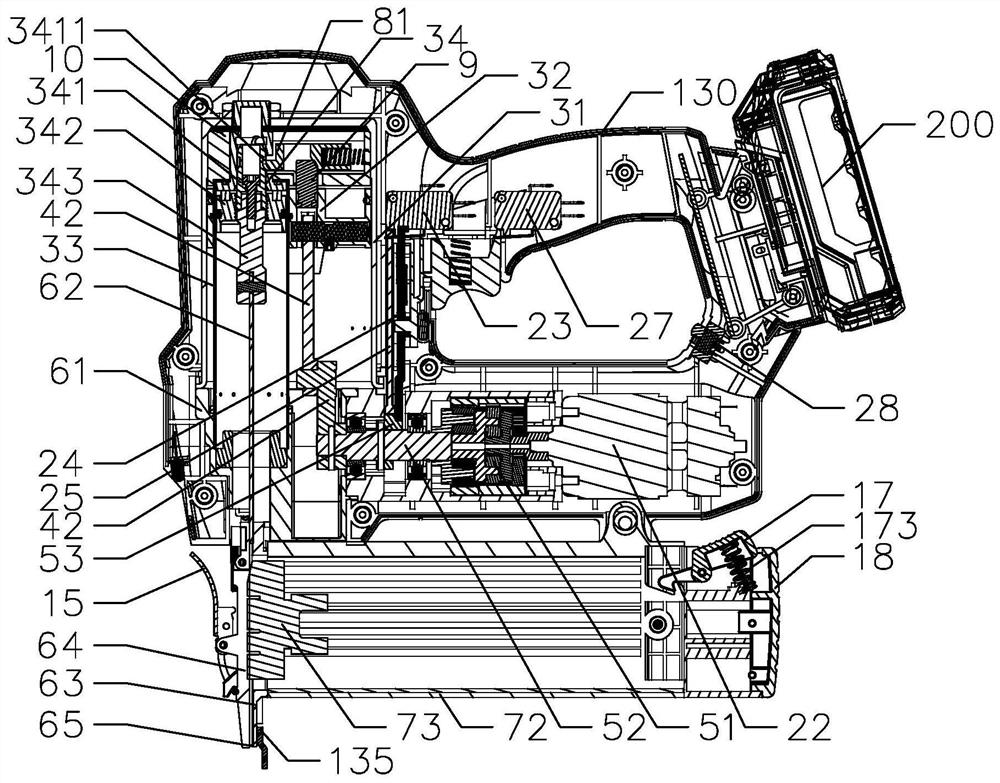

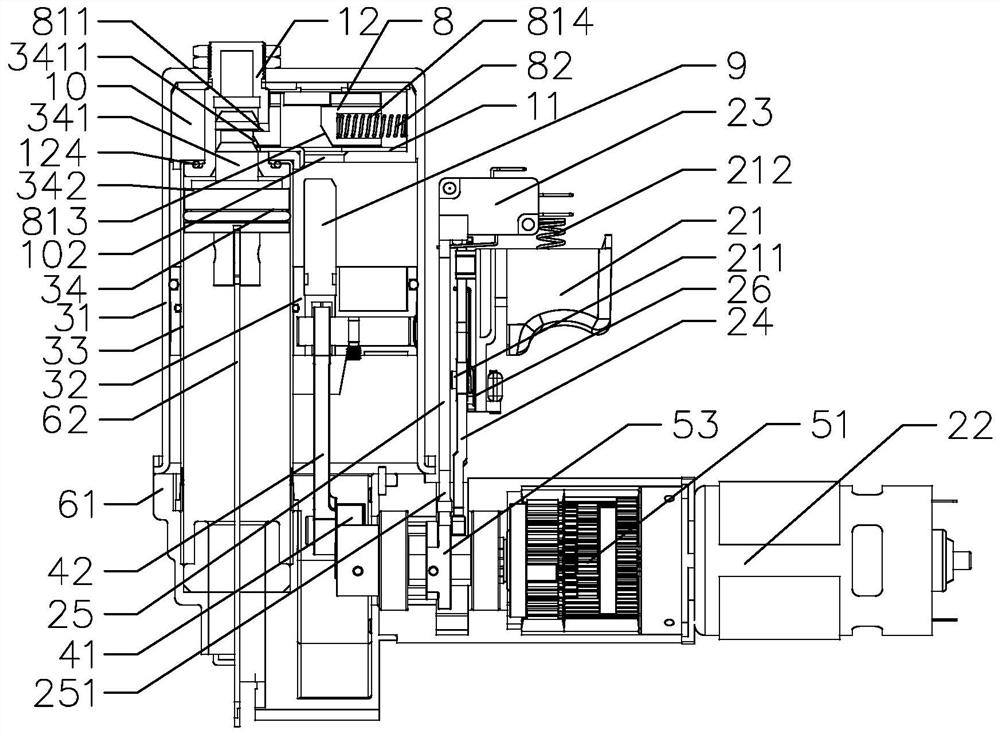

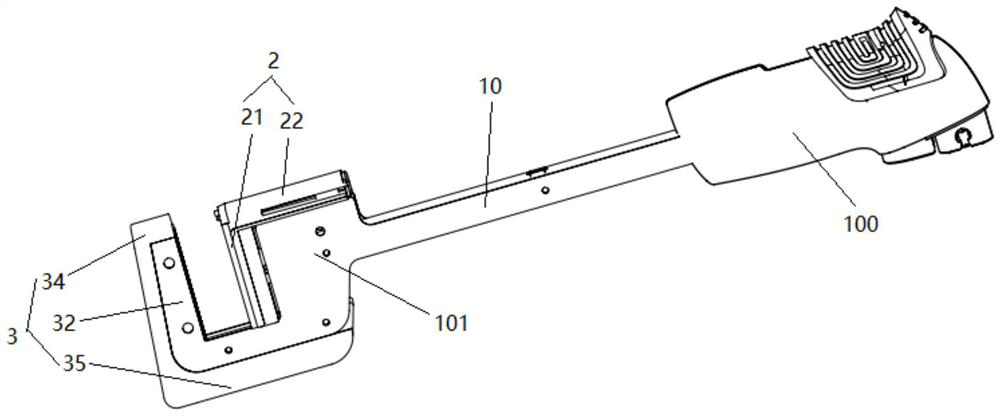

Multifunctional nail gun

PendingCN109571372ASimple structureReduce manufacturing costStapling toolsNailing toolsEngineeringNail gun

The invention provides a multifunctional nail gun. The multifunctional nail gun comprises a shell, a nailing part and a trip gear, wherein the nailing part is arranged at the front end of the shell, one part of the trip gear is arranged in the shell, and the other part of the trip gear extends to the outside of the shell; and the nailing part comprises a nail discharging part, a nail striking partand an adjusting device, wherein the nail discharging part is arranged at the front end of the bottom of the shell, a nail discharging groove is formed in the surface of one side of the nail discharging part, and is used for containing nails, a part of the nail striking part is inserted into the nail discharging groove, the trip gear controls the nail striking part to strike the nails, one part of the adjusting device is arranged outside the shell, and the adjusting device is used for adjusting the depth of the nail discharging groove.

Owner:HANGZHOU GREAT STAR IND CO LTD +1

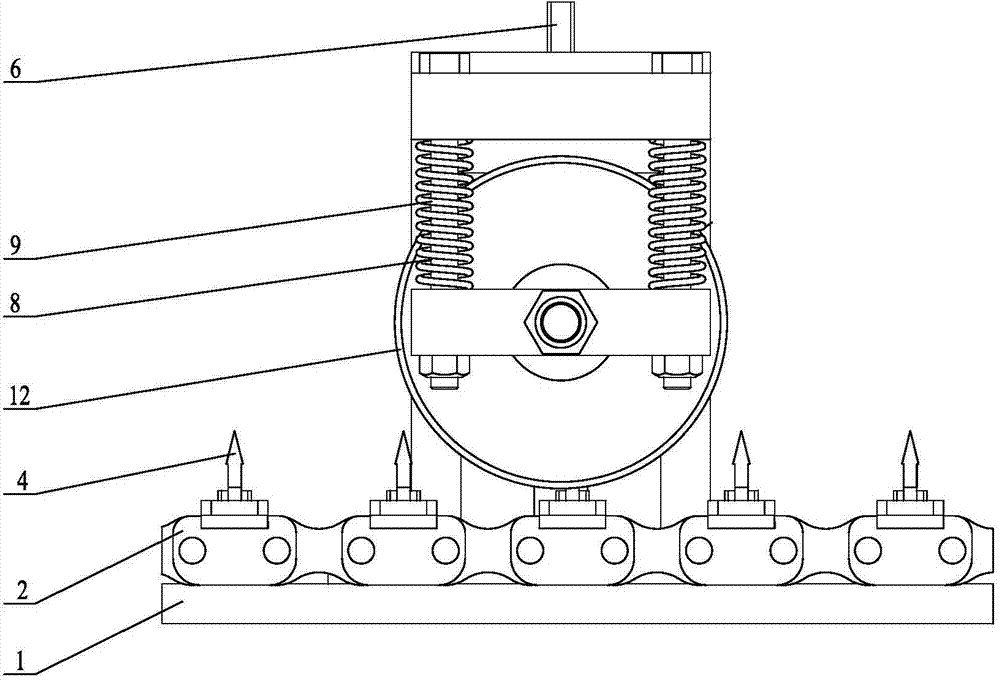

Automobile ceiling automatic line plate nailing mechanism

The invention relates to an automobile ceiling automatic line plate nailing mechanism. A conveying chain is arranged on a chain bracket, a nail seat is fixedly arranged at the outer side wall of the conveying chain, and a chain nail is fixedly arranged on the nail seat; the inner side of the chain bracket is provided with a regulating screw rod installing seat, a regulating screw rod is rotationally arranged on the regulating screw rod installing seat, a regulating screw nut is screwed on the regulating screw rod, a spring installing seat is fixedly arranged on the regulating screw nut, a spring post is fixedly arranged on the spring installing seat, a spring sleeves the spring post, a press wheel shaft installing seat is glidingly arranged on the spring post arranged under the spring, a press wheel shaft is fixedly arranged on the press wheel shaft installing seat, a press wheel is rotationally arranged on the press wheel shaft, the middle part of the wheel surface of the press wheel is provided with an annular groove, the annular groove corresponds to the chain nail, and in addition, the depth of the annular groove is greater than the height of the chain nail. The automobile ceiling automatic line plate nailing mechanism has the advantages that the nailing mechanism is simplified, the equipment cost and the energy source consumption are reduced, the nailing effect is improved, the product rejection rate is reduced, and the repair and the maintenance of equipment are convenient.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

Improved structure of nail-slot nail-ejection of nailing machine

InactiveCN101069963ANail structure improvementImprove nailing effectStapling toolsNailing toolsEngineeringElectrical and Electronics engineering

Owner:APEX MFG

Air inflated pistol

The invention discloses an inflated pistol, which comprises a pistol body and a pistol bore arranged in the pistol body. Symmetric first air cavities are formed in upper and lower inner walls of the pistol bore in a communication mode; second air cavities located at the left ends of the first air cavities are formed in the upper and lower inner walls of the pistol bore in a communication mode, anda third air cavity is formed in the inner wall of the right end of the pistol bore in a communication mode; an impact pipe body is arranged on the end face of the left end of the pistol bore, the impact pipe body is internally provided with an impact channel, The tail end of the right end of the impact pipe body is fixedly connected with a launching valve located in the third air cavity, the launching valve is internally provided with a launching cavity with a leftward opening and communicates with the impact channel, elastic switch valve assemblies located in the first air cavities are arranged on the upper and lower wall bodies of the impact pipe body, and openings are formed in the upper and lower wall bodies of the impact pipe body in a communication mode.

Owner:玉环市万进新能源科技有限公司

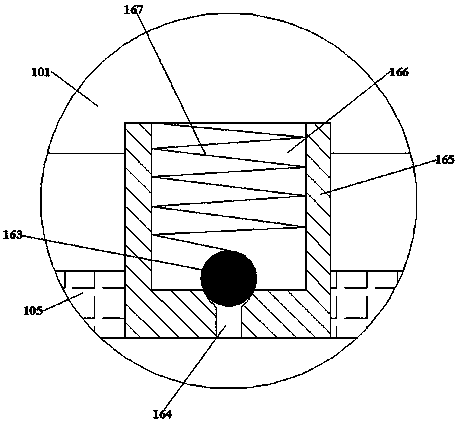

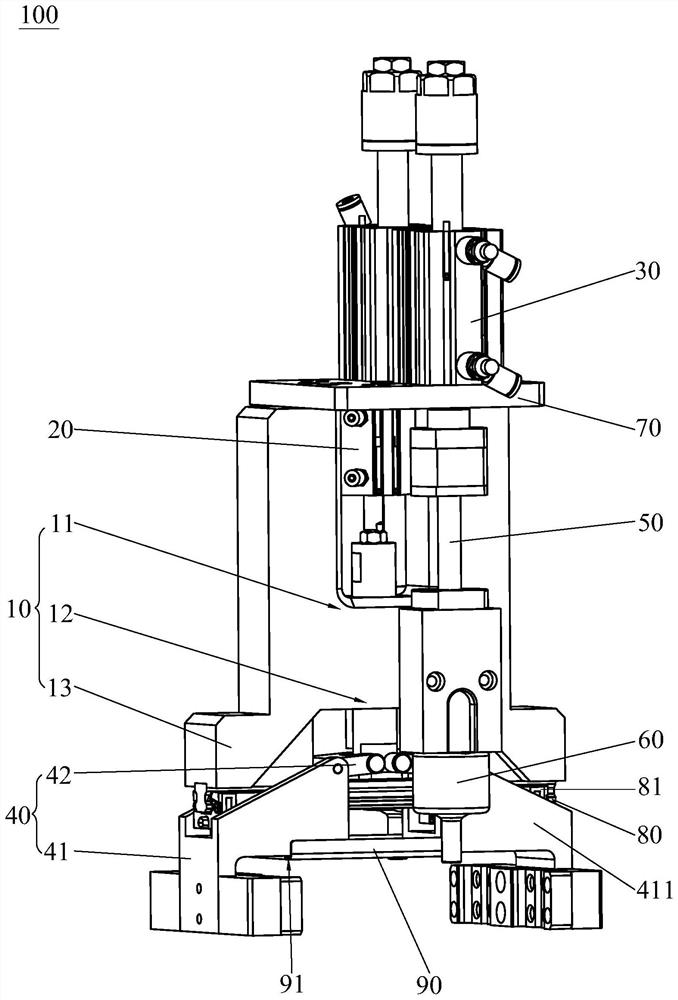

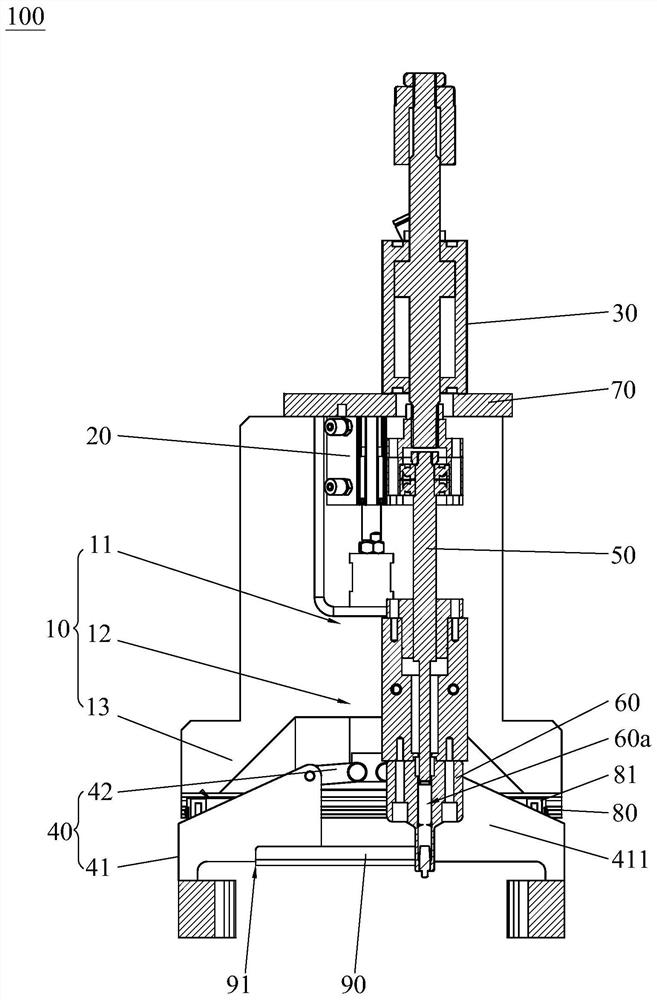

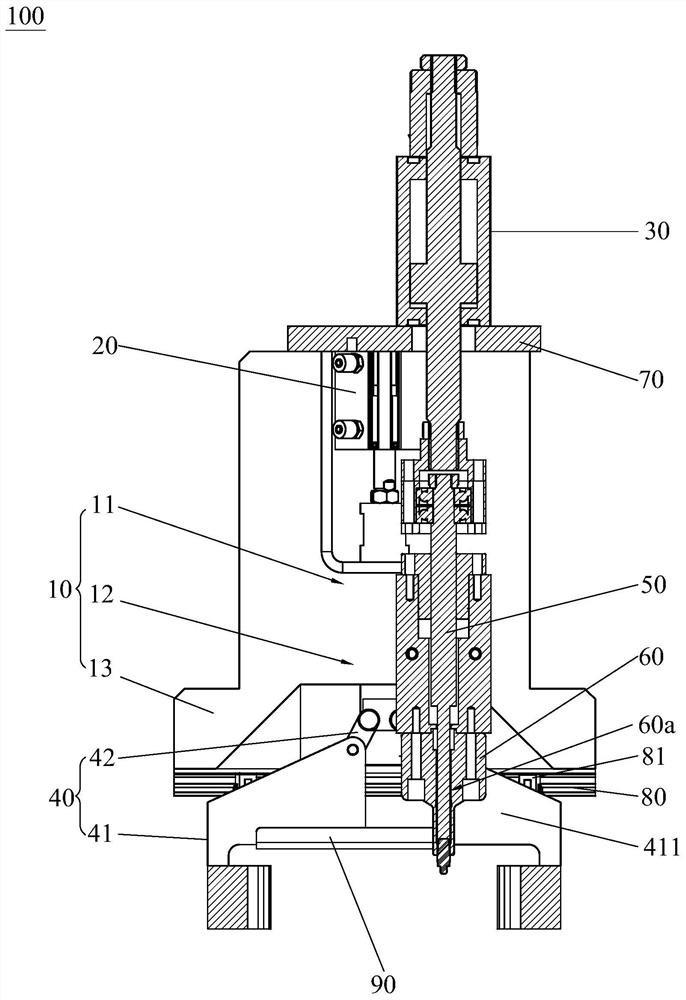

Robot nailing mechanism

ActiveCN108933297BEasy to prepare nailsImprove nailing effectFinal product manufactureSecondary cells charging/dischargingClassical mechanicsStructural engineering

The invention discloses a nailing mechanism of a manipulator, comprising a fixed seat, a first driving device, a second driving device, a gripper, a nailing rod and a nailing head, the first driving device and the second driving device are both arranged on the fixing seat, The jaws are set under the fixing base, and the nailing head is set on the side of the fixing base and above the jaws. The first driving device drives the jaws to clamp or loosen the battery, and the second driving device drives the nailing rod through the nailing rod. The nail head nails the clamped battery. When nailing the lithium battery, first drive the jaws to clamp the lithium battery through the first driving device, and then drive the nailing rod through the second driving device so that the nailing head nails the lithium battery; after the nailing is completed Finally, the second driving device line drives the nailing rod back so that the nail head is prepared for nailing. At this time, the first driving device drives the jaws to release the lithium battery; The nail heads are relatively stationary, which makes the nailing effect of the lithium battery better.

Owner:DONGGUAN TEC RICH ENGINEERING CO LTD

A bearing wall board and a method of producing the same

InactiveCN101219878AHigh strengthImprove flexibilityConstruction materialSolid waste managementFiberPolymer science

Owner:NICHIHA CORP

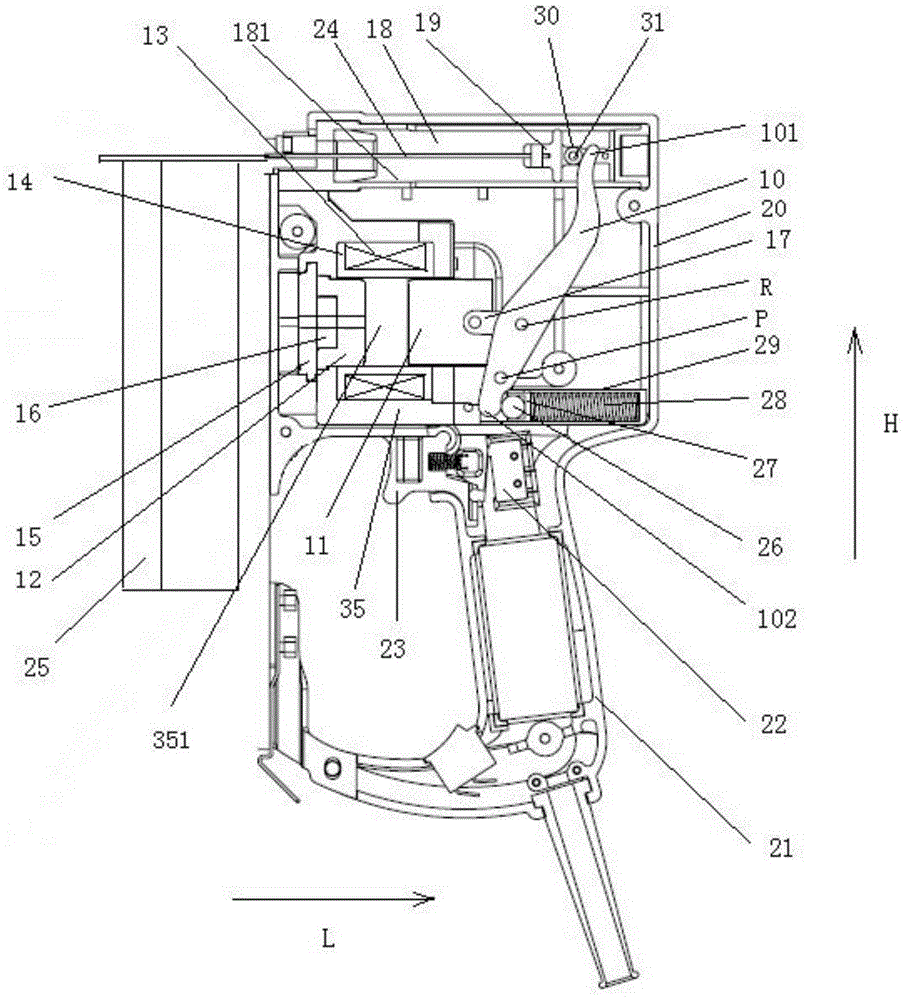

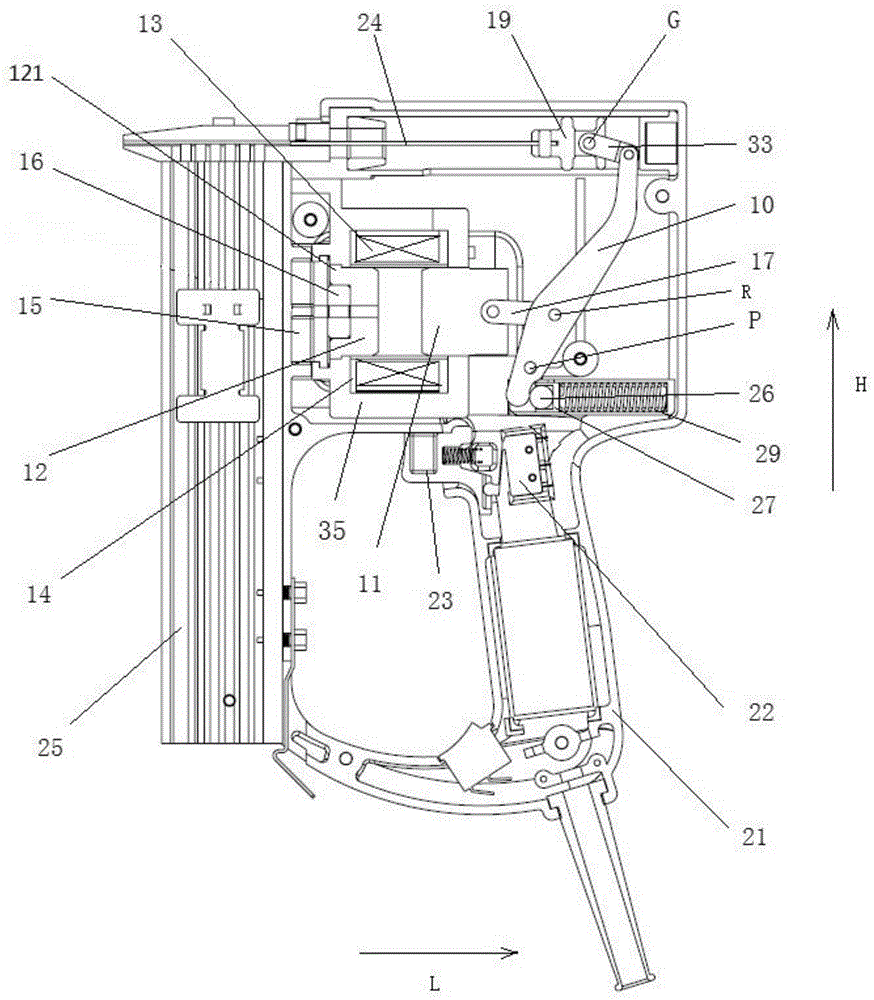

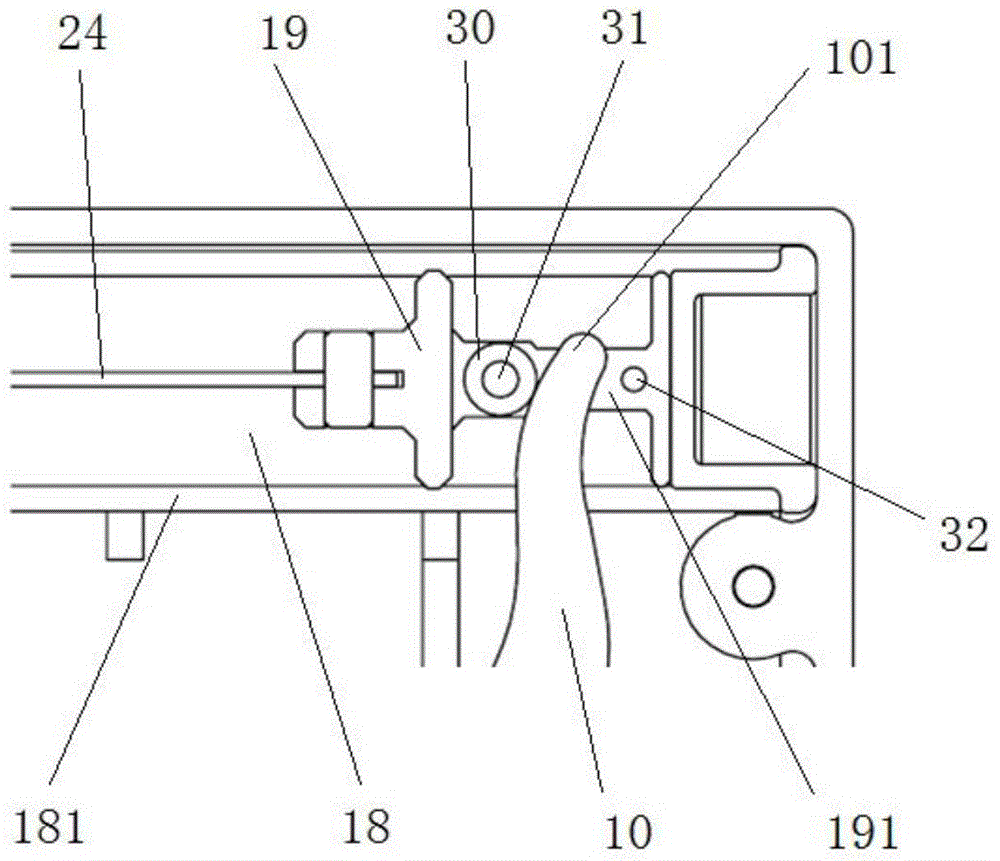

Electromagnetic nailing gun

InactiveCN105082063AReduce kinetic energyReduce movement speedNailing toolsHigh energyRestoration device

An electromagnetic nail gun includes a lever (10), a lever driving device and a slide device. The lever driving device includes an electromagnet and a driving iron core (11), the driving iron core (11) being connected to the lever and reciprocated in a predetermined direction to drive the lever to rotate. The electromagnet is used for driving the iron core to move. The slide device includes a slideway (18) and a slide (19) which could be brought to move along the slideway by the lever. The electromagnetic nail gun further includes a restoration device which could restore the lever after the electromagnetic nail gun finishes one nailing. The restoration device comprises a spring (28), the spring (28) applying a force on the lever to restore the lever. The maximal stretching amount of the spring is less than a stroke of the driving iron core. Due to the low velocity of a centroid of the spring, a driving force produced by the driving iron core is only fractionally transformed into kinetic energy of the spring. The electromagnetic nail gun has the advantages of high energy utilization rate and good nailing effect.

Owner:BEIJING DAFENG TECH

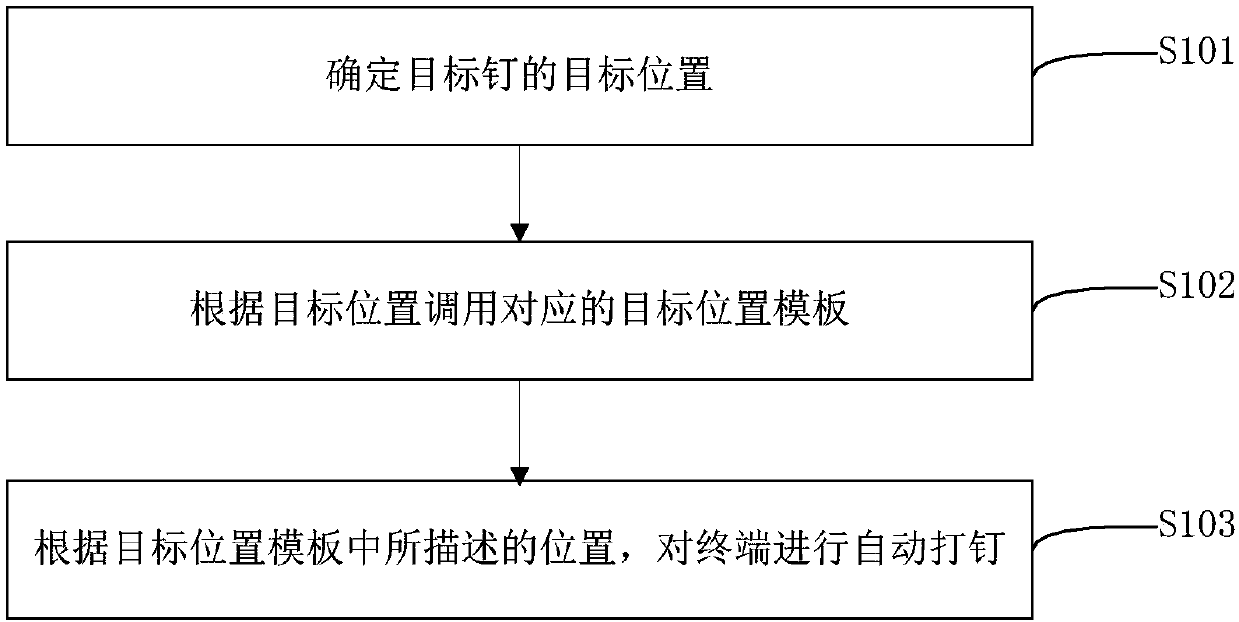

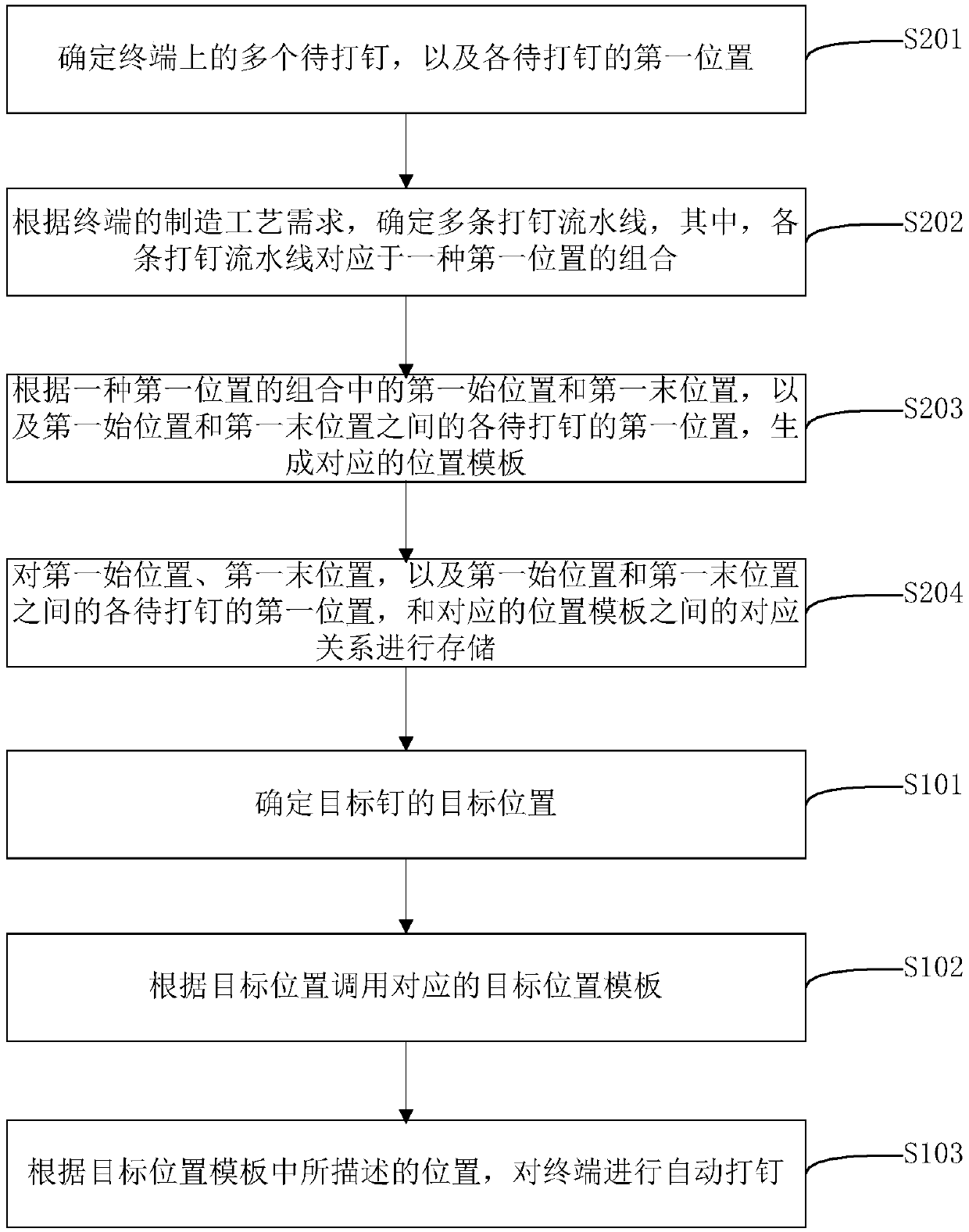

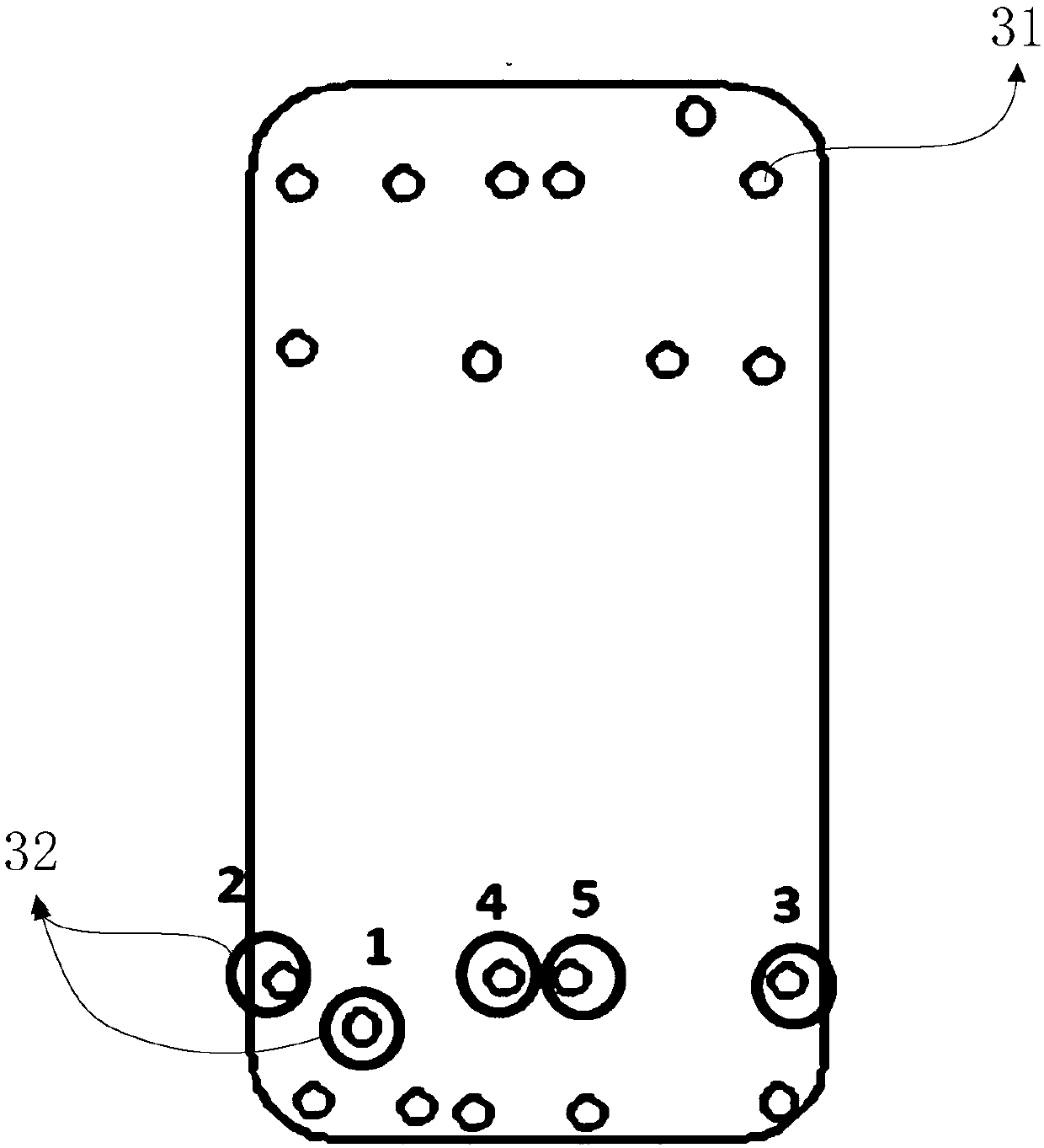

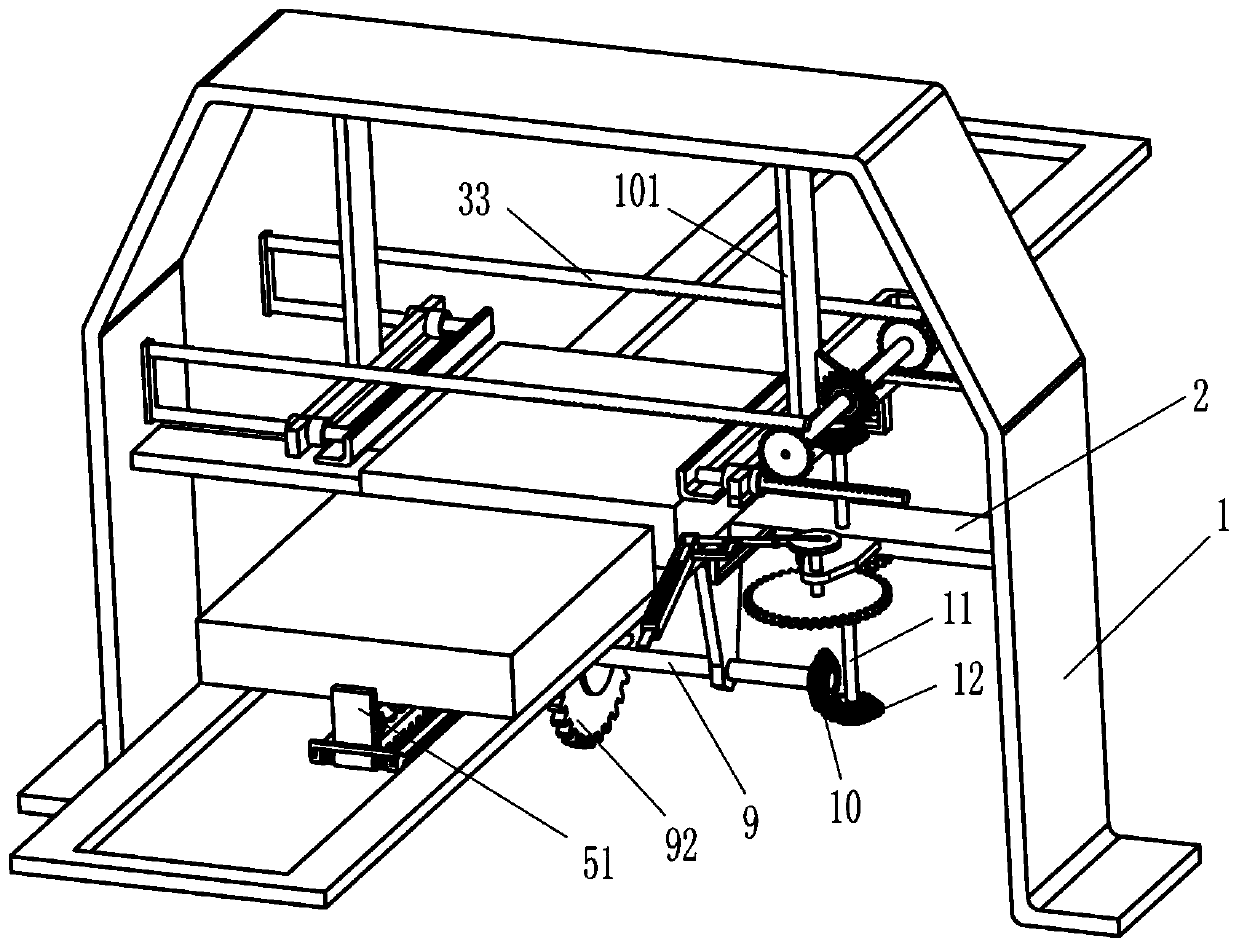

Terminal screw locking method, device and storage medium

ActiveCN109531730AHigh degree of automationImprove nailing effectStapling toolsNailing toolsComputer terminalEngineering

The invention provides a terminal screw locking method and device and a storage medium. The terminal screw locking method comprises the steps that a target position of a target screw is determined; acorresponding target position template is called according to the target position; and a terminal is automatically locked with screws according to the position described in the target position template. According to the terminal screw locking method and device and the storage medium, the automation degree of the terminal screw locking can be effectively improved, and the screw locking effect is improved.

Owner:OPPO CHONGQING INTELLIGENT TECH CO LTD

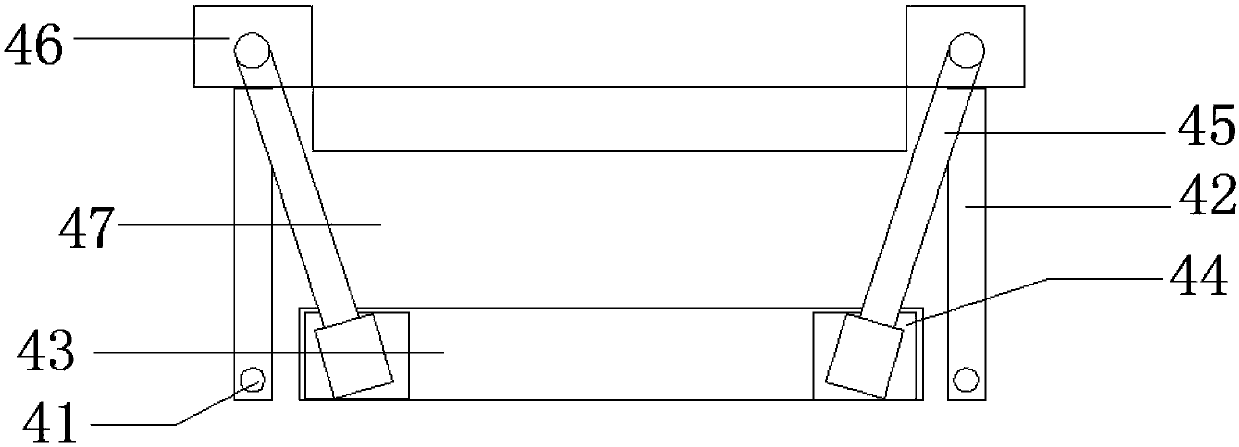

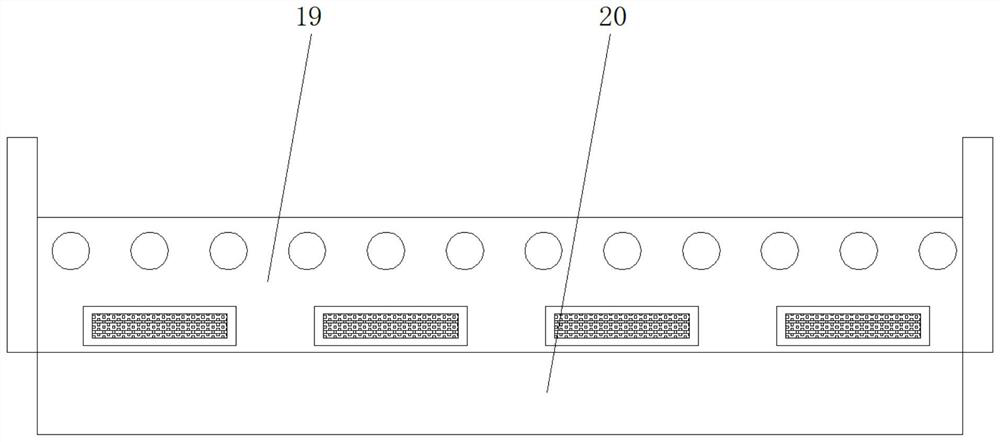

Television packaging edge folding and nailing device

ActiveCN111498203AImprove nailing efficiencyEasy to nailWrapper twisting/gatheringCartonStructural engineering

The invention relates to the technical field of packaging carton processing, in particular to a television packaging edge folding and nailing device. The television packaging edge folding and nailingdevice can work in cooperation with a television packaging assembly line, carries out rapid nailing operation on packaging cartons and is good in nailing effect. The television packaging edge foldingand nailing device comprises a mounting base, connecting frames, a hollow frame, a supporting rod, sliding rods, a connecting rod, a shifting device and the like; the two connecting frames are fixedlyinstalled on one side face of the mounting base, the hollow frame is fixedly installed on one side face of the mounting base, the supporting rod is fixedly installed on one side face of the hollow frame, the supporting rod is sleeved with the two sliding rods in a sliding mode, and the shifting device is arranged at one ends of the two sliding rods. The television packaging edge folding and nailing device can work in cooperation with a packaging assembly line of televisions, continuous nailing operation is conducted on packaging boxes in the conveying process, and the nailing efficiency is high.

Owner:合肥智龙机械设计有限公司

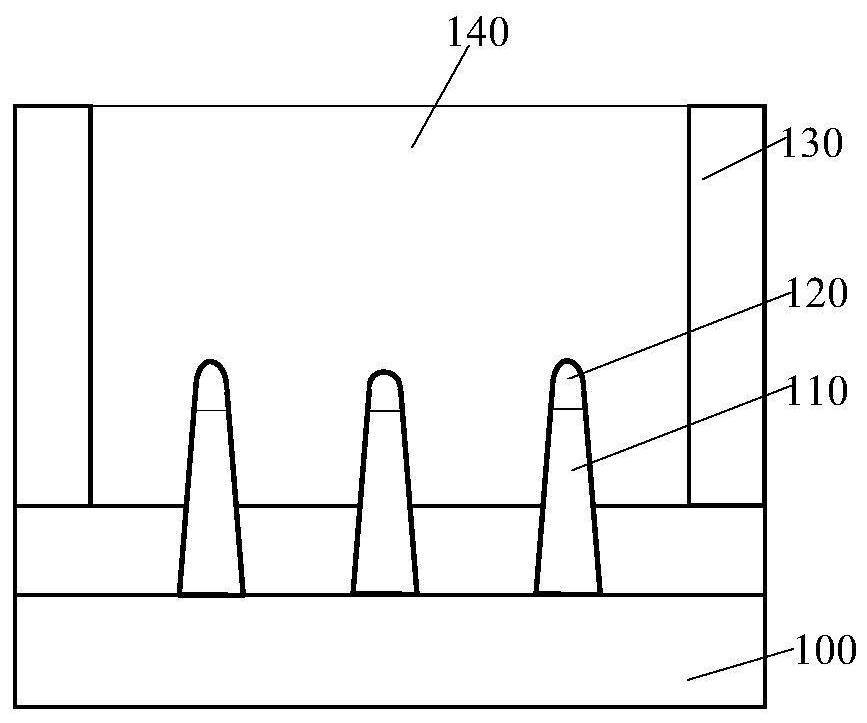

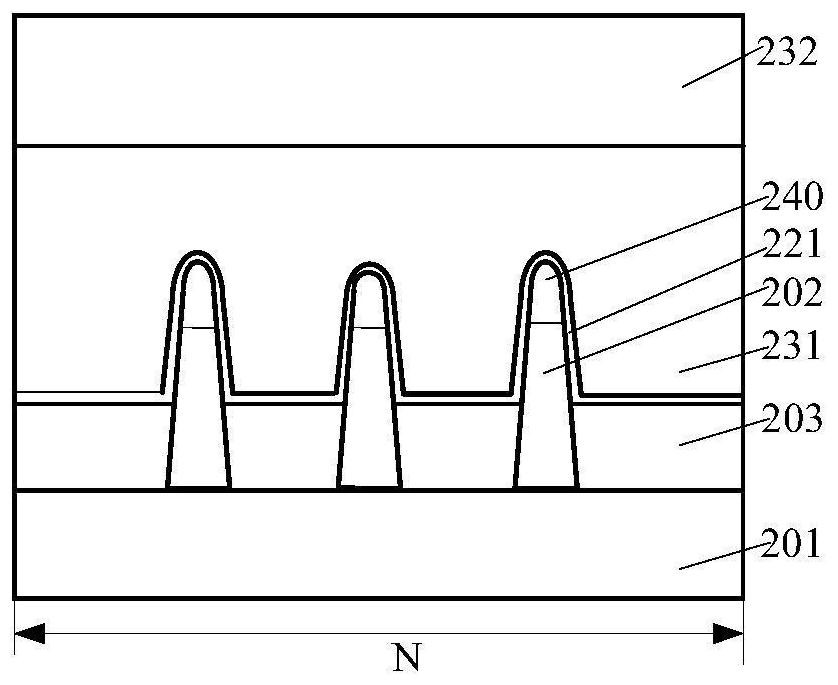

Semiconductor device and method of forming the same

ActiveCN109148577BImprove reliabilityGood shape consistencySemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device and a method for forming the same, wherein the method includes: providing a substrate with several fins on the substrate; forming an initial doping region and a dielectric layer, the initial doping regions are respectively located in the several fins, and initially The doped region includes a bottom region and a top region located on the bottom region, the dielectric layer covers the fin, the initial doped region and the substrate; a trench penetrating through the dielectric layer is formed in the dielectric layer, and the initially doped region is located in the trench bottom, and the trench exposes the top region; etching removes the top region at the bottom of the trench, so that the bottom region forms a doped region. The method improves the shape consistency of the top surface of the doped region in different fins at the bottom of the groove, and improves the reliability of the semiconductor device.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

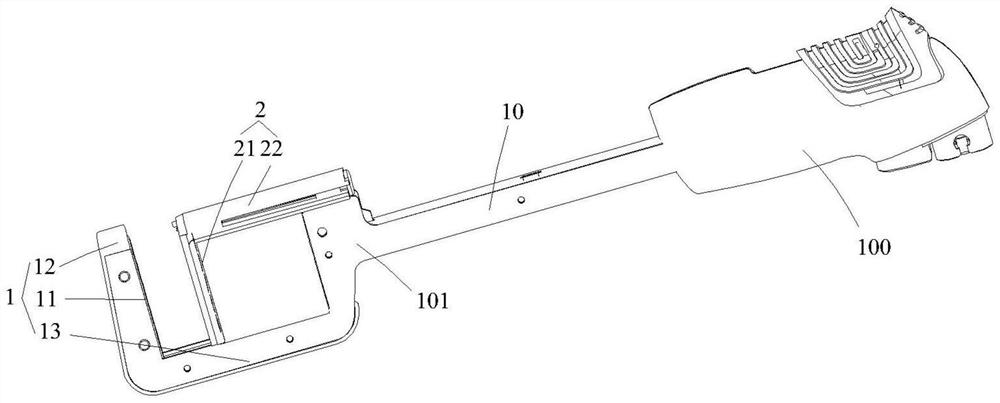

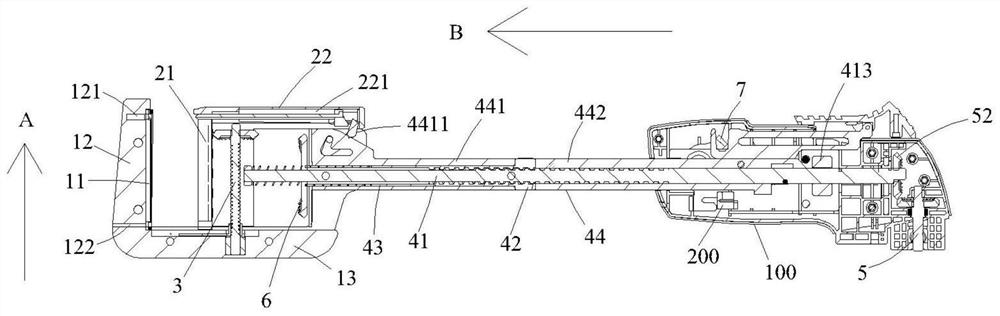

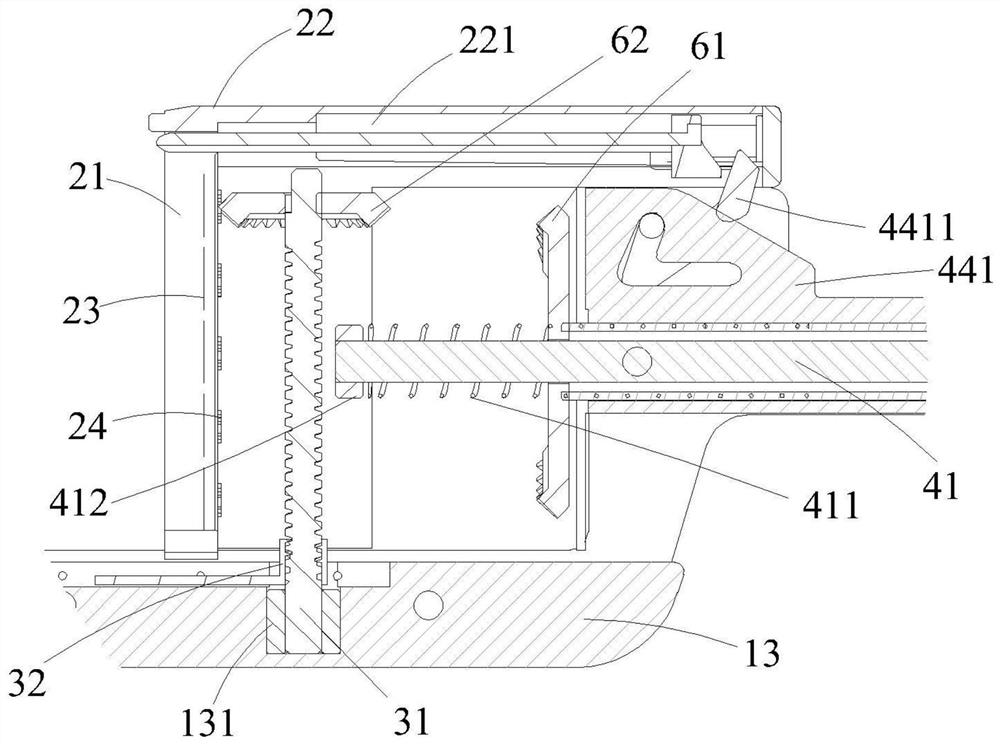

Surgical Instruments and Linear Staplers

ActiveCN111466974BAvoid deformationReduce firing forceSurgical staplesSurgical operationAnastomosis coupler

The invention relates to a surgical instrument and a linear stapler, which are provided with a push screw assembly and a direction-changing transmission device. When the stapling mechanism is closed, the direction-changing transmission device drives the first screw rod in the push screw assembly to rotate to make the sleeve The firing nut arranged thereon moves in the direction of the first axis relative to the first screw rod, so that the staples in the staple cartridge are fired sequentially. Therefore, the surgical instrument and the linear stapler adopt the method of sequentially forming staples, which can save the required percussion force, avoid deformation of the anvil, and have better staple forming effect, suturing effect and surgical safety.

Owner:SUZHOU YINGTUKANG MEDICAL TECH CO LTD

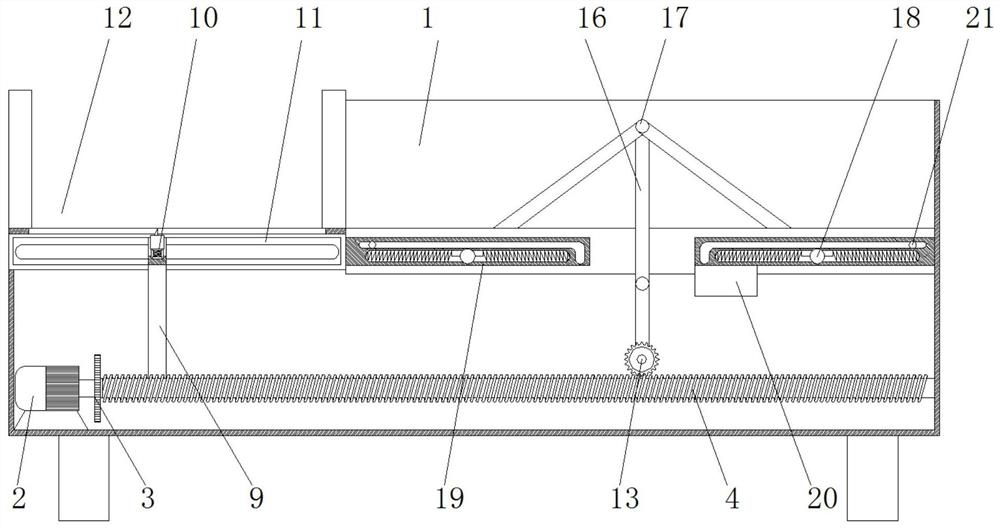

A nailing device with clamping function and capable of bending cardboard

ActiveCN111619161BWith clamping functionAchieve automatic feedingBox making operationsPaper-makingCardboardGear wheel

The invention relates to the technical field of cardboard processing, and discloses a nailing device with a clamping function and capable of bending cardboard, including a case, a motor is fixedly connected to the bottom of the case, and an output end of the motor is fixedly connected to a Transmission gear, the center of the circle of the No. 1 transmission gear is fixedly connected with a worm, the side of the No. 1 transmission gear is engaged with a reversing gear set, the side of the reversing gear set is engaged with a No. The center of the transmission gear is fixedly connected with a threaded rod, the surface of the threaded rod is engaged with an internal thread sleeve, and the upper end of the internal thread sleeve is fixedly connected with a stop rod. Through the rotation of the reversing gear set, the threaded rod rotates forward and backward. The surface of the threaded rod is engaged with an internal thread sleeve, and the upper end of the internal thread sleeve is fixedly connected with a feeding mechanism, so that automatic feeding can be achieved without manual feeding. Time, improve the effect of work efficiency.

Owner:HEFEI HEXIN PACKAGING

A device for folding and nailing TV packaging

ActiveCN111498203BImprove nailing efficiencyEasy to nailWrapper twisting/gatheringCartonStructural engineering

The invention relates to the technical field of packaging carton processing, in particular to a TV package folding and nailing device. The purpose of the present invention is to provide a TV packaging folding and nailing device that can cooperate with the TV packaging assembly line to quickly nail the packaging cartons and has good nailing effect. A folding and nailing device for TV packaging, including a mounting base, a connecting frame, a hollow frame, a support rod, a sliding rod, a connecting rod, and a toggle device; two connecting frames are fixedly installed on one side of the mounting base, and the The hollow frame is fixedly installed on one side of the mounting seat, and a support rod is fixedly installed on one side of the hollow frame, and two sliding rods are slidably set on the support rod, and a toggle device is provided at one end of the two sliding rods. . The present invention can cooperate with the packaging assembly line of the TV, and performs continuous nailing operation on the packing box during transmission, and the nailing efficiency is high.

Owner:合肥智龙机械设计有限公司

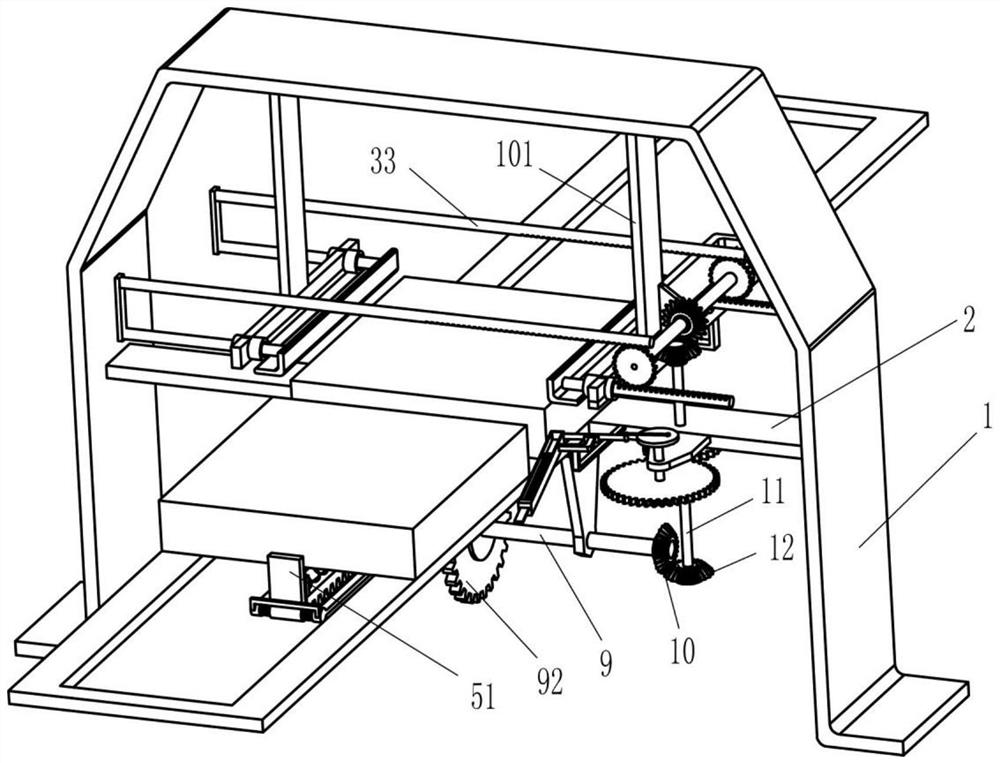

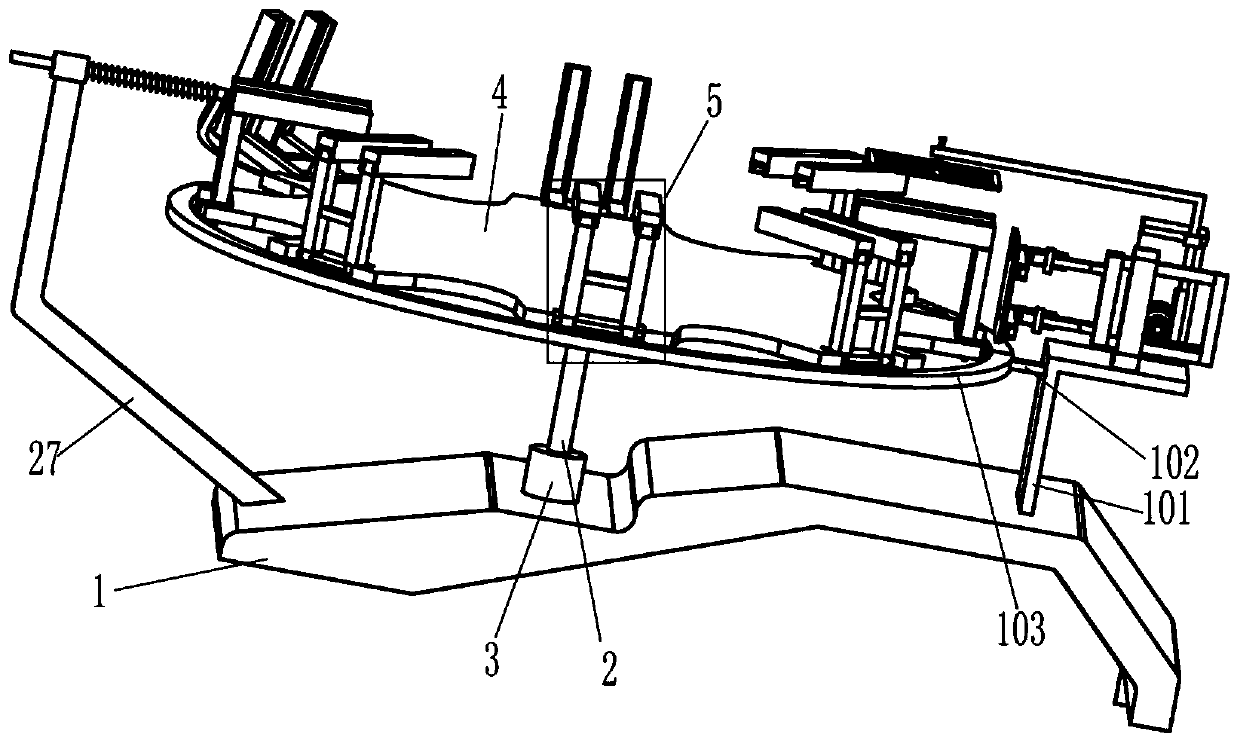

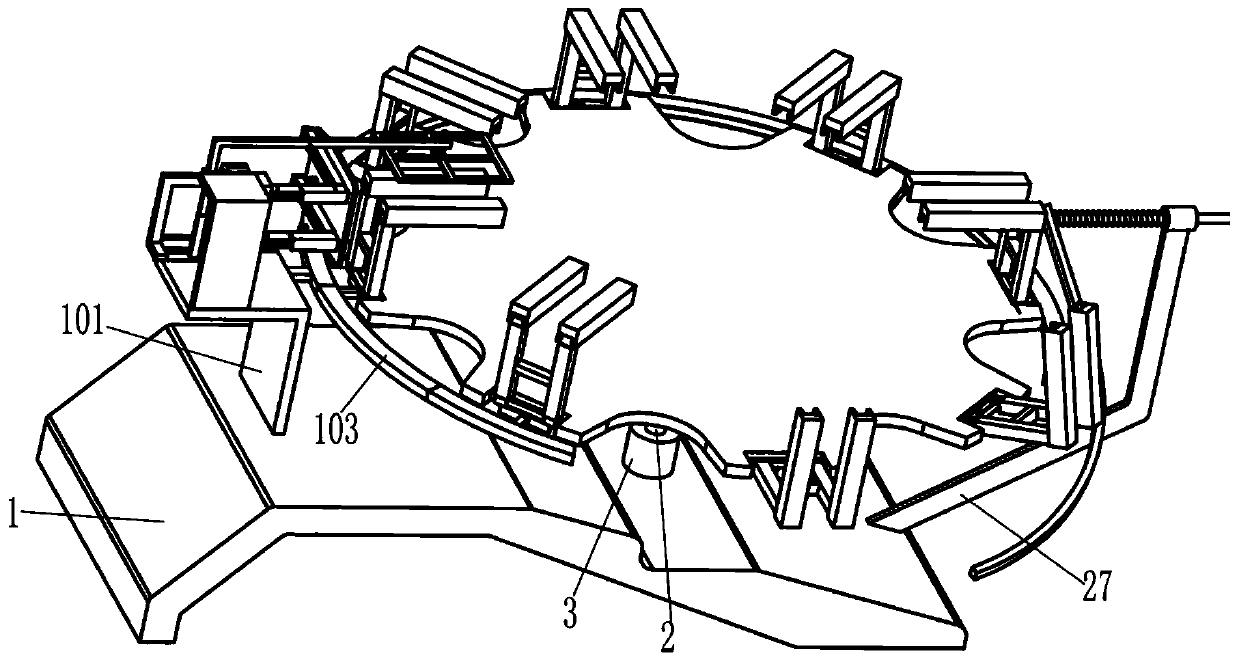

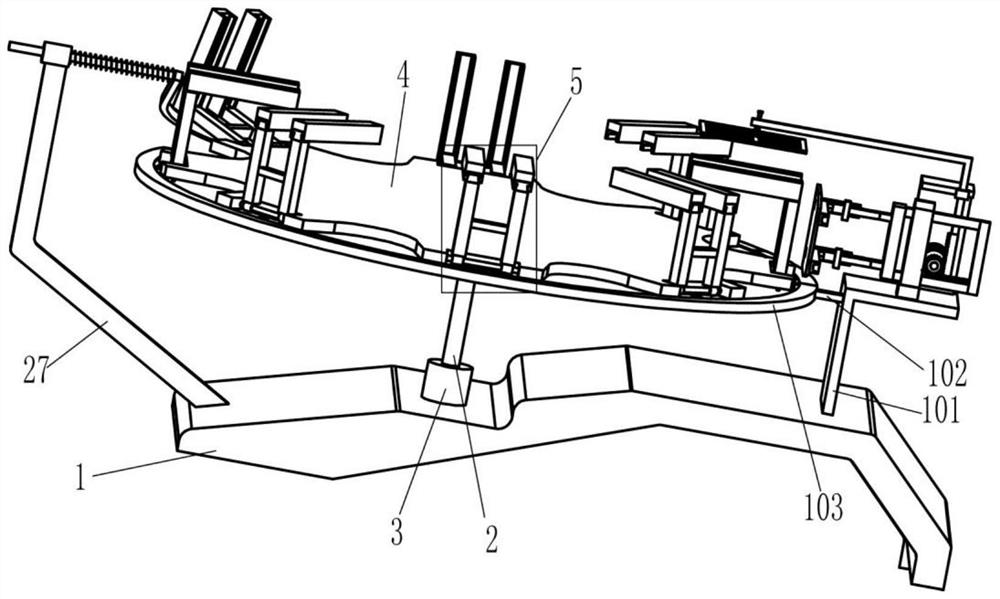

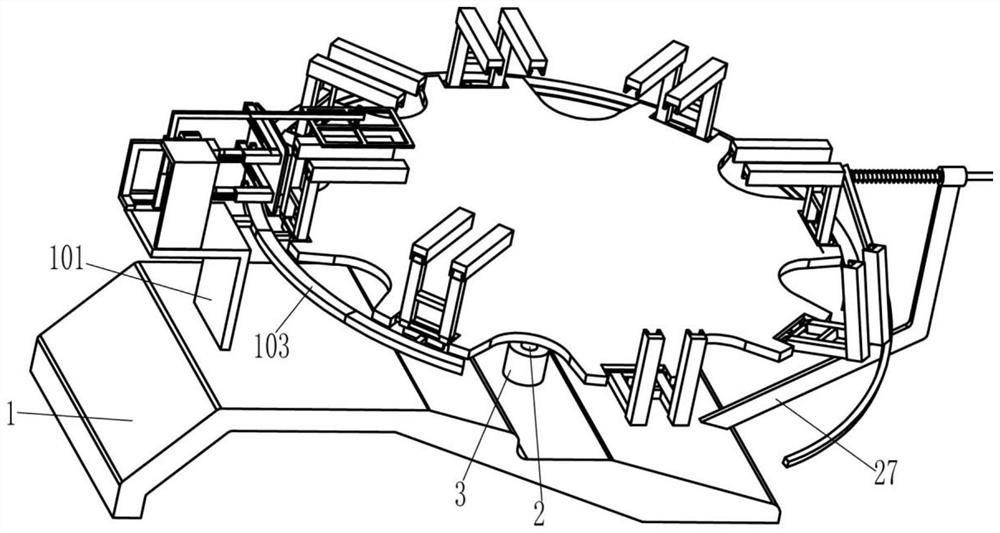

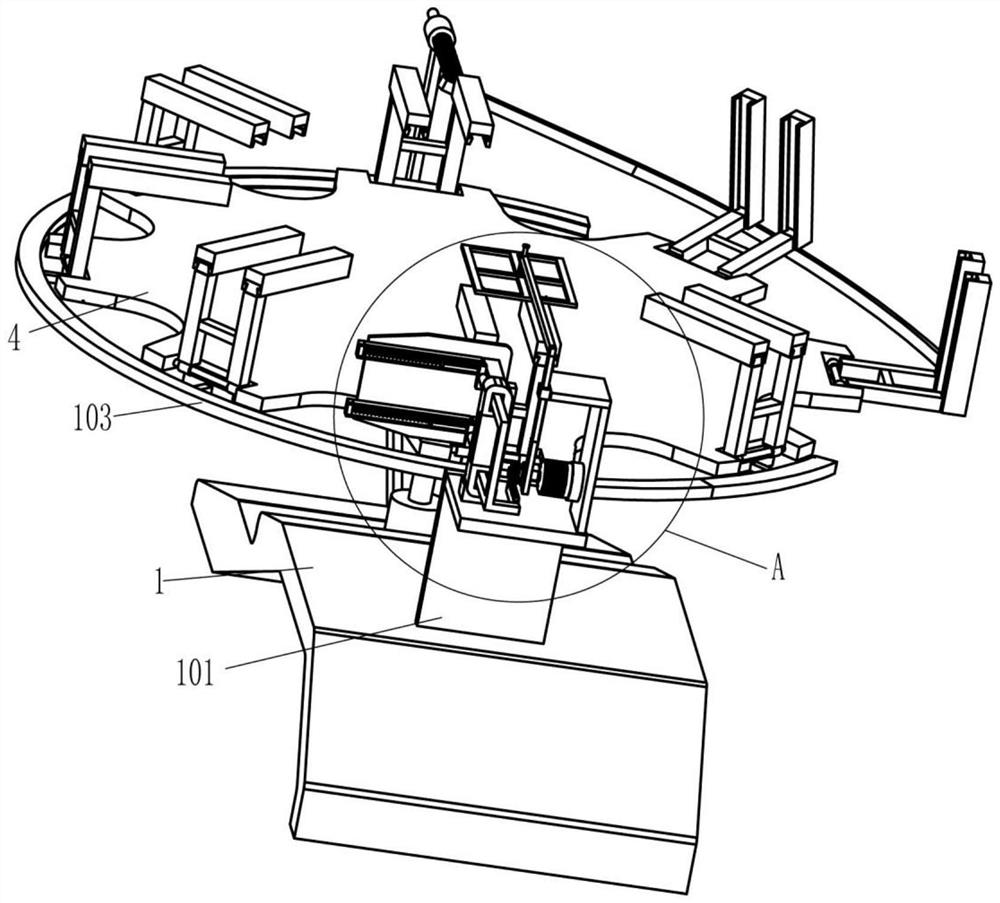

Rapid nailing device for carton manufacturing

ActiveCN111231406AEasy and fast operationImprove nailing efficiencyBox making operationsPaper-makingElectric machineryStructural engineering

The invention relates to the technical field of packaging cartons, in particular to a rapid nailing device for carton manufacturing. The rapid nailing device for carton manufacturing aims to accurately nail the side wall of a carton, enhance the stability of the carbon in the using process and enable the nailing efficiency to be high. According to the technical scheme, the rapid nailing device forcarton manufacturing comprises a support, a mounting frame, a fixed supporting plate, a circular sliding rail, a first rotating shaft, a first motor and the like, wherein the mounting frame is fixedly mounted on one side surface of the support, the fixed supporting plate is fixedly mounted on one side surface of the mounting frame, the circular sliding rail is fixedly mounted on one side surfaceof the fixed supporting plate, and the first motor is fixedly mounted on one side surface of the support. Eight placing devices are driven by a placing disc to rotate anticlockwise, the placing devices rotate anticlockwise to bring the carton needing to be nailed to the rear side of the nailing device, the nailing device can rapidly nail the carton, and the carton nailing efficiency is high.

Owner:台州富联包装股份有限公司

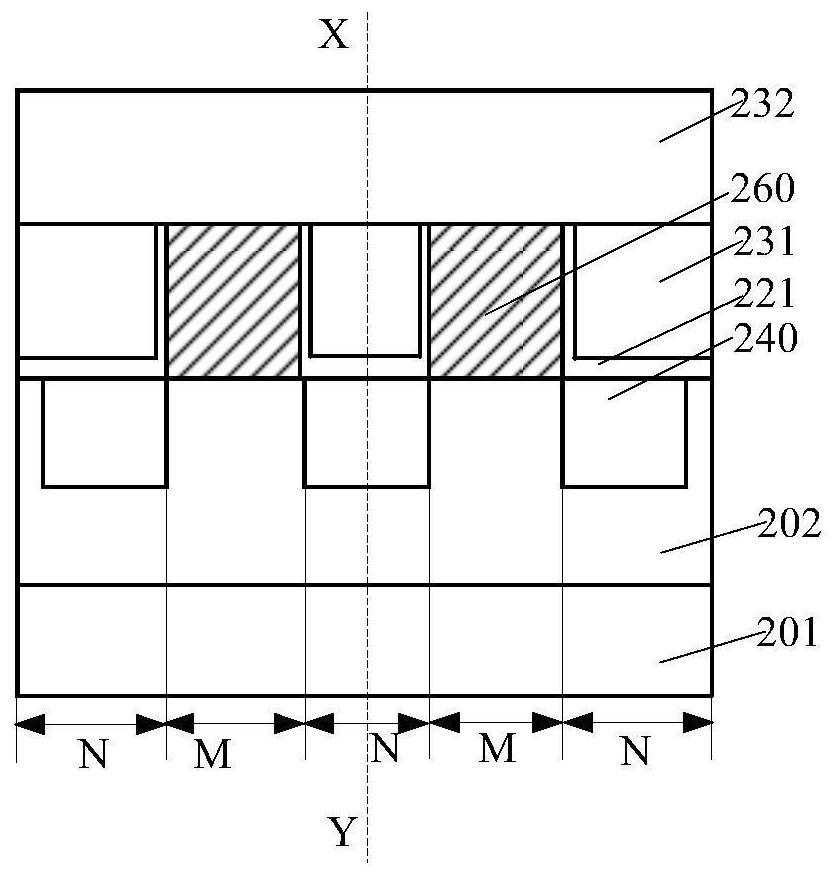

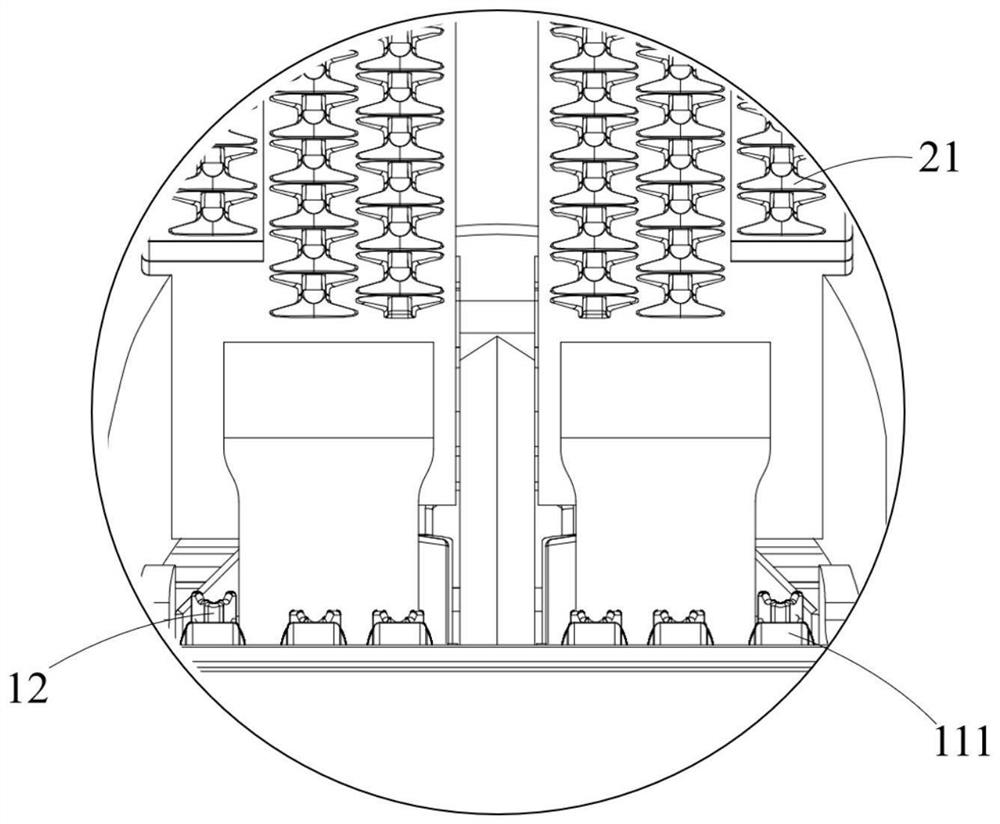

Nail abutting seat and anastomat

PendingCN114176691APromote healingImprove gripSurgical staplesStructural engineeringMechanical engineering

The invention provides a nail abutting seat and an anastomat. A first groove set and a second groove set which are located in the same plane are formed in the nail abutting seat, and the first groove set and the second groove set are symmetrically arranged in the extending direction of the nail abutting seat; the first groove set and the second groove set each comprise at least two rows of grooves parallel to the extending direction of the nail abutting base, and the concave depth of the grooves located on the outer side is larger than that of the grooves located on the inner side. Compared with the prior art, different abutting structures are arranged between the nail bin assembly and the nail abutting base, the grasping force of the nail bin assembly on tissue can be increased when the anastomat conducts anastomosis by increasing the surface area in contact with the tissue, the nail forming effect is better and more stable, and tissue healing is promoted.

Owner:WUXI BM PRECISION PARTS CO LTD

A stable nail gun

The invention provides a nail gun with stable nailing, which includes a casing, a trigger, a motor, a first cylinder, a second cylinder, a crank, a connecting rod, a nailing assembly and a nail feeding assembly, the second cylinder is located in the first cylinder, The first cylinder is equipped with a first piston, the second cylinder is equipped with a second piston, the connecting rod is connected to the first piston, and the motor is connected to the crank through the transmission mechanism and drives the first piston through the connecting rod in the first cylinder. Axial movement, the nailing assembly includes a striker, the striker is connected with the second piston, the upper end of the first cylinder is provided with a lock assembly that locks the second piston at a high point, the first piston is provided with an unlocking ejector rod, the first The piston moves upwards to drive the unlocking ejector to move upwards, and the unlocking ejector pushes the locking assembly to break away from the second piston, and the second piston moves downward under the air pressure to make the striker hit the gun nail, and the second piston is locked by the locking assembly The way of maintaining pressure can not only ensure a good nailing effect.

Owner:ZHEJIANG PRULDE ELECTRIC APPLIANCE CO LTD

Surgical Instruments and Linear Staplers

ActiveCN111466975BAvoid deformationReduce firing forceSuture equipmentsDiagnosticsSurgical operationAnastomosis coupler

The invention relates to a surgical instrument and a linear stapler, which are provided with a push screw assembly and a firing assembly. When the stapling mechanism is closed, the firing assembly drives the first screw rod in the push screw assembly to rotate, so that the screw rod sleeved on it The firing nut moves in the direction of the first axis relative to the first screw rod, so that the staples in the staple cartridge are fired sequentially, so that problems such as large and small heads and dovetails do not occur. Therefore, the surgical instrument and the linear stapler adopt the method of sequentially forming staples, which can save the required percussion force, avoid deformation of the anvil, and have better staple forming effect, suturing effect and surgical safety.

Owner:SUZHOU YINGTUKANG MEDICAL TECH CO LTD

Preparation process of special aluminum electrolytic capacitor for electric vehicle controller

PendingCN113593916AImprove nailing effectReduce feverLiquid electrolytic capacitorsWinding capacitor machinesAutomotive engineeringCapacitance

The invention discloses a preparation process of a special aluminum electrolytic capacitor for an electric vehicle controller, and aims to solve the technical problems that the service life of the electric vehicle controller is greatly restricted and the reliability of the electric vehicle controller is greatly reduced due to the fact that the magnitude of current borne by the aluminum electrolytic capacitor used by the existing electric vehicle controller is relatively common. The process roughly comprises the following steps of: nailing positive and negative aluminum foils to a leading-out wire, pasting a negative electrode pad foil at a negative electrode riveting position through a nailing machine, and winding a core package by intermediate pad electrolytic paper on an automatic winding machine; placing the core package in a high-temperature drying box to be dried, then taking out the core package and placing in electrolyte, and soaking the core package in the electrolyte in a vacuumizing and air pressurization mode; packaging the core package absorbed with the electrolyte by using an aluminum shell and a rubber sealing plug; and sleeving the packaged naked capacitor with an outer sheath sleeve with insulation and protection effects, and arranging the packaged naked capacitor in parallel according to positive and negative polarities for charging repair to obtain the aluminum electrolytic capacitor.

Owner:安远秦旭科技有限公司

Nailing clamp for slots

PendingCN107538437AFirmly connectedOperational securityMulti-purpose toolsStructural engineeringOperation safety

Owner:陆光华

Packaging box automatic nailing equipment

ActiveCN106742320BQuality improvementQuality assuranceWrapper twisting/gatheringControl engineeringControl theory

The invention provides an automatic nailing device for packaging boxes, which includes a frame, a feeding conveying mechanism, a servo positioning mechanism, an automatic box opening module, a profiling positioning module and an automatic nailing module. Located on one side of the frame, the servo positioning mechanism includes a synchronous conveyor belt on the frame and a servo motor for driving the synchronous conveyor belt, and the automatic box opening module includes a lower vacuum suction cup and a jacking cylinder , the automatic box-opening module also includes an upper vacuum suction cup and a box-opening cylinder, the profile positioning module is located on one side of the synchronous conveyor belt, and the automatic nailing module is located on the other side of the synchronous conveyor belt and is connected with The profiling positioning modules are opposite to each other. The invention centralizes the production of multiple nailing processes, can automatically complete the entire nailing process of the anti-counterfeit rivets of the packaging box, effectively improves the nailing efficiency, ensures the quality of the packaging box, meets the requirements of mass production, and saves costs.

Owner:武汉世豪同创自动化设备有限公司

An aluminum alloy door frame cover automatic compression nailing machine

ActiveCN107243960BImprove work efficiencyReduce labor intensityStapling toolsNailing toolsEngineeringStructural engineering

The invention relates to an aluminum alloy door frame cover automatic compression nailing machine, comprising a walking device, two rotating devices and two pressing nailing devices, the two rotating devices are symmetrically installed above the walking device, and two The rotating devices are arranged facing away from each other, and a pressing nailing device is installed above each rotating device. The present invention can solve the problems of low work efficiency, high labor intensity, inconvenient pressing and nailing at the same time, danger of manual nailing, and inconvenient nailing at some higher and lower positions in the existing manual pressing and nailing of the door frame cover. It has realized the function of fully mechanized pressing and nailing the aluminum alloy door frame cover, which has high work efficiency, low labor intensity, pressing and shooting nails can be carried out at the same time, purely mechanized nailing operation, and can adjust the angle positions of the door frame cover It has the advantages of automatic nailing operation and so on.

Owner:GUANGDONG GOLDEN ALUMINUM

A stainless steel sliding door frame cover automatic nailing installation vehicle

ActiveCN107139285BReduce labor intensityTo achieve the purpose of automatic nailingStapling toolsNailing toolsPush and pullJamb

Owner:徐州伟盛机械制造有限公司

A fast nailing device for carton making

ActiveCN111231406BImprove nailing efficiencyEasy to operatePaper-makingBox making operationsCartonElectric machinery

The invention relates to the technical field of packaging cartons, in particular to a fast nailing device for making cartons. The object of the present invention is to provide a quick nailing device for making cartons that can accurately nail the side walls of cartons, enhance the stability of the cartons during use, and has high nailing efficiency. The technical solution is: a fast nailing device for making cartons, including a support, a mounting frame, a fixed support plate, a circular slide rail, a first rotating shaft and a first motor, etc., and the mounting frame is fixedly installed on one side of the support. On the side, the fixed support plate is fixedly installed on one side of the installation frame, the circular slide rail is fixedly installed on one side of the fixed support plate, and the first motor is fixedly installed on one side of the support. The present invention drives eight placing devices to rotate counterclockwise through the placing disc, and the counterclockwise rotation of the placing devices can bring the cartons that need to be nailed to the rear side of the nailing device, and the nailing device can perform fast nailing on the cartons, Carton nailing efficiency is high.

Owner:台州富联包装股份有限公司

Air nailer

The invention discloses an air nailer, comprising a first cylinder, a second cylinder, a striker and a driving device, wherein the first cylinder comprises a first cylinder wall with a formed first chamber and a first piston; the second cylinder comprises a second cylinder wall with a formed second chamber and a second piston; the driving device comprises a driving member for driving the first piston; the first piston comprises a first surface connected with the driving member and a second surface; the second piston comprises a third surface connected with the striker and a fourth surface; thefirst chamber is divided by the first piston into a first chamber portion located on the side, where the first surface is arranged, of the first piston, and a second chamber portion located on the other side of the first piston; and the second chamber is divided by the second piston into a third chamber portion on the side, where the third surface is arranged, of the second piston, and a fourth chamber portion located on the other side of the second piston. The air nailer is further provided with a first air flow passage allowing the second chamber portion to communicate with the fourth chamber portion, and a second air flow passage allowing the first chamber portion to communicate with the third chamber portion. The air nailer provided by the invention has good nailing effect.

Owner:NANJING CHERVON IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com