Automobile ceiling automatic line plate nailing mechanism

A kind of automatic and plate technology, which is applied in the direction of nailing tools, staple nailing tools, manufacturing tools, etc., can solve the problems that the synchronization of the cylinder group cannot be guaranteed, the plate cannot be fully nailed, and the operation and maintenance of the mechanism are complicated, etc., and the improvement can be achieved. The effect of nailing, reducing product scrap rate, reducing equipment cost and energy usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with specific examples.

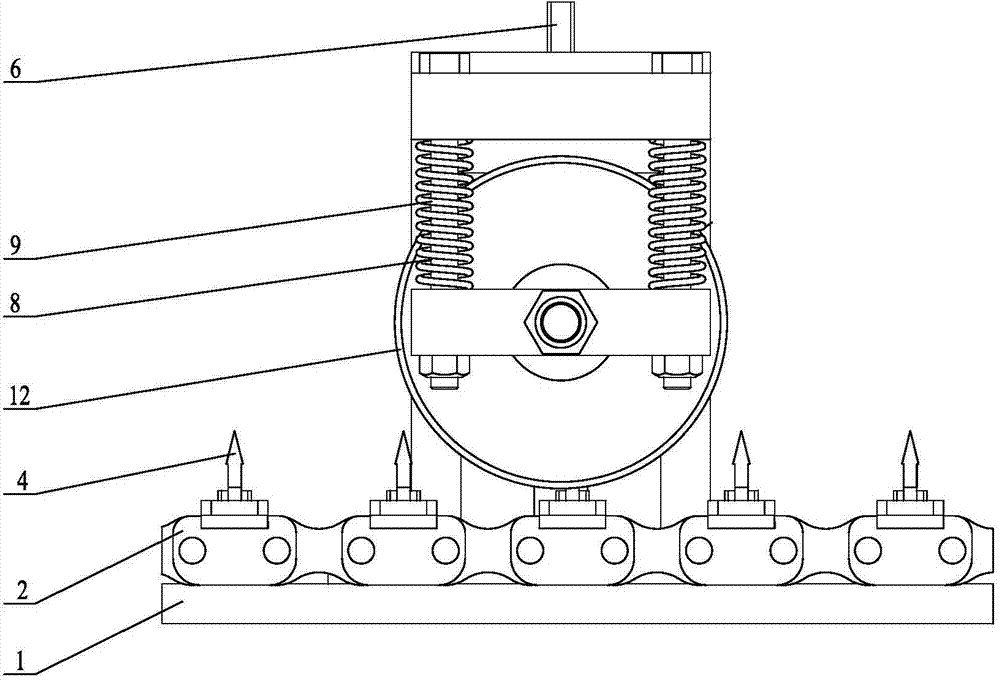

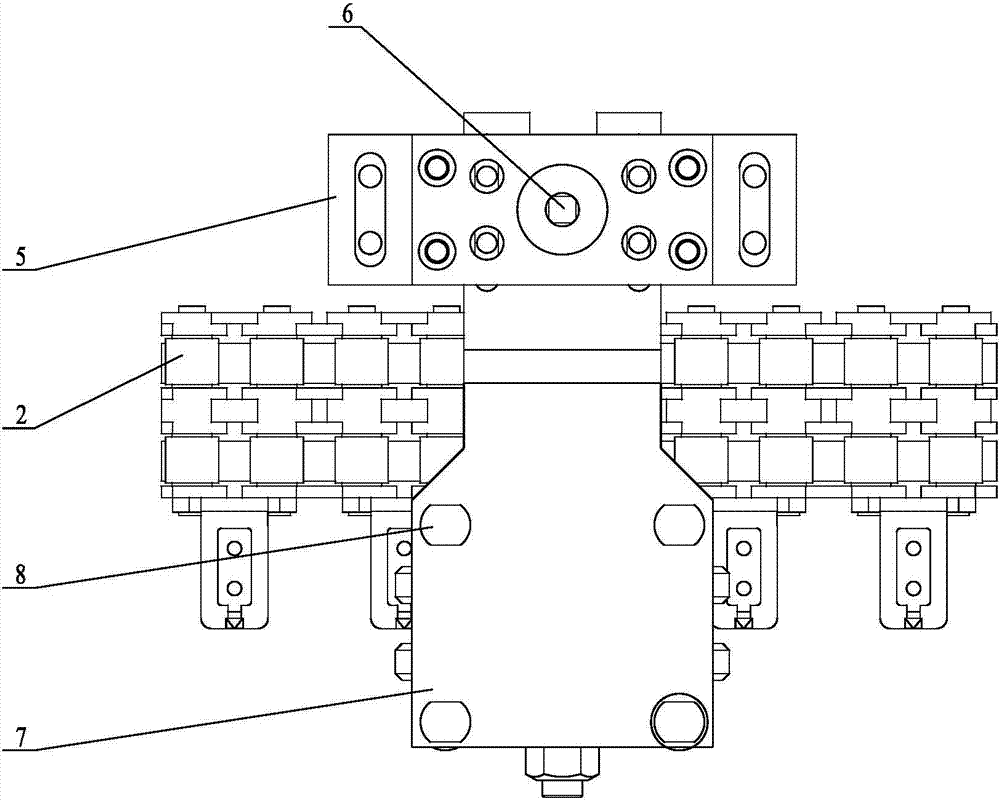

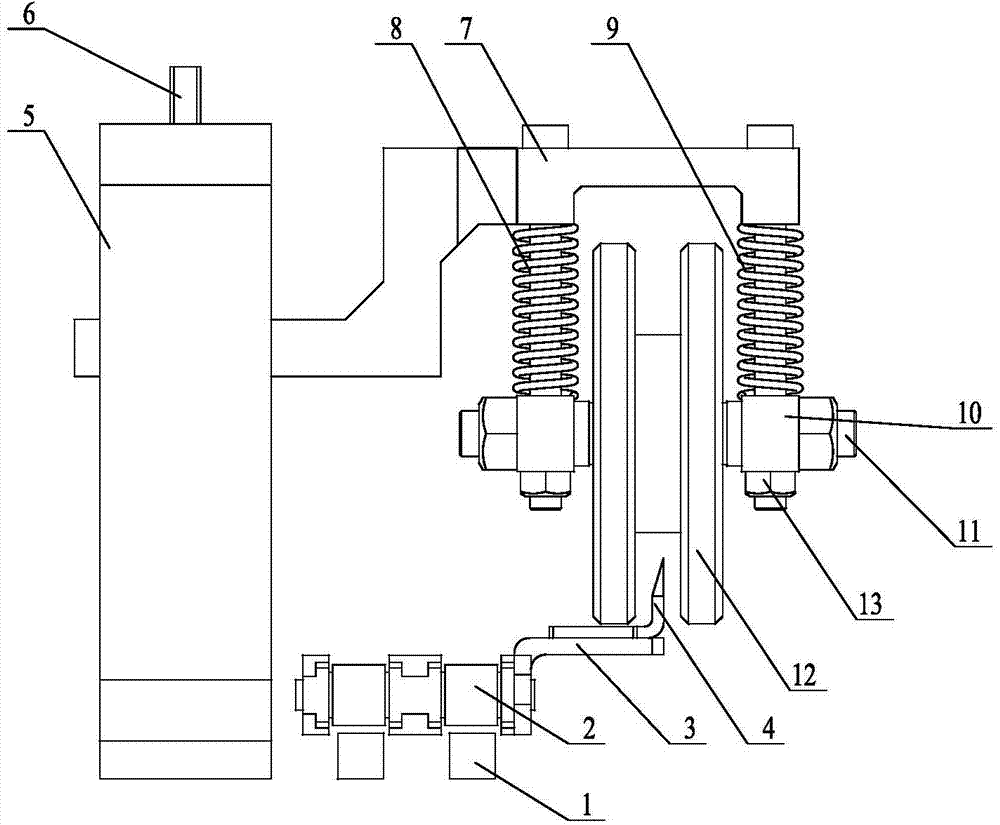

[0013] The car roof automatic line plate nailing mechanism is provided with a conveying chain 2 on the chain bracket 1, a nail seat 3 is fixed on the outer wall of the conveying chain 2, and a chain nail 4 is fixed on the nail seat 3; 1 There is an adjusting screw mounting seat 5 on the inner side, an adjusting screw 6 is rotated on the adjusting screw mounting seat 5, an adjusting nut is screwed on the adjusting screw 6, a spring mounting seat 7 is fixed on the adjusting nut, and a spring mounting seat 7 is fixed on the adjusting screw mounting seat 7 is fixed with a spring column 8, on the spring column 8 is covered with a spring 9, on the spring column 8 below the spring 9, a pinch roller shaft mounting seat 10 is slidably installed, and on the pinch wheel shaft mounting seat 10, a pinch wheel shaft 11 is fixed. On the pinch wheel shaft 11, pinch wheel 12 is installed in ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com