Surgical Instruments and Linear Staplers

A surgical operation and instrument technology, applied in the field of medical equipment, can solve problems such as large percussion force, tissue leakage, and deformation of the anvil of the cantilever beam structure, and achieve good nailing effect, saving percussion force, and avoiding deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0034] It should be noted that terms such as "upper", "lower", "left", "right", "inner" and "outer" in the present invention are only used to describe the present invention with reference to the accompanying drawings, and are not used as limiting terms.

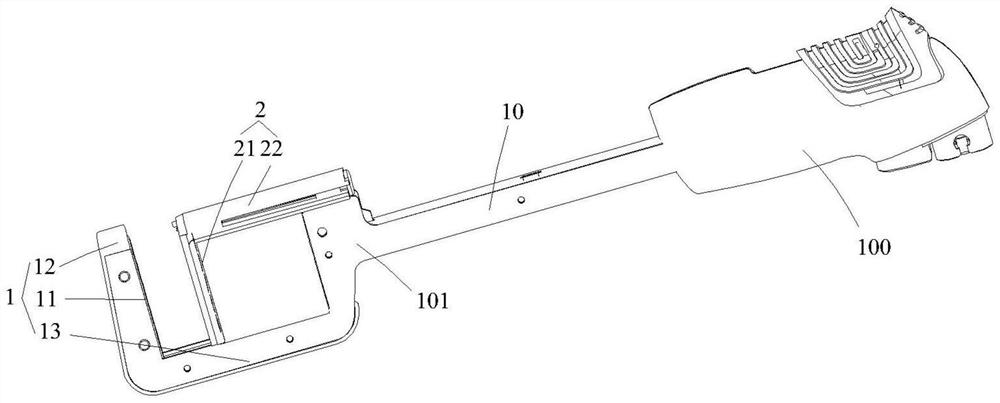

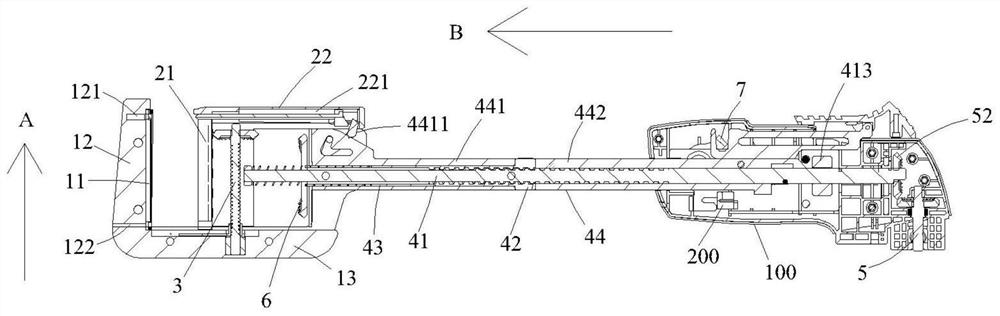

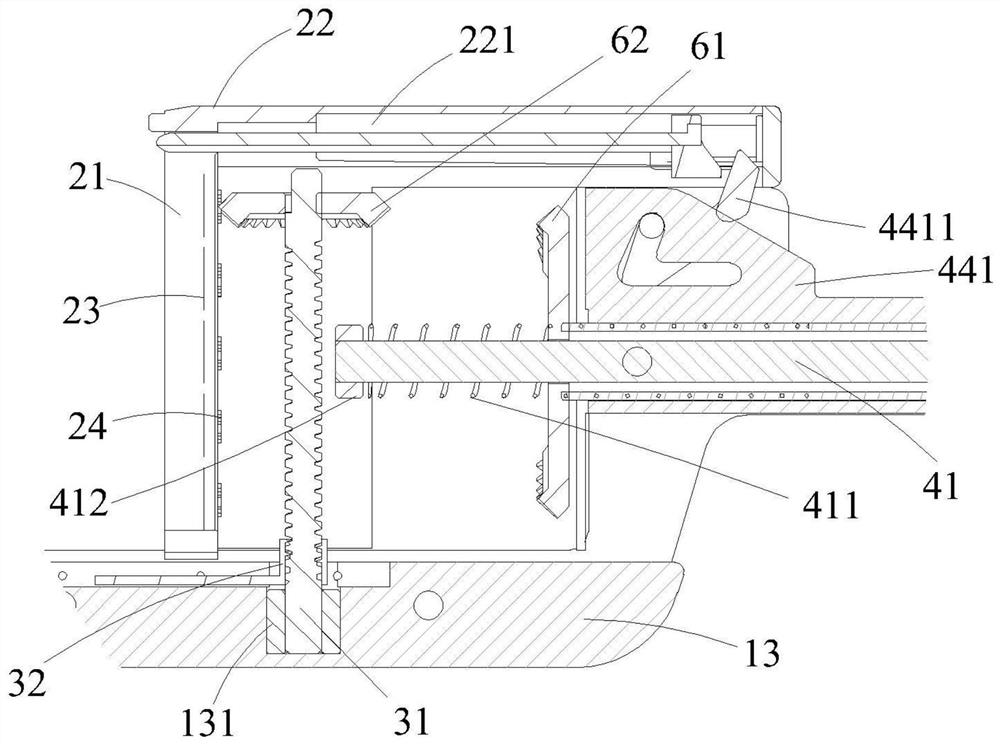

[0035] See Figure 1 to Figure 5 , a surgical instrument shown in an embodiment of the present invention includes:

[0036] The stapling mechanism (end effector) includes an anvil assembly 1 and a mounting part 101 for installing a staple cartridge assembly 2, on which a staple cartridge assembly 2 of different specifications can be installed according to actual needs. The staple cartridge assembly 2 includes a staple c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com