Patents

Literature

164results about How to "Good shape consistency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

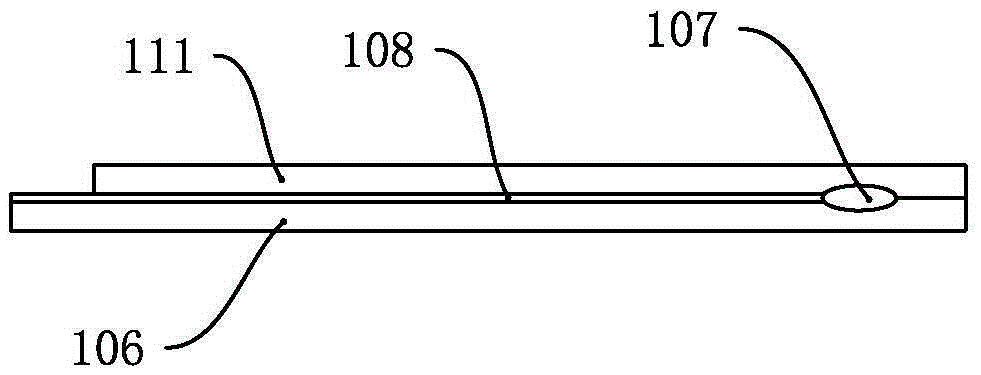

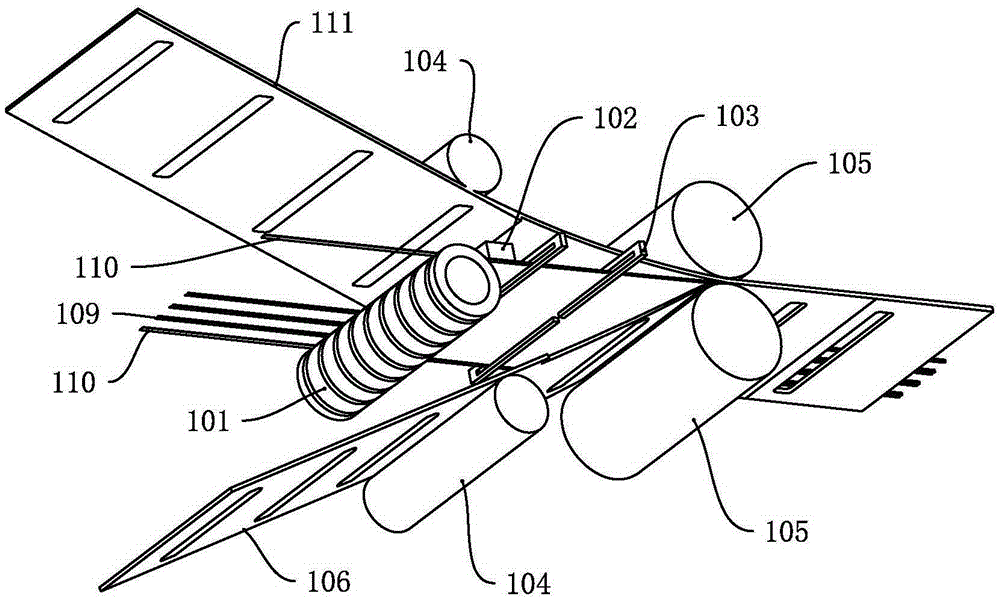

Micro semi-ring female die array-mode lapping and polishing method and device

ActiveCN105364641AImprove processing efficiencyEnsure consistencyLapping machinesLapping toolsMaterial removalGranularity

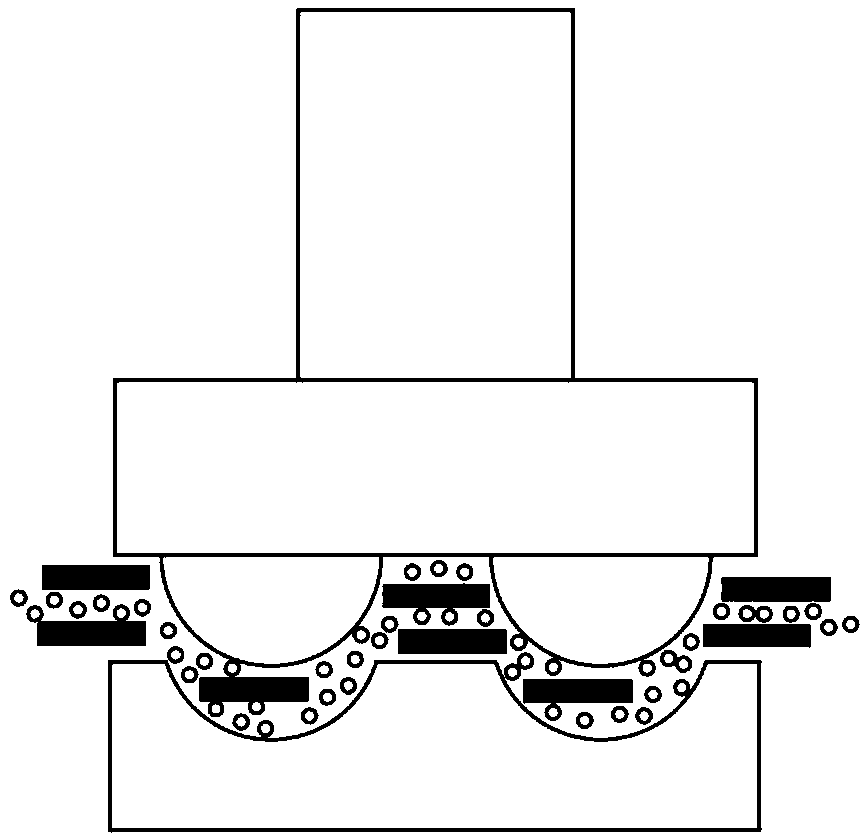

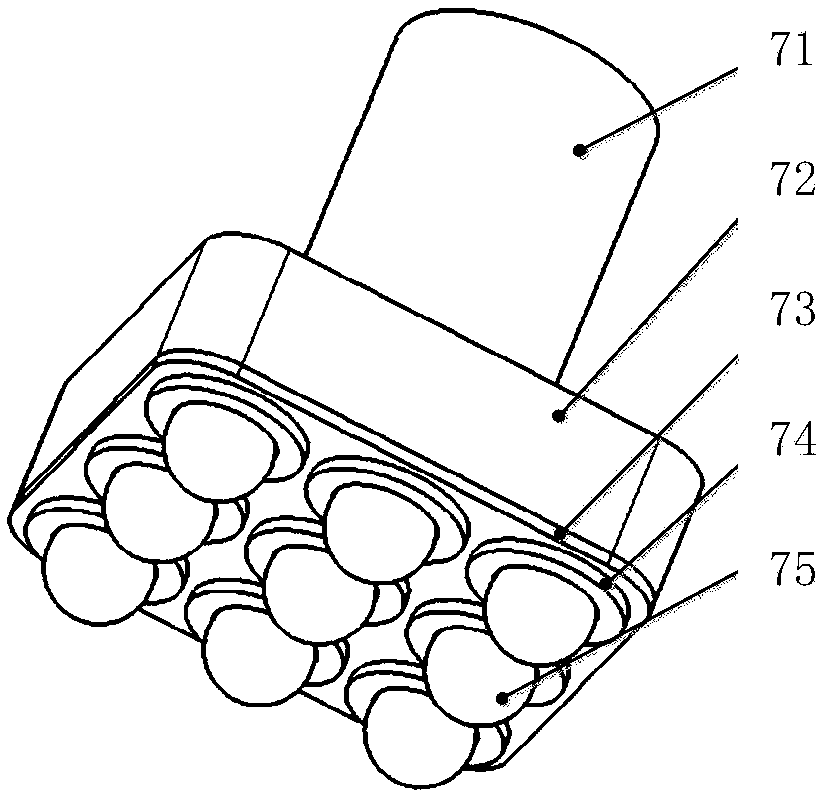

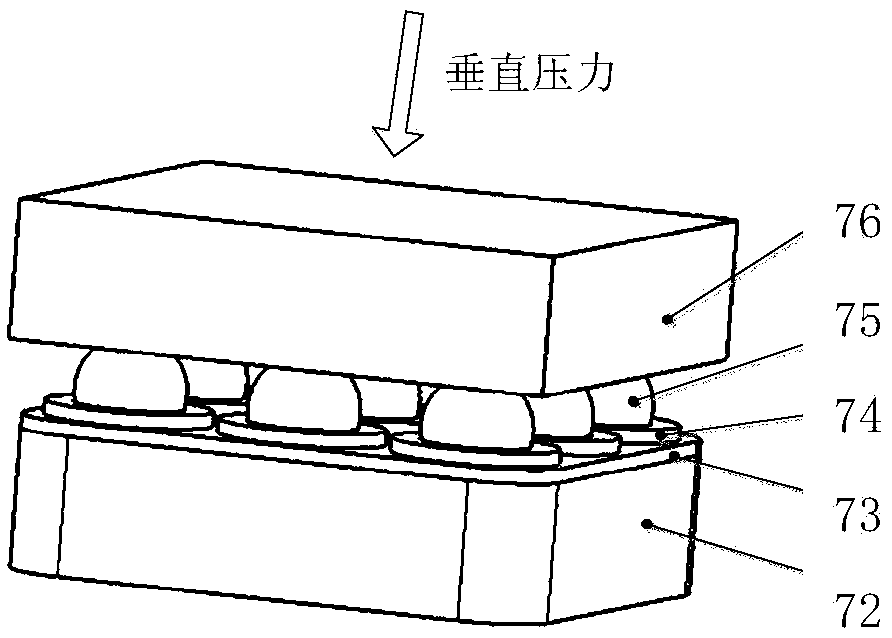

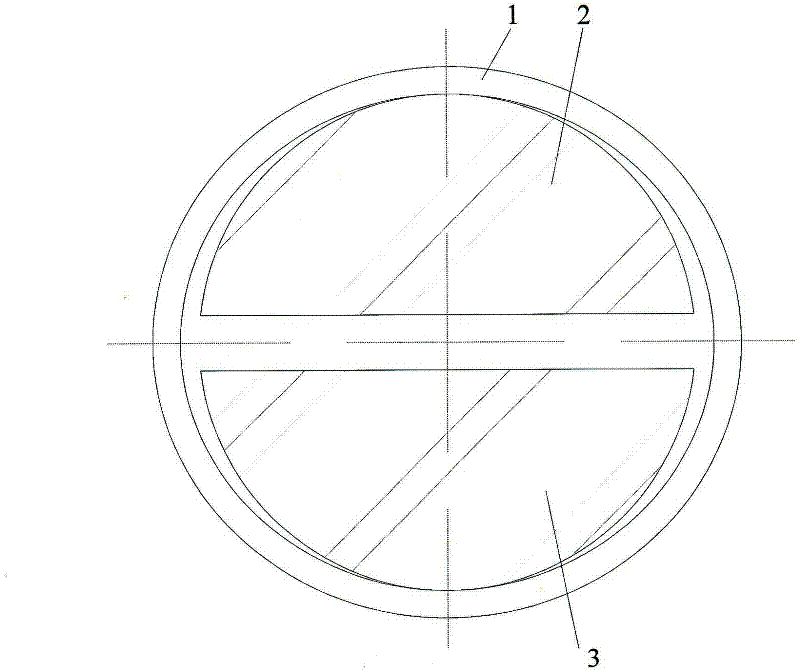

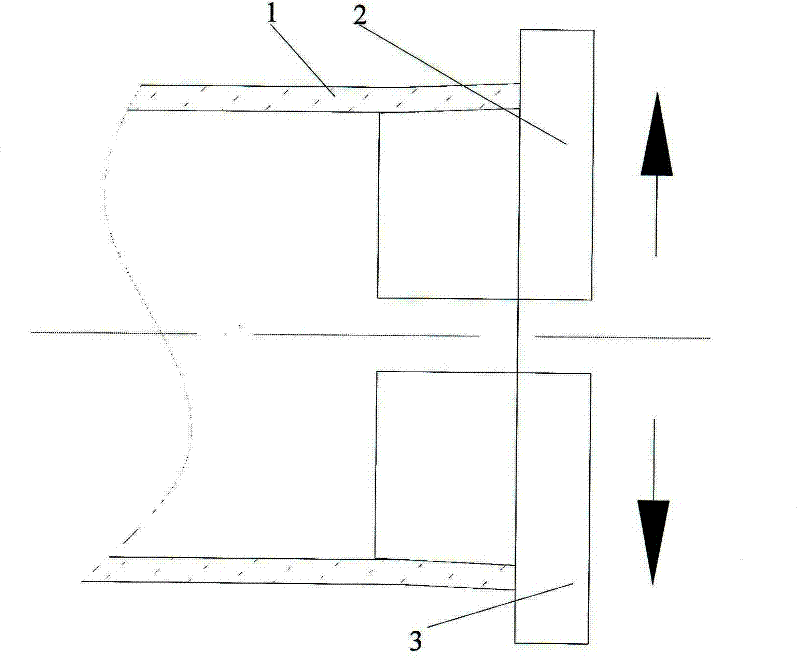

Disclosed is a micro semi-ring female die array-mode lapping and polishing method. The method includes the following steps that (1) a high-uniformity ultra-precise lapping and polishing die is manufactured, the upper end of a tool connecting rod is connected with a micro ultrasonic generator, the lower end of the tool connecting rod is connected with a positioning substrate, array apertures are formed in the positioning substrate, the size of the apertures is smaller than the diameter of precise spheres, spaces between the apertures and the precise spheres are filled with a binder, and part of the spheres is embedded into the apertures; and (2) the space between the high-uniformity ultra-precise lapping and polishing die and a substrate slice is filled with lapping and polishing liquid, the granularity of abrasive grains in the lapping and polishing liquid is nanoscale, the lapping and polishing die performs high-frequency micro ultrasonic vibration in the micro distance on the substrate slice, the ultrasonic vibration excites the abrasive grains in the lapping and polishing liquid to impact on the substrate slice at high speed, the lapping and polishing die performs feed movement downwards at set speed in the Z direction, and material removal of a micro semi-ring female die array is achieved. The invention further provides a micro semi-ring female die array-mode lapping and polishing device. The micro semi-ring female die array-mode lapping and polishing method and device can achieve the lapping and polishing effects of high efficiency, shape accuracy, shape uniformity and surface quality and low surface roughness.

Owner:ZHEJIANG UNIV OF TECH

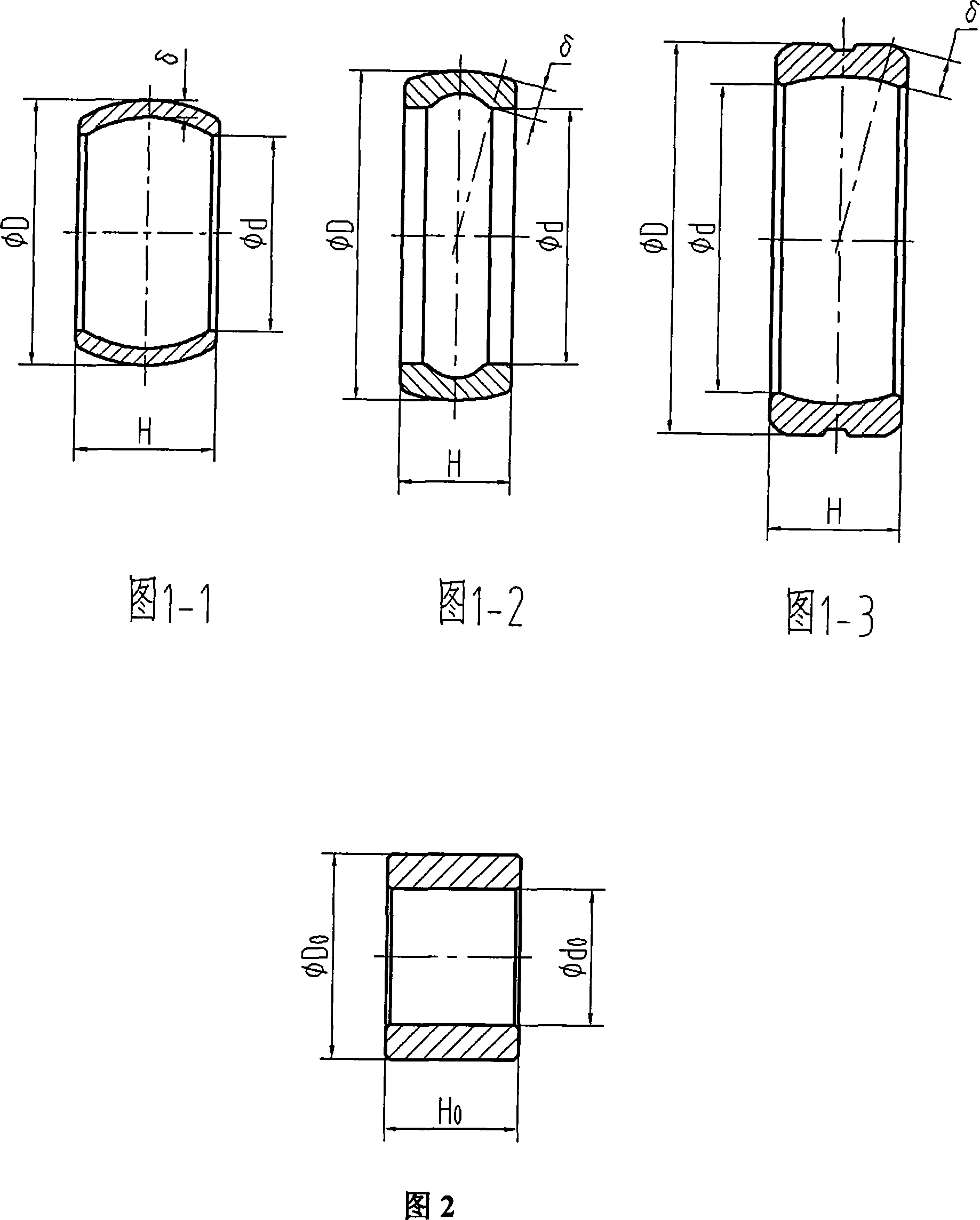

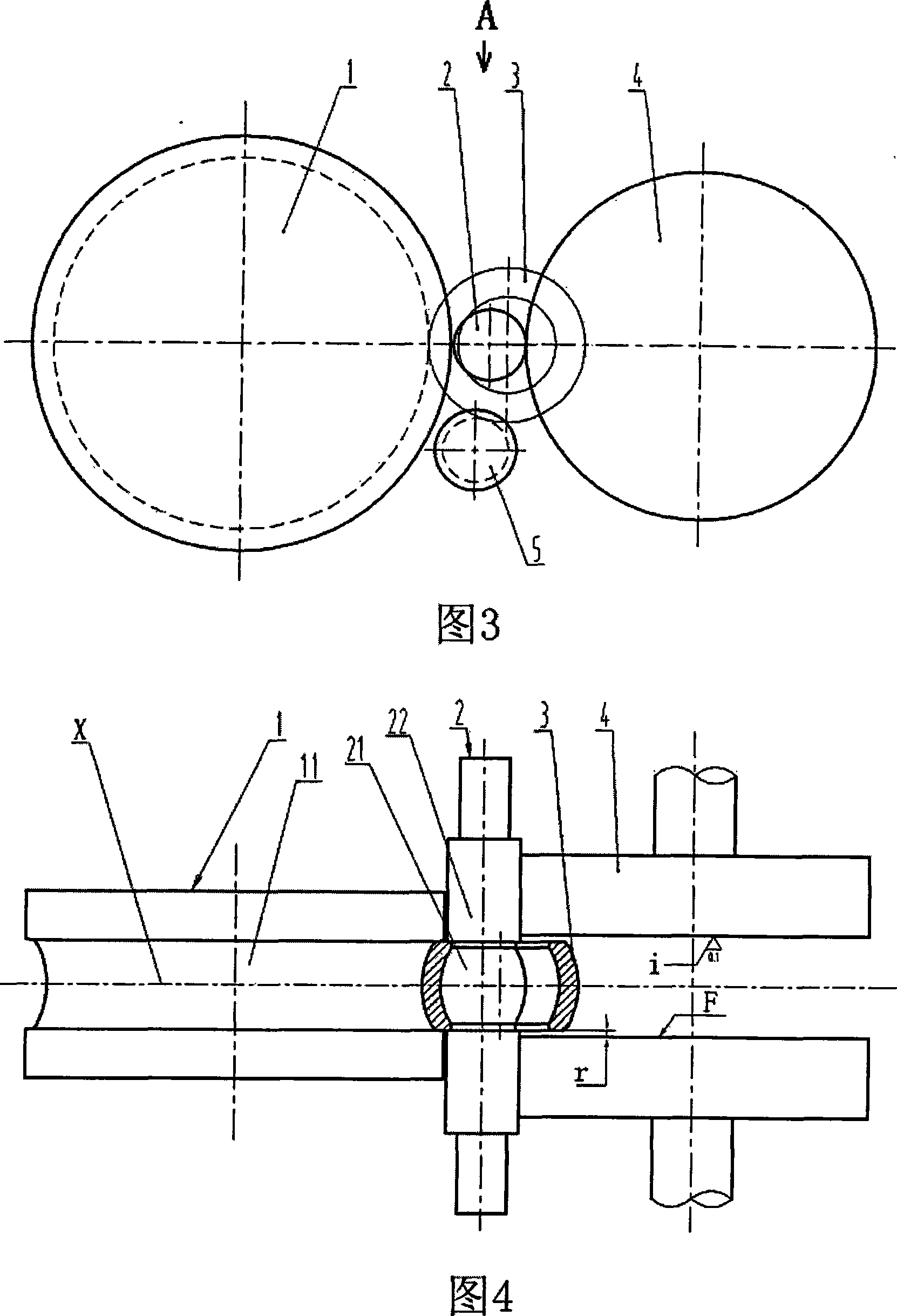

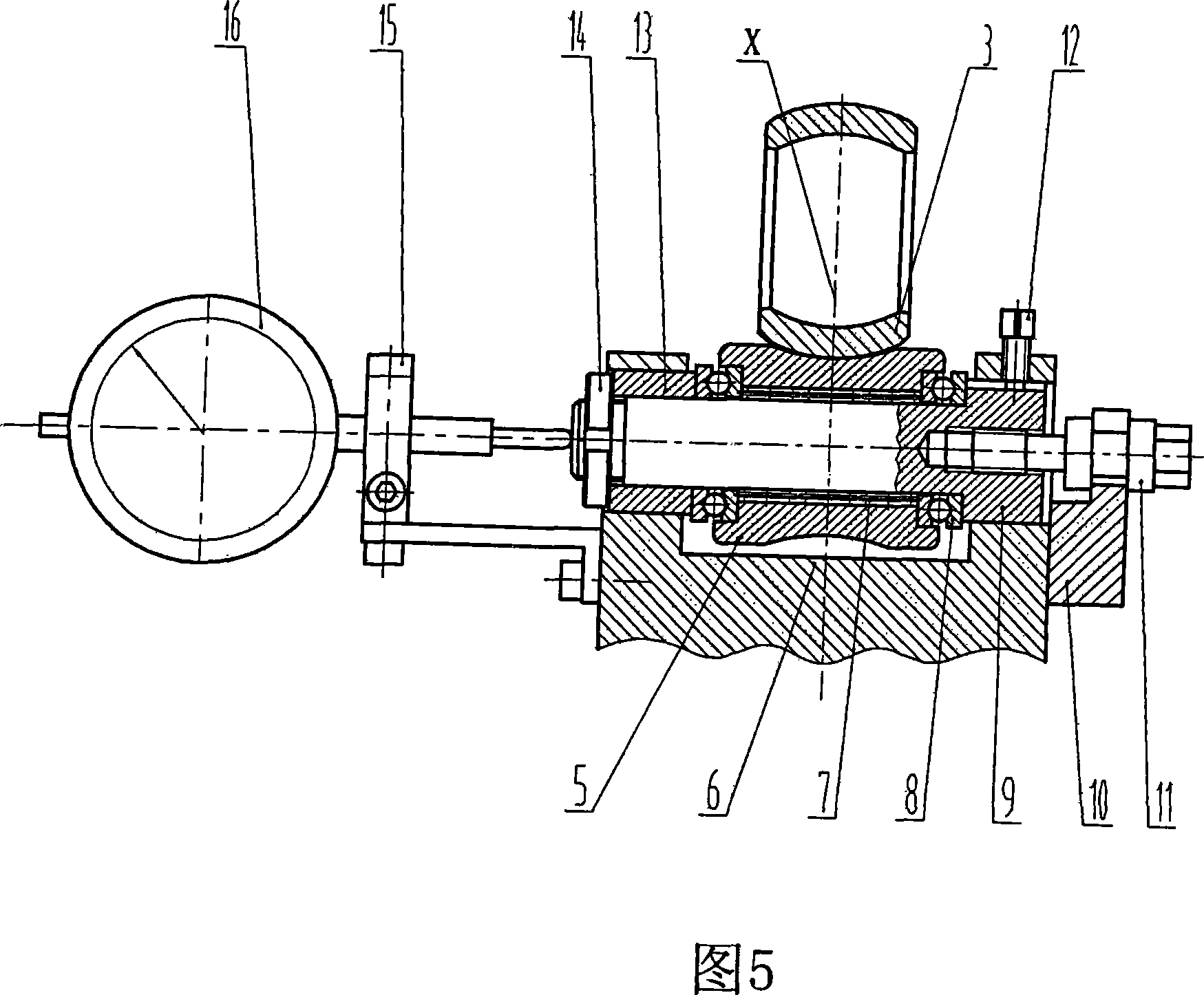

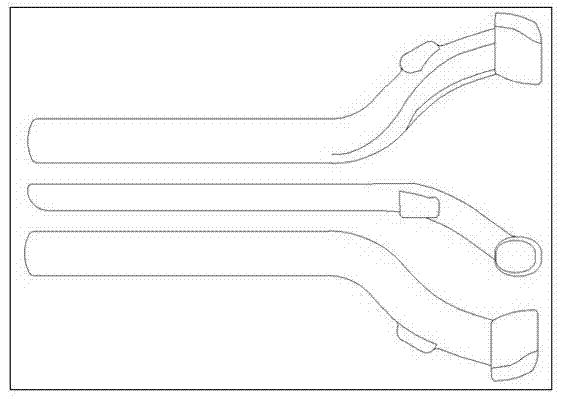

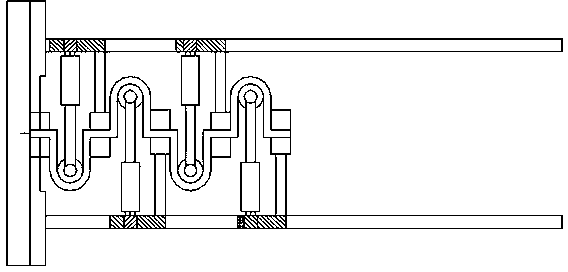

Processing method of enlarging cold-rolling of inside and outside spherical surface ferrule piece as well as device thereof

InactiveCN101176903AGood shape consistencyImprove mechanical propertiesMetal rollingHardnessMechanical property

A method and device for cold rolling and expanding processing of inner and outer spherical metal rings, relating to the technical field of bearing parts processing; what is to be solved is the technical problem of processing inner and outer spherical metal rings of bearing parts; the inner and outer spherical The method for processing metal rings includes the following steps: 1) steel reforming, wherein metal bars are transformed into rings; 2) material is softened, and the rings are subjected to heat treatment to obtain lower hardness so as to facilitate cold rolling; 3) cold rolling blanks Preparation, the ring is processed into a certain precision cold rolling blank by cutting; 4) cold rolling forming, the cold rolling process is performed, the outer circular concave groove of the rolling wheel and the outer cylindrical convex shape of the mandrel in the mold part The grooved shaft enables the workpiece to be formed, and the thrust surfaces of the supporting roller and the support wheel are used to stabilize the workpiece position and limit the axial movement of the workpiece. The invention has the characteristics of improving the mechanical properties of the ring parts, high production efficiency, good shape consistency of workpieces, high processing precision and high material utilization rate.

Owner:刘岷

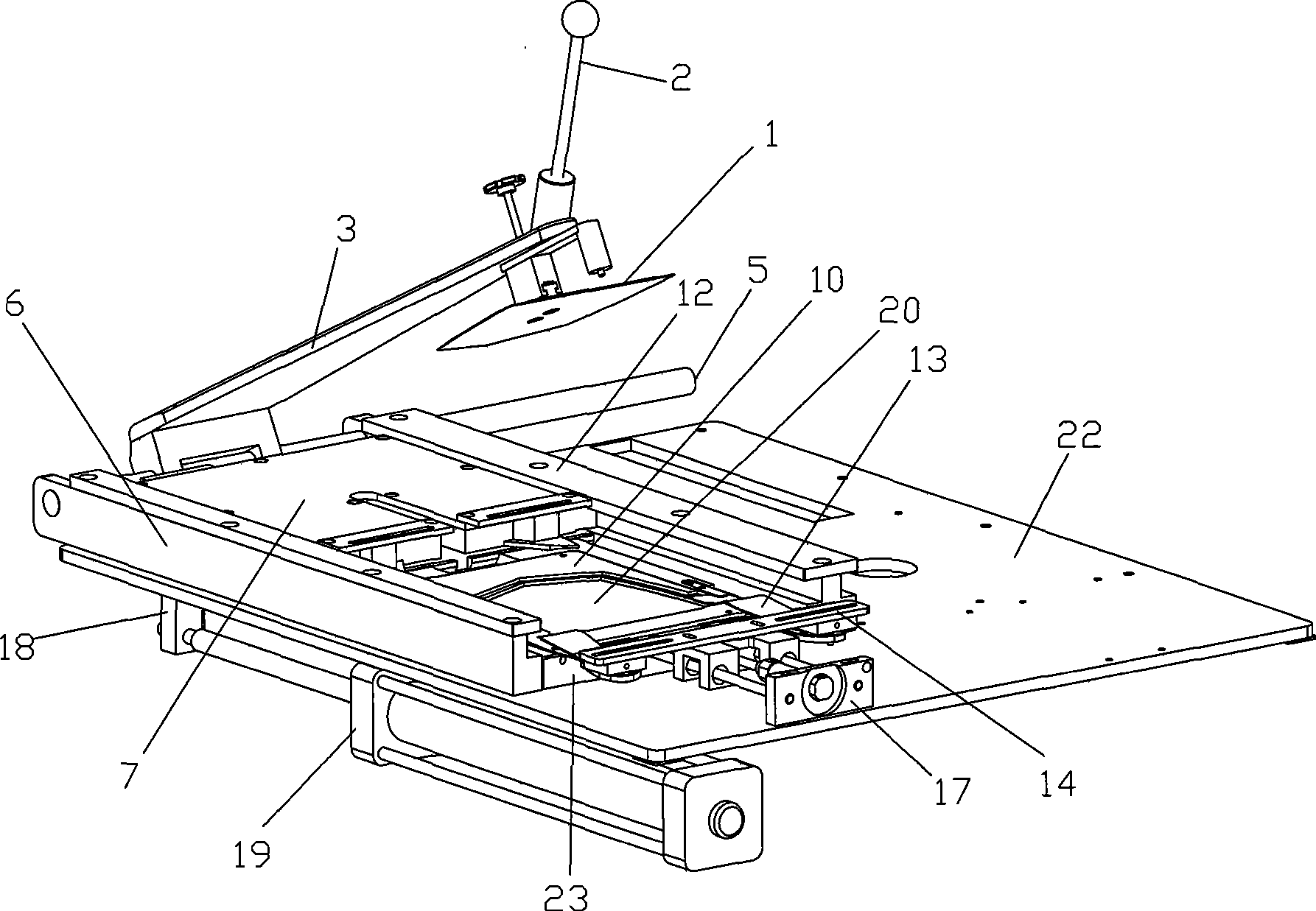

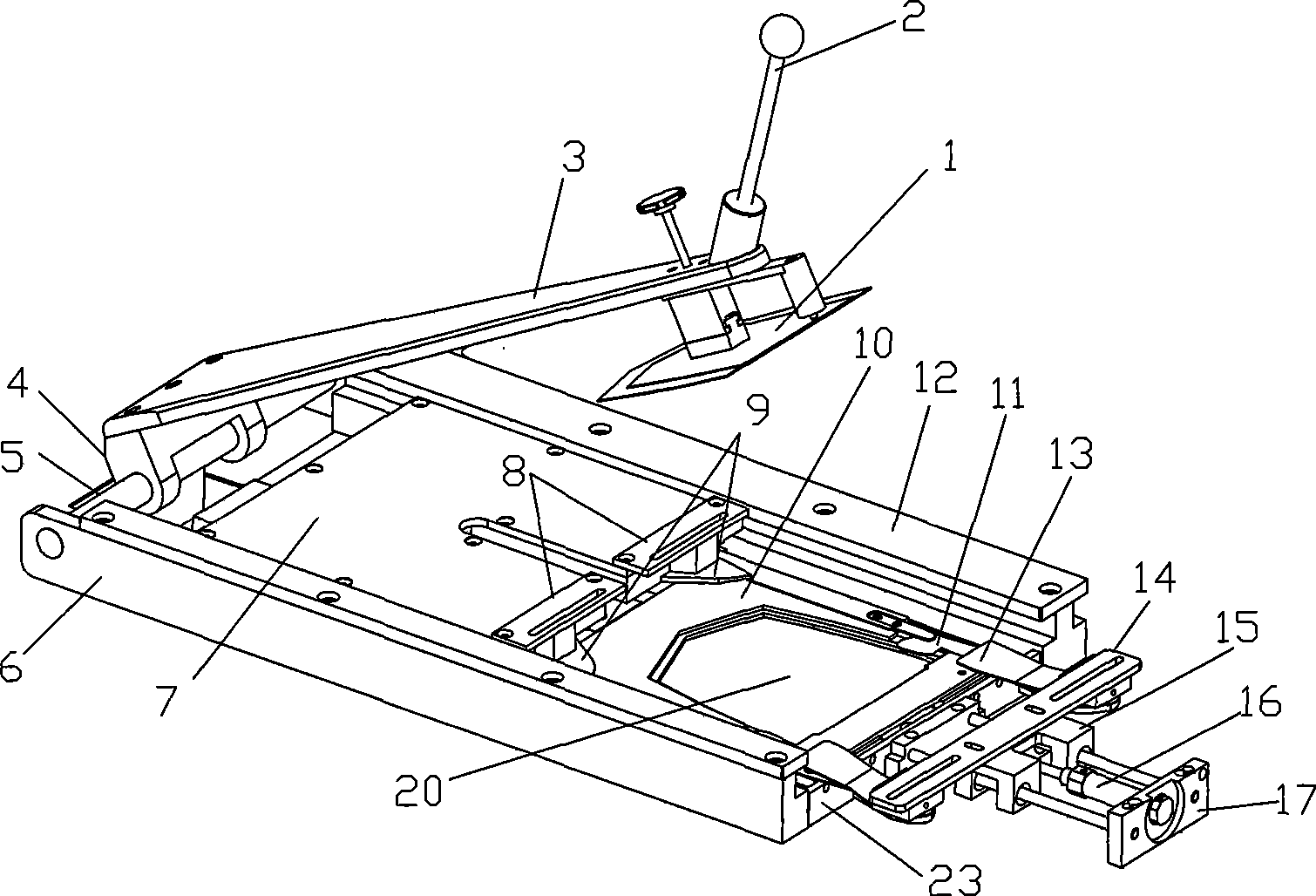

Automatic edge folding mechanism of whole ironing equipment

InactiveCN101377055AGood shape consistencyReduce manufacturing costIroning machinesIroning apparatusEngineeringMechanical engineering

Owner:FEIYUE

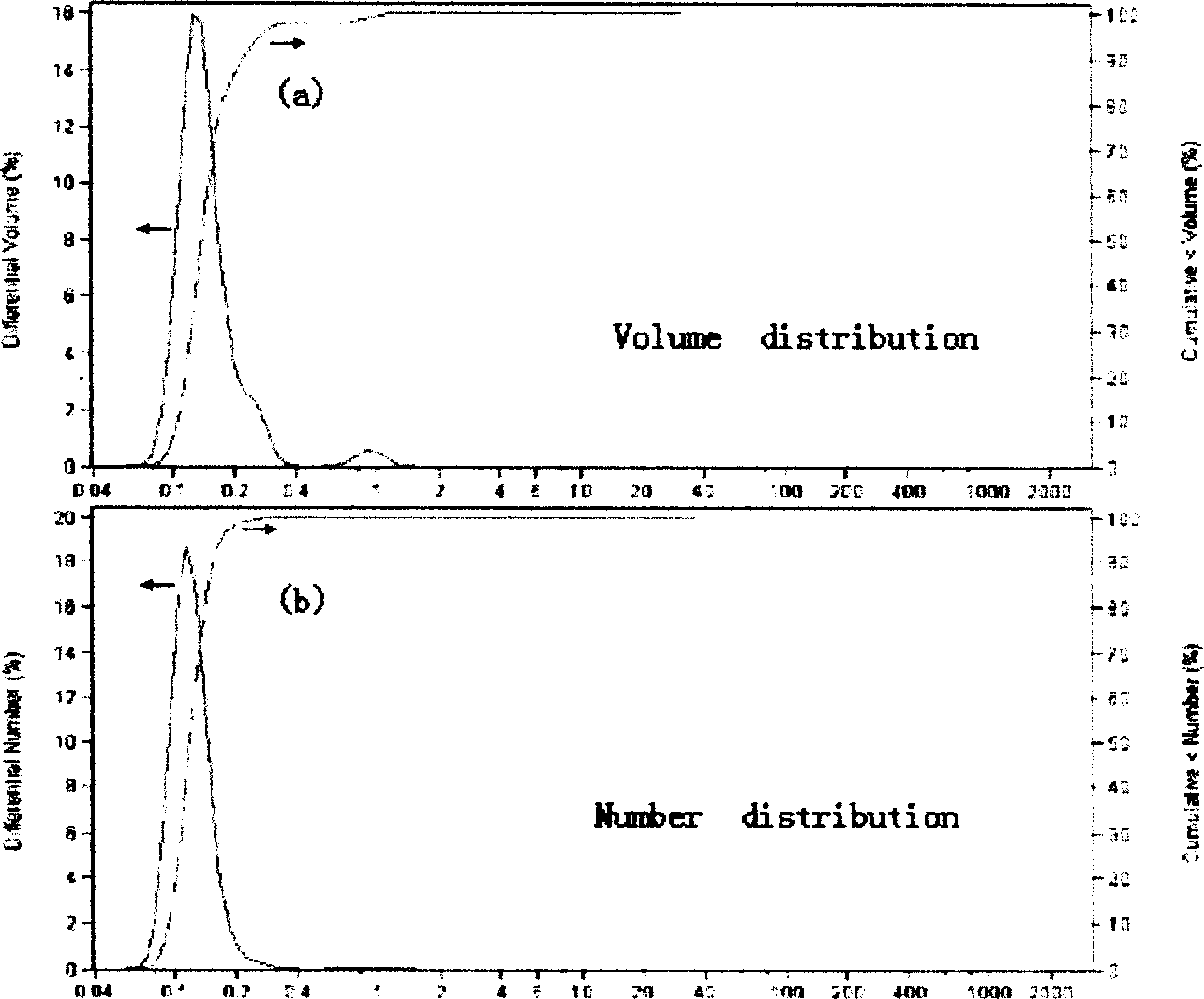

Process for preparing super fine cerium oxide for polishing

InactiveCN1821314ASmall specific surface areaUniform particle size distributionInorganic pigment treatmentOxalateCerium

The present invention relates to preparation process of superfine cerium oxide powder, and belongs to the field of the preparing technology of RE compound. The preparation process of superfine cerium oxide powder includes the following steps: preparing salt solution containing cerium ion, adding surfactant into the solution, contacting the solution with alkali matter to control the pH value of the reaction suspension and produce precipitate; converting the suspension with oxalic acid and controlling the pH value in the reaction end point; filtering, washing and drying the precipitate, scalding at 600-1000 deg.cto obtain the superfine cerium oxide powder of grain size 10 nm to 3 micron and specific surface area smaller than 50 sq m / g. The superfine cerium oxide powder is used as polishing material, especially for optical mask.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

Molding method for casting and forging structure piece of wheelchair frame

ActiveCN102363259AGood shape consistencyEliminate warpingMetal-working apparatusSolution treatmentWheelchair

The invention provides a molding method for casting and forging a structure piece of a wheelchair frame, which comprises the steps of: sawing and cutting an aluminum cast ingot with the outer circle of phi 200mm with a material trade mark of 6061 into blank with the length of 800mm; smelting; pouring; modeling; cutting a dead head; charging a casting blank, heating and fixing the temperature at 530 DEG C; forging and pressing the casting blank by a 5000-ton oil press and a forging mould; forging and pressing to obtain a forged piece; etching and washing; treating with solid solution; and manually correcting the specific deformation degree of the forged piece. The precast blank is cast and molded by the method, the shape of the blank is good in consistency, the shape of a curved surface iseasy to control, a casting material can be cyclically utilized, and the material utilization can be furthest improved; and the batch production practice proves that the finished forged piece producedby a casting and forging technological process has no forging defects, the thermal treatment performance meets the demand, and the final status of the forged piece completely accords with user demand.

Owner:HARBIN HAFEI IND

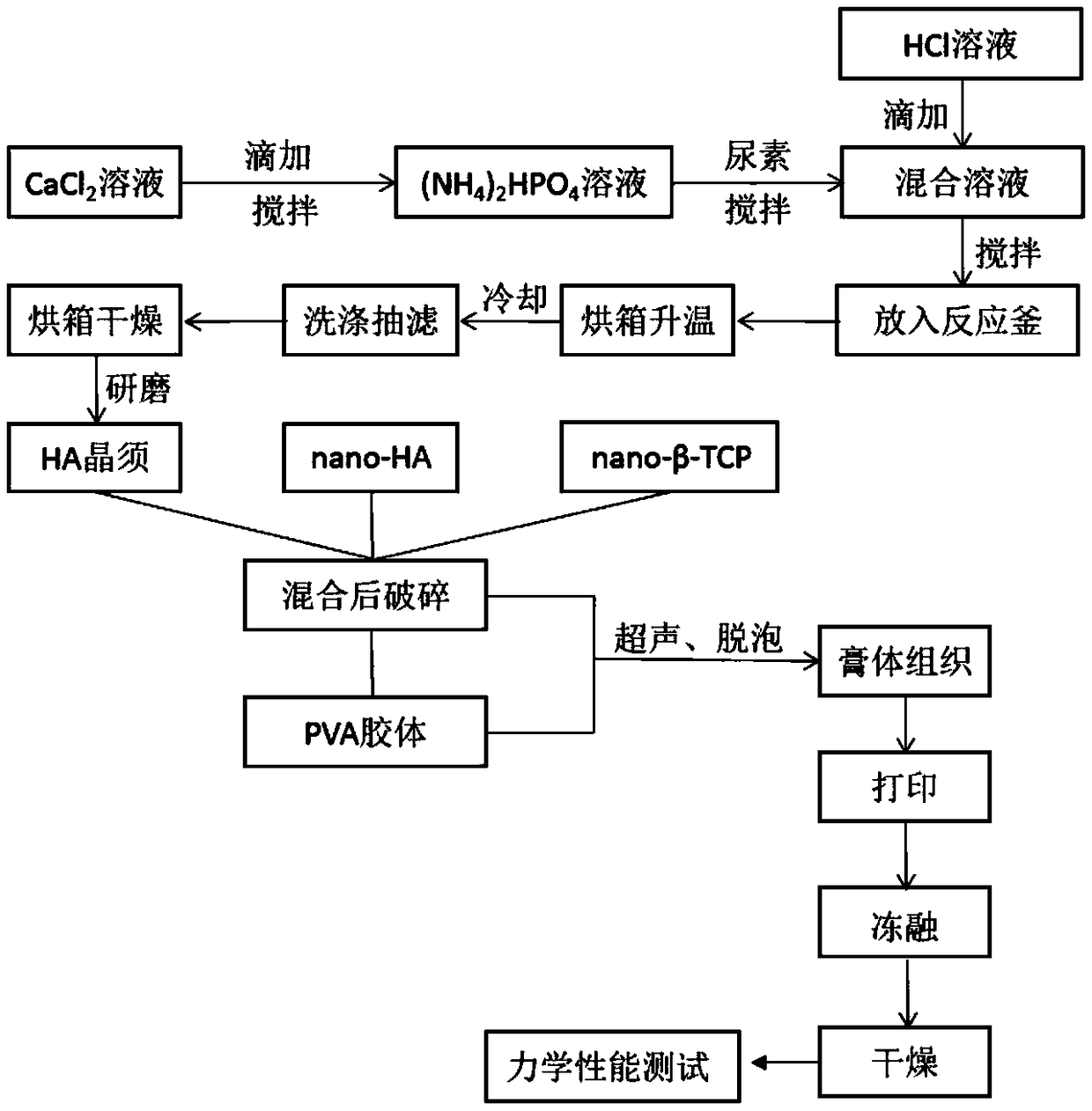

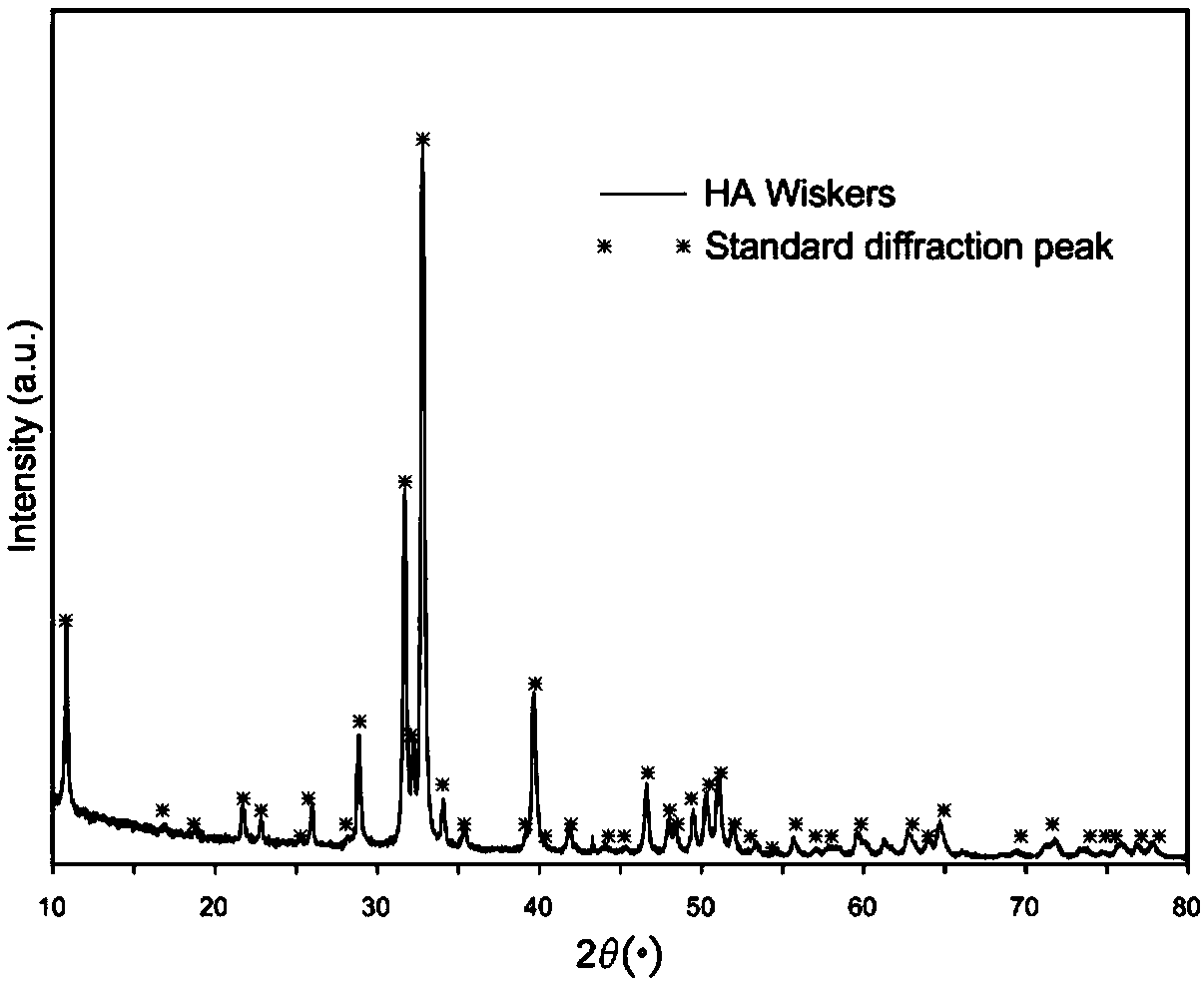

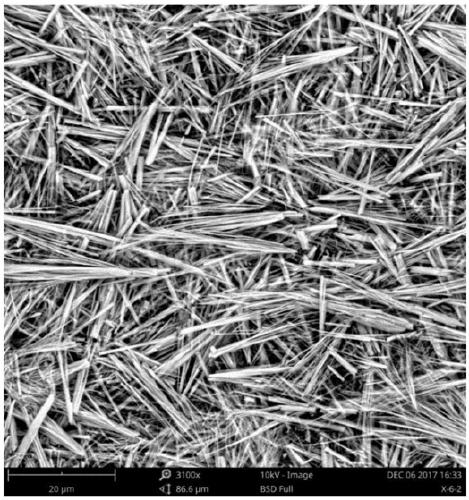

Artificial bone containing hydroxyapatite whiskers and diphasic calcium phosphate and preparation method of artificial bone

InactiveCN109133907APromote growthPromote healingPolycrystalline material growthAdditive manufacturing apparatusPorosityTri calcium phosphate

The invention discloses an artificial bone containing hydroxyapatite whiskers and diphasic calcium phosphate and a preparation method of the artificial bone. The hydroxyapatite whiskers, hydroxyapatite powder and beta-tricalcium phosphate are used as raw materials of the artificial bone, the artificial bone has an induction effect on growth of osteocytes, and growth and healing of the osteocytes are promoted; by controlling the ratio of the hydroxyapatite whiskers, the hydroxyapatite powder and the beta-tricalcium phosphate, the strength of the artificial bone is increased; the preparation method of the artificial bone is a 3D printing technology, on the one hand, the 3D printing technology can customize a stent according to the shape of a bone defect portion, and the shortcomings that bymanufacturing through a traditional mold, molding is required at first, then size is limited after molding, and the cost of the mold is high are overcome; and on the other hand, by the method, the aperture, the porosity and the connectivity of the stent can be controlled precisely, and an open porous structure and an interconnected network are of great important on cytotrophy supply, proliferationand differentiation and formation of tissues and blood vessels.

Owner:迈海新型材料科技(固安)有限公司

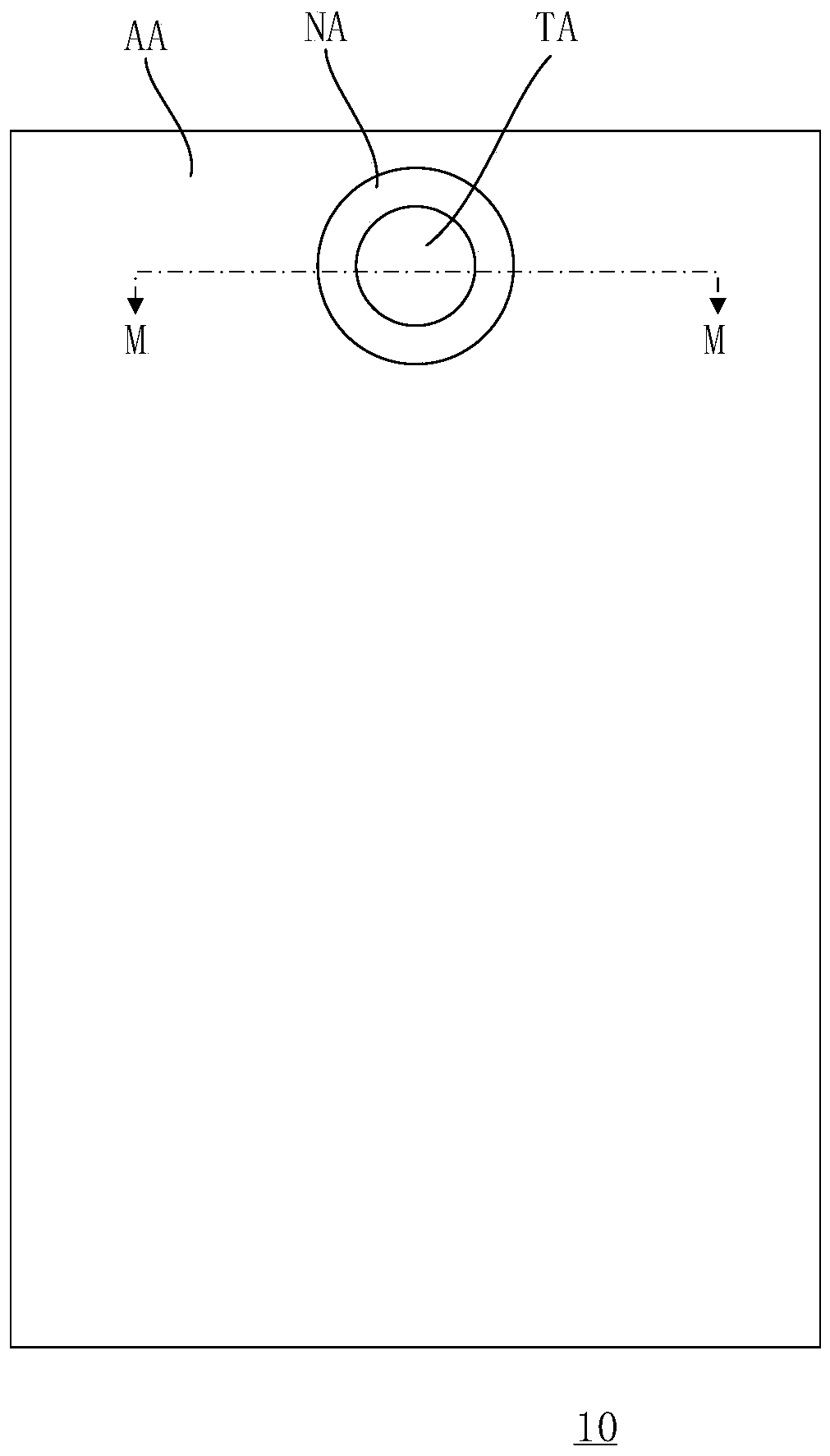

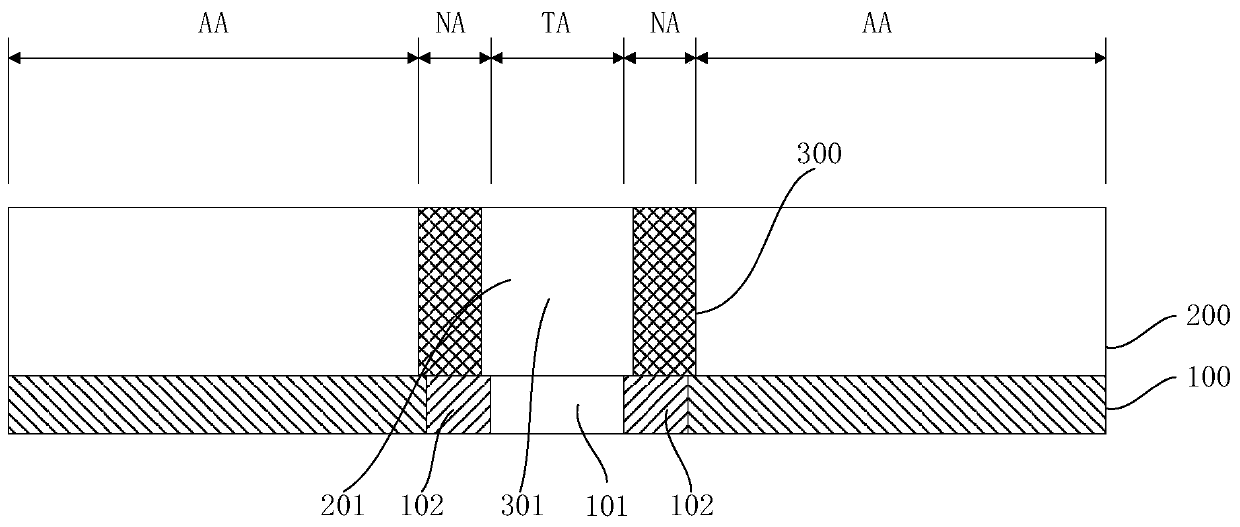

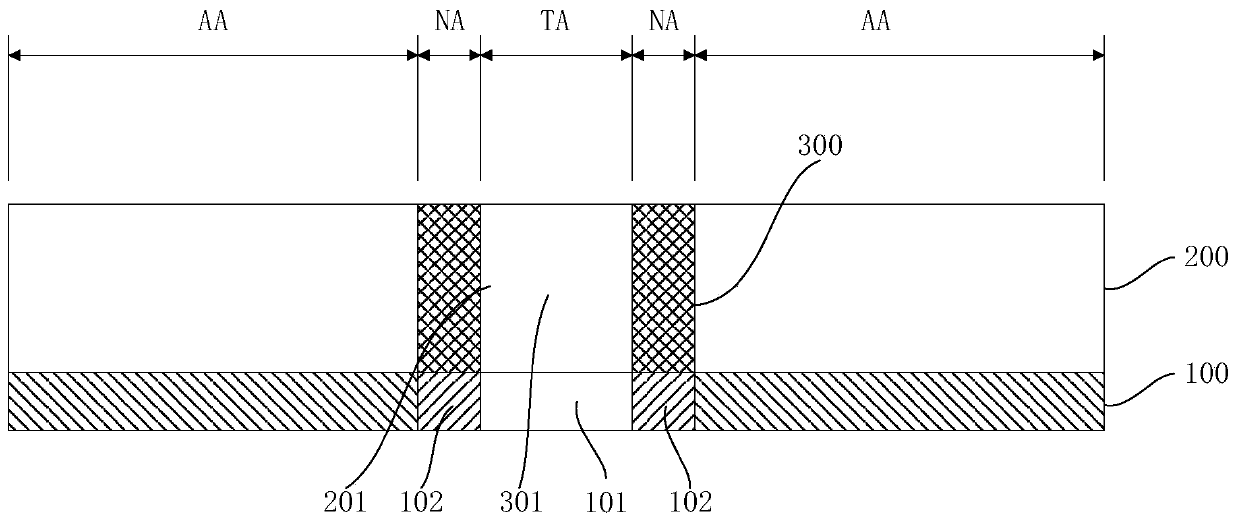

Display panel, manufacturing method thereof and display device

ActiveCN111430422AReduce process stepsImprove coaxialitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention discloses a display panel, a manufacturing method thereof and a display device. The display panel is provided with a display area, a light-transmitting area and a non-display area, and the display panel comprises a light-emitting device layer which is provided with a first through hole and a packaging edge area arranged around the first through hole, wherein the packaging edge area is located in the non-display area; an auxiliary element layer which is arranged on the light-emitting device layer in a stacked mode, wherein the auxiliary element layer is provided with a second through hole communicated with the first through hole in the axial direction, and the hole diameter of the second through hole is larger than that of the first through hole; and a first shading layer which is arranged in the second through hole and located in the non-display area, wherein the first shading layer is in a column shape with a hollow part and extends in the axial direction on the wall face of the second through hole, and the orthographic projection of the first shading layer on the light-emitting device layer is at least partially overlapped with the packaging edge area. According tothe display panel, light emitted by the light-emitting device layer can be prevented from entering the light-transmitting area.

Owner:HEFEI VISIONOX TECH CO LTD

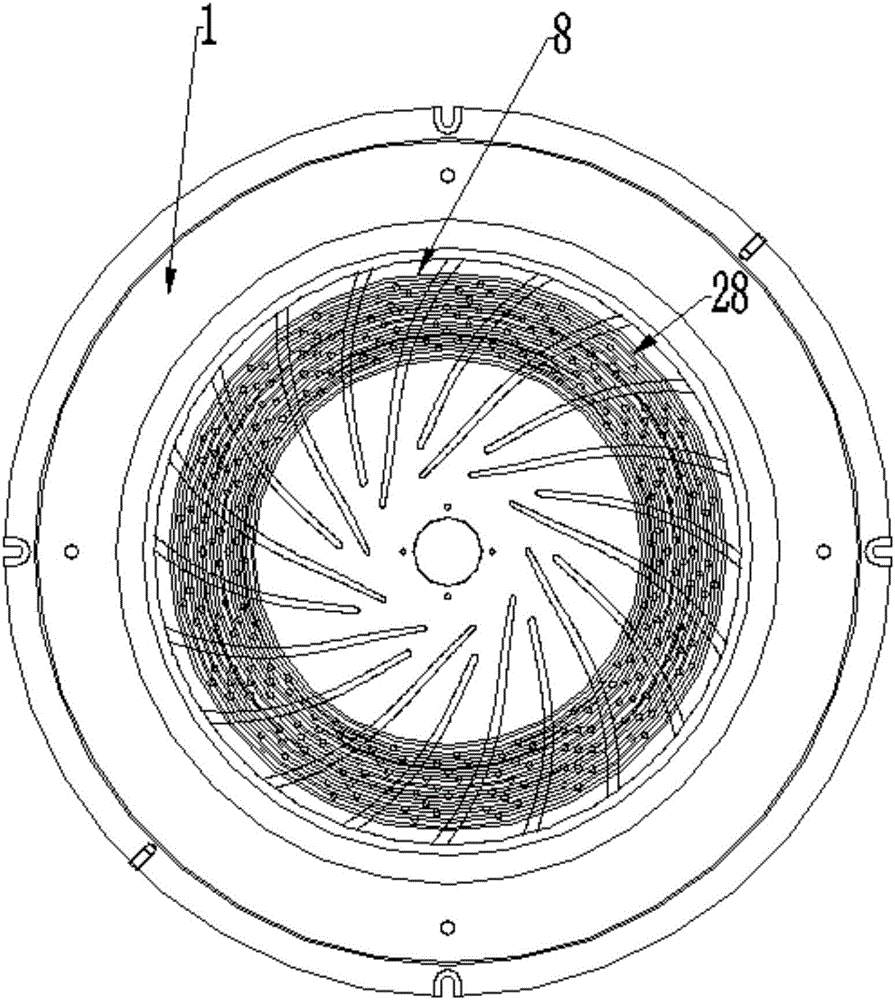

Manufacturing method for large thin-walled impeller

The invention discloses a manufacturing method for a large thin-walled impeller. An upper mold body of a mold is internally provided with annular grooves and exhaust plugs so that exhausting can be improved, a cooling cone is arranged on the upper mold body and cooling rings are arranged on the upper surface of the upper mold body so that the cooling speed of castings can be increased, and meanwhile a sand mold is used at the bottom of a gypsum core so that heat preservation of molten aluminum at the bottom and feeding of the castings can be facilitated. The program allowing integral casting of the thin-walled and large-size impeller to be achieved by improving exhausting and cooling is adopted for the mold, the forming quality is good, and precision is high; a first concave part is arranged to position the first circular face of the end portion of the impeller, the impeller is locked to a bottom plate through first pressing pieces, welding is not needed, and fixation is convenient and rapid; and after the first round of machining is conducted on the impeller, a second concave part is arranged to position the second circular face of the impeller, fastening is conducted through second pressing pieces, machining is conducted on the impeller in order, the situation that some faces are not machined due to clamps or other reasons is avoided, and the surface precision of the impeller is improved.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

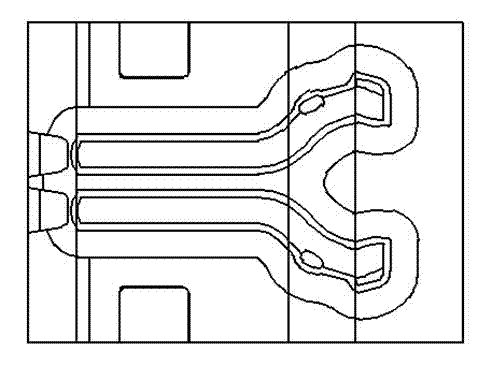

Manufacturing method for electrode of lithium niobate optical waveguide device

ActiveCN103353630AGuaranteed not to overlapImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusSputteringMetal strips

Disclosed in the invention is a manufacturing method for an electrode of a lithium niobate optical waveguide device. The manufacturing method comprises the following steps: using SiO2 as a mask and manufacturing an optical waveguide by using annealing proton exchange processing; utilizing the SiO2 mask as a mark to directly carry out self-alignment overlaying on the optical waveguide and an electrode graph; removing the SiO2 mask of the electrode zone by employing a method of combination of dry etching with wet etching; and utilizing sputtering and metal stripping technologies to manufacture the electrode graph and removing the residual SiO2 mask. When the method is used, the electrode graph can be formed at the lithium niobate optical waveguide and accurate overlaying between the optical waveguide and the electrode is ensured; the edge of the electrode is smooth; the defects are less; and the yield is high.

Owner:GUANGXUN SCI & TECH WUHAN

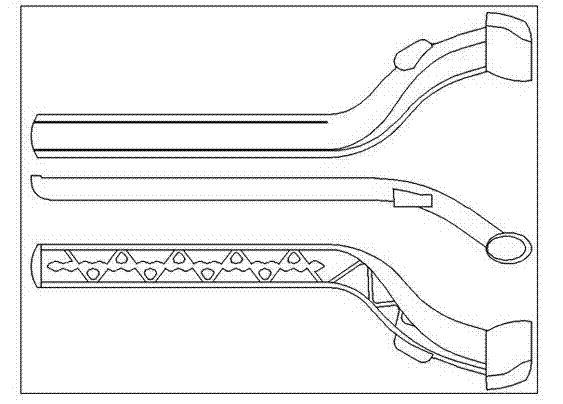

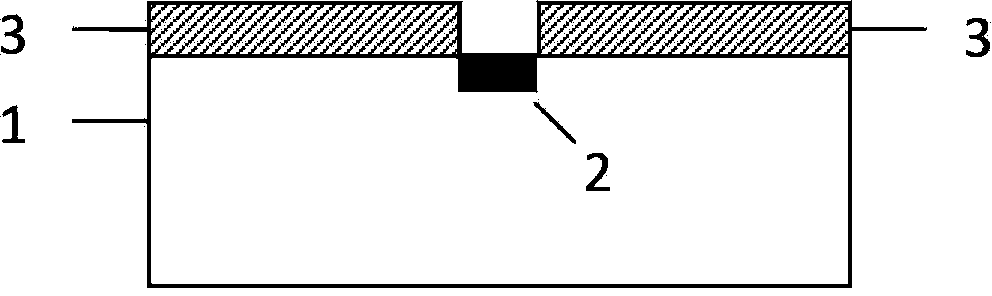

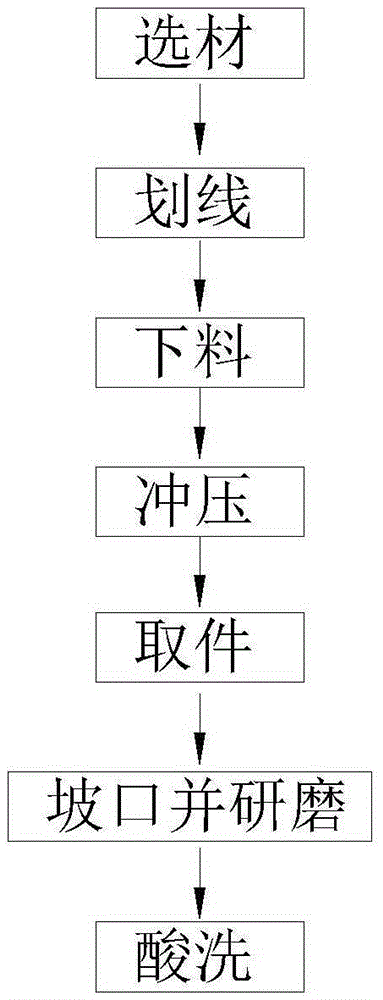

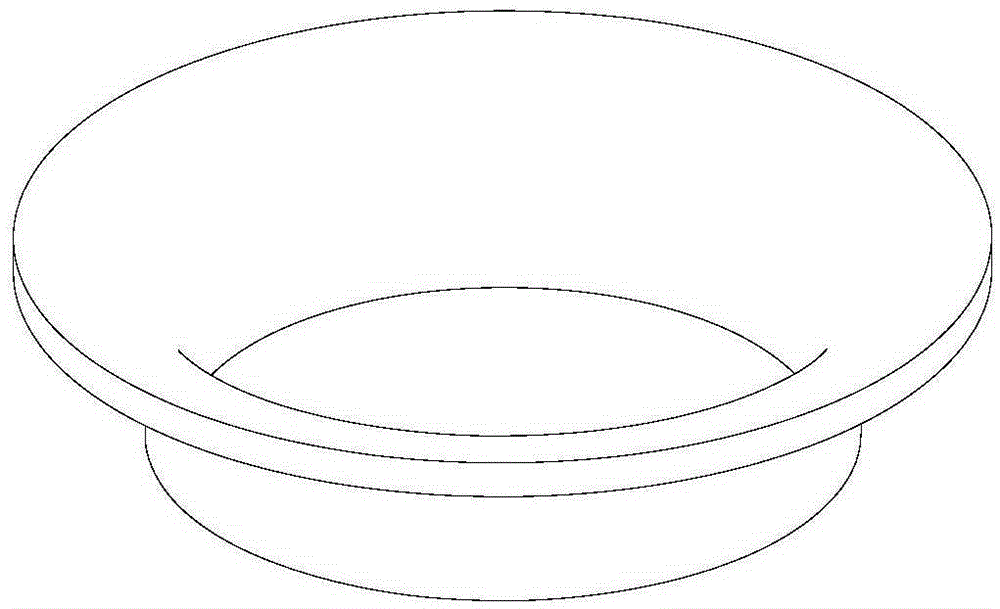

Machining method of horn-shaped seal head

ActiveCN105344872AGood shape consistencyAvoid Scrap SituationsHollow articlesEngineeringMachining process

The invention provides a machining method of a horn-shaped seal head. The machining method comprises machining steps including material selection, scribing, blanking, stamping, part taking, groove machining and grinding and acid pickling. The overall cold stamping is realized through preset clearance cooperation of an existing stamping machine and a stamping die, the machined seal head has good size and shape consistency, the accuracy requirement of a foreign power spinning machine is met, a curved surface machined through the stamping die is smooth, the curved surface of the seal head and the round section of a lower straight barrel are in smooth transition, the condition of scrapping caused by edges and marks and even cracking of the seal head in the machining process of the strong spinning machine is avoided, and the scrappage is very low; meanwhile, an ordinary operator of the stamping machine can master the machining method after a little training, the technical requirements for the operator are lower, the production efficiency is remarkably improved, and the delivery term is greatly shortened.

Owner:CHANGZHOU KUANGDA WEIDE MACHINERY

Manufacturing method and system for gypsum core used for casting of large impeller

The invention discloses a manufacturing method and apparatus for a gypsum core used for casting of a large impeller. The manufacturing method comprises the following steps: 1, inlaying cast mold low-melting-point alloy impeller blades in a gypsum core mold; 2, carrying out mixing to prepare gypsum slurry and adding the mixed gypsum slurry into a vacuum mixer; 3, carrying out vacuum-pumping and vibratory mixing on the gypsum slurry by using the vacuum mixer; 4, injecting the gypsum slurry having undergone bubble removal into the gypsum core under vacuum conditions and carrying out vibration and defoaming by using a vibration machine after completion of injection; 5, strickling the upper end of the gypsum core by using a tool after completion of injection; 6, placing the cured gypsum core on a special gypsum core drying bracket; 7, putting the bracket and the gypsum core into a drying machine; 8, taking the gypsum core and the bracket, separating the gypsum core from the bracket, collecting low-melting-point alloy for reuse, placing the gypsum core on a finishing rack, repairing flaws on the surface of the core and removing unwanted impurities; and 9, detecting the gypsum core before usage of the gypsum core.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

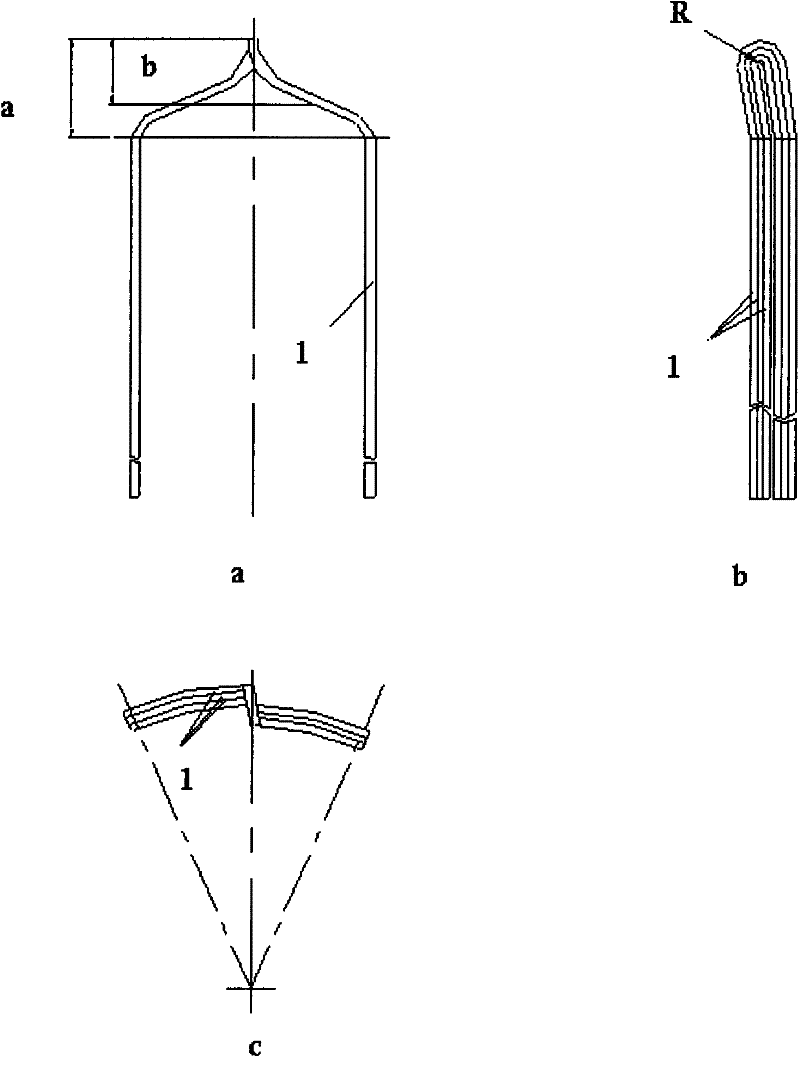

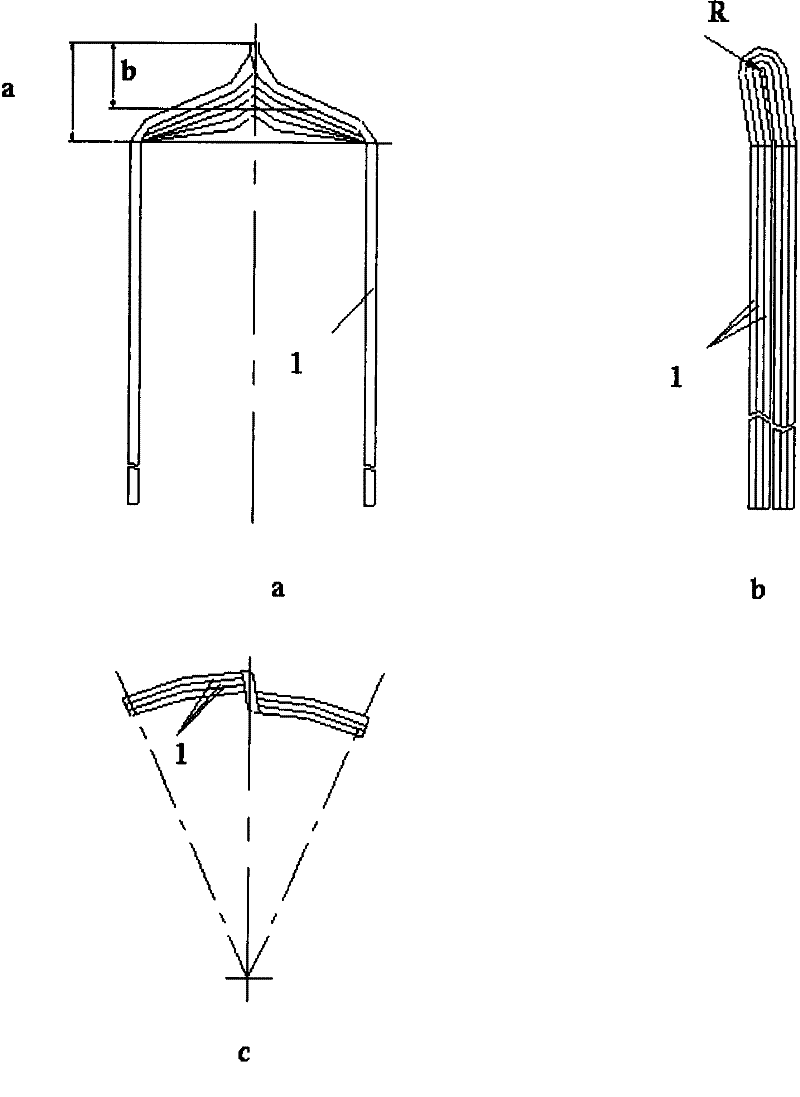

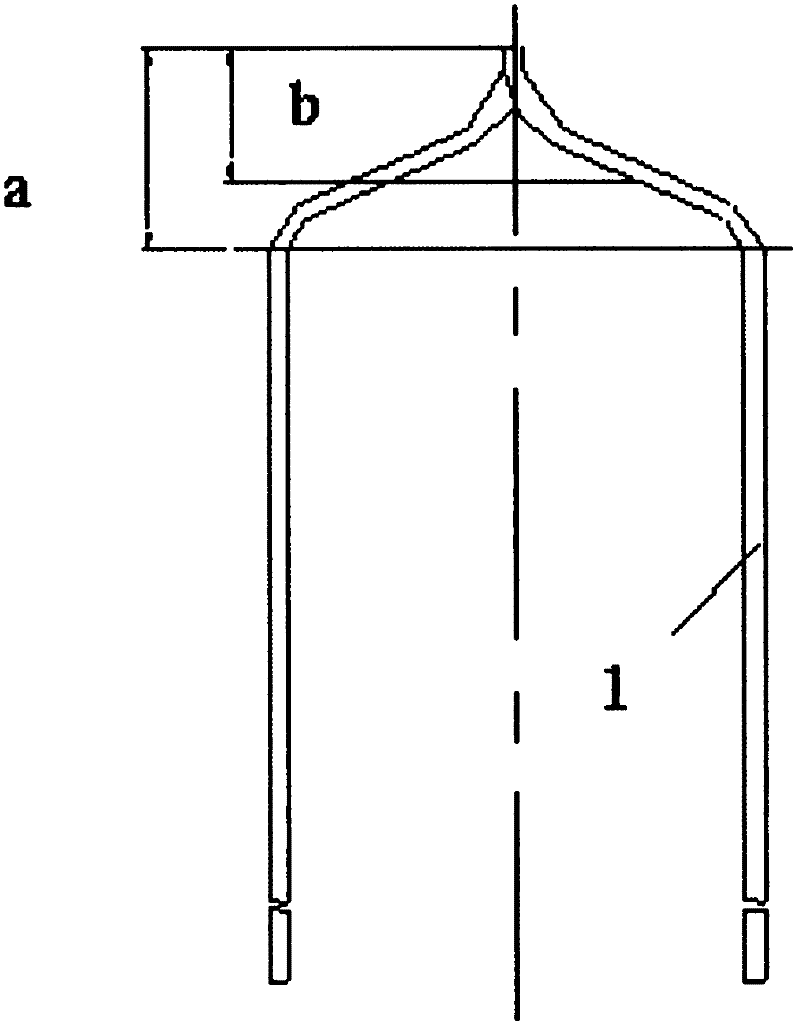

A method for forming multi-conductor parallel winding components

InactiveCN102299593AImprove insulation performanceImprove cooling effectManufacturing dynamo-electric machinesElectrical conductorEngineering

The invention relates to a forming method of a multi-conductor parallel winding element. The forming method provided by the invention is technically characterized by comprising the following steps: connecting N solid wires in parallel, and overlapping and fixing the middle parts of the solid wires by use of insulating tapes so as to form an integral wire; bending the integral wire into a U shape and dismantling the insulating tapes; and performing 1 / 2 overlapping by taking the bent part of the U shape of the integral wire as a center and performing drawing formation according to winding element chart requirements. The multi-conductor parallel winding element produced by the method provided by the invention has the advantages that the end socket of the element has no conductor separation phenomenon, the integral shape consistency is good and no conductor insulation damage is caused. When the stator / rotor winding of a motor is subjected to wire inserting, the element can be put into a groove easily, the size of a winding head after wire inserting is small, and the end sockets of the element are uniformly arranged in order, so that the insulation damage caused by squeezing and collision among conductors at the winding head of the motor winding being subject to wire inserting can be avoided, the turn-to-turn short circuit fault of the motor winding can be effectively prevented from being caused, and the insulating property of the motor winding and the heat dissipation performance of the winding head are improved.

Owner:SHAANXI AVIATION ELECTRICAL

Manufacturing method of multifunctional drill hard alloy

The invention discloses a manufacturing method of multifunctional drill hard alloy, which comprises the following steps of: placing hard-phase powder into an airflow pulverizer to be pulverized, then placing the pulverized material into a blending ball mill to be blended and ground to form slurry, filtering, drying and screening the slurry be pressed, squeezed and molded to form the multifunctional drill hard alloy. Through a high-energy breaking and airflow grading method, the hard-alloy powder with inherent defect is broken with brute force and then is shaped so as to give high energy to the surface of the hard phase, to reduce the defect of the hard-phase powder and to improve the powder energy; and through high-speed and high-efficient mixing and shaping, components are more uniformly mixed, and the consistence of the powder appearance can be improved, so that the alloy tissue crystal granularity is uniform in size, the consistence of the grain shape is good, no refined particle and oversized particle exist, the granularity is centralized, and no internal defect exists; and finally the performance of the multifunctional drill hard alloy material can be improved.

Owner:湖南奇力工具有限公司

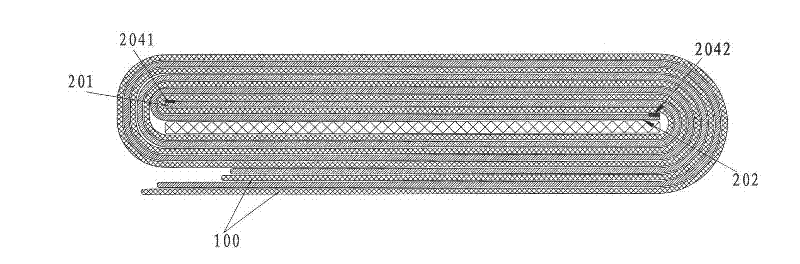

Lug, rolled lithium ion cell and soft-package rolled lithium ion battery

InactiveCN102332552AGuaranteed shape consistencyGood shape consistencyFinal product manufactureSecondary cellsAdhesivePhysical chemistry

The invention relates to the field of lithium ion battery designs, and discloses a lug, a rolled lithium ion cell and a soft-package rolled lithium ion battery. The lug comprises a foil and lug adhesive, the foil consists of a lathy section and a rectangular section, wherein the width of the rectangular section is larger than the width of the lathy section; and the lug adhesive is stuck on both surfaces of one predetermined section of the lathy section, and is a predetermined distance away from the rectangular section. The lug applied in the soft-package rolled lithium ion battery can help to improve the smoothness of the surfaces of the rolled cell and the soft-package rolled lithium ion battery and increase the convenience of production.

Owner:SHENZHEN GREPOW BATTERY CO LTD

Laminated lithium battery aluminum shell structure and manufacturing method thereof

ActiveCN105140429AImprove sealingImprove connection reliabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringSpot welding

The invention discloses a laminated lithium battery aluminum shell structure and a manufacturing method thereof. The structure comprises a shell bottom and a shell wall, wherein the shell bottom is completely located in the shell wall, the peripheral outline of the shell bottom is attached to the shell wall with a 0-0.2 mm gap reserved on each side, and the shell bottom and the shell wall are connected through friction stir spot welding. The laminated lithium battery aluminum shell structure manufactured with the method is high in strength reliability and sealing performance, neat and attractive in appearance, and capable of improving the shape consistency of batteries.

Owner:昆山斯格威电子科技有限公司

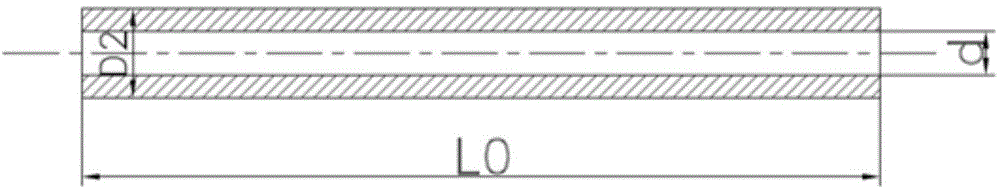

Precise forming method for automobile engine hollow valve blank with core bar

ActiveCN104924028AIncrease productivityGood shape consistencyMachines/enginesLift valveSpherical shapedGrain structure

The invention belongs to the technical field of metal plastic forming, and particularly provides a method for transverse rolling forming of an engine hollow valve blank. The transverse rolling method is used for symmetrically machining the hollow blank of a hollow valve; a conical table and a spherical table are formed on the machined hollow blank, and then a disc portion of the hollow valve is formed through die forging. Compared with the traditional solid valve drilling and backward extrusion process, the transverse rolling process is used for producing the automobile engine hollow valve blank, and the method has the advantages that production efficiency is high, and 6-12 blanks can be manufactured every minute through one machine; the material utilization rate is improved; the overall streamline distribution in the valve is reasonable, and the tissue is fine; all parts of the blank deform, a refined and even grain structure can be obtained, and the overall mechanical property of the valve can be conveniently improved.

Owner:UNIV OF SCI & TECH BEIJING +1

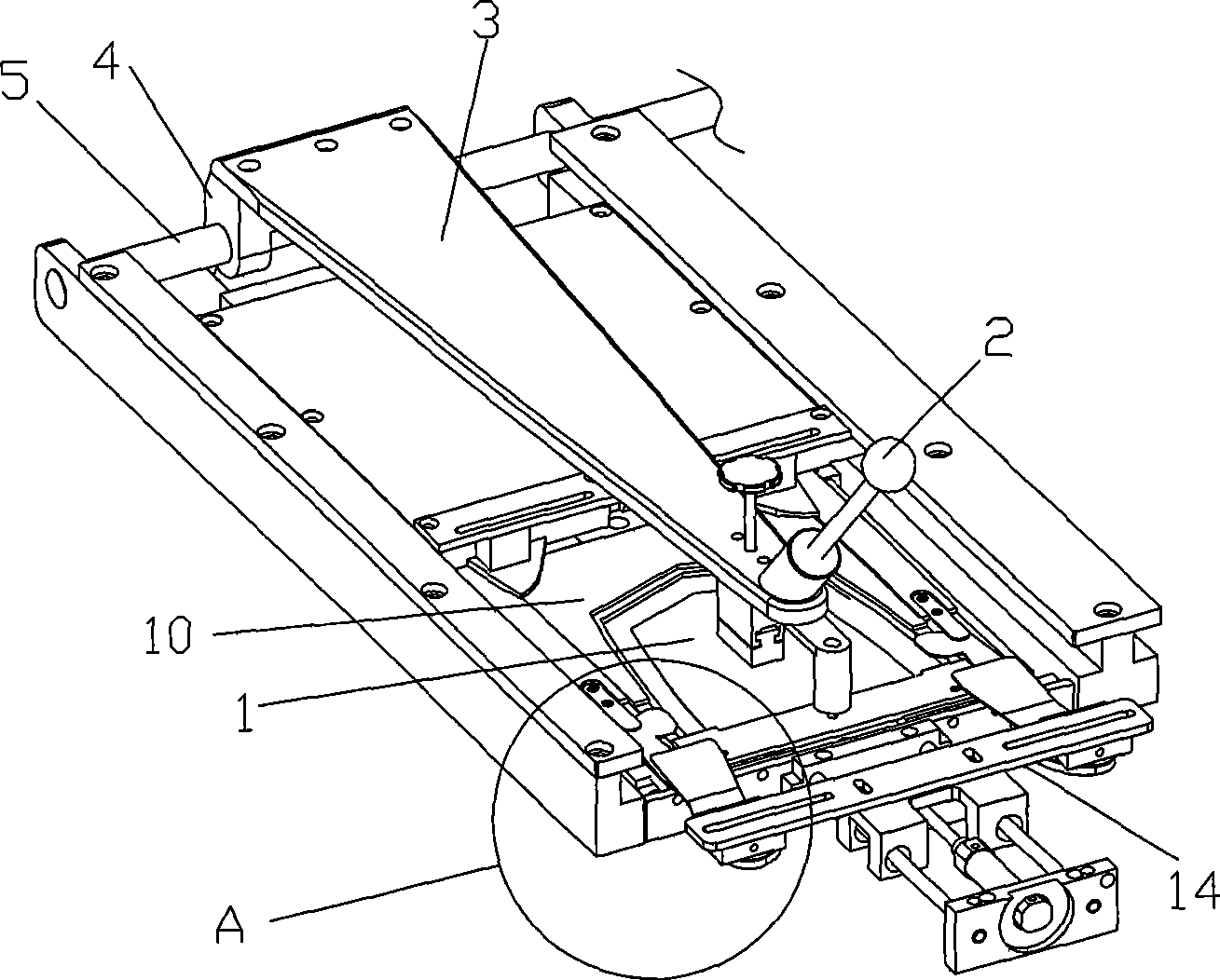

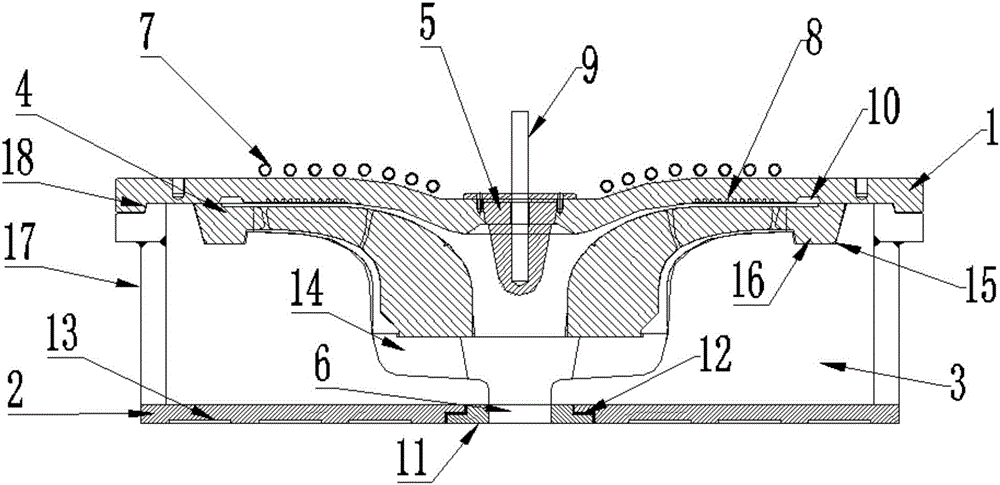

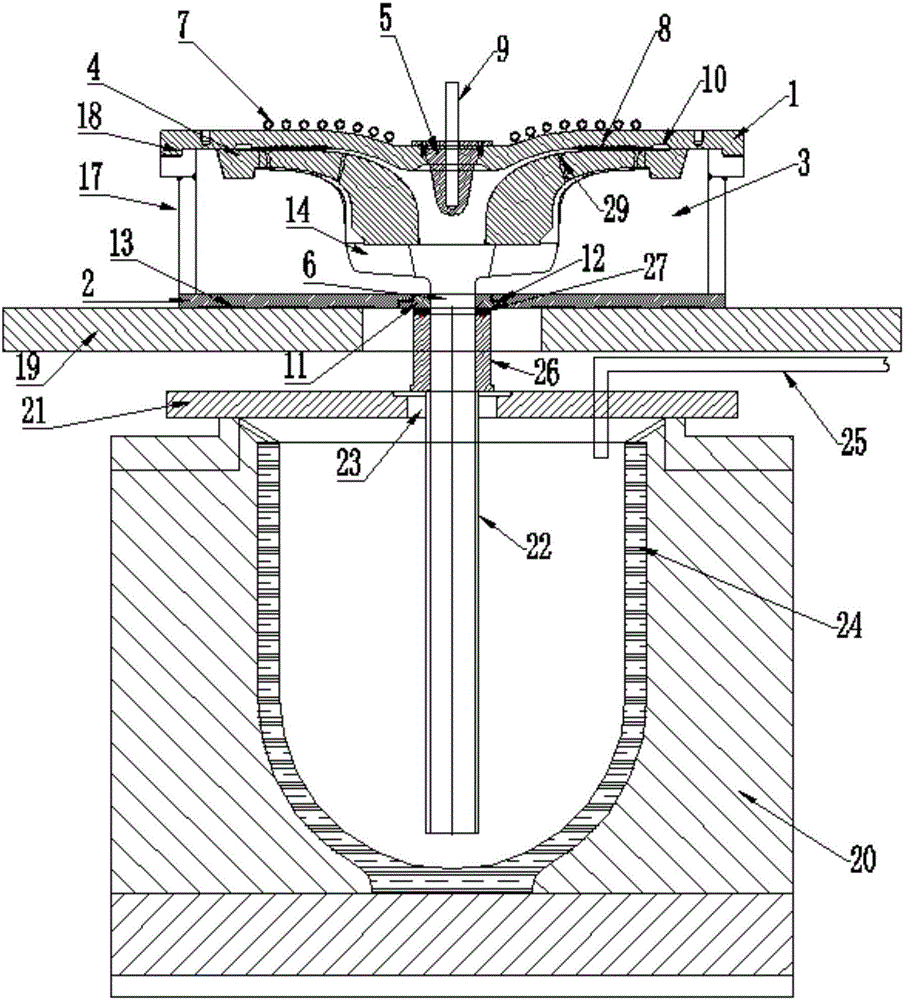

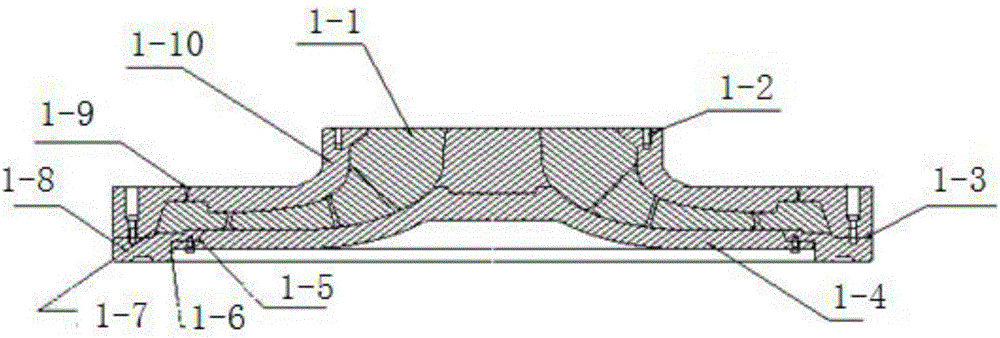

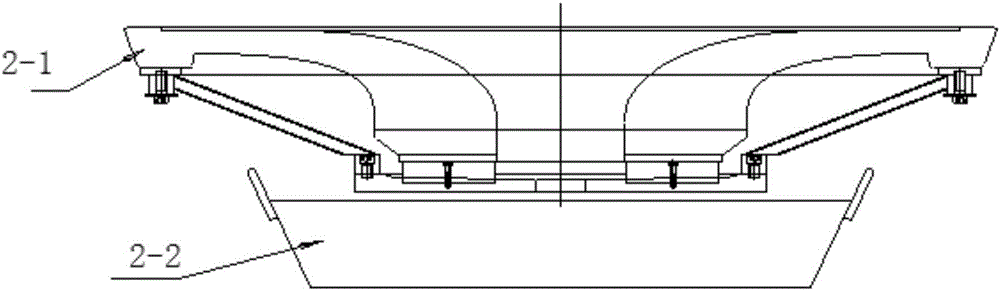

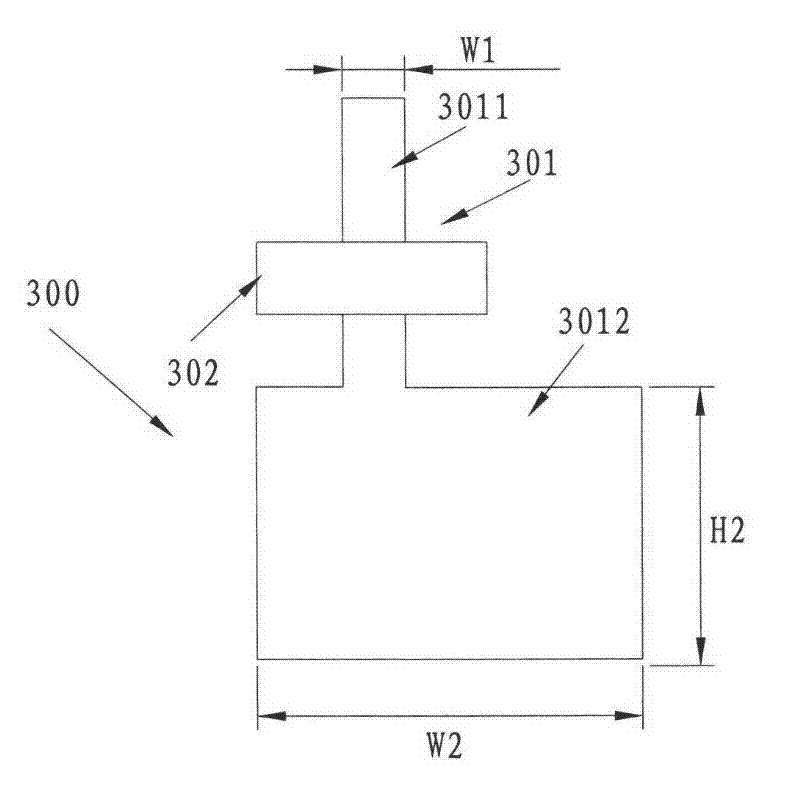

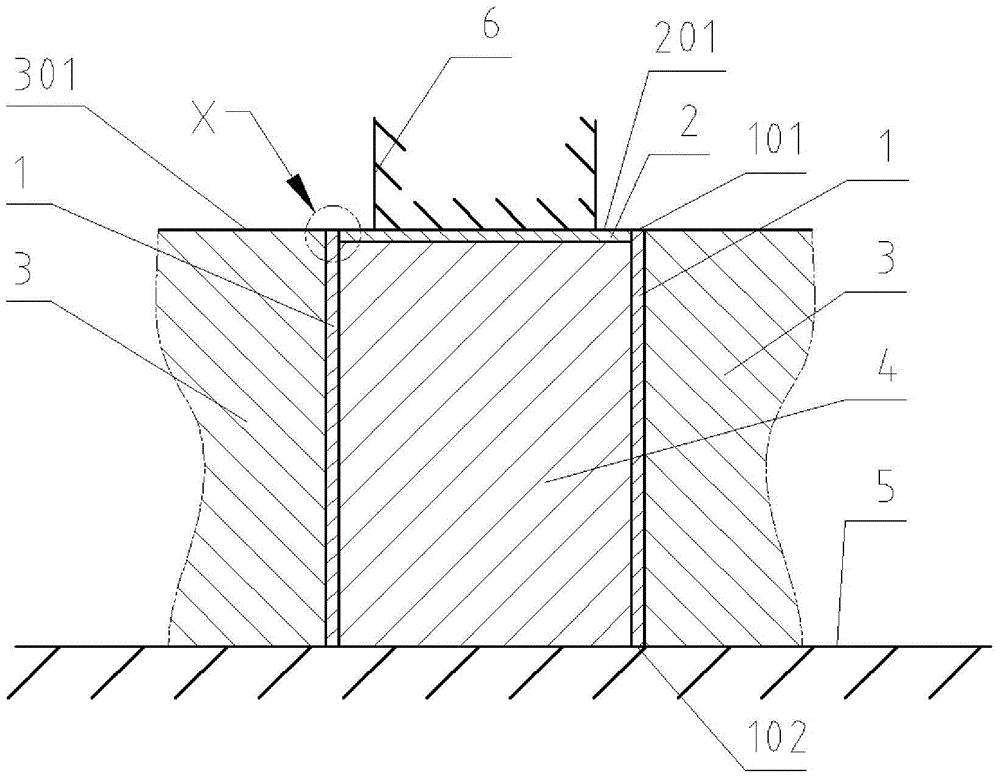

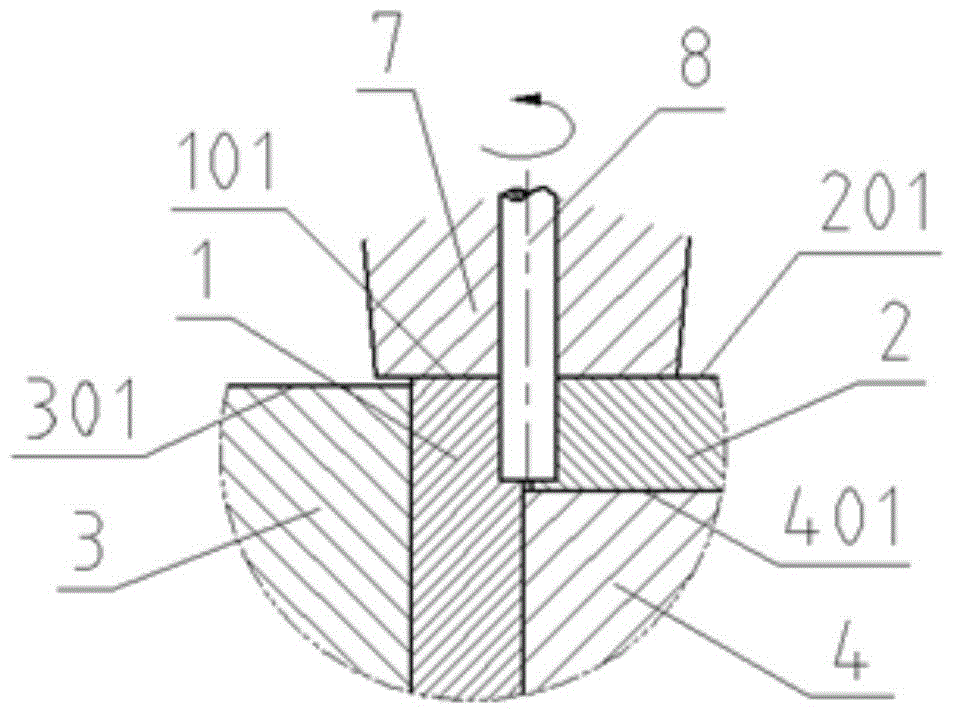

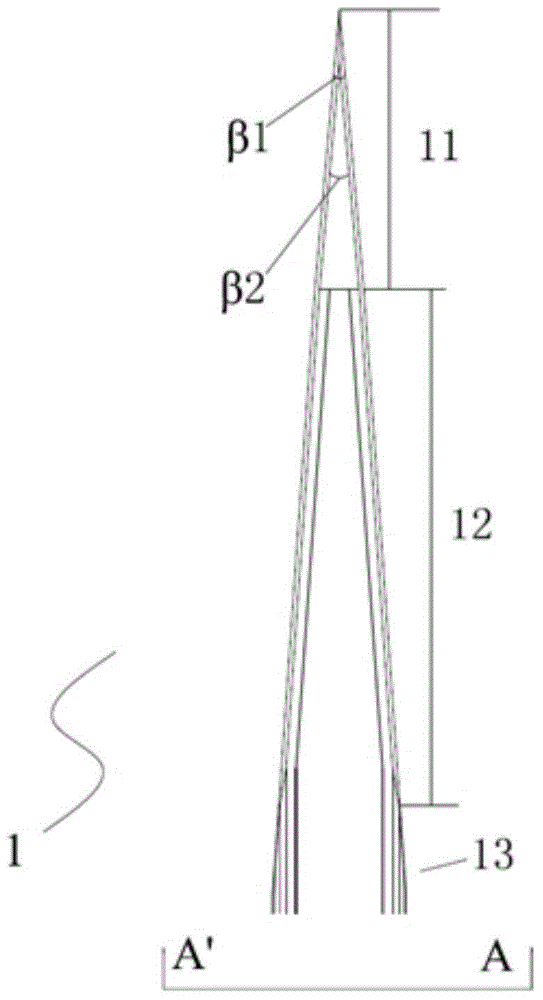

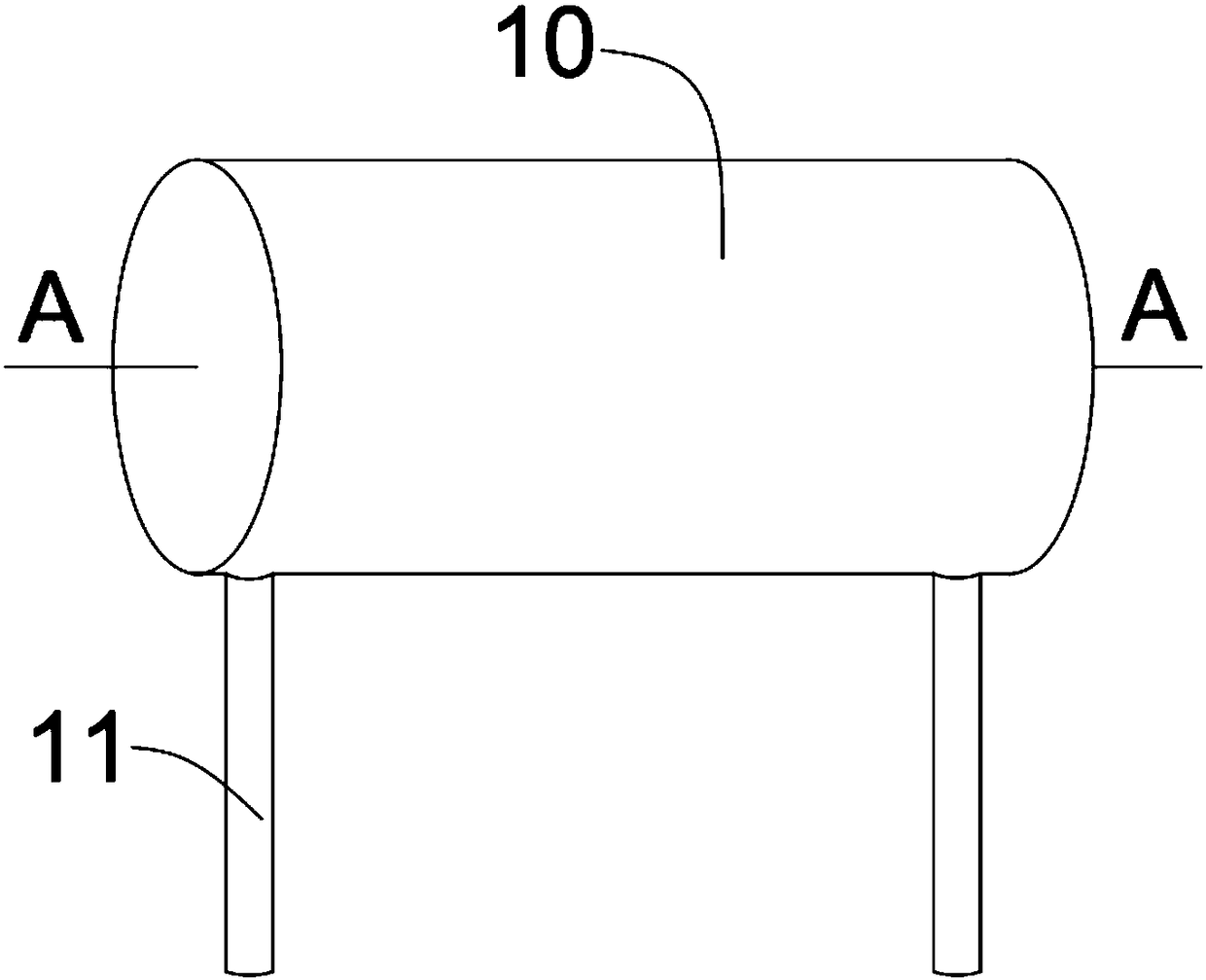

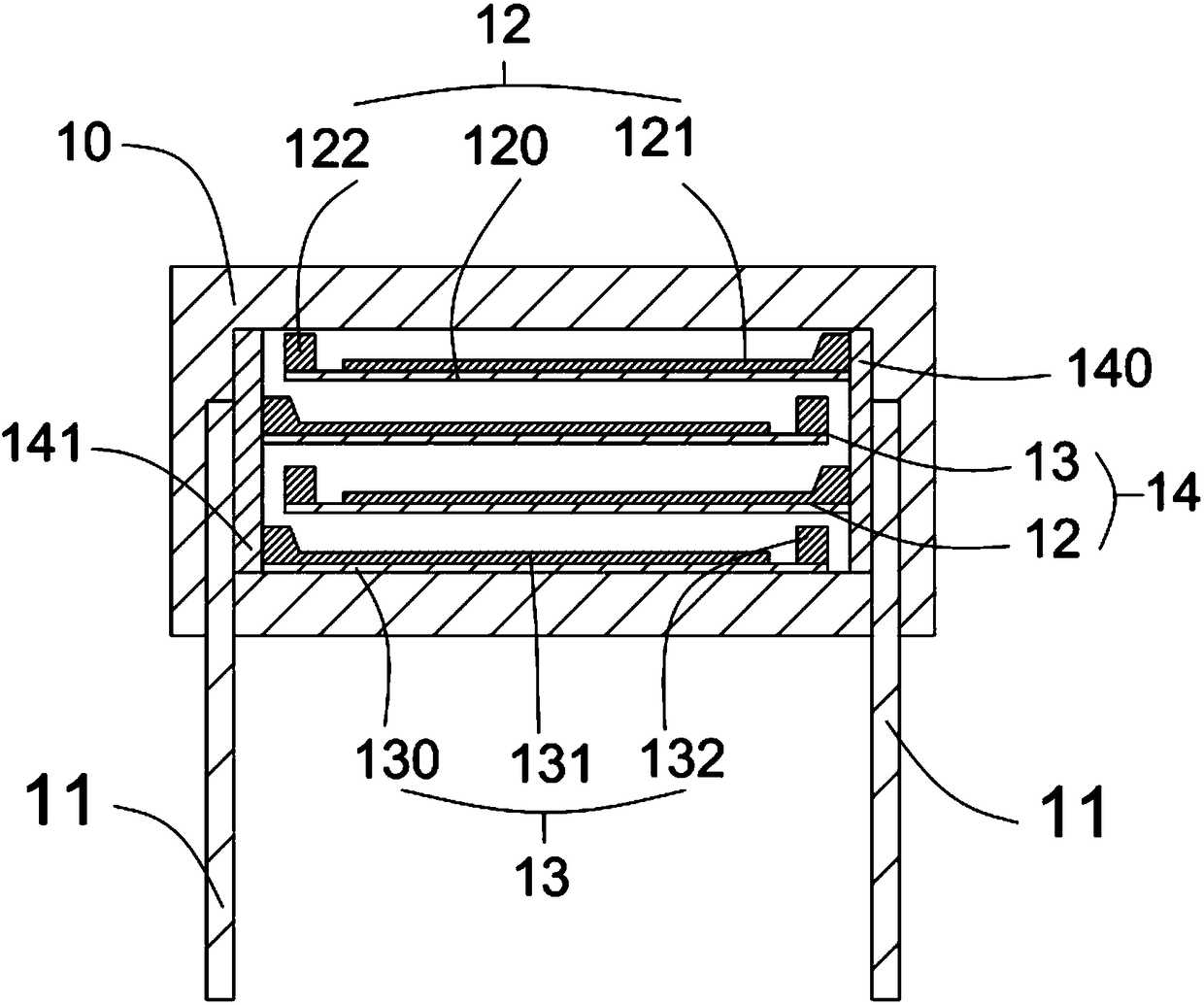

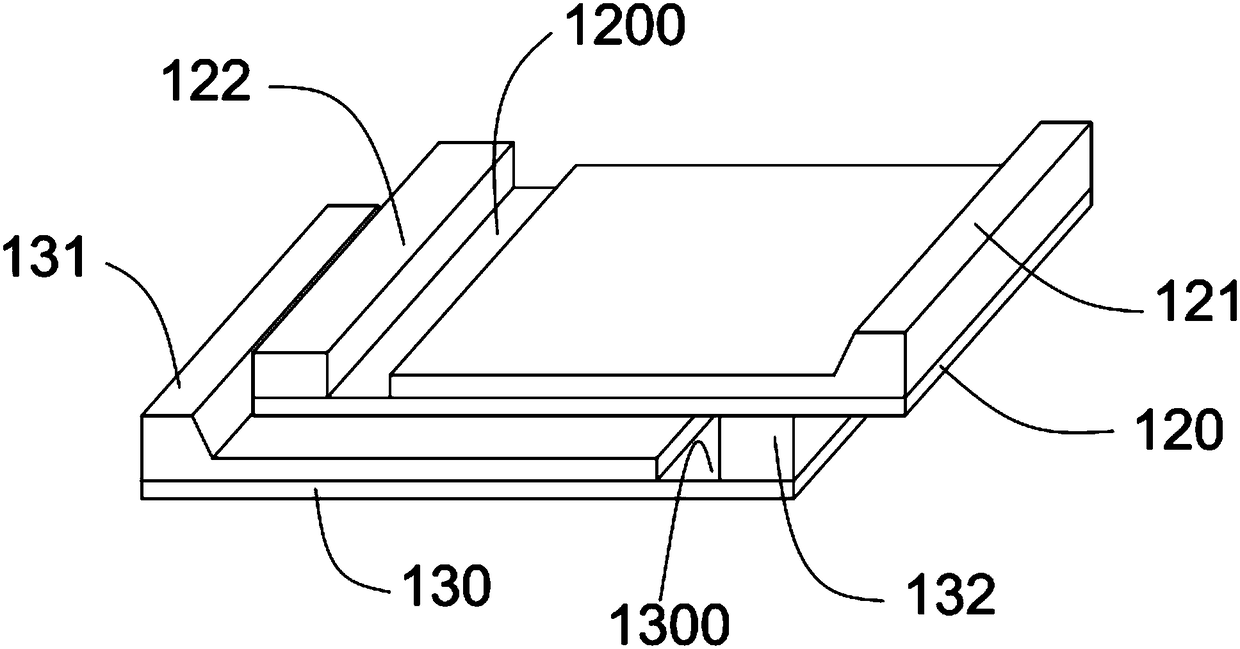

Metal halide lamp electrical arc tube and neck ampulla contracting shell interlocking machine, forming and necking method

InactiveCN101172764AUniform wall thicknessGood shape and size consistencyGlass reforming apparatusGlass productionMetal-halide lampAmpulla

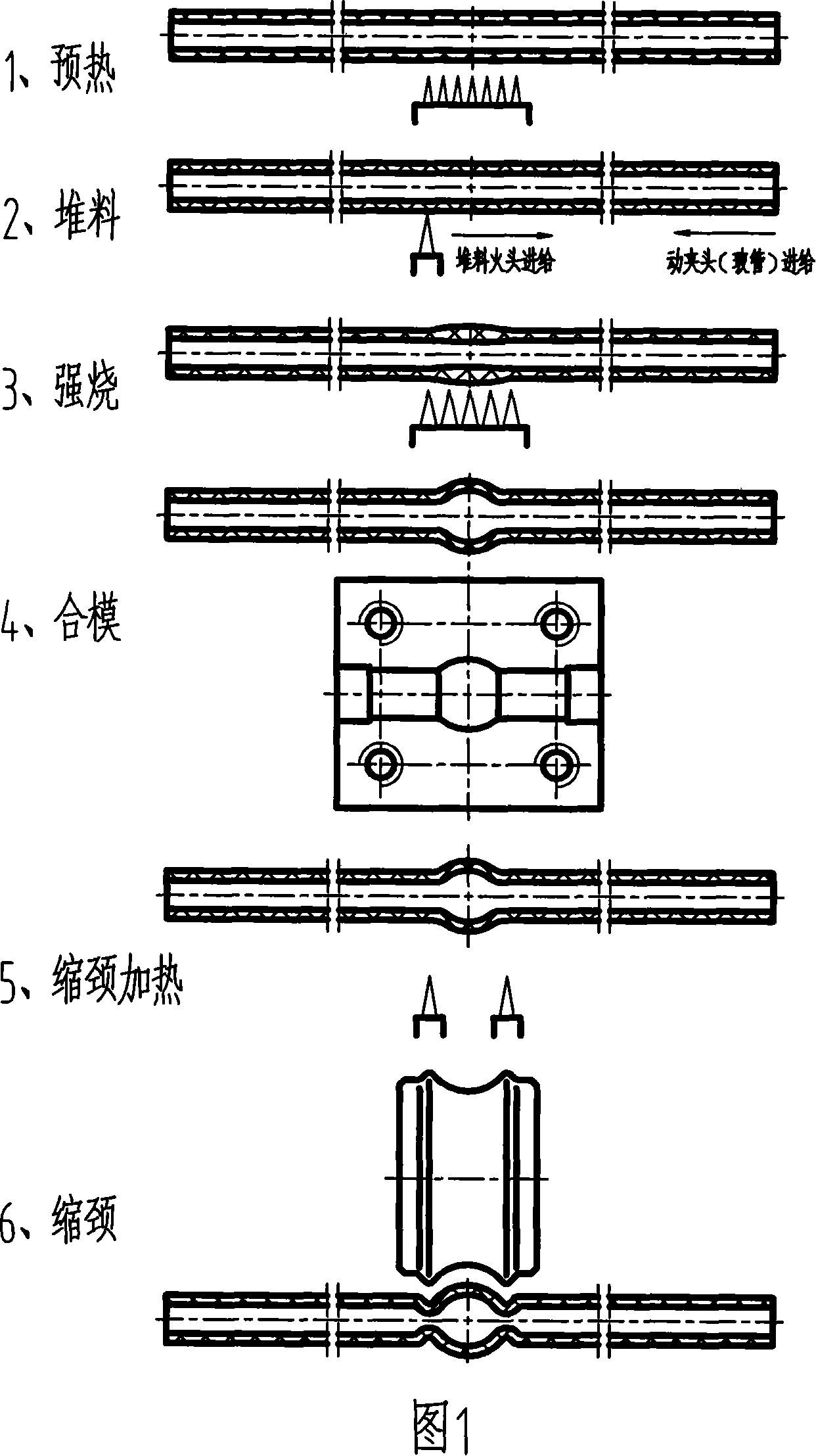

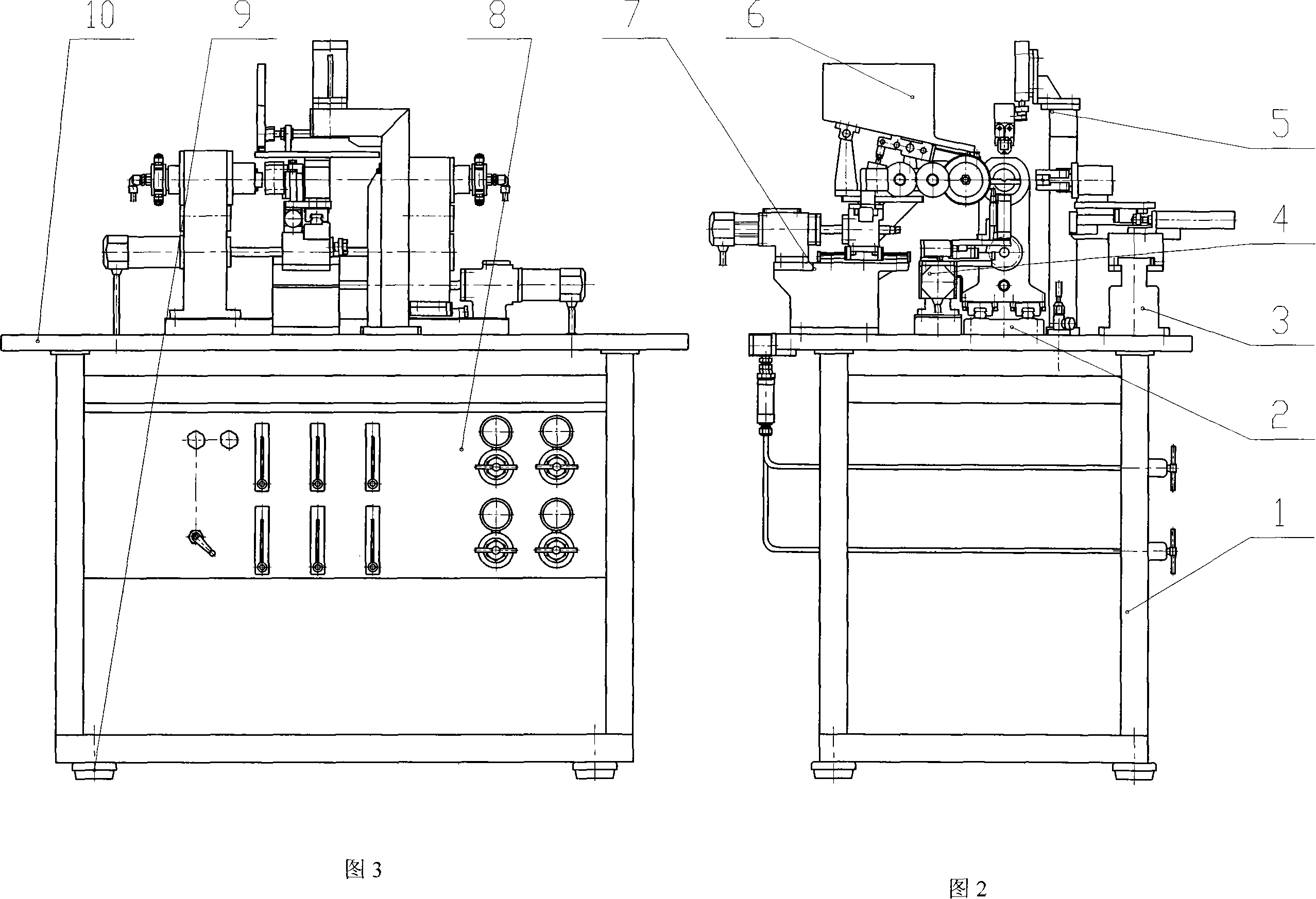

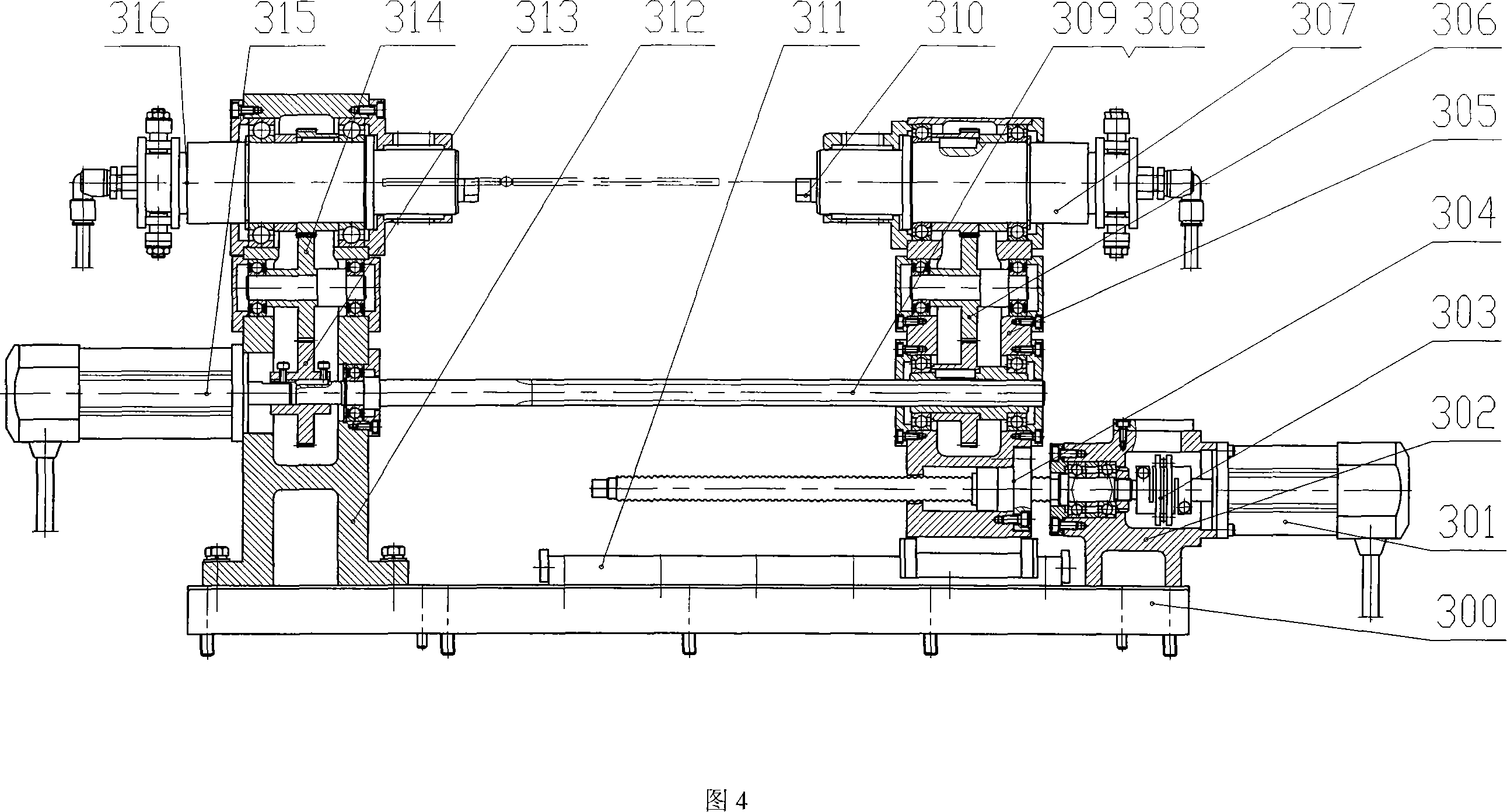

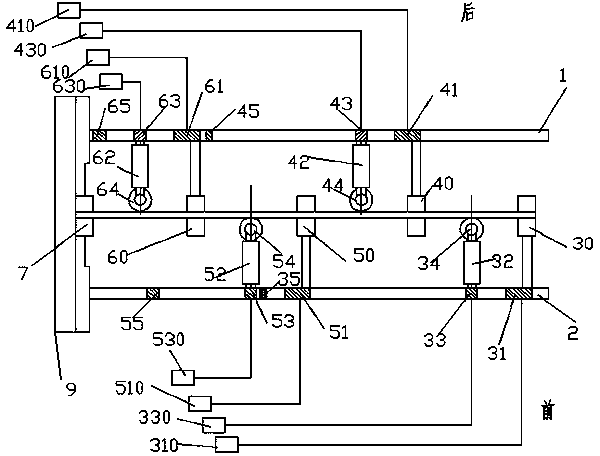

The invention discloses a metal halide lamp arc tube shrank neck shell interlocking machine and the shaping and neck shrinking method thereof. The interlocking machine comprises a machine frame (1), a clamp head and driving and reversing mechanism (2), a mould driving and reversing and mould closing shaping mechanism (3), a fire head moving mechanism (4), an automatic blanking mechanism (5), an automatic feed mechanism (6), a shrank neck trolley driving and reversing mechanism (7) and a fire head air supplying mechanism (8). The shaping and neck shrinking method comprises preheating, material piling, strongly burning, mould closing, and shrank neck heating and shrinking neck. Using the invention and the shaping and neck shrinking method ensure that the appearance and the size of the shell have good consistency and even wall thickness. The internal hole on the shrank neck part is controllable with good consistency, high production efficiency and rate of finished products.

Owner:SOUTHEAST UNIV

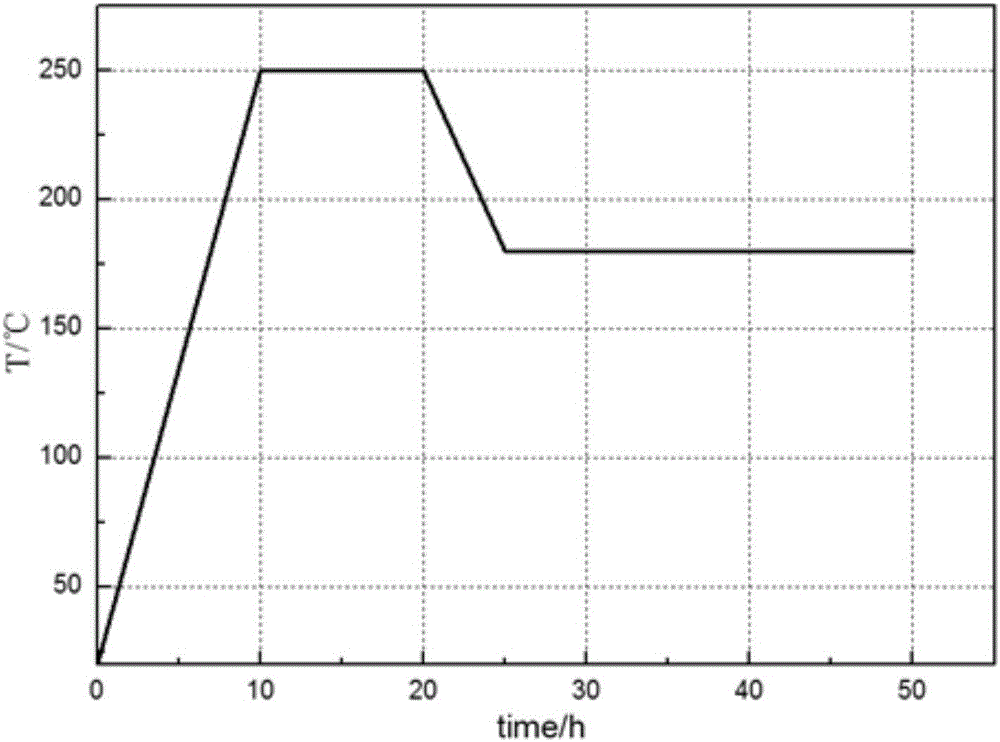

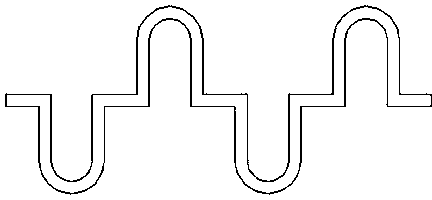

Furnace wire bending process adopting screw rod type clamping device and adopting heat treatment

The invention provides a furnace wire bending process adopting a screw rod type clamping device and adopting heat treatment. Row wires of furnace wires of a heating furnace are rectangular row wires formed by the furnace wires of the heating furnace through linear arrangement in a vertical direction, a bending device is used in the process and comprises a support frame, a front horizontal guide rail and a back horizontal guide rail are respectively arranged in a front position and a back position of the right side of the support frame, a support frame clamping device is arranged in the middle position of the right side of the support frame and is positioned between the front horizontal guide rail and the back horizontal guide rail, a first bending device is arranged at the right part of the back horizontal guide rail, a third bending device is arranged at the left part of the back horizontal guide rail, a second bending device is arranged at the right part of the front horizontal guide rail, a fourth bending device is arranged at the left side of the front horizontal guide rail, and the bending devices are respectively used for forming four U-shaped bending parts on the row wires of the furnace wires of the heating furnace from the left side to the right side.

Owner:广州市青荷金属制品有限公司

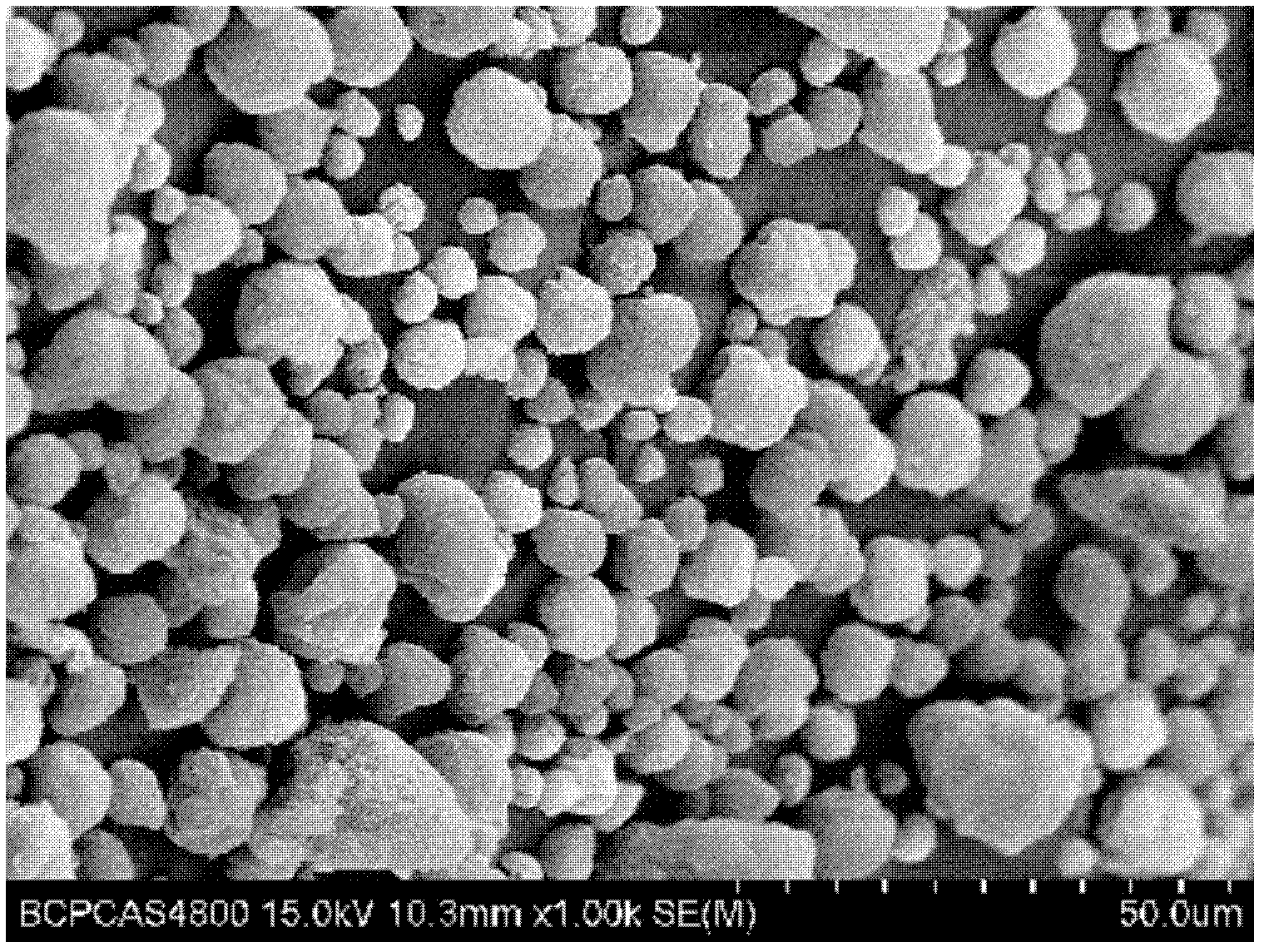

Preparation method of nickel-cobalt-manganese ternary precursor seed crystal

PendingCN113666434ASmall particle size distribution fluctuationsGood shape consistencyNickel compoundsManganeseSlurry

The invention discloses a preparation method of a nickel-cobalt-manganese ternary precursor seed crystal. The preparation method comprises the following steps: preparing a nickel-cobalt-manganese mixed salt solution, liquid caustic soda and an ammonia water solution; preparing a reaction base solution in a reaction kettle, and introducing N2; continuously introducing the nickel-cobalt-manganese mixed salt solution, the caustic soda liquid and the ammonia water solution into the reaction kettle respectively, and carrying out coprecipitation reaction; starting to overflow when the particle size D50 of the slurry generated by the coprecipitation reaction is 90-95% of the target particle size, stopping introducing N2 at the moment, and introducing oxygen into the residual slurry in the reaction kettle to oxidize Mn<2+> in the slurry into Mn<4+>; and stopping introducing oxygen when the slurry D00 in the reaction kettle is less than 1.0 mu m and the span d is greater than or equal to 0.9 to obtain the nickel-cobalt-manganese ternary precursor seed crystal. According to the method, Mn<2+> in the feed liquid is oxidized into Mn<4+> with smaller solubility product, the operation is simple, the pH value in the reaction process is stable, the balance between crystal nucleation and growth is easy to control, the particle size distribution fluctuation is small, and the morphology consistency of precursor particles is good.

Owner:格林爱科(荆门)新能源材料有限公司

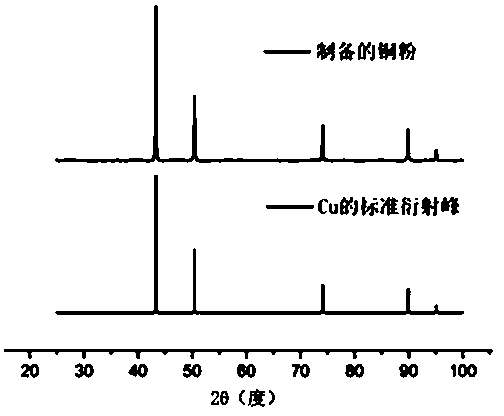

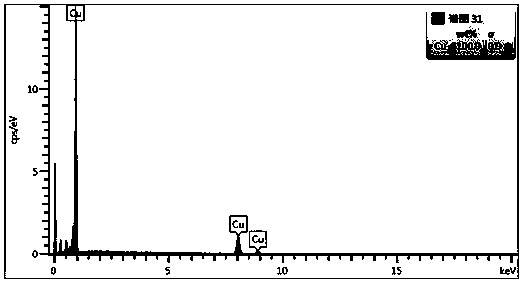

Method for preparing nano copper powder through fluorocarbon surfactant

A method for preparing nano copper powder through a fluorocarbon surfactant comprises the following steps that (1) an anionic fluorocarbon surfactant, a nonionic surfactant, an assistant, CuSO.5H2O and water are proportionally selected to prepare microemulsion; (2) the microemulsion is subjected to electrodeposition, and nano copper powder mixed liquor is obtained; (3) nano copper powder is extracted, the nano copper powder mixed liquor is subjected to filtering or centrifugal treatment, and after suction filtration and drying, nano copper powder is obtained; and (4) the nano copper powder isput into a packaging bag, and the packaging bag is sealed and stored after inert gases are injected into the packaging bag. According to the nano copper powder prepared through the method, the particle size is 20-100 nanometer, the purity is 99% or above, distribution of the particle size is uniform, and the appearance consistency is good; in the preparation process, the copper powder does not adhere to a cathode plate, the self-desorption performance is good, the cathode plate is easy to clean, and automatic continuous production can be achieved; the corrosion amount of an anode plates is small, environment pollution is small, and energy consumption is low; and the prepared nano copper powder is good in dispersity and easy to collect.

Owner:CENT SOUTH UNIV

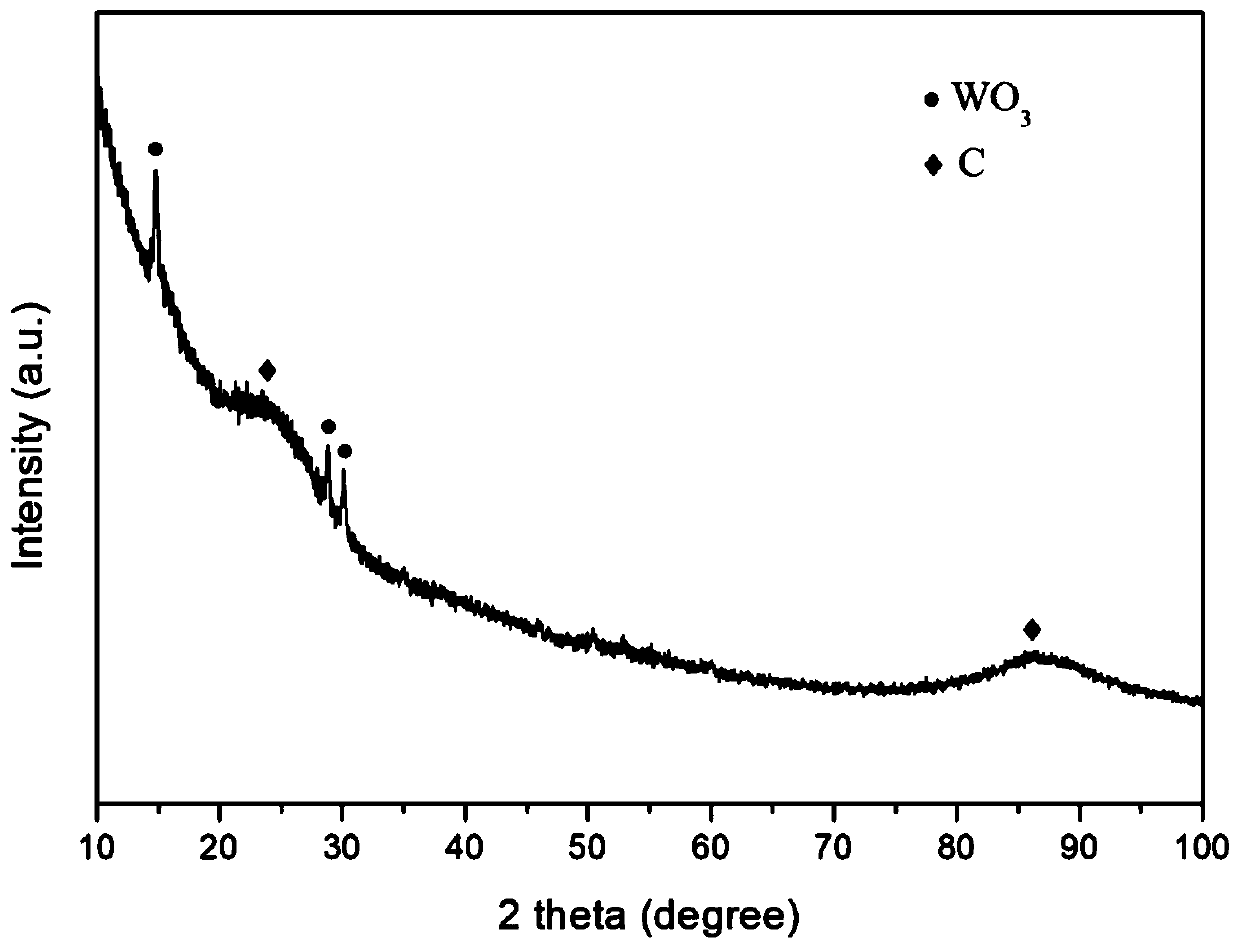

Method for preparing carbon-film-coated tungsten oxide nanospheres in one step by using hydrothermal process and application of carbon-film-coated tungsten oxide nanospheres

ActiveCN110563043ADetection application prospect is goodObvious Detection Application ProspectsTungsten oxides/hydroxidesCarbon preparation/purificationCarbon filmTungstate

The invention relates to a method for preparing carbon-film-coated tungsten oxide nanospheres in one step by using a hydrothermal process and application of the carbon-film-coated tungsten oxide nanospheres. The method comprises the following steps: respectively acquiring tungstate and a carbon source according to a mass ratio of 1: 0.5 to 1: 5, adding the tungstate and the carbon source into deionized water, and carrying out sufficient dissolving to obtain a mixed solution; putting the mixed solution into a reaction kettle, and performing natural cooling after a hydrothermal reaction to obtain a reacted turbid liquid; and cleaning and centrifuging the reacted turbid liquid with deionized water and ethanol, and performing vacuum drying to obtain the carbon-film-coated tungsten oxide nanospheres. The invention also provides a glucose detection sensor electrode prepared from the carbon-film-coated tungsten oxide nanospheres. Compared with the prior art, the preparation method disclosed by the invention has the advantages of simple process, safety, reliability and the like, and the formed detection electrode has the characteristics of high sensitivity, strong anti-interference performance, capability of monitoring blood glucose of a human body in a measurement range and the like.

Owner:SHANGHAI JIAO TONG UNIV

Round setting technique for pipe end of large-size pipe fitting

The invention relates to a round setting technique for a pipe end of a large-size pipe fitting. The round setting technique is characterized by comprising the following steps: firstly, preparing an end face of a pipe blank by swelling an inner swelling petal mould so as to cause the uniform peripheral stretching plastic deformation on the end face of the pipe blank, thereby increasing the perimeter of a geometrical neutral layer of the cross section of the pipe end; pressing the end face of the pipe blank by two semicircular petal moulds along the radial direction so as to cause the uniform compressing deformation on the end face of the pipe blank, thereby controlling the last ovality and cross-section perimeter size of the pipe end of the pipe blank; and controlling the molding precision of the pipe end within a tolerance allowed scope. The round setting technique has the advantages that the consistency of shape and size of the pipe end of the pipe blank is increased, the pipeline connection is conveniently performed and the production efficiency is increased at the same time.

Owner:YANSHAN UNIV

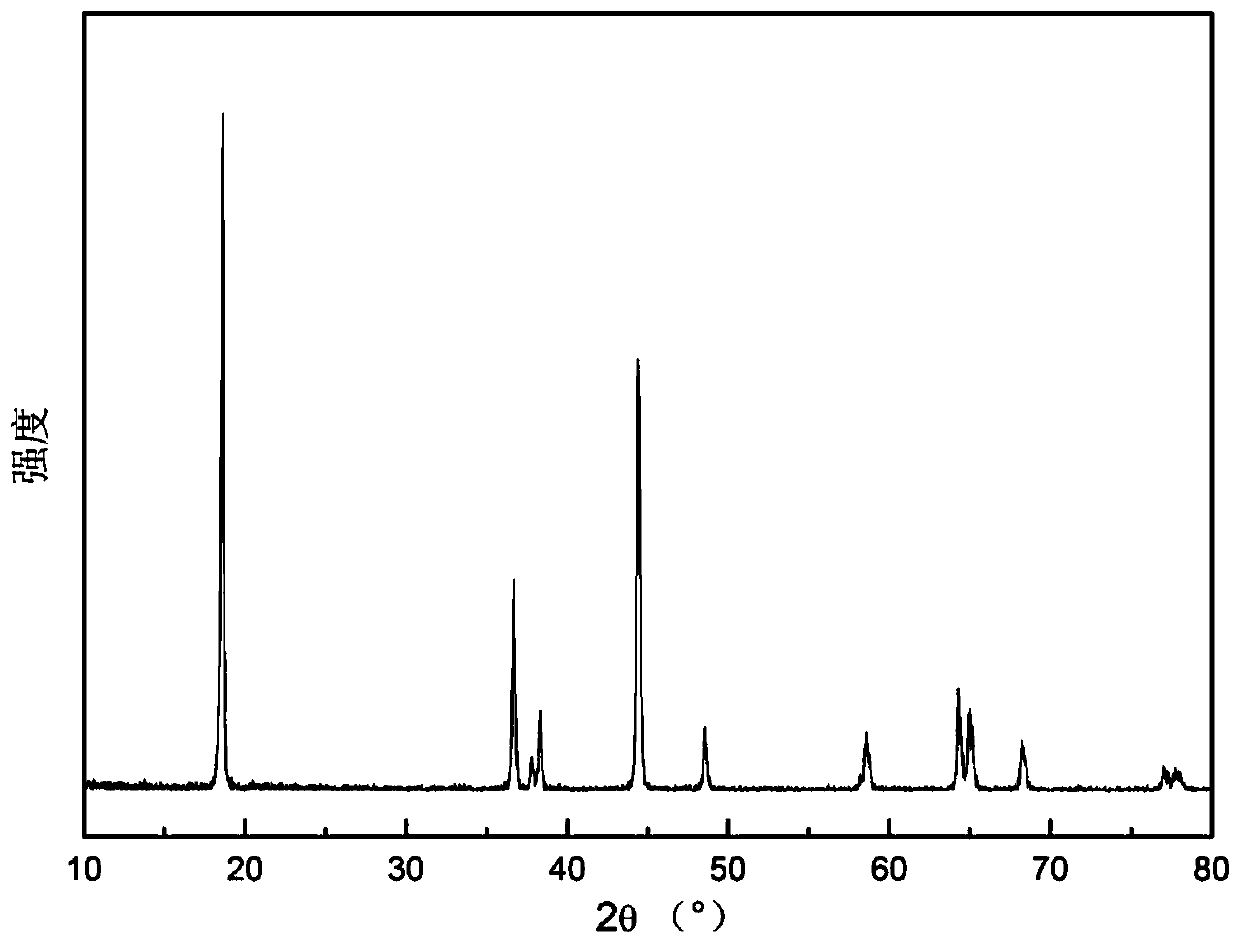

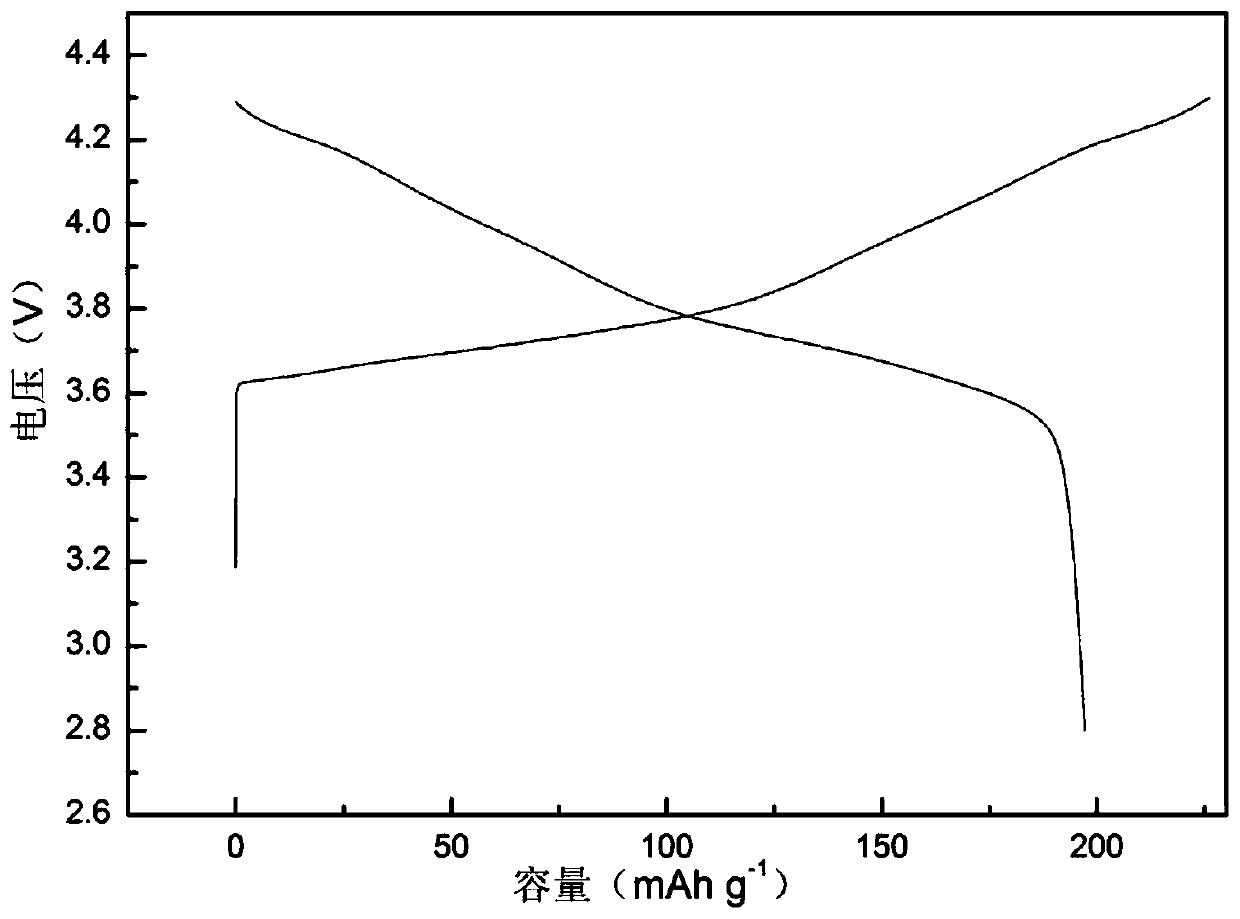

A kind of preparation method of high compaction density micron-scale single crystal ternary positive electrode material

ActiveCN106410182BImprove cycle performanceIncrease compaction densityCell electrodesSecondary cellsSingle crystalOxygen

The invention relates to a preparation method of a high compaction density micron-grade monocrystal ternary cathode material, and belongs to the technical field of lithium ion battery materials. The preparation method comprises the following steps: firstly ball-milling and smashing a ternary precursor, then uniformly mixing the ball-milled and smashed ternary precursor with an additive and carrying out high-temperature heat treatment to obtain a substance A; after uniformly mixing the substance A with a lithium salt in a ball-milling tank, putting the mixture in an oxygen-containing atmosphere for calcinations, and naturally cooling to obtain the ternary cathode material. The ternary cathode material is simple in preparation method technique and good in product appearance consistency, and is suitable for large-scale production; and the prepared ternary cathode material has the advantages of micron-grade monocrystal appearance, large compaction density and good electrochemical performance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

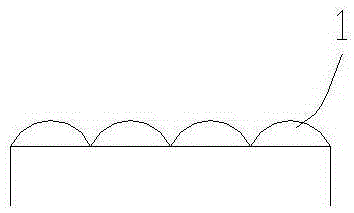

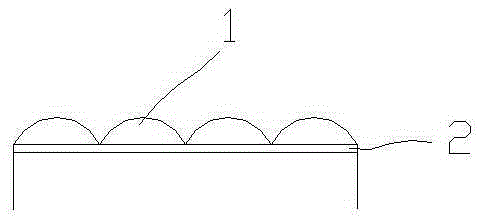

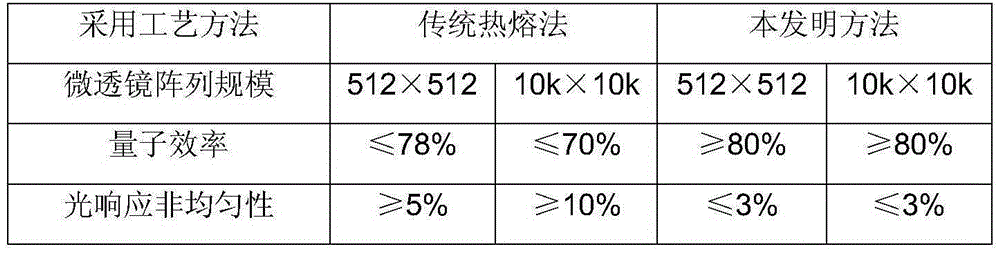

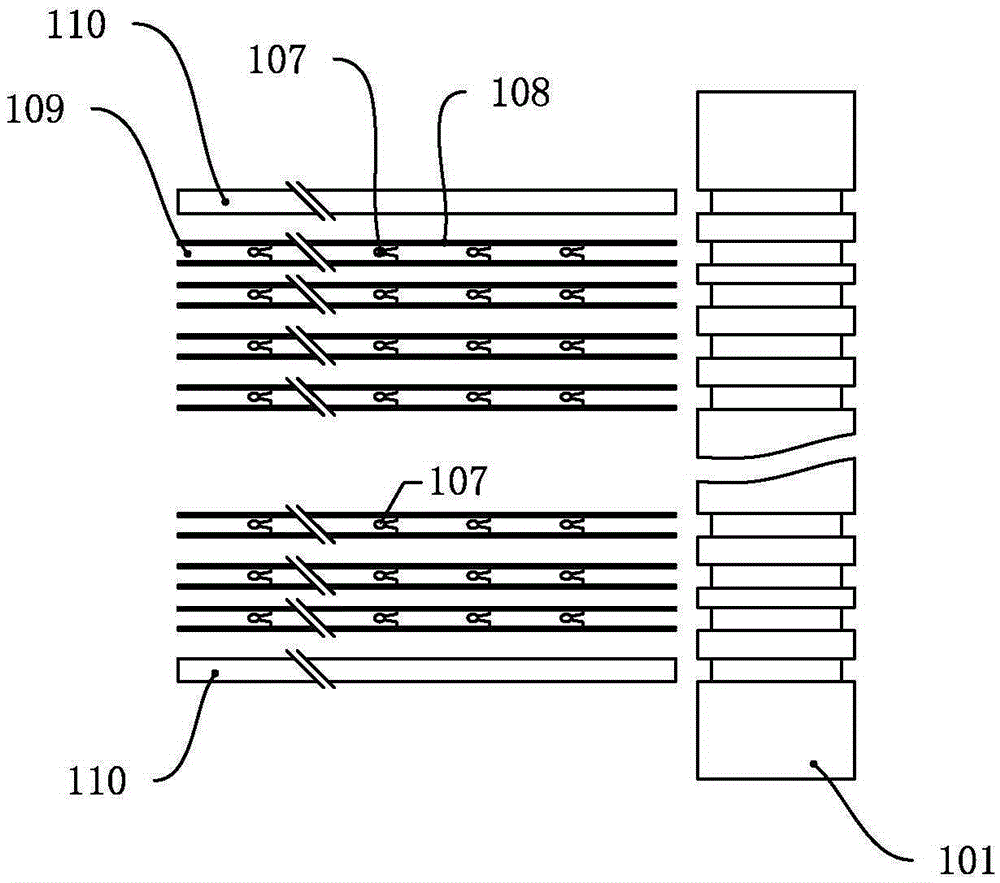

Large array high uniformity microlens array preparation method

The present invention discloses a large array high uniformity microlens array preparation method. Prior to the forming of the microlens, a mixture coating is arranged in advance between a wafer surface and a microlens material layer, and the fluidity of the microlens material in a molten state is restrained through the mixture coating. A novel microlens array preparation method is provided, and the microlens array manufactured by employing the method provided by the invention has the advantages of good feature consistencies, good focusing effects and good uniformities at different positions.

Owner:THE 44TH INST OF CHINA ELECTRONICS TECH GROUP CORP

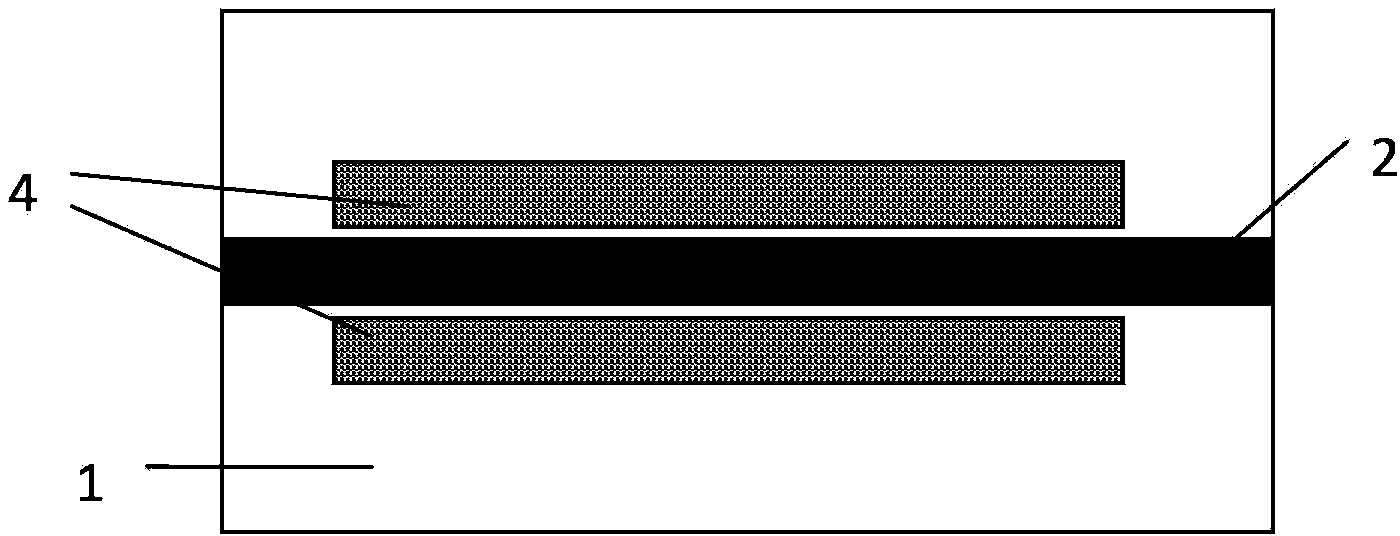

All-in-one thin film temperature sensor

InactiveCN105424214AGood shape consistencyGood consistency of reflection speedThermometers using electric/magnetic elementsUsing electrical meansHigh volume manufacturingOptoelectronics

The invention discloses an all-in-one thin film temperature sensor. A final product profile map of the invention is an NTC temperature sensor which comprises an upper thin film layer and a lower thin film layer, wherein at least two conducting wires are covered between the upper thin film layer and the lower thin film layer, and an NTC thermistor is welded between the conducting wires. The all-in-one thin film temperature sensor has the advantages that the NTC temperature sensor has good appearance consistency; the NTC temperature sensor has good responding speed consistency; equipment has a high degree of automation, and less staffs are required; and mass production can be realized easily.

Owner:SHENZHEN MINJIE ELECTRONICS TECH

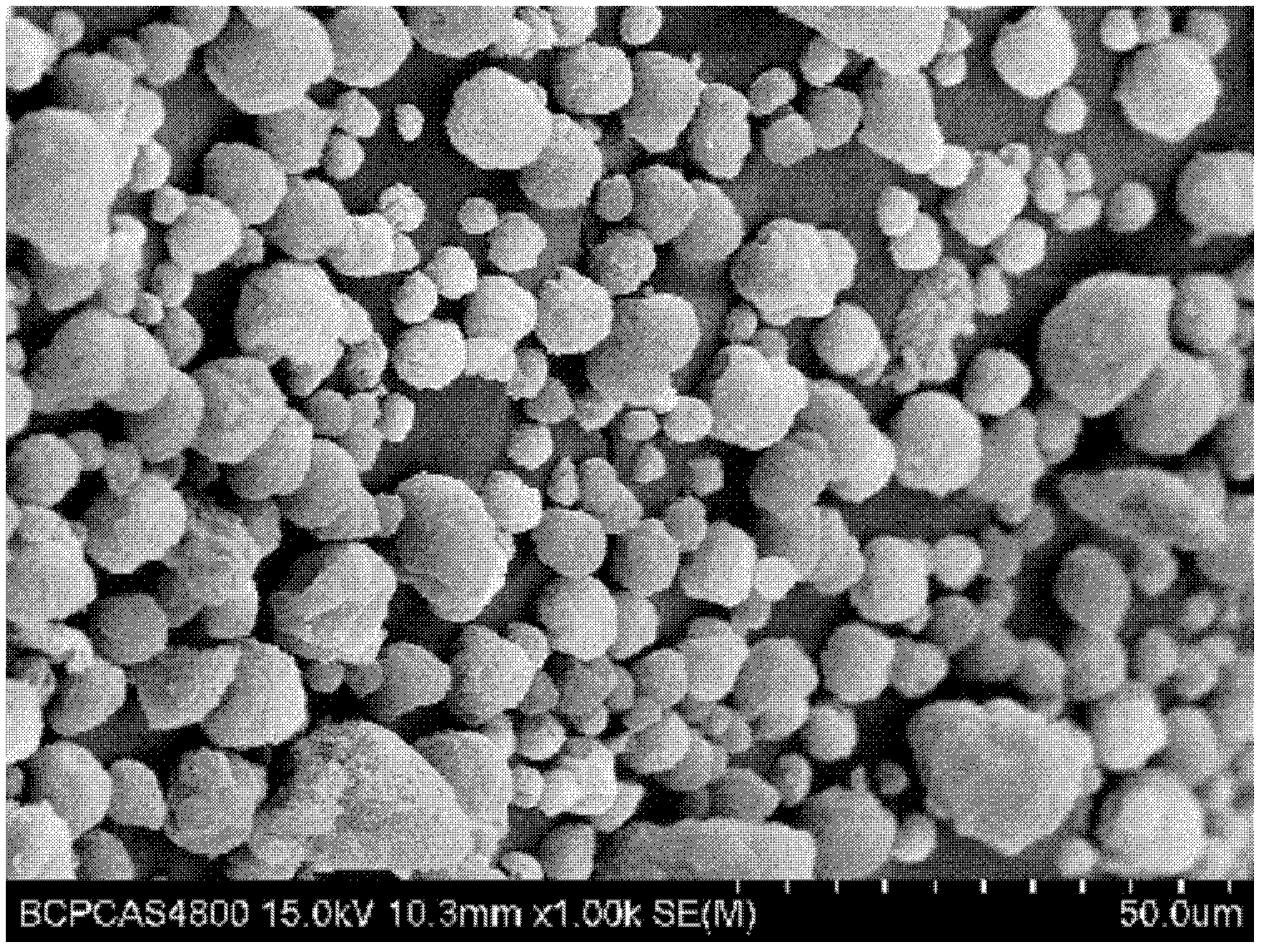

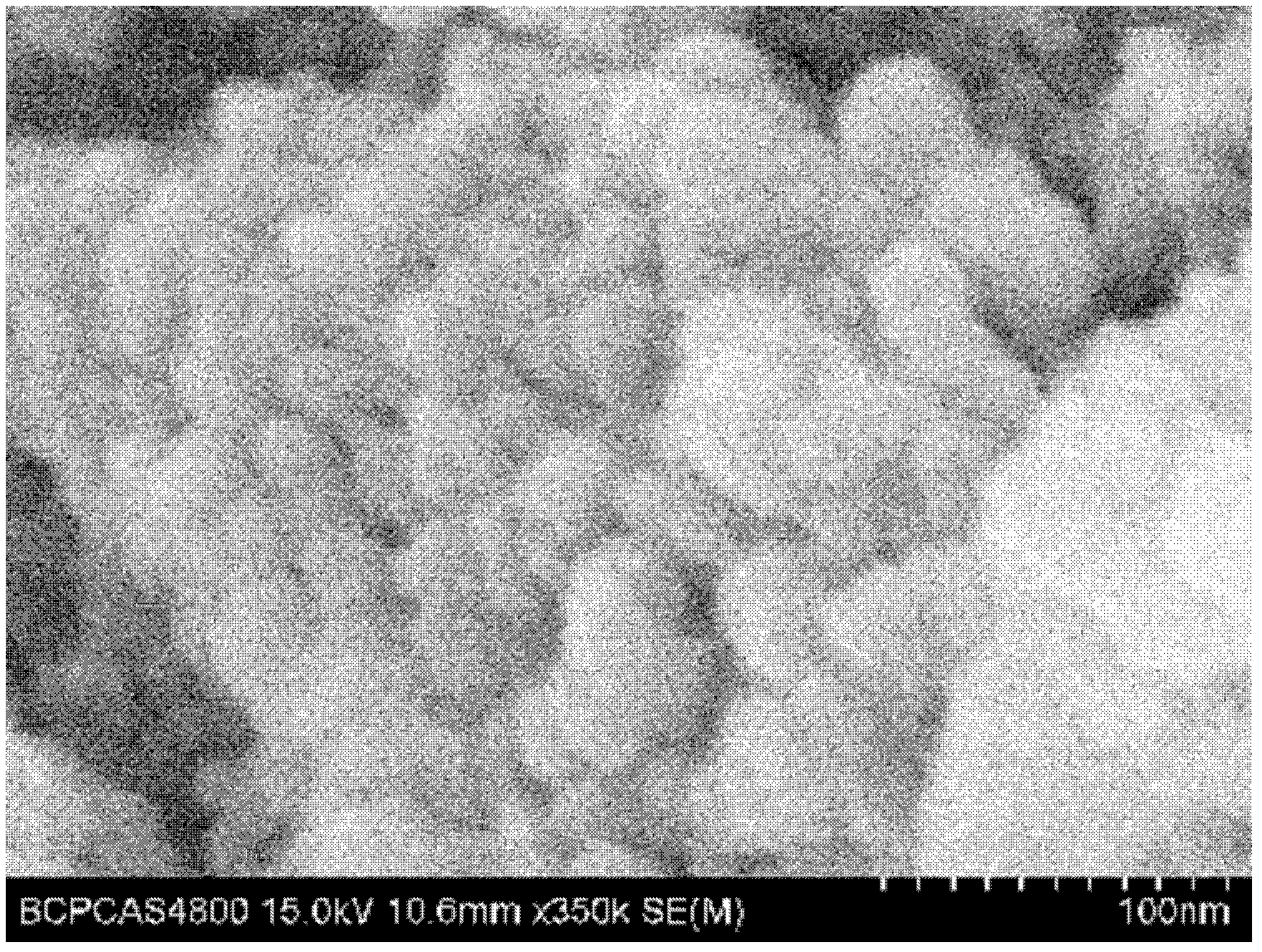

Preparation method of nano iron phosphate with globulomer structure for lithium iron phosphate

InactiveCN102303857AEasy to synthesizeGood shape consistencyCell electrodesNanotechnologyWater bathsLithium iron phosphate

The invention provides a preparation method of nano iron phosphate (FePO4.2H2O) with a globulomer structure for lithium iron phosphate. The preparation method comprises the following steps: dissolving soluble compounds which respectively contain Fe<3+> and PO4<3-> to form a homogeneous phase solution, regulating pH value with an alkaline solution, carrying out water bath heating on a mixed liquid until the effective component of the mixed liquid is sufficiently precipitated to form a white flocculent suspension, filtering and washing; and preparing primary particles by using a liquid phase control crystallization process, and carrying out secondary pelleting with a spray drying process so as to obtain FePO4.2H2O having the globulomer structure and a particle diameter of 5-20 mu m, wherein FePO4.2H2O is formed by agglomeration of primary particles with a particle diameter of 30 nm. According to the invention, prepared FePO4.2H2O has the advantages of uniform particle distribution, high tap density and high reaction activity, and the primary particle is of nano grade; and FePO4.2H2O is used as a raw material so as to improve the consistency of topography of a lithium iron phosphate material, thereby effectively reducing the particle diameter of a lithium iron phosphate positive electrode material and further improving the transmission efficiency of lithium ions in the lithium iron phosphate material; and FePO4.2H2O having a micron globulomer structure, which is obtained by secondary pelleting, is more beneficial to synthesis of a micro lithium iron phosphate material which is easy to coat.

Owner:IRICO

Moisture-proof thin film capacitor and preparation method thereof

PendingCN108597870AAvoid other featuresIncrease the effective areaThin/thick film capacitorFixed capacitor housing/encapsulationMetallised filmMoisture

The invention belongs to the technical field of metallized thin film capacitors, and particularly relates to a moisture-proof thin film capacitor and a preparation method thereof. According to the moisture-proof thin film capacitor provided by the invention, a low square resistance metal layer is added to a metallized film, when two metallized films are wound to form a film roll, the low square resistance metal layer does not form a string structure, thereby avoiding the influence on the other characteristics of the capacitor. Moreover, the low square resistance metal layer generates the riskof generating a corona effect, thus the risk of generating the corona effect is reduced, and meanwhile the speed of corona diffusion can be effectively reduced. Therefore, the low square resistance metal layer blocks the moisture, and meanwhile reduces the transfer rate of the moisture, thus ensuring the service life of the capacitor.

Owner:SICHUAN ZHONGXING ELECTRONICS

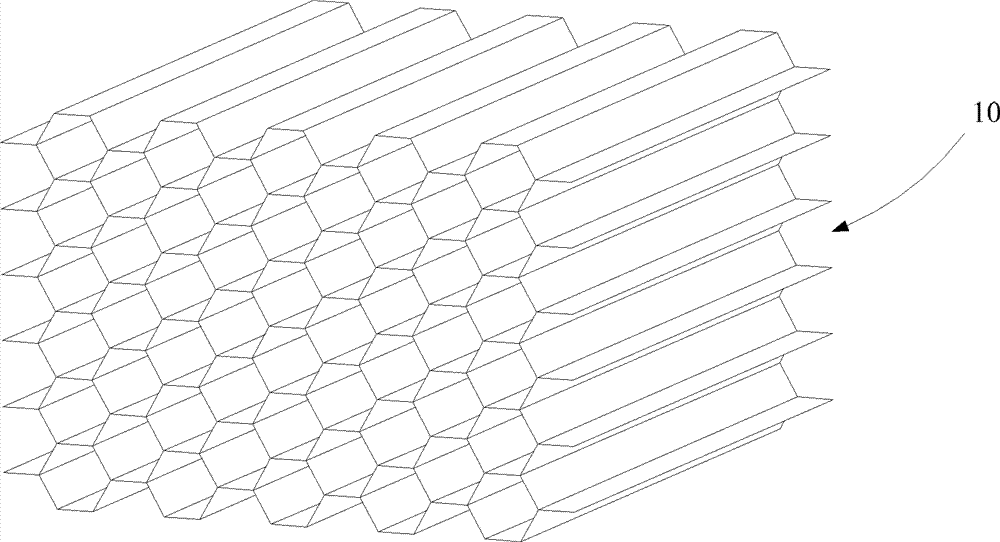

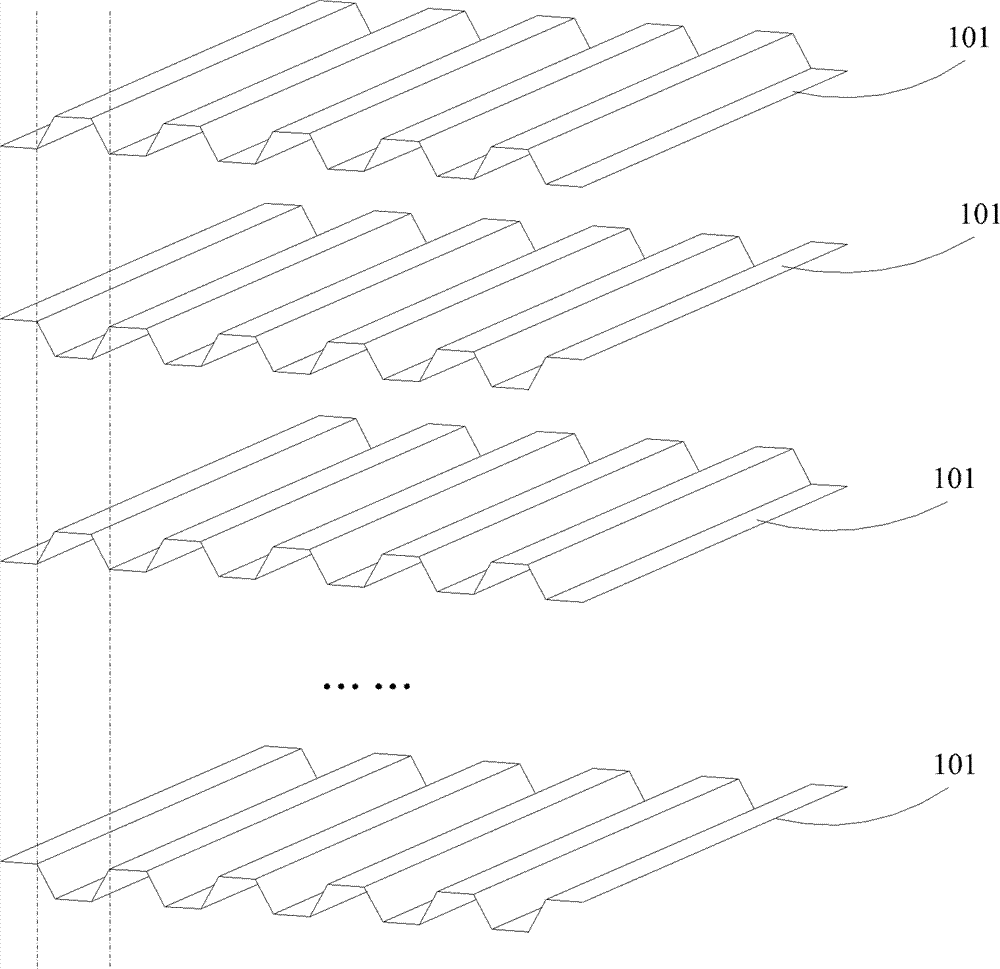

Honeycomb carbon fiber energy absorber and its manufacturing method and manufacturing equipment

The invention discloses a cellular carbon fiber energy absorber comprising a plurality of corrugated sheets bonded by using an adhesive and forming a cellular shape, wherein the corrugated sheets are obtained by molding carbon fiber cloth impregnated with resin. The invention also discloses a method for manufacturing the cellular carbon fiber energy absorber. The method comprises the steps that: the carbon fiber cloth is delivered into a resin transfer molding apparatus; the carbon fiber cloth is molded into corrugated sheets; and the corrugated sheets are delivered into a cellular molding apparatus, and are assembled into the cellular carbon fiber energy absorber. The invention also discloses equipment used for manufacturing the cellular carbon fiber energy absorber. The equipment comprises: a feeding apparatus used for delivering the carbon fiber cloth to the resin transfer molding apparatus; a resin transfer molding apparatus used for impregnating resin into the carbon fiber cloth and for molding the carbon fiber cloth; an auxiliary molding press roller used for pressing and rolling the carbon fiber cloth into corrugated shapes; and a cellular molding apparatus used for assembling the plurality of corrugated sheets into the cellular carbon fiber energy absorber. The cellular carbon fiber energy absorber provided by the invention has the advantages of small volume, light weight, high energy absorption efficiency, and good consistency.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

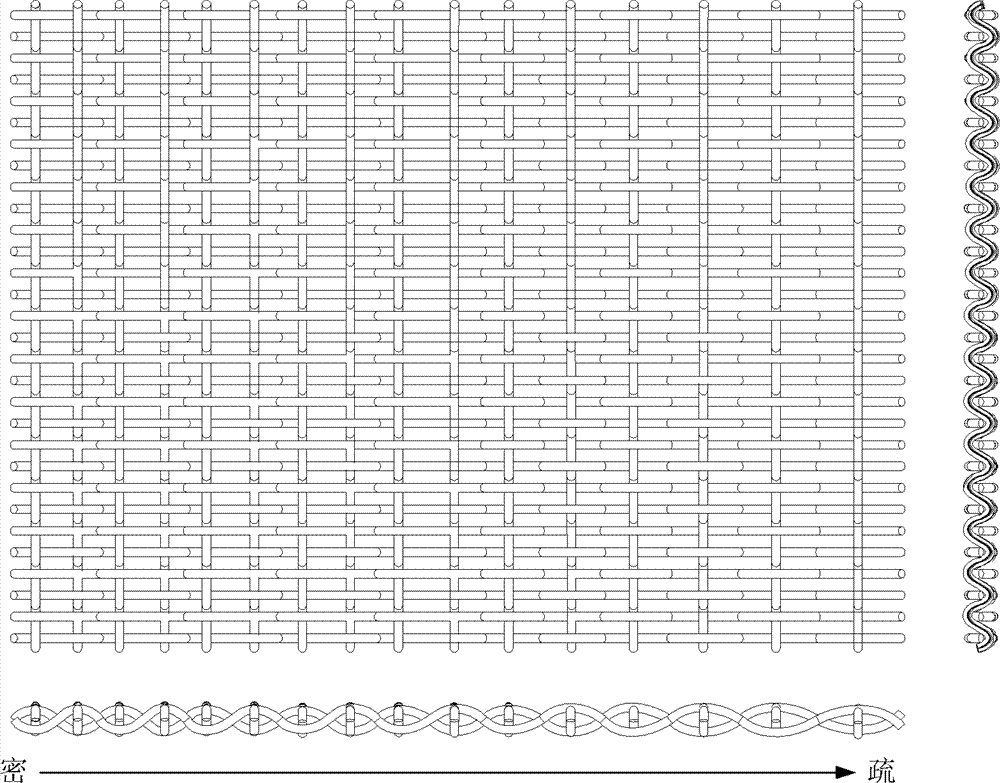

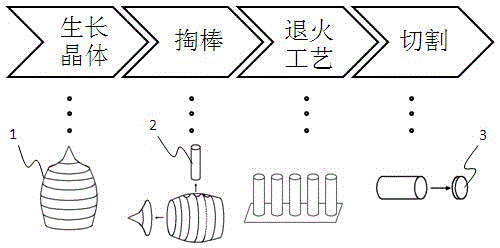

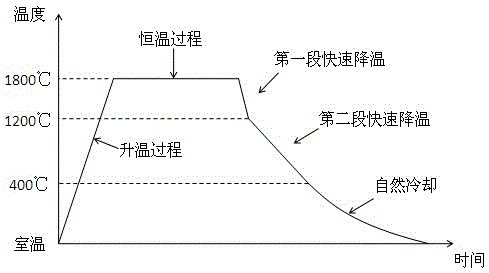

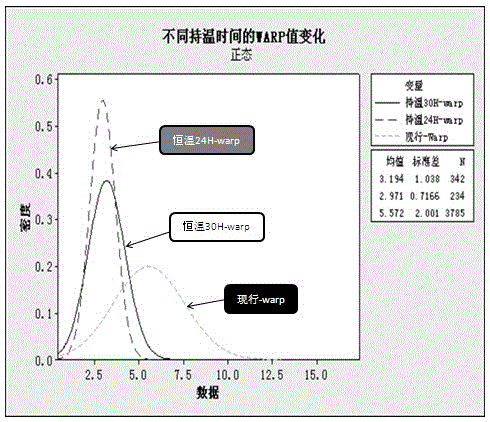

Method for producing crystal bars

ActiveCN106544738AAchieve annealingImprove consistencyPolycrystalline material growthAfter-treatment detailsWarming processCrystal growth

The invention discloses a method for producing crystal bars. The method is characterized in that before online cutting, crystal bars which are treated by a bar picking technology are placed in a high temperature annealing furnace for carrying out annealing; the annealing process mainly comprises the following step: a heating process, a constant temperature process, and a cooling process. The annealing process method of sapphire crystal bars is provided, unified annealing processing is carried out for crystal bars produced by different crystal growths and bar picking technology, residual stress in the crystal bars is eliminated, consistency of the quality of sapphire crystal bars is improved, and posterior wafer processing, and epitaxial yield rate and uniformity are improved.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

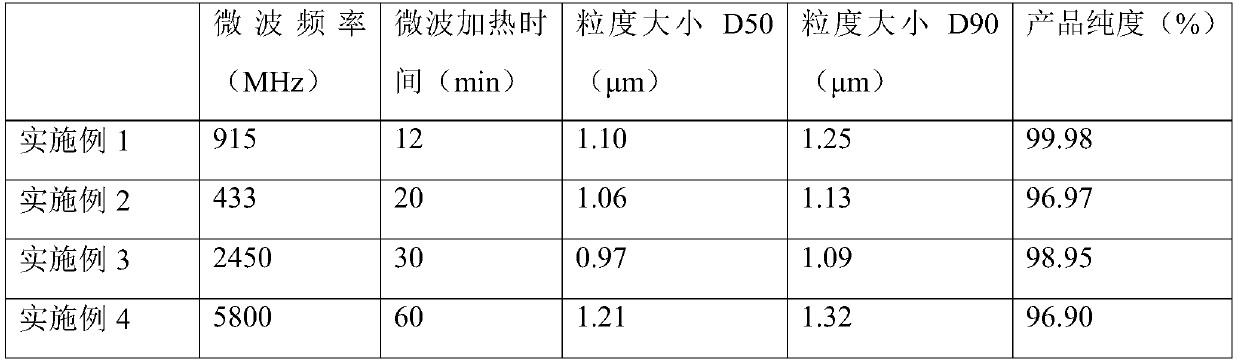

Microwave preparation method of lanthanum-cerium-terbium oxide fluorescent powder

ActiveCN111056564AUniform sizeReduce surface chargeLanthanum oxide/hydroxidesCerium oxides/hydroxidesOXALIC ACID DIHYDRATEUltrasound - action

The invention discloses a microwave preparation method of lanthanum-cerium-terbium oxide fluorescent powder, which comprises the following steps: taking oxalic acid, oxalate or ammonium bicarbonate asa precipitant; taking water and / or ethanol as a base solution, and adding a surface additive into the base solution; dropwise adding the raw material solution and a precipitant into the base solutionin twice under the action of ultrasonic waves and stirring, and aging, filtering and drying the obtained precipitate to obtain a lanthanum-cerium-terbium co-precipitate; putting the lanthanum-cerium-terbium co-precipitate into a microwave reactor for microwave heating; wherein the microwave power is 1-10 kW, the microwave heating frequency is 433-5900+ / -50 MHz, a microwave output mode comprises one or a combination of continuous waves and pulse waves, the working time is 12-60 min, and performing heat preservation for 1-2 h to obtain the lanthanum-cerium-terbium oxide. The lanthanum-cerium-terbium oxide prepared by the method is consistent in particle size and uniform in morphology.

Owner:GUANGXI ACAD OF SCI +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com