Manufacturing method for electrode of lithium niobate optical waveguide device

A production method, lithium niobate technology, applied in the field of communication, can solve the problems of easy corrosion of metal film, difficulty in ensuring accuracy and repeat consistency, etc., and achieve the effect of good consistency, insensitive peeling end point, and controllable corrosion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to better understand the present invention, the implementation manner of the invention will be described in detail below in conjunction with specific examples and accompanying drawings.

[0035] The specific production process of the inventive method is as Figure 4 shown, including the following steps:

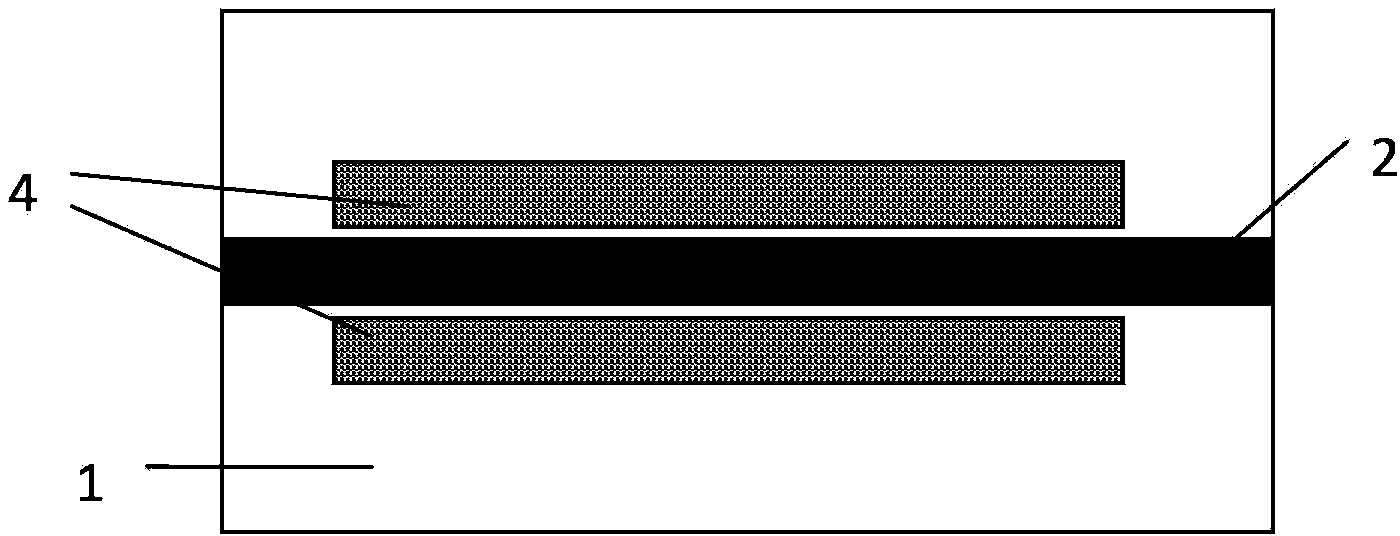

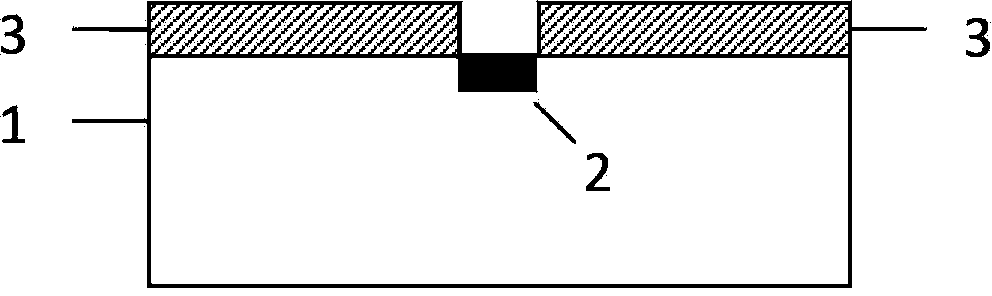

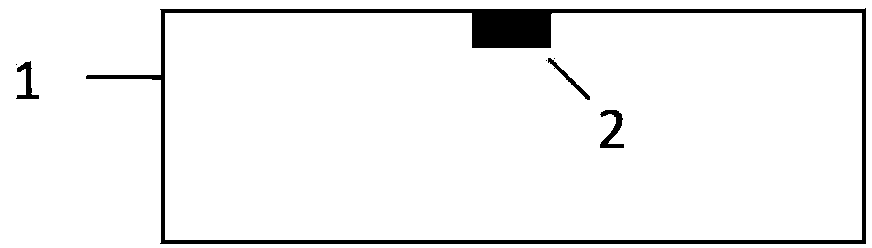

[0036] Step 1: Fabricate an optical waveguide on a lithium niobate substrate: grow a layer of SiO2 film with a thickness of 200nm on the surface of the lithium niobate substrate, and lithographically cut out a SiO2 mask corresponding to the optical waveguide. Using the SiO2 mask, through proton exchange and Subsequent atmosphere annealing technique forms an optical waveguide on the lithium niobate substrate, and the structure of the lithium niobate chip in this step is as follows Figure 3a As shown, it includes a lithium niobate substrate 1 and an optical waveguide 2 formed thereon, and a SiO2 mask layer 3 is provided on the surface of the lithium niobate su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com