Patents

Literature

155results about How to "Improve overlay accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

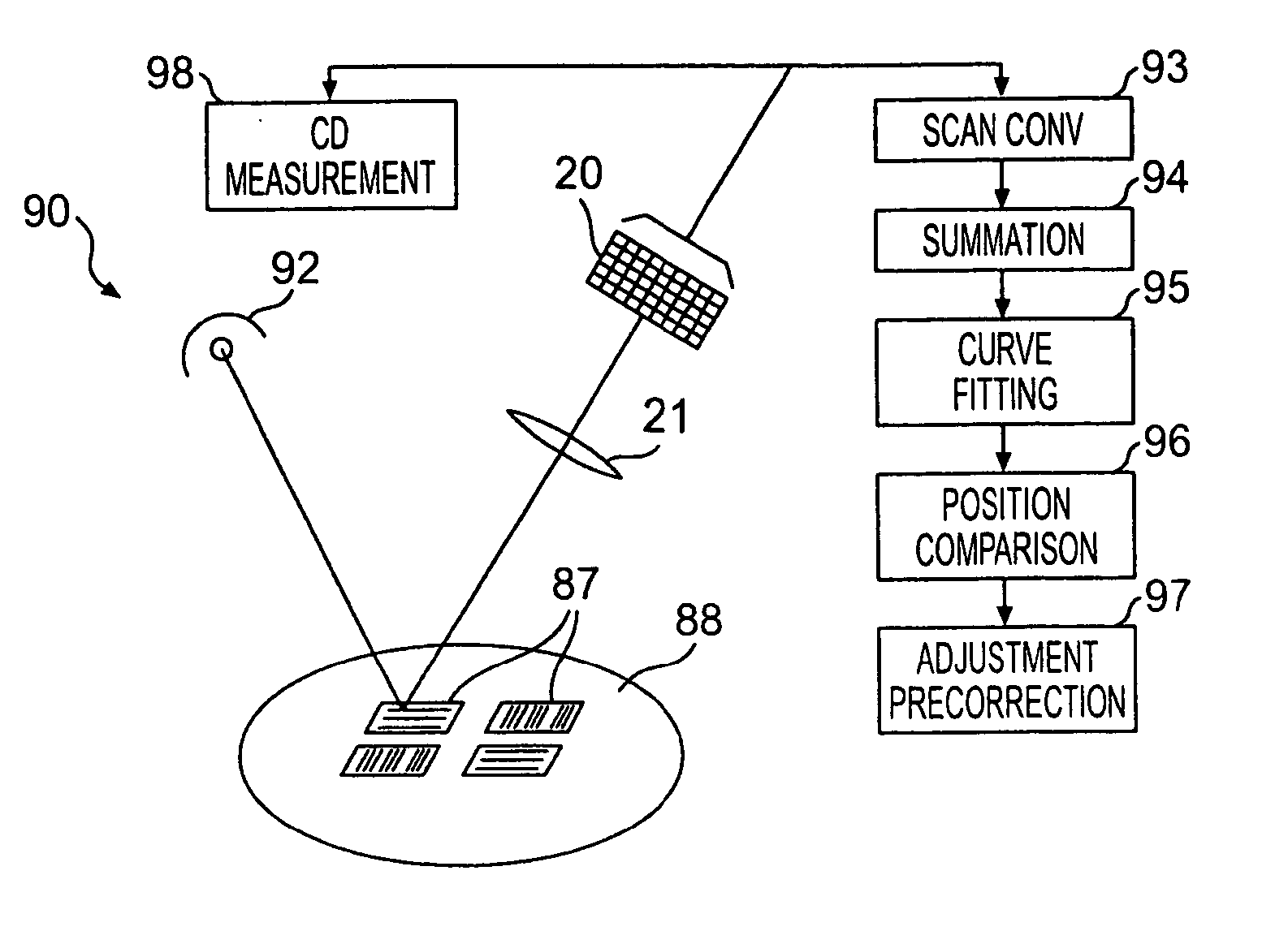

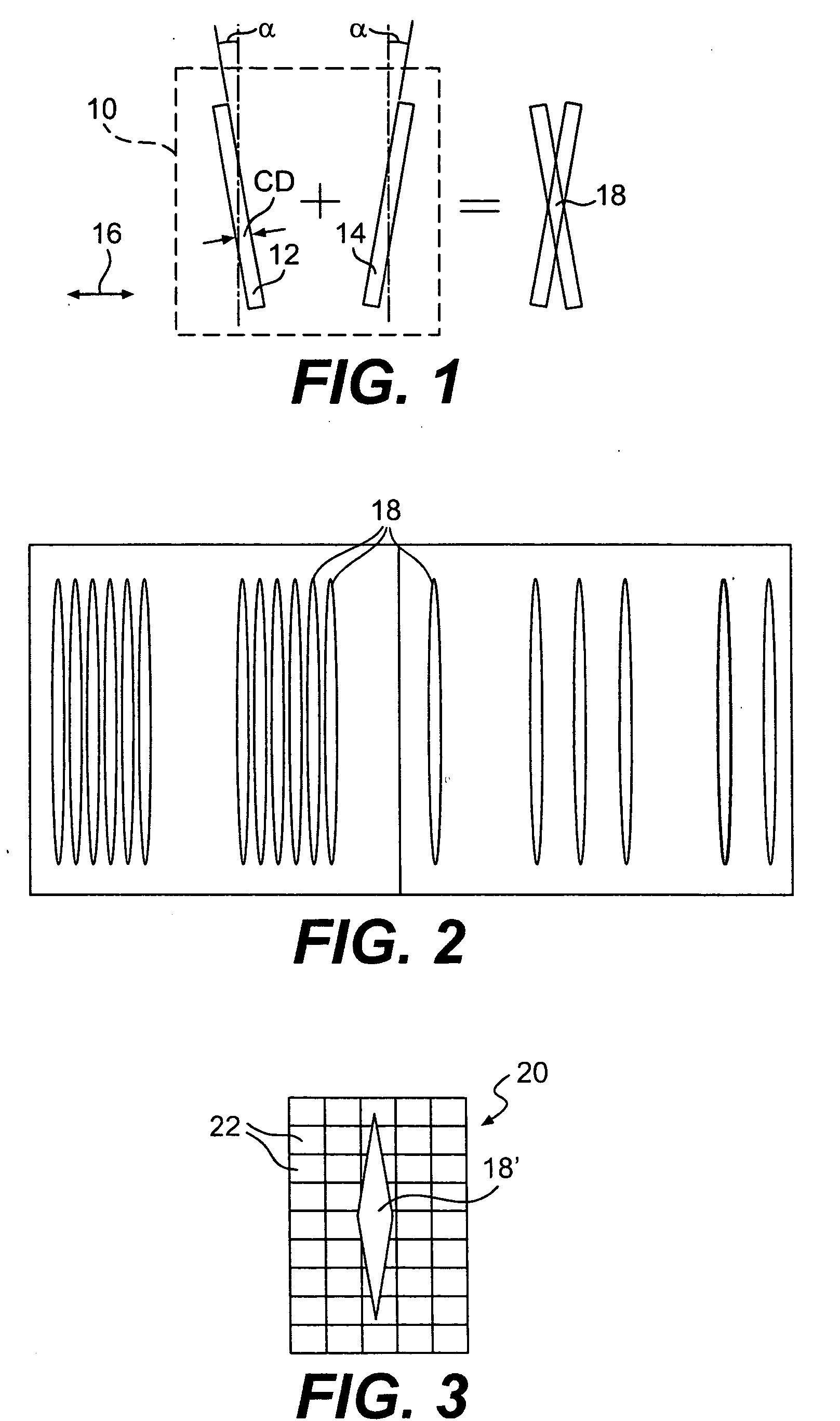

Method and apparatus for position measurement of a pattern formed by a lithographic exposure tool

InactiveUS6664121B2Improve overlay accuracySuppress mutationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsResistMetrology

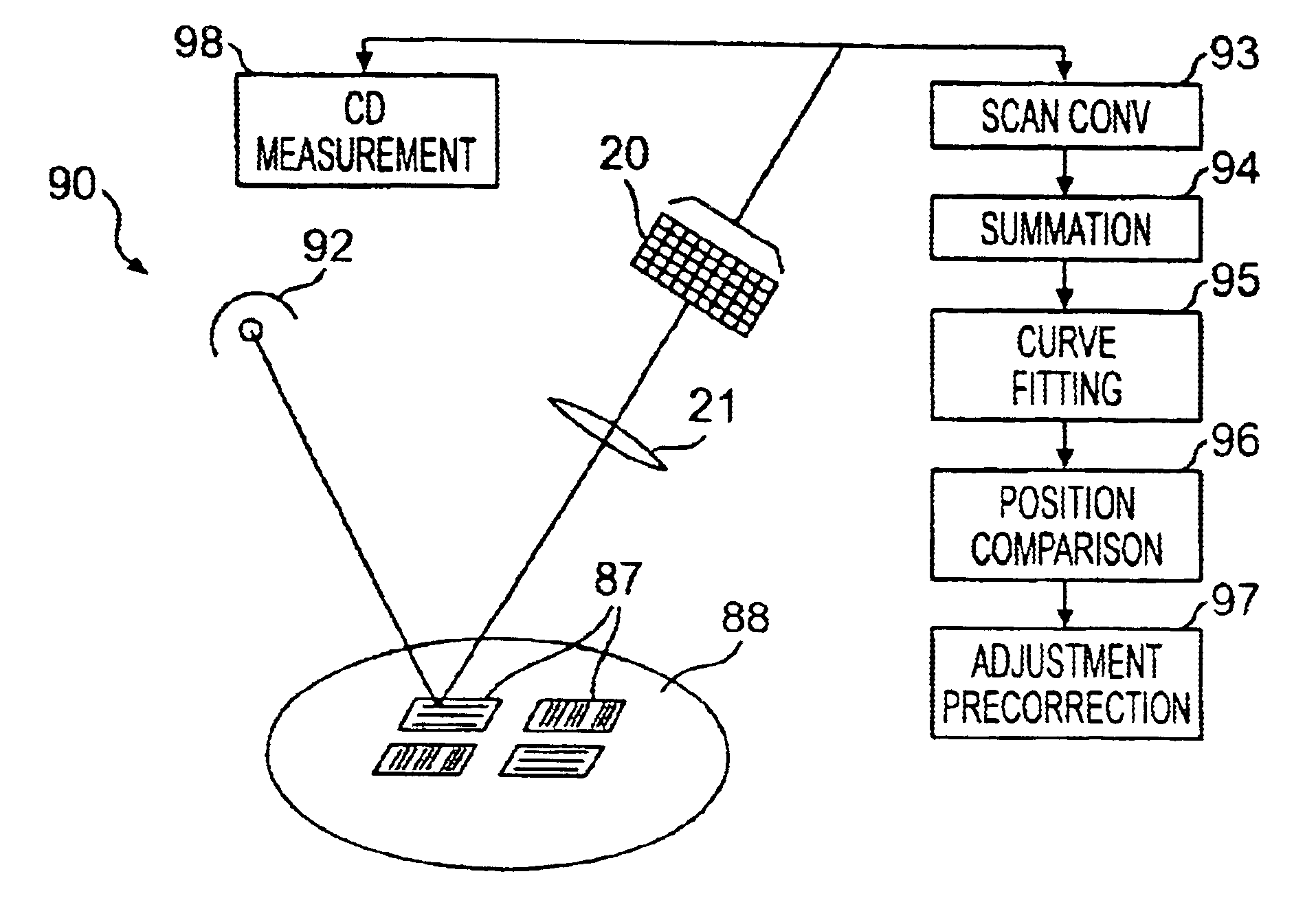

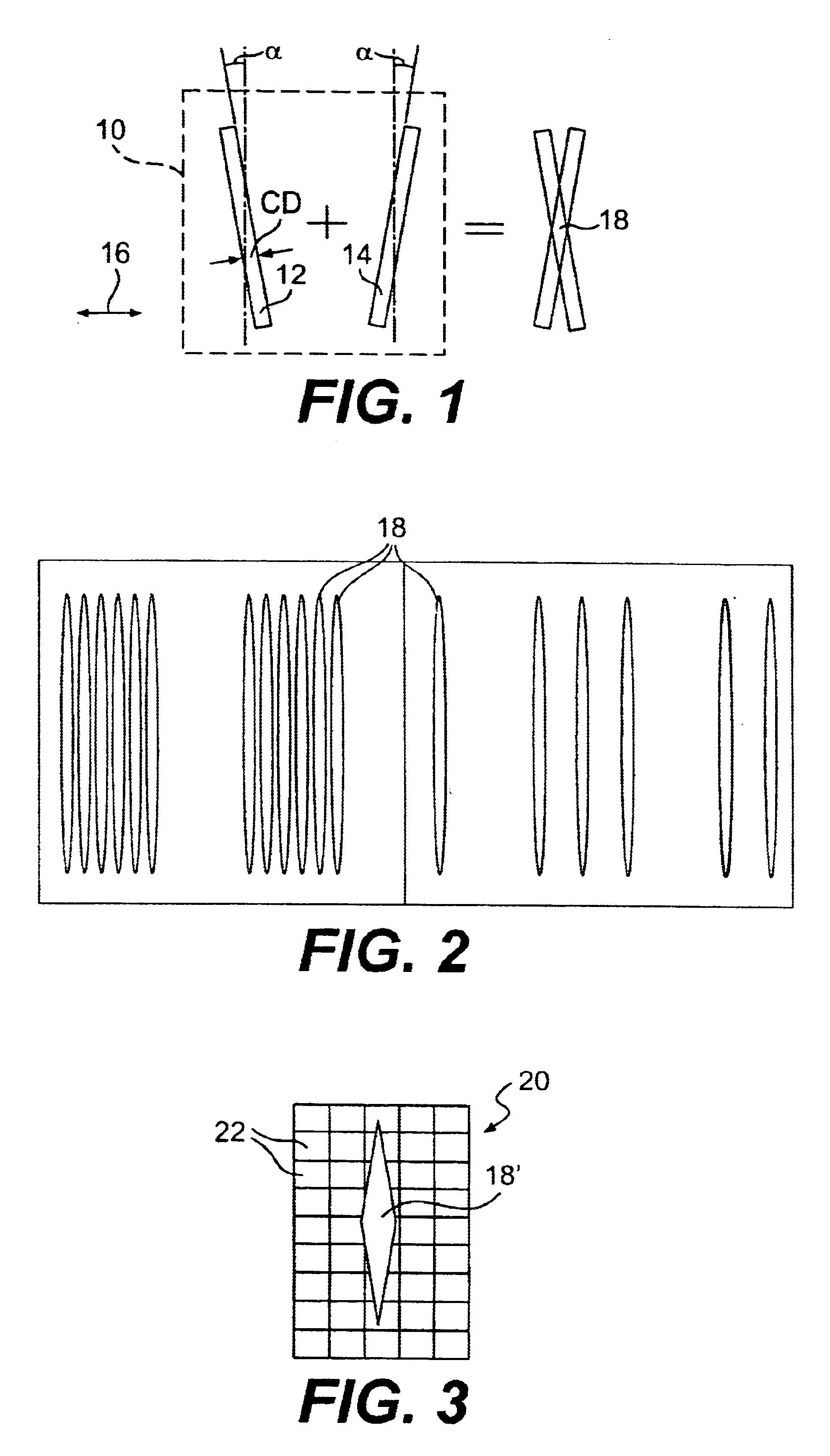

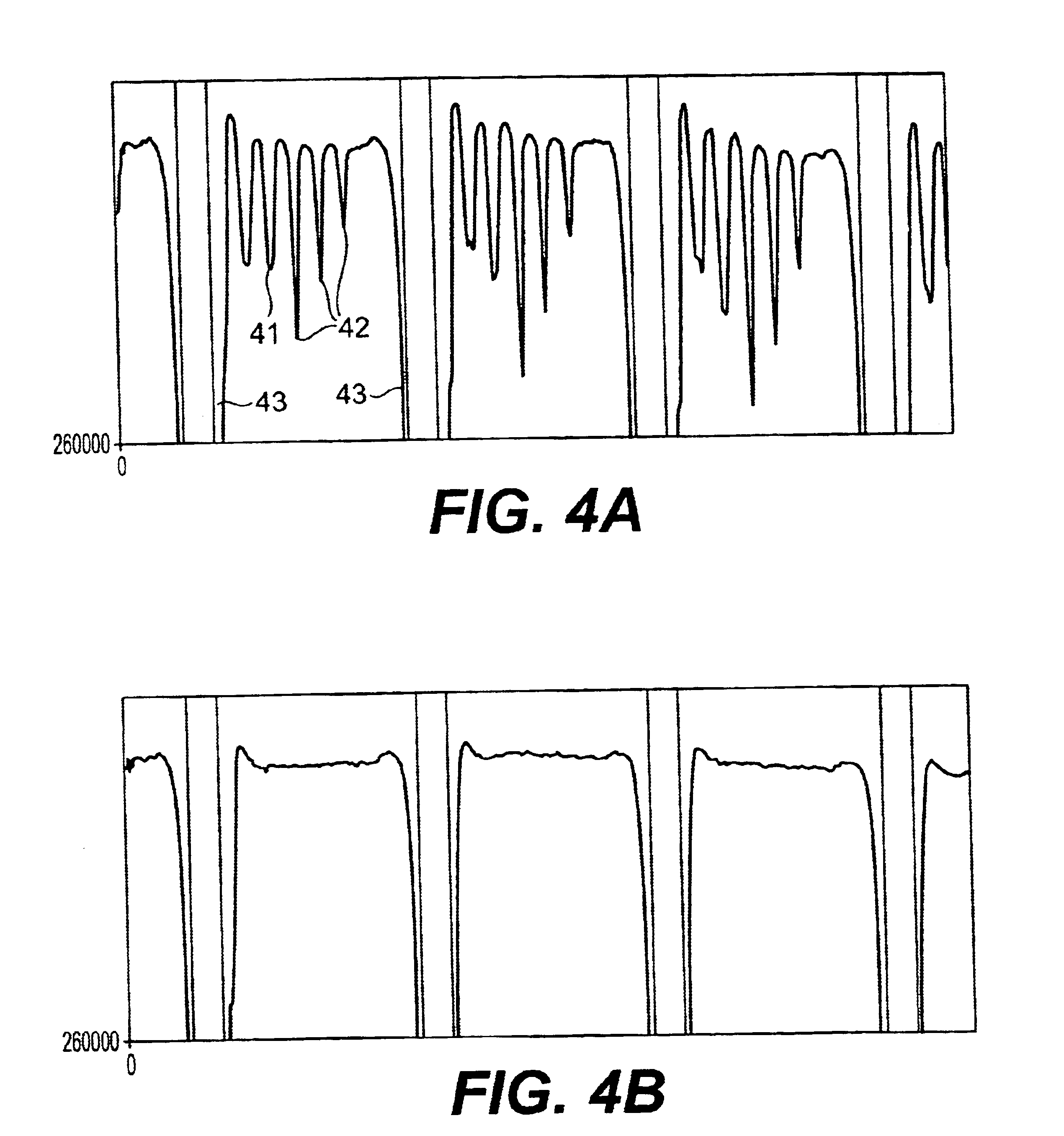

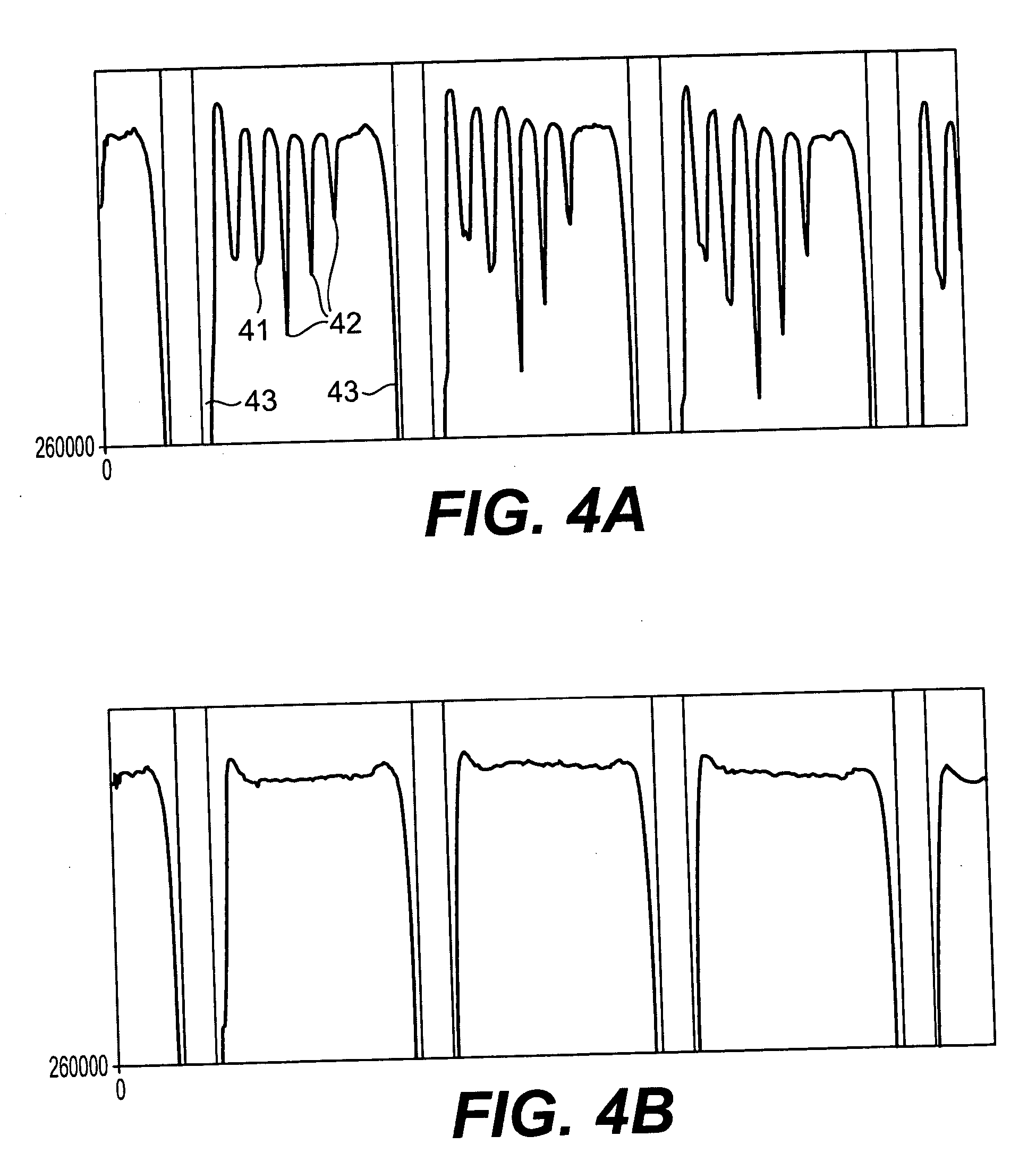

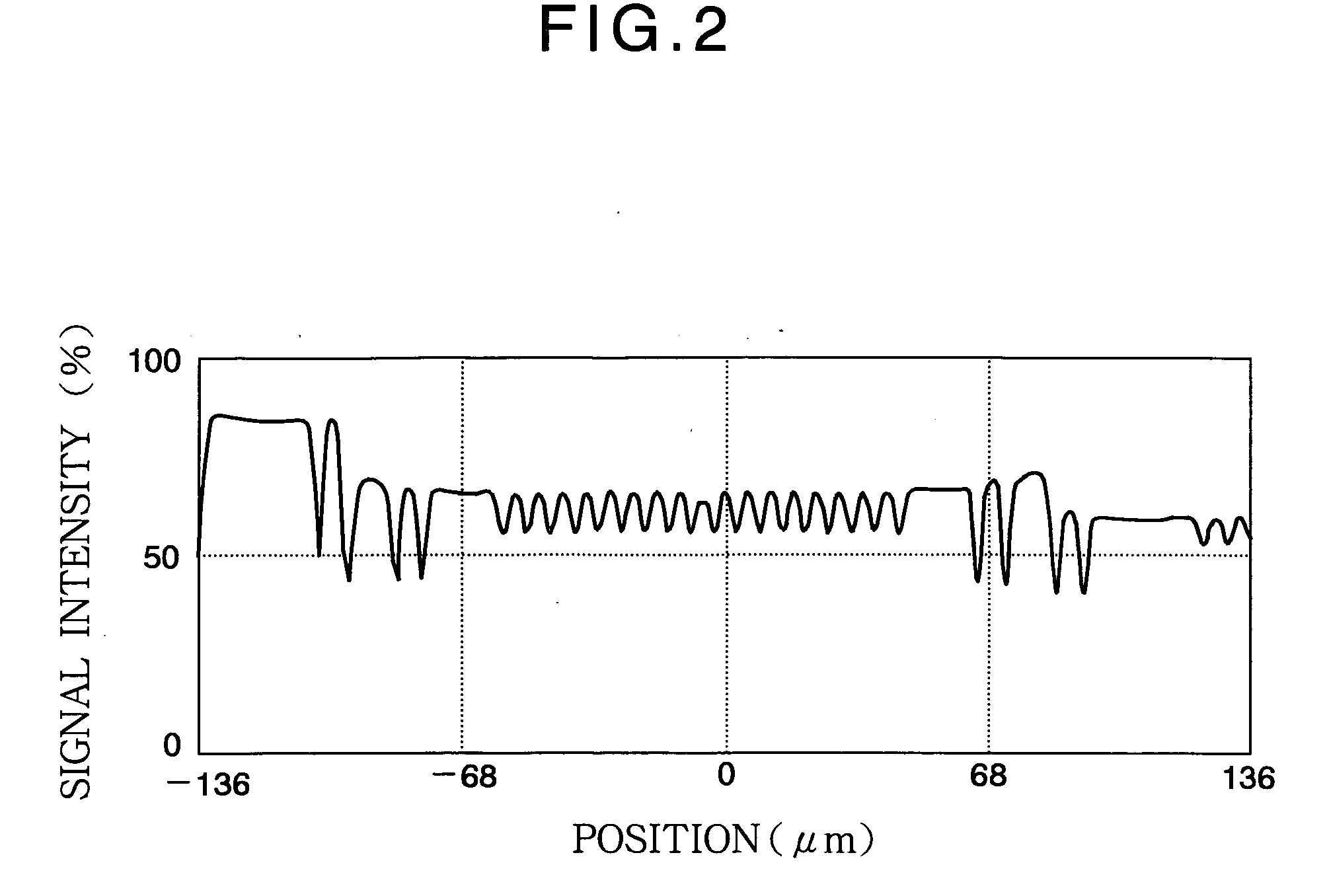

Variation in position of test marks formed of overlapping exposed features imaged by an imaging structure such as that of a lithography tool are characterized at high speed and with extremely high accuracy by imaging test marks formed in resist or on a target or wafer by a lithographic process, collecting irradiance distribution data and fitting a mathematical function to respective portions or regions of output data corresponding to a test mark of a test mark pattern such as respective maxima or minima regions or other regions of the irradiance distribution data to determine actual location and shift of position of respective patterns of test marks. Metrology fields are formed of patterns of test marks on test wafers or production wafers preferably including a critical dimension exposed at different focus distances and / or illumination conditions to capture position / aberration data for the imaging structure. The imaging structure can then be adjusted or corrected to minimize or eliminate aberrations of performance of the imaging structure or the performance on a complete lithographic process and / or to achieve overlay positioning with high accuracy and minimal requirements for wafer space.

Owner:NIKON PRECISION

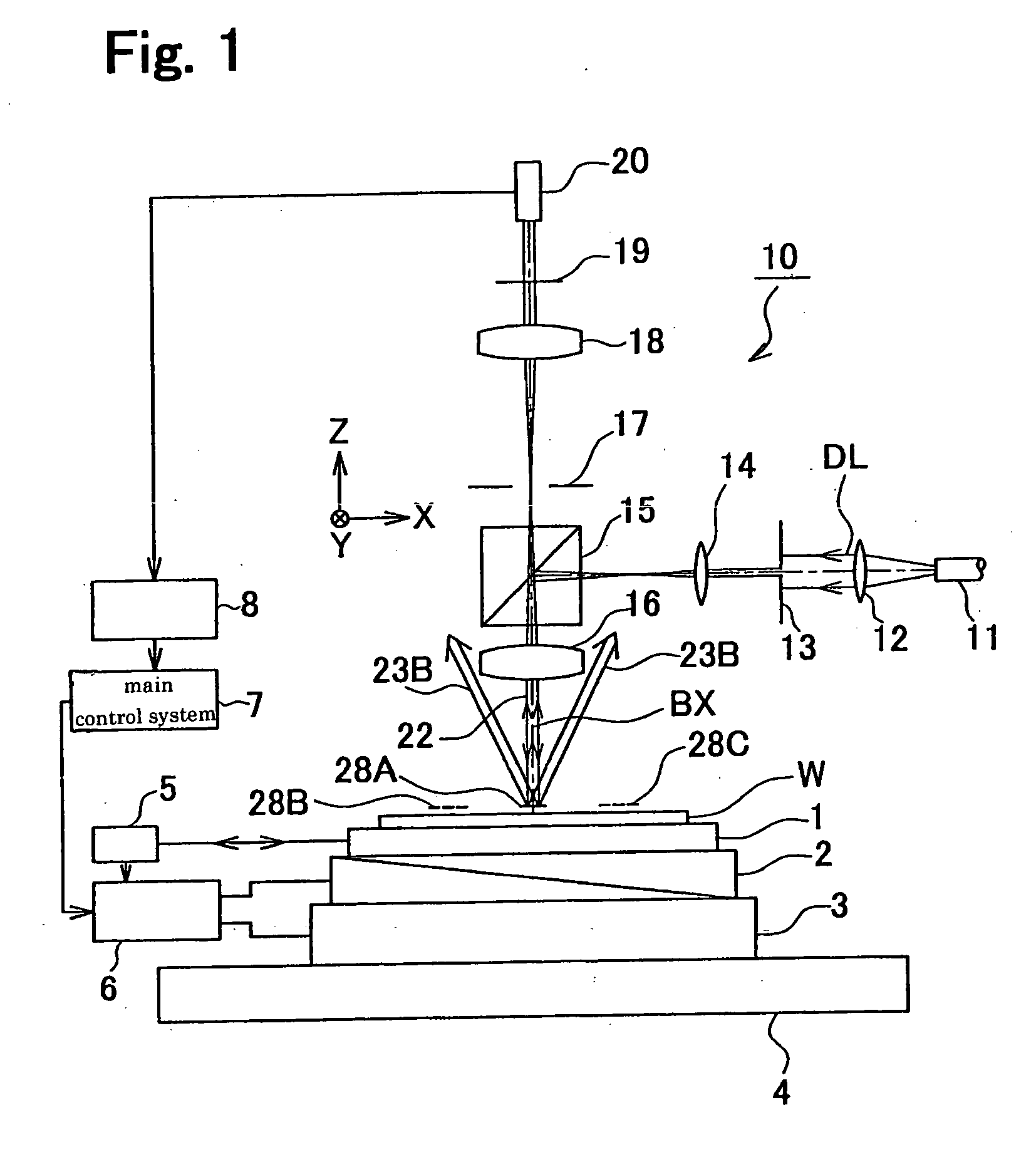

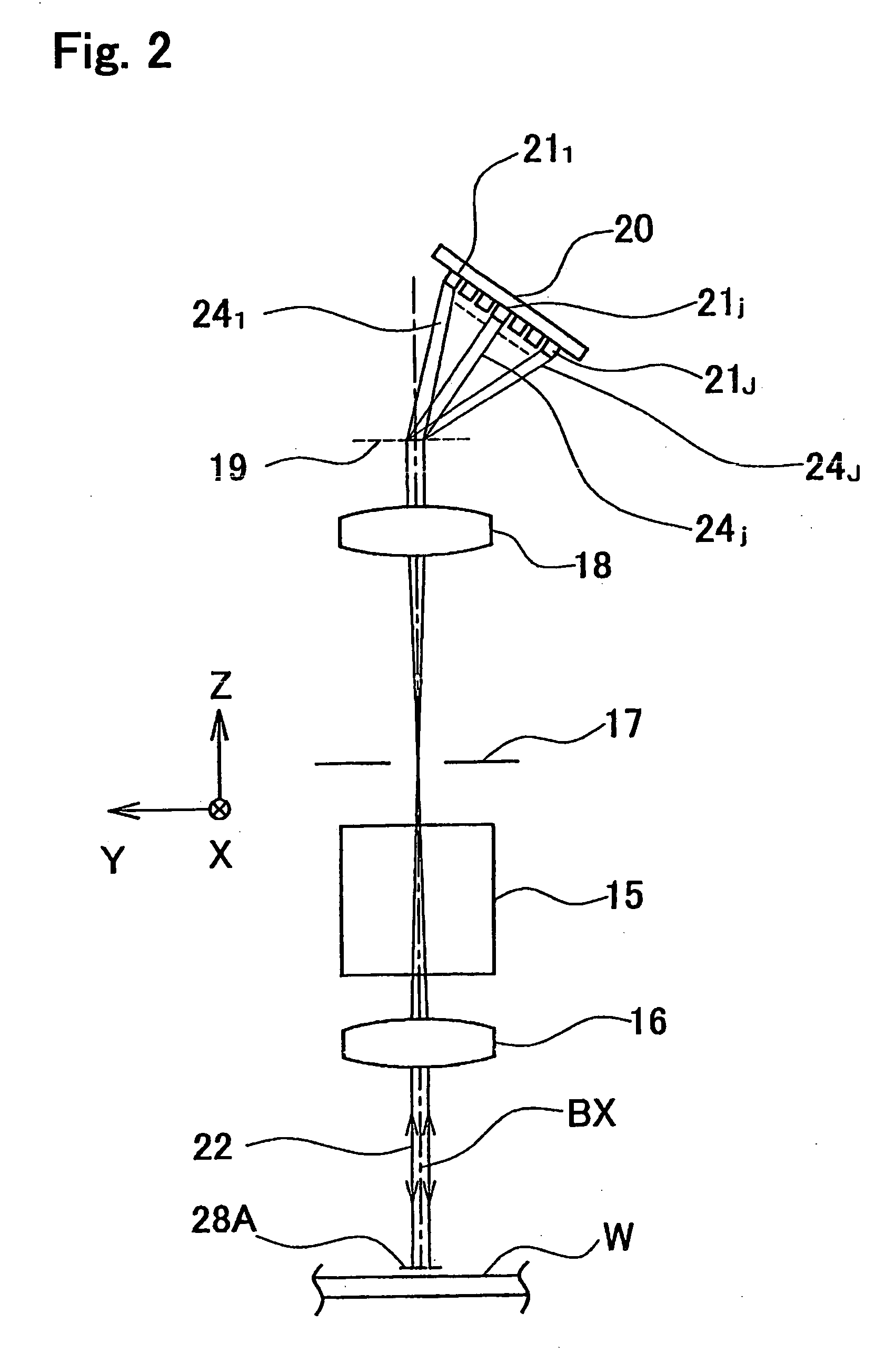

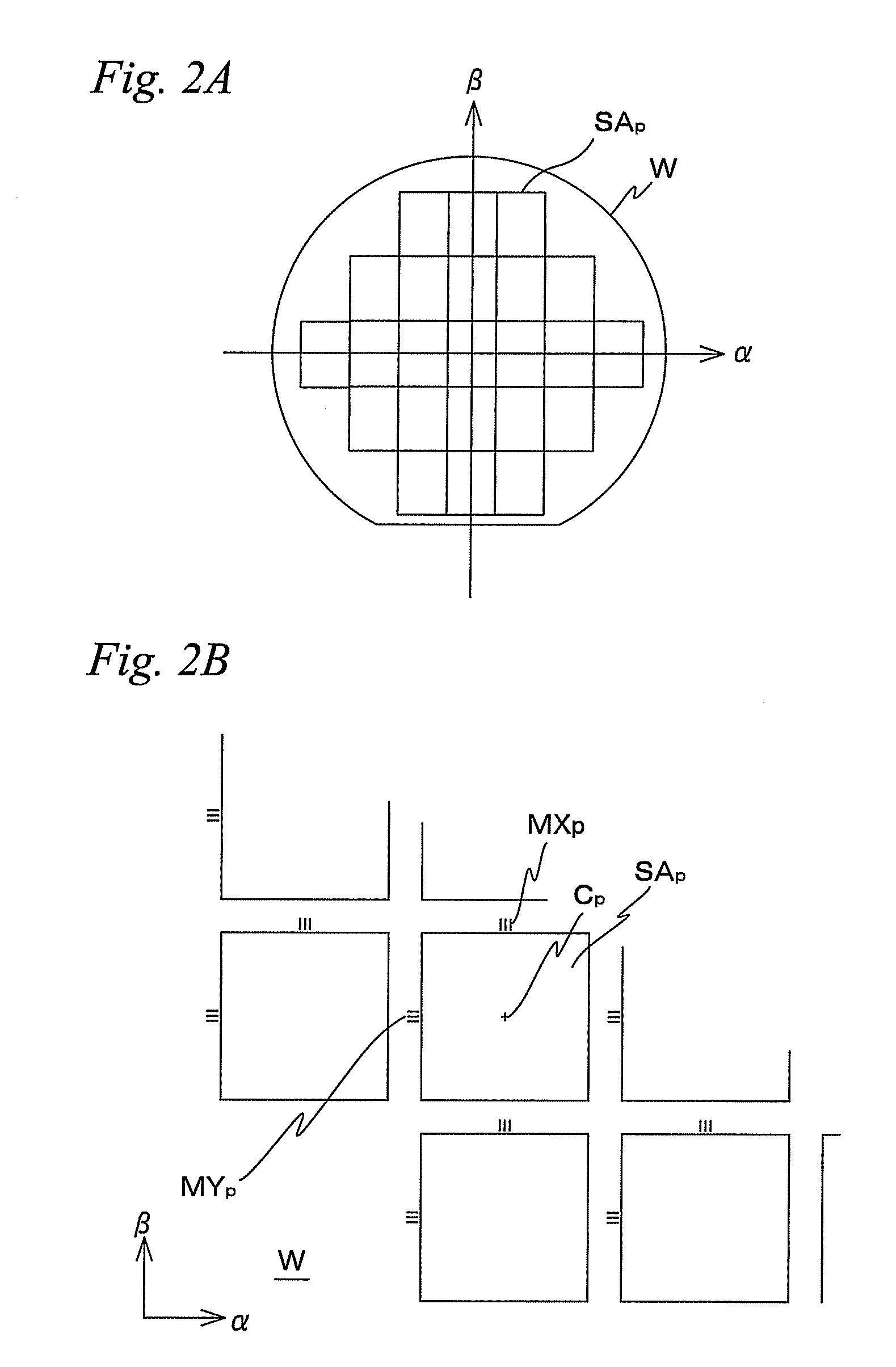

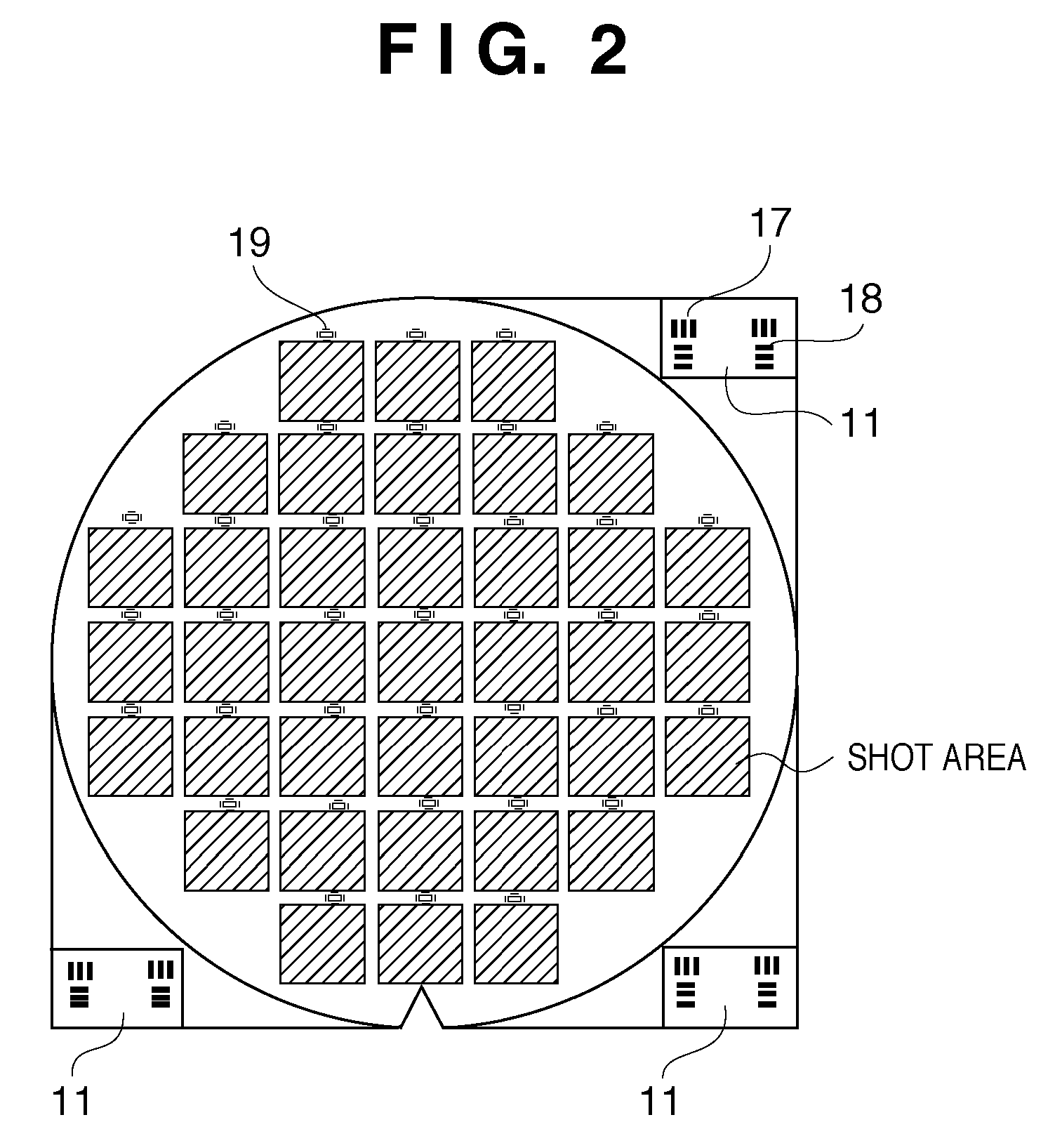

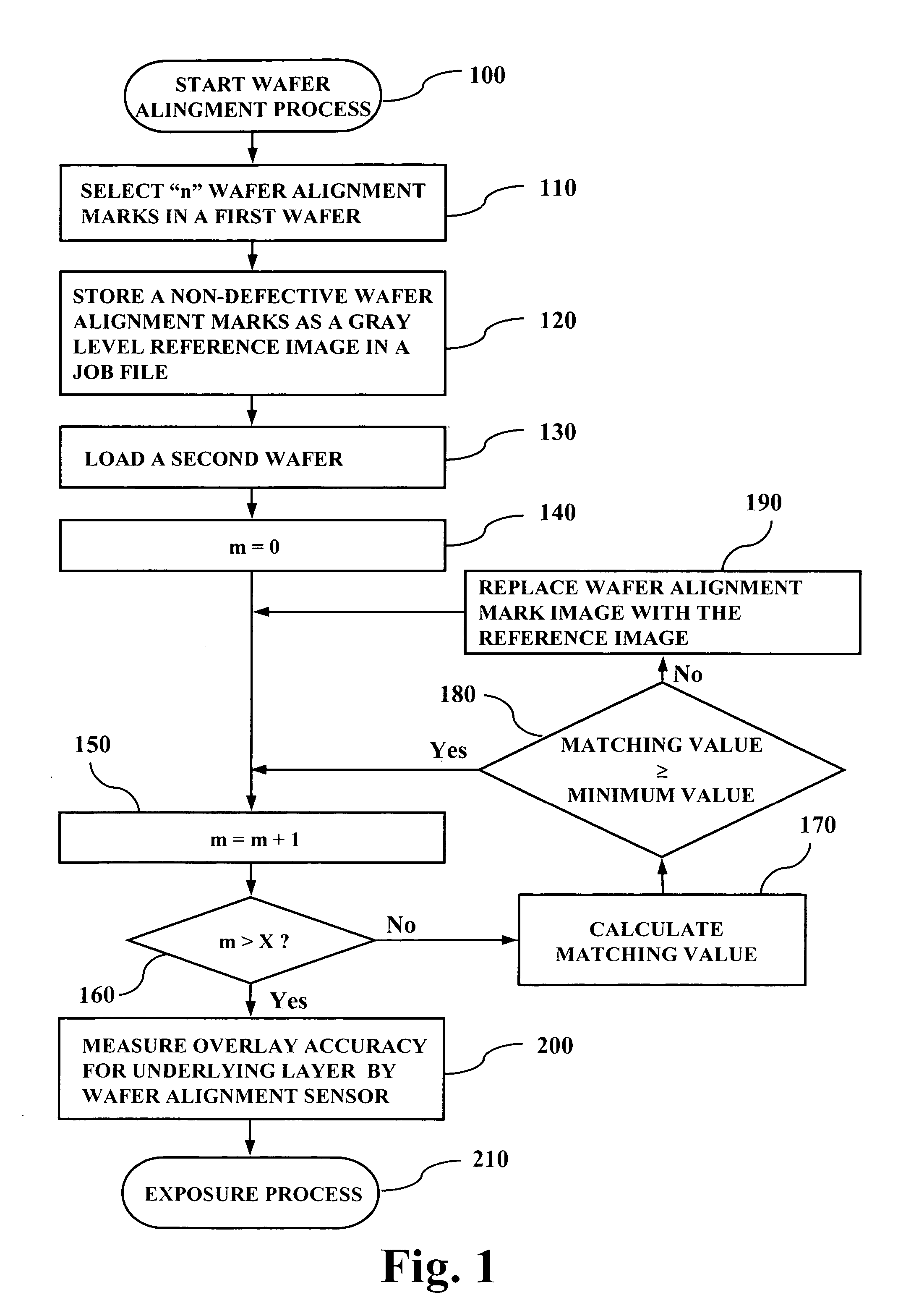

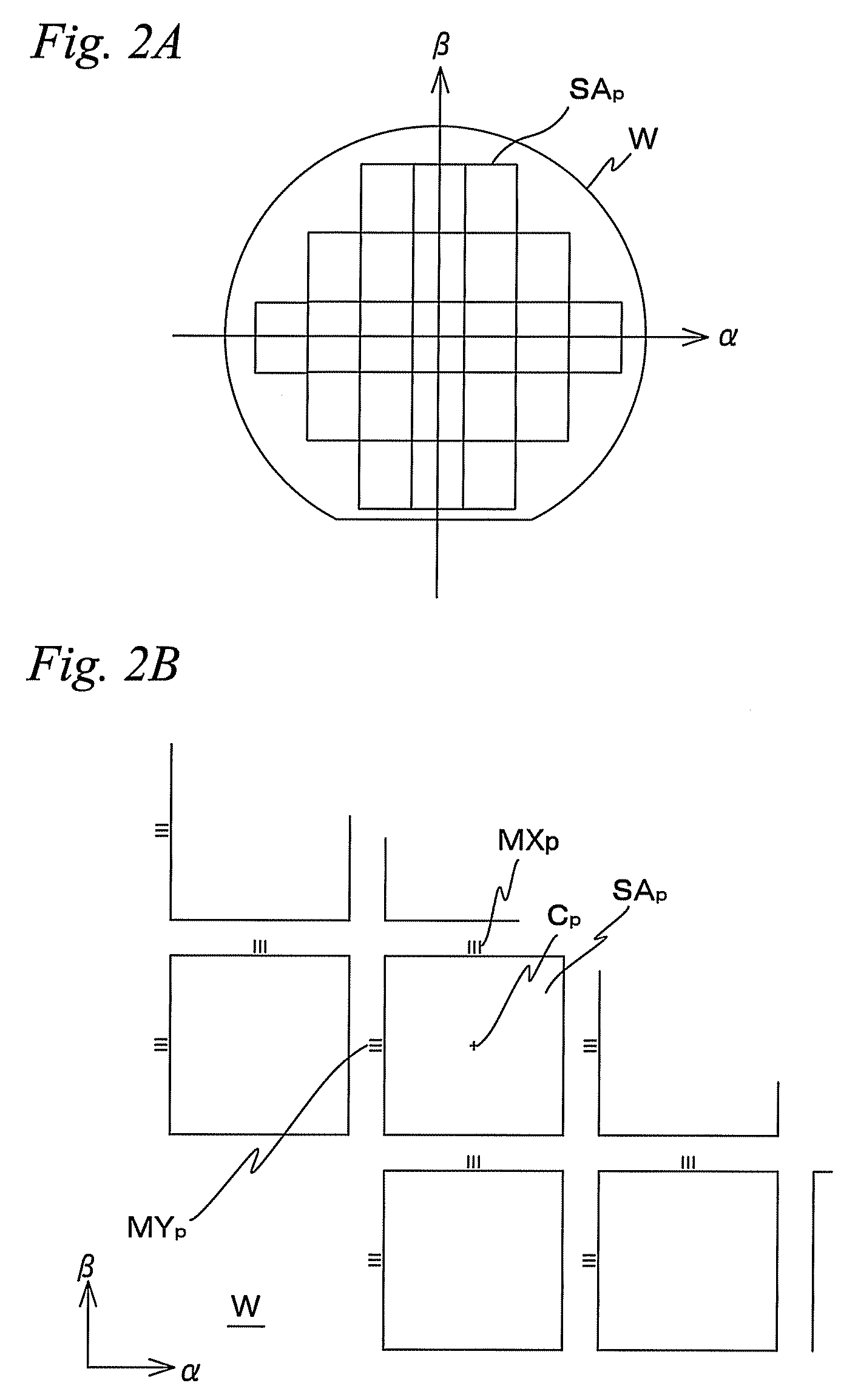

Positional information measuring method and device, and exposure method and apparatus

InactiveUS20060250597A1Easy to detectImprove accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusLength waveReflectometry

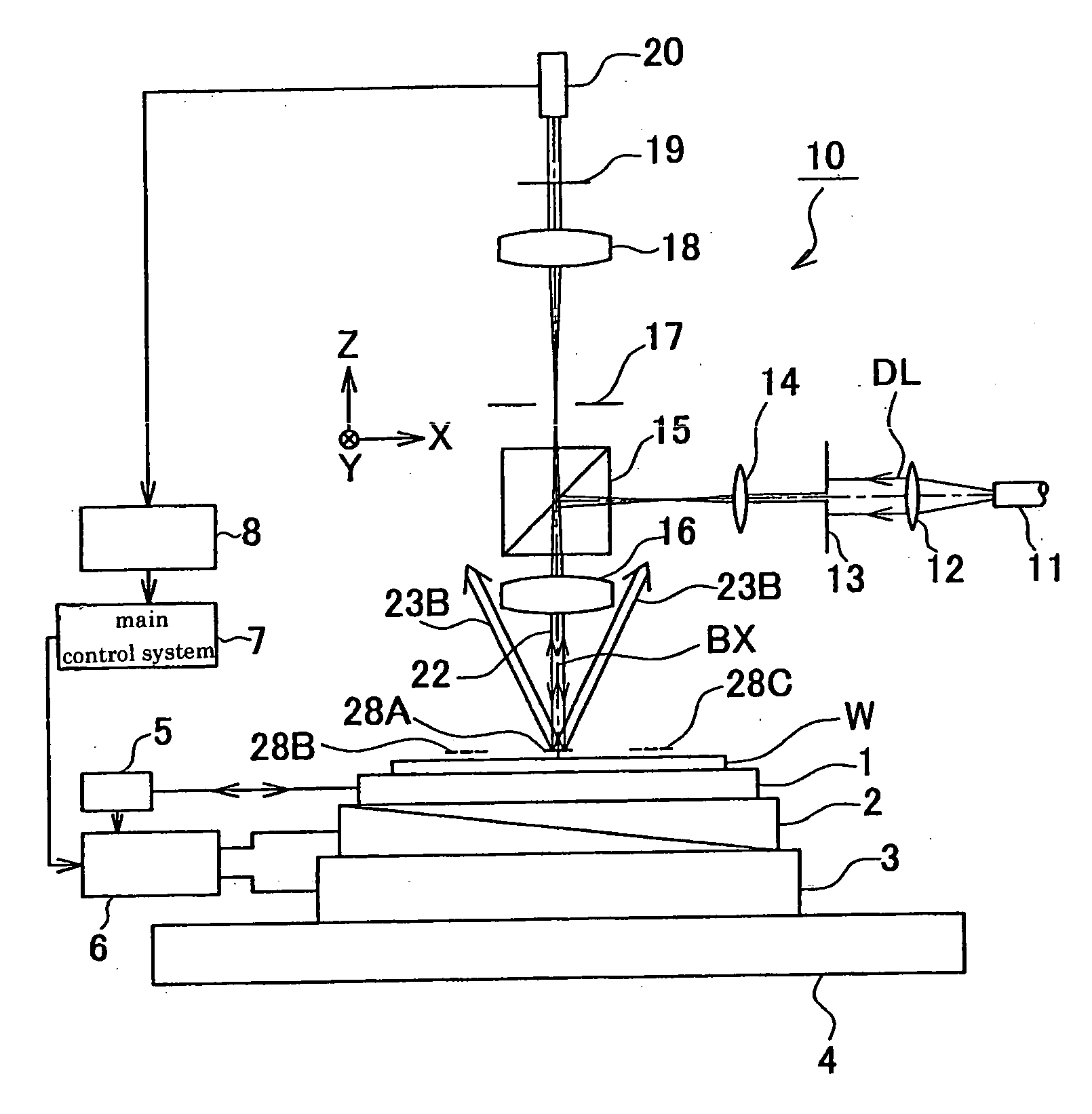

A position information measuring method capable of easily obtaining information on a relative position deviation between two marks by using scatterometry or reflectometry. Marks (25A) are formed on a wafer (W) at a pitch P1, and marks (28A) are formed on an intermediate layer (27) over them at a pitch P2 different from the pitch P1. A detection light (DL) is allowed to vertically enter the wafer (W) and a regular reflection light (22) from two marks (25A, 28A) only is spectrally separated on a wavelength basis for photoelectric converting. Wavelength-based reflectances are obtained from obtained detection signals, a reflectance at a specified wavelength is determined for each position in the measuring direction (X direction) of marks (25A, 28A), the shape of a Moire pattern formed by the overlapping of two marks (25A, 28A) is determined from the obtained reflectance distribution, and the position deviation amount of a mark (28A) is determined from the shape.

Owner:NIKON CORP

Method and apparatus for position measurement of a pattern formed by a lithographic exposure tool

InactiveUS20030215965A1Improve overlay accuracySuppress mutationSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsResistMetrology

Variation in position of test marks formed of overlapping exposed features imaged by an imaging structure such as that of a lithography tool are characterized at high speed and with extremely high accuracy by imaging test marks formed in resist or on a target or wafer by a lithographic process, collecting irradiance distribution data and fitting a mathematical function to respective portions or regions of output data corresponding to a test mark of a test mark pattern such as respective maxima or minima regions or other regions of the irradiance distribution data to determine actual location and shift of position of respective patterns of test marks. Metrology fields are formed of patterns of test marks on test wafers or production wafers preferably including a critical dimension exposed at different focus distances and / or illumination conditions to capture position / aberration data for the imaging structure. The imaging structure can then be adjusted or corrected to minimize or eliminate aberrations of performance of the imaging structure or the performance on a complete lithographic process and / or to achieve overlay positioning with high accuracy and minimal requirements for wafer space.

Owner:NIKON PRECISION

Alignment accuracy compensation method and device

ActiveCN106325001AImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusLithographic artistMachining system

The invention provides an alignment accuracy compensation method and device. The alignment accuracy compensation method comprises the steps of measuring first alignment accuracy of a current layer of lithography pattern and a previous layer of lithography pattern; measuring second alignment accuracy of the previous layer of lithography pattern and a more previous layer of lithography pattern; and calculating an error in the technical process on the basis of the first alignment accuracy and the second alignment accuracy for feeding the error into an exposure machine system. According to the alignment accuracy compensation method and device provided by the invention, by adopting the alignment accuracy among multiple layers as feedback, a dual damascene process window can be improved and higher alignment accuracy can be obtained for a dual damascene process.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Exposure method, exposure apparatus, and method for producing device

ActiveUS20080297751A1Precision productionImprove accuracyUsing optical meansPhotomechanical exposure apparatusPhysics

An exposure method includes measuring coordinates of alignment marks before and after exposing a first wafer to determine a fluctuation amount of a parameter of the alignment; measuring coordinates of alignment marks before exposing a second wafer to determine a parameter of the alignment; and aligning and exposing the second wafer based on a parameter obtained by correcting the parameter with the fluctuation amount determined for the first wafer. A high overlay accuracy can be obtained even when the alignment information is gradually changed, for example, due to the linear expansion and contraction of the substrate during the exposure of the substrate.

Owner:NIKON CORP

Alignment compensation system and method for lithographic apparatus

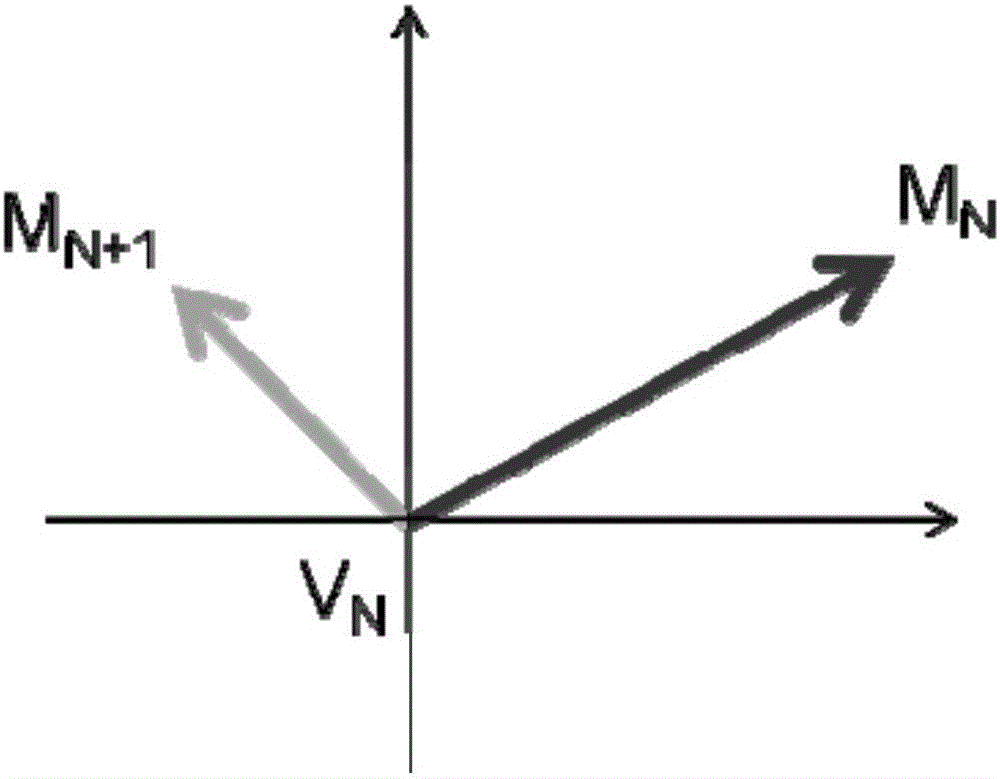

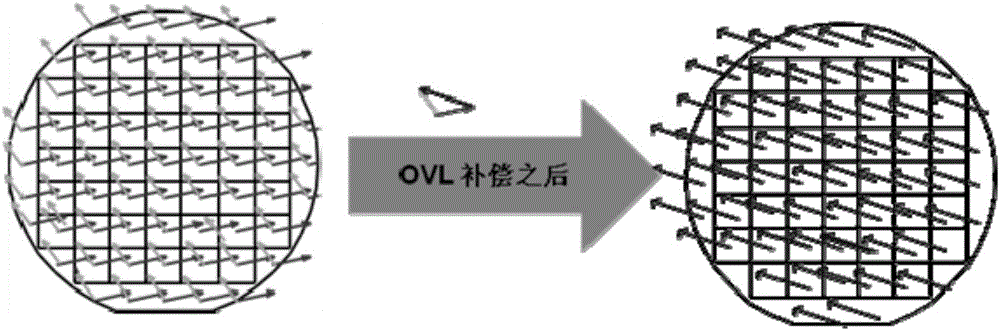

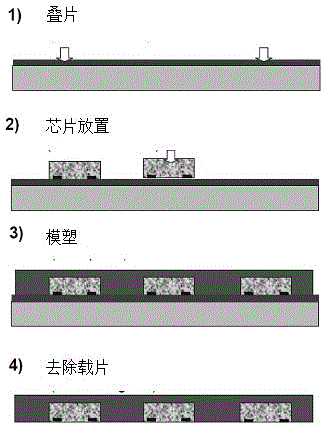

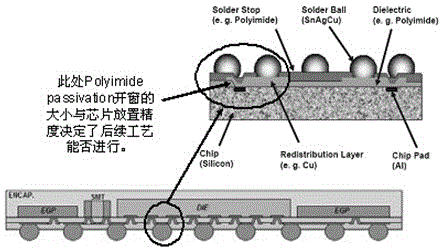

ActiveCN106547171AImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusDegrees of freedomPosition error

The invention discloses an alignment compensation system for a lithographic apparatus. The alignment compensation system comprises an illumination module used for providing a radiation beam, a mask platform used for bearing a pattern, a workbench used for bearing a to-be-exposed reconstituted wafer and supplying motion of at least one degree of freedom, a projection objective used for imaging the pattern to the to-be-exposed reconstituted wafer, and an alignment error measurement and compensation system used for measuring a relative position error between a position of a chip on the to-be-exposed reconstituted wafer and the pattern imaging position, and obtaining a correction model through calculation to compensate the relative position error. Meanwhile, the invention discloses an alignment compensation method for the lithographic apparatus.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

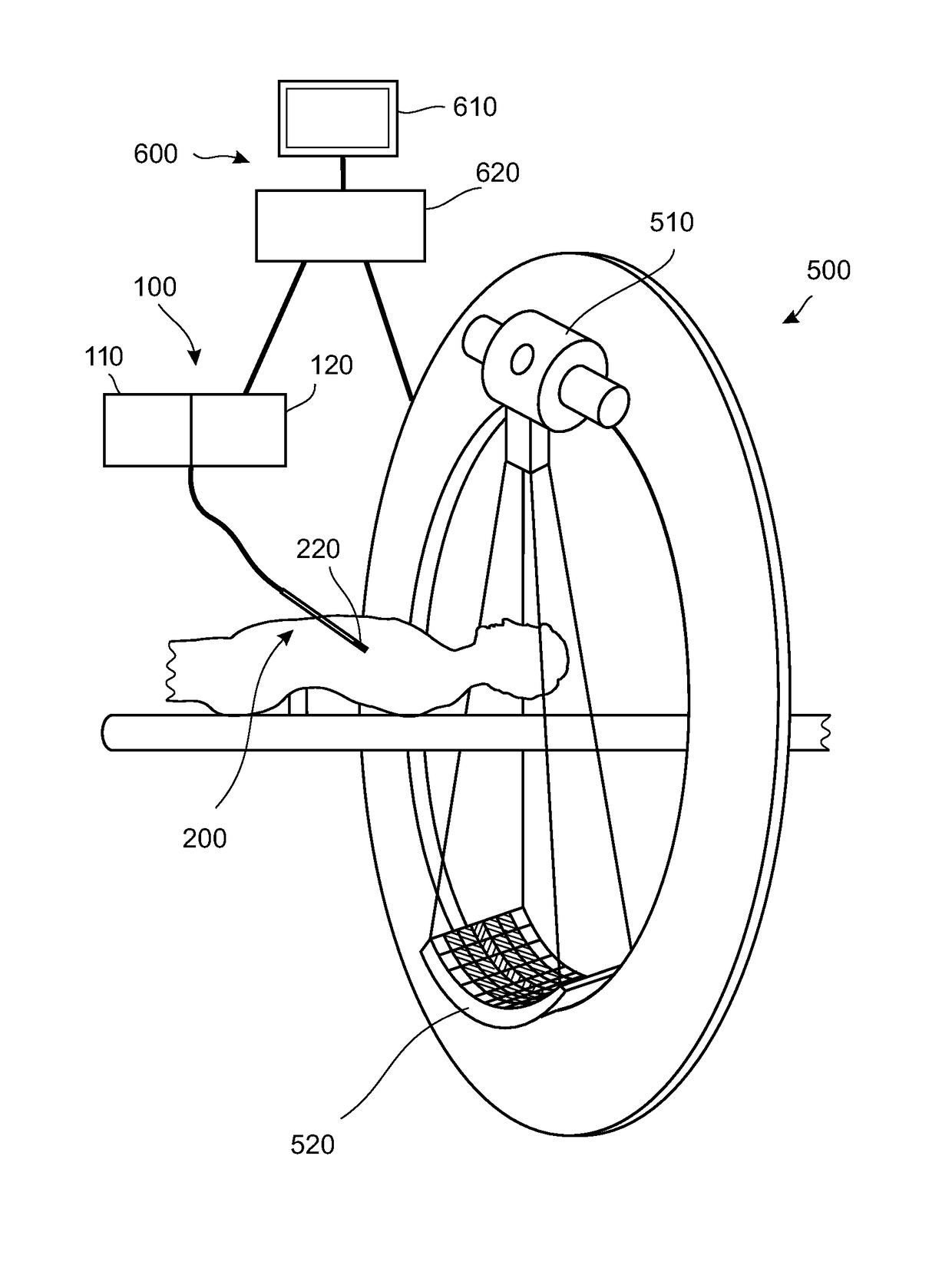

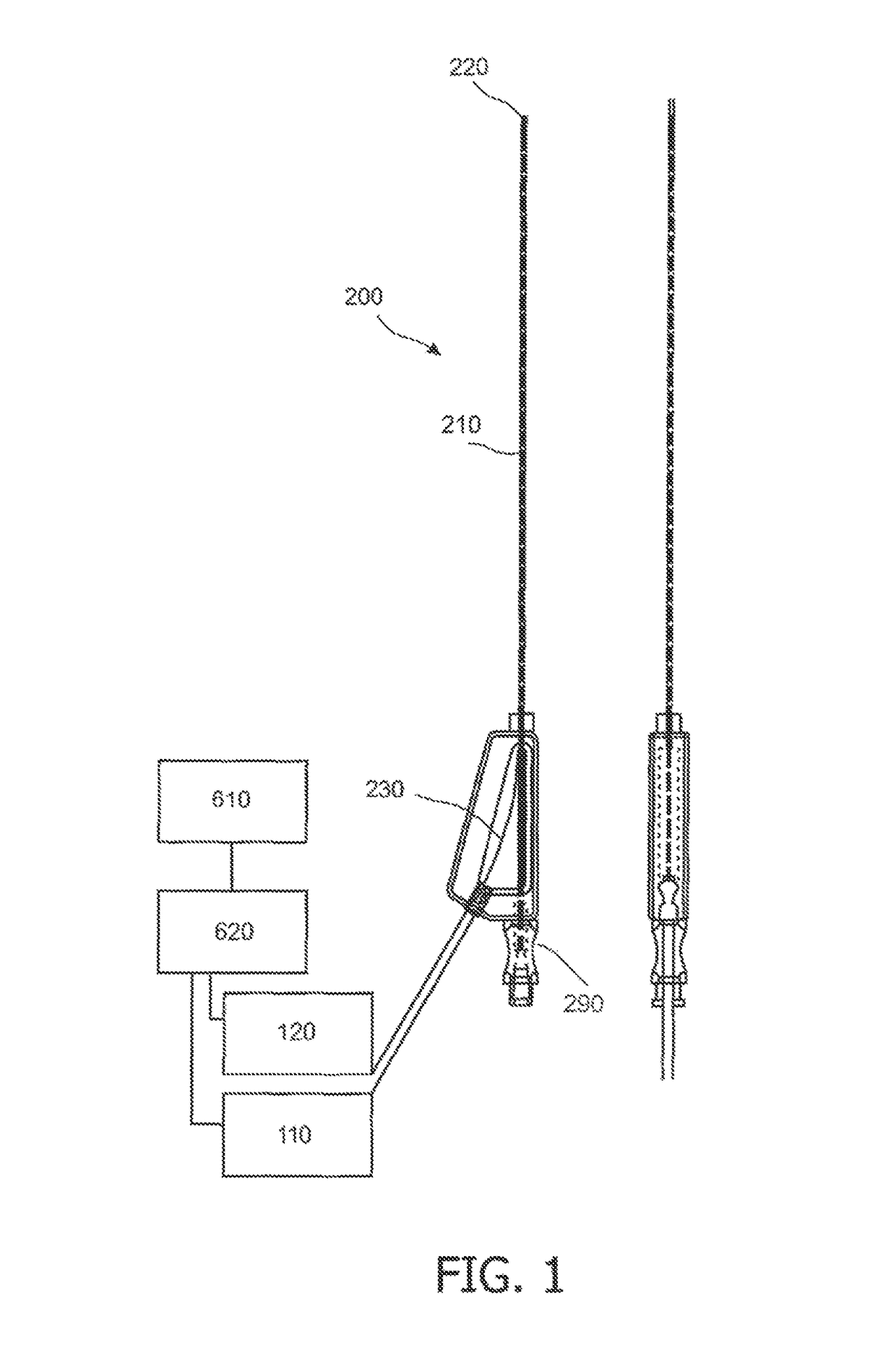

Re-calibration of pre-recorded images during interventions using a needle device

ActiveUS9980698B2Improve overlay accuracyImprove accuracyImage analysisSurgical needlesImaging equipmentComputer science

Re-calibration of pre-recorded images during interventions uses an interventional system including an imaging device providing images of an object, a needle device, and a processing device. The needle device includes a sensor for providing data corresponding to tissue properties. The processing device is configured to perform an overlay registration of pre-recorded images and live images provided by the imaging device, utilizing the data from the sensor. Thus, the accuracy of an overlay of images is increased.

Owner:KONINK PHILIPS ELECTRONICS NV

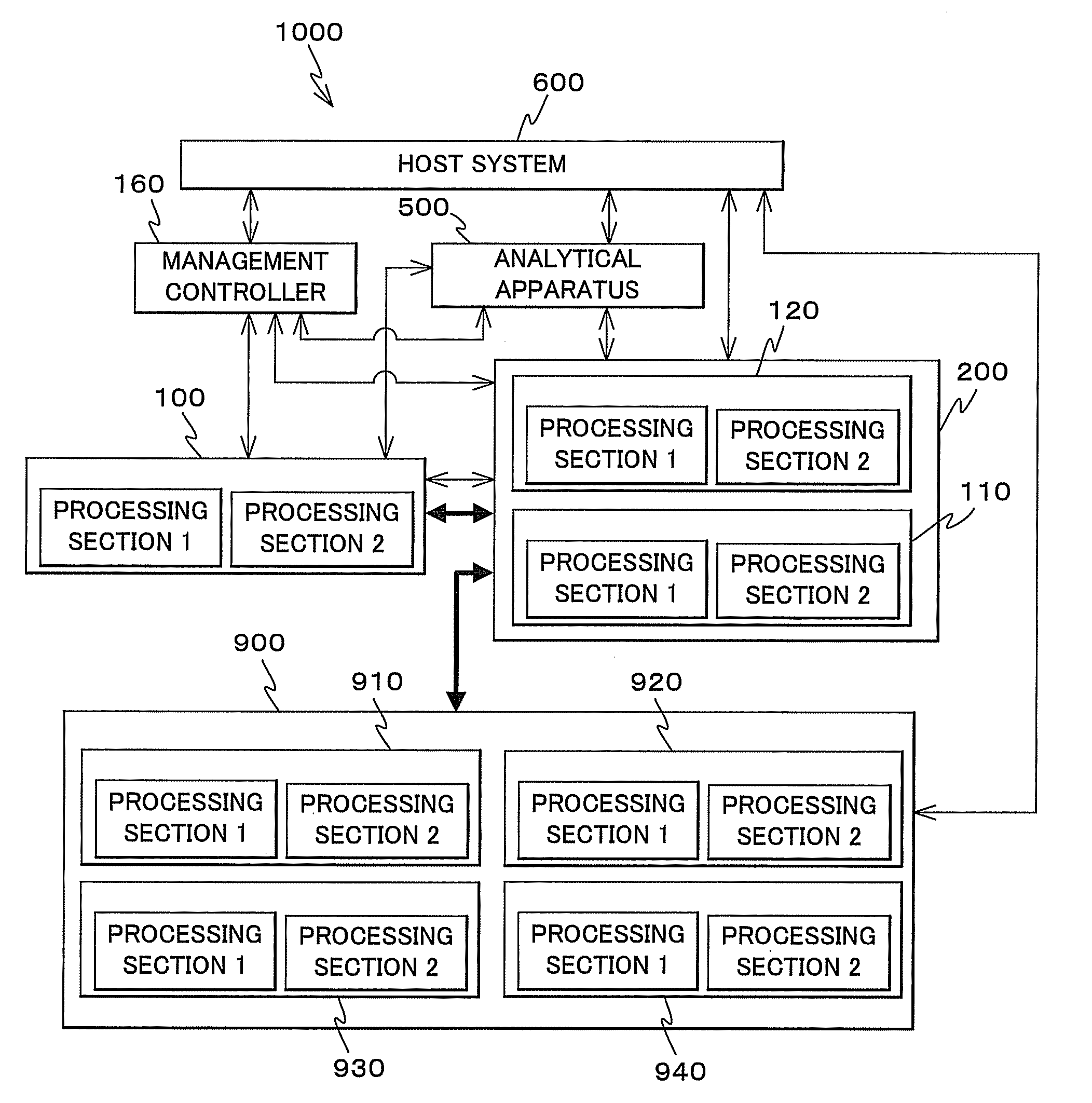

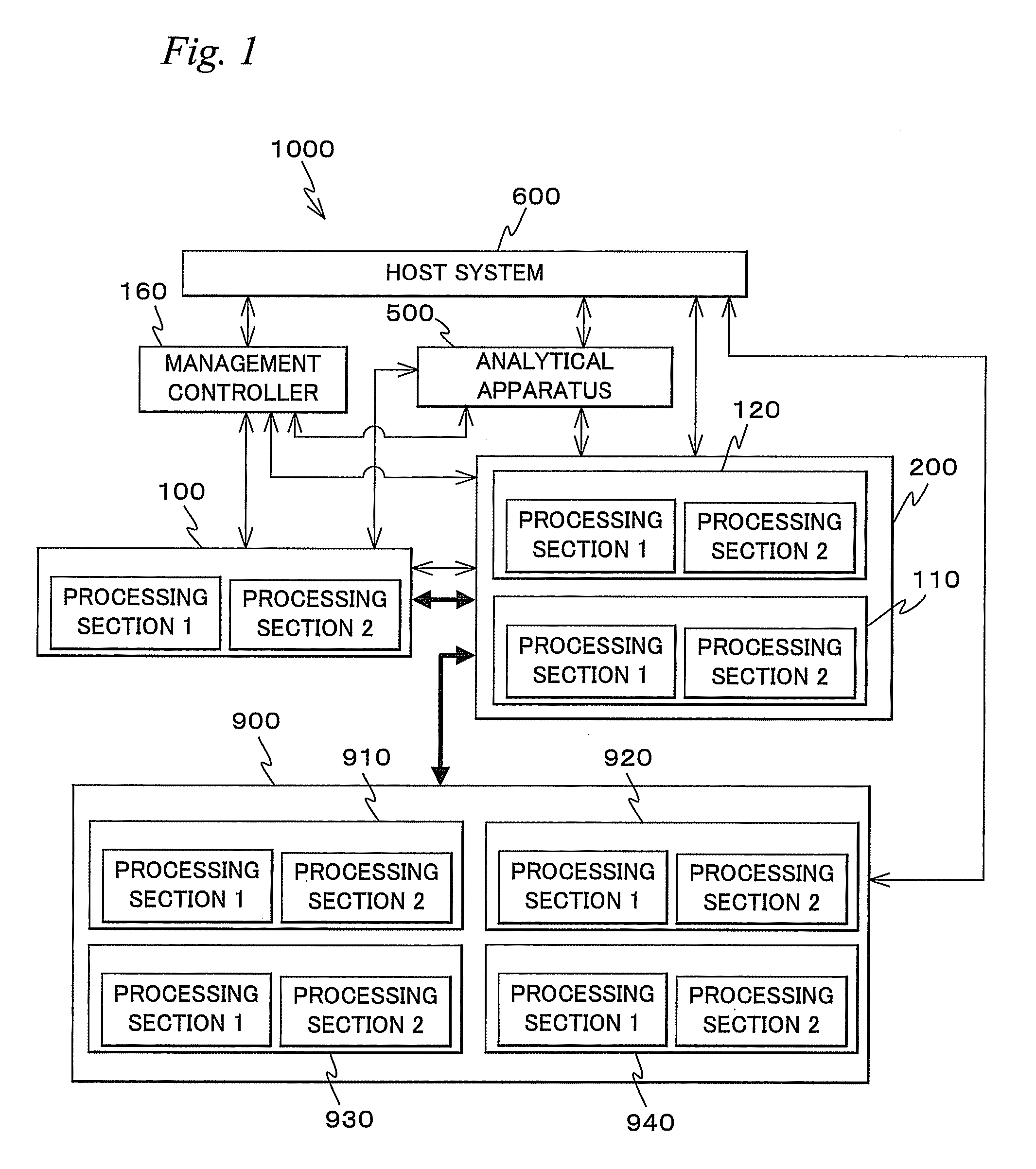

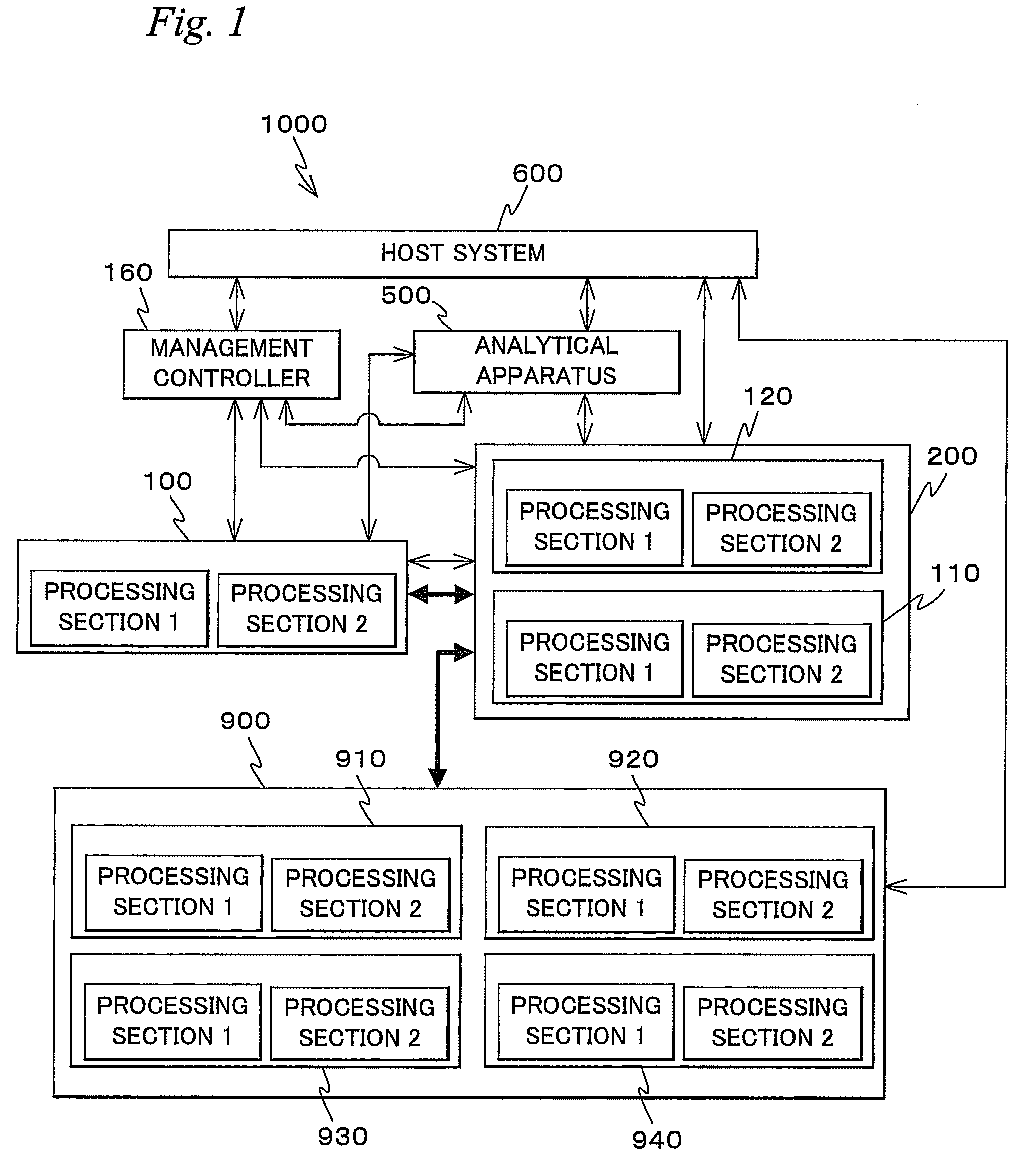

Overlay management method and apparatus, processing apparatus, measurement apparatus and exposure apparatus, device manufacturing system and device manufacturing method, and program and information recording medium

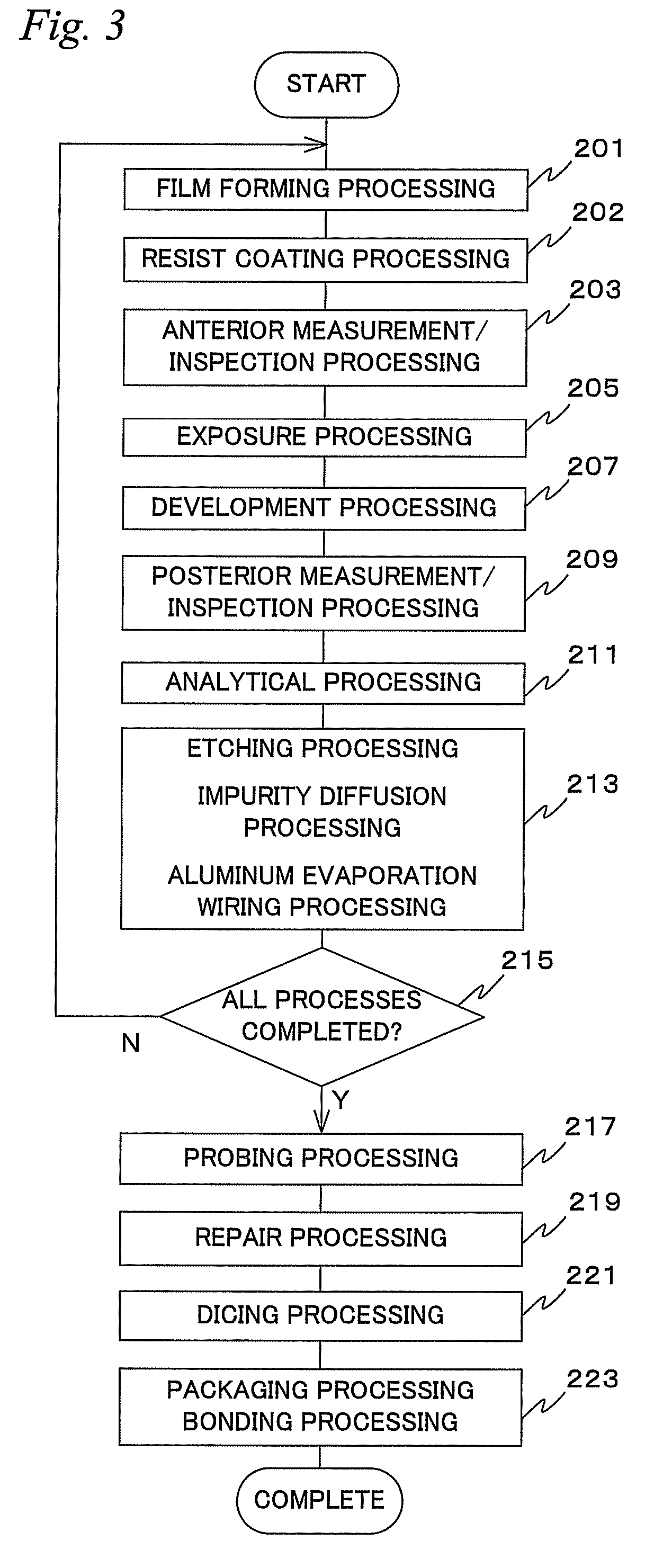

ActiveUS20080286667A1Increase productivityImprove overlay accuracyPhotomechanical apparatusUsing optical meansMeasuring equipmentProduction rate

In repeated processes (steps 201 to 213) of lot processing, an analytical apparatus detects abnormality of overlay, that is, deterioration of overlay accuracy in step 211 and optimizes an apparatus parameter of an exposure apparatus so that the abnormality is solved (so that the overlay accuracy is improved), and then the optimization result is promptly reflected in the exposure apparatus and a measurement / inspection instrument. Since such optimization is performed without stopping the lot processing, the productivity of devices is not lowered.

Owner:NIKON CORP

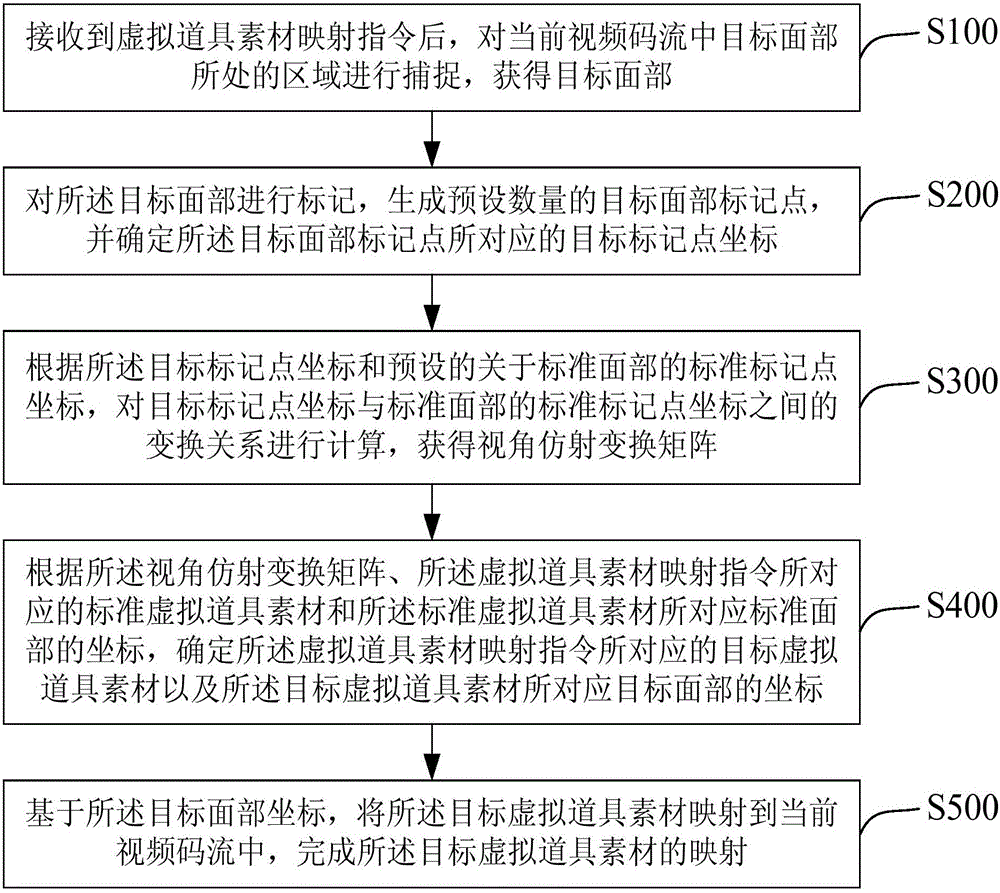

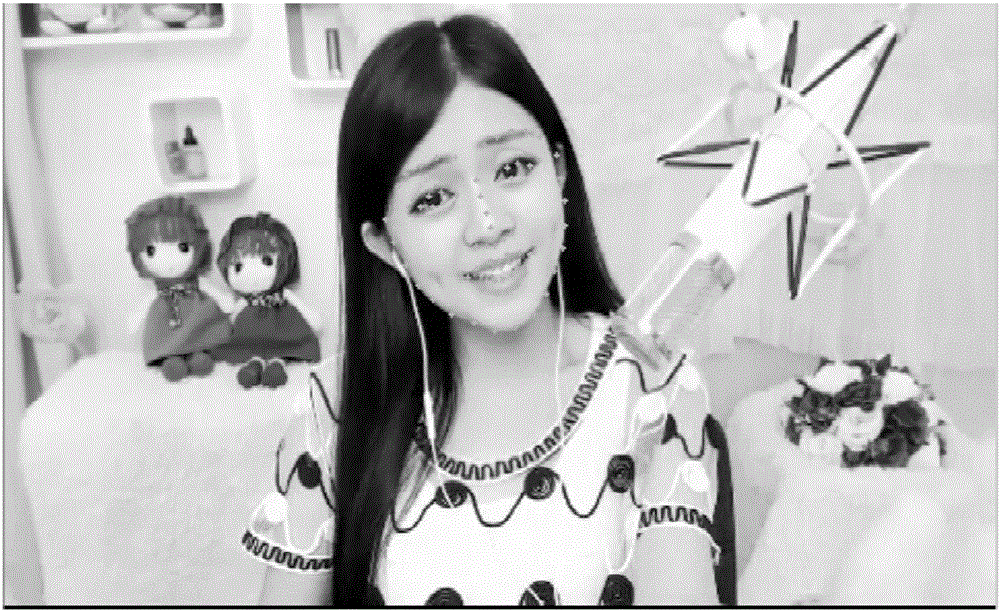

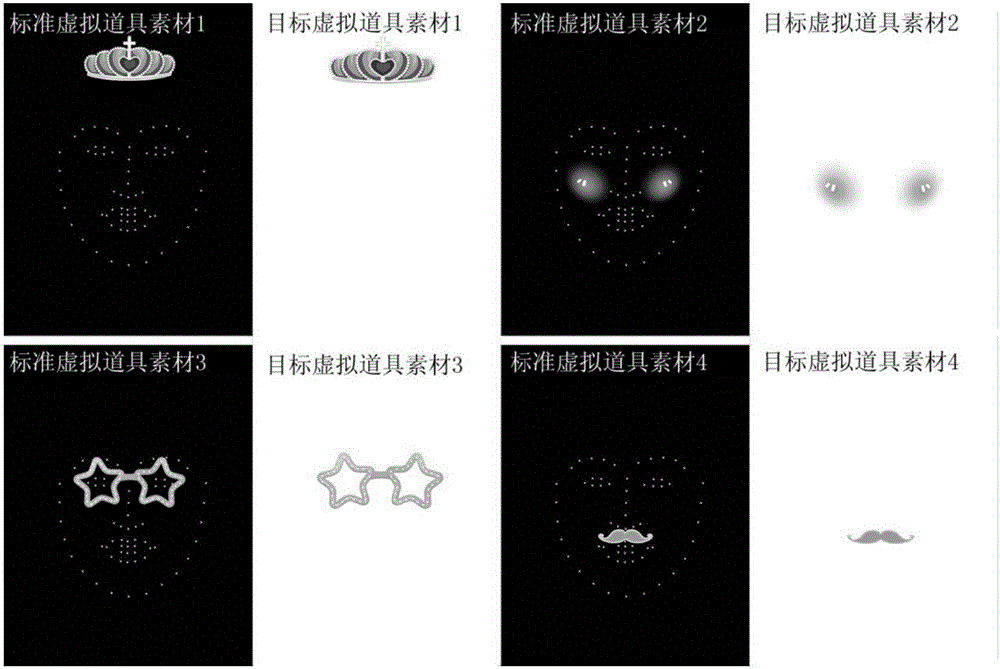

Image processing method and device

InactiveCN106028136AImprove overlay accuracyImprove experienceImage enhancementImage analysisVideo bitstreamImaging processing

The embodiment of the invention provides an image processing method and device. The method comprises the steps of after a system receives a virtual item material mapping instruction, capturing an area where a target face locates in a current video bitstream to obtain the target face; marking the target face area to generate multiple target marking points, and obtaining coordinates corresponding to the target marking points; calculating a view angle affine transformation matrix according to the coordinates of the target marking points and a standard marking point coordinate of a standard face; then calculating a target virtual item material and the coordinate thereof corresponding to the target face according to the view angle affine transformation matrix and the standard virtual item material and corresponding coordinate thereof; and mapping the target virtual item material to the current video bitstream, thereby finishing the mapping of a target virtual item. By applying the image processing method and device provided by the invention, the superposition accuracy between a virtual item and a corresponding part when the virtual item is worn in a live video can be improved; and thus, the user experience is improved.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

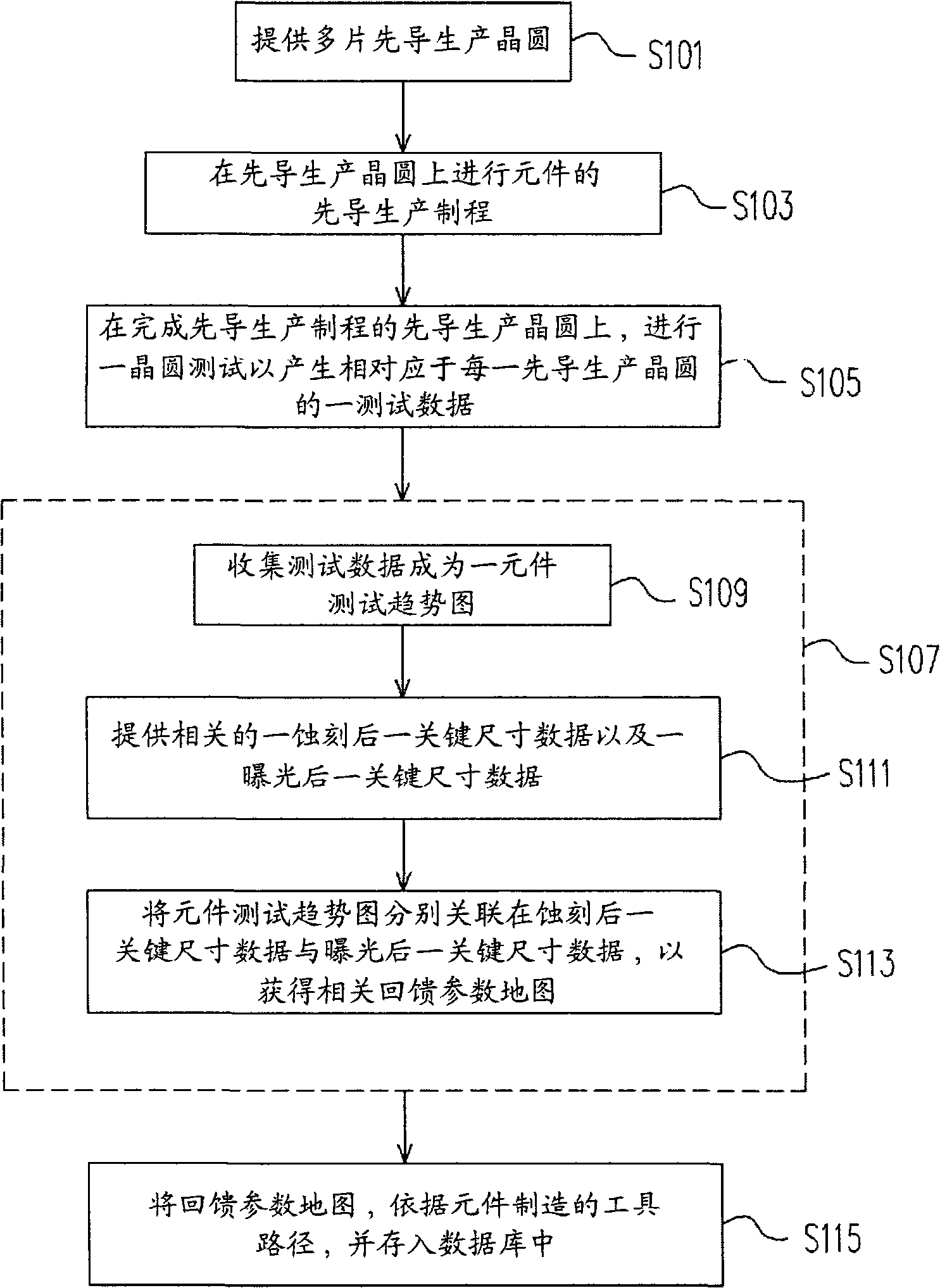

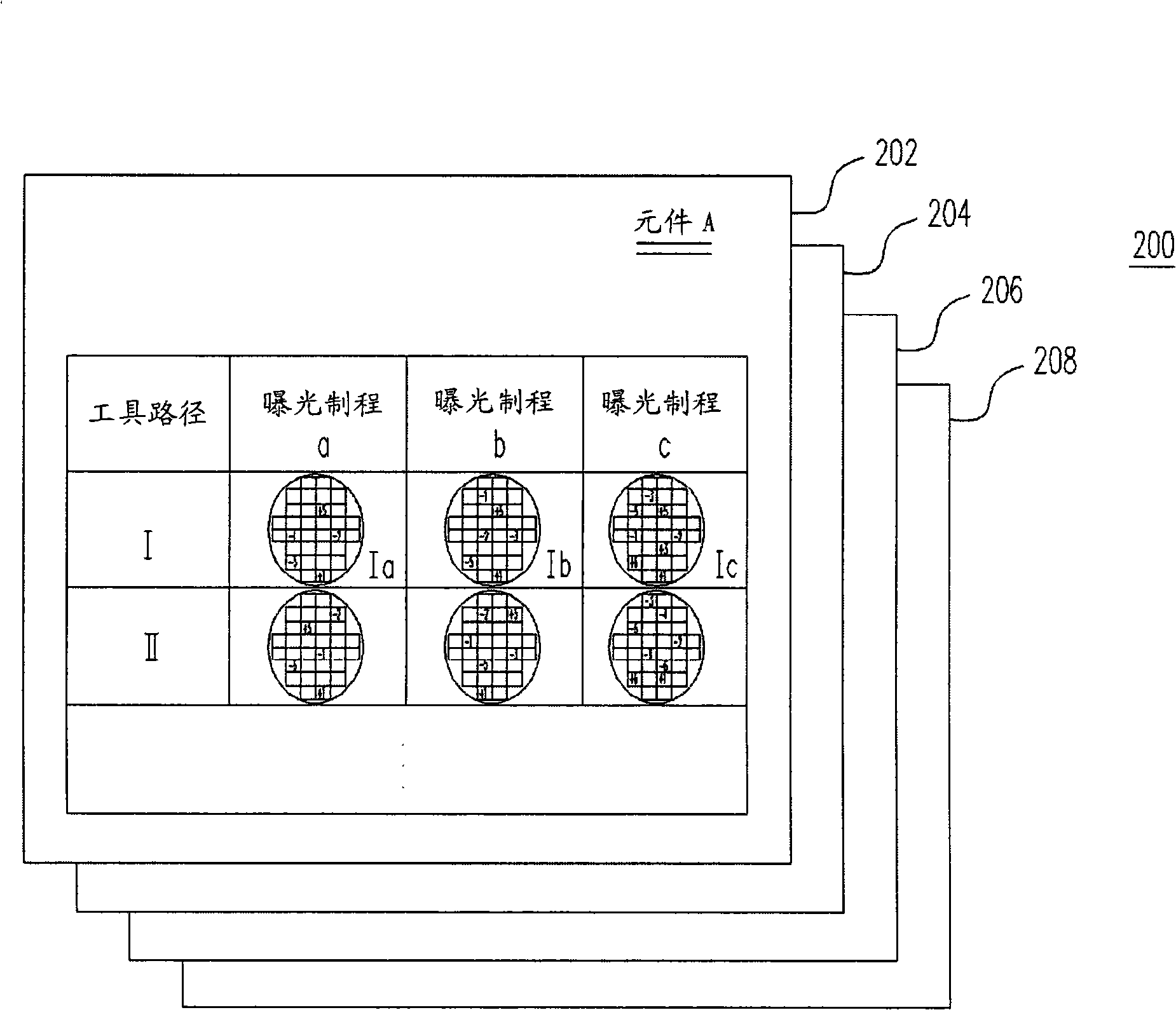

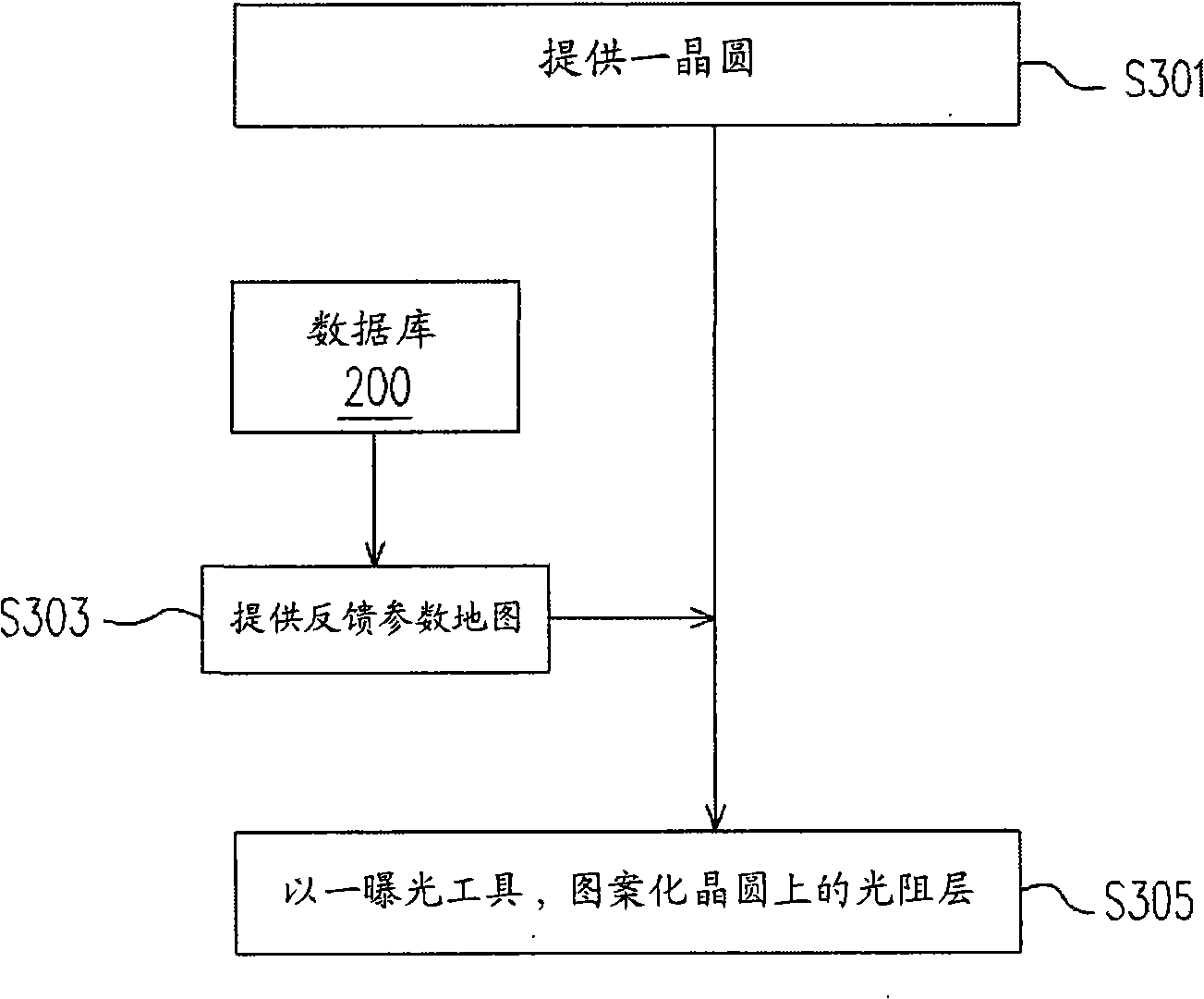

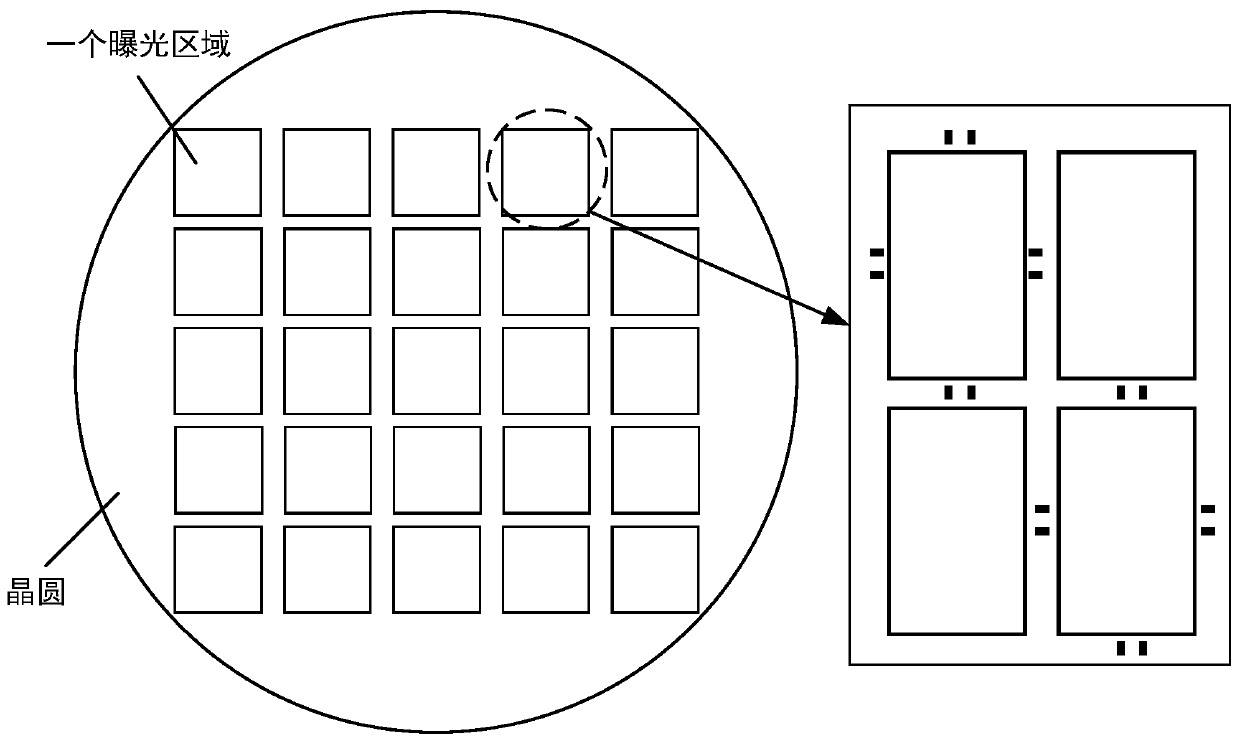

Exposure method

ActiveCN101493655AImprove consistencyImprove overlay accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringPhotoresist

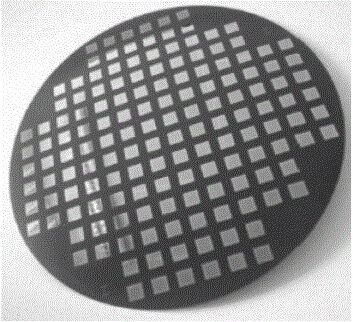

The invention provides an exposure method which is used for preparing an element, comprising the steps as follows: a wafer with a plurality of exposure areas is provided; wherein, the wafer is covered by an photoresist layer; a feedback parameter map with a plurality of exposure area feedback parameter groups is provided; the exposure area feedback parameter groups are respectively corresponding to the exposure areas of the wafer; at least one group of exposure area feedback parameter group out of the exposure area feedback parameter groups is different from other exposure area feedback parameter groups; according to the feedback parameter map, an exposure preparation is carried out sequentially on each exposure area of the wafer by an exposure tool so as to pattern the photoresist layer on the wafer; wherein, when the exposure tool carries out the exposure preparation on each exposure area, the exposure preparation parameter group of the exposure tool is adjusted at the exposure area feedback parameter group corresponding to each exposure area according to the feedback parameter map.

Owner:UNITED MICROELECTRONICS CORP

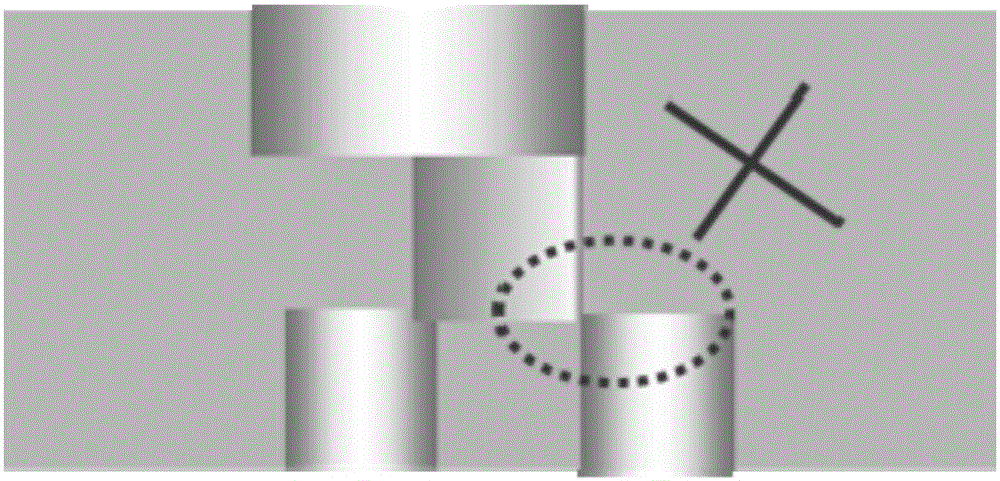

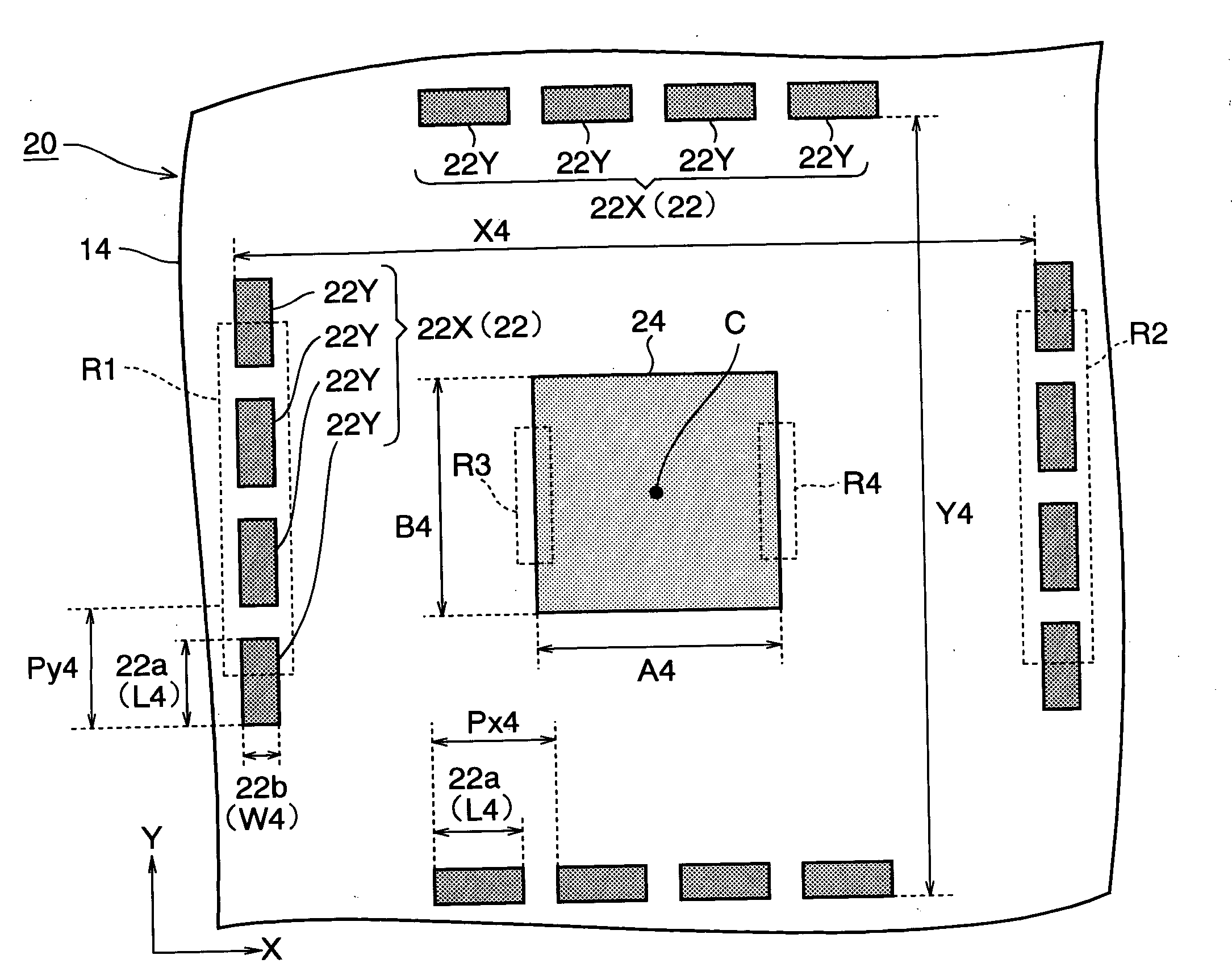

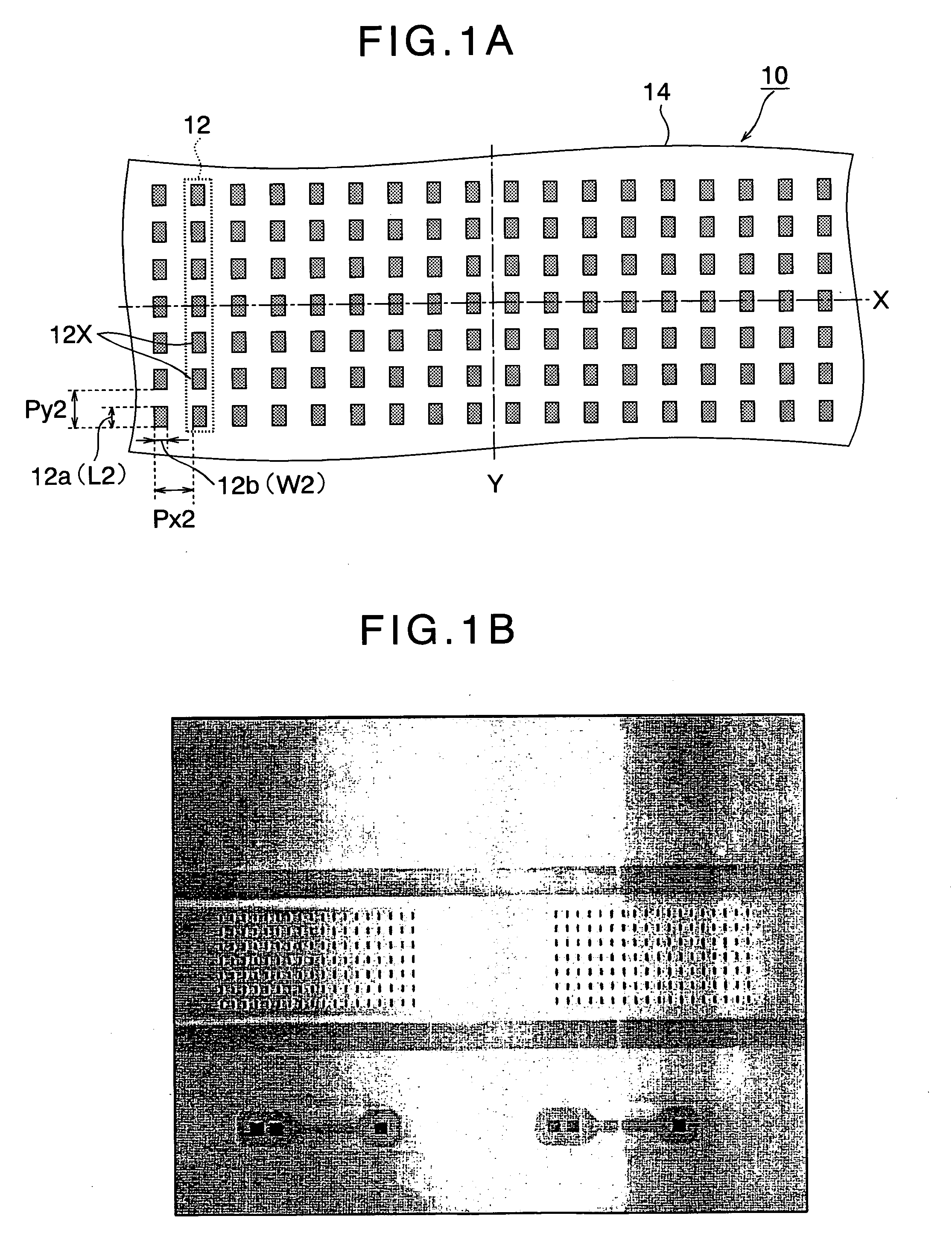

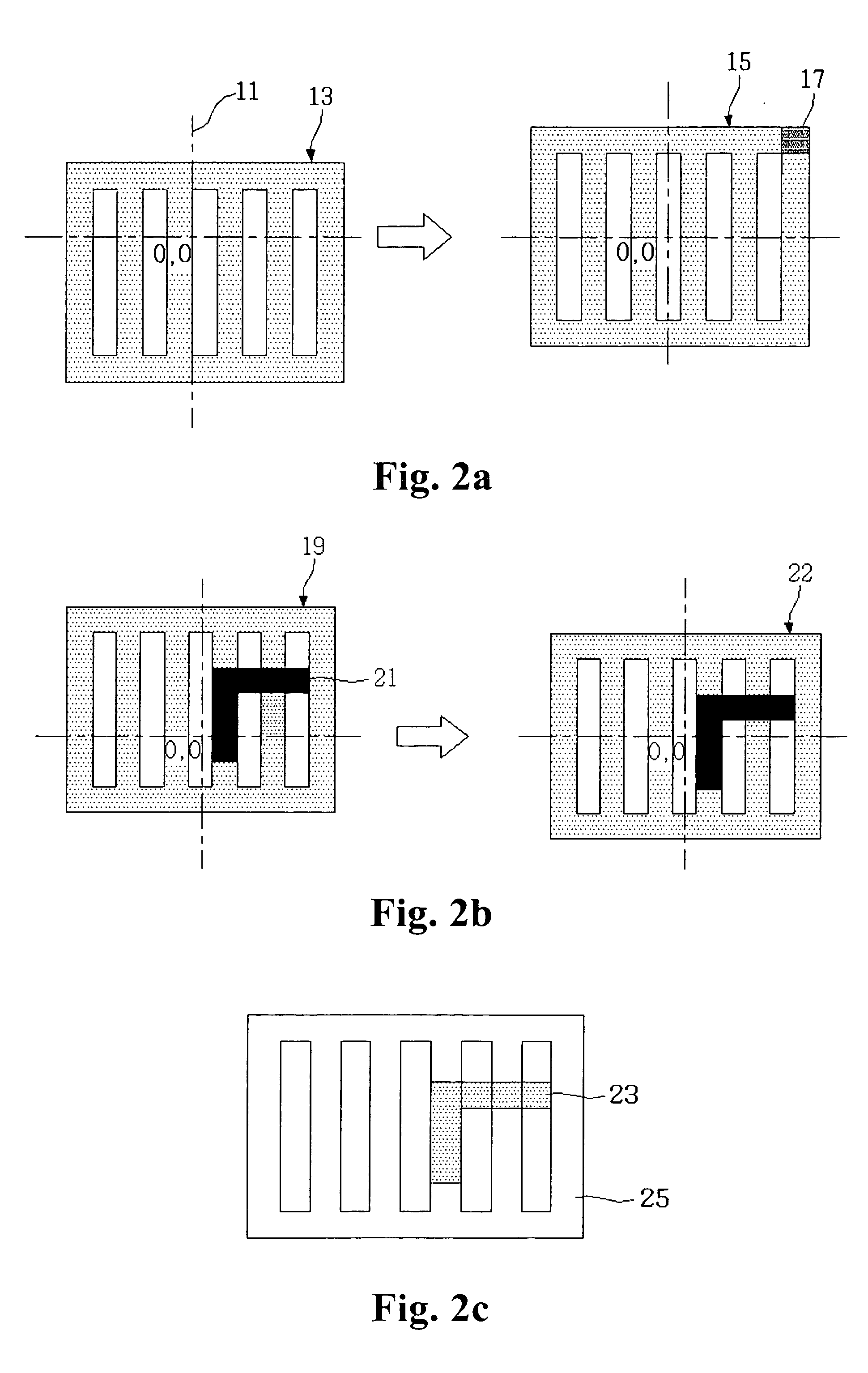

Alignment mark and overlay inspection mark

InactiveUS20070176305A1Avoid separationAvoid breakingSemiconductor/solid-state device detailsSolid-state devicesSemiconductorSemiconductor device

An alignment mark is formed on an underlying layer and disposed on a region in which a semiconductor device is not formed. The alignment mark includes a plurality of strip-shaped patterns detectable by an optical imaging device. The patterns have long axes and short axes. The patterns are arranged in a matrix of rows and columns in such a manner that the long axes are substantially perpendicular to the direction of the alignment adjustment.

Owner:LAPIS SEMICON CO LTD

Mask alignment device and photoetching device using same

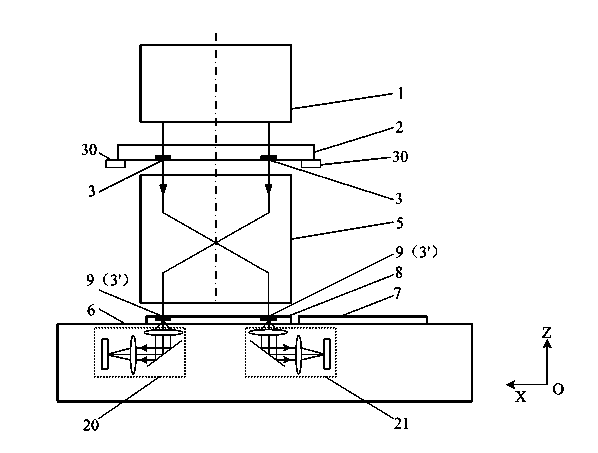

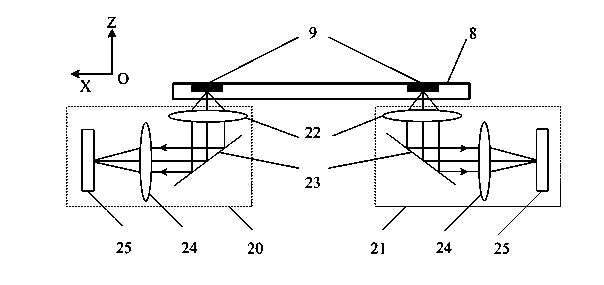

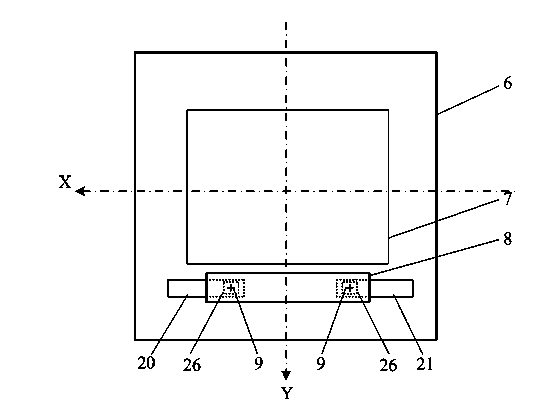

ActiveCN103383531AReduced working distance requirementsReduce structural complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusImage detectionLighting system

The invention discloses a mask alignment device and a photoetching device using same. The mask alignment device comprises 1, an illumination system for providing a light source to irradiate a first mark and a second mark, 2, a projection objective lens for imaging the first mark, 3, a first support device for supporting the first mark, wherein the first mark is located on a mask plate, 4, a second support device for supporting the second mark, wherein the second mark is located on a reference plate, and 5, an imaging detection system for detecting the deviation of a first mark imaging position and a second mark position. The mask alignment device is characterized in that the imaging detection system is fixed in the second support device; the second mark is located in a view field of the imaging detection system; and the projection objective lens and the imaging detection system use the illumination system in common.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

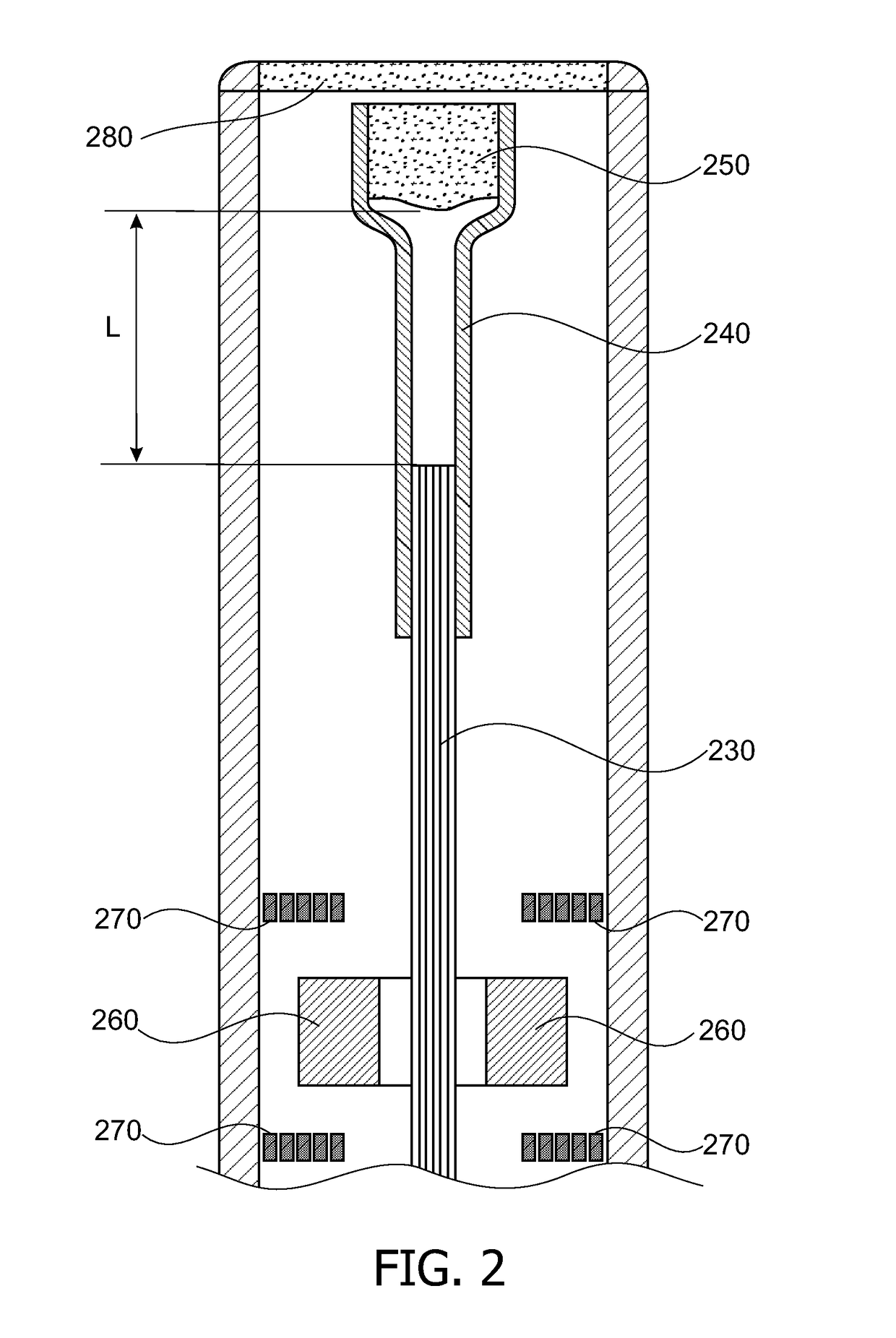

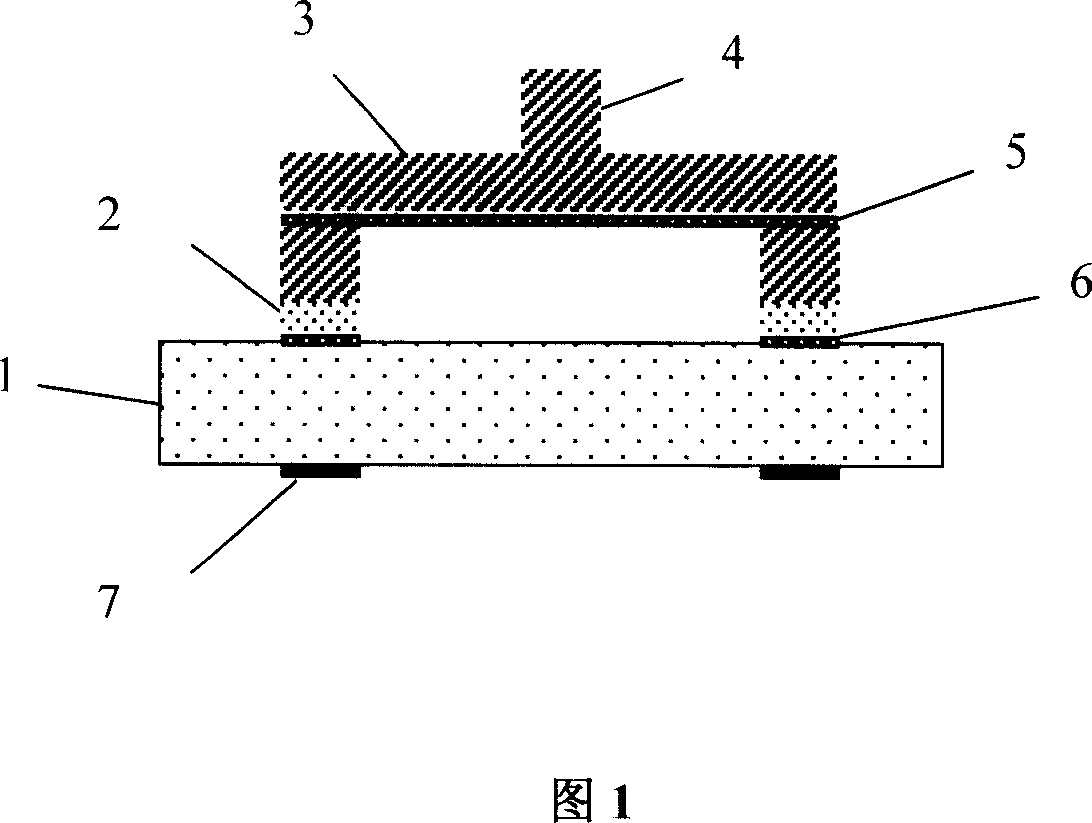

Simple-beam type microelectronic mechanical system detection card and producing method thereof

InactiveCN1936593AImprove adaptabilityControl shape and sizeSemiconductor/solid-state device testing/measurementElectronic circuit testingLithographic artistLIGA

This invention relates to a simple beam MEMS explore cards preparation methods, using UV-LIGA many lithography, preparation of flexible probe in the metal films with electroplating process, using the simple structure probe instead of the cantilever beam to bear the stress and greater oxide film holes, and regulate the probe displacement through the design of thickness of simple beams. Chip cards in accordance with the present invention, are obtained by the joint distribution and arrangement of the functions of the simple beam array, simply supported beam probe in the middle, and ensure the location of the needle position consistent with the corresponding pin chip. The bottom end of SR beam is the plating metal wire, which external from the bottom end around to the probe extension spot welding to connect to the corresponding printed circuit board, thus testing machine connected to the signal from the probe circuit. The invention process is simple, high productivity, control probe shape and size very well, high accuracy, suitable for mass production.

Owner:SHANGHAI JIAO TONG UNIV

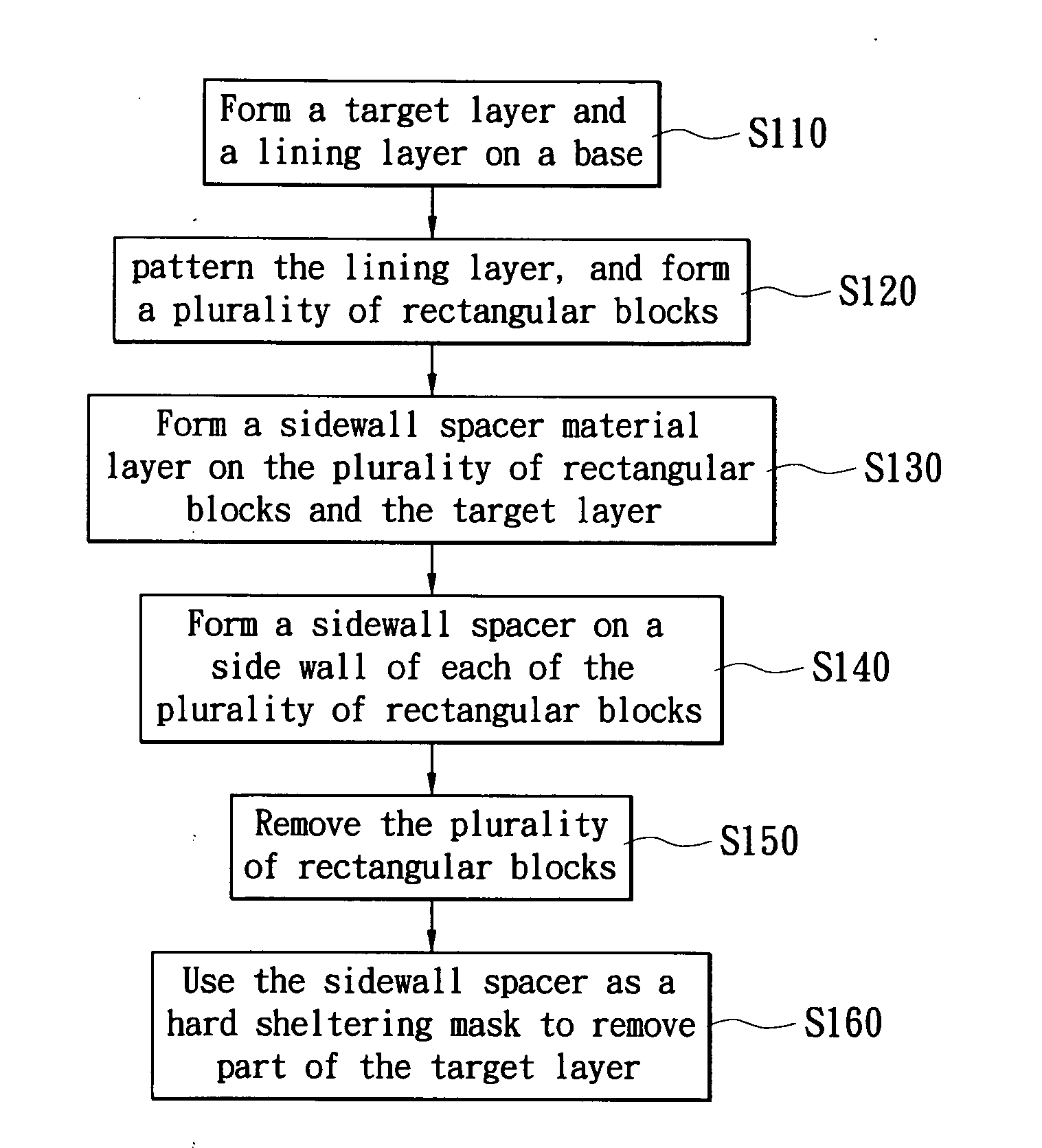

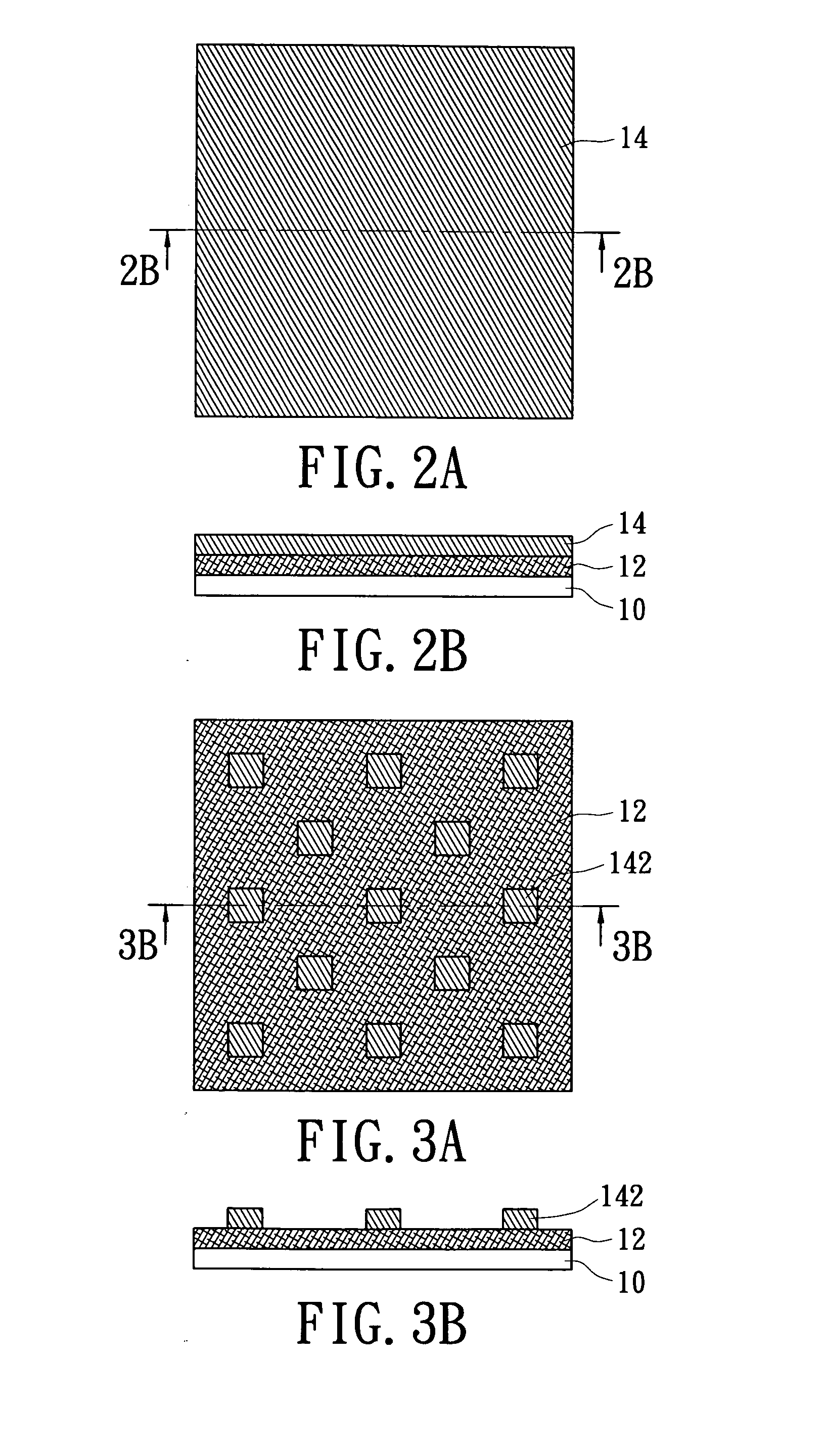

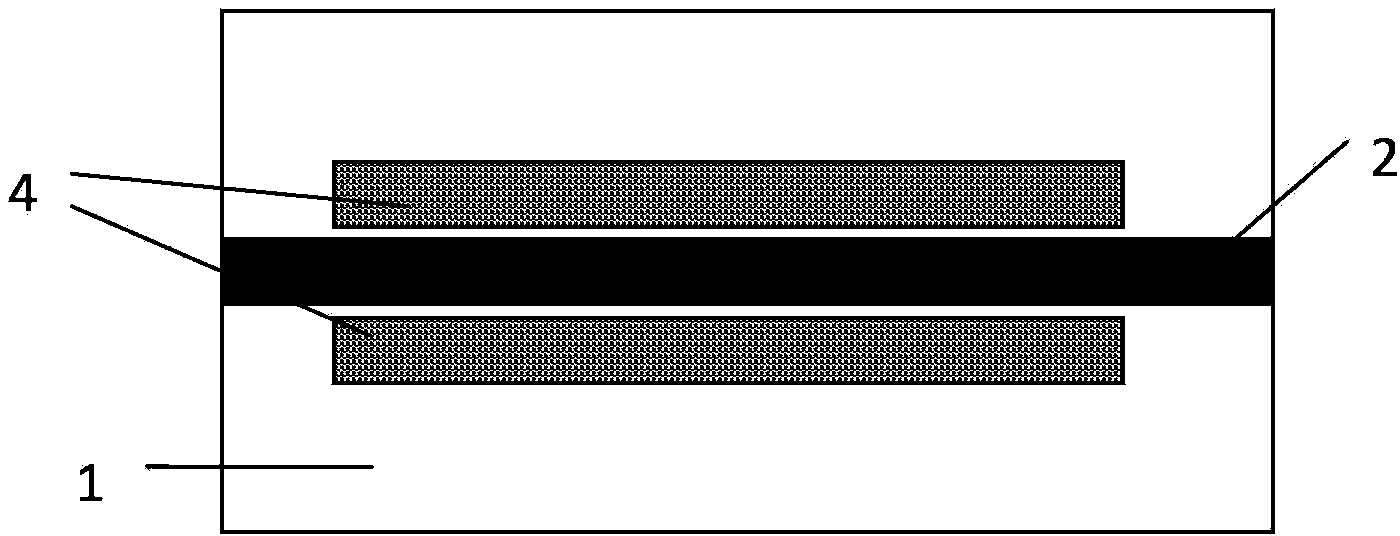

Patterning method in semiconductor manufacturing process

ActiveUS20090227108A1Improve overlay accuracySmall dimensionSemiconductor/solid-state device manufacturingEngineeringSemiconductor

A patterning method in a semiconductor manufacturing process includes the following steps. A base is provided. A target layer and a lining layer are sequentially formed on the surface of the base. The lining layer is patterned to form a plurality of rectangular blocks. A sidewall spacer material layer is formed on the rectangular blocks and the target layer. Part of the sidewall spacer material layer is removed to form a sidewall spacer on the side wall of each of the plurality of rectangular blocks. The plurality of rectangular blocks is removed, and the sidewall spacer is used as a hard sheltering mask to etch and remove part of the target layer. The overlay accuracy is improved and the dimension of the electronic elements can be reduced so that a lot of two-dimension structures can be manufactured on the wafer substrate.

Owner:NAN YA TECH

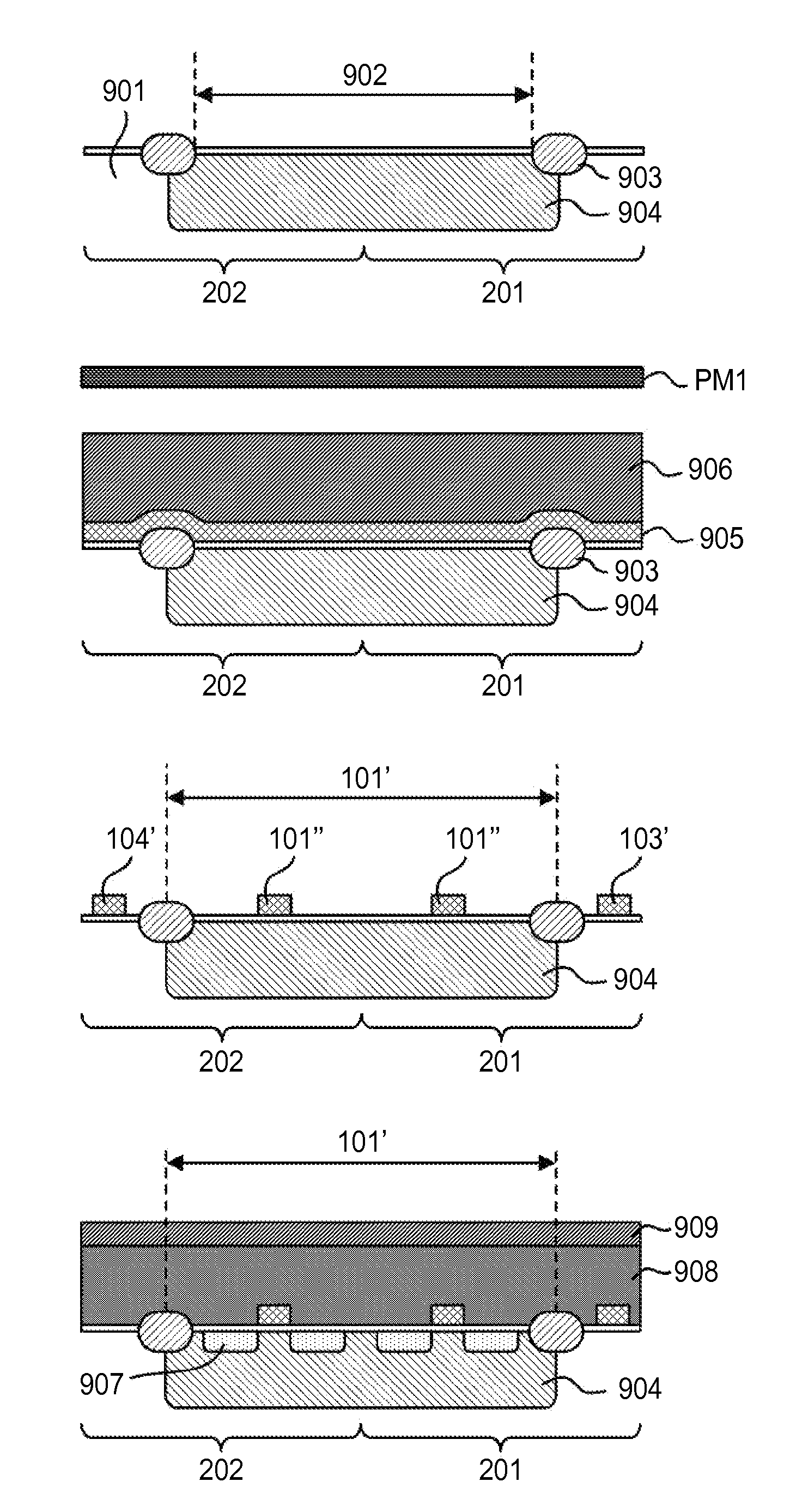

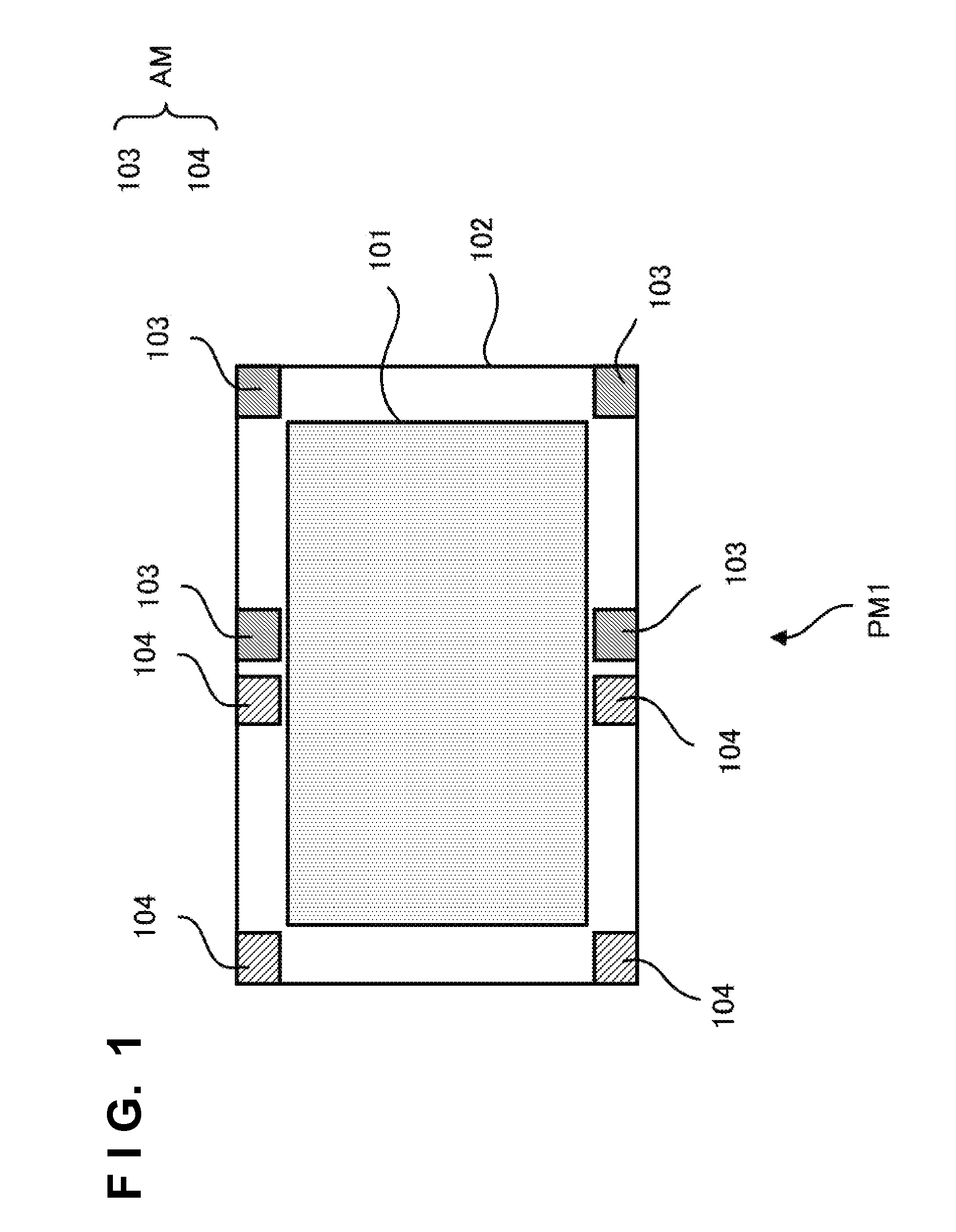

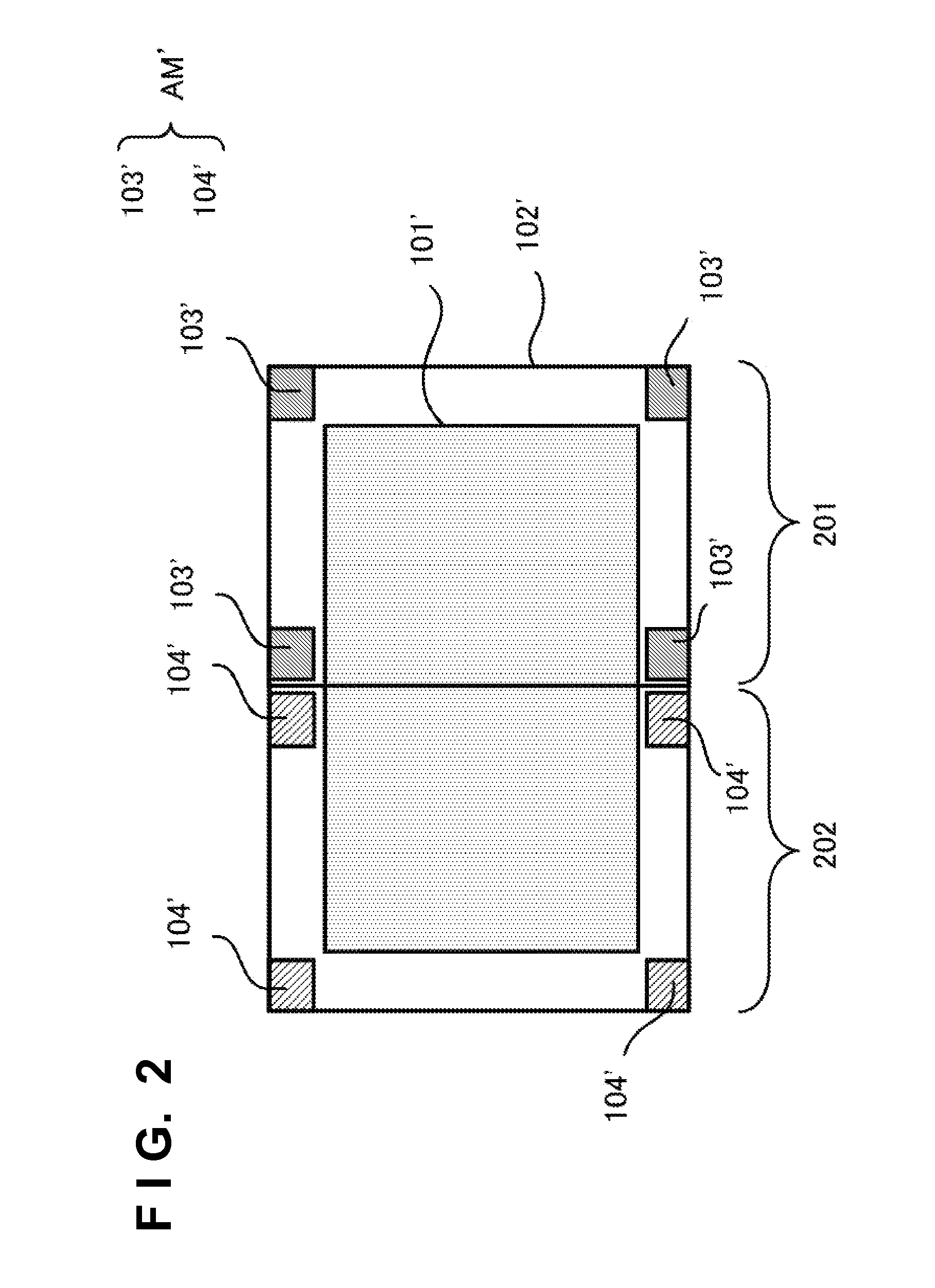

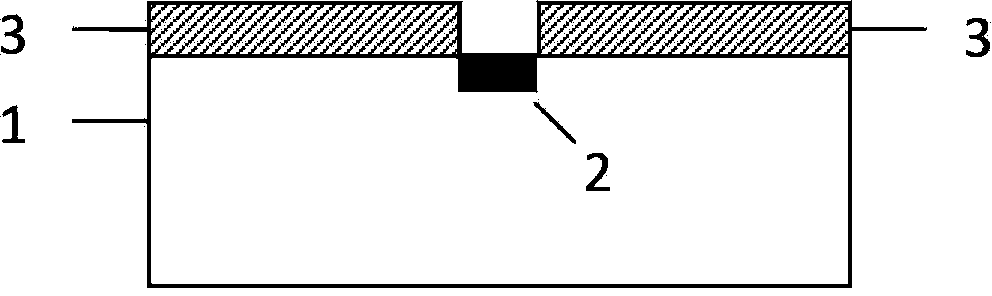

Semiconductor device and method for manufacturing the same

ActiveUS20130032956A1Improve overlay accuracyImprove accuracySemiconductor/solid-state device detailsSolid-state devicesOne shotPhotolithography

A method for manufacturing a semiconductor device includes a first photolithography step of forming a first device pattern corresponding to a first pattern, and a plurality of alignment marks corresponding to a plurality of marks, upon a step of exposing the entire device region in one shot using a first mask including the first pattern and the plurality of marks, and a second photolithography step of, after the first photolithography step, forming second device patterns respectively corresponding to second patterns in a plurality of divided regions which form the device region, upon steps of individually exposing the plurality of divided regions using second masks each including the second pattern corresponding thereto.

Owner:CANON KK

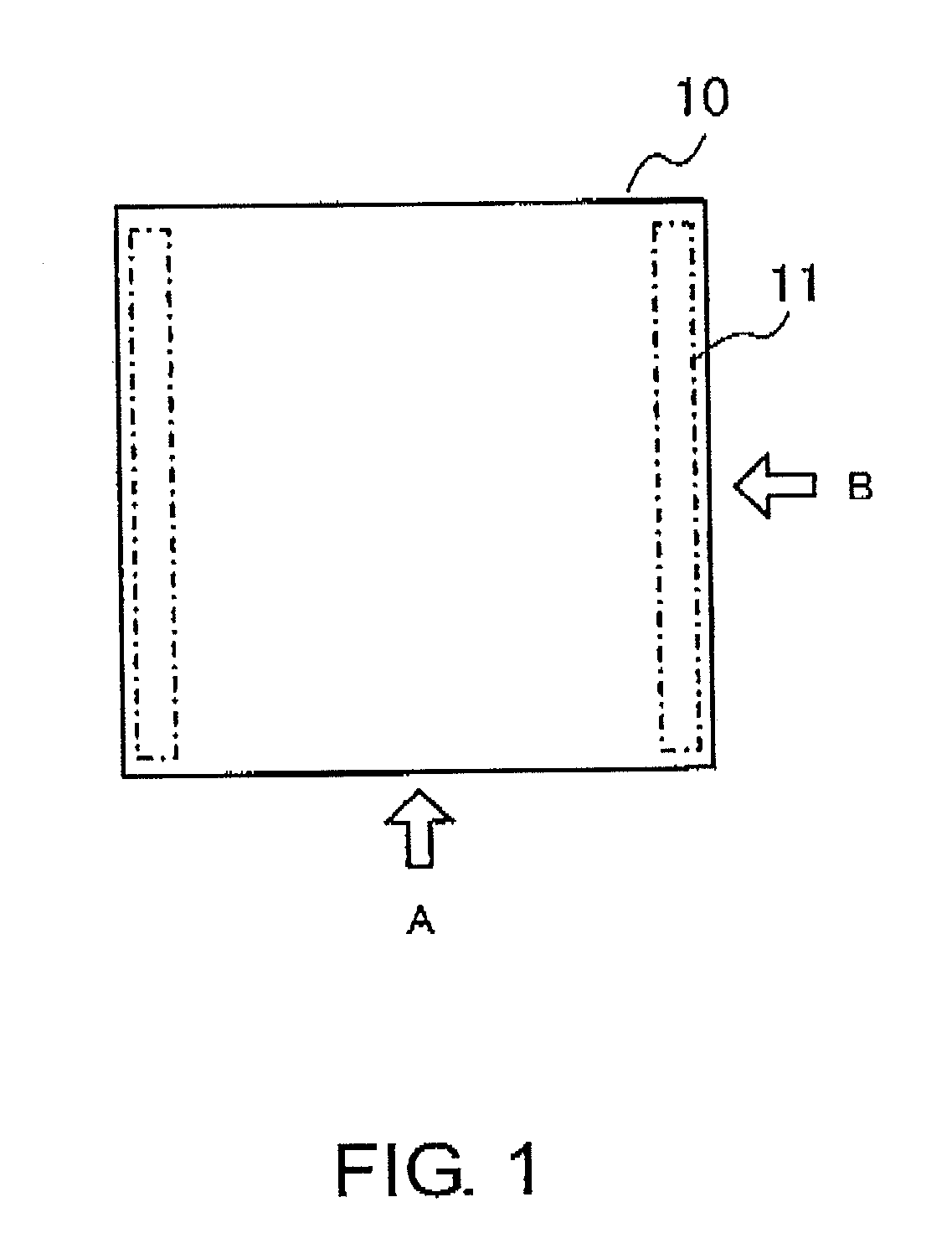

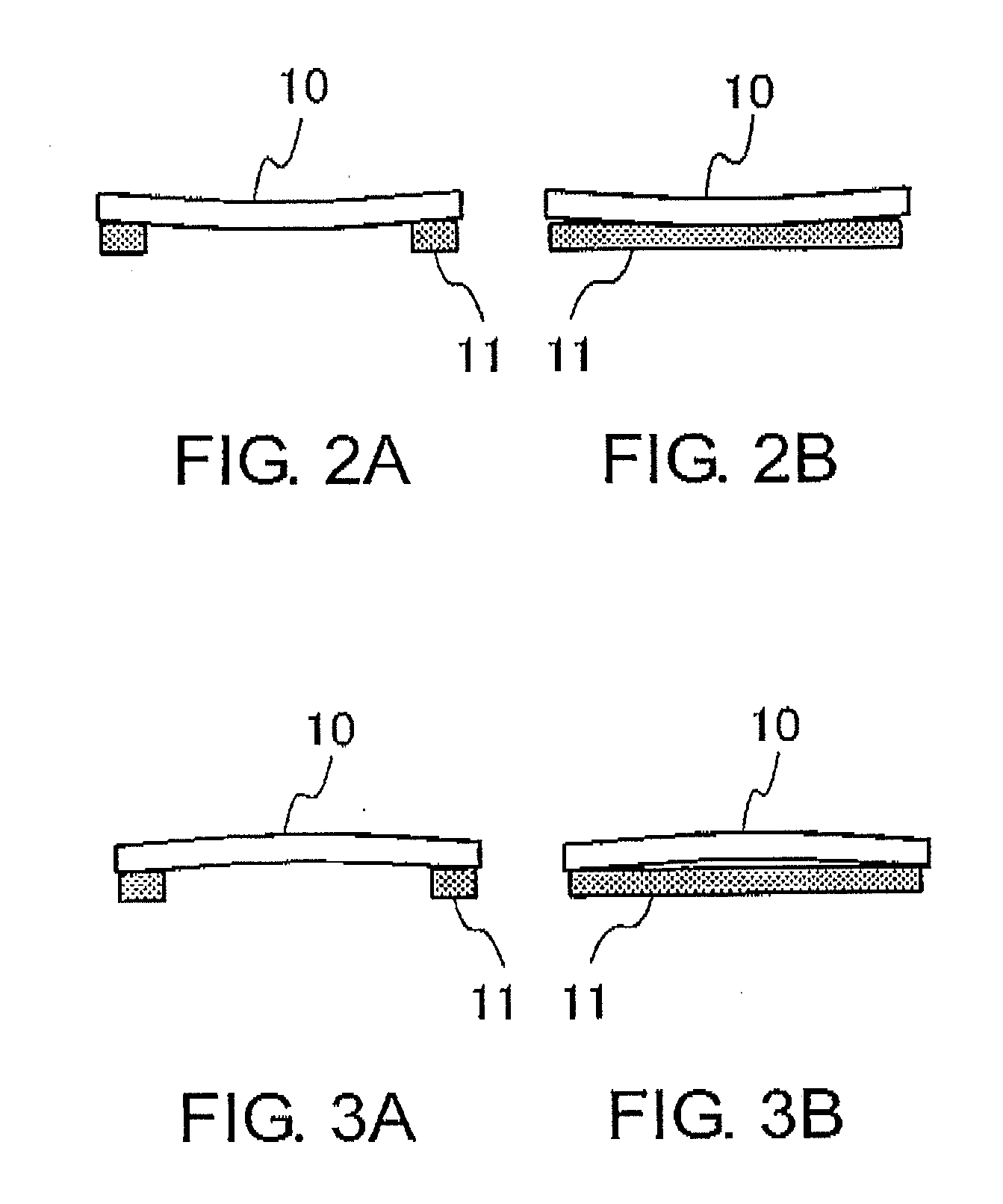

Mask blank substrate set and mask blank set

ActiveUS20100081067A1Improve overlay accuracyImprove accuracyVacuum evaporation coatingSemiconductor/solid-state device manufacturingEngineeringPellicle membrane

A substrate set is a mask blank substrate set including a plurality of substrates each for use in a mask blank for producing a photomask to be chucked on a mask stage of an exposure apparatus. In each of the substrates in the mask blank substrate set, a main surface, on the side where a thin film for forming a transfer pattern is to be formed, has a convex shape being relatively high at its center and relatively low at its peripheral portion. In each substrate, the flatness in a 142 mm square area, including a central portion, of the main surface is 0.3 μm or less and the difference upon fitting to a reference main surface of a reference substrate is 40 nm or less.

Owner:HOYA CORP

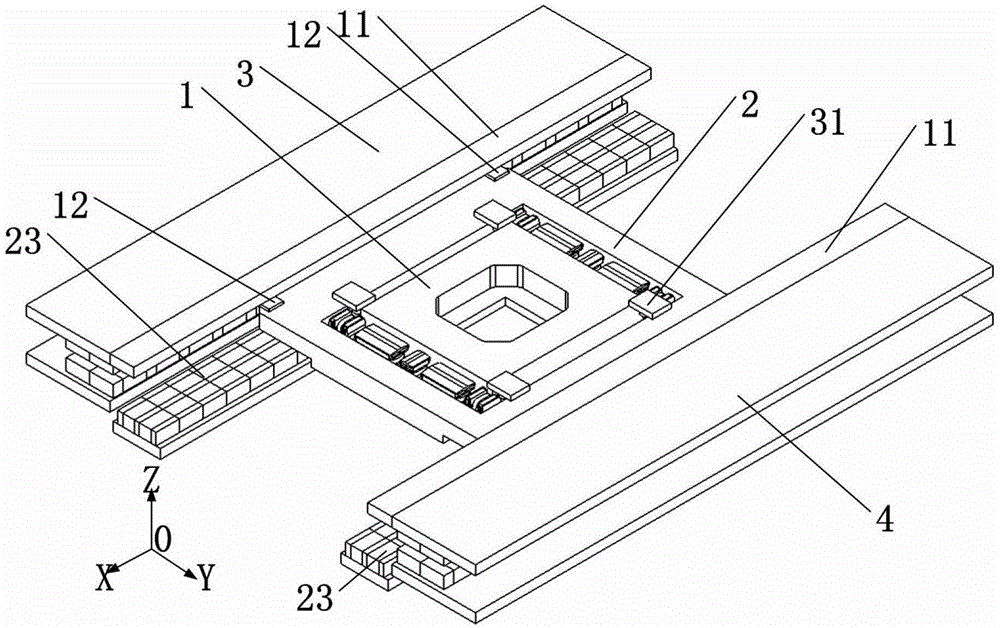

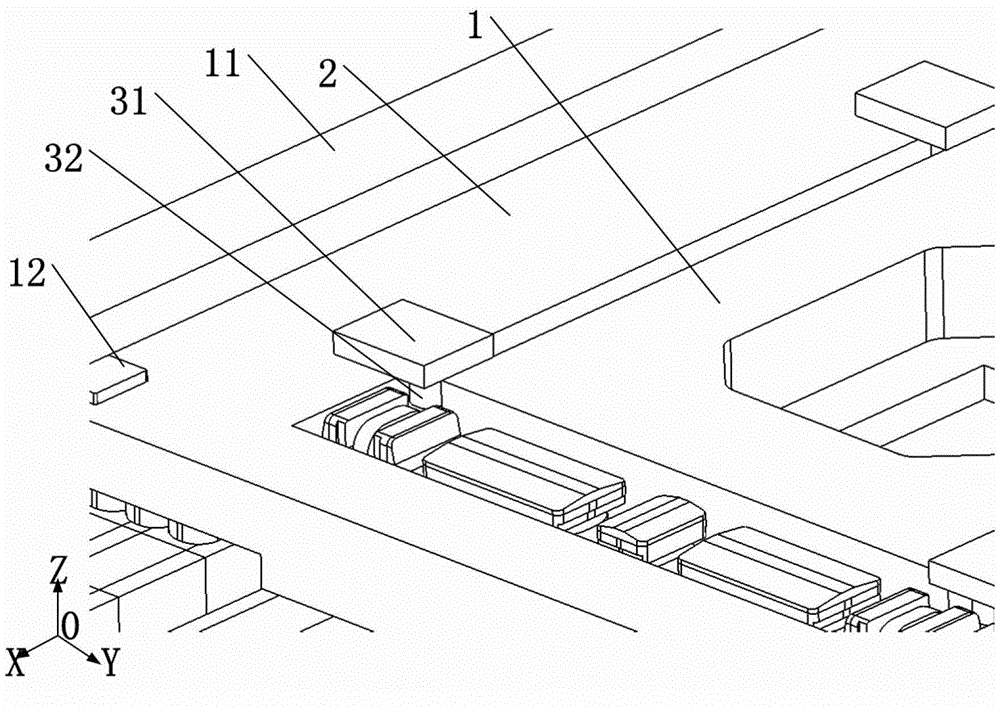

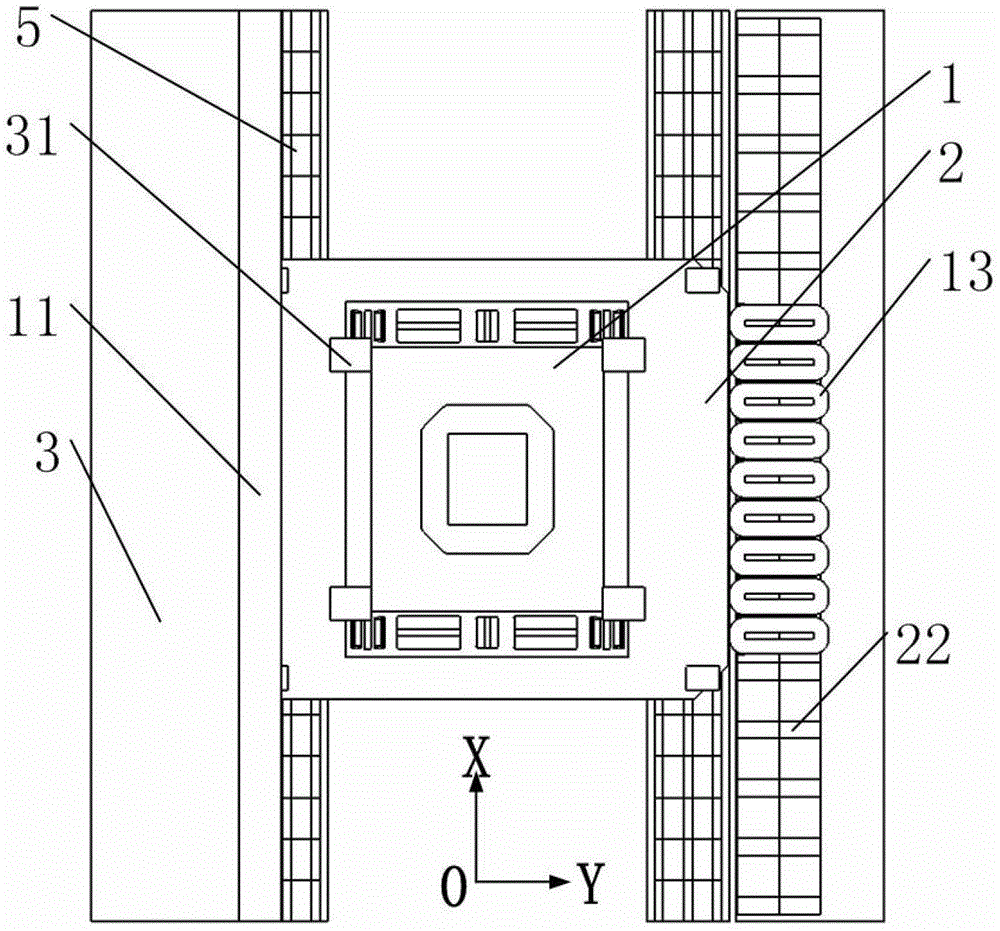

Mask platform system with six-degree-of-freedom coarse drive platform

ActiveCN103186058ASimple system structureAvoid vibration and noisePhotomechanical exposure apparatusMicrolithography exposure apparatusProduction rateSix degrees of freedom

A mask platform system with a six-degree-of-freedom coarse drive platform is mainly used in a photoetching system. The system comprises the coarse drive platform, a fine drive platform and a rack, wherein the coarse drive platform comprises a coarse drive platform body, a drive device and a coarse drive platform gravity balance component, the coarse drive platform body is arranged at the outer part of the fine drive platform to surround the fine drive platform in the middle, and the drive device comprises two groups of X-direction linear motors distributed symmetrically around the direction of an X-axis and four groups of two-degree-of-freedom linear motors driving a Y-direction and a Z-direction to achieve the six-degree-of-freedom motion of the coarse drive platform. The six-degree-of-freedom coarse drive platform and the six-degree-of-freedom fine drive platform are matched, so that the speed, acceleration and control bandwidth of a mask platform are increased and the requirements of high motion precision and location precision are met while the posture of the mask platform is regulated, and furthermore, the production rate, the alignment precision and the resolution ratio of a photoetching machine are improved.

Owner:TSINGHUA UNIV +1

Exposure method, exposure apparatus, and method of manufacturing device

InactiveUS20090231569A1Improve overlay accuracyIncrease costPhotomechanical apparatusPhotographic printingPhysicsPosition detector

The first evaluation value is obtained by evaluating an electrical signal containing the position information of a mark in accordance with an evaluation criterion. The first overlay error generated by the exposure apparatus is estimated based on the first evaluation value, the second evaluation value obtained by evaluating an electrical signal in a position detector of the another exposure apparatus in accordance with the evaluation criterion, and the second overlay error generated by another exposure apparatus. The exposure apparatus exposes a substrate while positioning it so as to reduce an overlay error generated by the exposure apparatus to an error smaller than the first overlay error based on the basis of an output from the position detector of the exposure apparatus, which detects the position of the mark, and the estimated first overlay error.

Owner:CANON KK

Manufacturing method for electrode of lithium niobate optical waveguide device

ActiveCN103353630AGuaranteed not to overlapImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusSputteringMetal strips

Disclosed in the invention is a manufacturing method for an electrode of a lithium niobate optical waveguide device. The manufacturing method comprises the following steps: using SiO2 as a mask and manufacturing an optical waveguide by using annealing proton exchange processing; utilizing the SiO2 mask as a mark to directly carry out self-alignment overlaying on the optical waveguide and an electrode graph; removing the SiO2 mask of the electrode zone by employing a method of combination of dry etching with wet etching; and utilizing sputtering and metal stripping technologies to manufacture the electrode graph and removing the residual SiO2 mask. When the method is used, the electrode graph can be formed at the lithium niobate optical waveguide and accurate overlaying between the optical waveguide and the electrode is ensured; the edge of the electrode is smooth; the defects are less; and the yield is high.

Owner:GUANGXUN SCI & TECH WUHAN

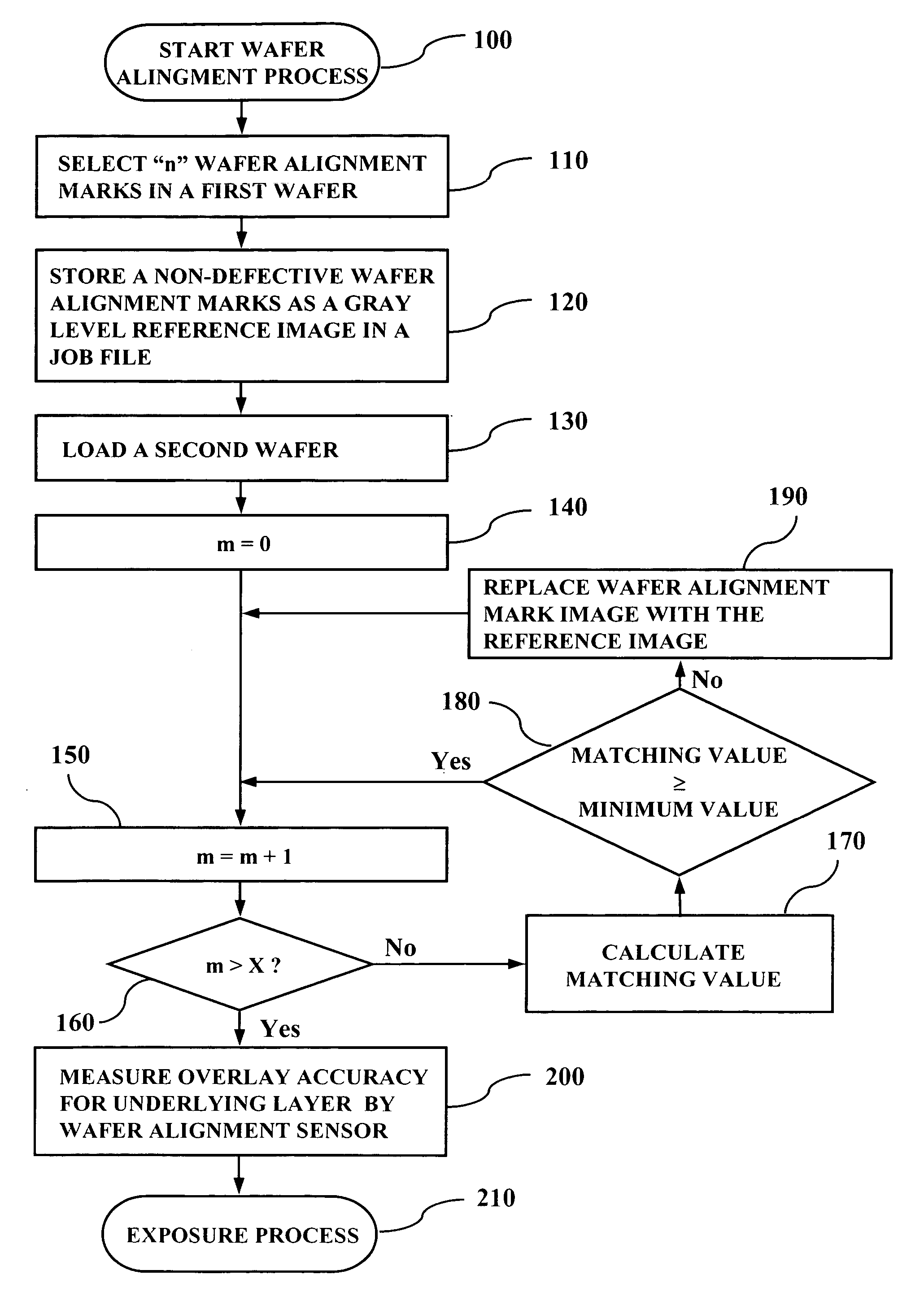

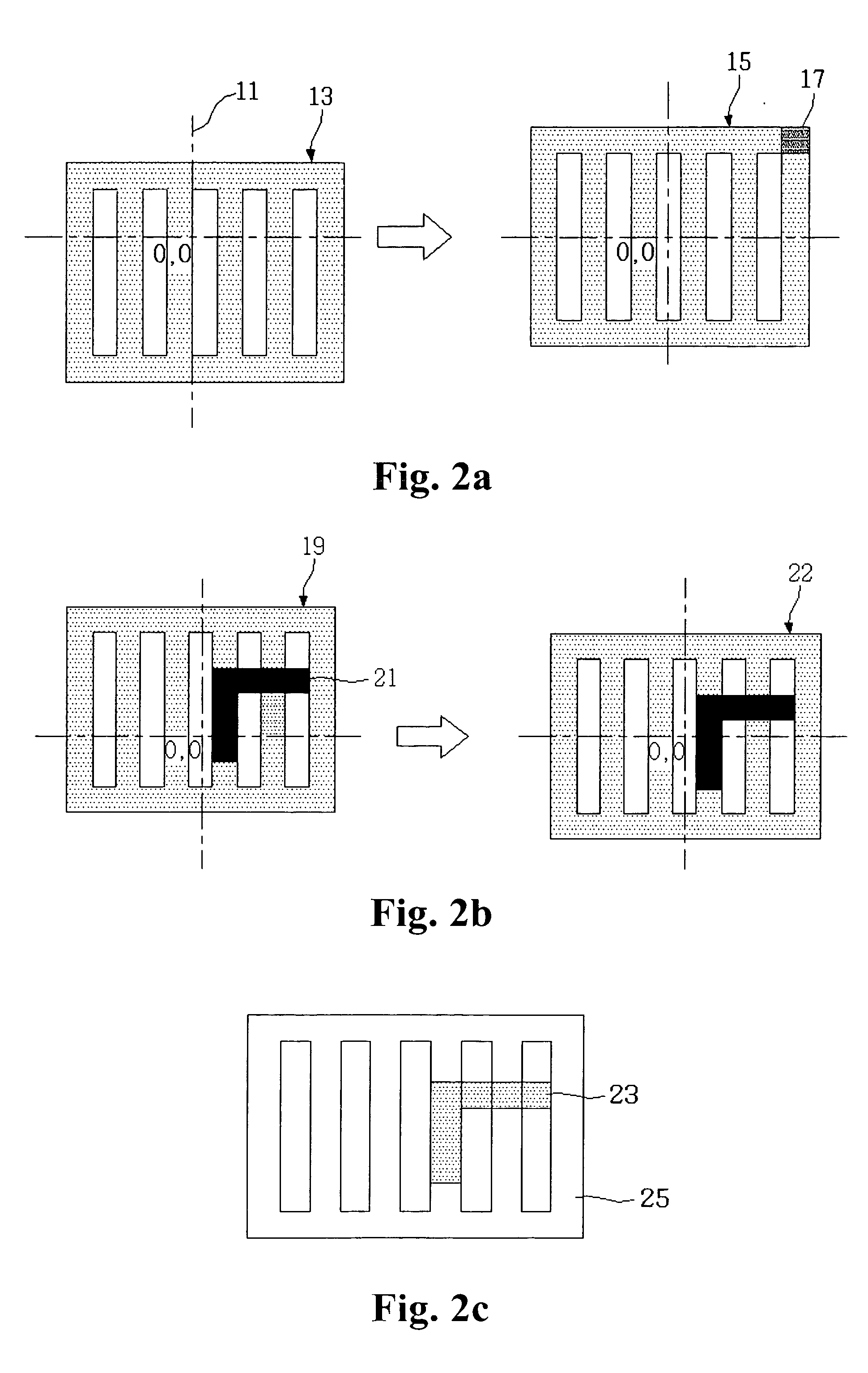

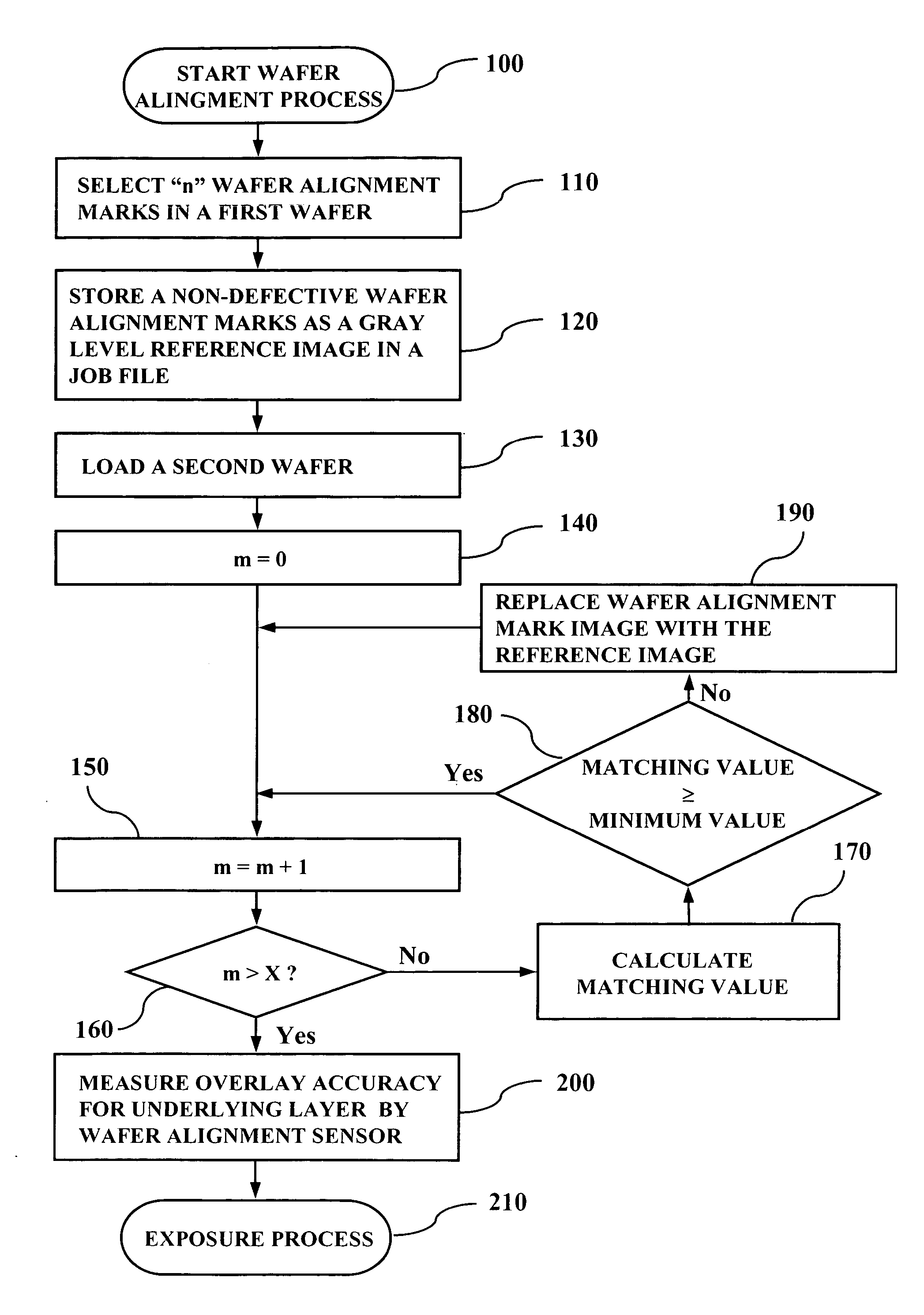

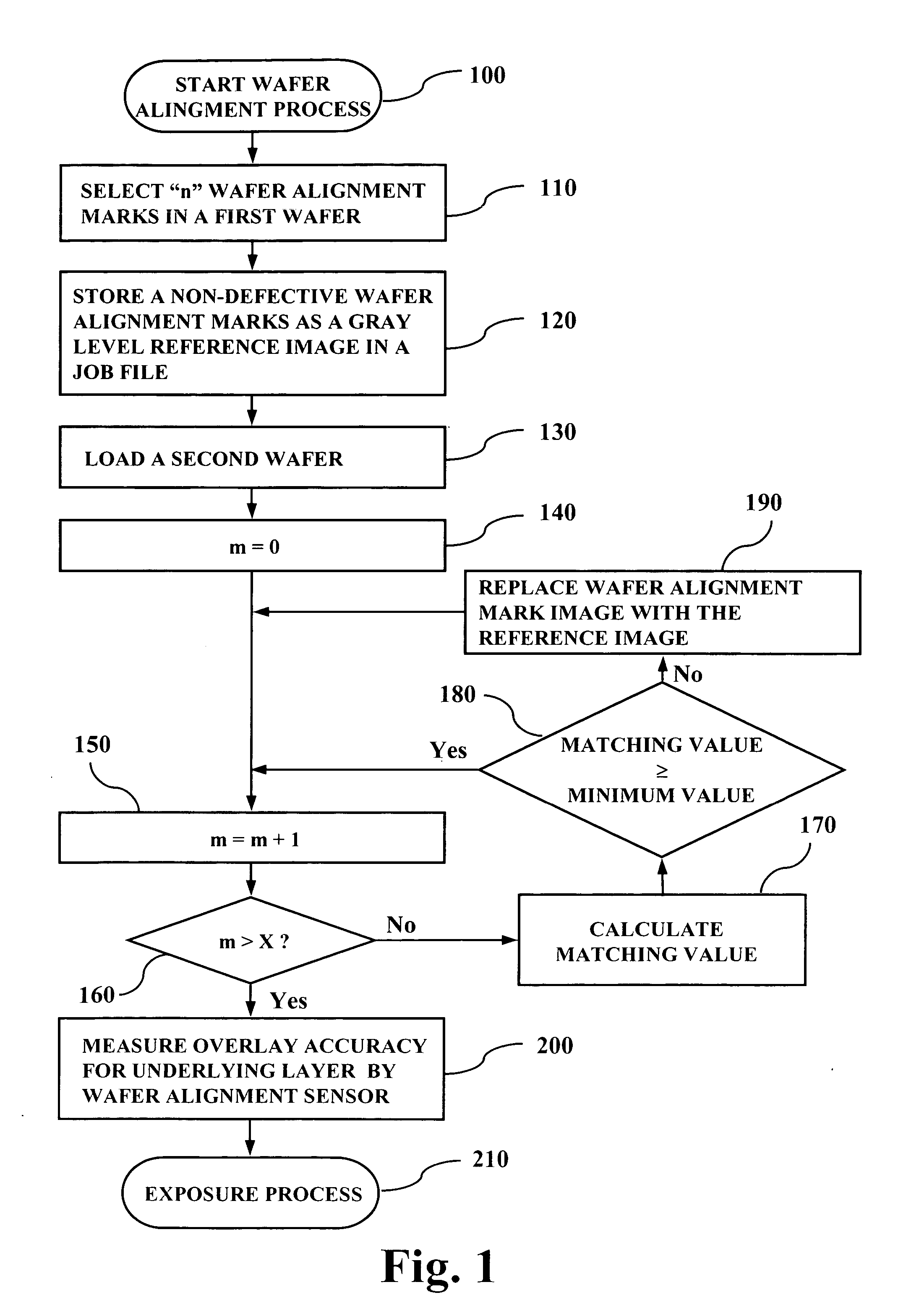

Method for aligning wafer

InactiveUS7123362B2Improve overlay accuracyCoupling device detailsSemiconductor/solid-state device manufacturingGray levelReference image

A method for aligning wafer includes selecting a nun-defective wafer alignment mark of a first wafer loaded in an exposure apparatus, and storing non-defective wafer alignment marks as a gray level reference image. A plurality of wafer alignment marks of a loaded second wafer are stored. Each of the plurality of wafer alignment mark images of the second wafer are respectively compared with the reference image of the first wafer pixel by pixel to obtain matching value for each of the plurality of the wafer alignment mark images. Each of the plurality of values of the matching values are compared with a set minimum value. The wafer alignment mark image having the matching value smaller than the minimum value with the reference image is replaced. The alignment information for an underlying layer using a wafer alignment information for an underlying layer using a wafer alignment sensor is obtained.

Owner:SK HYNIX INC +1

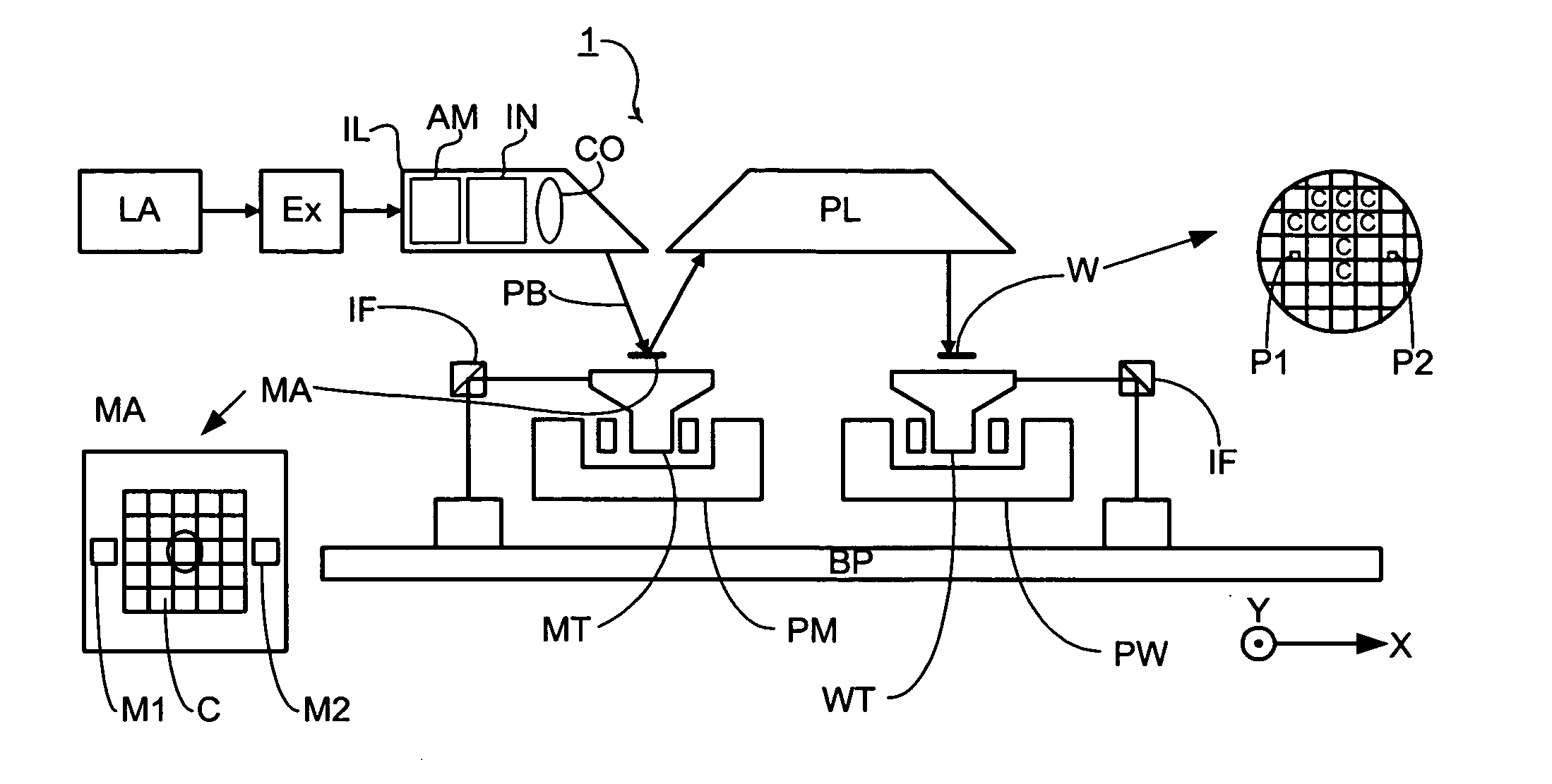

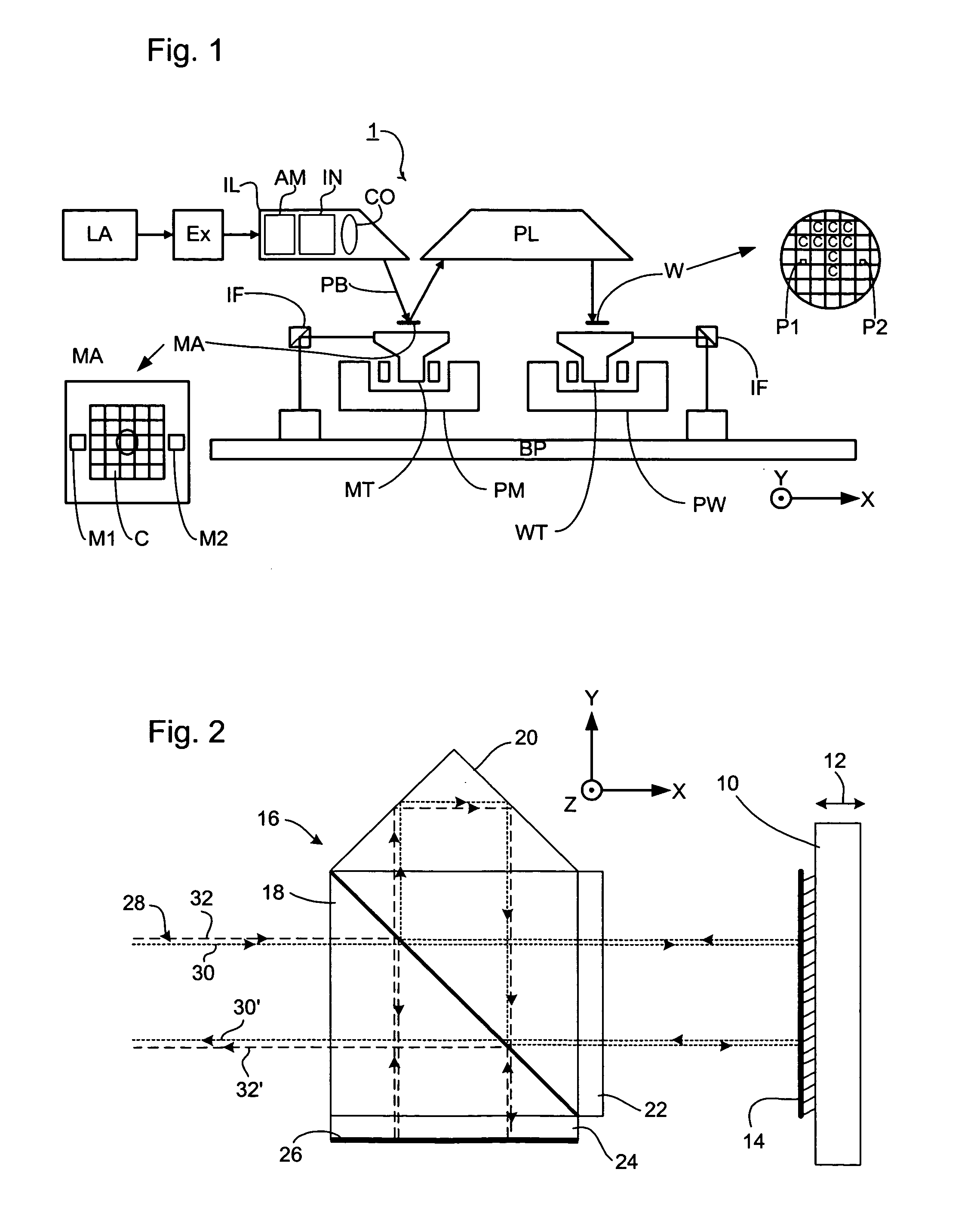

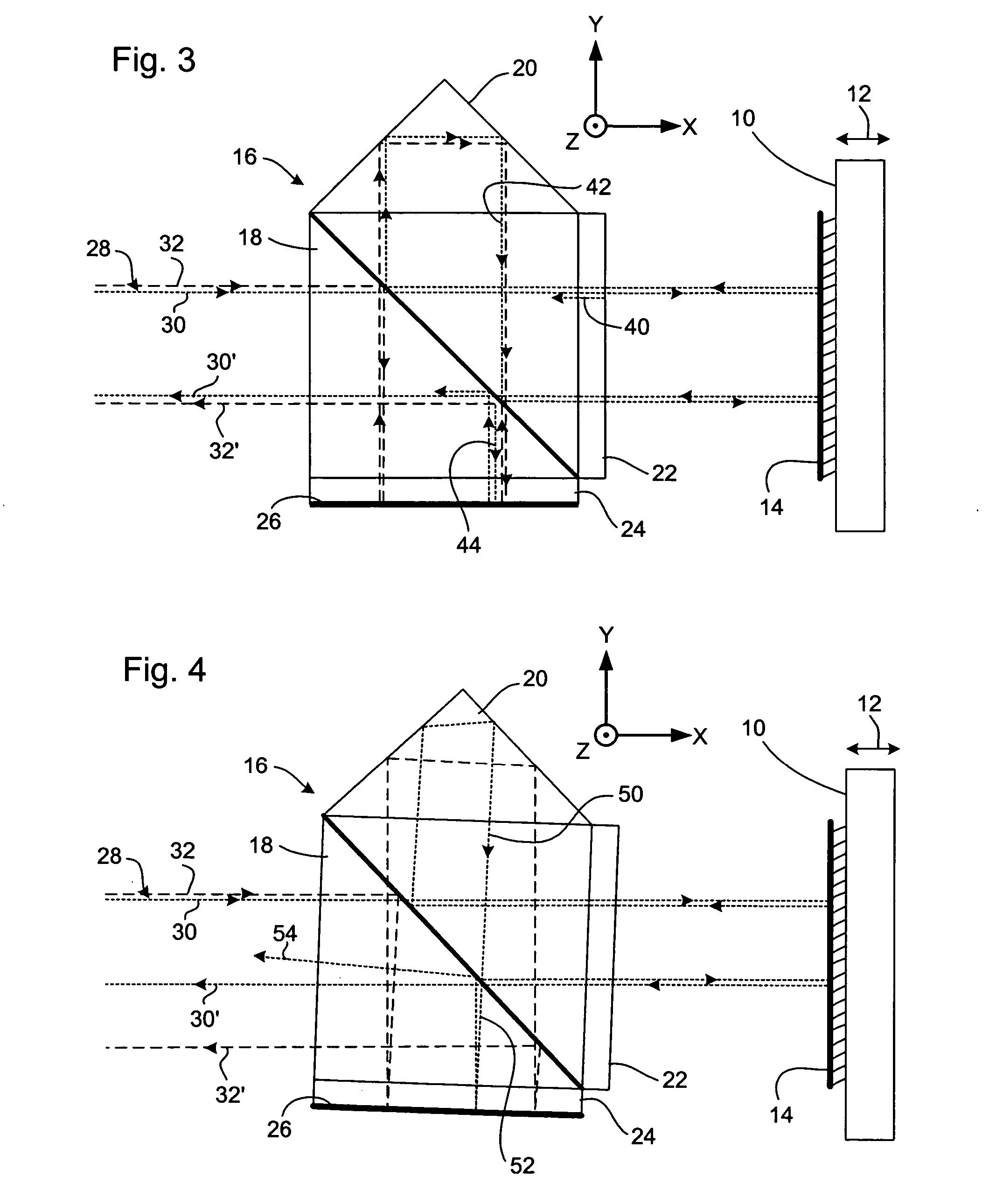

Lithographic apparatus and device manufacturing method

InactiveUS20050110971A1Good effectImprove positioning reliabilitySemiconductor/solid-state device manufacturingUsing optical meansBeam splitterRadiation

Embodiments of the invention include an interferometer measurement system in which at least one reflective surface is arranged such that, in use, the beam path of interferometer radiation of the interferometer measurement system incident on the at least one reflective surface has an offset angle in the range of from 0.1 to 10 milliradians with respect to the normal to the at least one reflective surface. In that way, the effect of spurious radiation on the interferometer measurement system produced within the interferometer measurement system may be suppressed. In another embodiment, a parallel-sided plate is used in an interferometer measurement system to obtain a signal dependent on the angle of a beam of radiation reflected from a mirror. In that way, the flatness of the mirror can be mapped. One surface of the plate is a beam-splitter and the opposite surface of the plate is a reflector.

Owner:ASML NETHERLANDS BV

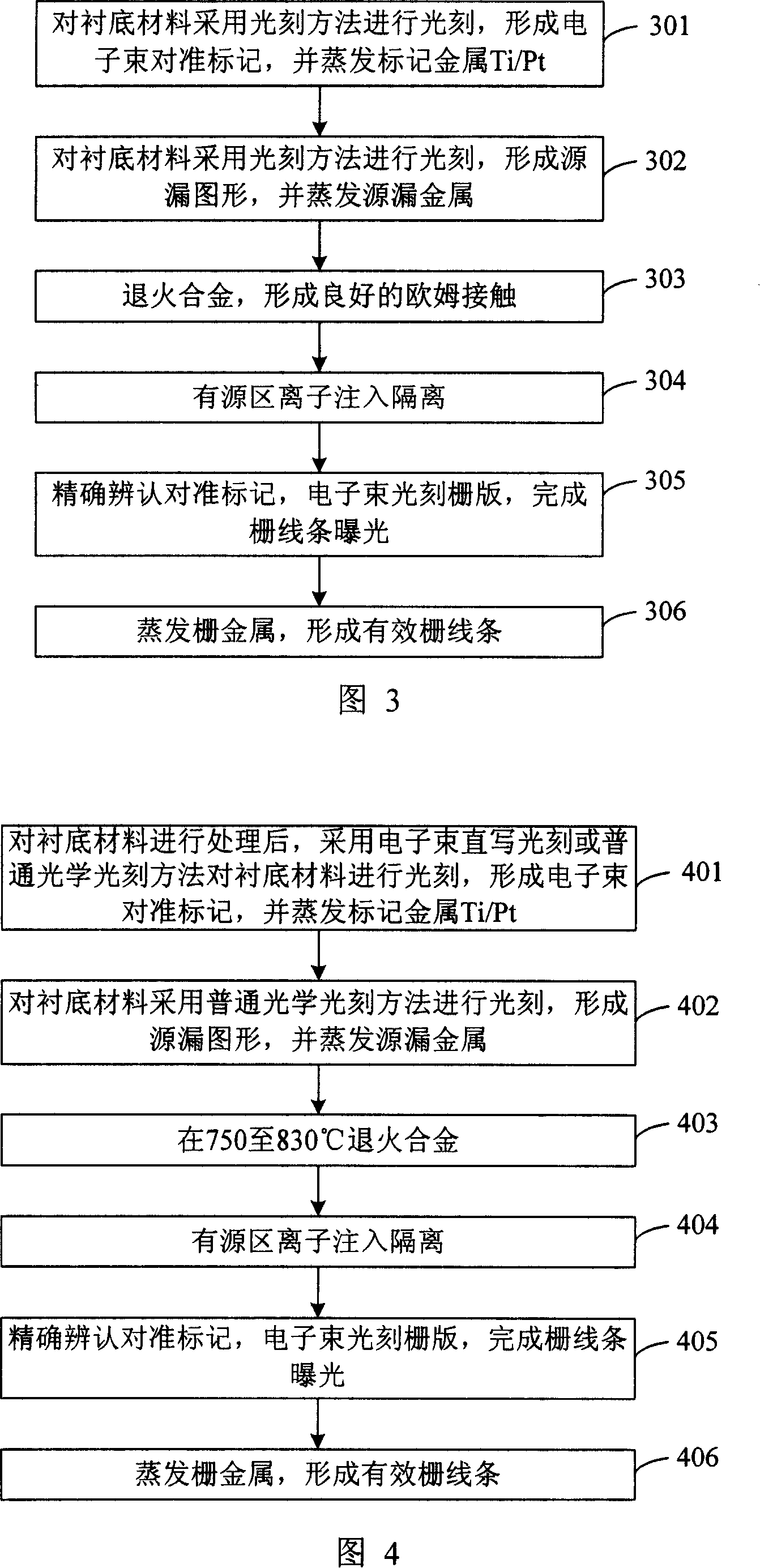

Electron beam alignment mark manufacture method and its uses

InactiveCN101149563AGood lookingResolved an issue where alignment marks could not be read accuratelyElectric discharge tubesSemiconductor/solid-state device manufacturingChiselNitrogen

This invention discloses a sort of manufacturing method of the electron beam alignment mark, and it adopts the Ti / Pt metal configuration to be the metal configuration of the alignment mark. It adopts the photo-etching method to process the photo-etching to this underlay material, it forms the electron beam alignment mark in the aluminium-gallium-nitrogen extension layer of the furthest top course of the underlay material. This invention discloses a sort of manufacturing method of the effective bar line by the electron beam alignment mark. A. Adopt the photo-etching method to process the photo-etching to this underlay material, and form the electron beam alignment mark, at last vaporize the marker metal Ti / Pt. B. Adopt the photo-etching method to process the photo-etching to this underlay material, and from the source-drain figure, at last vaporize the source-drain metal. C. Put out a fire to the alloy, and form the good ohm contact. D. Insulate the ion which is in the active area. E. chisel it by the electron beam, achieve the exposal of the bar line. F. Vaporize the bar metal, and form the effective bar line. It availably resolves the problem that the color of the alignment mark metal is changed after the high temperature anneal and it leads that the electron beam exposal device cannot differentiate the alignment mark well and truly by this invention.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

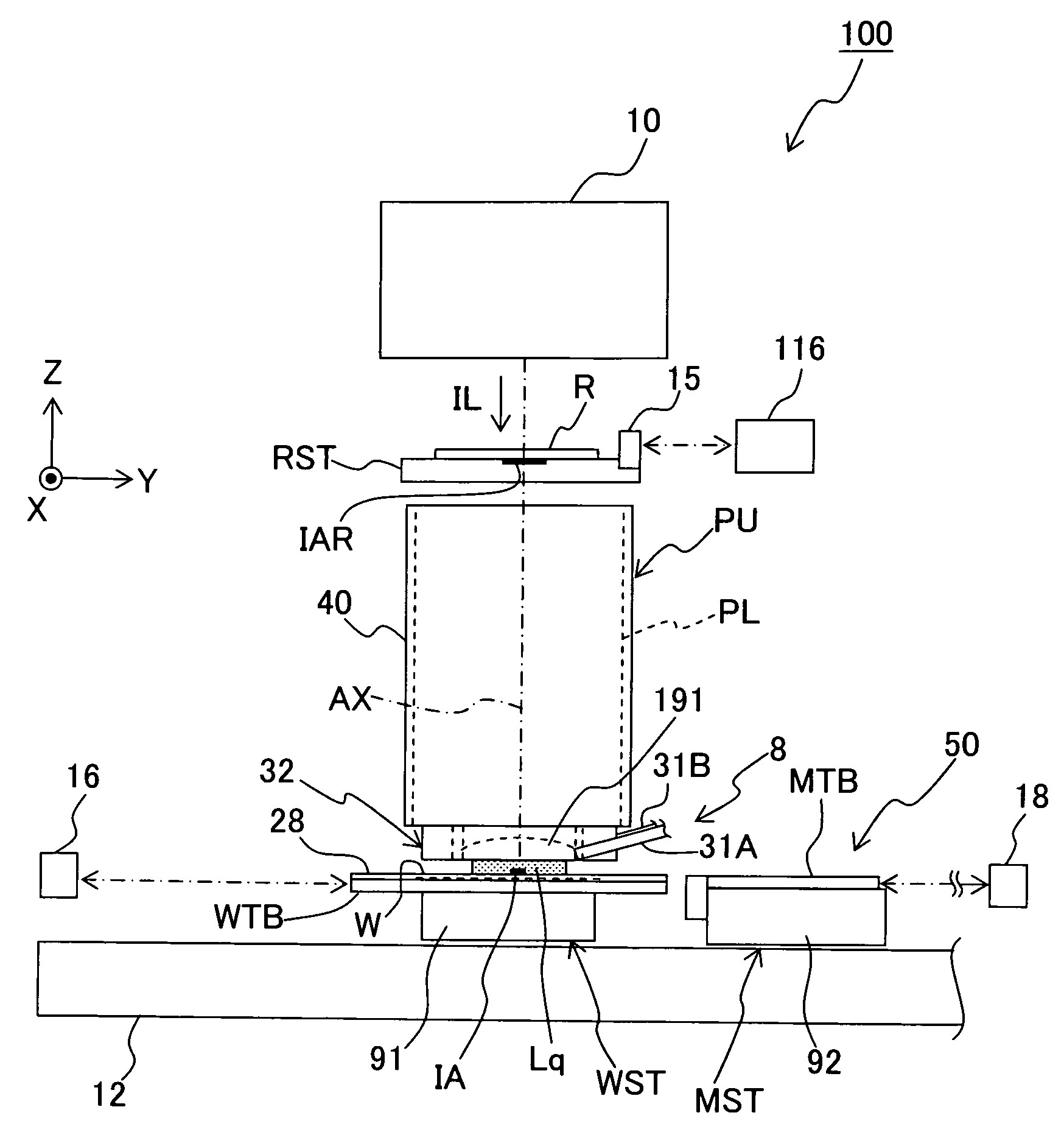

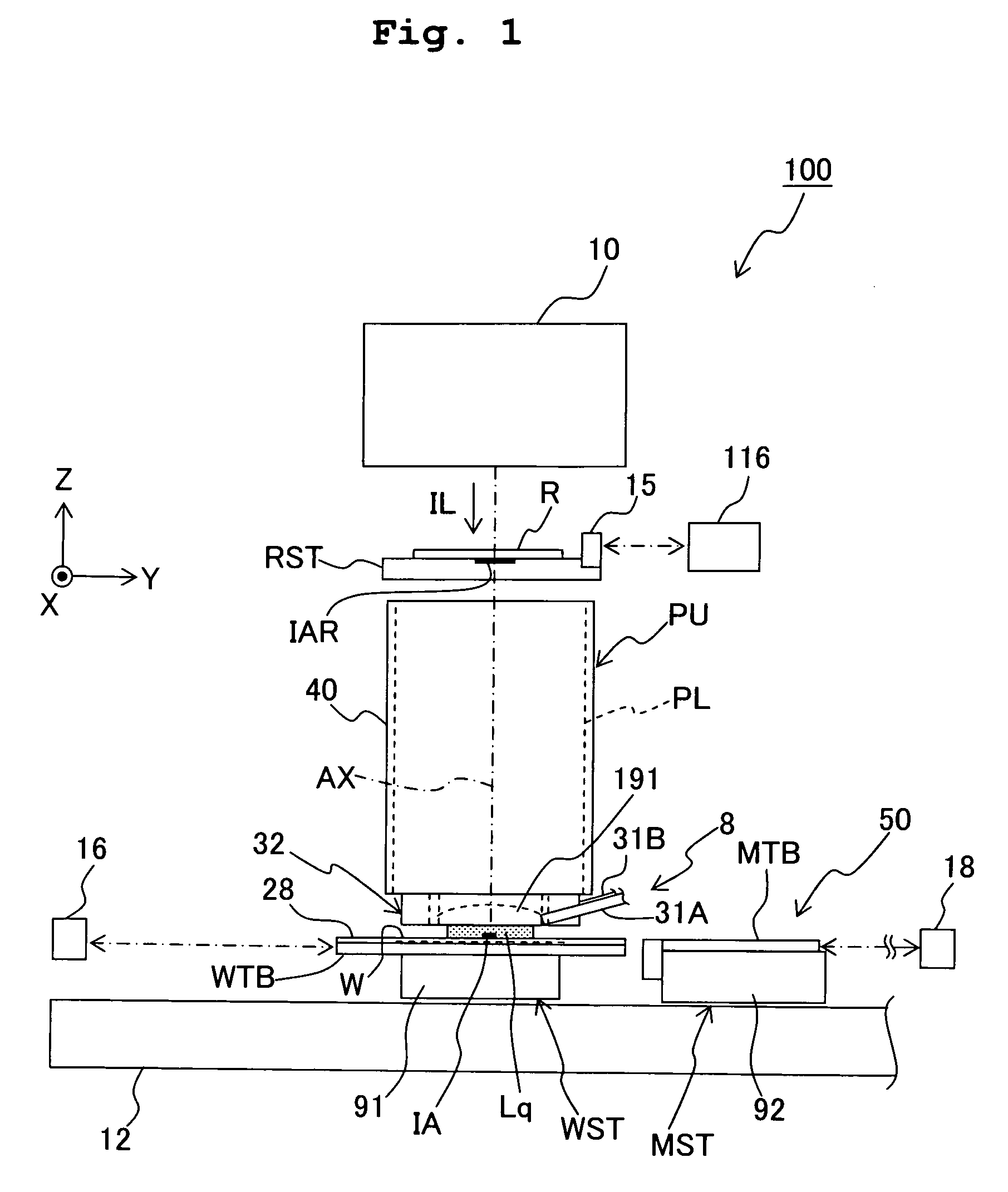

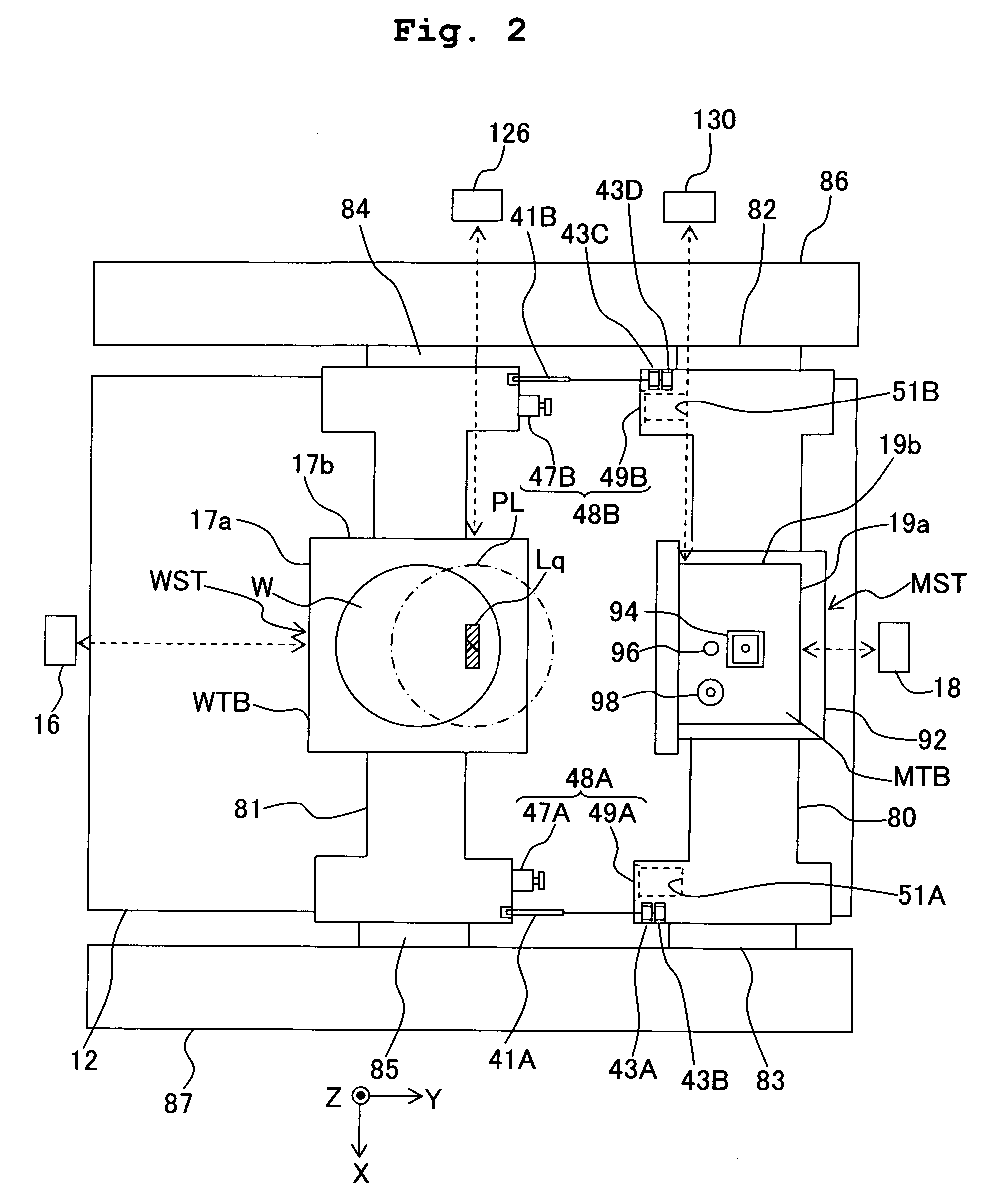

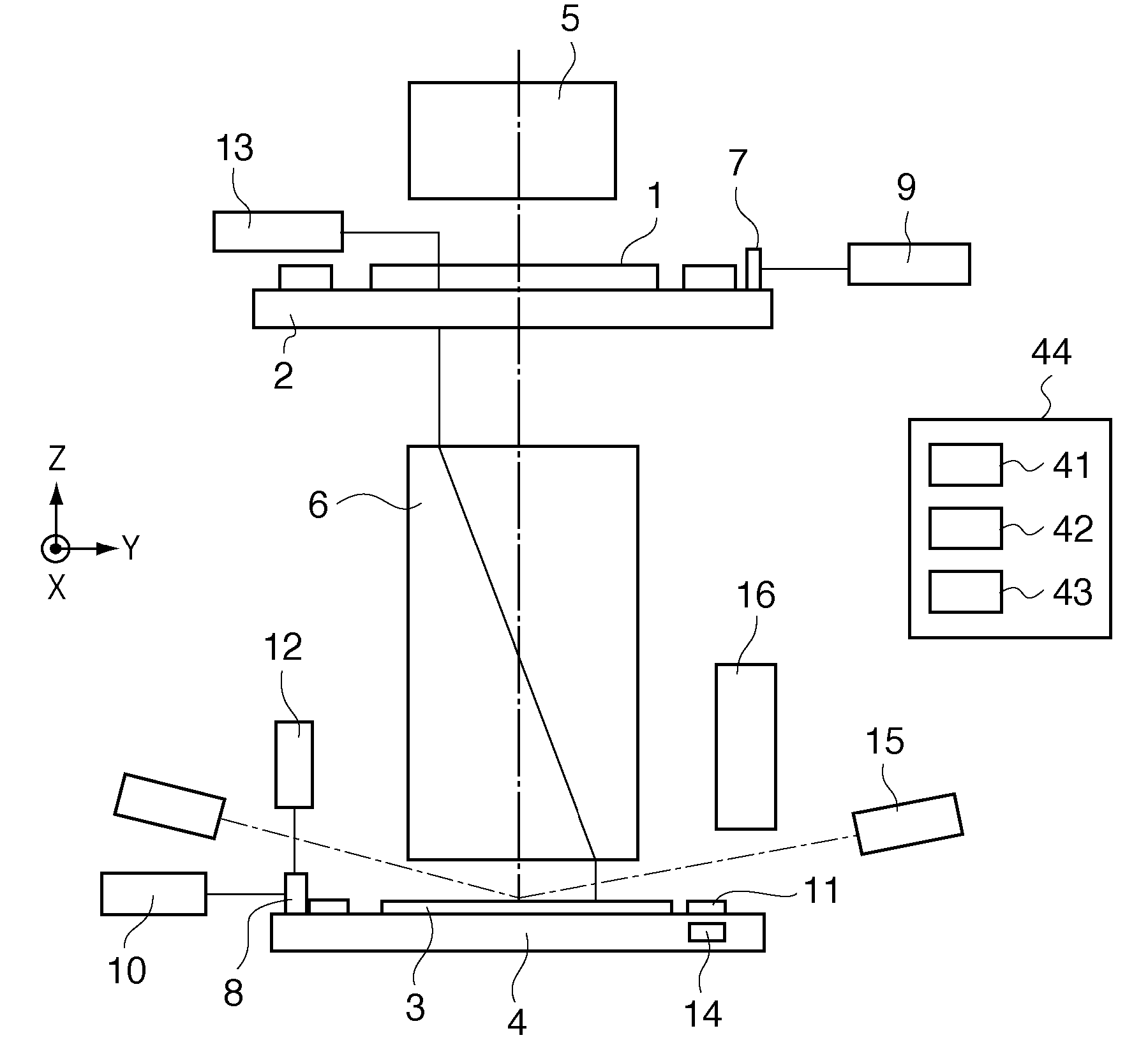

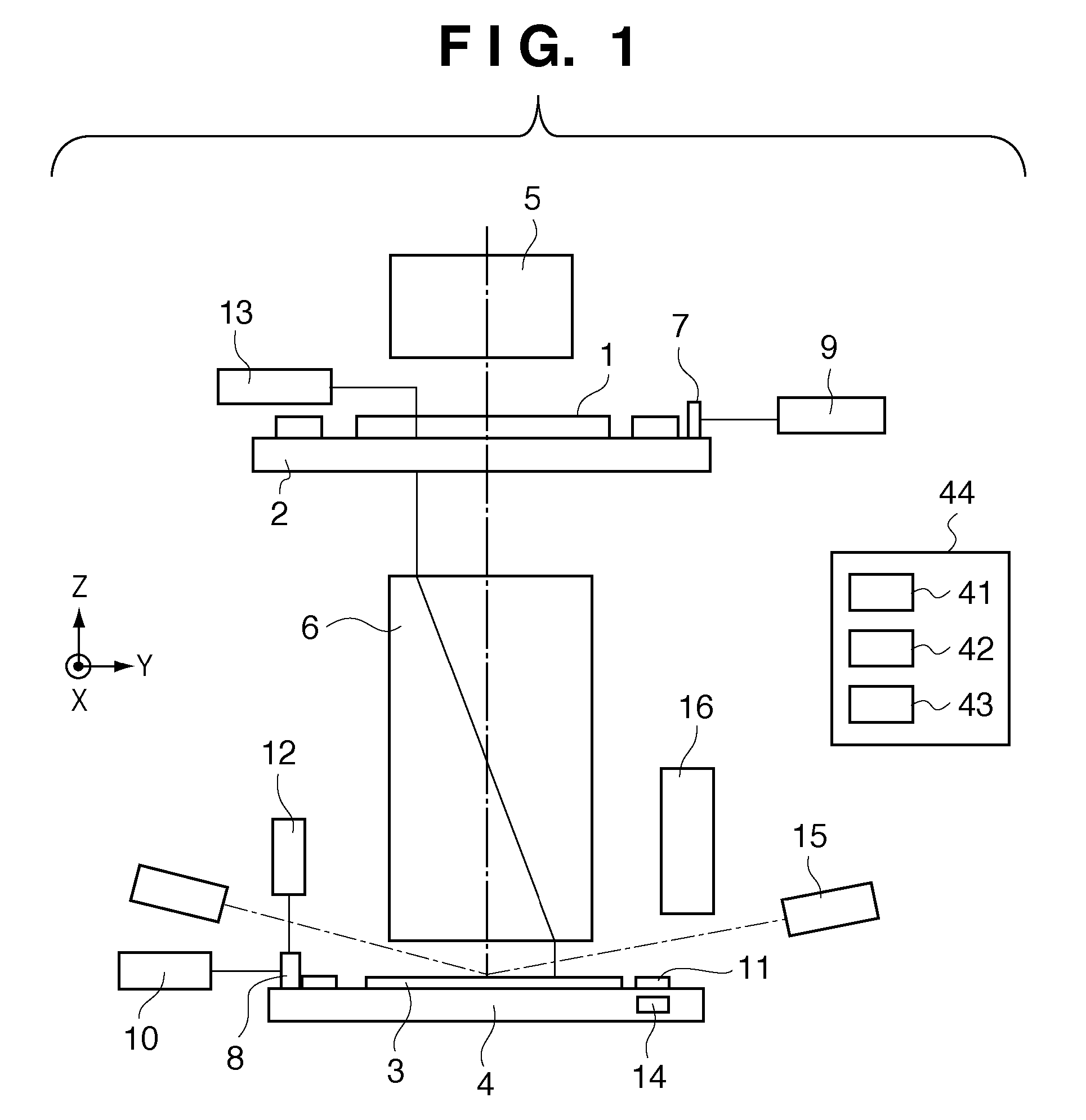

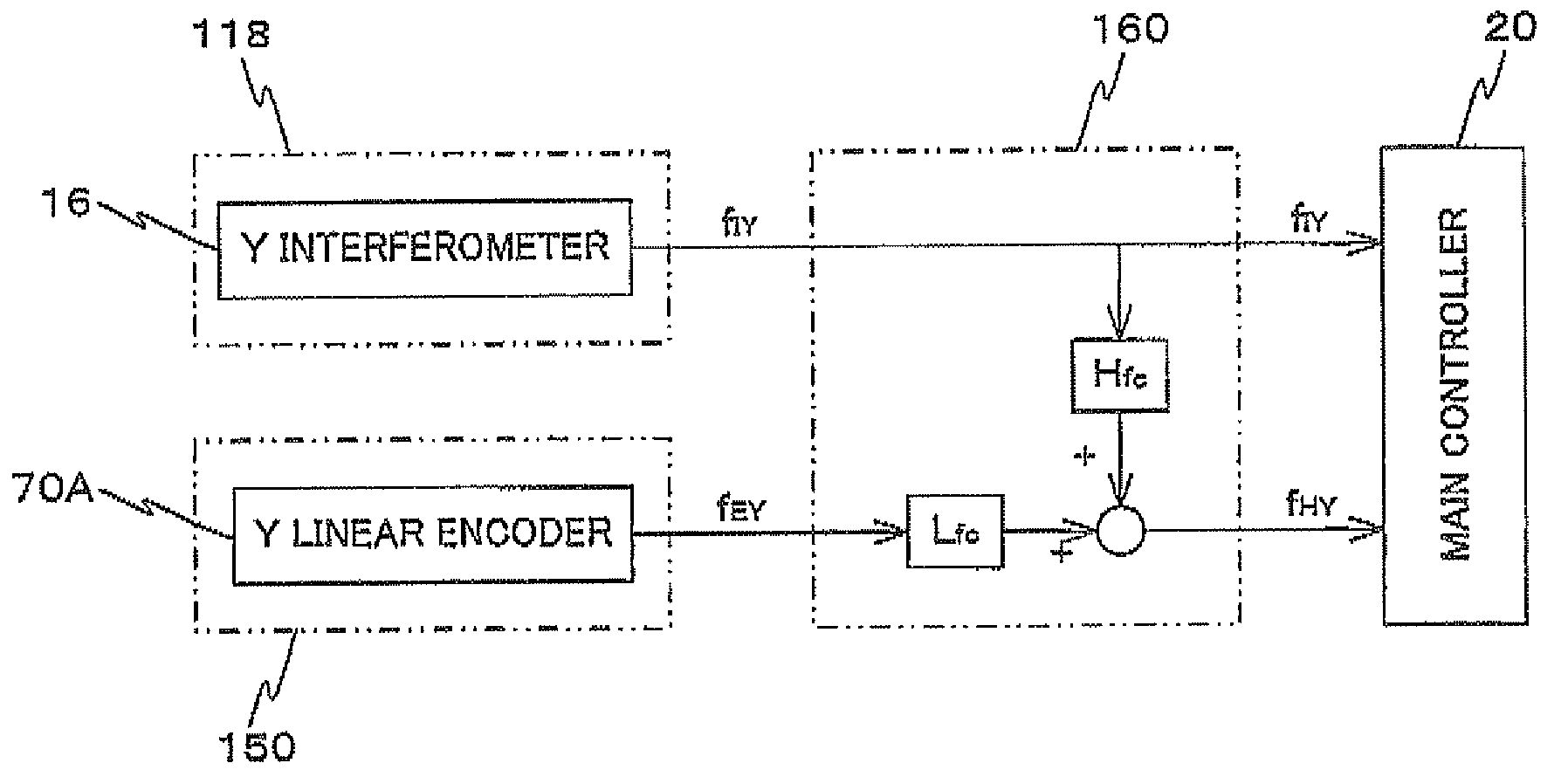

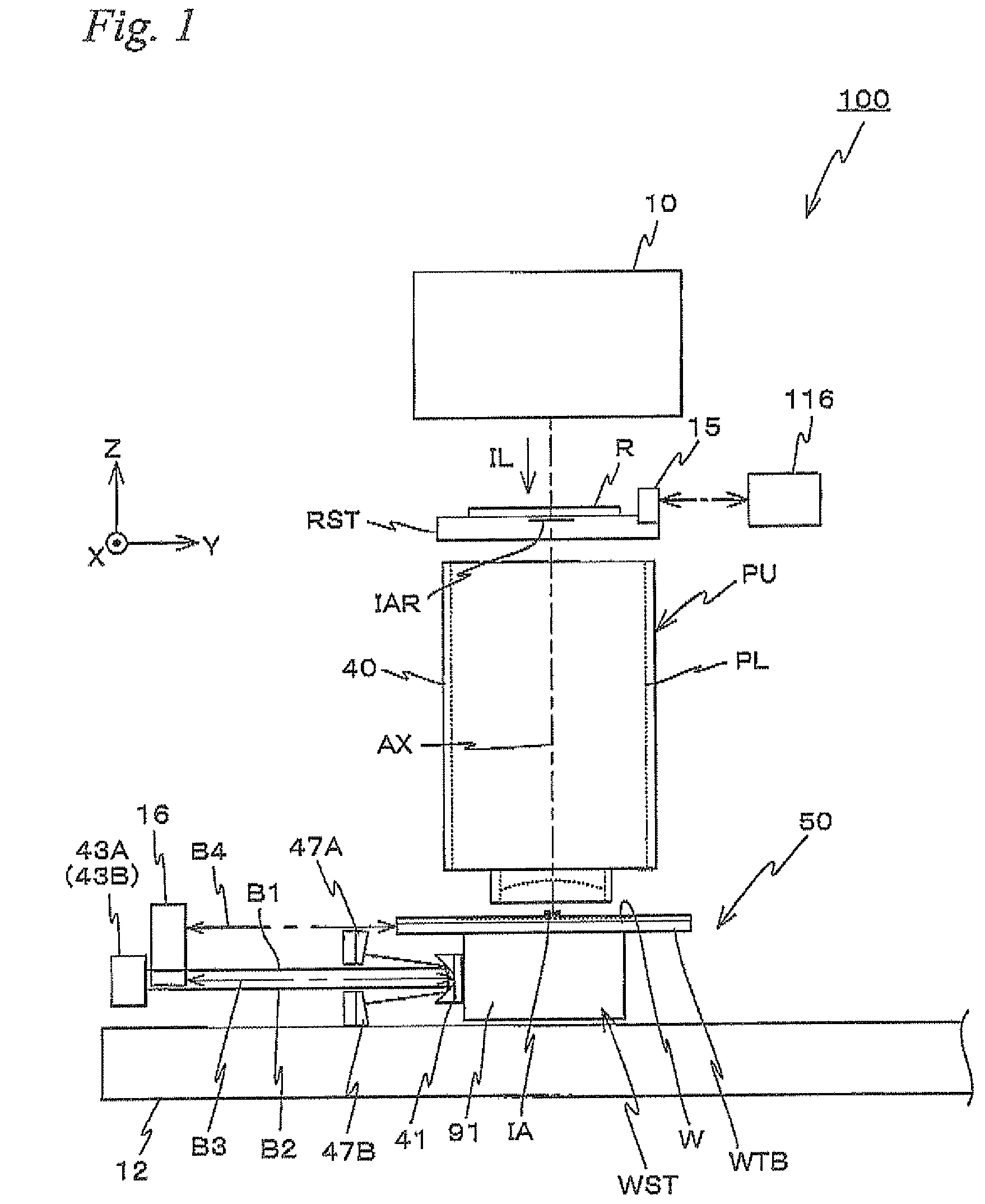

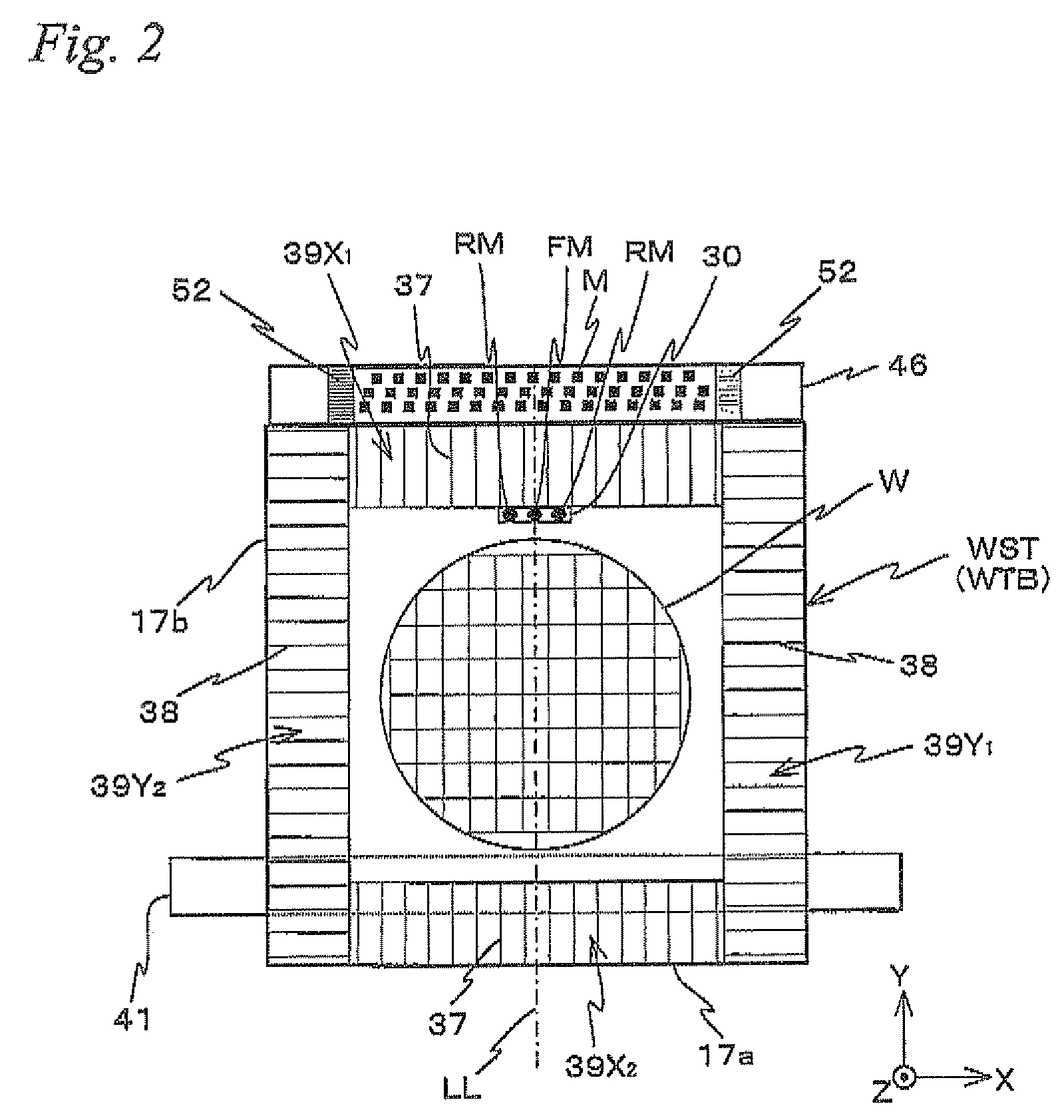

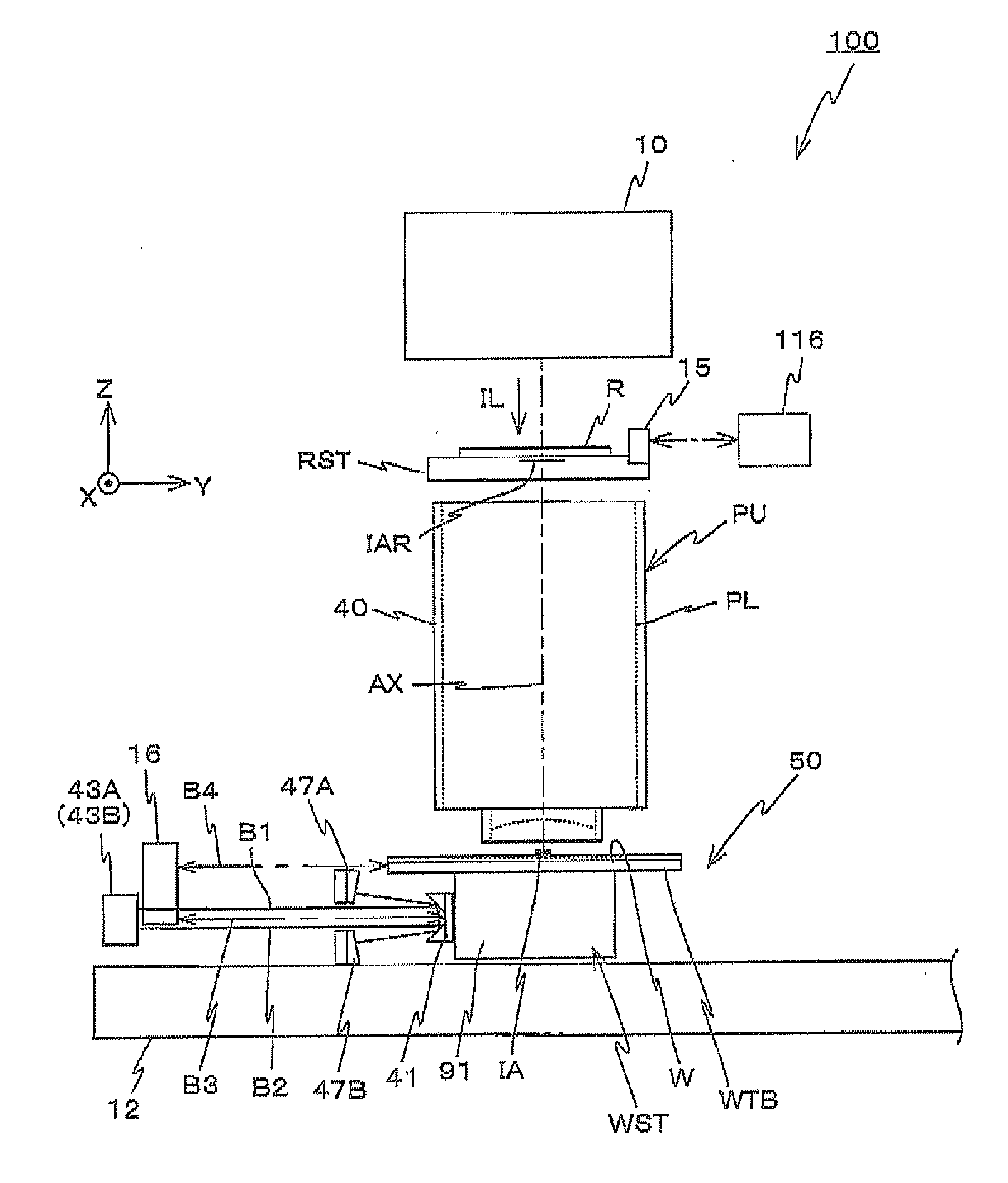

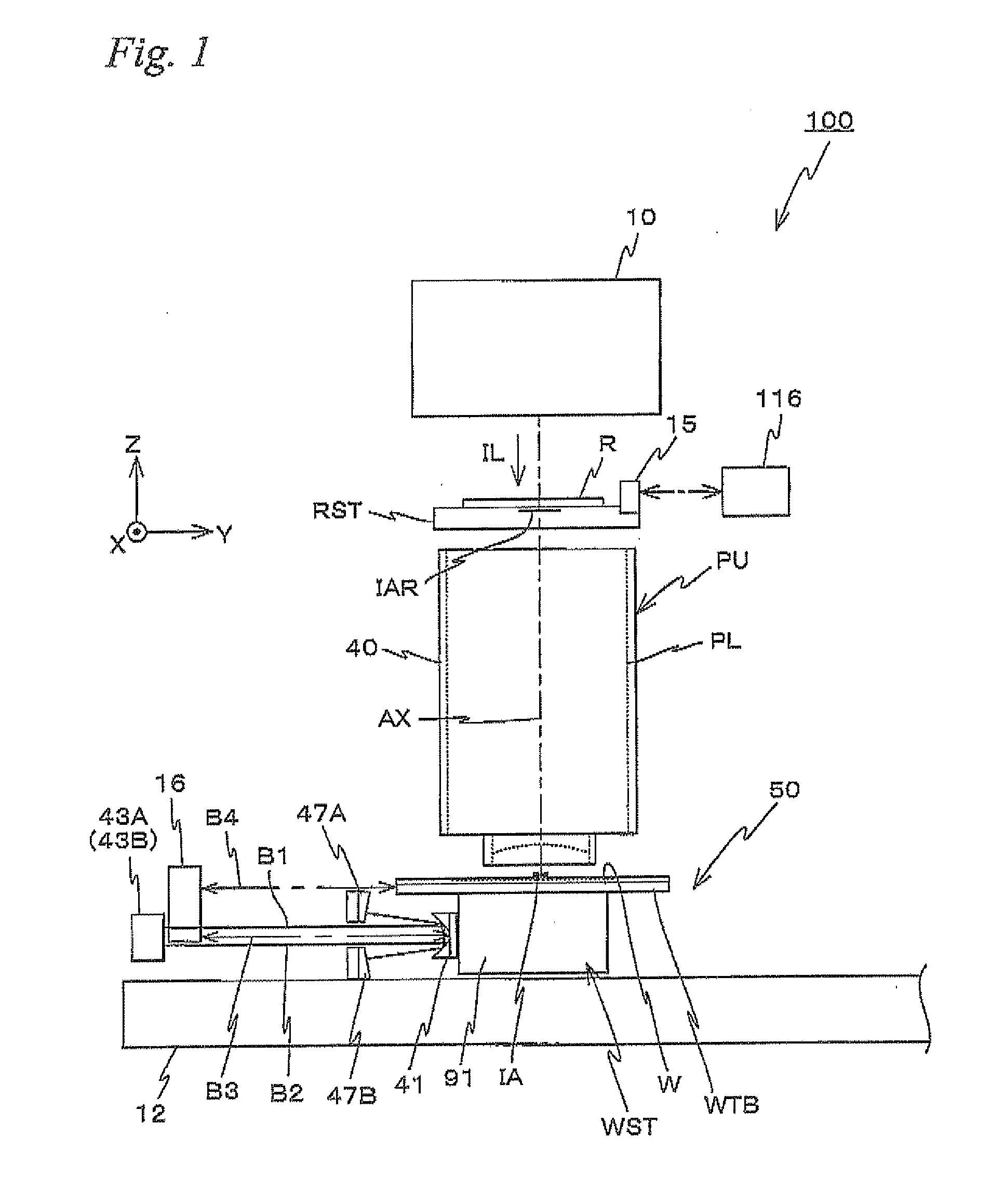

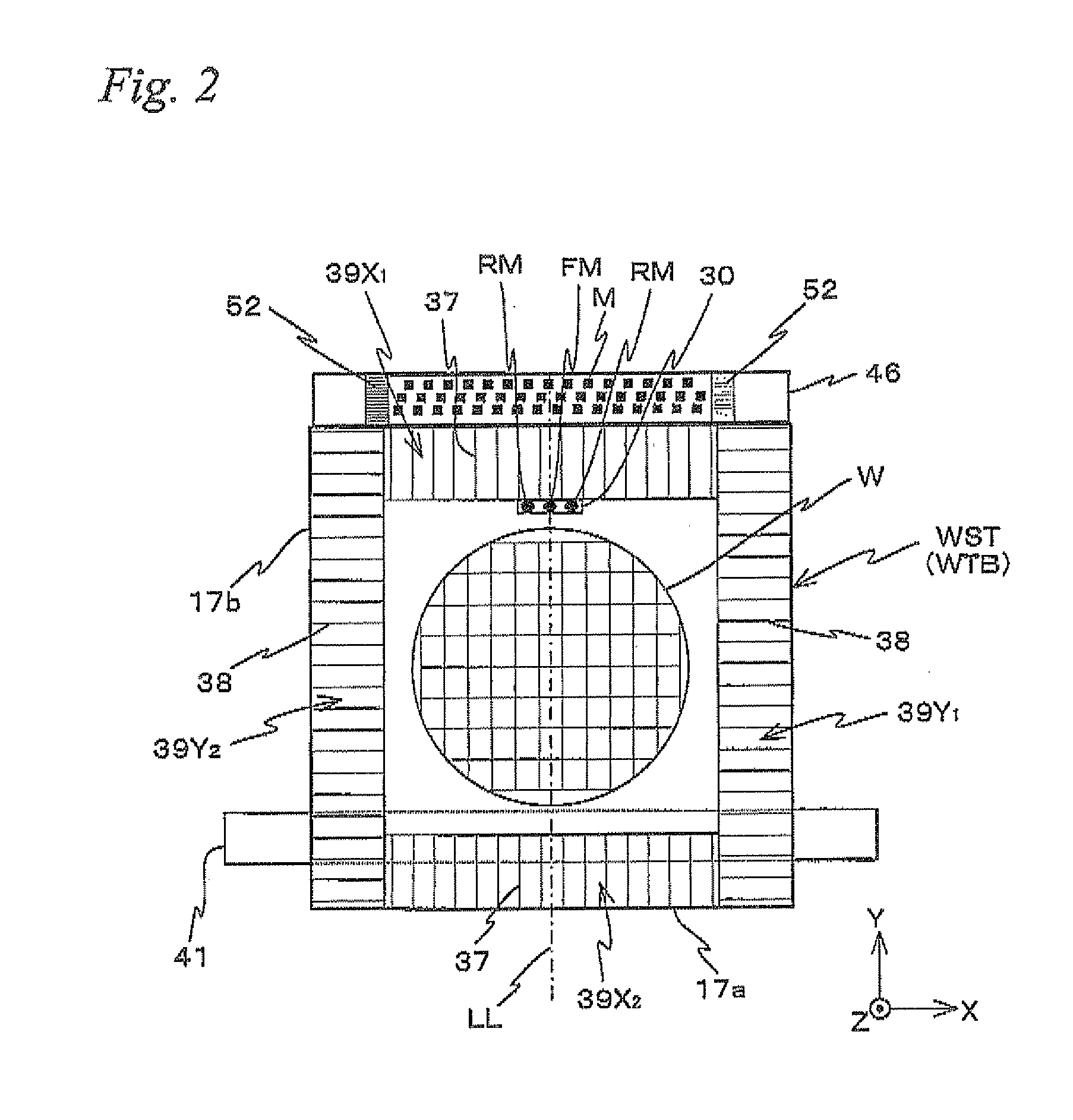

Movable body drive method, movable body apparatus, exposure method, exposure apparatus, and device manufacturing method

ActiveUS8488106B2Improve accuracyGood precisionProgramme controlPhotomechanical apparatusPosition controlAcoustics

A stage is driven (position control) using a hybrid signal which is obtained by synthesizing an output signal of an interferometer (an interferometer system) and an output signal of an encoder (an encoder system) that are made to pass through a high pass filter and a low pass filter, respectively. A cutoff frequency is set to a frequency corresponding to a speed slightly smaller than the speed of the stage at the time of scanning exposure. This allows the stage to be driven using an interferometer whose linear measurement is high at the time of scanning exposure, and using an encoder whose measurement reproducibility is high at the time of stepping.

Owner:NIKON CORP

Movable body drive method, movable body apparatus, exposure method, exposure apparatus, and device manufacturing method

ActiveUS20110177461A1Easy to measureImprove measurement repeatabilityProgramme controlSemiconductor/solid-state device manufacturingEngineeringComputer science

A stage is driven (position control) using a hybrid signal which is obtained by synthesizing an output signal of an interferometer (an interferometer system) and an output signal of an encoder (an encoder system) that are made to pass through a high pass filter and a low pass filter, respectively. A cutoff frequency is set to a frequency corresponding to a speed slightly smaller than the speed of the stage at the time of scanning exposure. This allows the stage to be driven using an interferometer whose linear measurement is high at the time of scanning exposure, and using an encoder whose measurement reproducibility is high at the time of stepping.

Owner:NIKON CORP

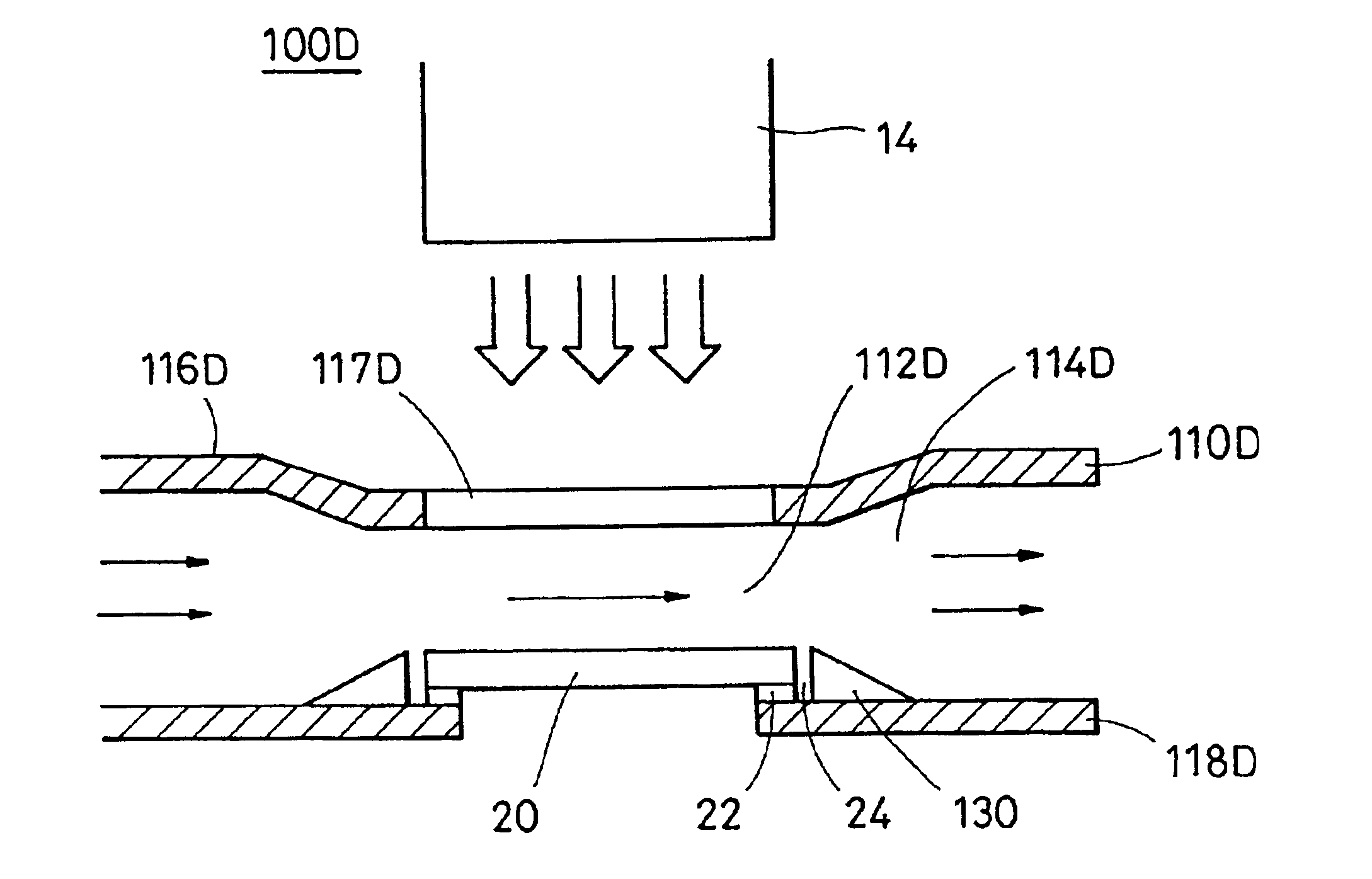

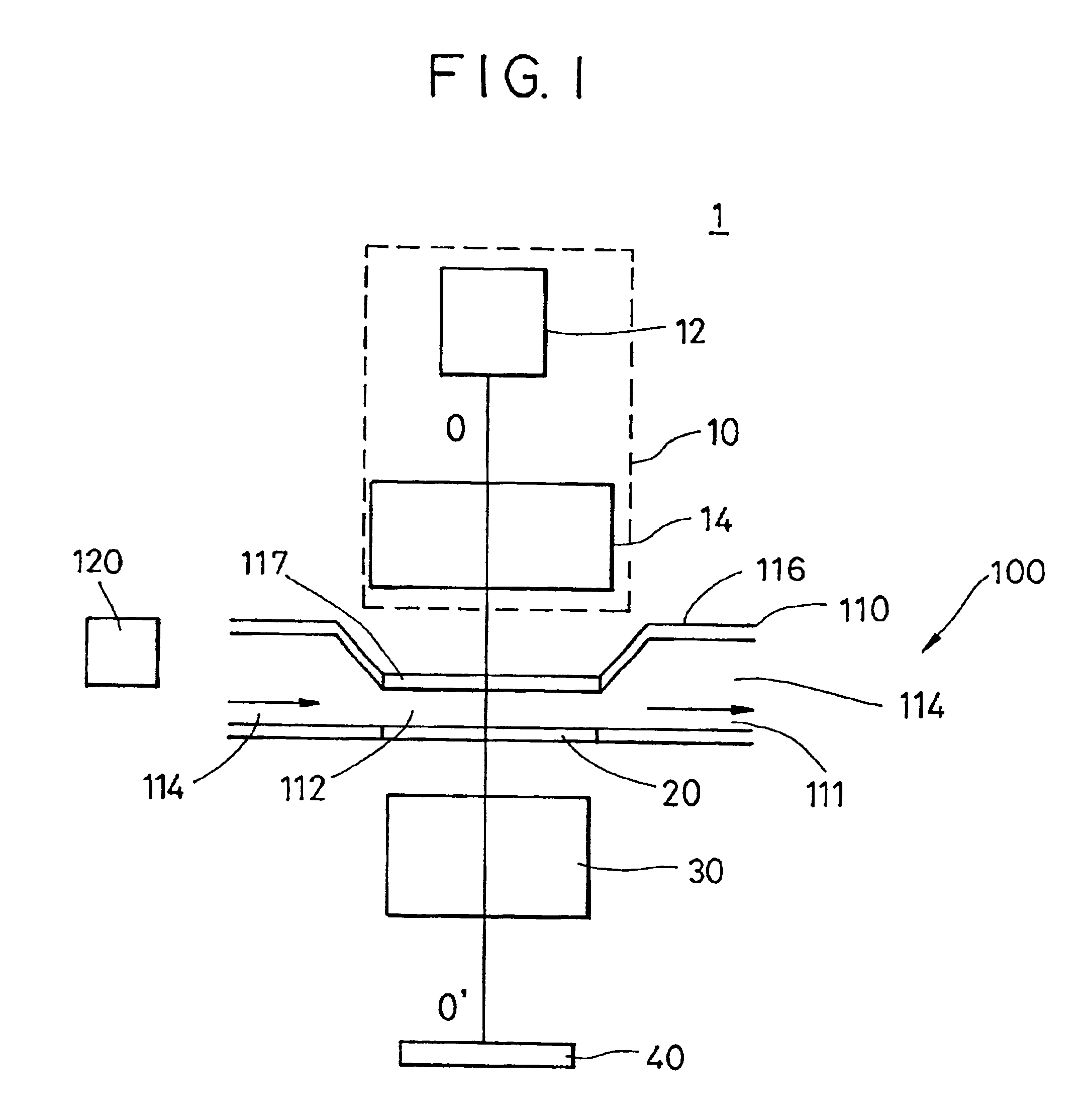

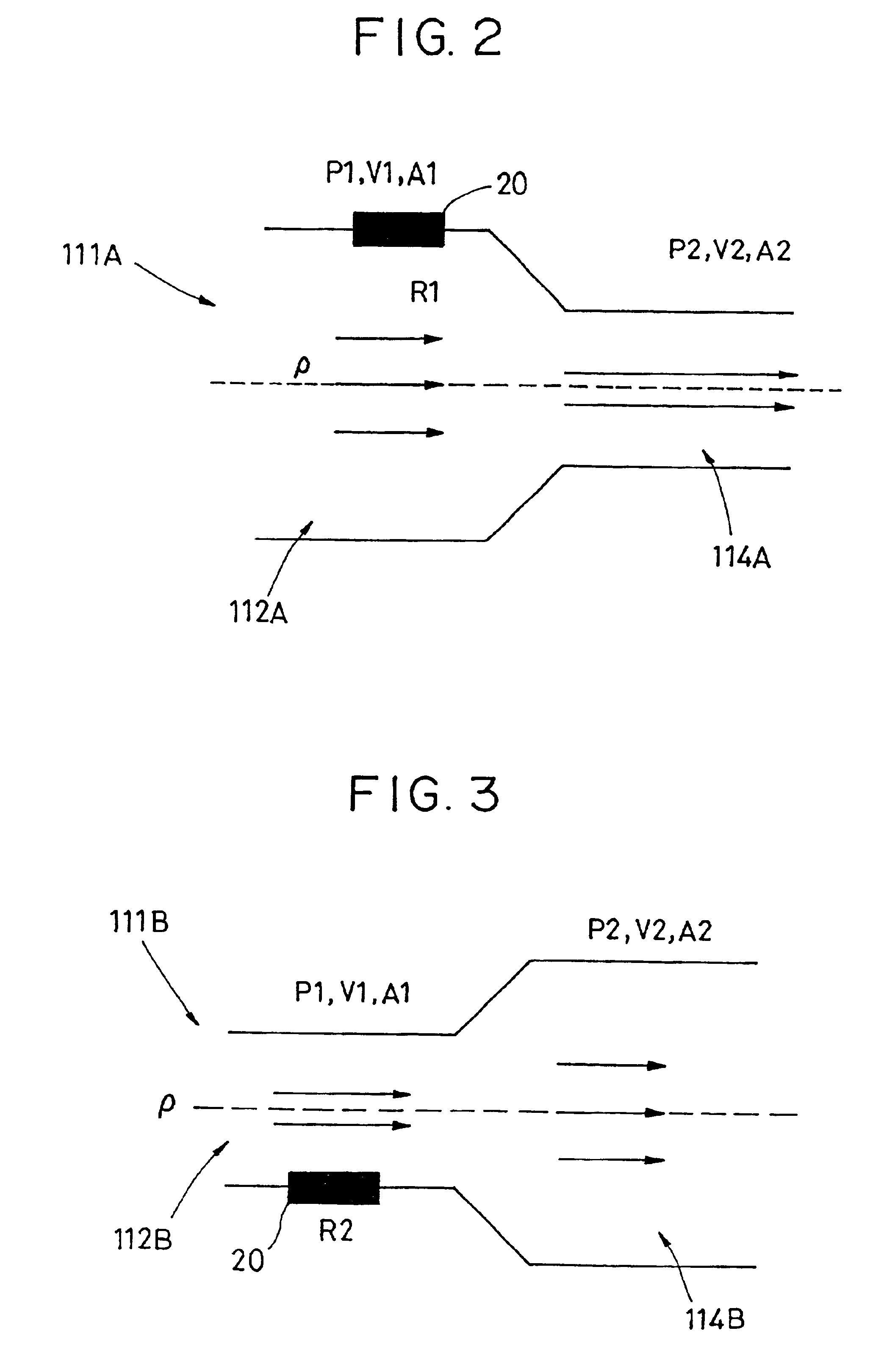

Correcting device, exposure apparatus, device production method, and device produced by the device production method

InactiveUS6951766B2Improve overlay accuracySemiconductor/solid-state device manufacturingSolid state diffusion coatingReticlePhysics

A correcting device that properly maintains the flatness of a mask, an exposure apparatus in which overlay accuracy is increased by making use of the correcting device, and a device production method. The correcting device includes a gas flow path including a first area and a second area. The first area is formed above a reticle having formed thereon a pattern that is projected onto a material to be processed in order to form an image of the pattern on the material to be processed. The second area is connected to the first area, has a cross-sectional area that is different from that of the first area, and is not disposed in line with the reticle. The correcting device also includes a blowing section that blows gas to the gas flow path.

Owner:CANON KK

Overlay management method and apparatus, processing apparatus, measurement apparatus and exposure apparatus, device manufacturing system and device manufacturing method, and program and information recording medium

ActiveUS7718327B2Improve overlay accuracySimple process conditionsPhotomechanical apparatusUsing optical meansProduction rateComputer science

In repeated processes (steps 201 to 213) of lot processing, an analytical apparatus detects abnormality of overlay, that is, deterioration of overlay accuracy in step 211 and optimizes an apparatus parameter of an exposure apparatus so that the abnormality is solved (so that the overlay accuracy is improved), and then the optimization result is promptly reflected in the exposure apparatus and a measurement / inspection instrument. Since such optimization is performed without stopping the lot processing, the productivity of devices is not lowered.

Owner:NIKON CORP

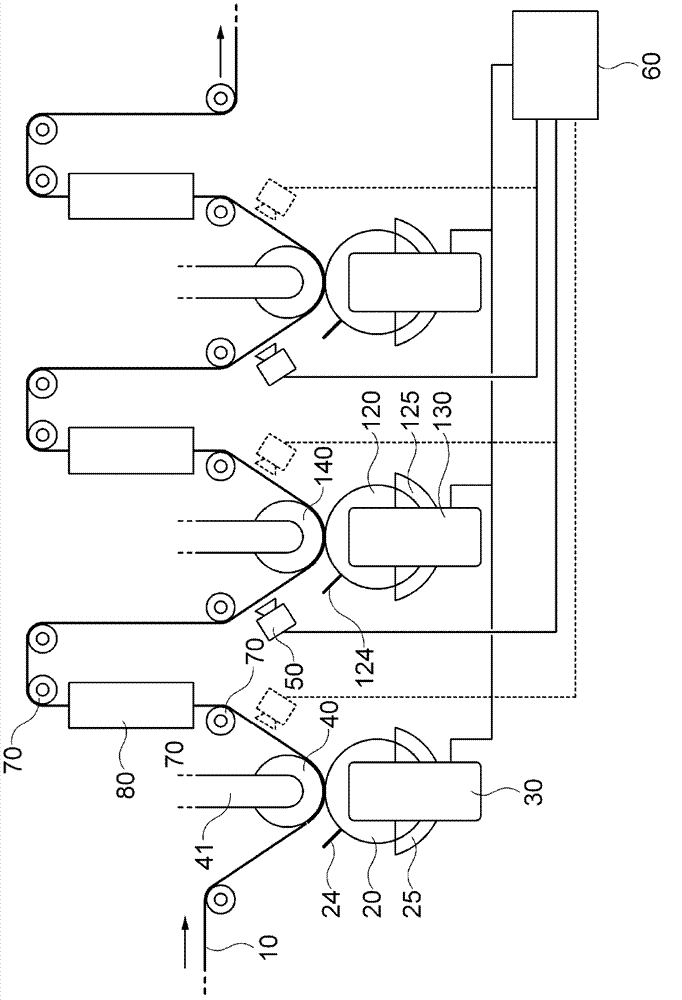

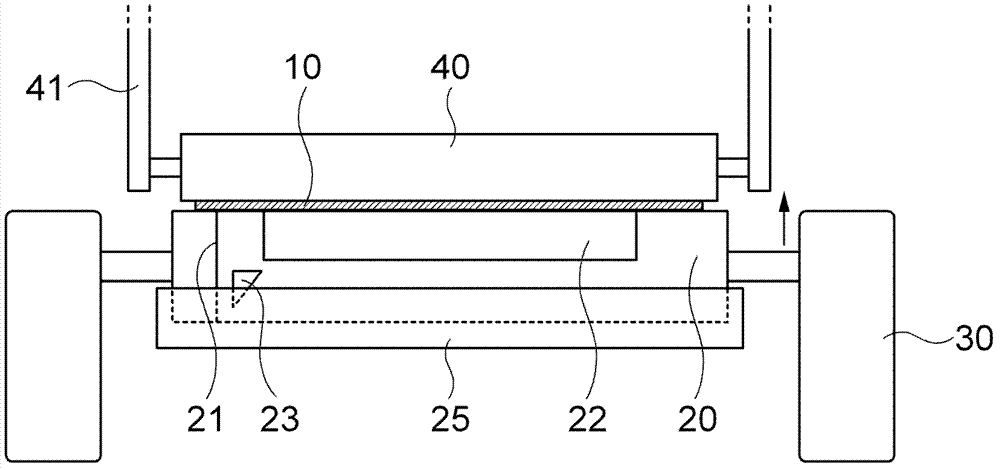

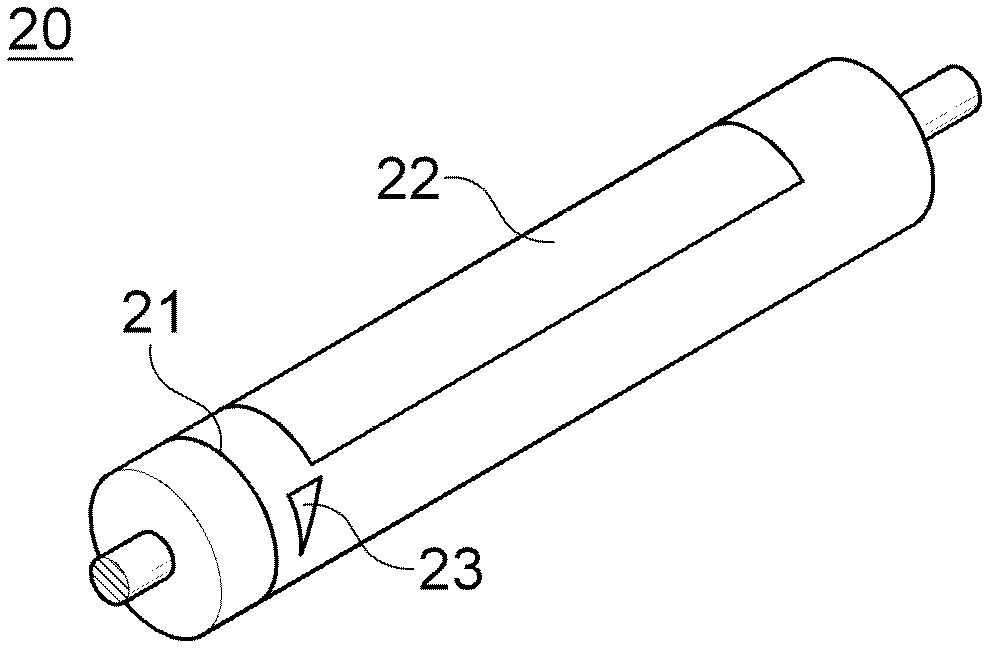

Gravure printing apparatus

ActiveCN103158332AHigh print definitionImprove overlay accuracyRotary intaglio printing pressPrinting press partsEngineeringControl unit

The invention discloses a gravure printing apparatus which comprises a gravure cylinder for printing patterns, aligning marks and referential lines onto a print substrate, a driving unit supporting and rotating both ends of the gravure cylinder, a pressurizing cylinder facing the gravure cylinder maintaining the print substrate therebetween and pressing the print substrate, a sensor unit formed at one side of the pressurizing cylinder to sense the aligning marks and referential lines, and a control unit which controls the gravure cylinder according to the error of the aligning marks and referential lines sensed by the sensor unit. The gravure cylinder allows sensing and calibrating pattern printing state on a real-time basis, thereby improving the pattern superimposing accuracy of the printing substrate. The gravure cylinder drives the gravure cylinder through a non-contact bearing to calibrate micro-flow of printing errors and retain optimal printing pressure, thereby improving printing quality and uniformity.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

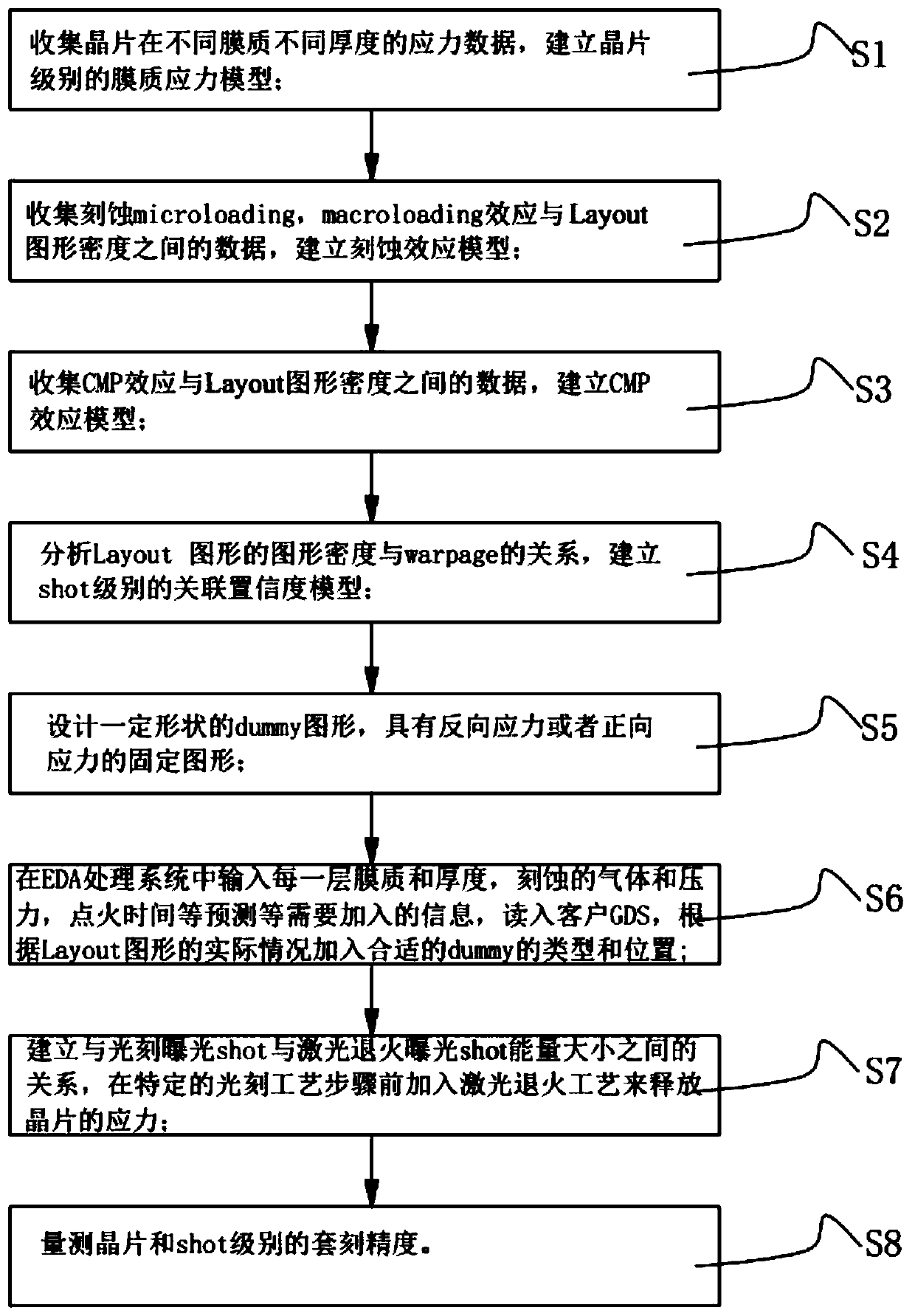

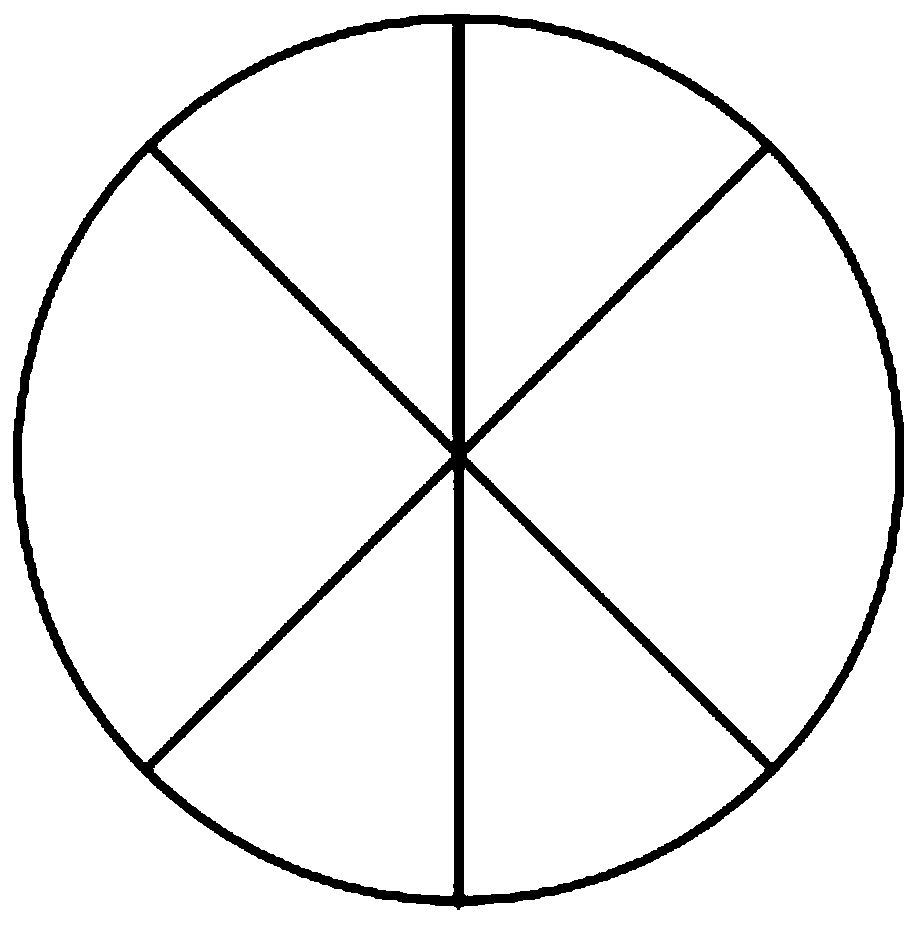

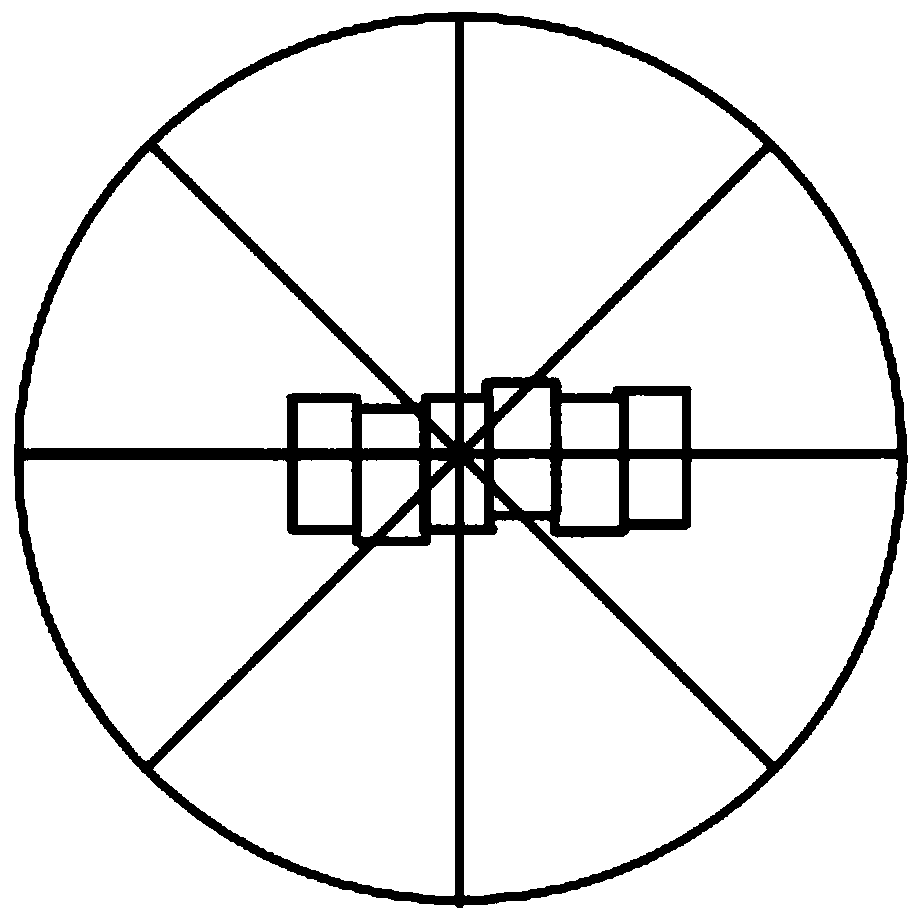

Method for improving warping degree of silicon wafer and increasing alignment precision

ActiveCN109709774AChange warpageGuaranteed releasePhotomechanical exposure apparatusMicrolithography exposure apparatusInternal stressDesign pattern

The invention discloses a method for improving the warping degree of a silicon wafer and increasing the alignment precision, and the method comprises the following steps: changing the layout and the graph density through an added specific auxiliary design graph so as to provide reverse stress or forward stress on a wafer; then, keeping an auxiliary design pattern in a subsequent chemical mechanical polishing process or an etching process, so as to achieve the purpose of changing the warping degree of the wafer; meanwhile, introducing a laser annealing process before a photoetching process stepin order to ensure the release of the internal stress of the whole wafer Shot, and cooperatively adjusting the energy of laser annealing and the size of Shot to achieve the purposes of releasing thewafer stress at a specific position through cooperating with the size of the photoetching exposure Shot.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for aligning wafer

InactiveUS20050185183A1Improve overlay accuracyCoupling device detailsSemiconductor/solid-state device manufacturingValue setGray level

A method for aligning wafer is provided, the method including loading and aligning a first wafer in an exposure apparatus, selecting a non-defective wafer alignment mark among a plurality of wafer alignment marks of the first wafer and storing the non-defective wafer alignment marks as a gray level reference image in a job file, loading a second wafer and storing a plurality of wafer alignment marks of the second wafer as gray level wafer alignment mark images, respectively comparing each of the plurality of wafer alignment mark images of the second wafer with the reference image of the first wafer pixel by pixel to obtain matching value for each of the plurality of the wafer alignment mark images, comparing each of the plurality of the matching values with a minimum value set in the exposure apparatus, replacing the wafer alignment mark image having the matching value smaller than the minimum value with the reference image, and obtaining an alignment information for an underlying layer using a wafer alignment sensor.

Owner:SK HYNIX INC +1

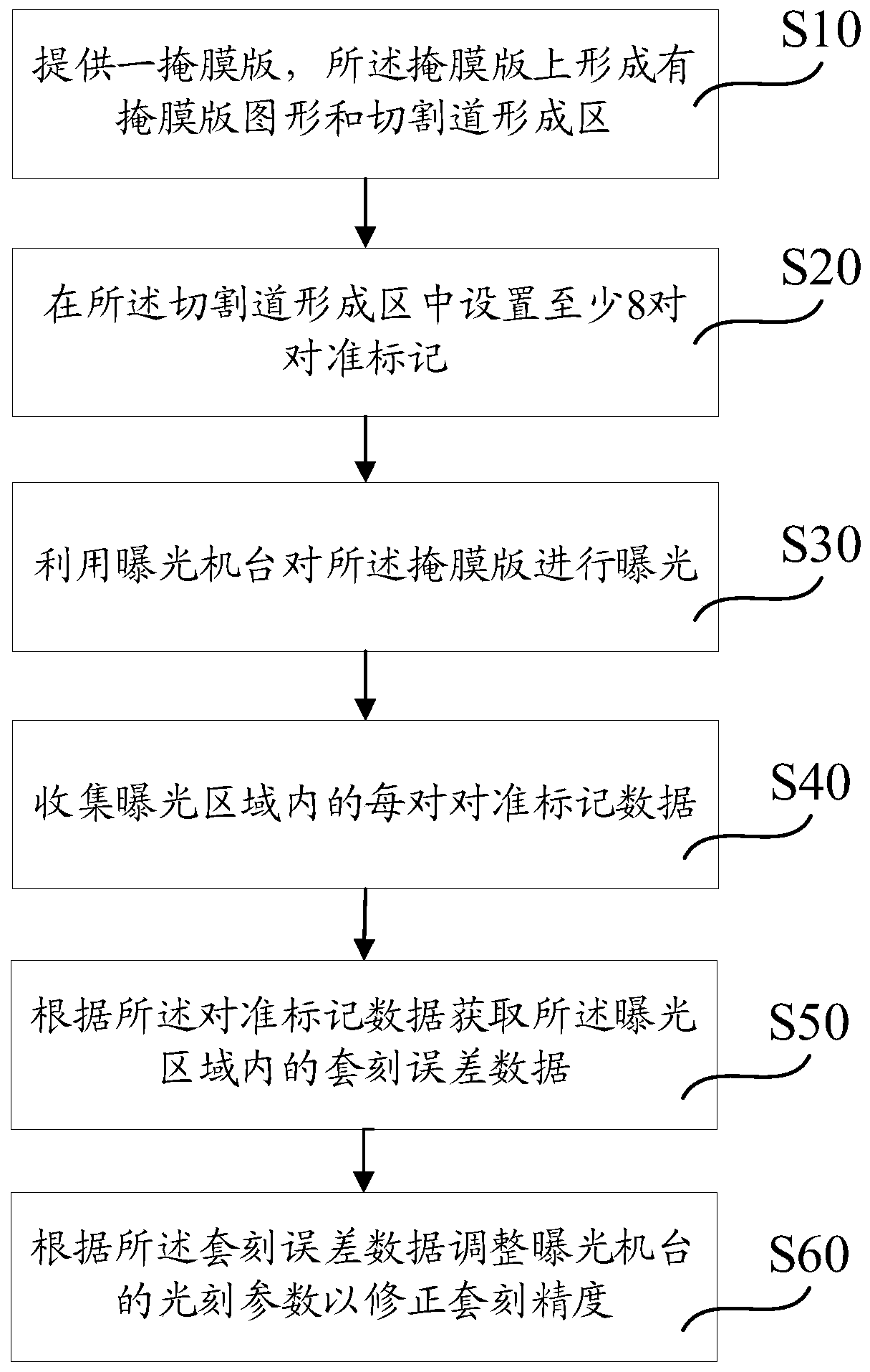

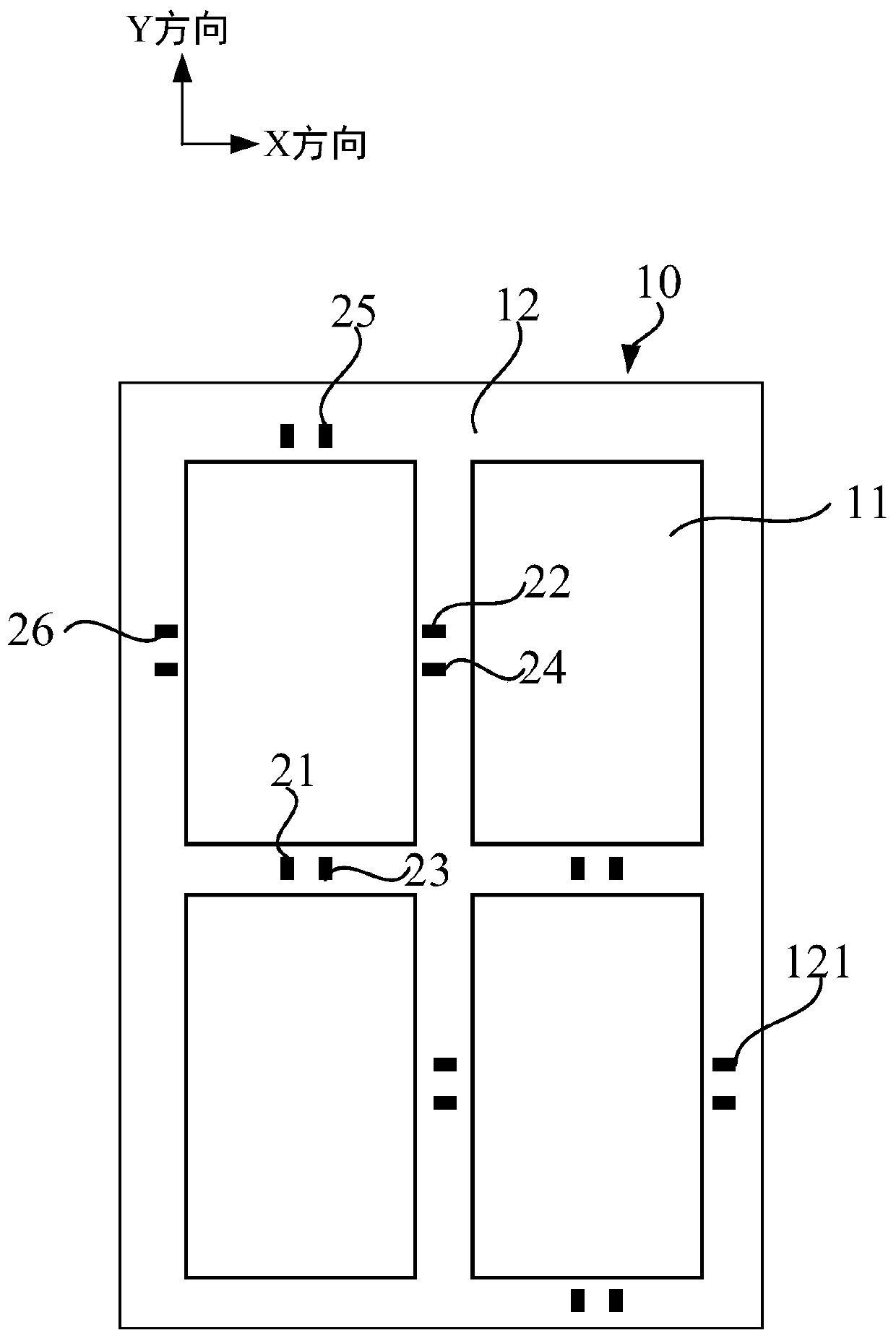

Overlay precision correction method

ActiveCN110531591AReduce overlay errorImprove overlay accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsEngineering

The invention provides an overlay precision correction method. The method comprises the following steps of providing a mask plate on which a mask plate pattern and a cutting channel forming region areformed, and arranging at least eight pairs of alignment marks in the cutting channel forming region; exposing the mask plate by using an exposure machine bench; collecting all alignment mark data inan exposure region; acquiring overlay error data in the exposure region according to the alignment mark data; and adjusting photoetching parameters of the exposure machine bench according to the overlay error data so as to correct overlay precision. The at least eight pairs of alignment marks are arranged in the cutting channel forming region to obtain the overlay error data in the exposure regionso as to introduce a correction amount of a high-order number, and high-order correction in the exposure region can be realized on the basis of linear correction so that the overlay errors are reduced, and overlay precision is improved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com