Electron beam alignment mark manufacture method and its uses

An alignment mark and production method technology, applied to the photoengraving process, circuit, discharge tube and other directions of the pattern surface, can solve the problem that the electron beam exposure machine cannot accurately identify the alignment mark, etc., achieves the ideal of ohmic contact, reduces the Errors and the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

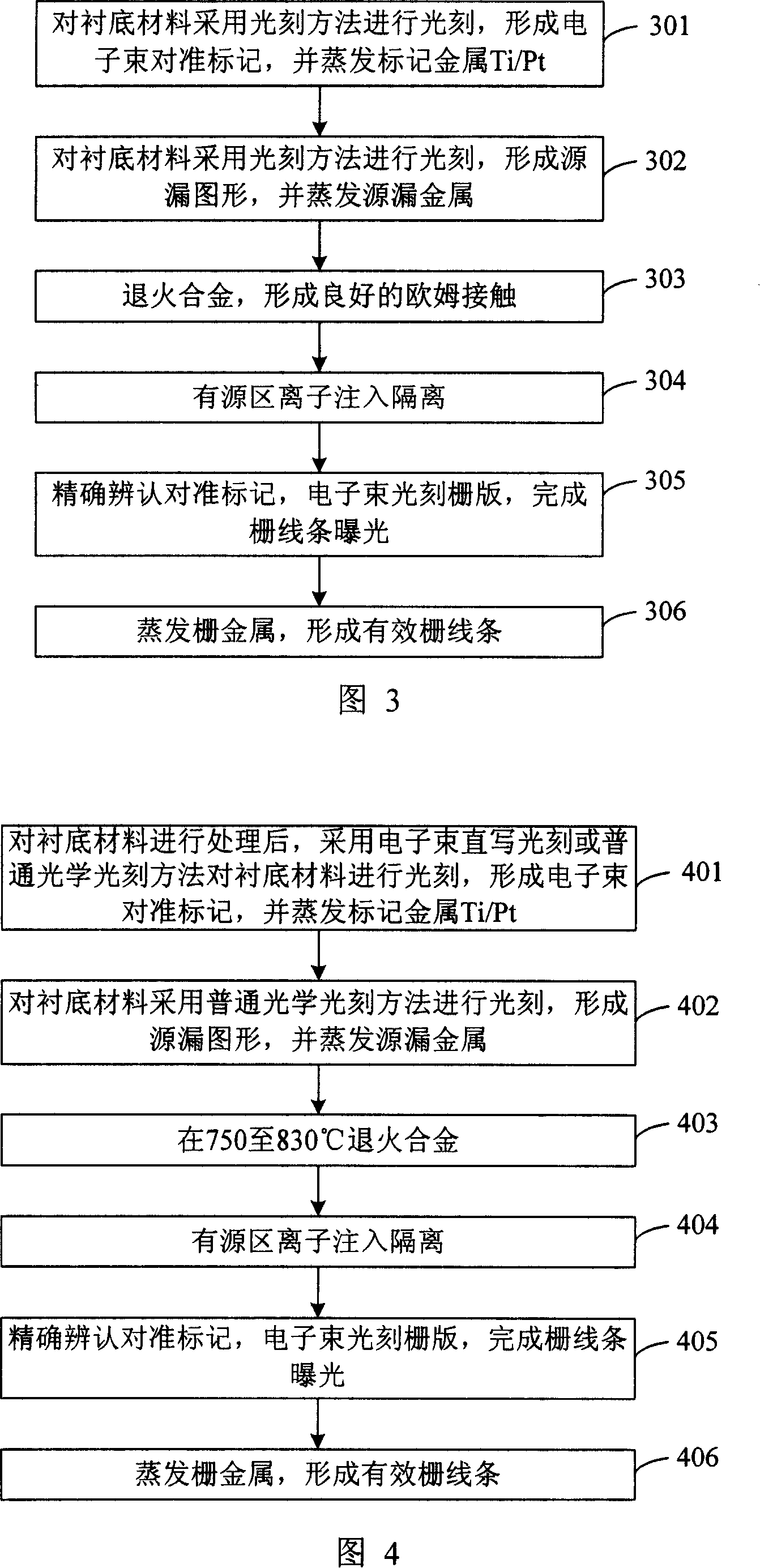

[0057] As shown in FIG. 4, FIG. 4 is a flow chart of a method for making effective grid lines using electron beam alignment marks according to an embodiment of the present invention. The method includes the following steps:

[0058] Step 401: After the substrate material is processed, photolithography is performed on the substrate material by electron beam direct writing lithography or ordinary optical lithography to form an electron beam alignment mark, and evaporate the marked metal Ti / Pt; the mark The metal composition of metal Ti / Pt is: Ti / Pt=60 / 1000 Ȧ.

[0059]Step 402: Perform photolithography on the substrate material by using ordinary optical lithography method to form source and drain patterns, and evaporate source and drain metals;

[0060] As shown in FIG. 5 , FIG. 5 is a schematic view showing the morphology of a novel alignment mark metal (Ti / Pt=60 / 1000 Ȧ) structure before annealing manufactured according to an embodiment of the present invention.

[0061] Step 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com