Exposure method

An exposure method and exposure area technology, applied in the exposure field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

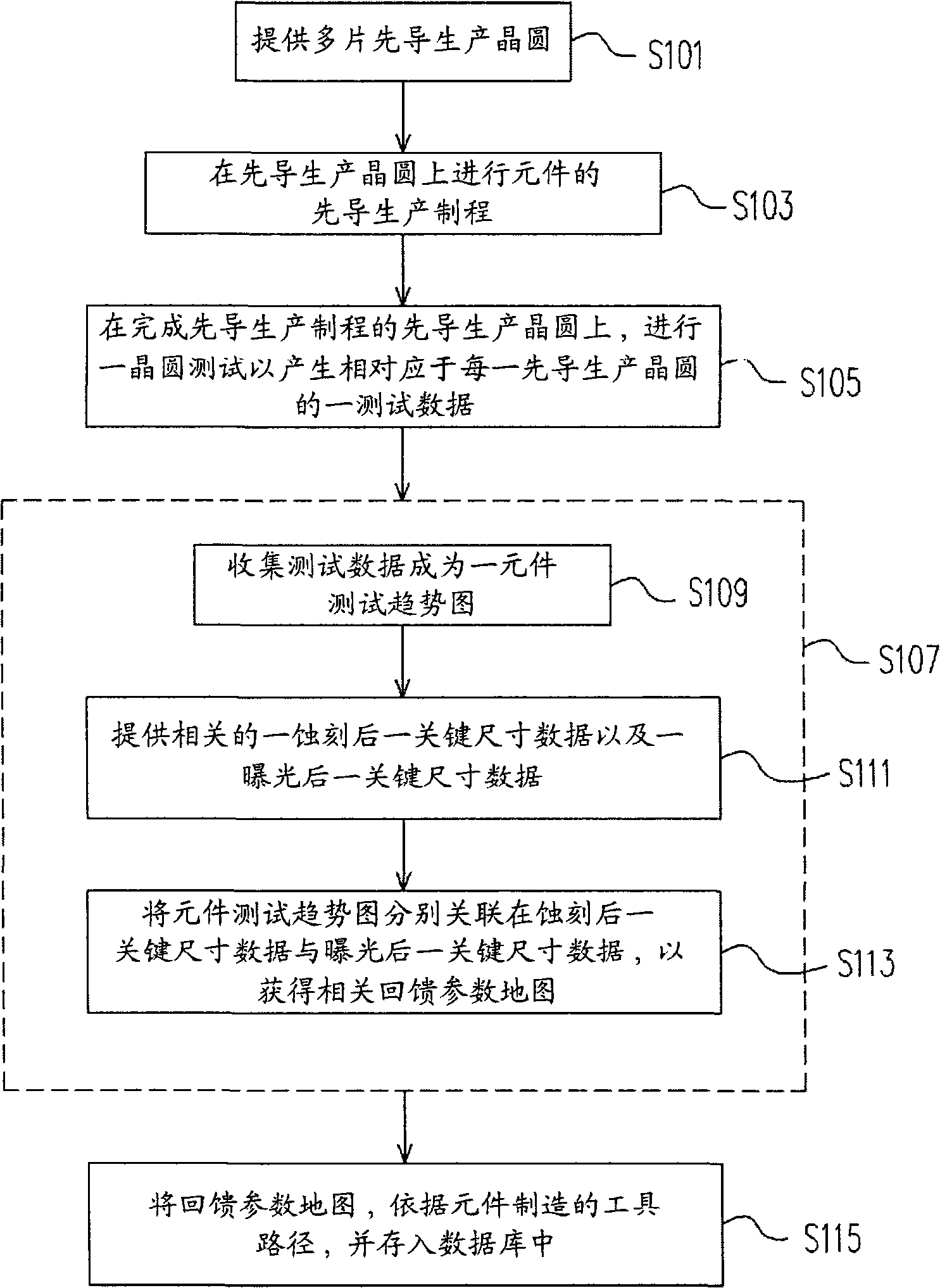

[0025] figure 1 Shown is a flow chart of a method for forming a feedback parameter map according to the present invention. Please refer to figure 1 , first provide a plurality of pilot production wafers (pilot-run wafer) in step S101. Wherein, the quantity of the pilot production wafers may be the quantity of a batch of wafers, for example, 25 wafers. Afterwards, in step S103 , a pilot run of a device is performed on each pilot wafer with a tool path. Among them, a component may be as small as a simple circuit component, or as large as a product with a complex circuit layout. In addition, the so-called toolpath refers to several kinds of process machines required to perform a series of process operations for producing the above-mentioned components, and the machines are sorted into a toolpath according to the sequence of process operations for producing the above-mentioned components. Afterwards, in step S105, a wafer test (wafer acceptable test, WAT) is performed on each ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com