Mask alignment device and photoetching device using same

A technology for mask alignment and support device, applied in the field of integrated circuit equipment manufacturing, can solve the problems of high cost, complex structure, and inability to obtain the drift amount in real time, and achieve the effect of reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

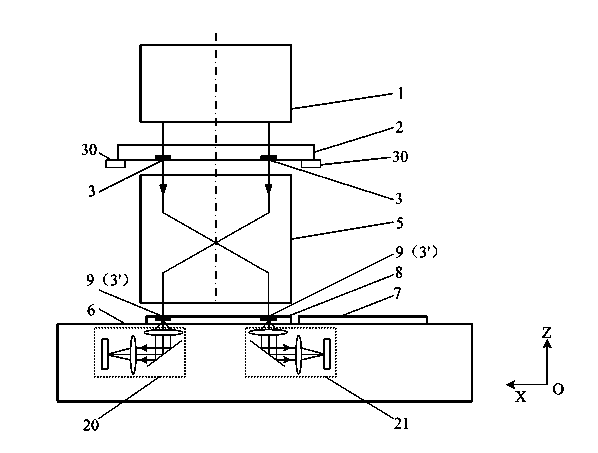

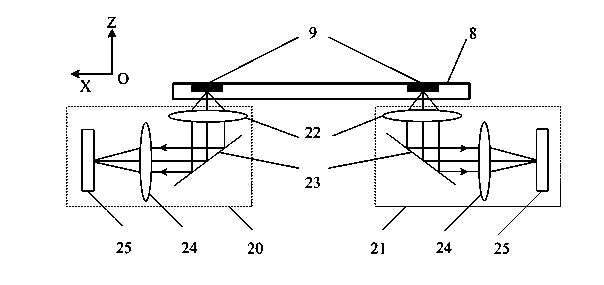

Image

Examples

Embodiment approach

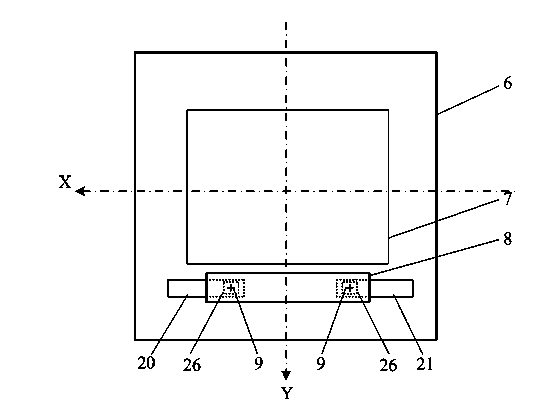

[0040] The present invention also provides a third preferred embodiment, which is as follows Figure 8 shown in. In this embodiment, the die alignment sensors 20 and 21 are arranged in the vertical direction, and the reflective surface is omitted in this embodiment.

[0041] Compared with the prior art, the mask alignment device provided by the present invention and the lithography apparatus using the device place the mask alignment sensor on the workpiece stage, thereby reducing the requirement for the working distance of the mirror image of the projection object, thereby reducing the projection The structure of the objective lens is complex and can effectively control the conjugate distance and weight of the projection objective lens.

[0042] Secondly, the mask alignment sensor can move with the workpiece stage into the exposure field of the projection objective, so the alignment light source can share the exposure light source when the mask marks are aligned, thereby redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com