Gallium nitride-based vertical structure light emitting diode with current blocking layer and manufacturing method thereof

A technology of light-emitting diodes and current blocking layers, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of light-emitting layer falling off, bonding failure, and large difference in thermal expansion coefficient, etc., achieve good light reflection, and realize current distribution adjustment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

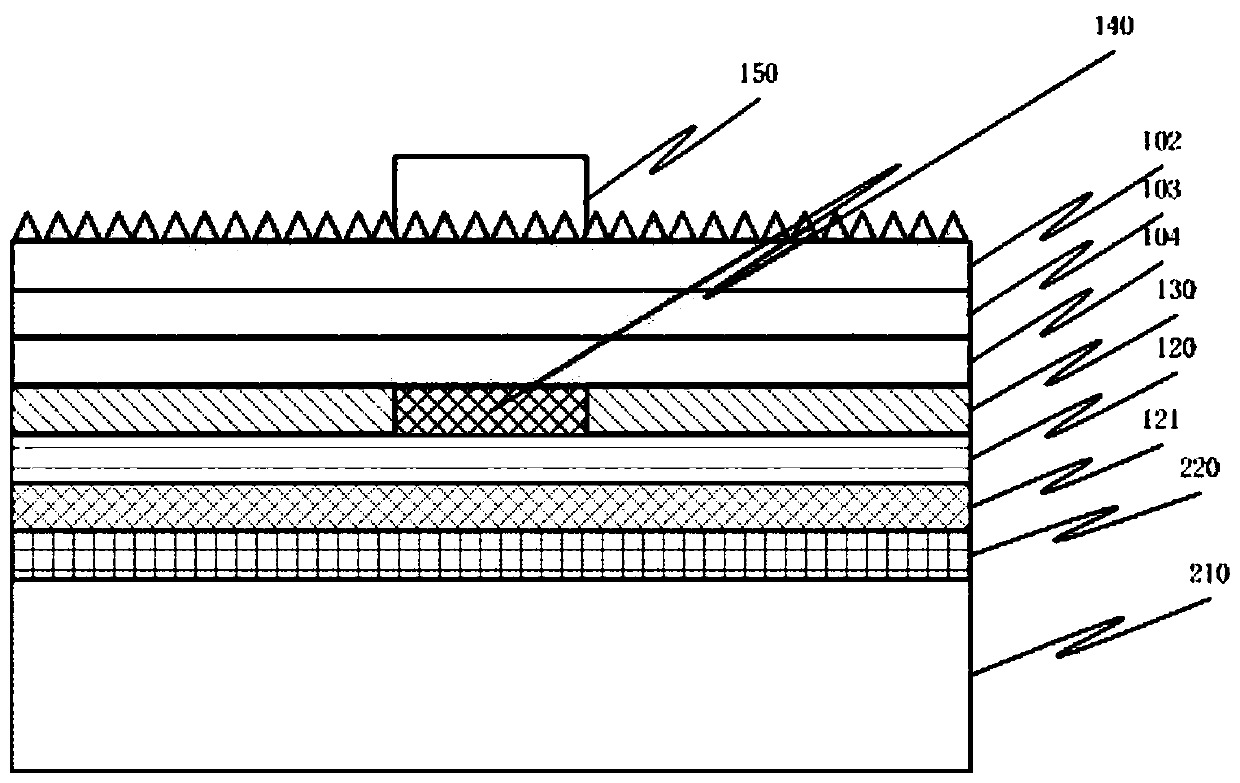

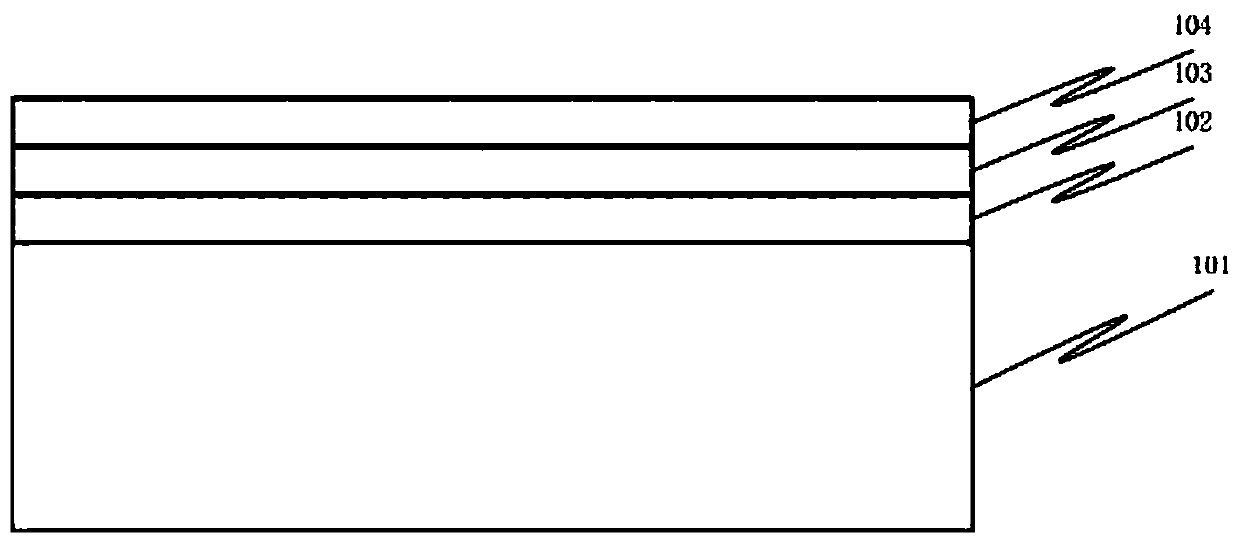

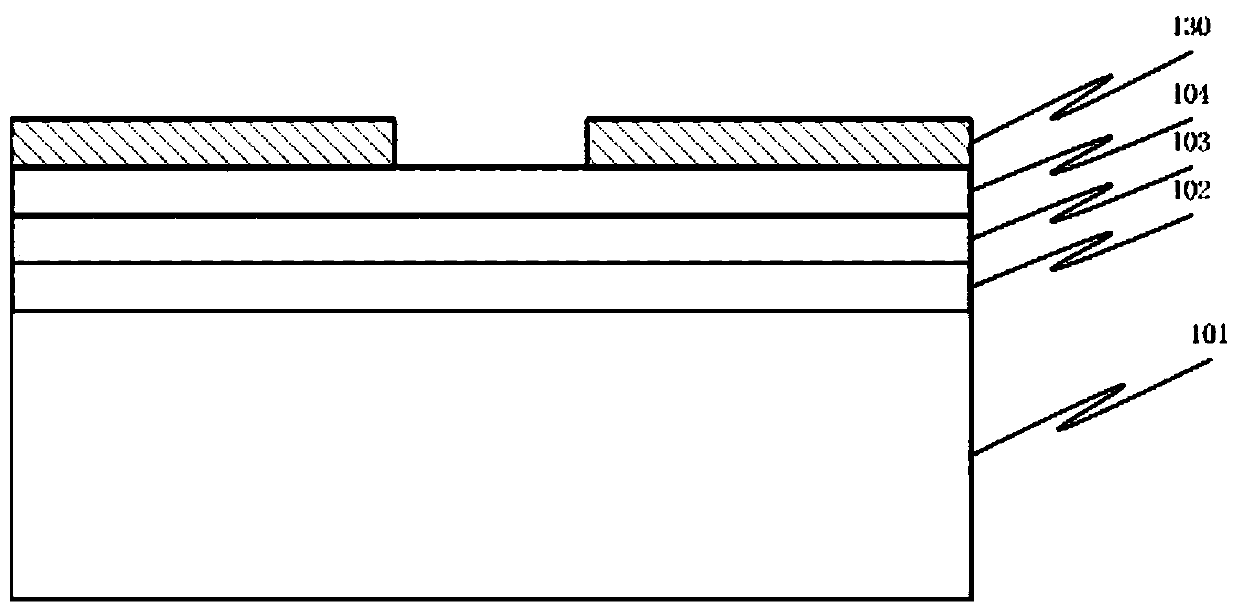

[0045] The main purpose of the present invention is to provide a vertical GaN-based light-emitting diode, the specific structure is as follows figure 1 As shown, the present invention uses Al metal as the current blocking layer of the vertical GaN-based light-emitting diode. The use of Al metal as the current blocking layer is mainly based on the following reasons: 1. When the heat treatment temperature is lower than 320 ° C, the Al metal forms a non-ohmic contact with the p-GaN surface, so the Al metal can block the current; 2. 1. Pressure and heating are required during the bonding process. When the two are combined, the thermal expansion coefficients of Ag and Al are 19.5E-6 / K and 23.2E-6 / K, respectively, which are close in size. In addition, Al and p-GaN have good adhesion , so it is eas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com