Aromatic polycarbonate resin composition, process for producing resin composition, and molded article

A technology of polycarbonate resin and production method, applied in the field of resin molded products, to achieve the effects of excellent flame retardancy, excellent appearance, and excellent molding stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6 and comparative example 1-12

[0263] Each of the above components was blended at the ratios (parts by weight) shown in Tables 2-4, mixed by drum, and then fed to a twin-screw extruder (12 blocks, TEX30XCT) manufactured by Japan Steel Works, Ltd. ) in the hopper (hopper). Each resin component was melt-kneaded under conditions of cylinder temperature: 270°C, 200 rpm, and extrusion speed: 25 kg / hour. The molten resin composition extruded in strand form was quenched in a water bath, and pelletized by a pelletizer to obtain polycarbonate resin composition pellets described in Tables 2-4. The obtained resin composition was evaluated for each item by the above-mentioned method.

[0264] The results are shown in Tables 2-4.

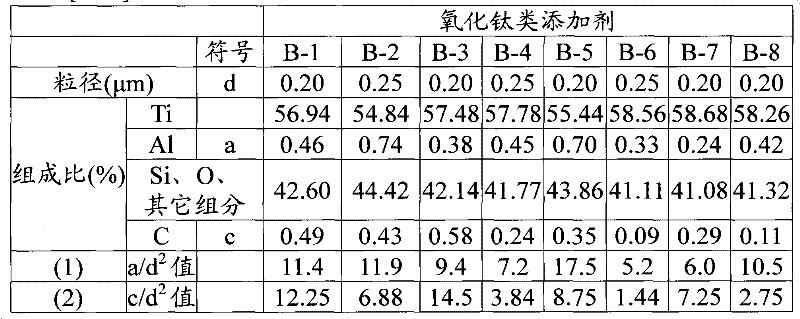

[0265] [Table 2]

[0266]

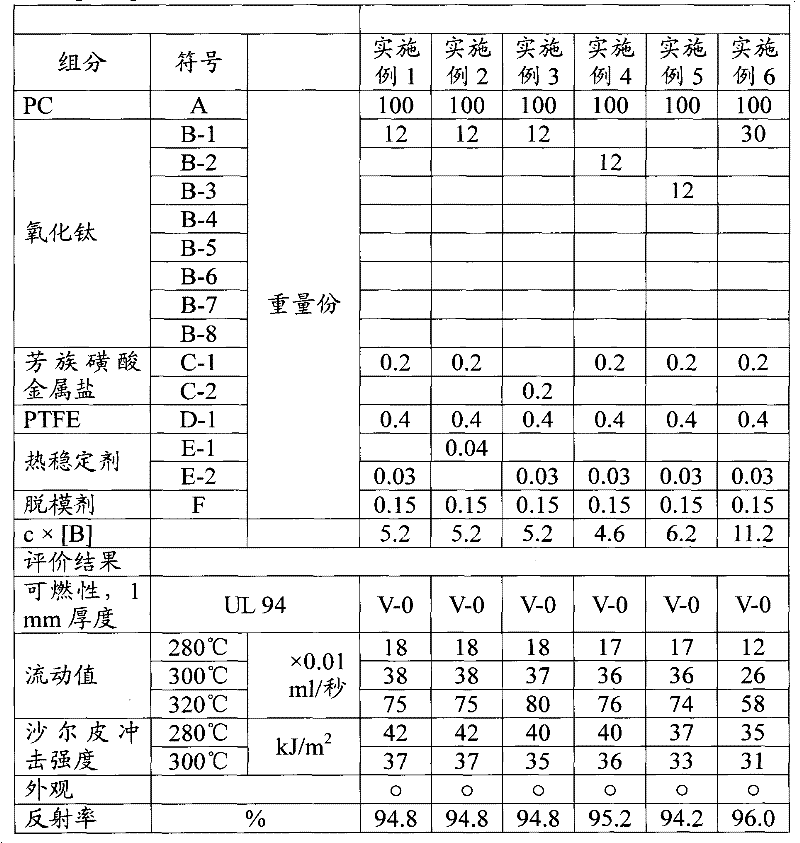

[0267] [table 3]

[0268]

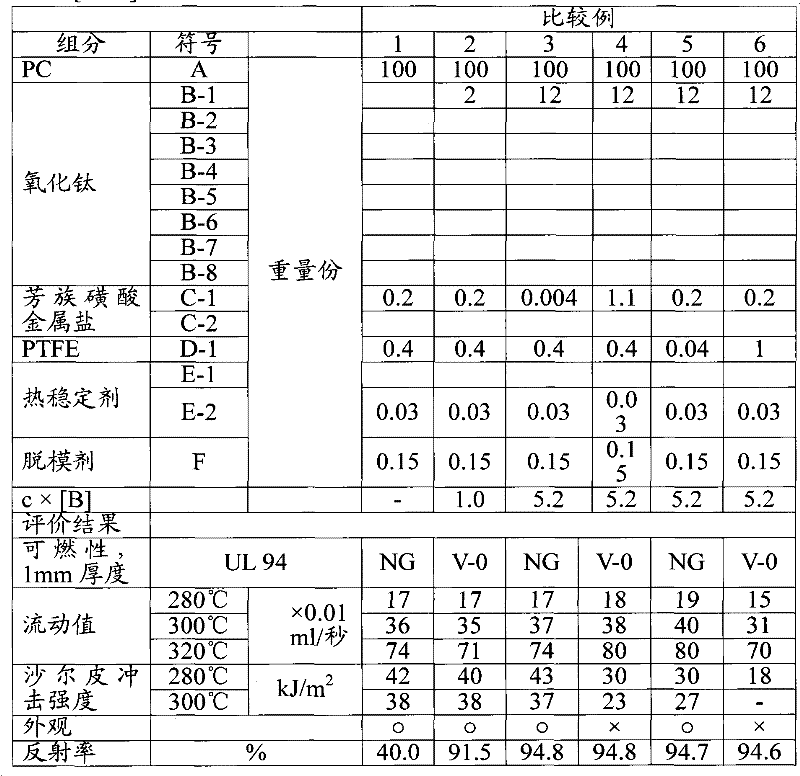

[0269] [Table 4]

[0270]

[0271] From the results shown in Table 2, the following can be found.

[0272] The resin compositions according to Examples 1-6 of the present invention have excellent thermal stability, flammab...

Embodiment 7-13 and comparative example 13-14

[0275] [material to use]

[0276] The raw materials used in Examples 7-13 and Comparative Examples 13-14 are as follows.

[0277]

[0278] The same "Iupiron (registered trademark) H-3000" as used in the aforementioned Examples 1-6 and Comparative Examples 1-12 was used.

[0279]

[0280] The titanium oxide-based additive (B-1) used in the preceding examples was used: trade name "Kronos 2233", produced by Kronos Titan GmbH. (particle size: 0.20 μm, Al content a: 0.46% by weight, carbon content c: 0.49 % by weight, a / d 2 =11.4, c / d 2 = 12.25).

[0281]

[0282] Aromatic sulfonic acid metal salt compounds (C-3)-(C-5)

[0283] Various metal aromatic sulfonate salts with different pH were prepared as follows.

[0284] p-Toluenesulfonic acid was dissolved in ion-exchanged water to prepare a 20% aqueous solution. Thereafter, aqueous sodium p-toluenesulfonate solutions having different pHs were prepared by adding aqueous sodium hydroxide solution while adjusting the additi...

Embodiment 14-15 and comparative example 15

[0307] [material to use]

[0308] The raw materials used in Examples 14-15 and Comparative Example 15 are as follows.

[0309]

[0310] The same polycarbonate resin as used in the foregoing Examples and Comparative Examples was used.

[0311]

[0312] Titanium oxide-based additive (B-1) produced by Kronos Titan GmbH. used previously: trade name "Kronos 2233" (particle size d: 0.20 μm, Al content "a": 0.46% by weight, carbon content: 0.49% by weight %, a / d 2 =11.4, c / d 2 = 12.25).

[0313]

[0314] Sodium p-toluenesulfonate (NATS(C-1)) used in the previous examples was used.

[0315]

[0316] (D-1) "Polyflon F-201L", produced by Daikin Industries, Ltd.

[0317]

[0318] The same heat stabilizer (E-1), heat stabilizer (E-2) and release agent (F) as those used in the aforementioned Examples 1-6 and Comparative Examples 1-12 were used.

[0319] The above-mentioned components were blended at the ratios (parts by weight) shown in Table 6, mixed by a drum, and then fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com