Manufacturing method for large thin-walled impeller

A manufacturing method and impeller technology, which is applied in the field of impeller manufacturing, can solve the problems of flow cooling medium damage, low structure and performance, and reduce machining accuracy, and achieve the effects of improving exhaust and cooling, high surface roughness, and improving surface accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

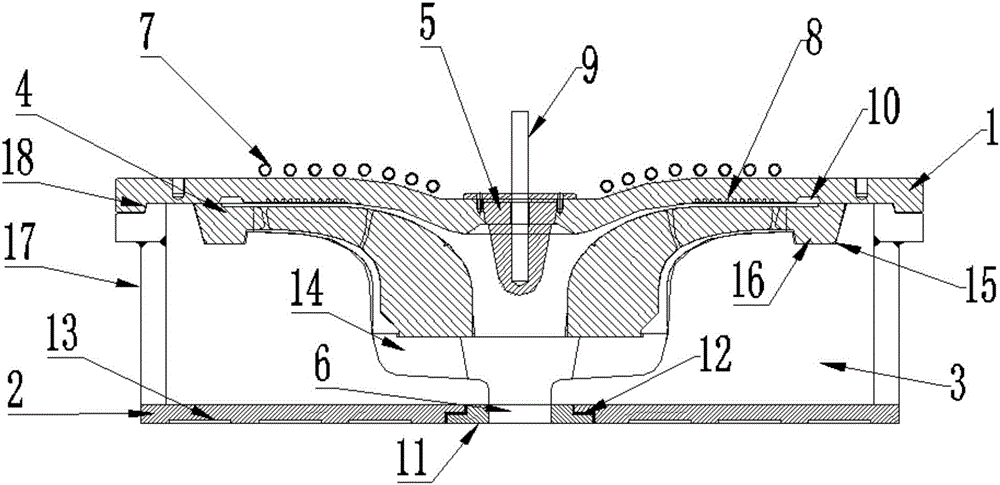

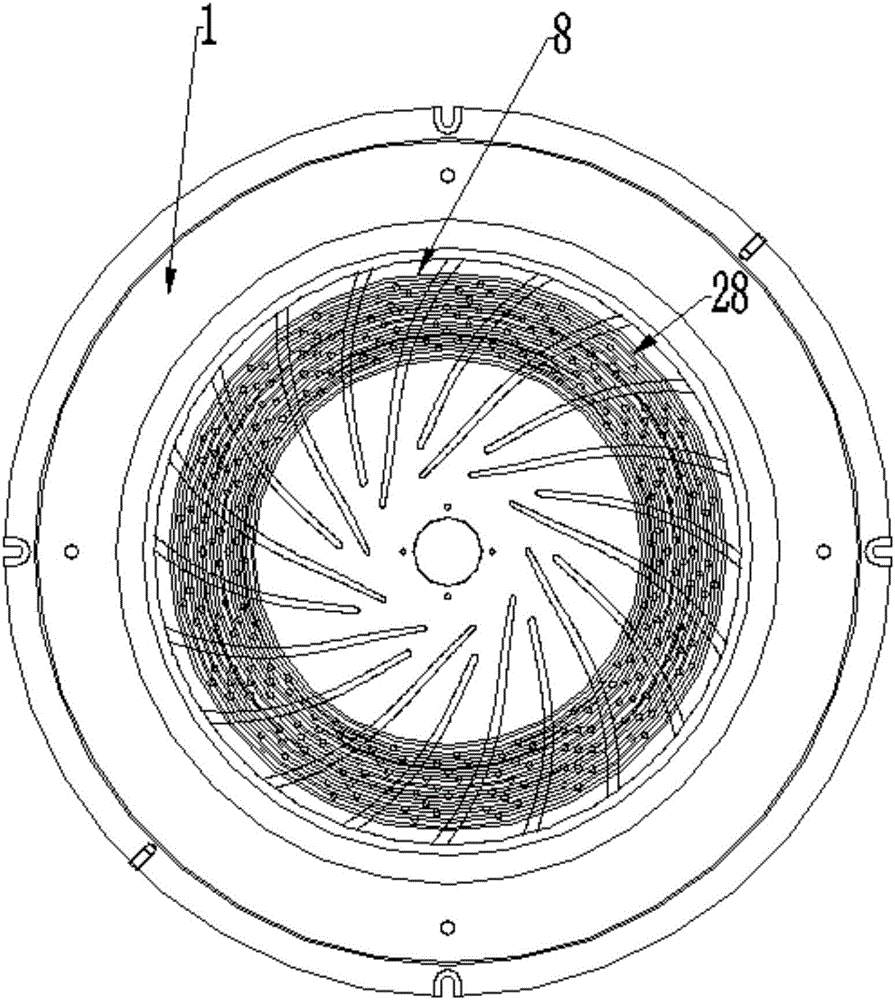

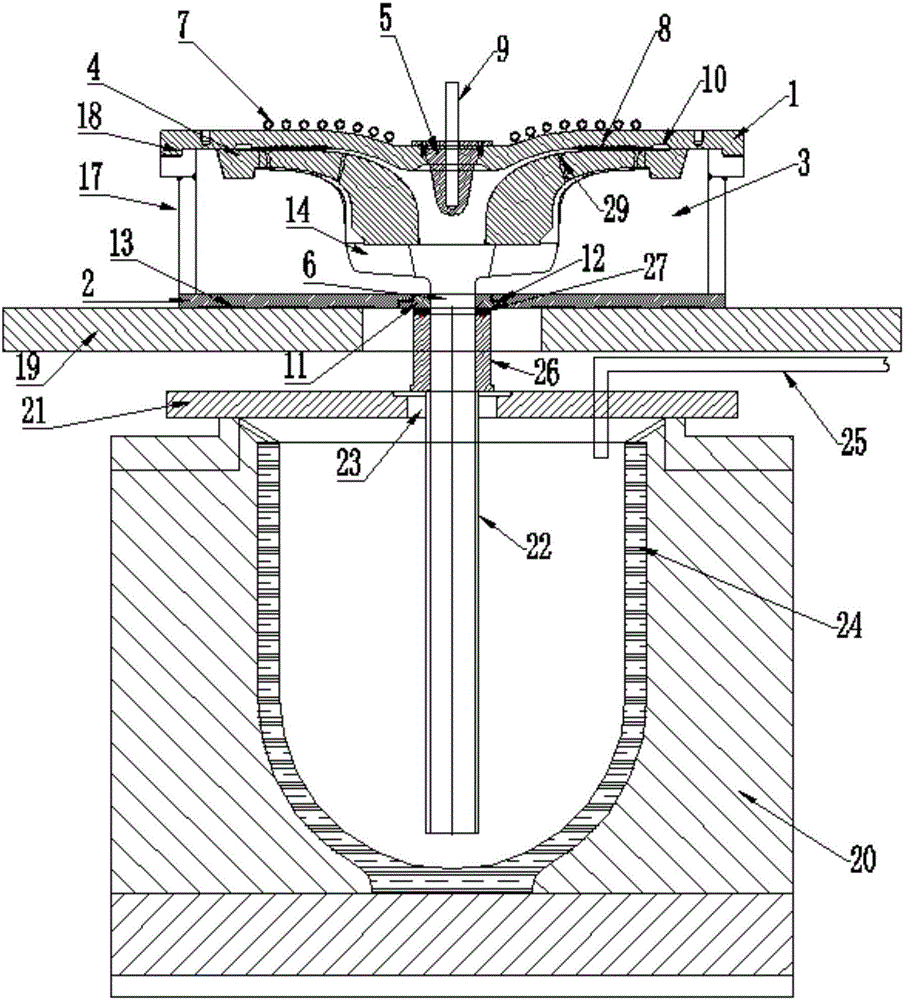

[0080] Such as figure 1 As shown, the casting mold includes an upper mold 1 and a lower mold 2 correspondingly arranged up and down, and a sand mold 3 and a core 4 are arranged in the cavity formed by the upper mold 1 and the lower mold 2, and the upper mold 1 and the lower mold 2 select metal Mold, core 4 selects gypsum core; Upper mold 1 is provided with cooling cone 5 for cooling the inside of the impeller, lower mold 2 is provided with gate 6 for casting solution to enter, and the top of upper mold 1 is provided with for cooling The upper mold 1 is provided with a plurality of cooling rings 7 for jet cooling, and the lower surface of the upper mold 1 is provided with a plurality of ring grooves 8 for exhausting the gas generated during the casting process. The combination of the core 4 and the sand mold 3 in the mold is beneficial to the heat preservation of the bottom aluminum liquid and the feeding of the casting; the cooling ring 7 and the cooling cone set on the upper...

Embodiment 2

[0121] The fixture in the heat treatment in this embodiment includes a heat-resistant supporting plate for placing the impeller, and a blade fixing protection device for protecting the upper and lower blades is provided on the upper surface of the heat-resistant supporting plate. The center of the protection device has a cooling medium flow channel opening; the upper and lower blades are protected by the blade fixing protection device to effectively prevent the deformation of the blades.

[0122] The vane fixing protection device includes an upper vane cover plate arranged above the flow channel opening, and a lower vane cover plate located below the flow channel opening. The upper vane cover plate and the lower vane cover plate are respectively arranged horizontally. A plurality of connecting pieces are arranged vertically, leaving a cooling medium inlet.

Embodiment 3

[0124] The fixture in the turning process in this embodiment includes a bottom plate, and the working surface of the bottom plate is provided with a concave part, and the concave part is matched with the working surface where the large circular surface of the impeller end is located, and the edge of the concave part is provided for locking the first circular surface of the impeller end to the bottom plate The first pressing part is detachably provided on the working surface of the bottom plate for locking the second round surface of the impeller end to the bottom plate. The second pressing part is provided with the second pressing part.

[0125] This solution omits the second recess in the first solution, which can also satisfy the rapid positioning of the impeller. At this time, the fastening plate in the second pressing part is preferably fastened by the bolts arranged in a triangle, so as to improve stability sex.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com