Automatic edge folding mechanism of whole ironing equipment

A kind of equipment and automatic technology, applied in the direction of wrinkle-removing and flattening equipment, ironing machine, washing device, etc., can solve the problems of increased workload, low work efficiency, high labor cost, etc., to reduce production costs, improve work efficiency, Good shape consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

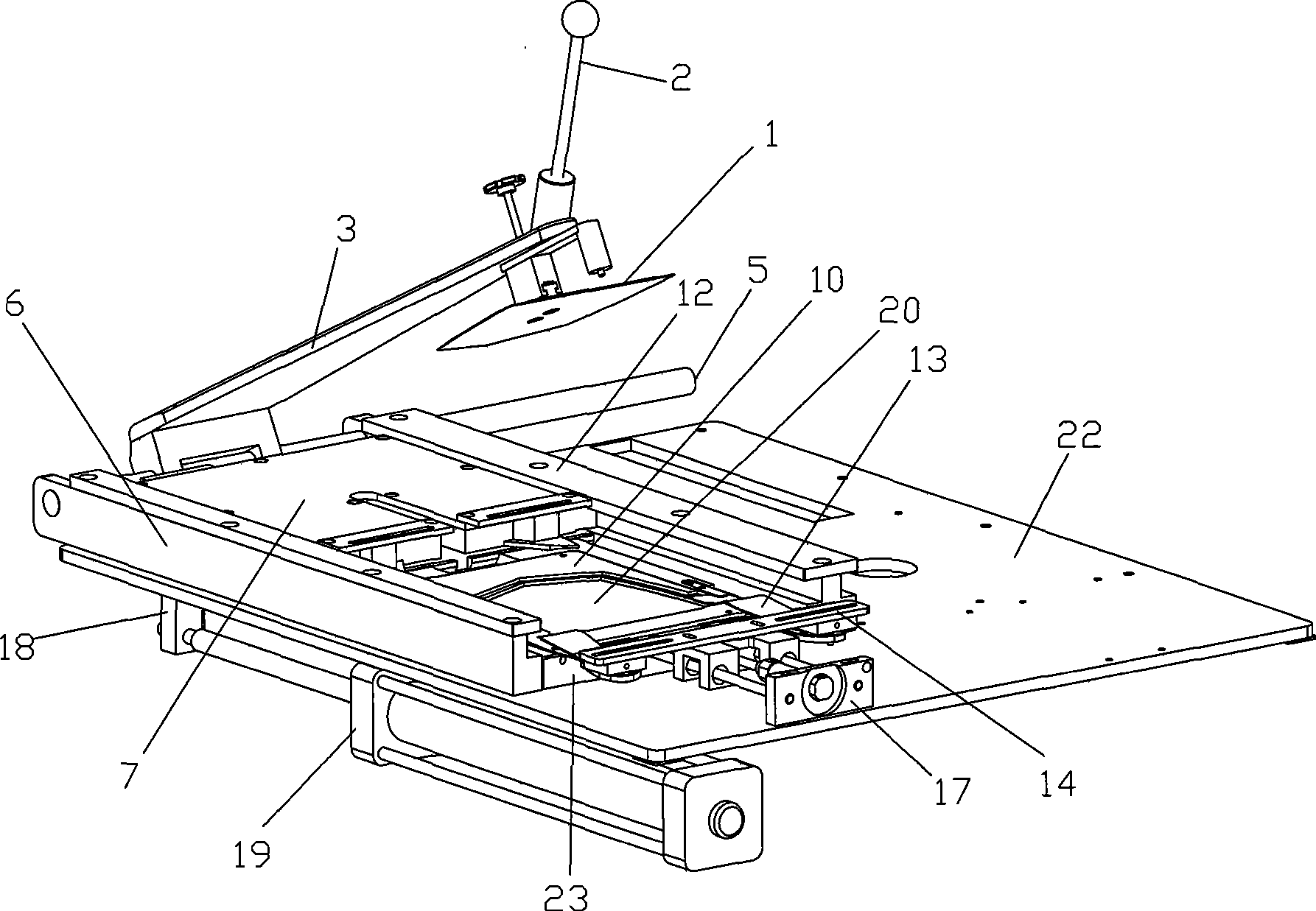

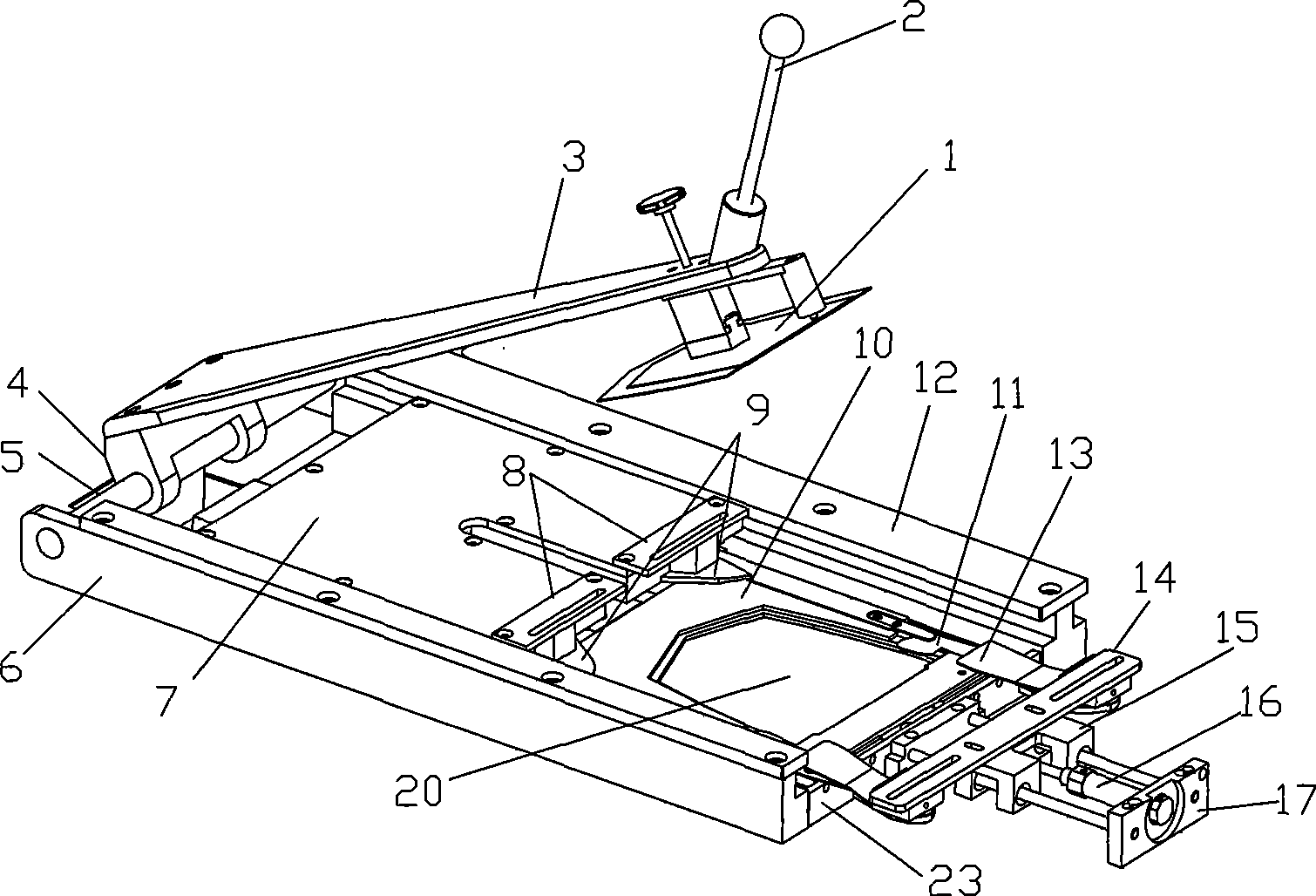

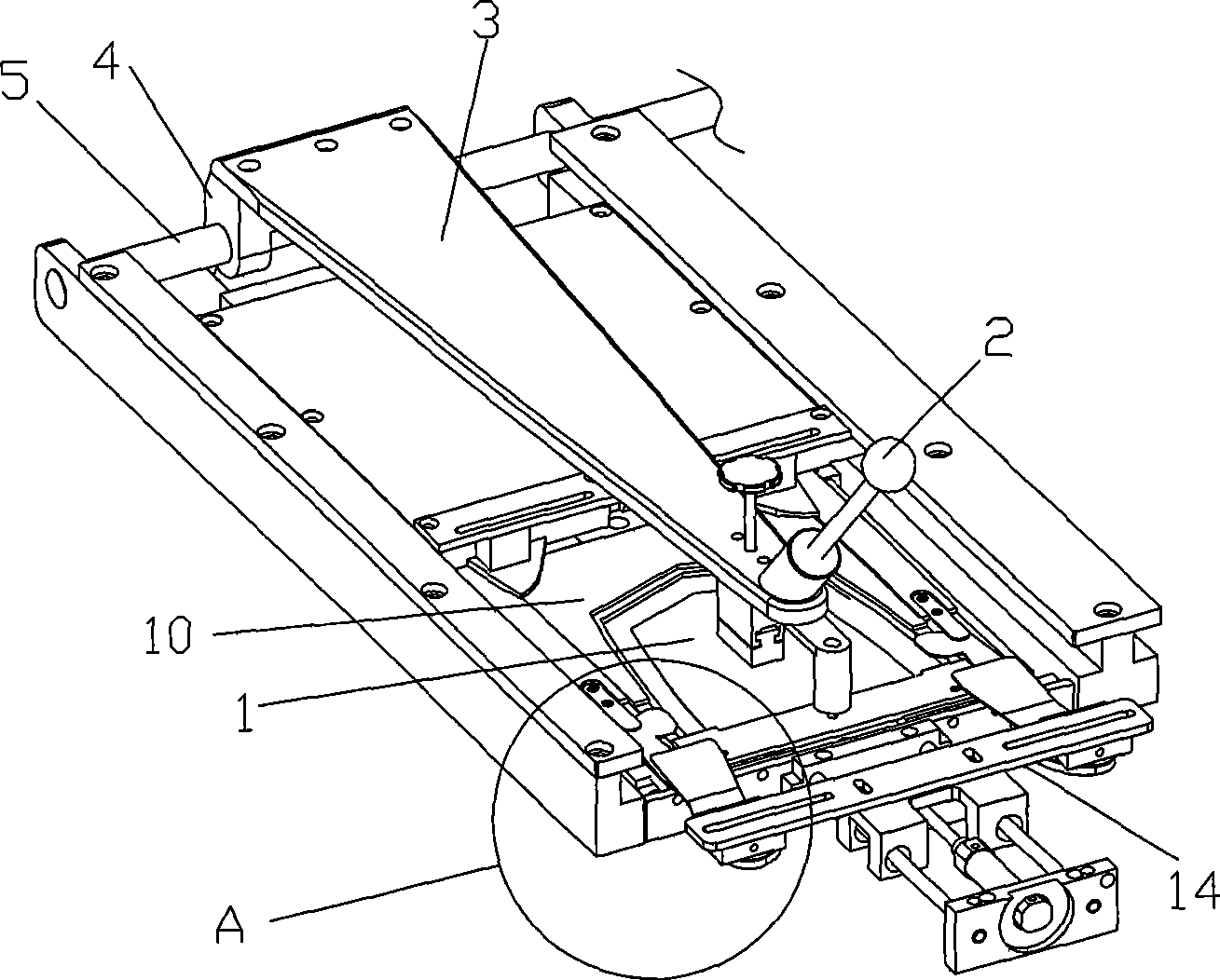

[0015] refer to figure 1 , figure 2 with Figure 5 , the top of the platen 22 of the present invention is provided with a guide rail frame, and the guide rail frame is composed of a left guide rail 6, a right guide rail 12, a transverse shaft 5 and an end plate 23, wherein the left guide rail 6 and the right guide rail 12 are arranged in parallel, and the front end between the two An end plate 23 is provided, a transverse shaft 5 is provided at the rear end, and slide grooves are formed on the insides of the left guide rail 6 and the right guide rail 12 . The guide rail frame top is provided with pressing plate 3, and the front end width of pressing plate 3 is less than the tail end width, and pressing plate seat 4 is equipped with in the tail end, and pressing plate seat 4 is looped in transverse shaft 5. The upper template 1 is installed under the front end of the pressing plate 3 through the mounting block, and the upper template 1 and the mounting block are detachably c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com