Honeycomb carbon fiber energy absorber and its manufacturing method and manufacturing equipment

A honeycomb and carbon fiber technology, applied in the field of energy absorbers, can solve the problems of low energy absorption efficiency, high production cost, and difficulty in processing high-strength metals, and achieve volume and weight reduction, good shape consistency, and high energy absorption efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

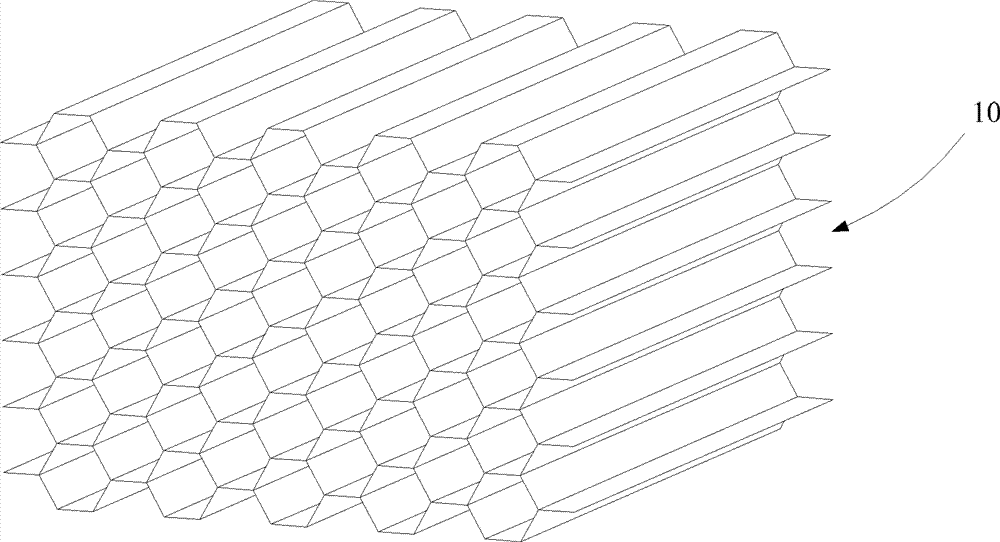

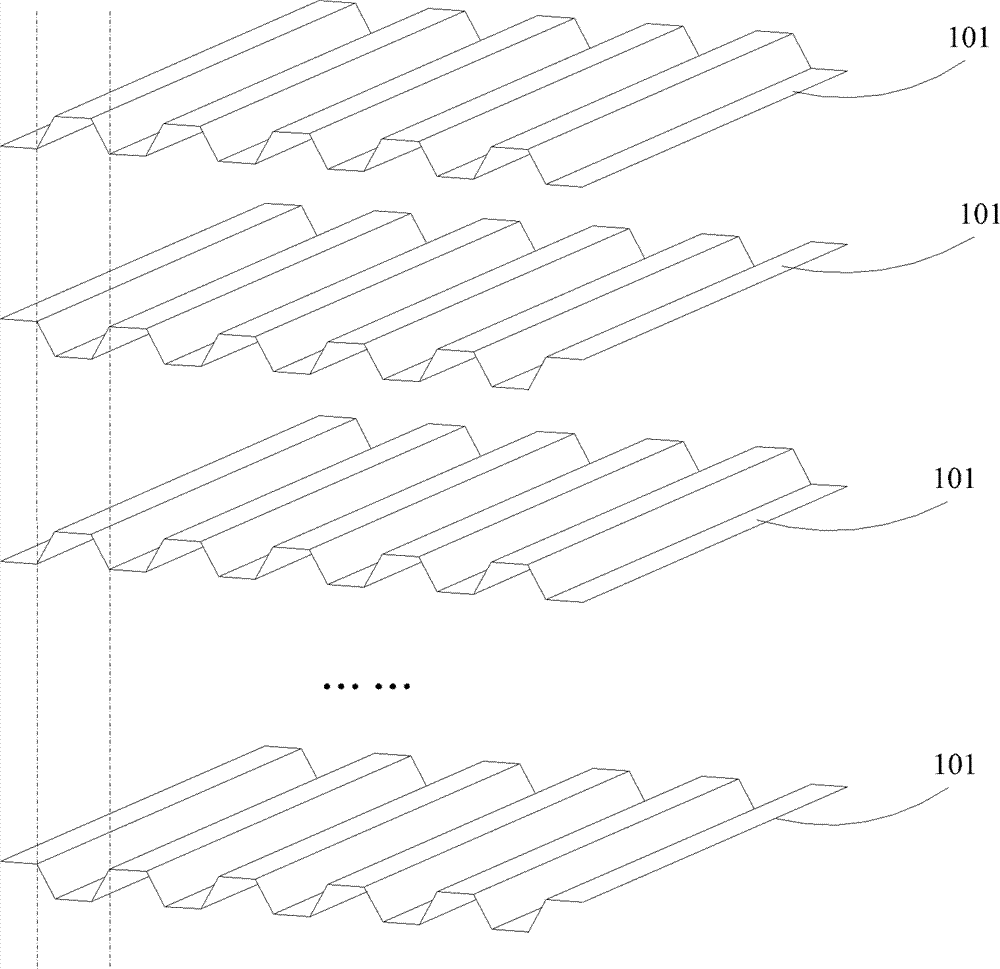

[0028] figure 1 It is a structural schematic diagram of a honeycomb carbon fiber energy absorber according to an embodiment. figure 2 for figure 1 Exploded diagram of the honeycomb carbon fiber energy absorber. Such as figure 1 and figure 2 As shown, the honeycomb carbon fiber energy absorber 10 includes a plurality of corrugated sheets 101 glued together to form a honeycomb. Wherein the corrugated sheet 101 is formed by impregnating carbon fiber cloth with resin.

[0029] Carbon fiber cloth is woven from carbon fiber precursors. It has the advantages of light weight, high strength, high modulus, high temperature resistance up to 2000 ° C, corrosion resistance and fatigue resistance significantly higher than steel and aluminum.

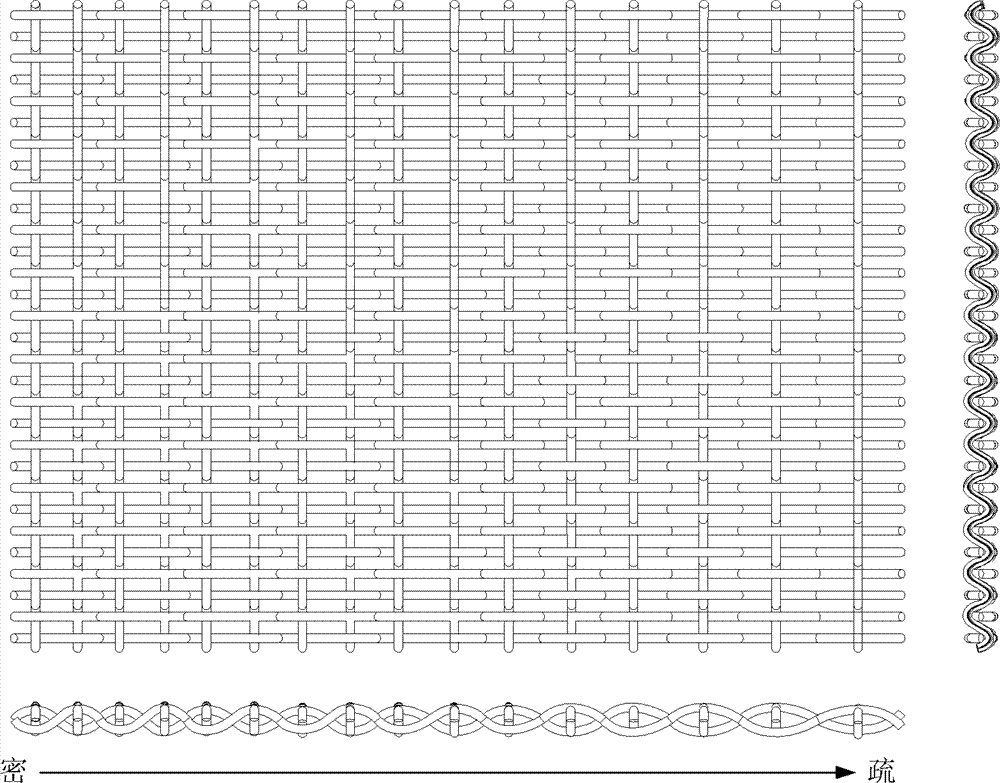

[0030] In one embodiment, the carbon fiber cloth is evenly woven. Uniform weaving means that the spacing between carbon fiber precursors extending in the same direction is consistent, for example, the spacing between carbon fiber precursors ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com