All-in-one thin film temperature sensor

A thin-film temperature and integrated technology, which is applied to thermometers, instruments, and thermometers with electric/magnetic elements that are directly sensitive to heat, can solve the problems of limited use environment and application range, unmeasurable temperature, and detachment, and achieve reflection Consistent speed, light weight, demanding effects

Inactive Publication Date: 2016-03-23

SHENZHEN MINJIE ELECTRONICS TECH

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current film-type thermistor mainly encapsulates the bare-chip thermistor in the film through a metal bracket, and then solders the metal bracket and the pins of the thermistor by soldering. Since the melting temperature of the solder is about 180°C, and When the temperature exceeds 180°C, the connection between the pins of the thermistor and the bracket will be separated due to the melting of the solder, resulting in the inability to measure the temperature. Moreover, the longest length of this film-type thermistor is generally only 50mm, and it needs to be connected through a wire. connection, and the connection must be insulated, so its use environment and application range are relatively limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

no. 2 example

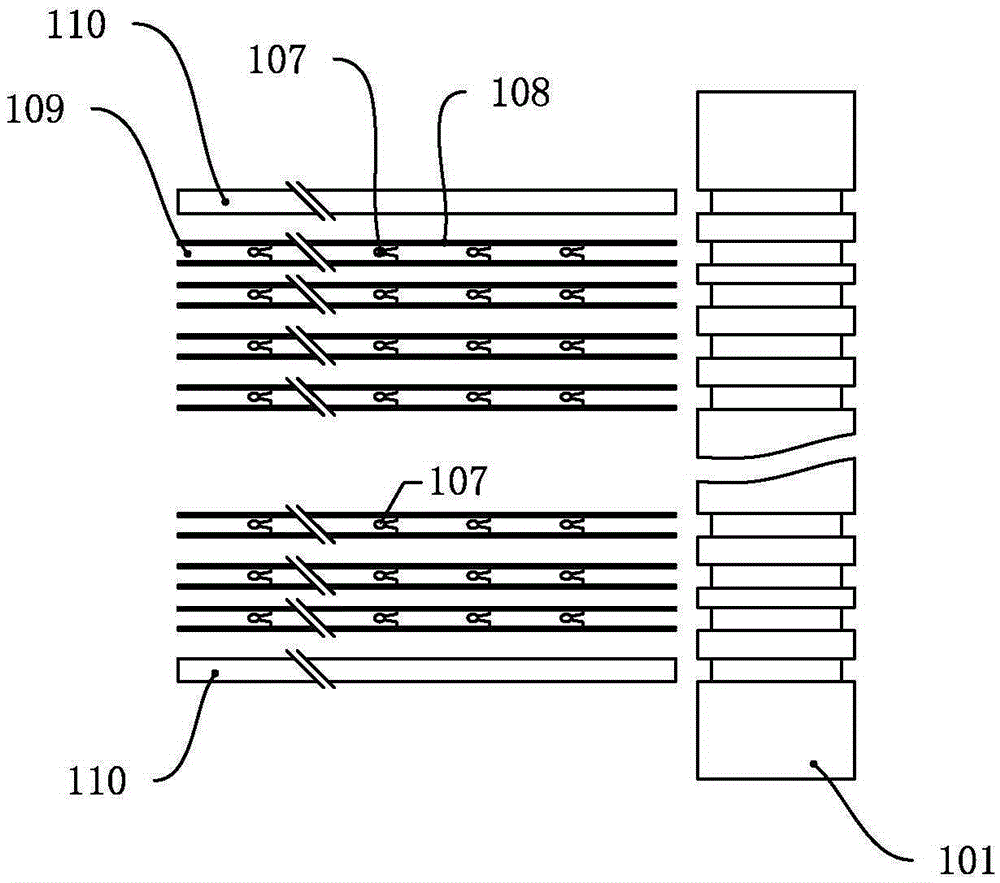

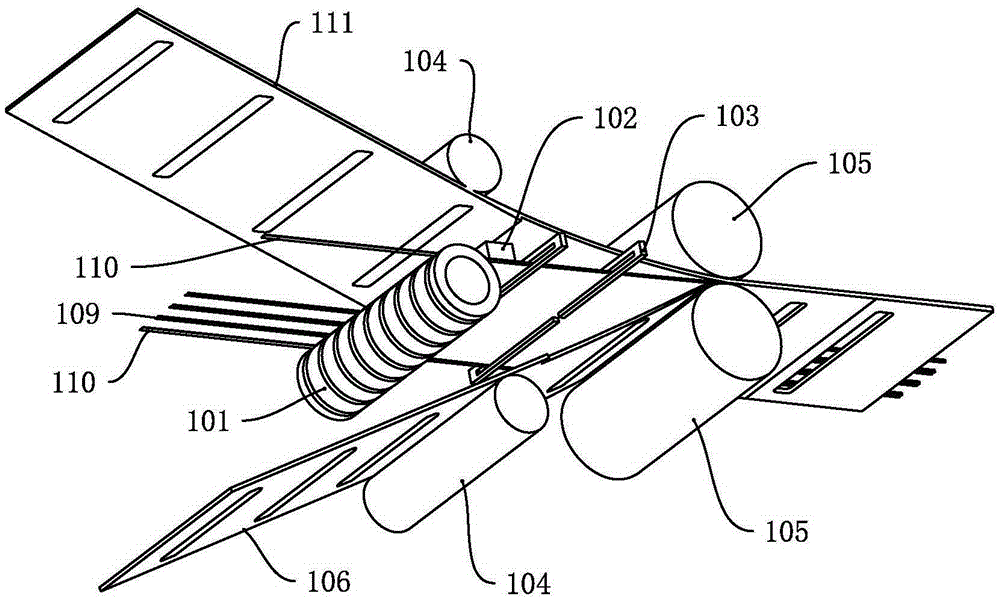

[0042] Second embodiment, such as Figure 4 As shown, the difference between this embodiment and the first embodiment is: the manipulator is replaced by a guide wheel, and the wire and film with thermistor are sent into the heating roller, and the others are the same.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

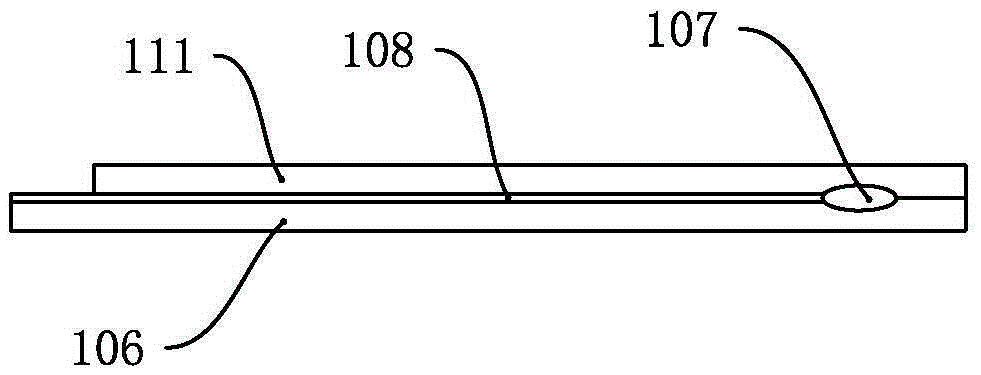

The invention discloses an all-in-one thin film temperature sensor. A final product profile map of the invention is an NTC temperature sensor which comprises an upper thin film layer and a lower thin film layer, wherein at least two conducting wires are covered between the upper thin film layer and the lower thin film layer, and an NTC thermistor is welded between the conducting wires. The all-in-one thin film temperature sensor has the advantages that the NTC temperature sensor has good appearance consistency; the NTC temperature sensor has good responding speed consistency; equipment has a high degree of automation, and less staffs are required; and mass production can be realized easily.

Description

technical field [0001] The invention relates to an integrated film temperature sensor and production equipment. Background technique [0002] The thermistor temperature sensor is a temperature sensor that uses the principle that the resistance value of a conductor or semiconductor changes with temperature to measure temperature, including thin-film thermistors and NTC temperature sensors. The current film-type thermistor mainly encapsulates the bare-chip thermistor in the film through a metal bracket, and then solders the metal bracket and the pins of the thermistor by soldering. Since the melting temperature of the solder is about 180°C, and When the temperature exceeds 180°C, the connection between the pins of the thermistor and the bracket will be separated due to the melting of the solder, resulting in the inability to measure the temperature. Moreover, the longest length of this film-type thermistor is generally only 50mm, and it needs to be connected through a wire. T...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01K7/22

Inventor 伍洁漫王莉花国樑彭华军

Owner SHENZHEN MINJIE ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com