Method for preparing carbon-film-coated tungsten oxide nanospheres in one step by using hydrothermal process and application of carbon-film-coated tungsten oxide nanospheres

A tungsten oxide and nanosphere technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, tungsten oxide/tungsten hydroxide, etc., can solve the problem that the circuit component system cannot meet the measurement requirements, the accuracy requirements are very high, and the convenience is not enough. problem, to achieve good glucose detection performance, excellent electrochemical performance, strong anti-interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

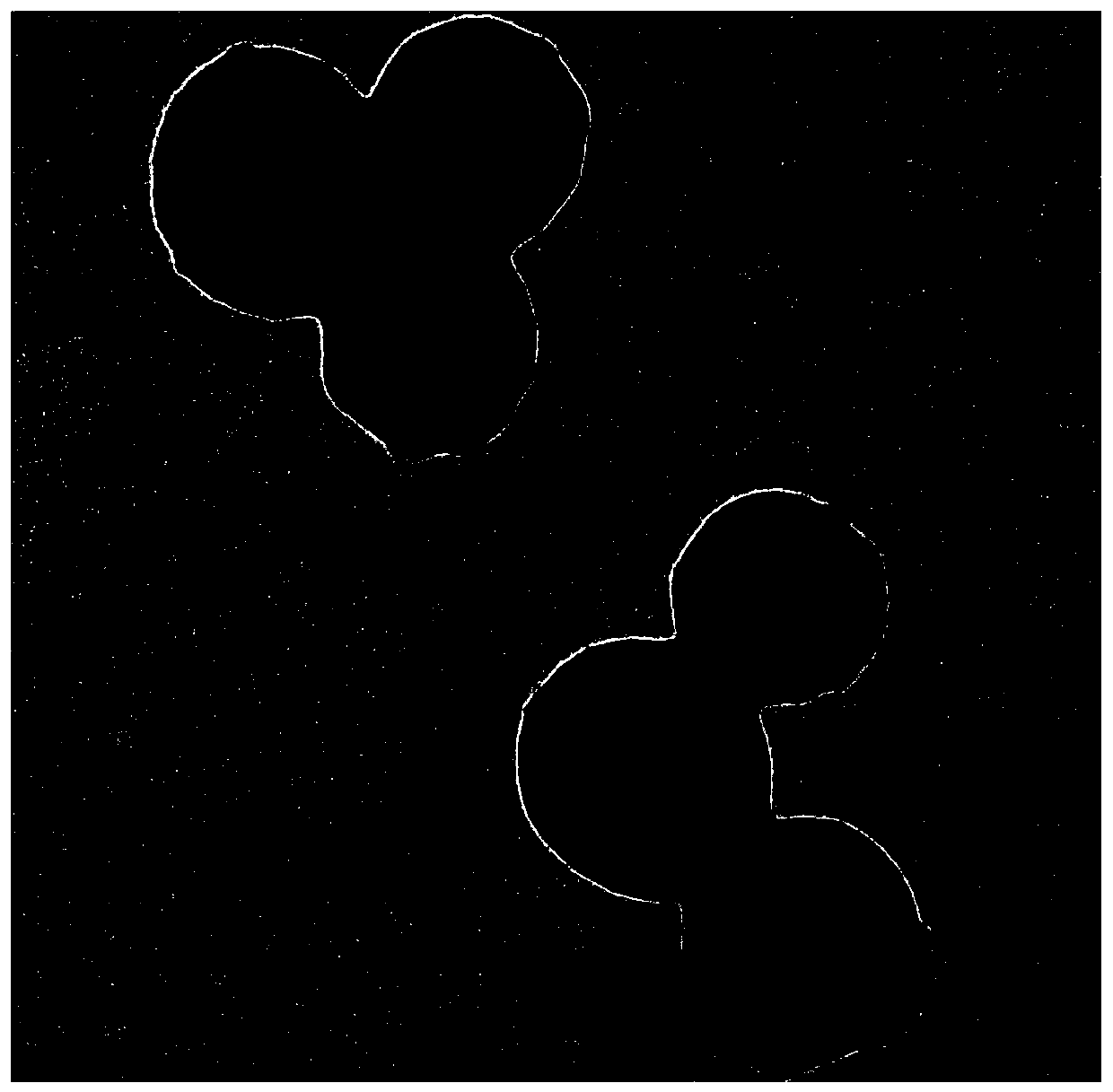

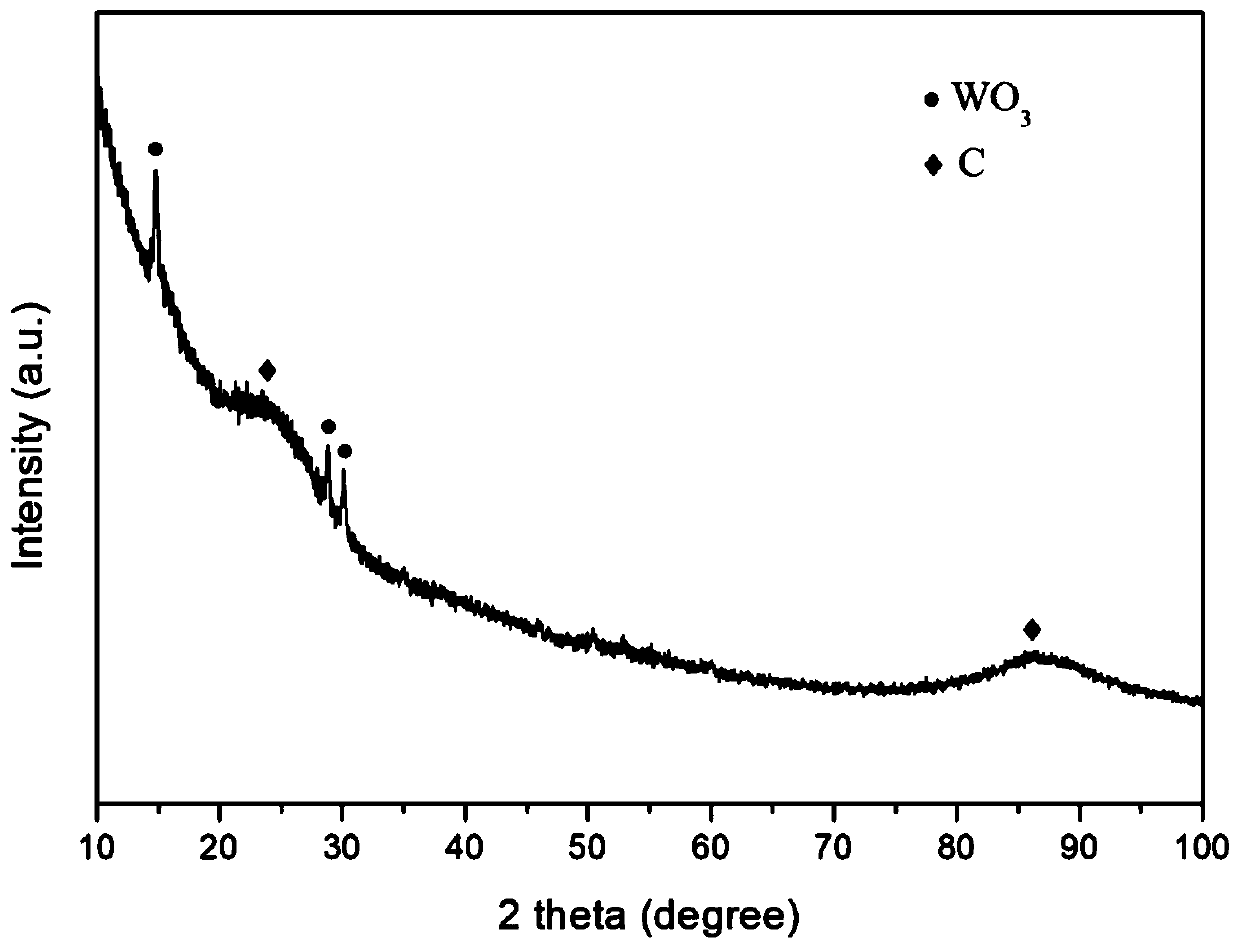

[0043] Weigh 57mg of ammonium paratungstate and 100mg of glucose; fully dissolve the above-weighed ammonium paratungstate in 36ml of deionized water under the condition of ultrasonic heating and heating at 60°C, put in the weighed glucose and stir evenly; put the above-mentioned mixed solution of ammonium paratungstate and glucose into into the reaction kettle, heated at 180°C for 12 hours, then cooled naturally for 10 hours to obtain the turbid liquid after the reaction; the obtained turbid liquid was alternately washed and centrifuged with deionized water and ethanol for several times until the supernatant was nearly colorless, The obtained solid precipitate was vacuum-dried at 40° C. for 12 hours to obtain carbon film-coated tungsten oxide nanosphere powder.

Embodiment 2

[0045] Weigh 57mg of ammonium paratungstate and 100mg of glucose; fully dissolve the above-weighed ammonium paratungstate in 36ml of deionized water under the condition of ultrasonic heating and heating at 60°C, put in the weighed glucose and stir evenly; put the above-mentioned mixed solution of ammonium paratungstate and glucose into Put it into the reaction kettle, heat the hydrothermal reaction at 180°C for 10 hours, then cool it naturally for 10 hours to obtain the turbid liquid after the reaction; wash the obtained turbid liquid with deionized water and ethanol alternately and centrifuge several times until the supernatant is nearly colorless, The obtained solid precipitate was vacuum-dried at 40° C. for 12 hours to obtain carbon film-coated tungsten oxide nanosphere powder.

Embodiment 3

[0047] Weigh 57mg of ammonium paratungstate and 50mg of glucose; fully dissolve the above-weighed ammonium paratungstate in 36ml of deionized water under the condition of ultrasonic heating and heating at 60°C, put in the weighed glucose and stir evenly; put the above-mentioned mixed solution of ammonium paratungstate and glucose into Put it into the reaction kettle, heat the hydrothermal reaction at 180°C for 10 hours, then cool it naturally for 10 hours to obtain the turbid liquid after the reaction; wash the obtained turbid liquid with deionized water and ethanol alternately and centrifuge several times until the supernatant is nearly colorless, The obtained solid precipitate was vacuum-dried at 40° C. for 12 hours to obtain carbon film-coated tungsten oxide nanosphere powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com