Patents

Literature

92results about How to "Continuous bending" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

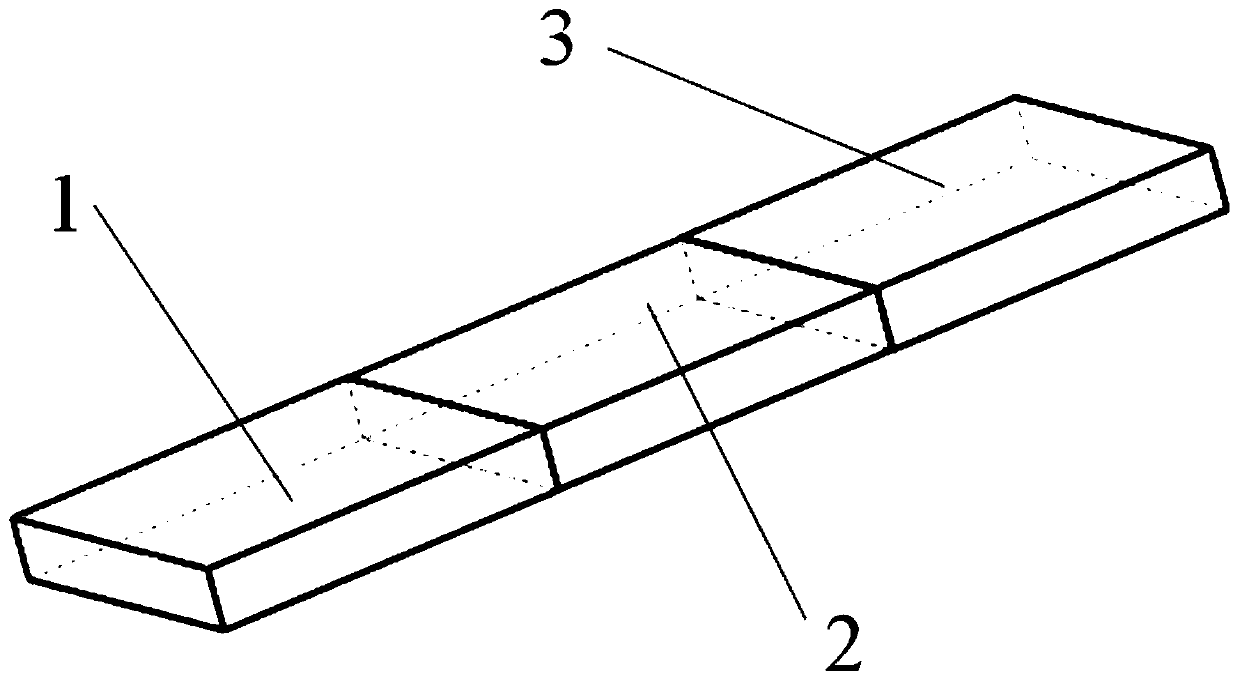

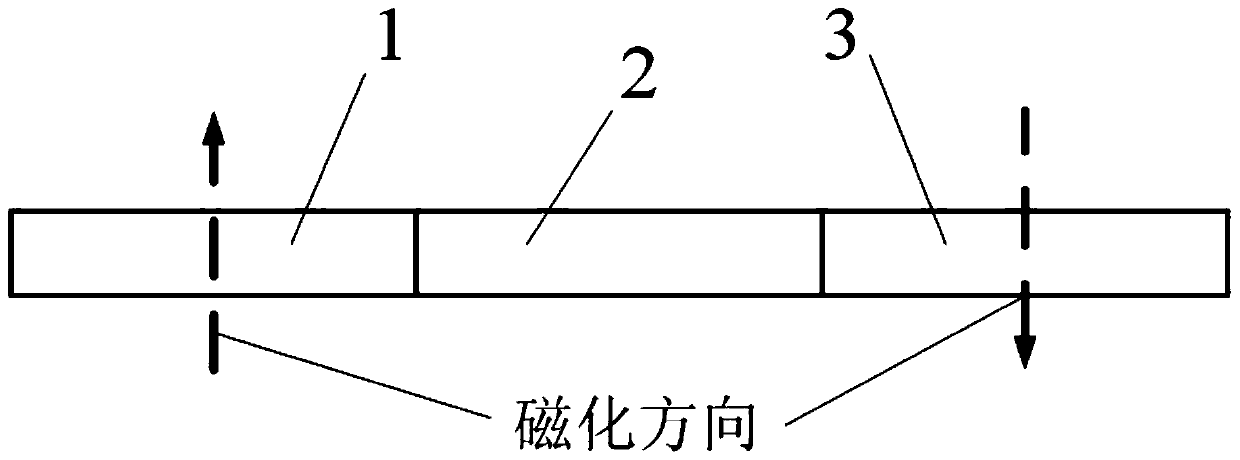

Magnetic control micro soft crawling robot and preparation and application method thereof

ActiveCN110722545AContinuous bendingContinuum stretching exerciseProgramme-controlled manipulatorClassical mechanicsMechanical engineering

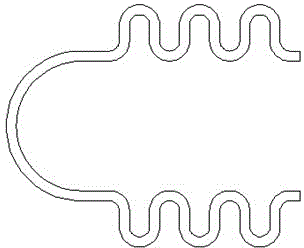

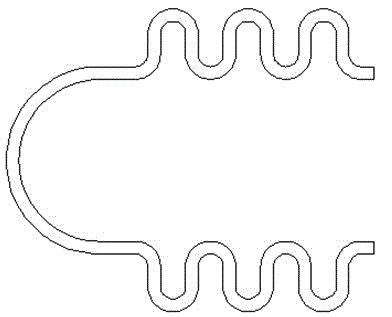

The invention relates to a magnetic control micro soft crawling robot. The magnetic control micro soft crawling robot comprises a head part, a tail part and a joint, wherein the head part and the tailpart are positioned on the same plane, and the joint is connected with the head part and the tail part. The head part and the tail part are magnetized, the head part is magnetized in the direction perpendicular to the plane where the robot is positioned upwards, the tail part is magnetized in the direction perpendicular to the plane where the robot is positioned downwards, and the joint can be bent into an arch shape under the action of an external magnetic field. The invention further provides a preparation method and an application method of the magnetic control micro soft crawling robot. The magnetic control micro soft crawling robot can be driven by an alternating magnetic field to achieve crawling or steering movement.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

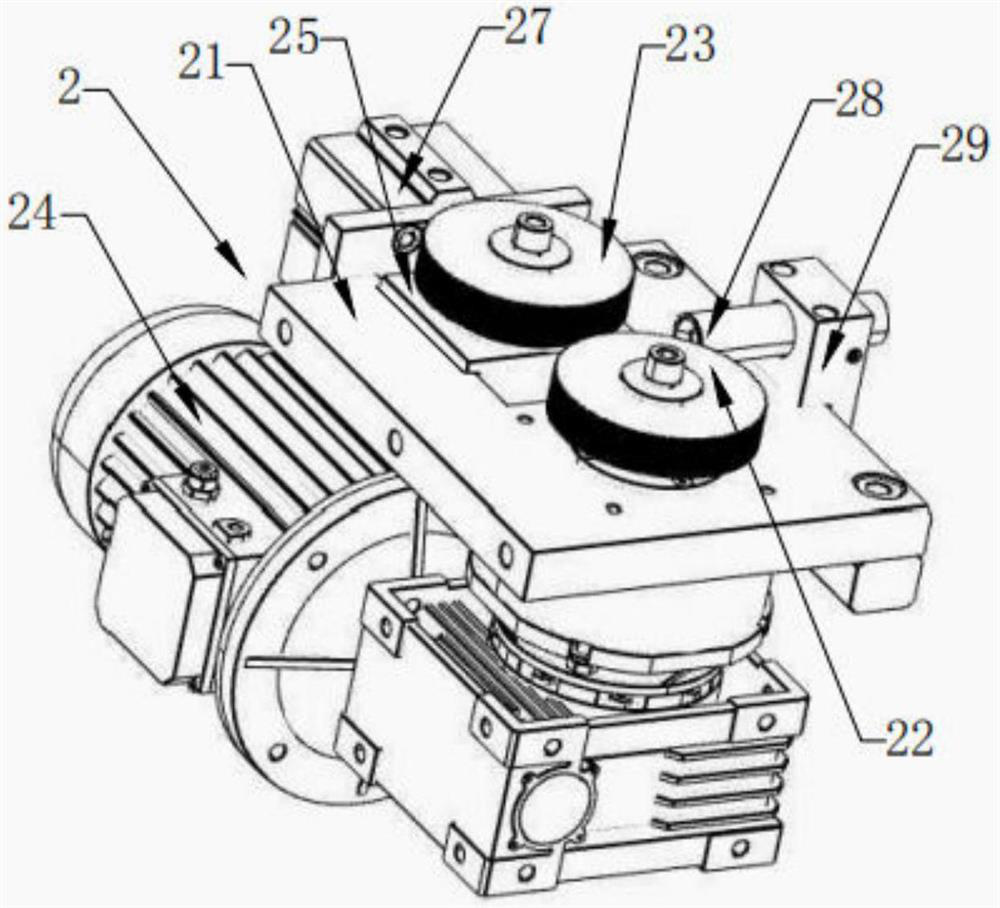

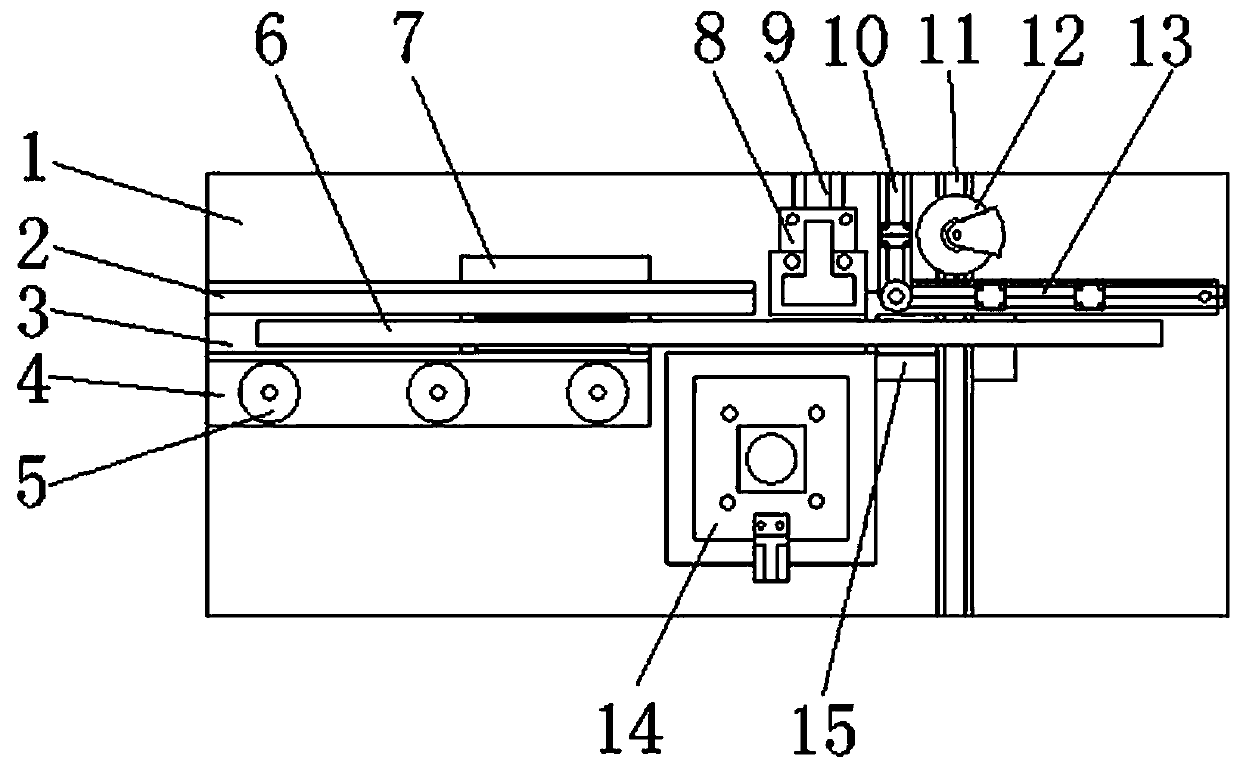

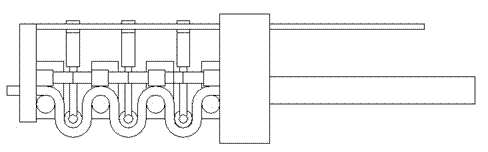

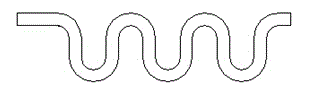

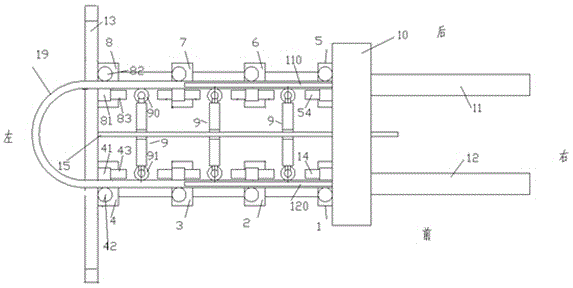

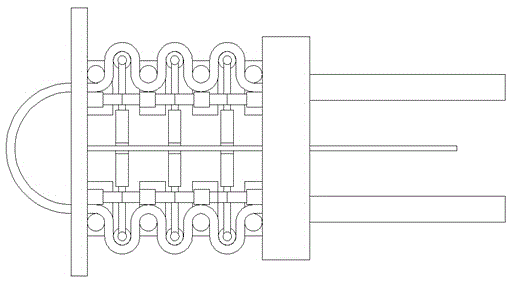

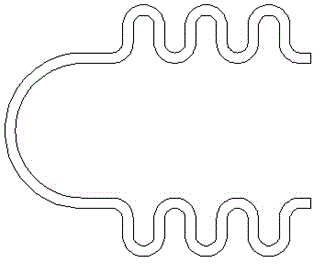

Bender of steel-wire mesh

The invention, which relates to the field of the steel-wire mesh processing equipment, provides a bender of a steel-wire mesh. The bender comprises a rack and a power unit. The rack includes a first side support plate and a second side support plate; and a moulding channel is encircled by the first side support plate and the second side support plate. One end of the moulding channel is feeding end of a steel-wire mesh and the other end is a discharging end of the steel-wire mesh. Power rollers and moulding rollers are successively arranged from the steel-wire mesh feeding end and the steel-wire mesh discharging end; the power rollers and the moulding rollers and the first side support plate and the second side support plate are in rotating cooperation mode. A steel-wire mesh feeding channel is formed between the upper power roller and the lower power roller of each pair of power rollers; and an upper pressing wheel and a lower pressing wheel is arranged at each pair of moulding rollers. At the marching direction of the steel-wire mesh, the external diameter of the upper pressing wheel and the external diameter of the lower pressing wheel are increased successively; and the distance between the each two adjacent two lower pressing wheels is reduced. The power unit and the power rollers are in transmission connection. According to the bender, the multiple moulding rollers are bent step by step for moulding; the moulding precision is high; continuous bending is realized; and the processing efficiency is high.

Owner:四川鸥克建材科技有限公司

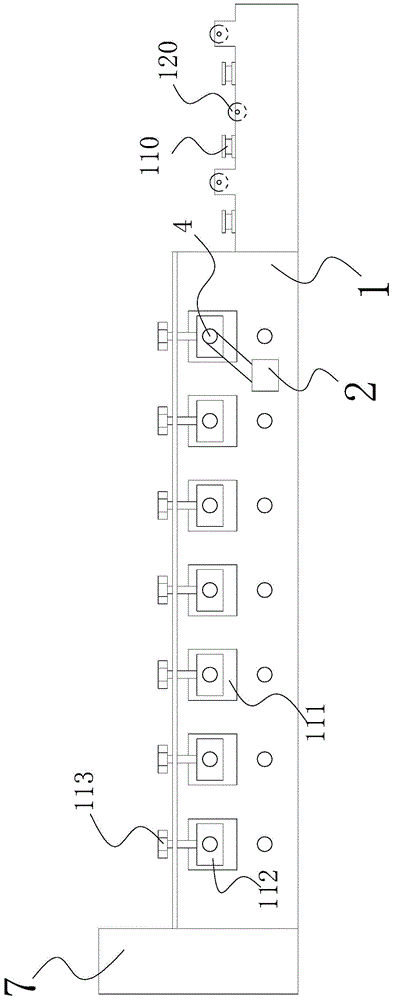

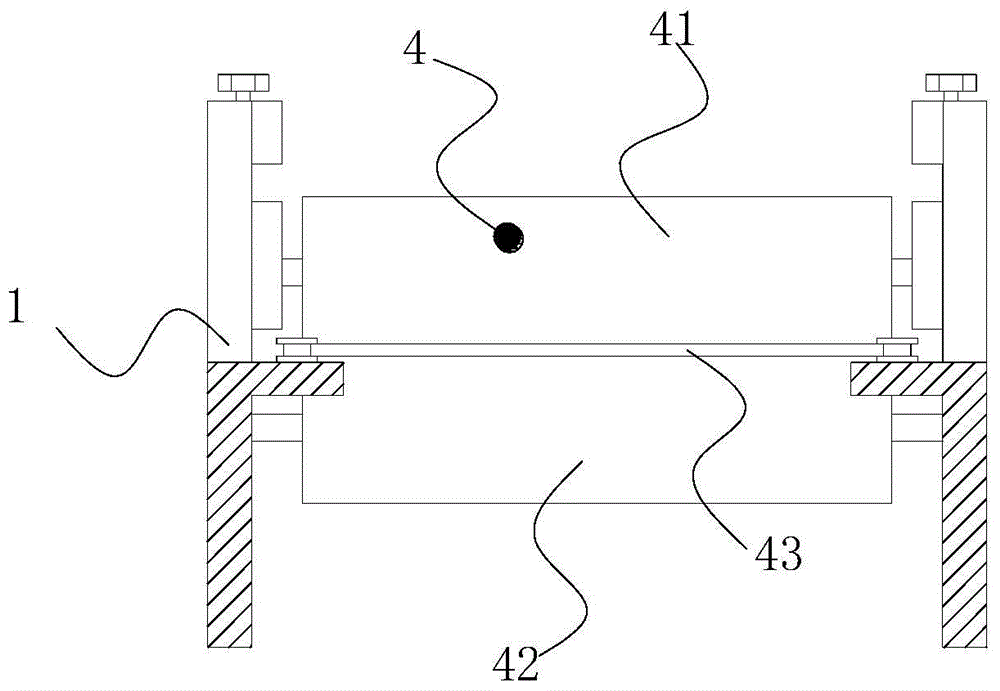

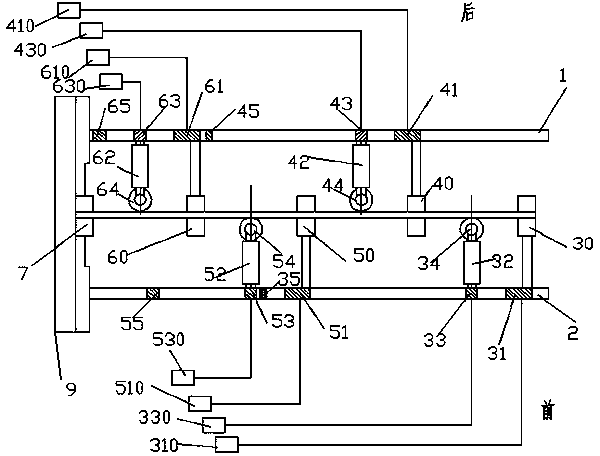

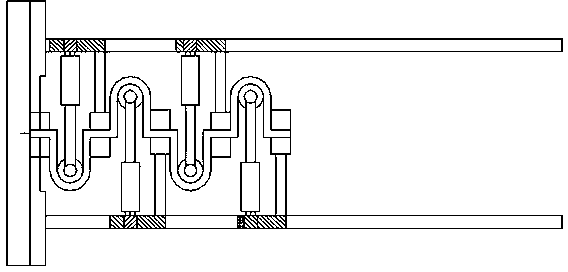

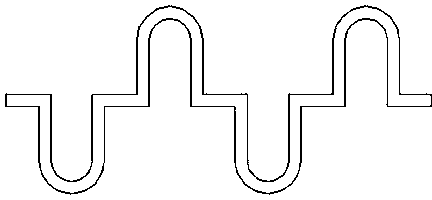

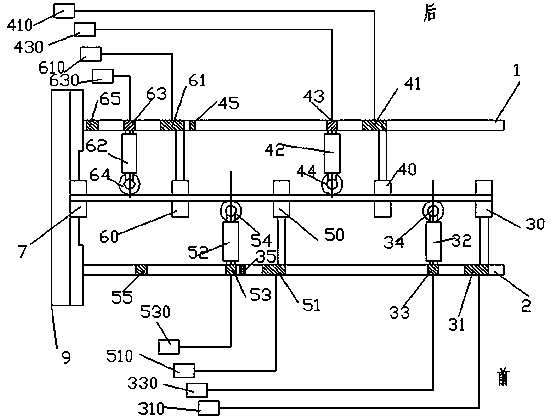

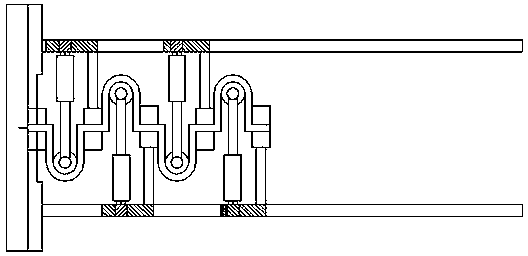

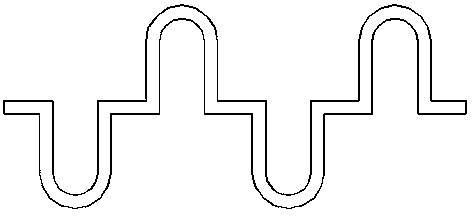

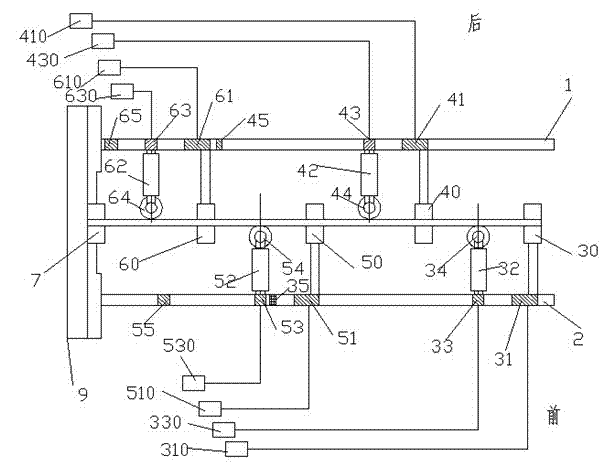

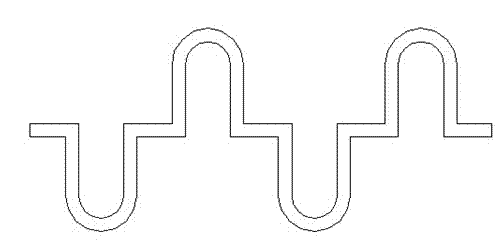

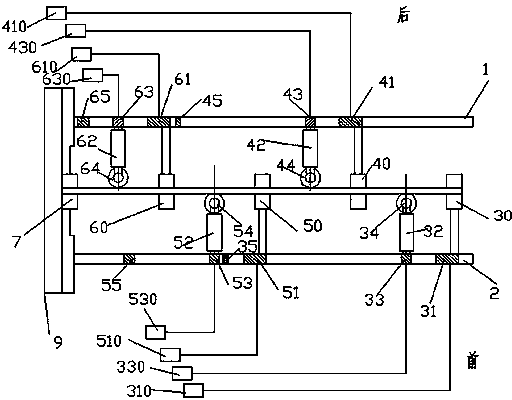

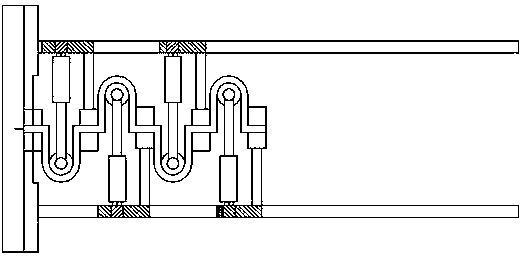

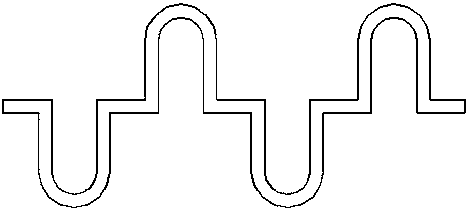

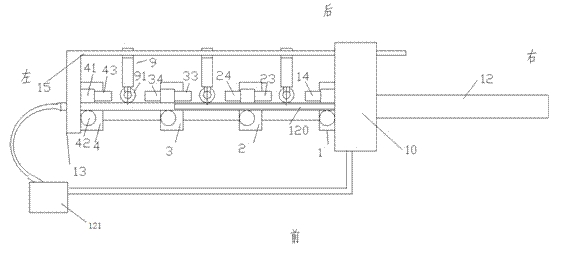

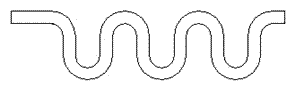

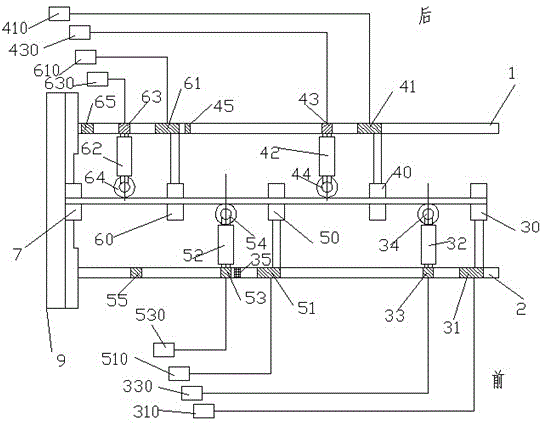

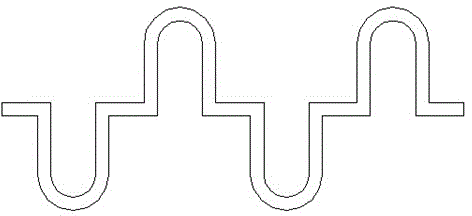

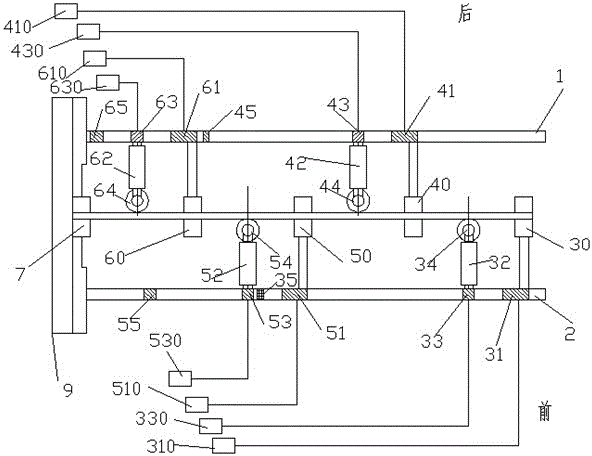

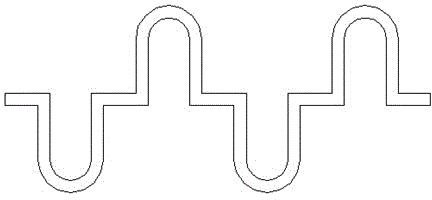

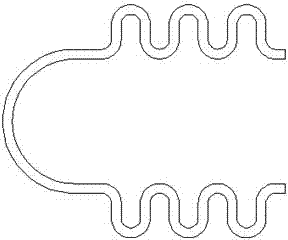

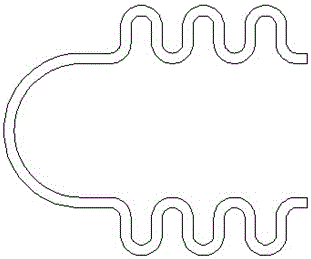

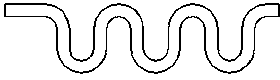

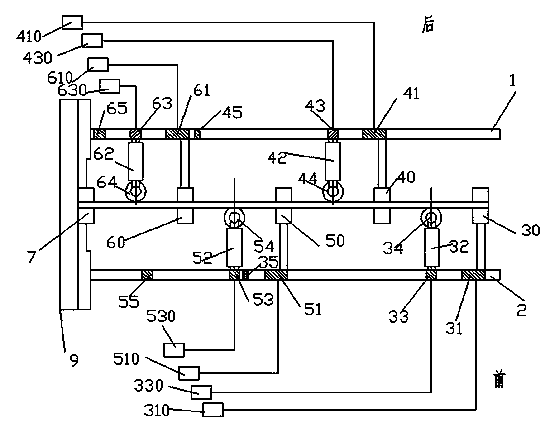

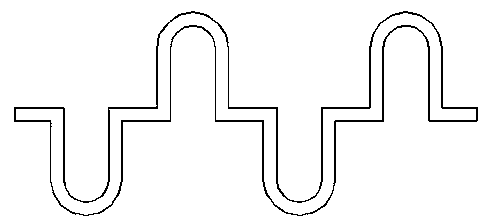

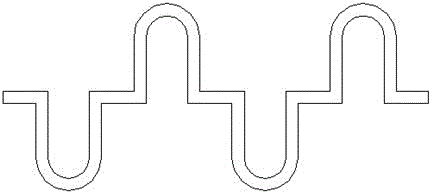

Furnace wire bending process adopting screw rod type clamping device and adopting heat treatment

The invention provides a furnace wire bending process adopting a screw rod type clamping device and adopting heat treatment. Row wires of furnace wires of a heating furnace are rectangular row wires formed by the furnace wires of the heating furnace through linear arrangement in a vertical direction, a bending device is used in the process and comprises a support frame, a front horizontal guide rail and a back horizontal guide rail are respectively arranged in a front position and a back position of the right side of the support frame, a support frame clamping device is arranged in the middle position of the right side of the support frame and is positioned between the front horizontal guide rail and the back horizontal guide rail, a first bending device is arranged at the right part of the back horizontal guide rail, a third bending device is arranged at the left part of the back horizontal guide rail, a second bending device is arranged at the right part of the front horizontal guide rail, a fourth bending device is arranged at the left side of the front horizontal guide rail, and the bending devices are respectively used for forming four U-shaped bending parts on the row wires of the furnace wires of the heating furnace from the left side to the right side.

Owner:广州市青荷金属制品有限公司

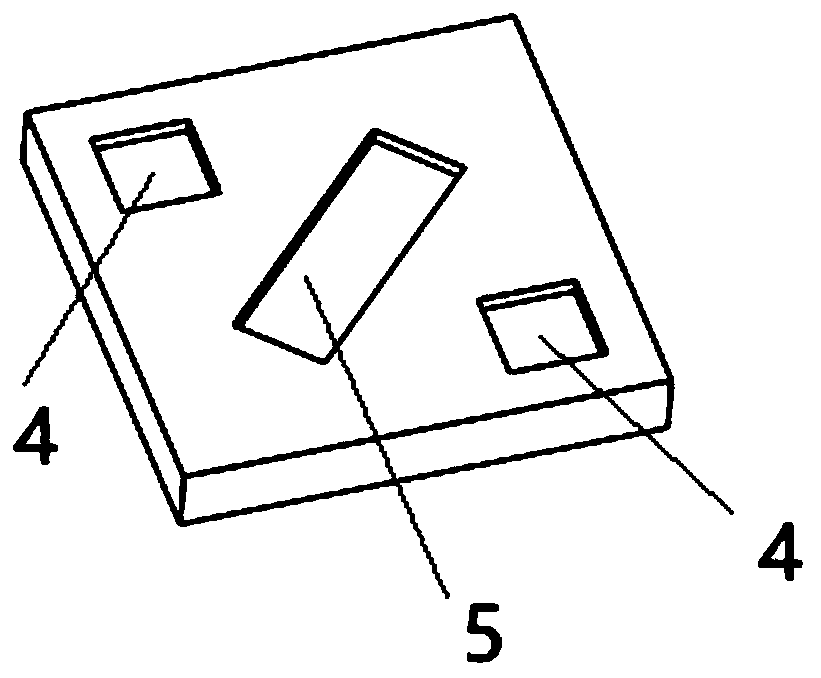

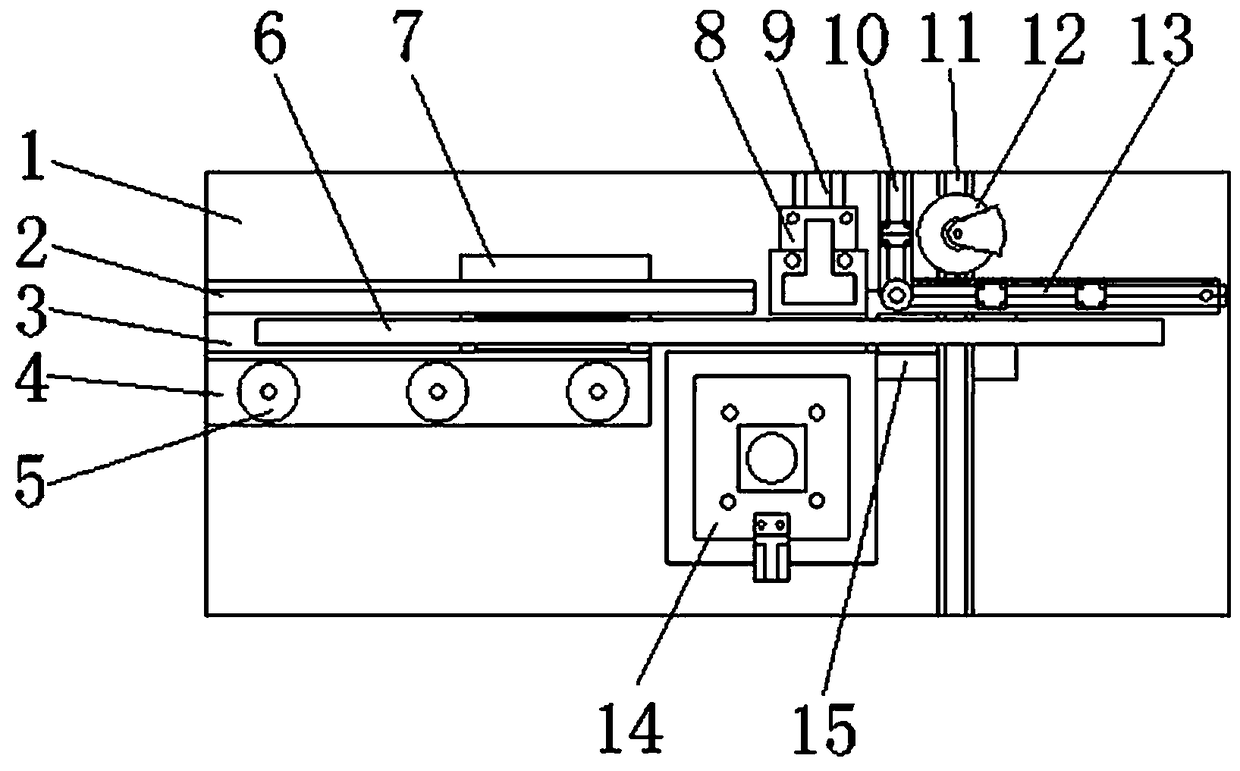

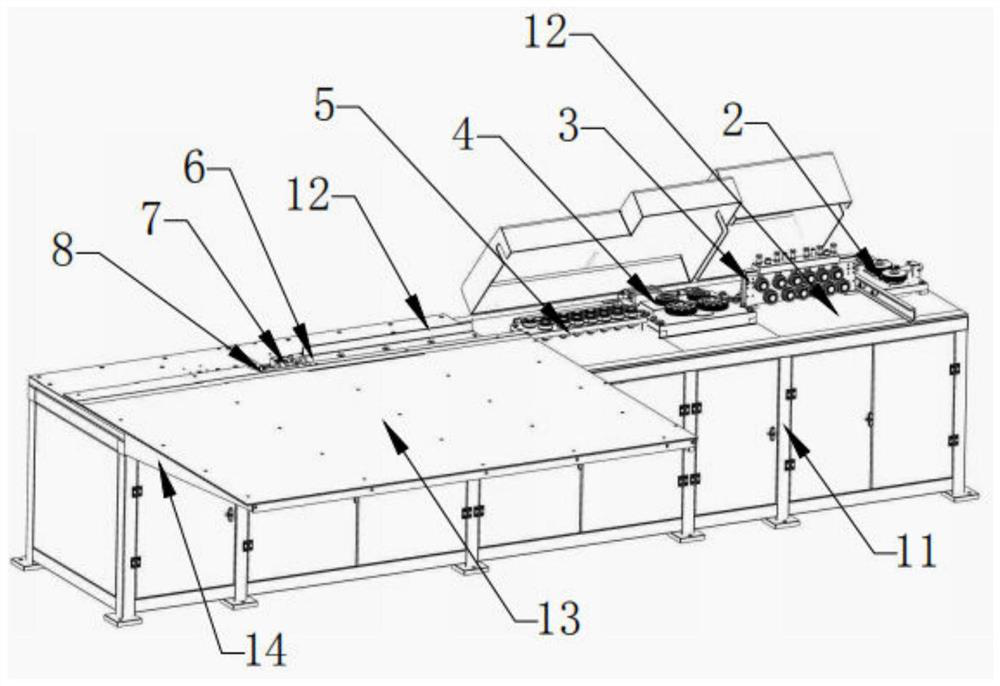

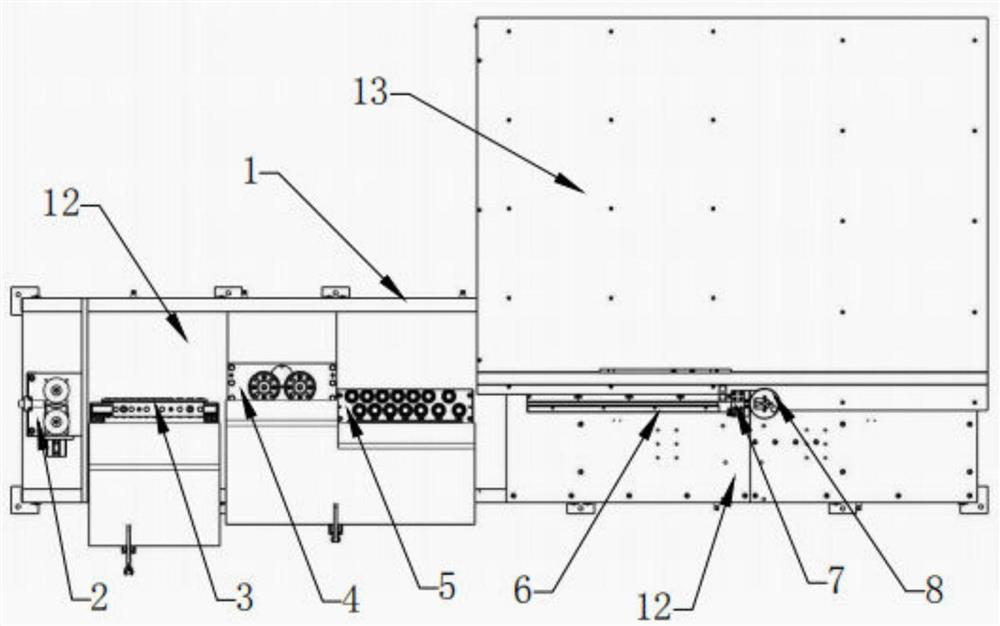

Automatic bending device for hollow glass aluminum parting strip

ActiveCN108188295AImprove quality and aestheticsReduce manual handlingMetal-working feeding devicesPositioning devicesAluminiumEngineering

The invention relates to an automatic bending device for a hollow glass aluminum parting strip and belongs to the technical field of mechanical devices. According to the automatic bending device, an aluminum strip to be bent is put between a baffle and a conveyor belt from a material inlet, rotating rollers rotate to convey the aluminum strip into a bending device, a fixing device moves along a guide rail to fix the aluminum strip on the upper surface of a bending mold after the aluminum strip reaches the designated position, a hydraulic device drives a bending arm to bend the aluminum strip along the bending mold, meanwhile, an extrusion roller moves along the guide rail to extrude the aluminum strip, a travel sensor records the travel of the aluminum strip, and a pushing device pushes the aluminum strip out from the interior of the bending device after the bending is completed. By the adoption of the automatic bending device, the quality and beauty of aluminum plate bending can be improved, continuous bending can be performed, and the device has high working efficiency, has high precision of aluminum plate bending and has the wide application prospect.

Owner:佛山途荣五金制品有限公司

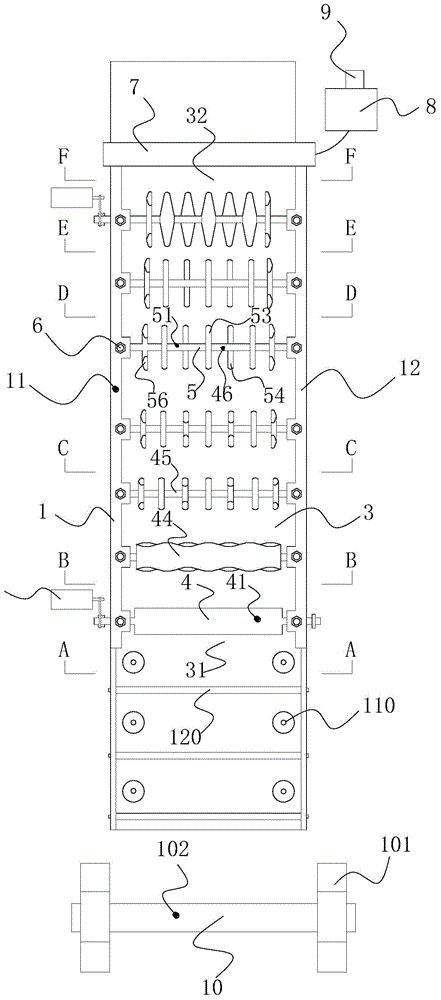

Steel bar straightening, bending and shearing continuous production device

The invention discloses a steel bar straightening, bending and shearing continuous production device which comprises a rack, and a steel bar straightening mechanism, a steel bar shearing mechanism anda steel bar bending mechanism are sequentially installed from the feeding end to the discharging end of the rack. A steel bar traction mechanism is further arranged in front of the steel bar straightening mechanism, and a steel bar coarse positioning mechanism is further arranged between the steel bar shearing mechanism and the steel bar straightening mechanism. A to-be-machined steel bar is fedinto the steel bar straightening mechanism, the steel bar coarse positioning mechanism and the steel bar shearing mechanism through the traction mechanism, then enters a steel bar positioning piece ofthe steel bar bending mechanism, then rotates back and forth multiple times through a movable bending rod, and is bent after the to-be-machined steel bar rotates back and forth four times through themovable bending rod in the rotating process, a stirrup is formed, the stirrup and the to-be-machined steel bar are cut off through upward swinging of a movable cutter of a steel bar swinging and shearing assembly, and bending and shearing machining are repeated after machining of one stirrup is completed.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

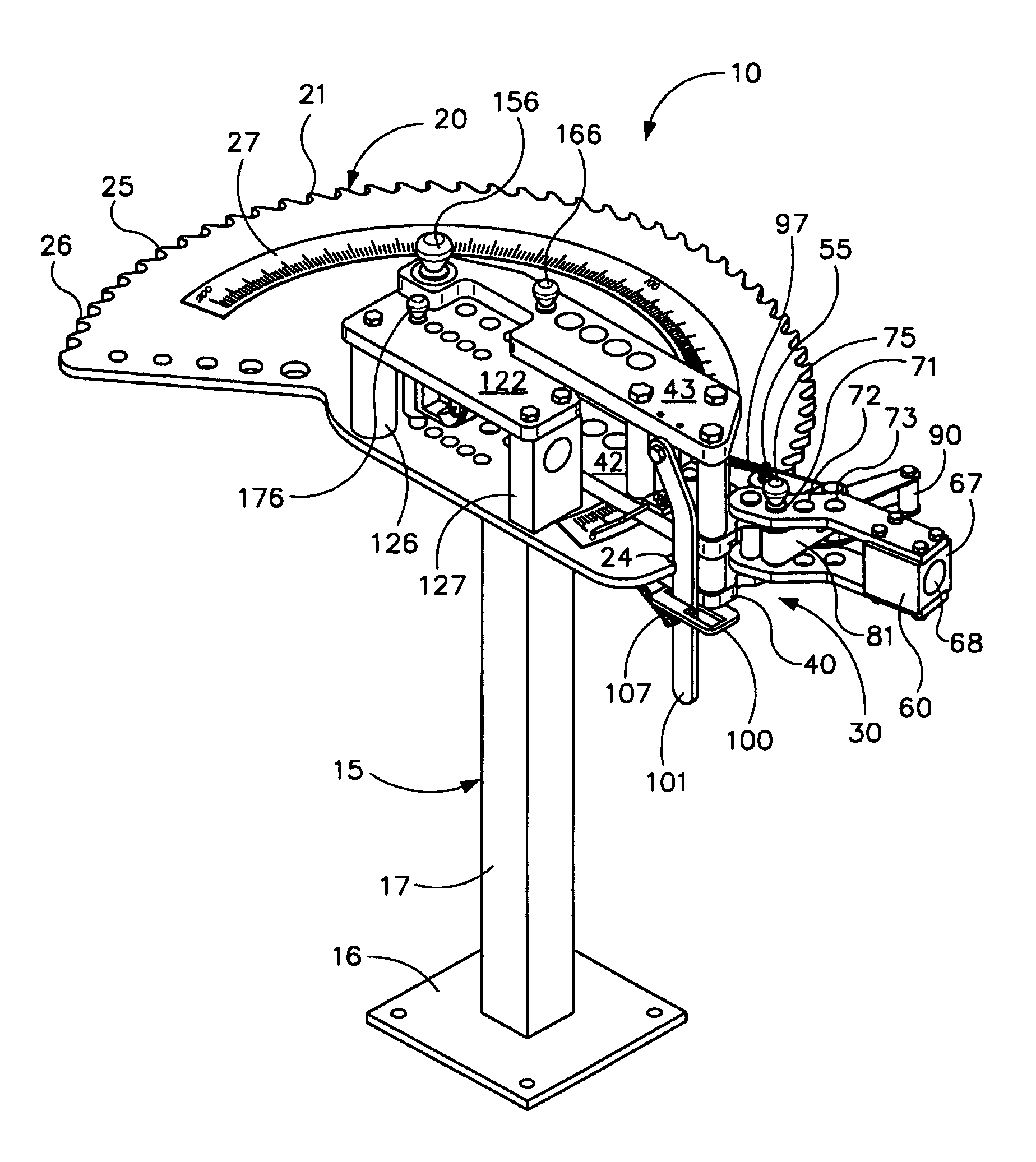

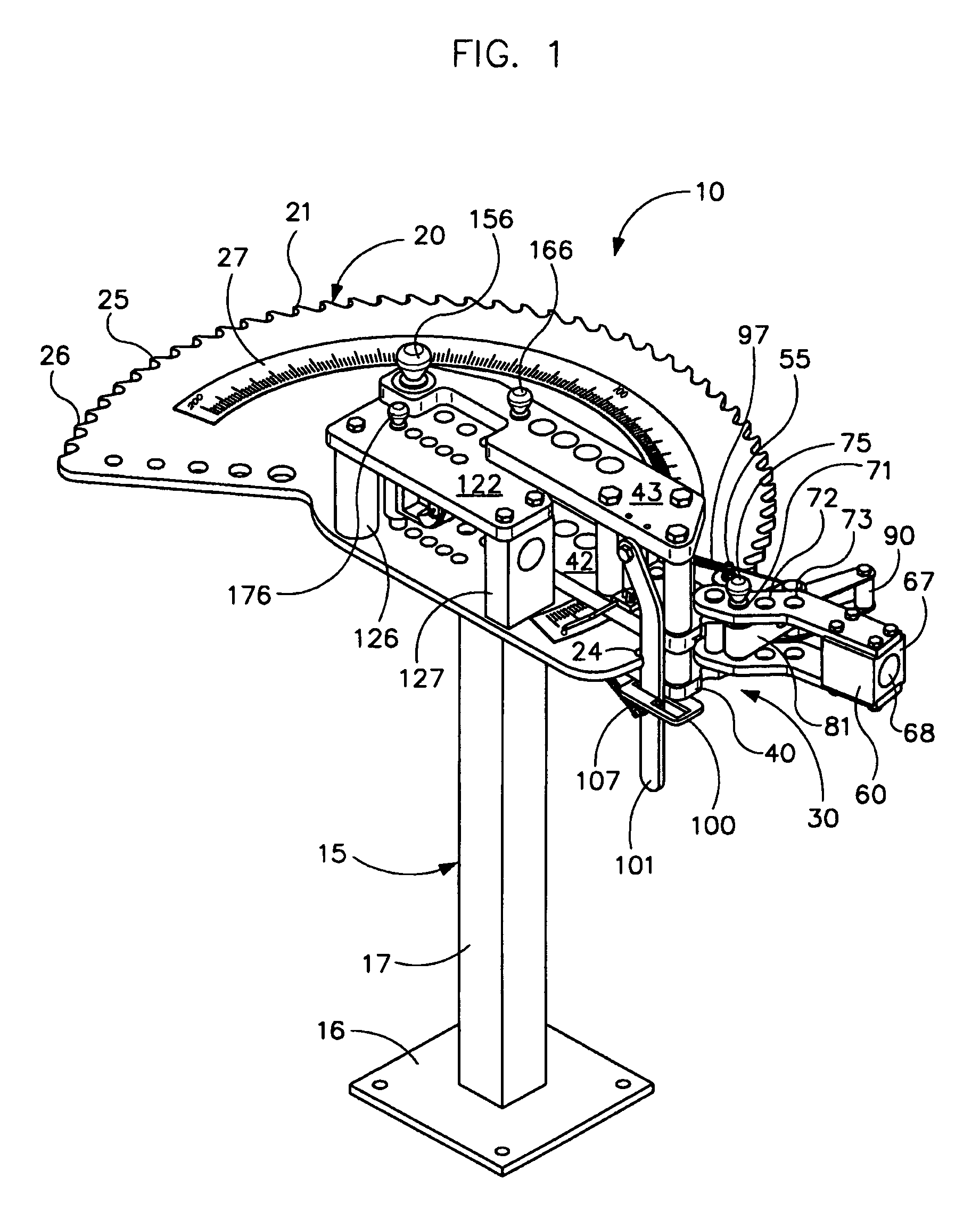

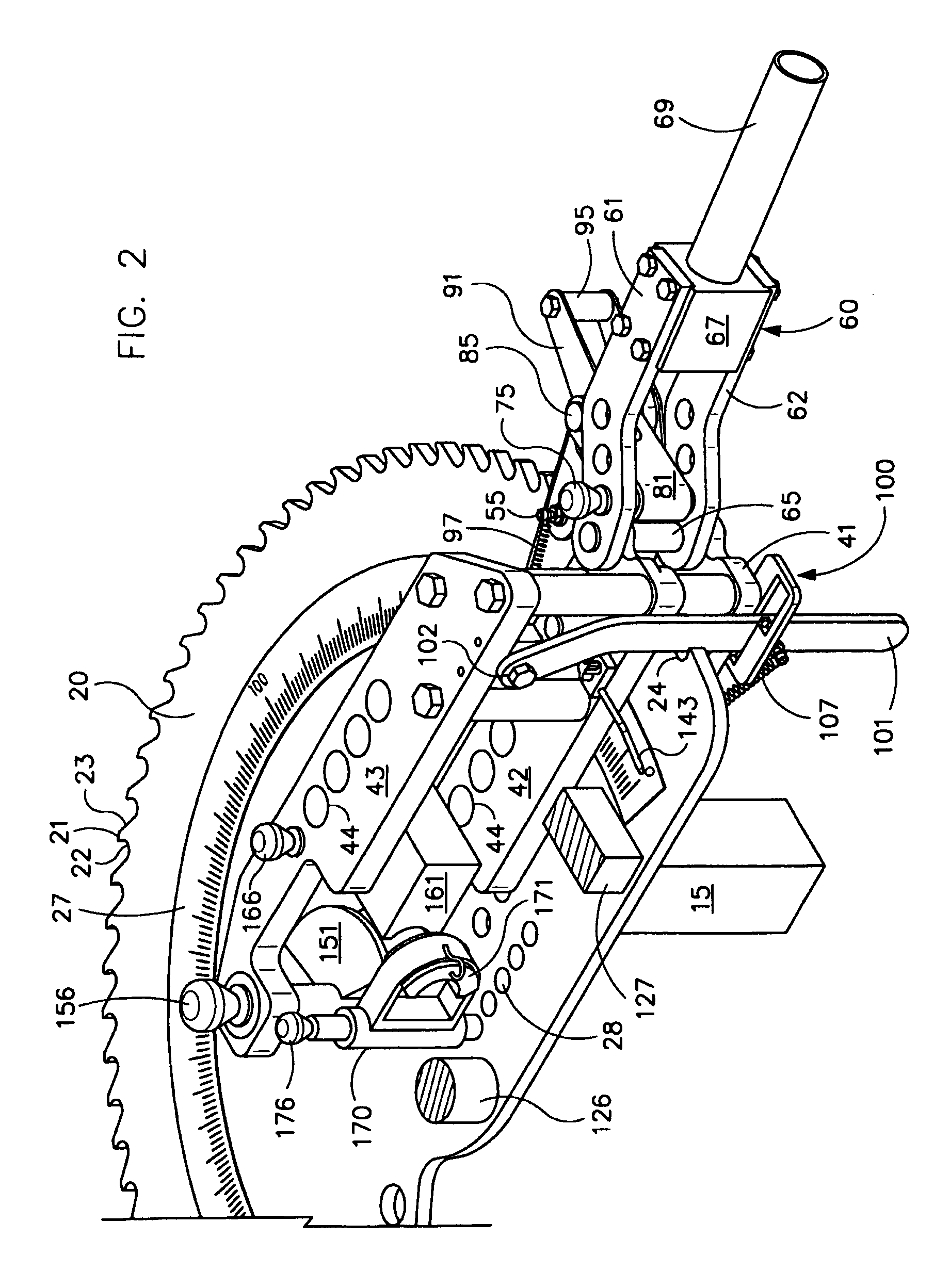

Tube bending machine

This invention is a manually operated tube bending machine with a power drive mechanism that is adjustably set to a desired bend speed. The bending machine includes a bending die, a counter die and a rotating hook die to form a desired bend into a tube or pipe. The tube bender includes a drive wheel with ratchet teeth around its perimeter. A drive pin grips one of the ratchet teeth. The drive pin is secured to a lever and torque bar. During each bending stroke, the lever and torque bar incrementally rotate the drive wheel a desired amount. The rotation of the drive wheel and hook die draw the tube through the bending and counter dies to bend the tube. An anti-spring back mechanism holds the position of the drive wheel while the power drive mechanism is advanced to grip the next ratchet tooth of the drive wheel.

Owner:JPW IND

Process for bending furnace wires by using screw rod type clamping device and integrated circuit controller

The invention discloses a process for bending furnace wires by using a screw rod type clamping device and an integrated circuit controller. The furnace wire winding displacement of a heating furnace is a rectangular winding displacement formed by arranging the furnace wires of the heating furnace linearly in a longitudinal direction. In the process, a bending device is applied. The bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are arranged one after the other on the right side of the bracket; a bracket clamping device is arranged in the middle of the right side of the bracket, and is positioned between the front horizontal guide rail and the back horizontal guide rail; a first bending device is arranged on the right part of the back horizontal guide rail; a third bending device is arranged on the left part of the back horizontal guide rail; a second bending device is arranged on the right part of the front horizontal guide rail; a fourth bending device is arranged on the left part of the front horizontal guide rail; the bending devices are used for forming four U-shaped bending parts in sequence from left to right respectively on the furnace wire winding displacement of the heating furnace.

Owner:张翠翠

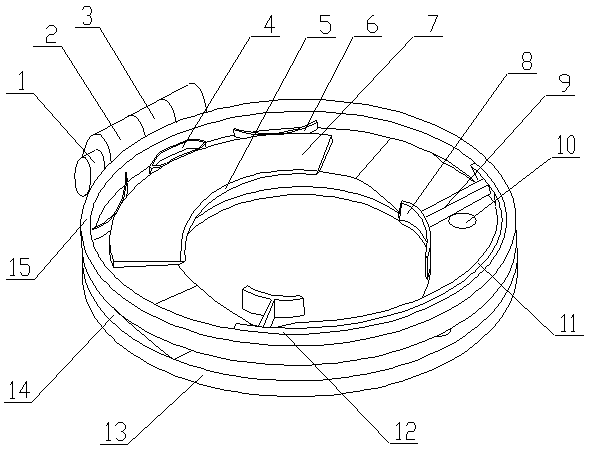

Building construction plastic tube bending device

The invention relates to a building construction plastic tube bending device, and discloses a device for carrying out bending on a single plastic tube by a size of a clamping angle between a base anda towing ring and matching of heating of a heating plate. The building construction plastic tube bending device is characterized in that a base plate is arranged on the base; the base is of a ring-shaped structure; a rubber cushion is arranged in an inner ring of the base; the base is provided with a plurality of fixed holes; the base plate is of a semicircle shape and bevel angles are respectively formed at both ends of the base plate; a thickness of the base plate is equal to that of the base; a power shaft sleeves the outer edge of the base by two connection sleeves and is positioned at themiddle position of the base plate; the outside of the towing ring is hinged with the power shaft by a hinged sleeve; the towing ring is made of a rigid material; a supporting ring is arranged on theinner wall of the towing ring and corresponds to the hinged sleeve; the supporting ring is of a hexagon shape; an inner supporting plate is of an arc structure; the middle part of the outside of the inner supporting plate is arranged on the supporting ring.

Owner:中铁十八局集团北京工程有限公司

Furnace wire bending process with application of hydraulic cylinder type horizontal driver and integrated circuit controller

Disclosed is a furnace wire bending process with the application of a hydraulic cylinder type horizontal driver and an integrated circuit controller. The wire arrangement of a heating furnace is a rectangular wire arrangement formed by arranging linear heating furnace wires linearly in the vertical direction, and a bending device is used in the process. The bending device comprises a support, the right side of the support is provided with a front horizontal guide rail and a rear horizontal guide rail in a front position and a rear position respectively, the middle of the right side of the support is provided with a support clamping device which is arranged between the front horizontal guide rail and the rear horizontal guide rail, a first bending device is arranged on the right of the rear horizontal guide rail, a third bending device is arranged on the left of the rear horizontal guide rail, a second bending device is arranged on the right of the front horizontal guide rail, a fourth bending device is arranged on the left of the front horizontal guide rail, and the four bending devices are respectively used for sequentially forming four U-shaped bending portions from left to right on the heating furnace wire arrangement.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

An automatic bending device for hollow glass aluminum spacers

ActiveCN108188295BQuality improvementImprove aestheticsMetal-working feeding devicesPositioning devicesEngineeringStructural engineering

The invention relates to an automatic bending device for a hollow glass aluminum parting strip and belongs to the technical field of mechanical devices. According to the automatic bending device, an aluminum strip to be bent is put between a baffle and a conveyor belt from a material inlet, rotating rollers rotate to convey the aluminum strip into a bending device, a fixing device moves along a guide rail to fix the aluminum strip on the upper surface of a bending mold after the aluminum strip reaches the designated position, a hydraulic device drives a bending arm to bend the aluminum strip along the bending mold, meanwhile, an extrusion roller moves along the guide rail to extrude the aluminum strip, a travel sensor records the travel of the aluminum strip, and a pushing device pushes the aluminum strip out from the interior of the bending device after the bending is completed. By the adoption of the automatic bending device, the quality and beauty of aluminum plate bending can be improved, continuous bending can be performed, and the device has high working efficiency, has high precision of aluminum plate bending and has the wide application prospect.

Owner:佛山途荣五金制品有限公司

Furnace wire bending process adopting hydraulic cylinder type horizontal driver and bending force sensor

The invention provides a furnace wire bending process adopting a hydraulic cylinder type horizontal driver and a bending force sensor. Row wires of furnace wires of a heating furnace are rectangular row wires formed by the furnace wires of the heating furnace through linear arrangement in a vertical direction, a bending device is used in the process and comprises a support frame, a front horizontal guide rail and a back horizontal guide rail are respectively arranged in a front position and a back position of the right side of the support frame, a support frame clamping device is arranged in the middle position of the right side of the support frame and is positioned between the front horizontal guide rail and the back horizontal guide rail, a first bending device is arranged at the right part of the back horizontal guide rail, a third bending device is arranged at the left part of the back horizontal guide rail, a second bending device is arranged at the right part of the front horizontal guide rail, a fourth bending device is arranged at the left side of the front horizontal guide rail, and the bending devices are respectively used for forming four U-shaped bending parts on the row wires of the furnace wires of the heating furnace from the left side to the right side.

Owner:NANJING SERM ELECTRICAL

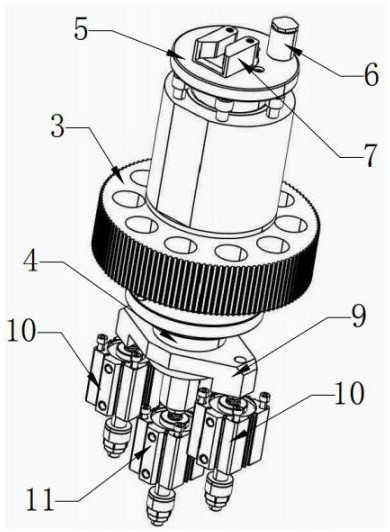

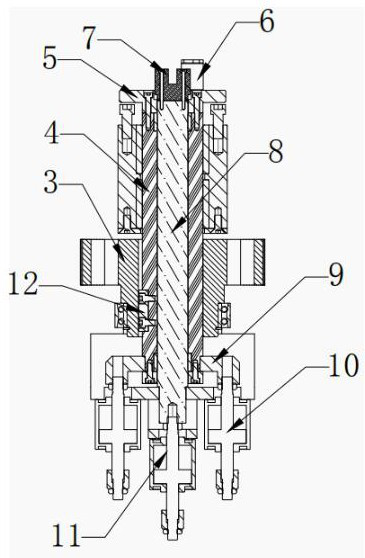

Steel bar bending mechanism applied to automatic hoop bending machine

The invention discloses a steel bar bending mechanism applied to an automatic hoop bending machine. The mechanism comprises a rotating motor and a bending head capable of rotating in the circumferential direction driven by the motor, and a movable bending rod is detachably mounted on the bending head; a steel bar positioning part is detachably installed on the bending head, beside the movable bending rod, and a steel bar positioning groove is formed in the middle of the steel bar positioning part; a vertically arranged hollow outer shaft is fixedly installed under the bending head, the hollowouter shaft can rotate driven by a bending motor, and drive the movable bending rod to rotate synchronously, steel bars protruding out of the steel bar positioning groove are bent at a set angle, andwhen bending, the end, close to the movable bending rod, of the steel bar positioning part forms a steel bar abutment part; the mechanism also comprises a second telescopic cylinder, and through starting the second telescopic cylinder, the hollow outer shaft and the bending head can be driven to expand and contract up and down; the hollow outer shaft sleeves an inner telescopic shaft, and the steel bar positioning part and the inner telescopic shaft can expand and contract up and down driven by a first telescopic cylinder.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

A construction plastic pipe bending device

The invention relates to a building construction plastic tube bending device, and discloses a device for carrying out bending on a single plastic tube by a size of a clamping angle between a base anda towing ring and matching of heating of a heating plate. The building construction plastic tube bending device is characterized in that a base plate is arranged on the base; the base is of a ring-shaped structure; a rubber cushion is arranged in an inner ring of the base; the base is provided with a plurality of fixed holes; the base plate is of a semicircle shape and bevel angles are respectively formed at both ends of the base plate; a thickness of the base plate is equal to that of the base; a power shaft sleeves the outer edge of the base by two connection sleeves and is positioned at themiddle position of the base plate; the outside of the towing ring is hinged with the power shaft by a hinged sleeve; the towing ring is made of a rigid material; a supporting ring is arranged on theinner wall of the towing ring and corresponds to the hinged sleeve; the supporting ring is of a hexagon shape; an inner supporting plate is of an arc structure; the middle part of the outside of the inner supporting plate is arranged on the supporting ring.

Owner:中铁十八局集团北京工程有限公司

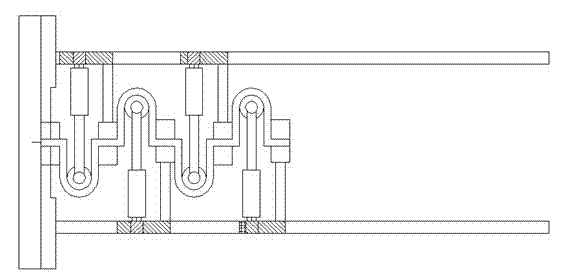

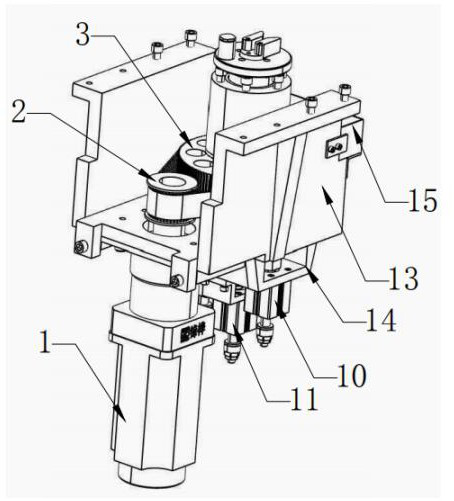

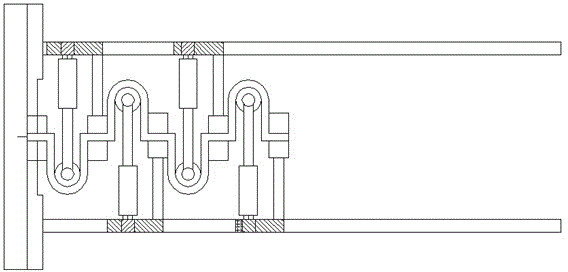

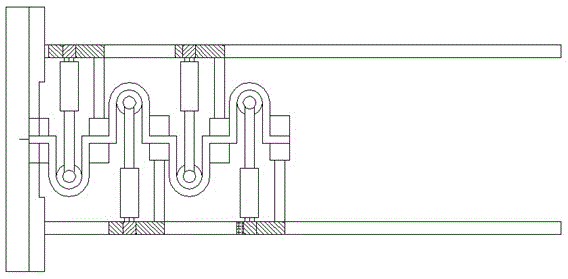

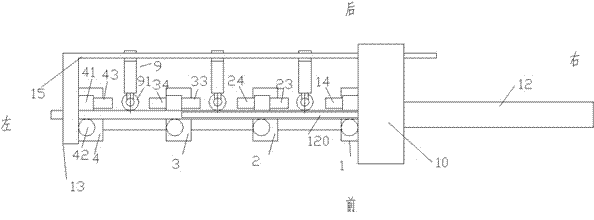

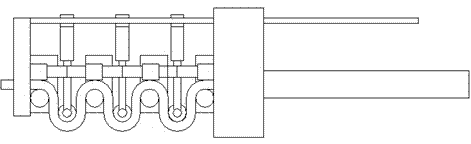

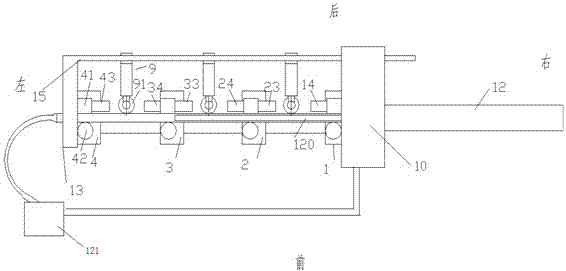

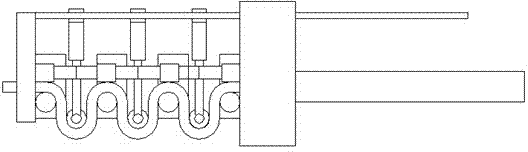

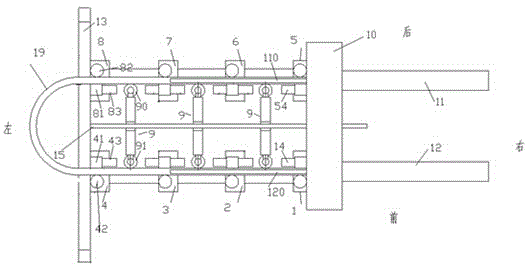

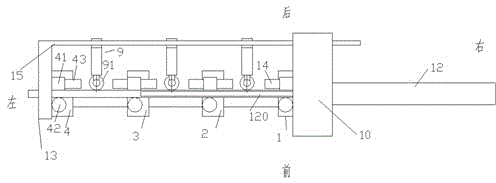

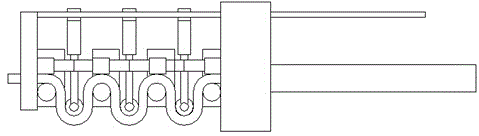

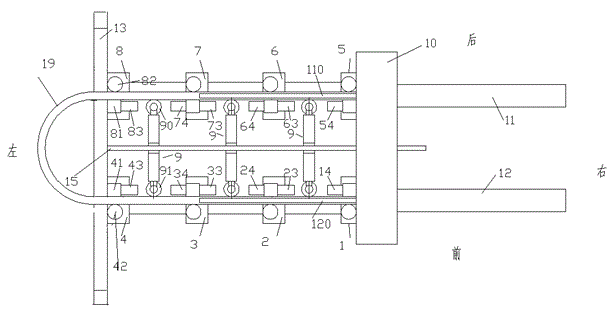

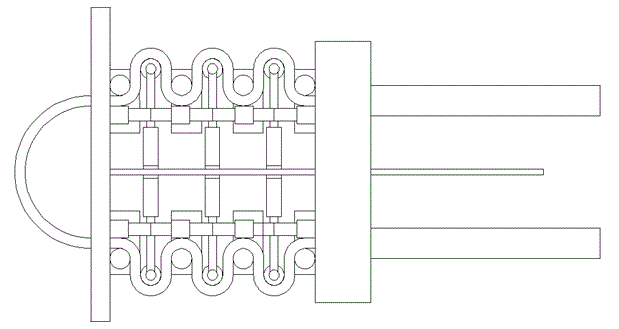

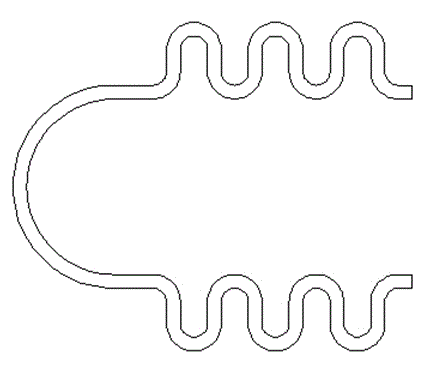

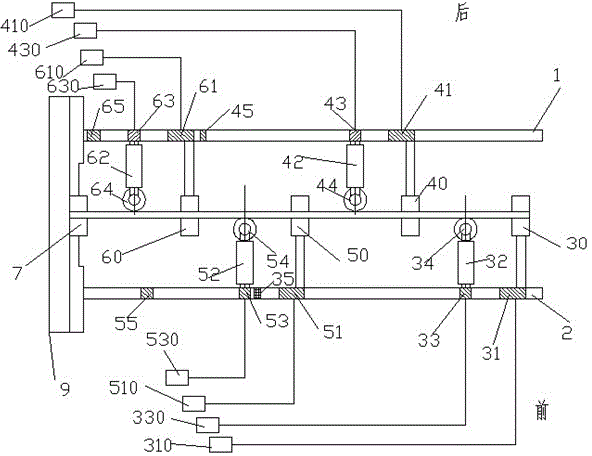

Bending technology for furnace tube of linear heating furnace

InactiveCN103920767AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

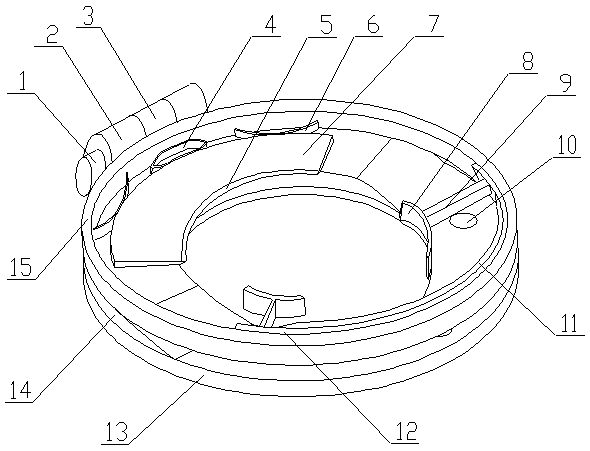

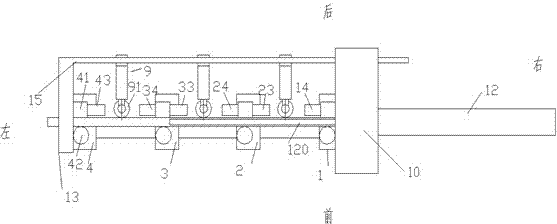

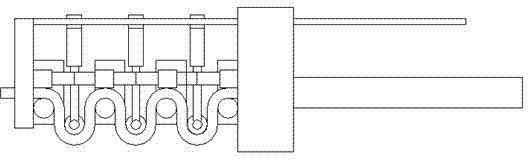

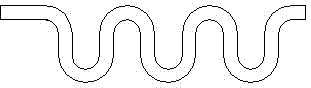

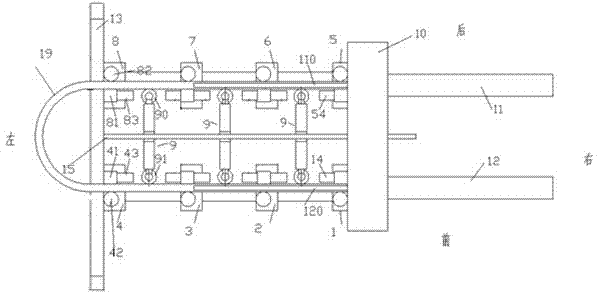

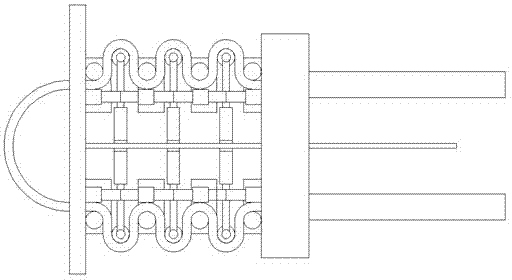

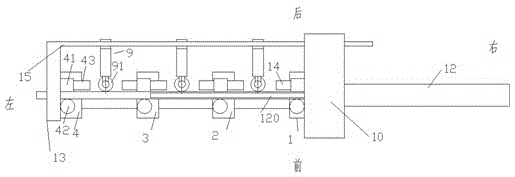

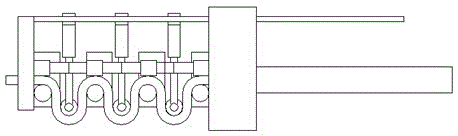

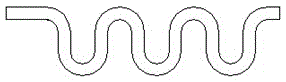

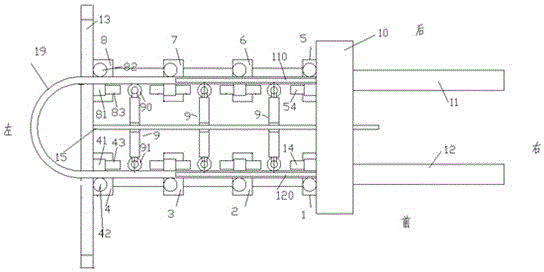

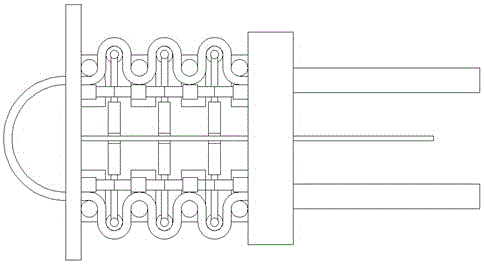

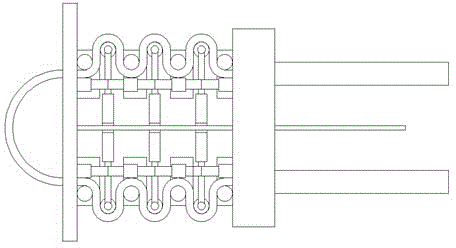

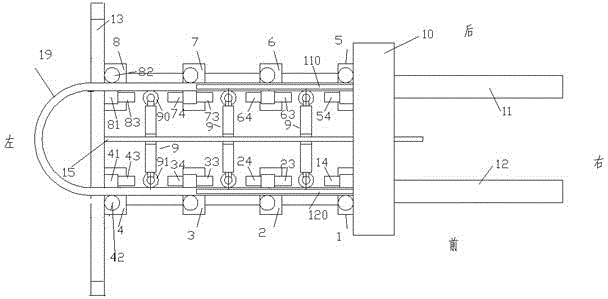

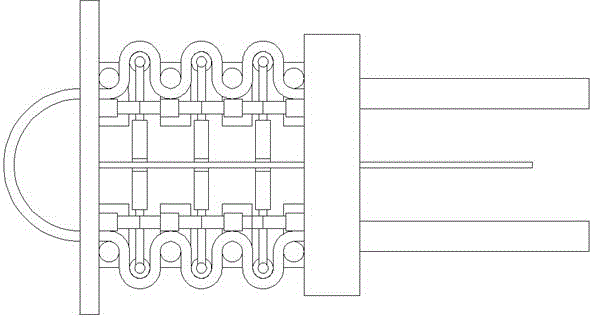

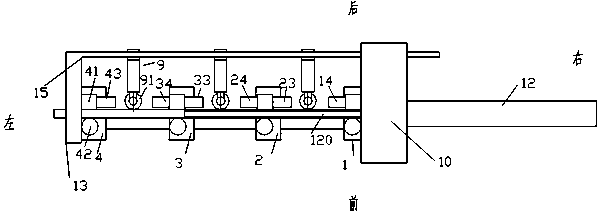

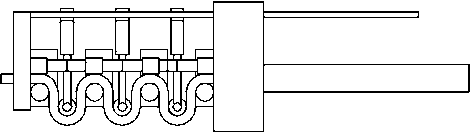

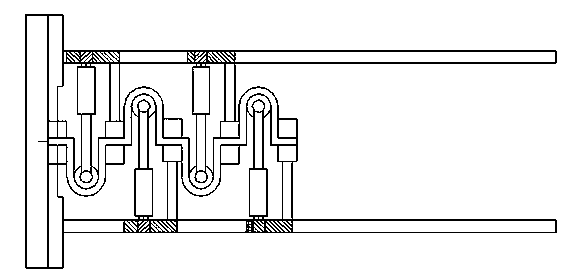

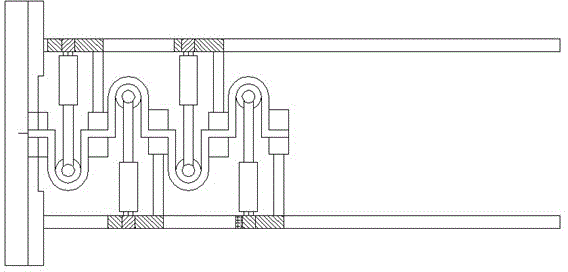

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:方自成

Furnace wire bending process using hydraulic cylinder type horizontal driver and performing thermal treatment

The invention discloses a furnace wire bending process using hydraulic cylinder type horizontal driver and performing thermal treatment. The furnace wires of heating furnaces are distributed in the way that the linear furnace wires of the heating furnaces are linearly arranged up and down to form into a rectangular wire array; the process adopts bending devices, the bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are respectively arranged in the front and back of the right side of the bracket, a bracket clamping device is arranged at the middle position of the right side of the bracket and is arranged between the front and back horizontal guide rails, the right part of the back horizontal guide rail is provided with a first bending device, the left part of the back horizontal guide rail is provided with a third bending device, the right part of the front horizontal guide rail is provided with a second bending device, the left part of the front horizontal guide rail is provided with a fourth bending device, the bending devices are respectively arranged on the furnace wire array of the heating furnaces so as to form four U-shaped bending parts sequentially from left to right.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Nickel-chromium alloy furnace wire bending process for performing stress-relieving thermal treatment

The invention discloses a nickel-chromium alloy furnace wire bending process for performing stress-relieving thermal treatment. The furnace wire winding displacement of a heating furnace is rectangular winding displacement formed by linearly arranging furnace wires of the linear heating furnace in the longitudinal direction. In the process, a bending device is used. The bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are arranged respectively one after the other on the right side of the bracket; the middle of the right side of the bracket is provided with a bracket clamping device which is positioned between the front horizontal guide rail and the back horizontal guide rail; the right portion of the back horizontal guide rail is provided with a first bending device; the left portion of the back horizontal guide rail is provided with a third bending device; the right portion of the front horizontal guide rail is provided with a second bending device; the left portion of the front horizontal guide rail is provided with a fourth bending device. The bending device is used for forming four U-shaped bent portions in sequence from left to right on the furnace wire winding displacement of the heating furnace.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:海门江海建设投资有限公司

U-shape Furnace Tube Bending Process Using Fixture Locking Rail Mechanism and Carrying out Pressure Keeping and Sizing

InactiveCN103894463BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Owner:南通市海门江海建设投资有限公司

Bending Process of a Linear Heating Furnace Tube

InactiveCN103934331BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:董璞玉

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:南通江海港建设工程有限公司

Bending Process of a Linear Heating Furnace Tube

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:徐州博创建设发展集团有限公司

U-shape Furnace Tube Bending Process Using Fixture Locking Rail Mechanism and Fixture Position Sensor

ActiveCN103861922BGuaranteed shape accuracyAvoid insufficient clamping forceLocking mechanismEngineering

The invention discloses a U-shaped heating furnace tube bending technology which uses furnace tube bending equipment. The furnace tube bending equipment comprises a left machine frame and a pushing and pressing mechanism, wherein the pushing and pressing mechanism is located on the right side of the left machine frame, a guide rod is fixedly arranged in the middle of the right side of the left machine frame and extends horizontally in the left-right direction, the left end of the guide rod is fixedly connected with the left machine frame, the right end of the guide rod is connected with the middle of the pushing and pressing mechanism in a sliding mode, a channel used for allowing an original U-shaped furnace tube to pass through to be fed and a well machined furnace tube to pass through to be discharged is formed in the left machine frame, and three bending hydraulic devices are arranged on the guide rod and between the left machine frame and the pushing and pressing mechanism in a sliding mode in sequence from left to right.

Owner:郎溪品旭科技发展有限公司

Bending process of u-shaped furnace tube using bending roll distance sensor and pressure-holding finalization

Owner:XUZHOU MASTER MECHANICAL TECH CO LTD

U-shaped furnace pipe bending process for carrying out heating fluid heating and carrying out ejection and material returning

InactiveCN103846325BGuaranteed shape accuracyAvoid insufficient clamping forceMetal-working feeding devicesPositioning devicesEngineeringMachining process

Owner:广州市火龙焊接设备有限公司

Linear type heating furnace tube bending technology

InactiveCN103934332AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:HUAIAN KANGNUOKE COLOR PRINTING

Furnace wire bending technology adopting screw type clamping device and bending force sensor

The invention relates to a furnace wire bending technology adopting a screw type clamping device and a bending force sensor. Arrangement of heating furnace wires is performed in the manner that the straight heating furnace wires are linearly arranged in the perpendicular direction to form rectangular wire arrangement. A bending device is adopted in the technology. The bending device comprises a supporting frame. A front horizontal guiding rail and a rear horizontal guiding rail are arranged on the right side of the supporting frame in a front-and-back mode respectively. A supporting frame clamping device is arranged in the middle of the right side of the supporting frame and located between the front horizontal guiding rail and the rear horizontal guiding rail. A first bending device body is arranged on the right of the rear horizontal guiding rail, a third bending device body is arranged on the left of the rear horizontal guiding rail, a second bending device body is arranged on the right of the front horizontal guiding rail and a fourth bending device body is arranged on the left of the front horizontal guiding rail. The bending device bodies are used for sequentially forming four U-shaped bent parts from left to right in arrangement of the heating furnace wires.

Owner:方大力 +4

Bending Process of a Linear Heating Furnace Tube

ActiveCN103934333BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringHeating furnace

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:JIANGSU BINXIN STEEL GRP

U-shaped heating furnace tube bend process for conducting heating fluid heating and pressure maintaining forming

Disclosed is a U-shaped heating furnace tube bend machining technology. Furnace tube bending equipment is used, the furnace tube bending equipment comprises a left rack and a pushing mechanism, and the pushing mechanism is arranged on the right side of the left rack. A guide rod is fixedly arranged in the middle part of the right side of the left rack, and the guide rod extends horizontally in the left-right direction. The left end of the guide rod is fixedly connected with the left rack, the right end of the guide rod is connected with the middle of the pushing mechanism in a sliding mode, and a channel used for allowing an original U-shaped furnace tube to be fed and to penetrate through and allowing a machined furnace tube to be discharged and to pass through is formed in the left rack. Three bending hydraulic devices are sequentially arranged from left to right in a sliding mode on the guide rod between the left rack and the pushing mechanism.

Owner:JIANGSU JINSHENGYUAN SPECIAL VALVE

U-shaped furnace tube bending process for stress relief heat treatment and pressure maintaining and finalizing

InactiveCN103861919BGuaranteed shape accuracyAvoid insufficient clamping forceStress relievingEngineering

The invention provides a bending technology for U-shaped heating furnace tubes. According to the bending technology, a furnace tube bending device is applied. The furnace tube bending device comprises a left machine frame and a pushing and pressing mechanism, wherein the pushing and pressing mechanism is located on the right side of the left machine frame, a guide rod is fixedly arranged at the middle position of the right side of the left machine frame, the guide rod horizontally extends leftwards and rightwards, the left end of the guide rod is fixedly connected with the left machine frame, and the right end of the guide rod is connected with the middle portion of the pushing and pressing mechanism in a sliding mode. A channel is arranged in the left machine frame, and the channel is used for feeding and penetrating of original U-shaped furnace tubes and discharging of the machined furnace tubes. Three bending hydraulic devices are sequentially arranged on the portion, between the left machine frame and the pushing and pressing mechanism, of the guide rod from left to right in a sliding mode.

Owner:江苏振强不锈钢制品有限公司

Wire bending process using bending force sensor and heat treatment

InactiveCN103769502BGuaranteed shape accuracyContinuous bendingWire articlesEngineeringHeating furnace

The invention discloses a furnace wire bending process using a bending force sensor and performing thermal treatment. The furnace wires of heating furnaces are distributed in the way that the linear furnace wires of the heating furnaces are linearly arranged up and down to form into a rectangular wire array; the process adopts bending devices, the bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are respectively arranged in the front and back of the right side of the bracket, a bracket clamping device is arranged at the middle position of the right side of the bracket and is arranged between the front and back horizontal guide rails, the right part of the back horizontal guide rail is provided with a first bending device, the left part of the back horizontal guide rail is provided with a third bending device, the right part of the front horizontal guide rail is provided with a second bending device, the left part of the front horizontal guide rail is provided with a fourth bending device, the bending devices are respectively arranged on the furnace wire array of the heating furnaces so as to form four U-shaped bending parts sequentially from left to right.

Owner:陈艳昭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com