Process for bending furnace wires by using screw rod type clamping device and integrated circuit controller

A clamping device and integrated circuit technology, applied in the field of furnace wire bending technology, can solve the problems of low shape accuracy, uneven processing deformation, long processing process, etc., and achieve high shape accuracy, good shape consistency, and small processing space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

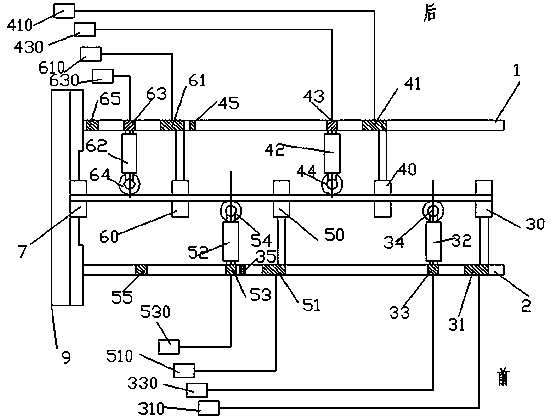

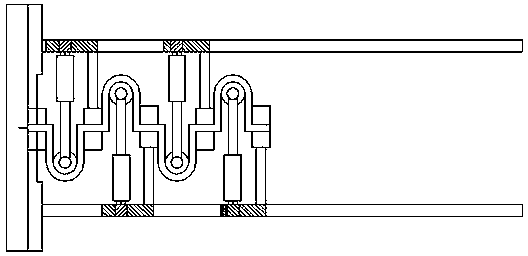

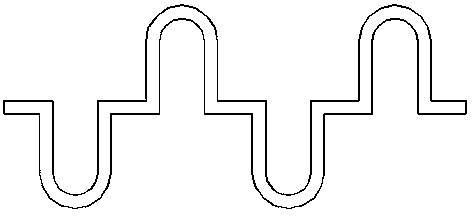

[0029] Attached below Figure 1-6 The present invention will be described in detail.

[0030] A furnace wire bending process using a screw-type clamping device and an integrated circuit controller, the furnace wire is a heating furnace wire, and is processed in the form of a heating furnace wire row 10, the heating furnace wire The cable 10 is a rectangular cable formed by linearly arranging linear heating furnace wires in the up and down direction. The process uses a bending device, and the bending device includes a bracket 9 . A front horizontal guide rail 2 and a rear horizontal guide rail 1 are respectively arranged at a rear position, and a bracket clamping device 7 is arranged at the middle position on the right side of the bracket 9, and the bracket clamping device 7 is located between the front horizontal guide rail 2 and the rear horizontal guide rail 1 , the first bending device is provided on the right part of the rear horizontal guide rail 1, the third bending dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com