Composite mold for integrally molding inner profile of ribbed composite wall panel

A composite material and integral molding technology, which is applied in the field of composite molds for integrally forming the inner surface of reinforced composite wall panels, can solve problems affecting the internal quality or assembly of components, insufficient rigidity of rubber soft molds, and dense pores in the R corner area, etc. , to achieve the effect of increasing stiffness, avoiding frequent repairs, and avoiding dense pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

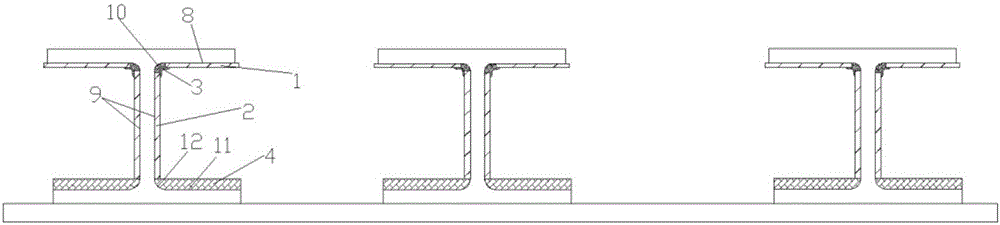

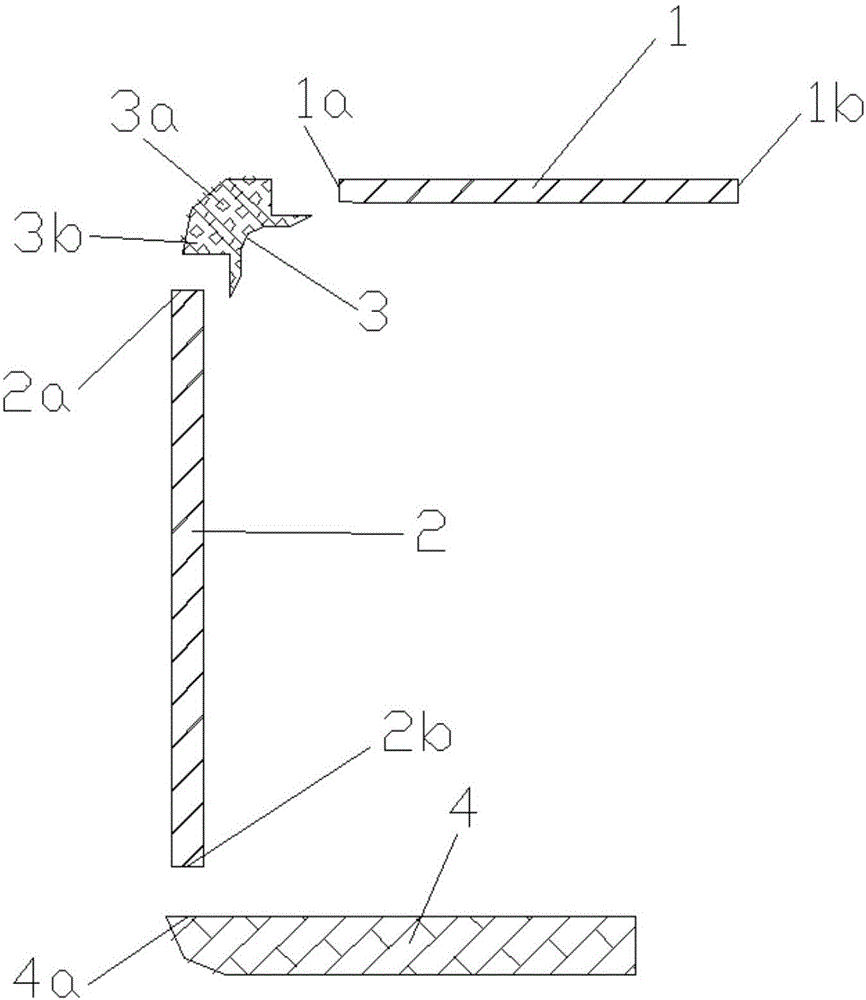

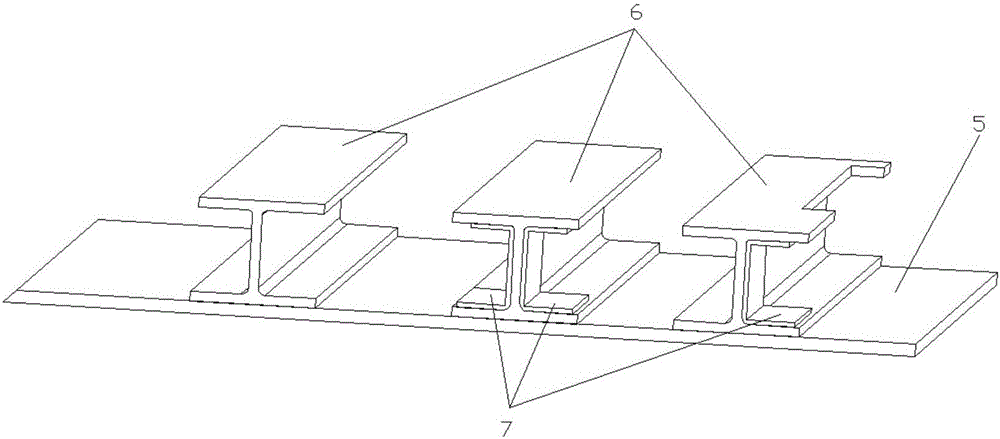

[0029] Embodiment 1: The external dimensions of the "I" type reinforced wall panel are 2500 mm × 2500 × 240 mm (length × width × height), and the skin 5 is longitudinally equipped with 3 reinforcements 6 with an "I" type cross section. The dimensions of the upper and lower R angles are both R5, which are integrally formed by RFI technology, such as image 3 shown. The inner profile of the rib is assembled with the U-shaped metal part 7 in some areas, so the lower profile of the upper flange of the rib is 8, the inner profile of the web of the rib is 9, the inner profile of the R angle of the upper rib is 10, and the lower profile of the rib is The surface accuracy of the upper profile 11 of the flange and the inner profile 12 of the R angle under the rib must be controlled within a certain deviation range to meet the assembly requirements. Here we adopt the mold solution of the present invention.

[0030]a "I" type rib upper flange lower profile 8 and rib web inner profile 9 ...

Embodiment 2

[0035] Example 2: "J" type reinforced panel structure such as Figure 7 , "J"-shaped reinforced wall panels have an overall dimension of 2000mm×1500×140mm (length×width×height), and there are three reinforcements 6 with a "J"-shaped section in the longitudinal direction on the upper skin 5, and the upper and lower ribs The size of the R angle is R3, and it is integrally formed by RFI technology. The ribs are opened in the web area, and the U-shaped metal parts 7 corresponding to the openings should be assembled to the inner profile of the "J" rib, so the lower profile of the upper flange of the rib is 8, and the inner profile of the web of the rib is 9 1. The surface accuracy of the inner profile surface 10 of the R angle on the rib, the upper profile surface 11 of the lower flange of the rib and the inner profile surface 12 of the R angle under the rib must be precisely controlled to ensure the compatibility with the outer profile of the U-shaped metal part 7 Assembly coordi...

Embodiment 3

[0040] Example 3: "C" type reinforced panel structure such as Figure 9 , "C" type reinforced wall panel dimensions are 2000mm × 800 × 100mm (length × width × height), the skin 5 is longitudinally equipped with 3 reinforcements 6 with a cross-section of "C" type, and the R angle on the ribs The dimension is R5, and the dimension of the lower R angle is R3. The lower flange of the rib and the skin are interlayer reinforced by stitching, and are integrally formed by RFI technology. The two outer ribs are opened in the web area, and the U-shaped metal parts 7 corresponding to the openings must be assembled in the opening area of the inner surface of the "C"-shaped rib. In order to ensure the forming quality and assembly of the "C"-shaped rib Requirement, here we still adopt the mold scheme of the present invention.

[0041] a "C" shaped rib upper flange lower profile 8 and rib web inner profile 9 are planar structures, choose 2mm thick aluminum plate to process upper flange ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com