Patents

Literature

124results about How to "Small processing space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

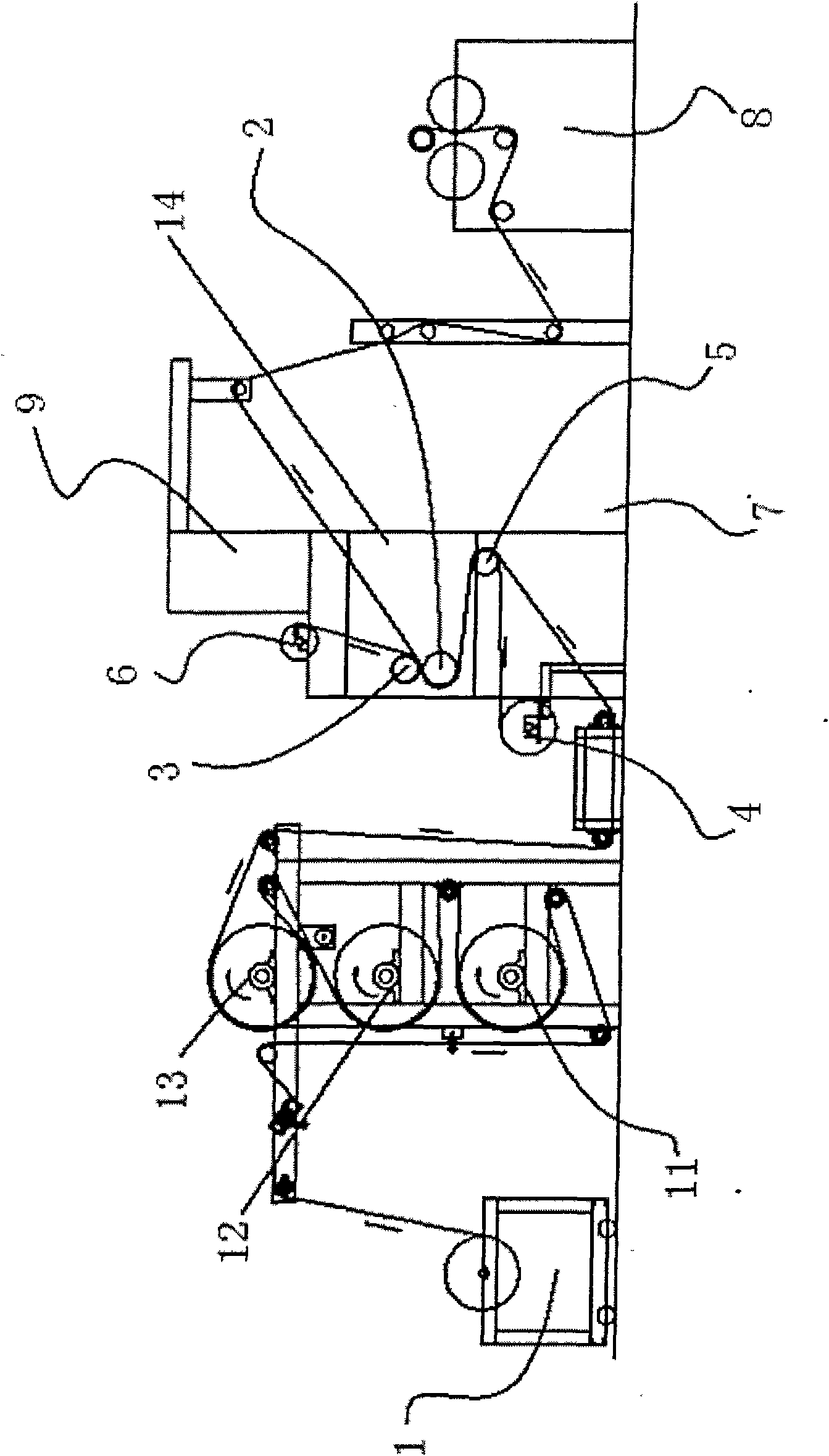

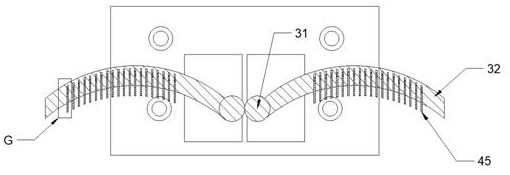

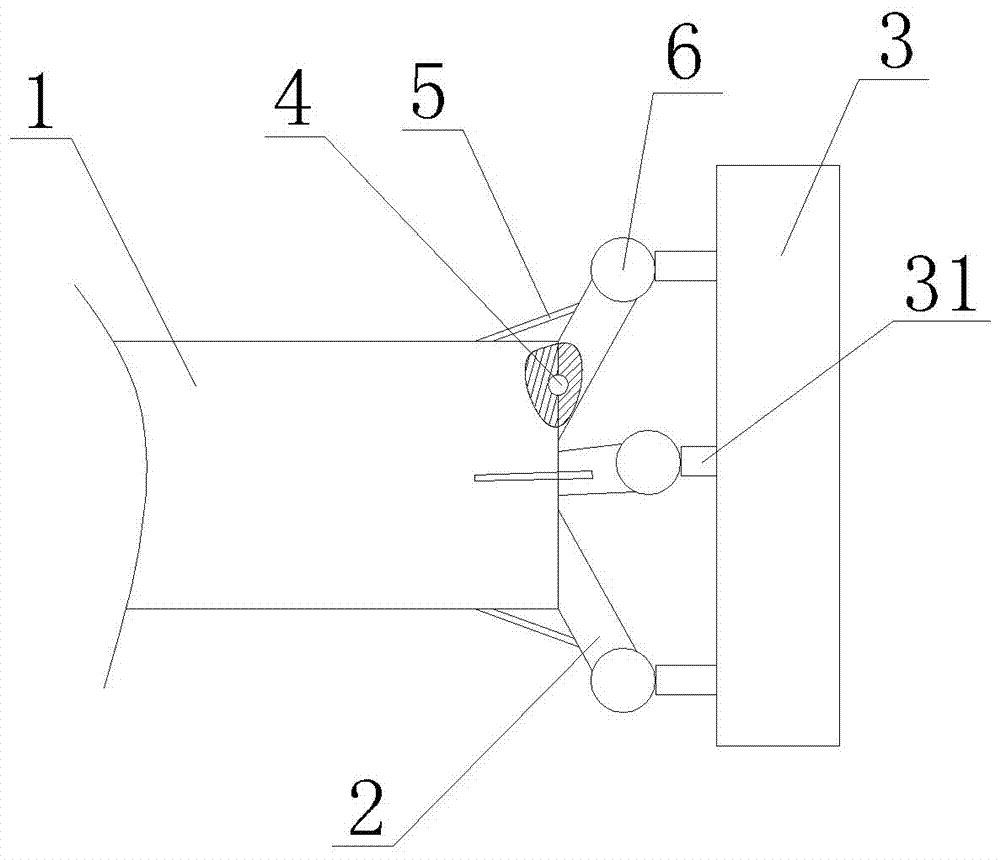

Processing technology and embossing machine of flocking product

InactiveCN101638839AQuality assuranceGuaranteed lamination effectTransfer printingPattern makingPulp and paper industryStamping process

A processing technology of a locking product comprises the following steps: feeding fabric and papers, embossing, pattern printing, recovering and coiling, namely feeding the fabric to an embossing machine and feeding the paper to the embossing machine, then simultaneously feeding the fabric and the paper to an embossing barrel of the embossing machine, ensuring the fabric to be formed with a specific pattern by mutually pressing of the embossing barrel and an embossing roller and transferring the pattern on the paper surface to the fabric surface, and finally, recovering the paper and coilingfinished fabric. Meanwhile, steps of the embossing and the pattern printing also comprise a pressing procedure. The embossing process and a heat-transfer printing process or a gold stamping process can be simultaneously realized by selecting heat printing transfer paper or gold and silver powder paper. An embossing machine used in the processing technology comprises a fabric feeding device, the embossing barrel, the embossing roller, a coiling device, a paper feeding device, a recovery device and a machine frame; and a pressing device is positioned between the paper feeding device and the embossing roller and arranged to be a rotatable roller. The processing technology has advantages of being simple and economical, simple processing and low cost. The embossing machine has advantages of excellent performance, simple structure and low cost.

Owner:DONGGUAN ALPHA FLOCK

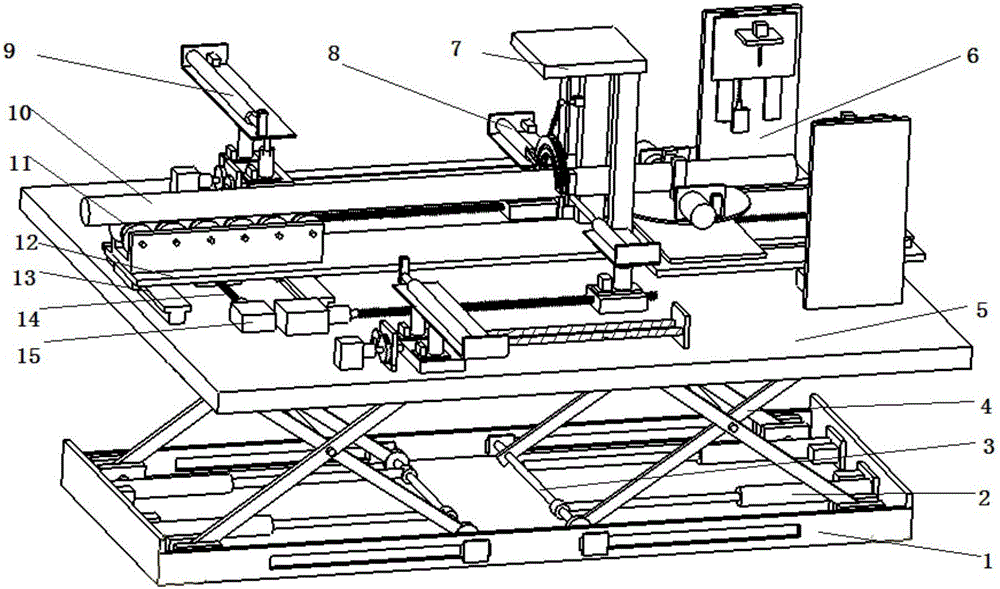

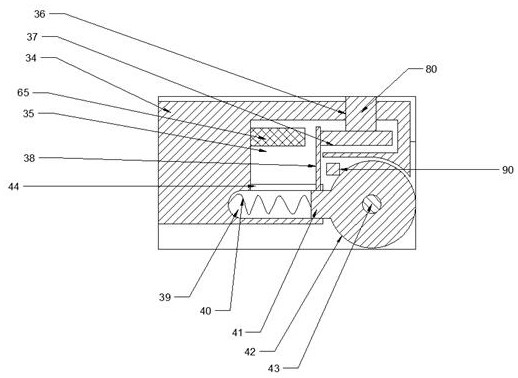

Equal-length glass tube batch production cutting device

InactiveCN106495457AReduce workloadReduce time for step-by-step processingEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides an equal-length glass tube batch production cutting device which comprises a base and a lift plate. A pad plate is slidably connected to the lift plate, rollers are arranged on the pad plate, a clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism, the first clamping mechanism comprises a first motor and a first transmission rod, the cutting mechanism comprises a support and a cutter arranged on the support, a first arc connection plate and a second arc connection plate are arranged on the support, the milling mechanism comprises a side wall and a milling cutter slidably connected with the side wall, and a sliding plate is slidably connected to the pad plate. By using the equal-length glass tube batch production cutting device, cutting and milling of equal-length glass tubes can be completely efficiently, staff's manual operation during the entire process is omitted, potential safety hazards of staff are reduced, production efficiency is improved, and machining cost is reduced.

Owner:天津南玻节能玻璃有限公司

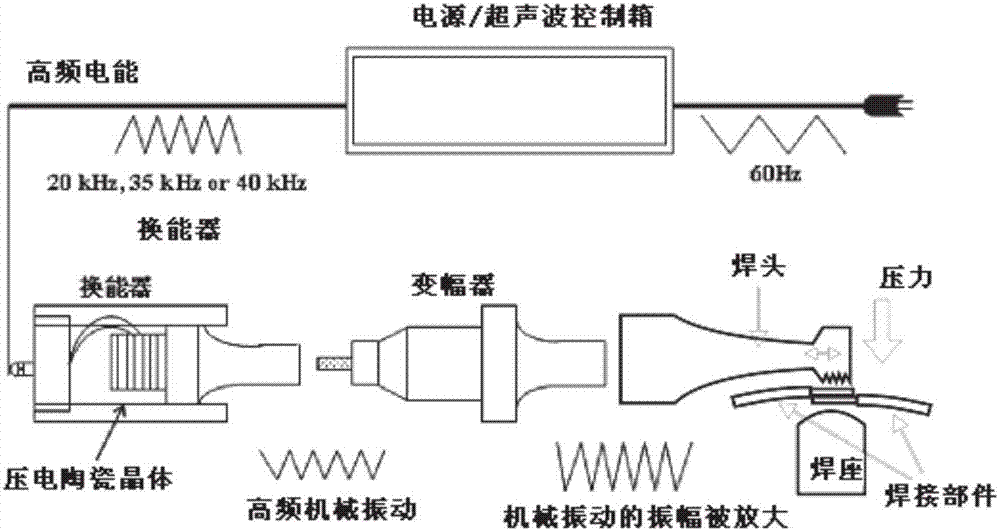

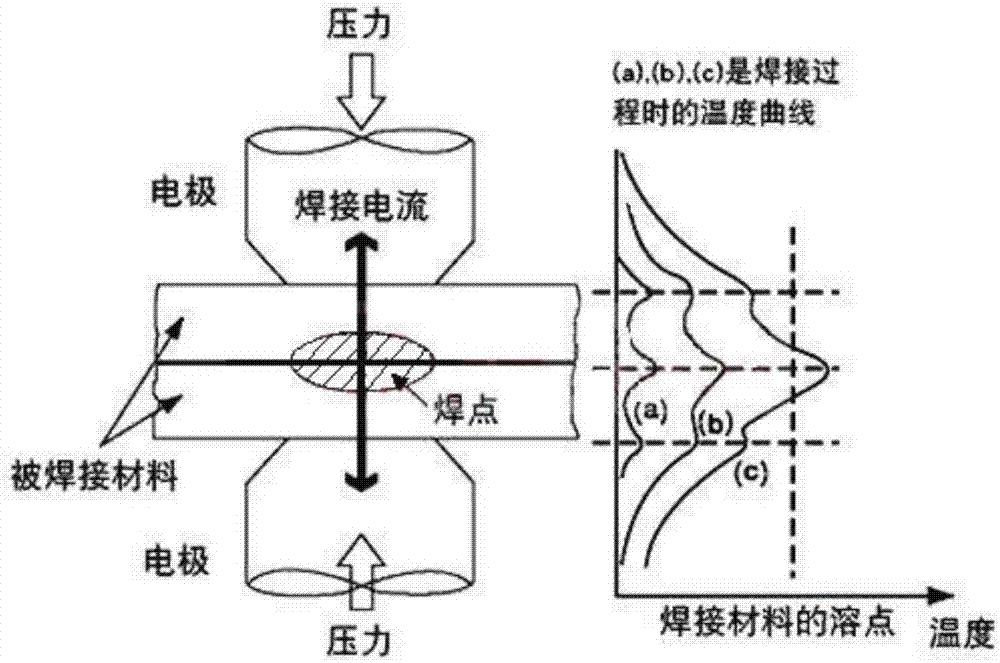

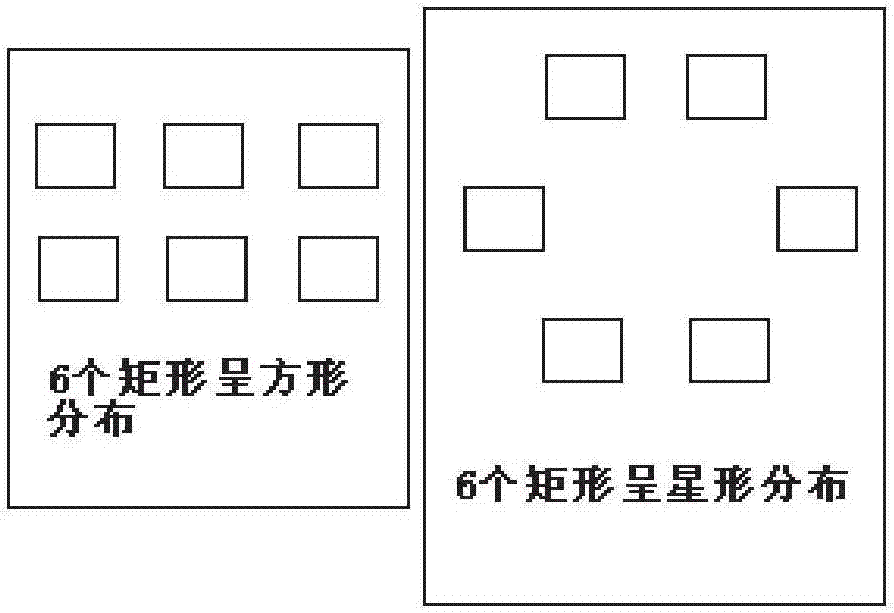

Process for welding caps and plate lugs of lithium batteries

The invention provides a process for welding caps and plate lugs of lithium batteries. The process comprises the following steps of (1) selecting the model of a laser device: selecting a 50-150W Fiber laser device as a welding light source; (2) configuring a laser optical device; (3) pretreating the plate lugs and the caps before welding; (4) conducting butting joint on the caps and the plate lugs, reasonably selecting a welding area and reasonably selecting a welding area press-fitting process; (5) adopting a welding trace capable of enhancing the welding strength: selecting and arranging 2-8 chamfered rectangles into a certain shape, adopting a spiral line filled trace; (6) setting laser parameters: setting the power to be 40-120 W, the frequency to be 60-650 KHz and the pulse width to be 20-200 ns: and (7) adopting an air blowing protection system for protection in the welding process.

Owner:深圳市吉祥云科技有限公司

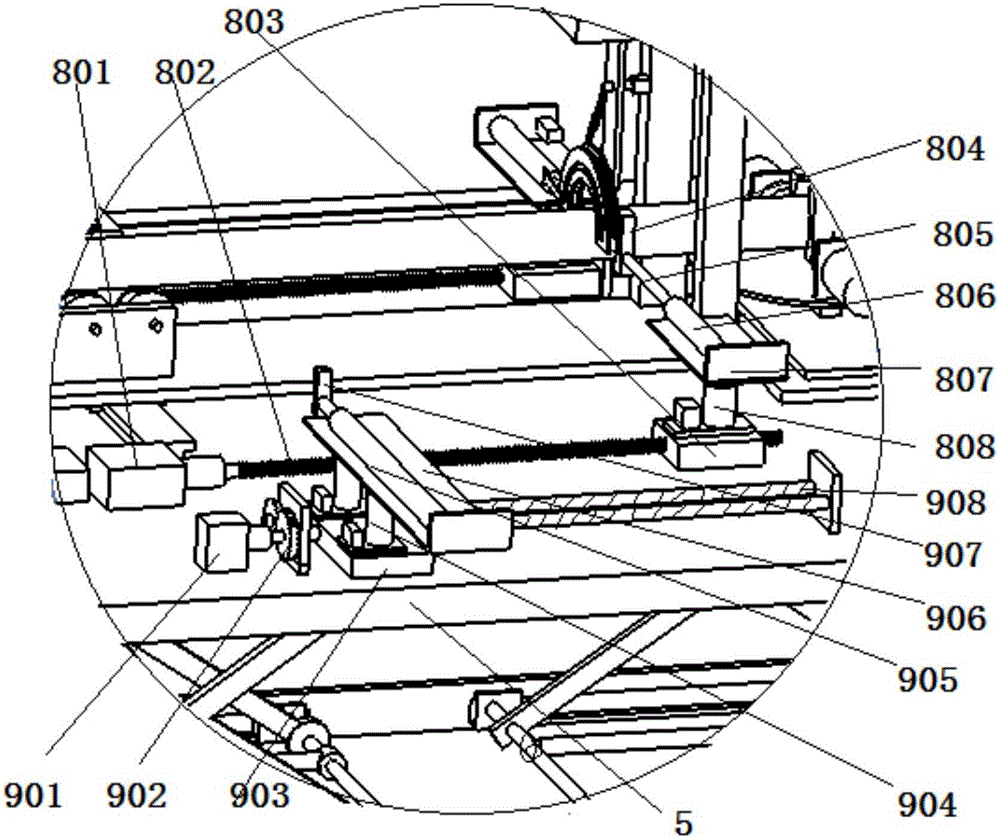

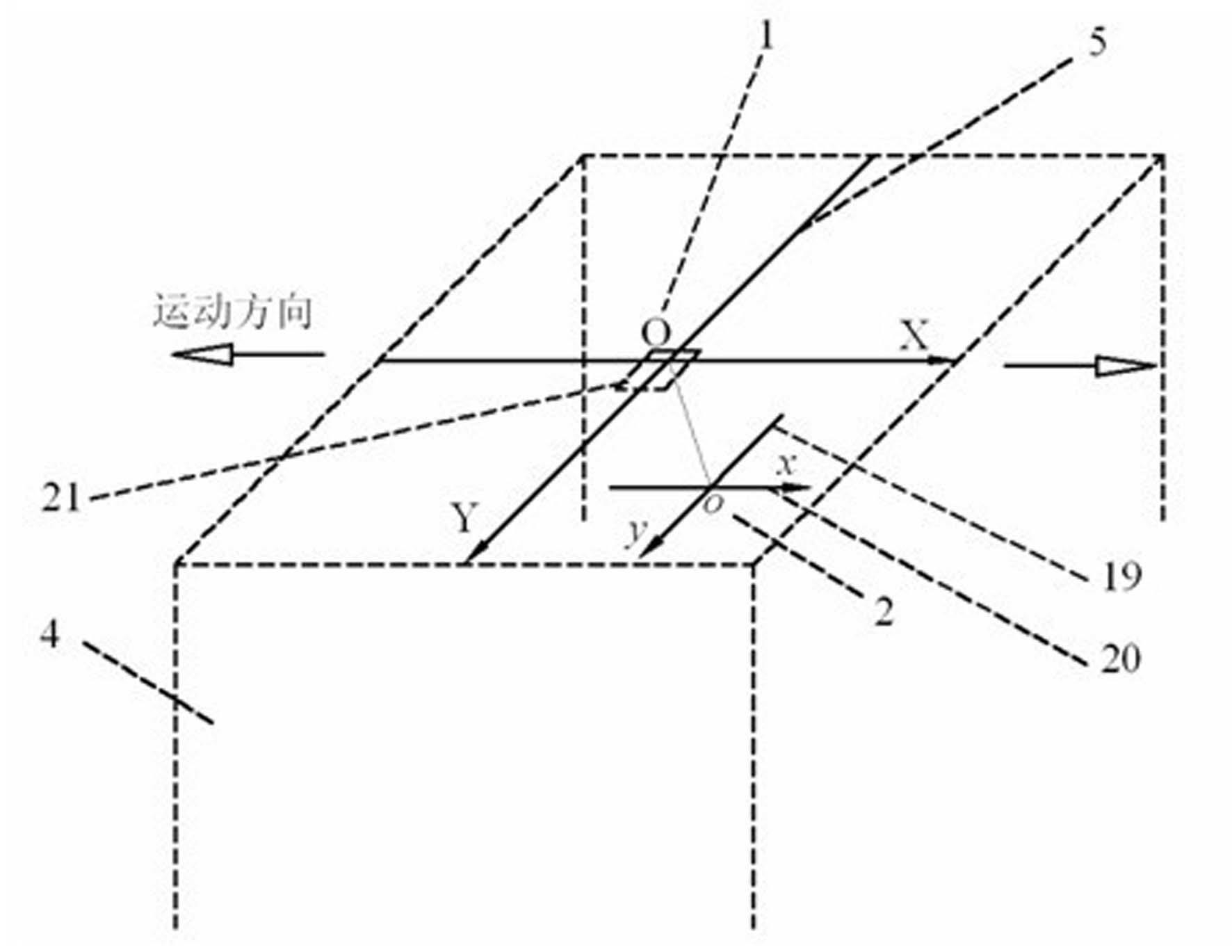

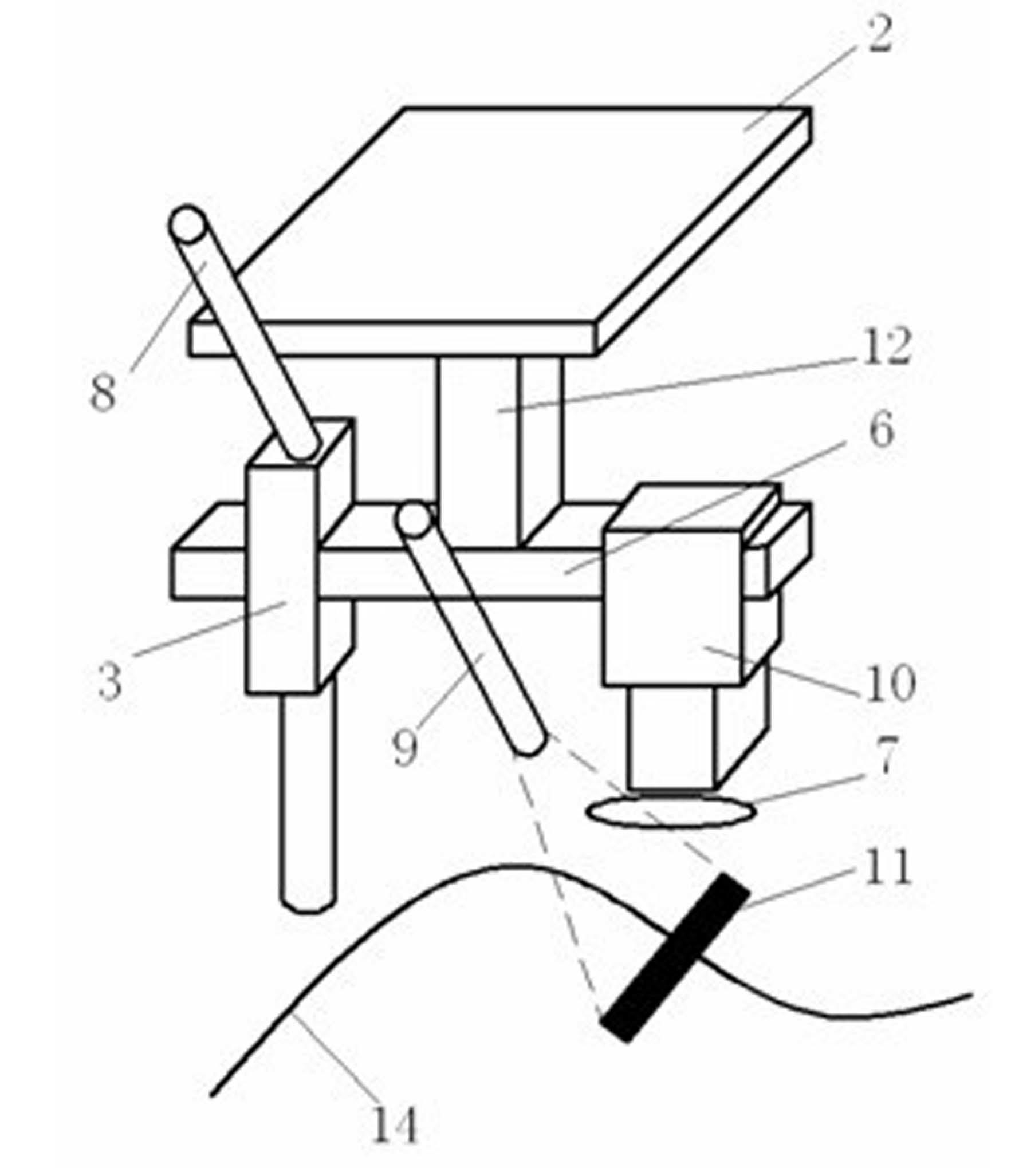

Switching macro micro laser high-speed cutting machine tool

InactiveCN102632336AWith redundant degrees of freedomReduce effective inertiaLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a switching macro micro laser high-speed cutting machine tool which comprises a macro-driven platform and a micropositioner. The switching macro micro laser high-speed cutting machine tool is characterized in that the micropositioner is arranged on the macro-driven platform, and the micropositioner is provided with a micropositioner support; the micropositioner support is provided with a support tail end connecting rod, and the support tail end connecting rod is provided with a structured light vision sensing system and a laser cutting head; the micropositioner support is mutually fixedly connected with a sliding block arranged on a macro-driven Y guide rail through a micromotion y guide slide and a micromotion x guide rail, the structured light vision sensing system mainly consists of a structured light laser, a camera and a light filter, wherein the structured light laser is arranged in the front of the camera; the emitted laser stripe is projected on the surface of a kerf, and the reflected light enters the camera through the optical filter so as to be imaged; and a macro-driven X guide rail arranged in an X direction is provided with bibcocks, and the micropositioner is arranged on the macro-driven Y guide rail arranged in a Y direction. The switching macro micro laser high-speed cutting machine tool provided by the invention has the advantages of simple structure, high cutting efficiency and the like.

Owner:SHENYANG LIGONG UNIV

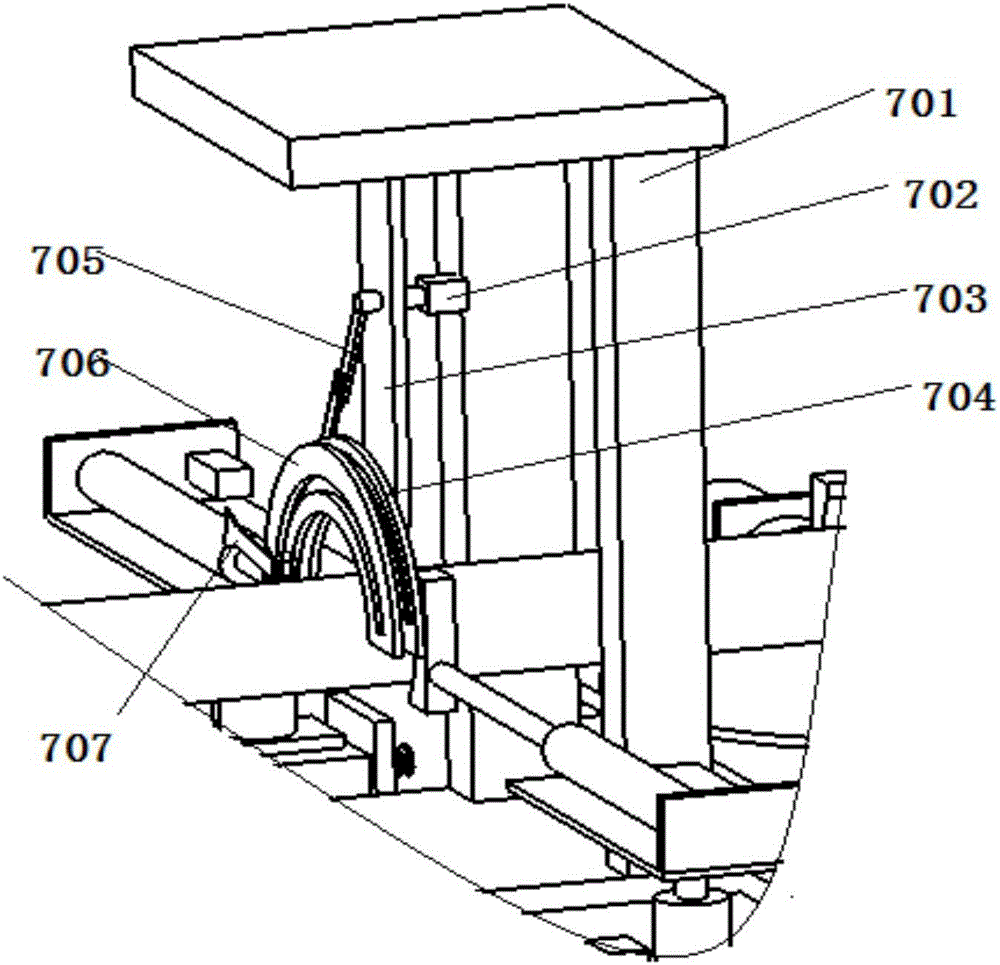

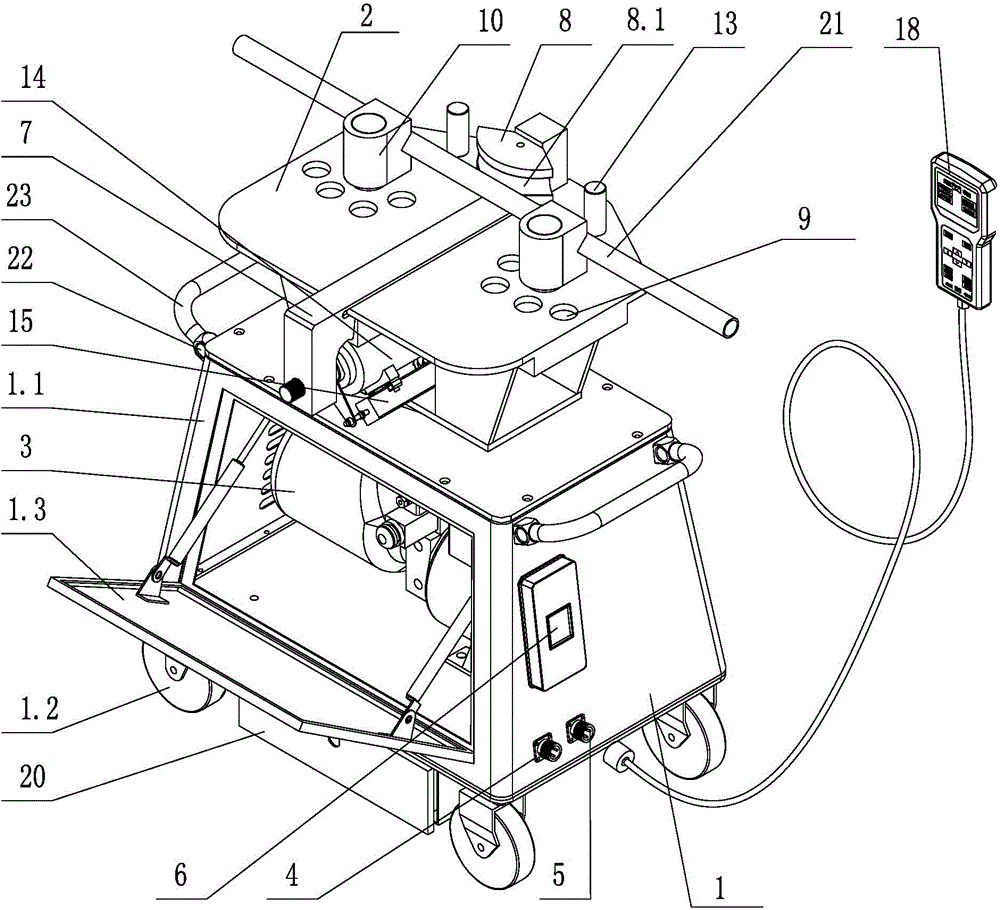

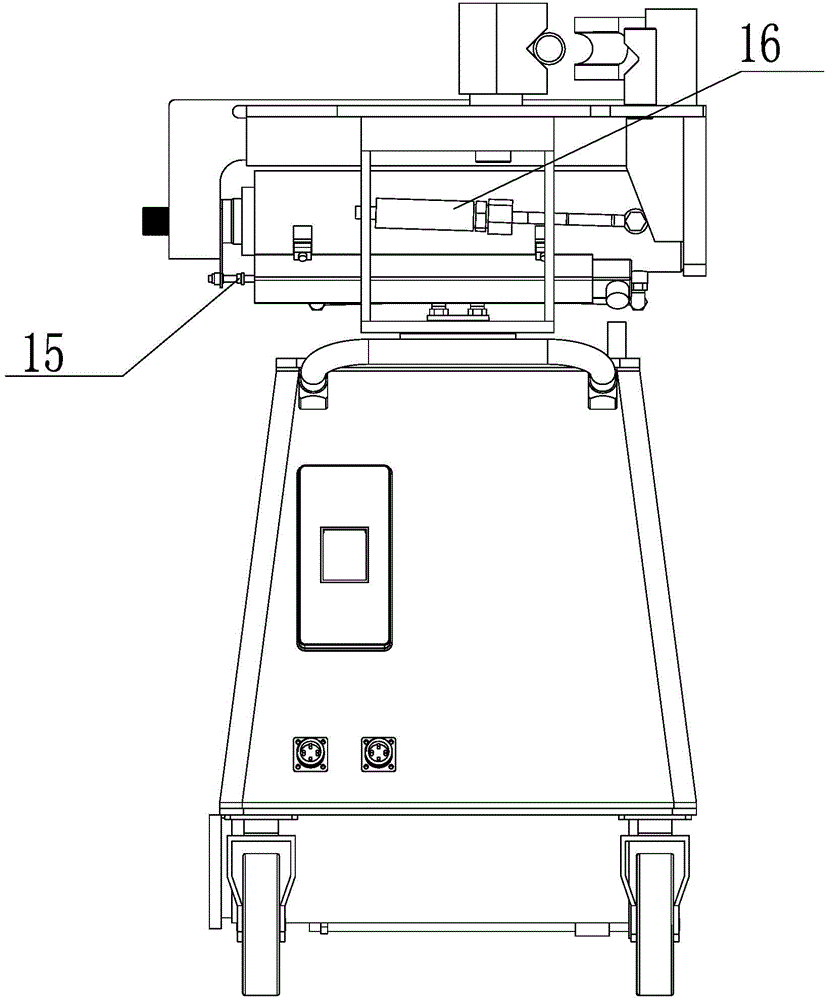

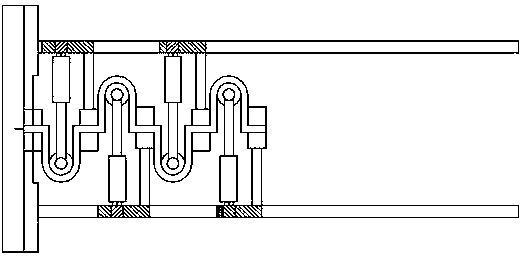

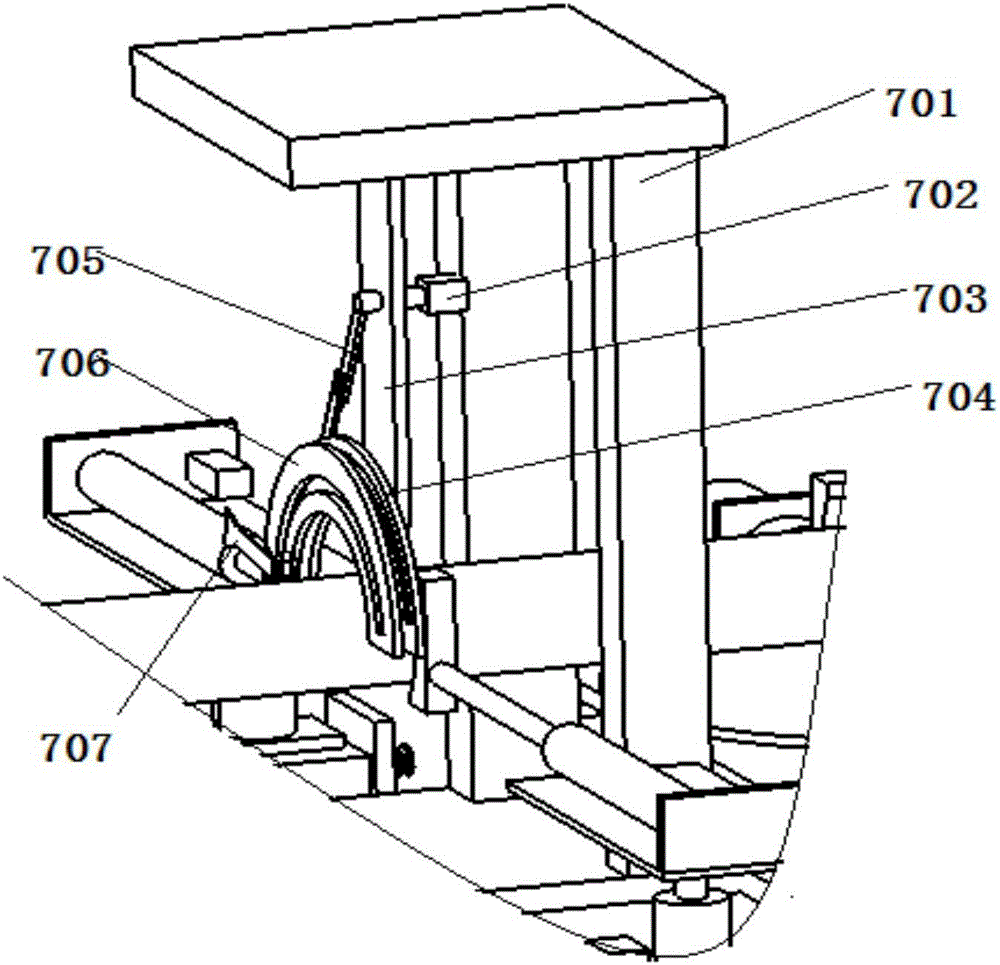

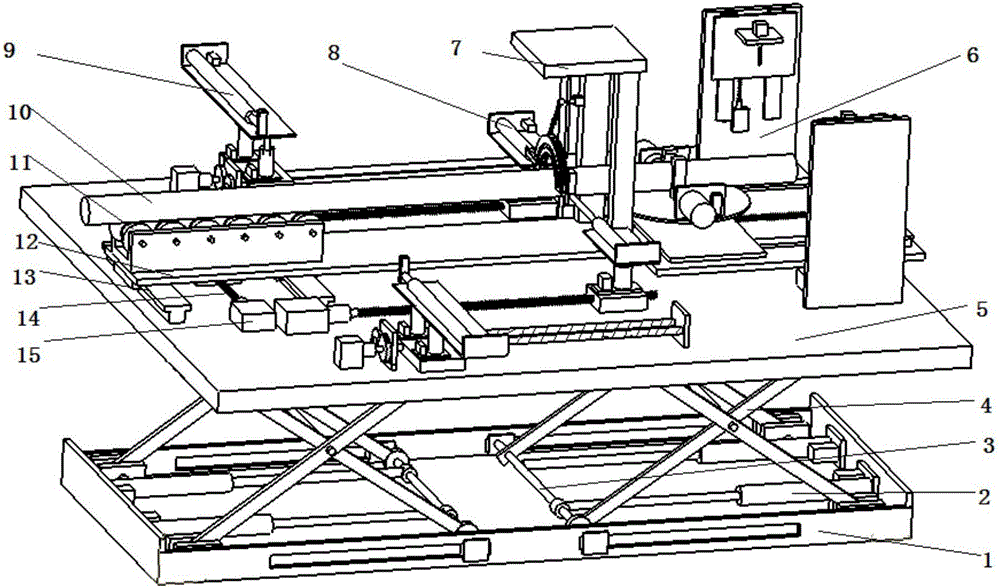

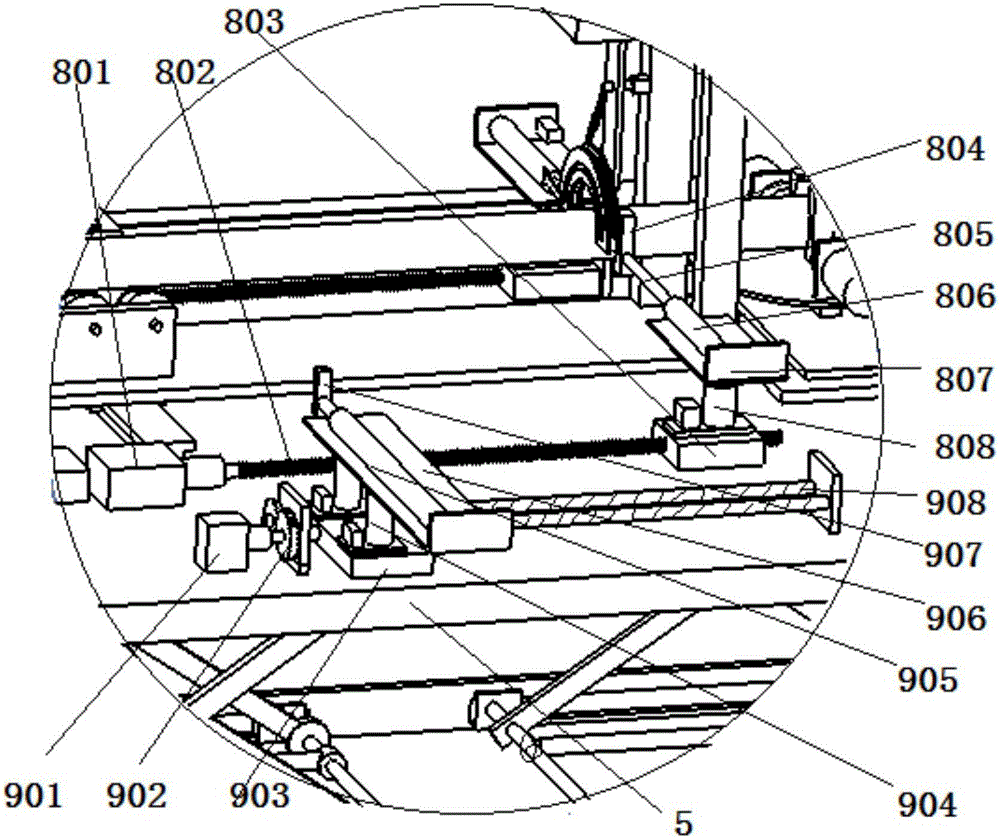

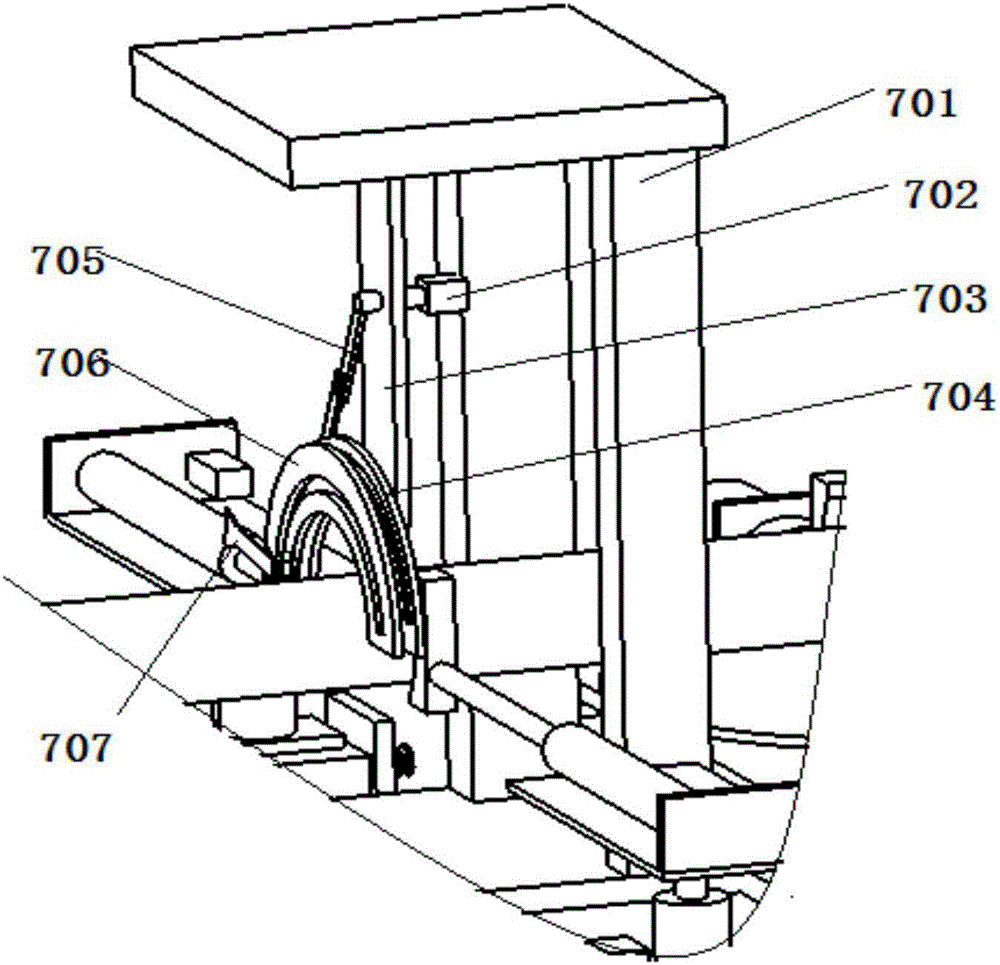

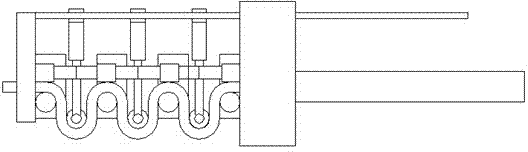

Numerical control push type pipe bending machine and bending method thereof

The invention discloses a numerical control push type pipe bending machine and a bending method thereof. The pipe bending machine comprises a power vehicle which can move freely and an operation table disposed at the top of the power vehicle. The power vehicle comprises a carriage and wheels which are disposed at four corners of the bottom of the carriage. A hydraulic power station is disposed inside the carriage. Two ends of the hydraulic power station are fixed inside two ends of the carriage. A carriage door is disposed on one side of the carriage. The outer wall, close to the carriage door, of the lower portion at one end of the carriage is respectively provided with a wire inlet connector and a computer socket. A power switch is disposed above the wire inlet connector and the computer socket. An oil cylinder is disposed in the operation table. A bending die is disposed on the table board of the operation table. The operation table is further provided with a slide plate for connecting the oil cylinder and the bending die. A plurality pairs of pin holes for disposing a fixing rack are formed in the table board of the operation table. The numerical control push type pipe bending machine is simple in structure, high in pipe bending strength, high in section forming quality, small in size and machining space, and capable of batch machining.

Owner:WUHAN HUAYE AUTOMATION MACHINERY

Multifunctional guillotine shear

InactiveCN101229618AAchieve bendingRealize the processing effectFeeding apparatusOther manufacturing equipments/toolsRear quarterMetallic materials

The invention discloses a multi-functional plate shearing machine and solves the technical issues that the plate shearing machine has single function in the prior art. The multi-functional plate shearing machine of the invention consists of a left side plate, a right side plates, a base, a motor, a pressure plate spring, an upper cutter rest and a bottom cutter rest; wherein, the upper cutter rest which is provided with an upper cutter edge is arranged inside a large guide rail of the left and the right side plates; the bottom cutter rest which is provided with a bottom cutter edge is positioned at the bottom of the left and the right side plates; a bending top plate is arranged on the top of the left and the right side plates and a bending / stamping top die is arranged in the lower part of the bending top plate while the bending / stamping bottom die is arranged in the upper part of the upper cutter rest. The multi-functional plate shearing machine of the invention integrates all the functions respectively realized by a plurality of devices into one device and ensures that the plate shearing machine can not only conduct the plate shearing for metal materials, but also implement the bending or the stamping of the materials so that the processing space occupied by the machine is saved, thus reducing investment cost of the machine.

Owner:杨胜杰

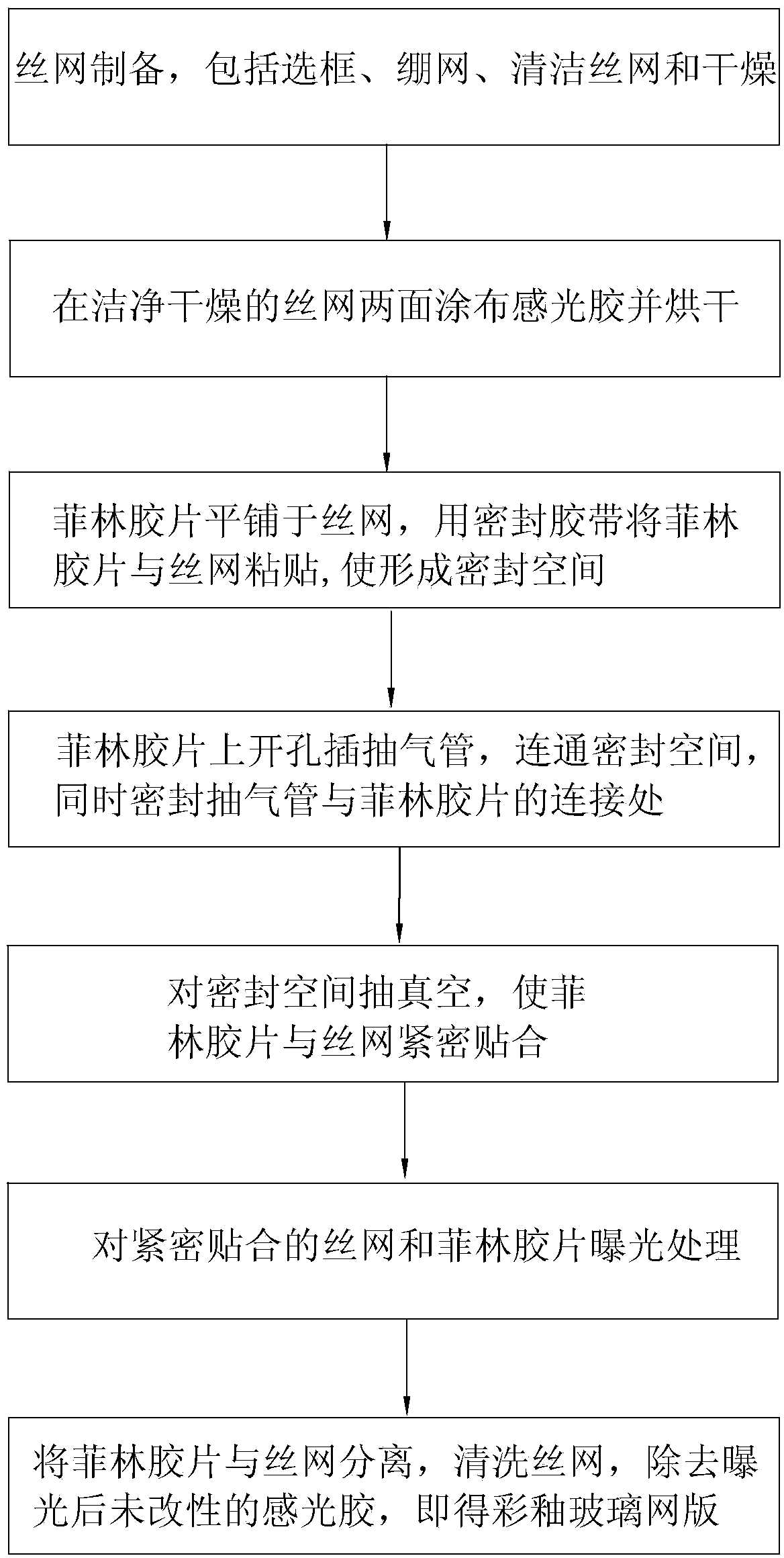

Manufacturing method for enameled glass screen printing plate and enameled glass

The invention relates to the relevant technical field of enameled glass manufacturing and in particular relates to a manufacturing method for an enameled glass screen printing plate. The manufacturing method comprises the steps of silk screen preparation, photosensitive resist coating and plate burning, wherein the plate burning step specifically comprises the substeps of stacking and adhering a silk screen and a film to form a closed space between the silk screen and the film, vacuumizing the closed space to fit the film and the silk screen, and exposing the laminated silk screen and the film. According to the manufacturing method, the adopted equipment is simple, and a special plate burning machine for plate burning is not needed, so that the cost is saved; during manufacturing, size limitation is avoided, and manufacturing of multiple enameled glass screen printing plates with different sizes, in particular manufacturing of large-size enameled glass screen printing plates, is realized; furthermore, the operating method is simple and is convenient to use; a large operating space is not needed; the manufacturing method can be suitable for various factory environments.

Owner:东莞南玻工程玻璃有限公司 +1

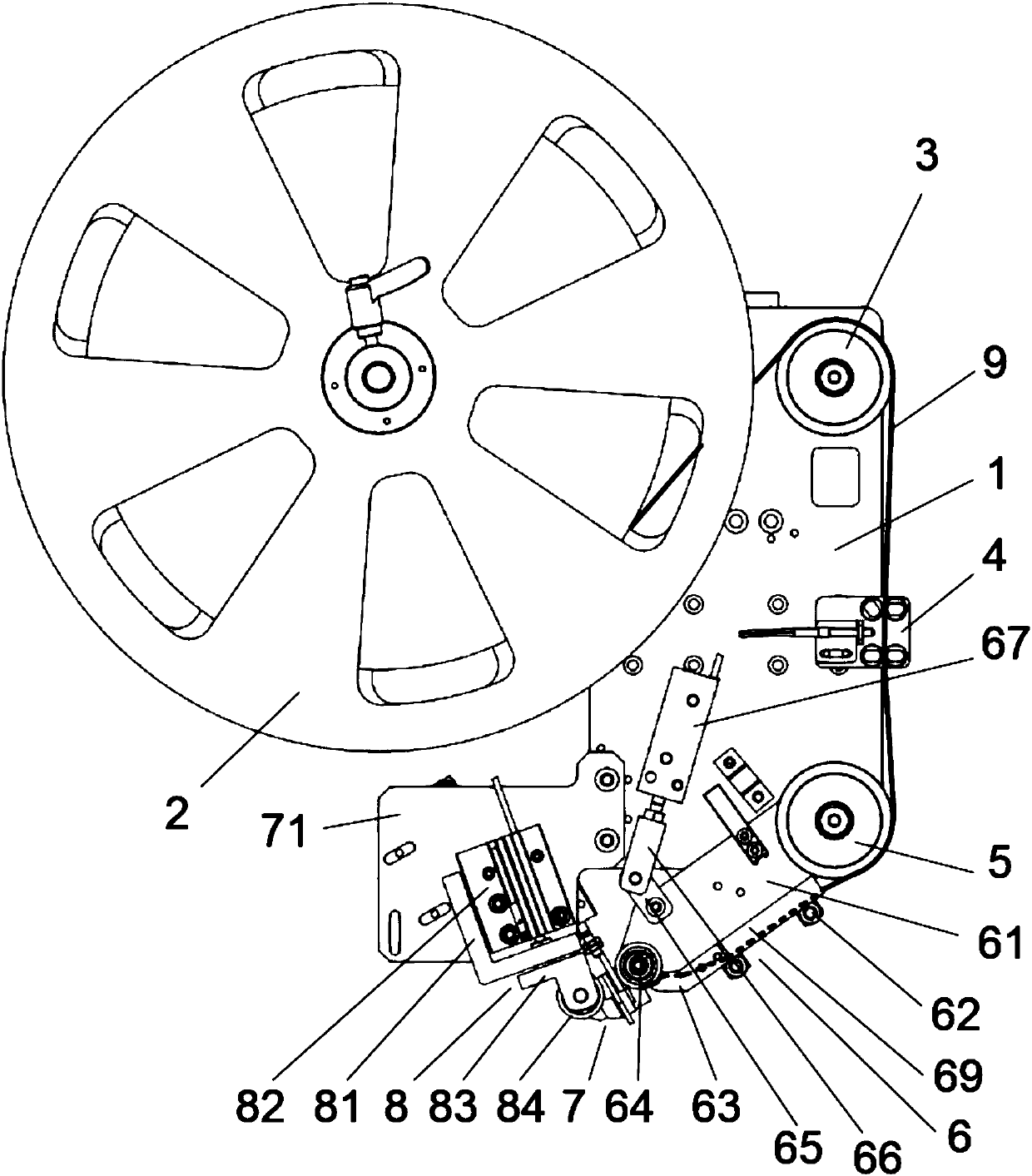

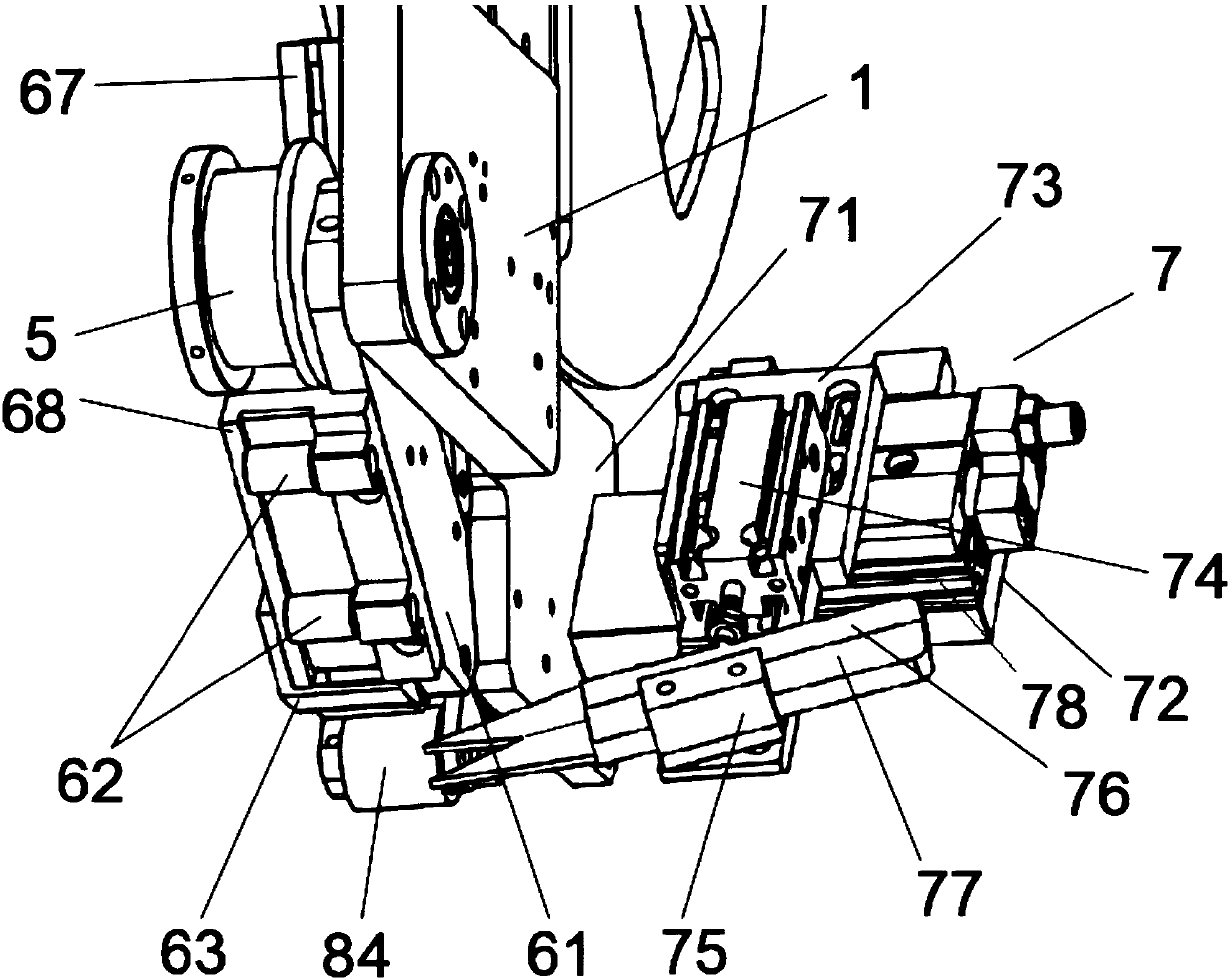

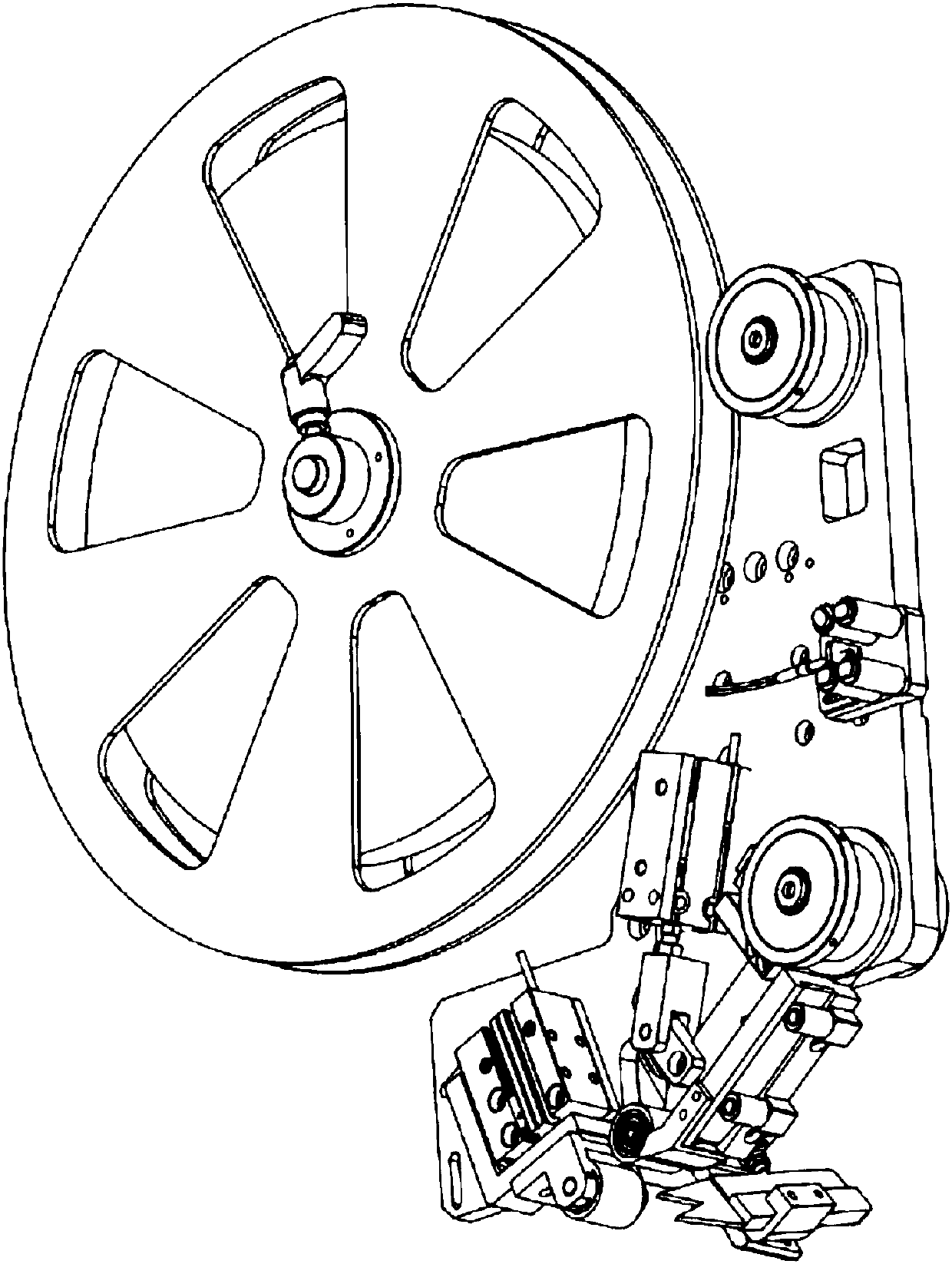

Rolling type flat adhesive tape sticking device

The invention relates to a rolling type flat tape sticking device. A rolling type flat tape sticking device includes a mounting plate; a feeding tray is fixed on the upper left of the mounting plate, a first guide roller is fixed on the upper right, a sensor is fixed on the middle position of the right end, and a lower right is fixed with a A second guide roller; a rolling device is arranged on the left side of the second guide roller, and a shearing device and a leveling device are fixed on the left side of the rolling device. The rolling type flat tape sticking device of the invention has the advantages of simple structure, stable action, high dimensional control precision, compact overall structure and saving processing space; , and then use the flat pressing roller to carry out the side pressing, so that the adhesive tape on the bottom film has a high flatness, good quality of the adhesive, and is very beautiful.

Owner:苏州恒铭达电子科技股份有限公司

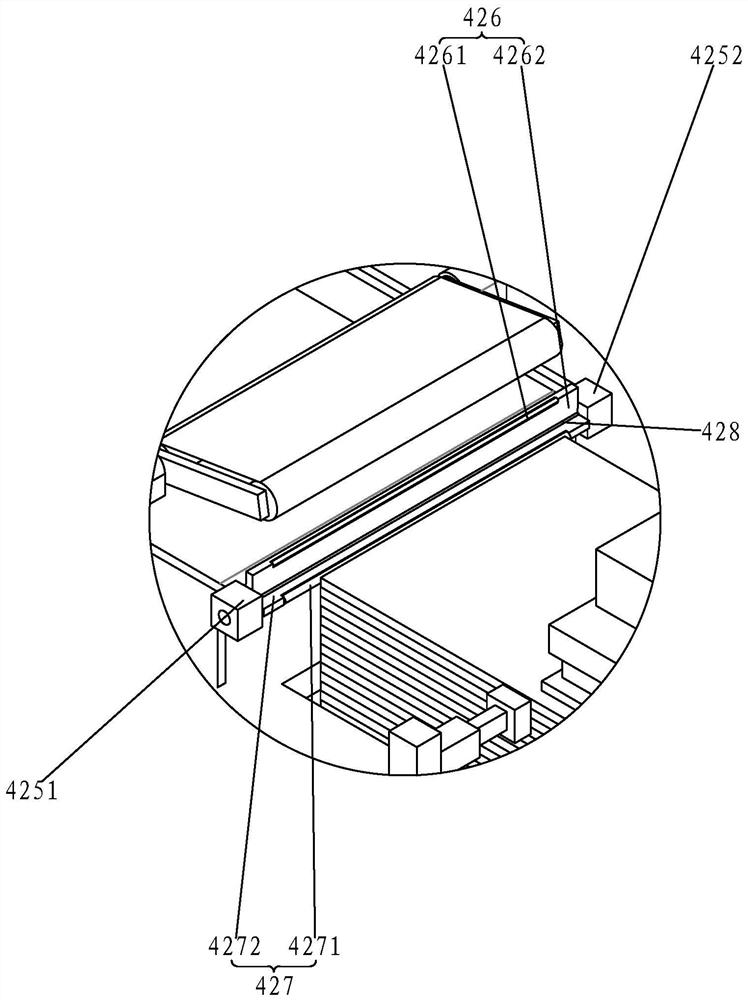

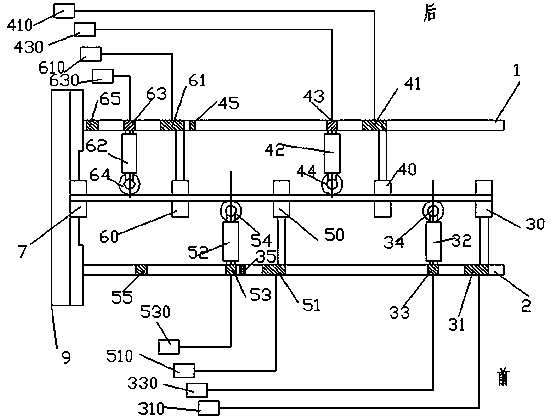

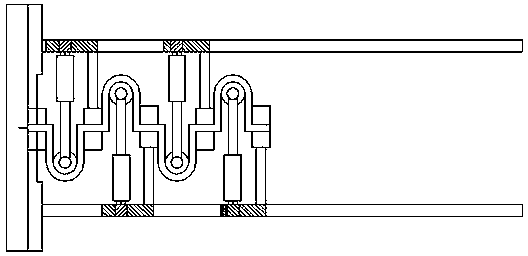

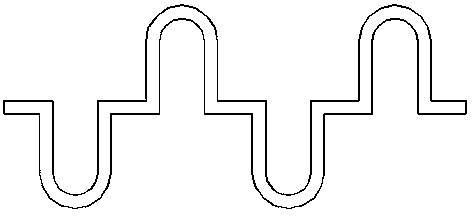

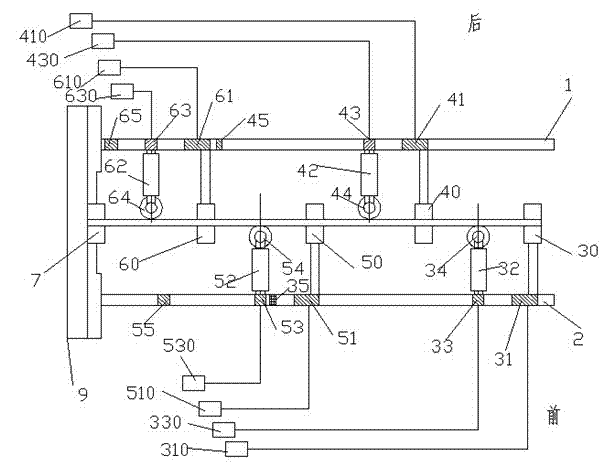

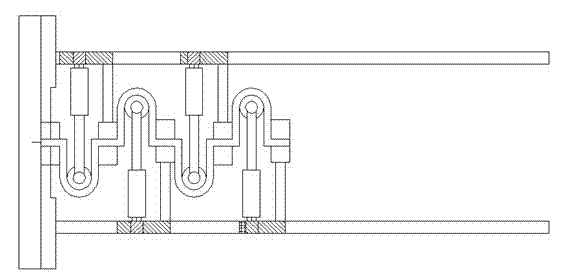

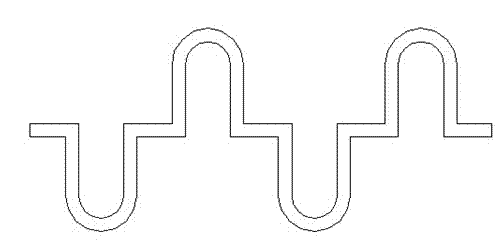

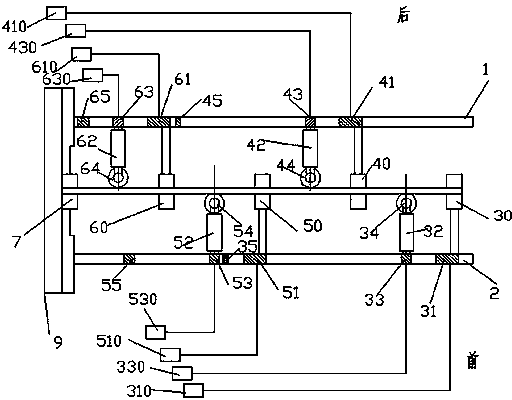

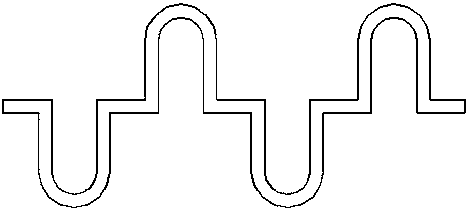

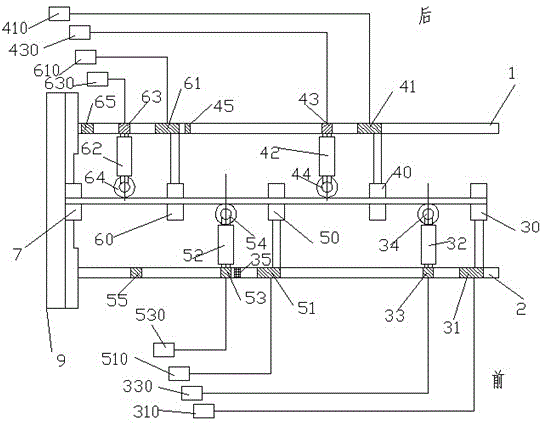

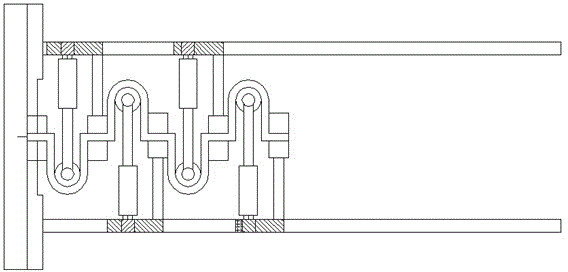

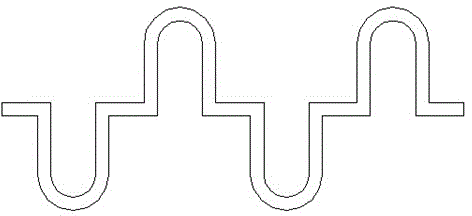

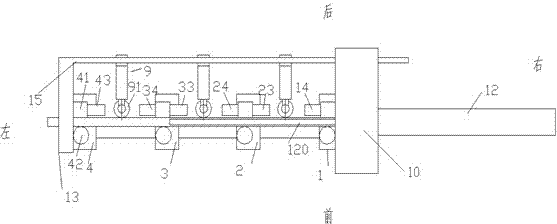

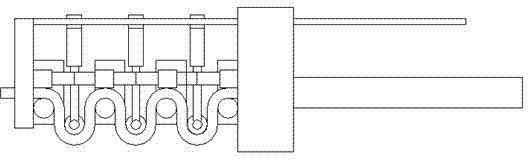

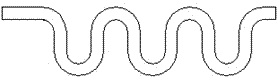

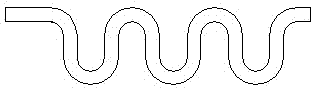

Furnace wire bending process adopting screw rod type clamping device and adopting heat treatment

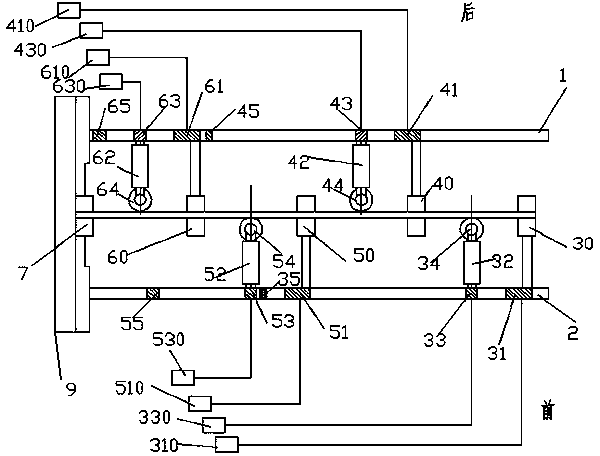

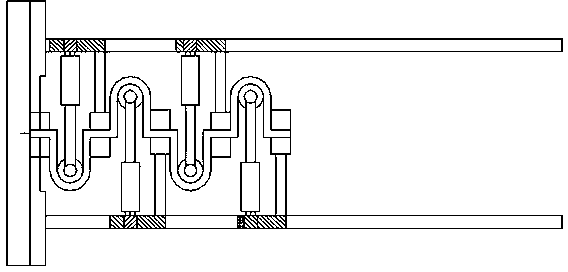

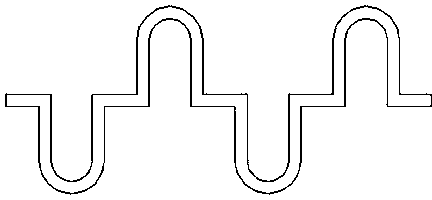

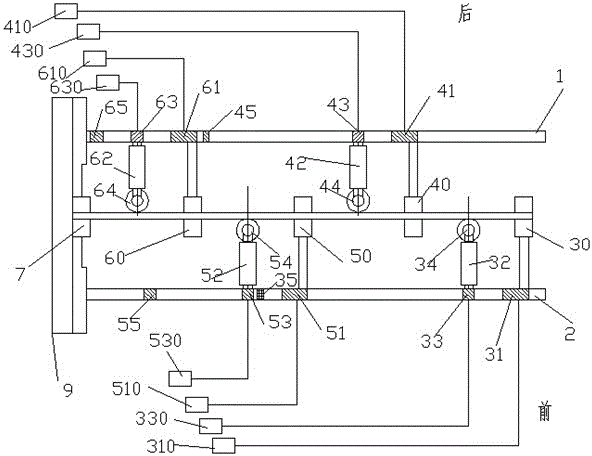

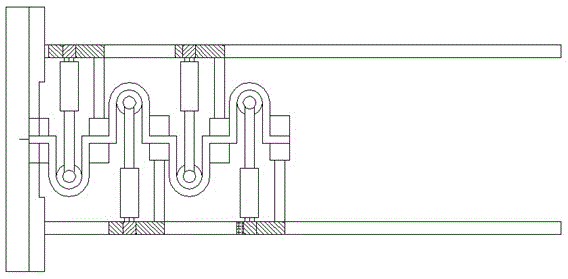

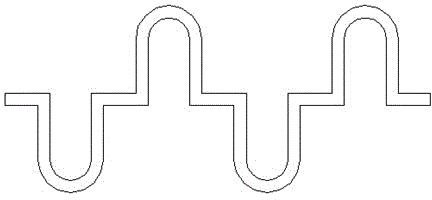

The invention provides a furnace wire bending process adopting a screw rod type clamping device and adopting heat treatment. Row wires of furnace wires of a heating furnace are rectangular row wires formed by the furnace wires of the heating furnace through linear arrangement in a vertical direction, a bending device is used in the process and comprises a support frame, a front horizontal guide rail and a back horizontal guide rail are respectively arranged in a front position and a back position of the right side of the support frame, a support frame clamping device is arranged in the middle position of the right side of the support frame and is positioned between the front horizontal guide rail and the back horizontal guide rail, a first bending device is arranged at the right part of the back horizontal guide rail, a third bending device is arranged at the left part of the back horizontal guide rail, a second bending device is arranged at the right part of the front horizontal guide rail, a fourth bending device is arranged at the left side of the front horizontal guide rail, and the bending devices are respectively used for forming four U-shaped bending parts on the row wires of the furnace wires of the heating furnace from the left side to the right side.

Owner:广州市青荷金属制品有限公司

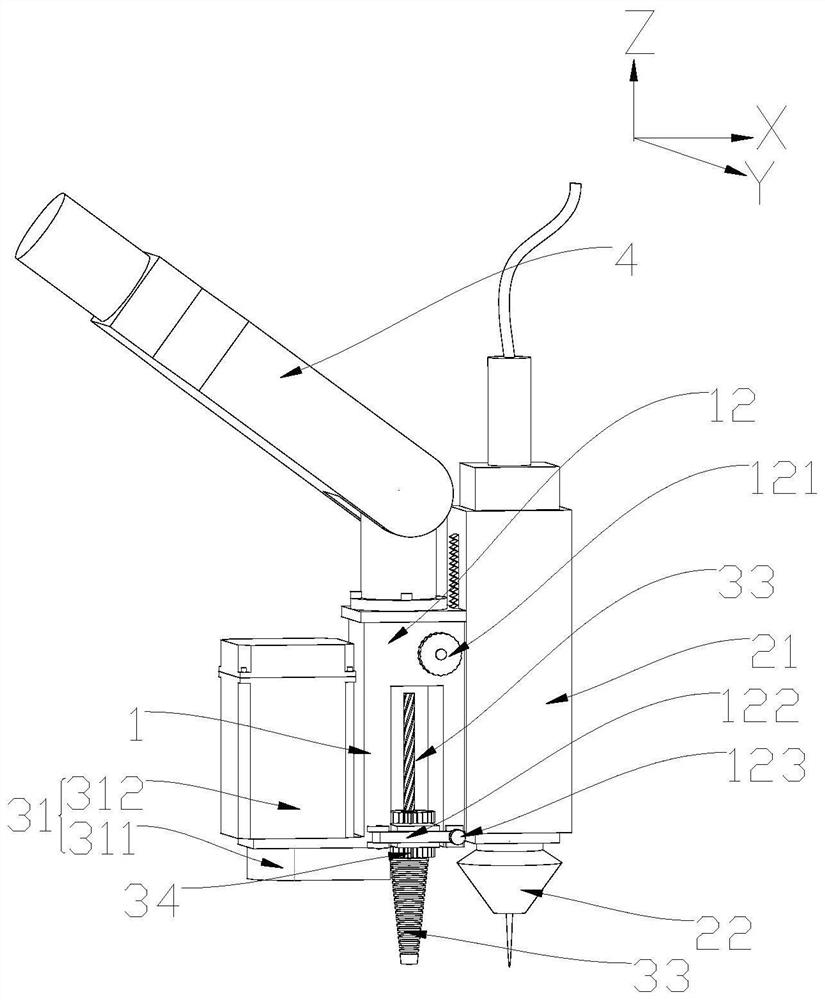

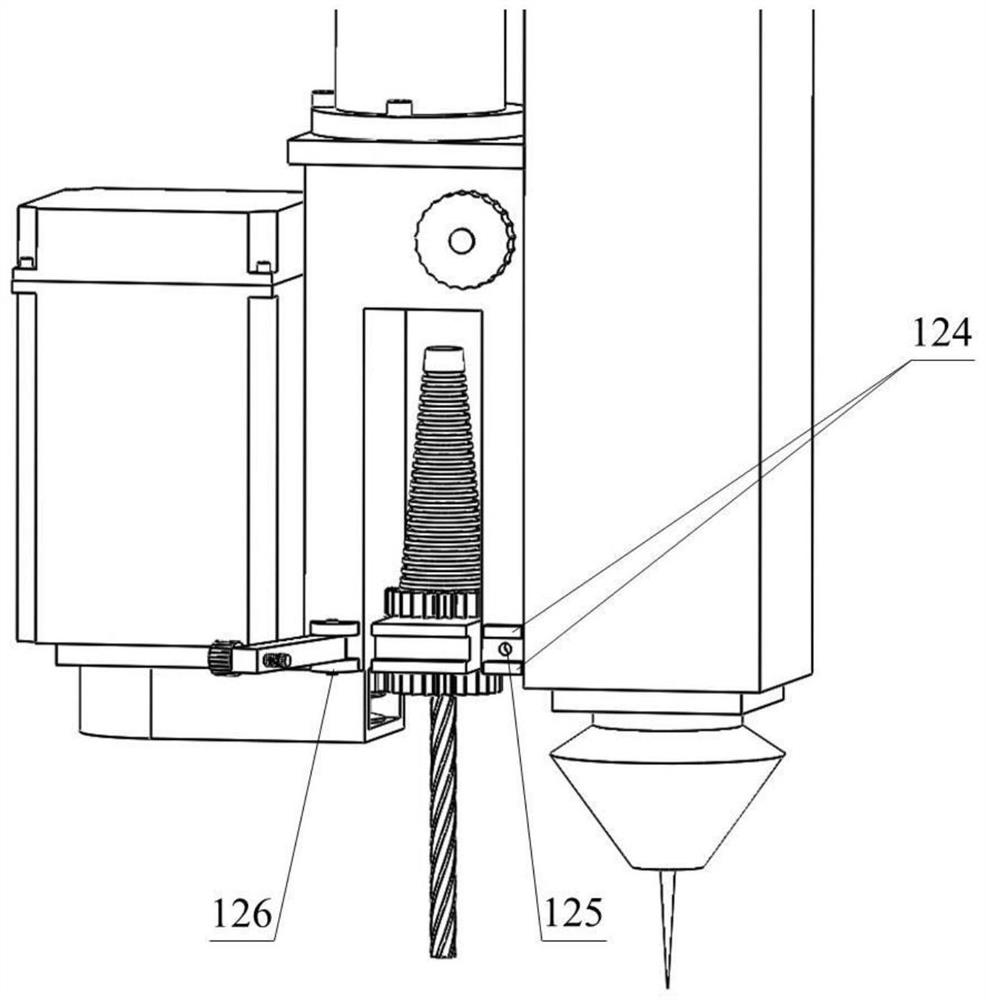

Laser and friction composite additive and subtractive machining device and method

PendingCN113275897AReduce residual stressReduce distortionOther manufacturing equipments/toolsLaser beam welding apparatusMilling cutterElectric machinery

The invention provides laser and friction composite additive and subtractive machining device and method. The device comprises a frame body, a first additive and subtractive assembly and a second additive and subtractive assembly, wherein, the first additive and subtractive assembly comprises a laser head and a powder feeding nozzle, a guide rail in the vertical direction is arranged on the side face of the laser head, the powder feeding nozzle is arranged at the tail end of the laser head, and the powder feeding nozzle is suitable for feeding metal powder to a laser focus of the additive laser source; the frame body comprises a support and a holder, the holder is parallel to the laser head, and a first movement unit suitable for being matched with the guide rail is arranged on the side face of the holder, so that the laser head can be adjusted to move in the vertical direction relative to the holder; and the second additive and subtractive assembly comprises a driving motor, a milling cutter, a rotating friction head and a rotating base, the rotating base is rotationally connected with the holder, and the rotating friction head and the milling cutter are parallel to the laser head and are arranged at the two ends of the rotating base in the height direction correspondingly. The device is compact in structure and low in manufacturing cost.

Owner:广东中科德弗激光科技有限公司

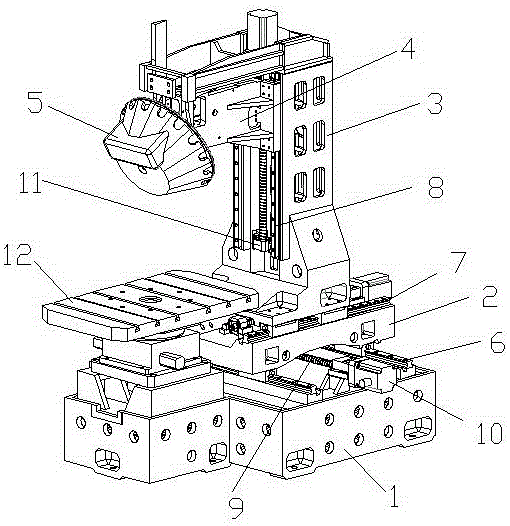

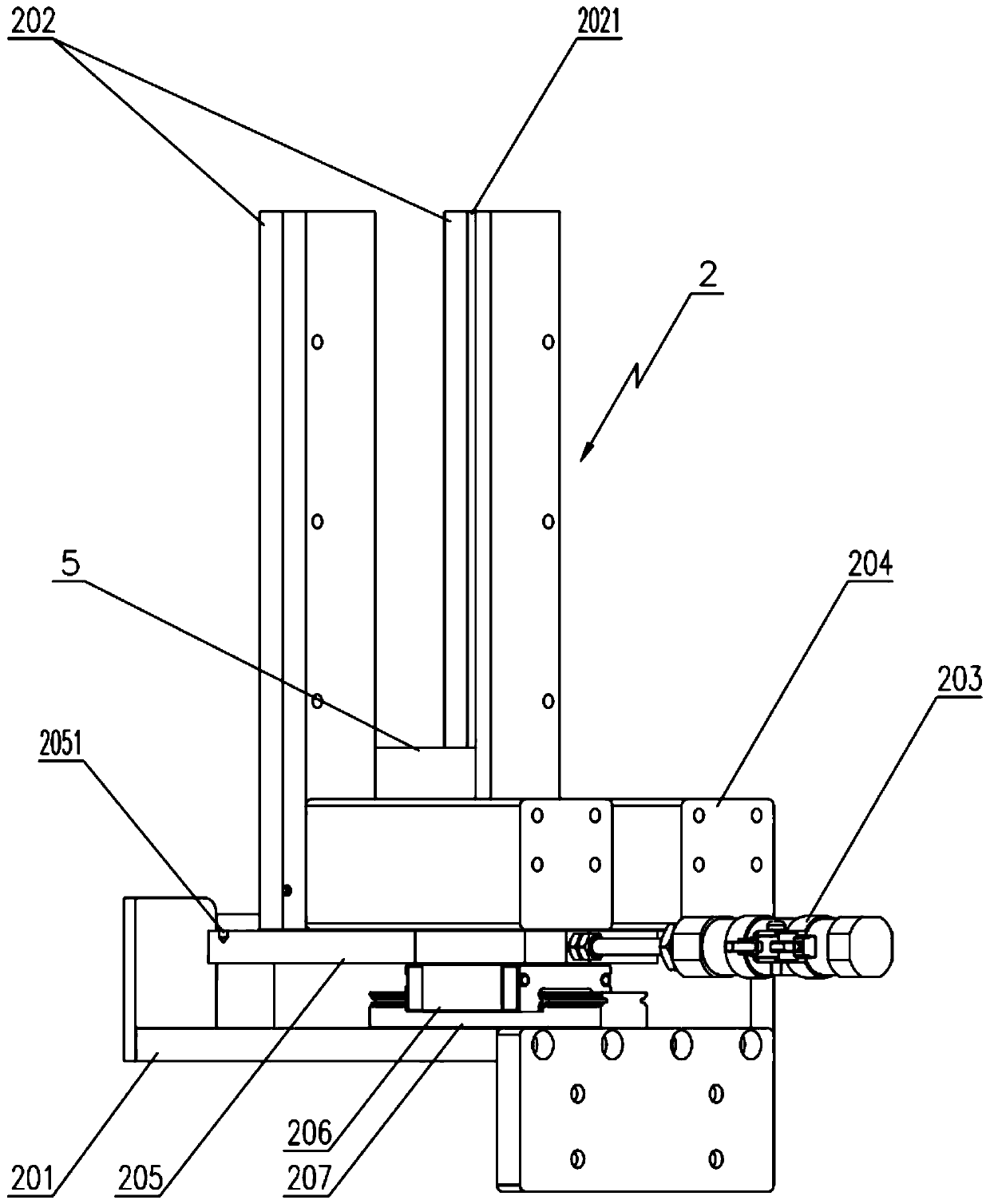

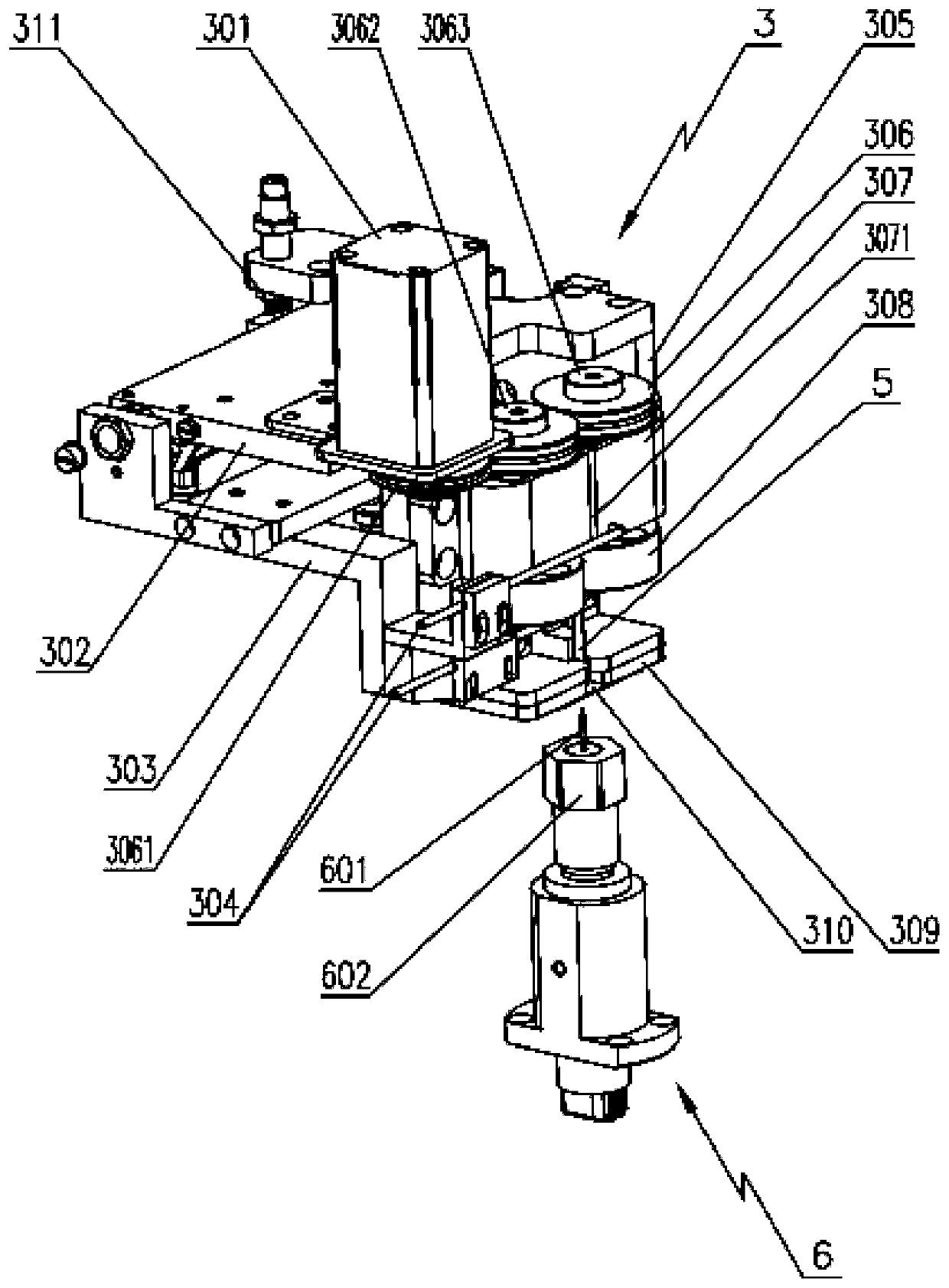

All-movable column drilling and tapping device

InactiveCN105855890ASmall processing spaceImprove efficiencyFeeding apparatusOther manufacturing equipments/toolsMachining

The invention discloses a full-moving column drilling and tapping device, which comprises a base, the front end of the base is provided with a workbench that can rotate in a horizontal plane, the rear end is provided with a saddle, and the saddle is provided with a column. A headstock that can move up and down relative to the column is arranged on the column, and a tool magazine located above the workbench is arranged on the headstock. By setting the worktable for fixing the workpiece as a rotatable structure, and by setting the headstock for fixing the tool magazine as a structure with adjustable positions in front and back, left and right, up and down, it is convenient for the tool to select a suitable processing station and saves money. The processing space is increased, and the efficiency is improved.

Owner:ZHENJIANG FUDE NC MACHINE TOOL TECH CO LTD

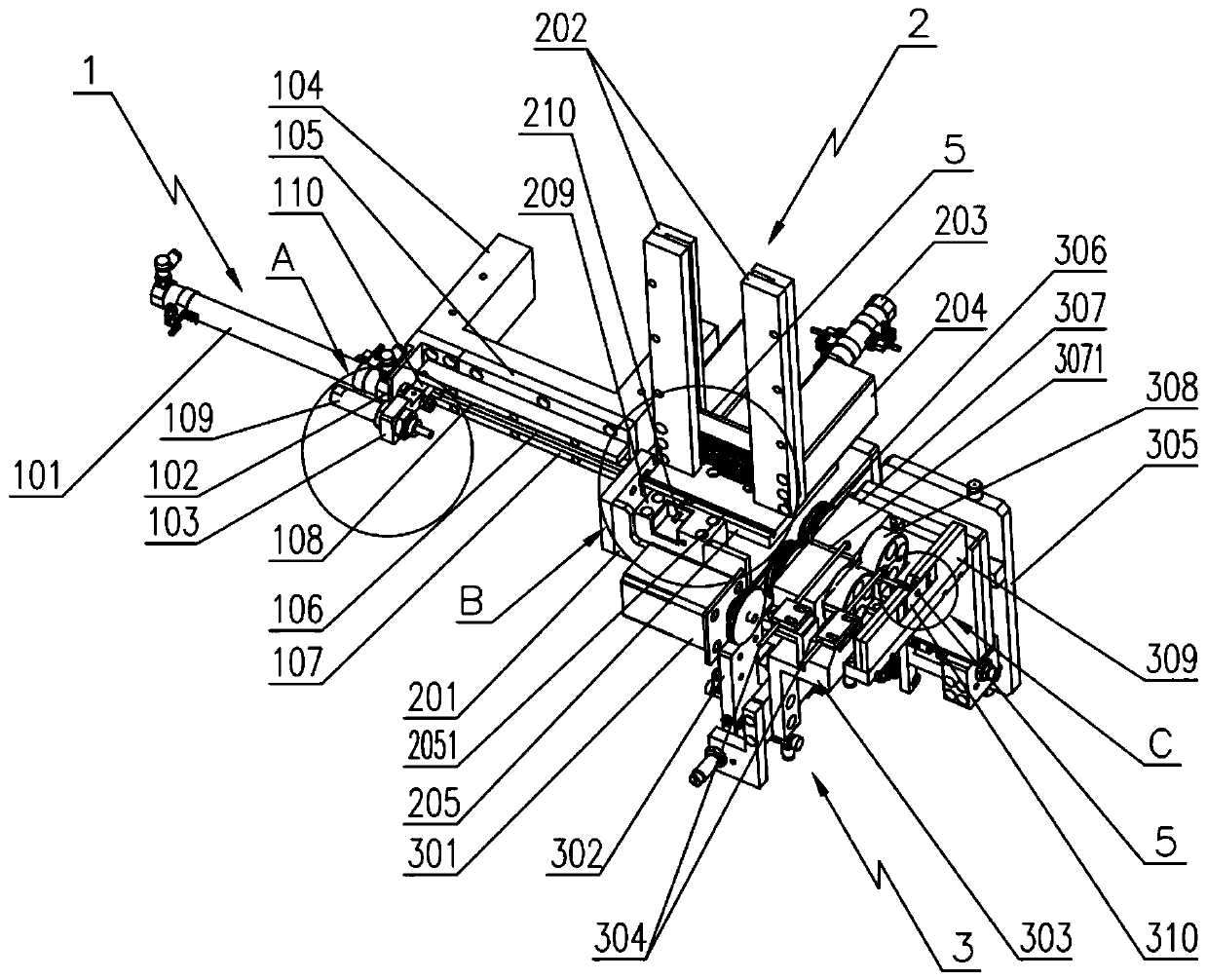

Automatic PIN feeding, discharging and punching mechanism for grinding machine

The invention discloses an automatic PIN feeding, discharging and punching mechanism for a grinding machine. The automatic PIN feeding, discharging and punching mechanism comprises a PIN storage assembly used for storing and providing PINs, wherein one side of the PIN storage assembly is connected with a PIN feeding assembly matched with the PIN storage assembly, the other side of the PIN storageassembly is connected with a driving assembly, and a rotating assembly is installed on the back face of the driving assembly; and the driving assembly converts the horizontally-arranged PINs into vertically-arranged PINs, and enables the PINs to correspond to inner holes of welding pins needing to be machined. According to the automatic PIN feeding, discharging and punching mechanism for the grinding machine, the PIN storage assembly is arranged, so that the PINs are stored in batches, rapid and automatic feeding is facilitated, and automation is easy to achieve; furthermore, the pushing process of the PINs is continuously completed through an ejector rod and multiple guide grooves, and automatic feeding and discharging of the PINs are completed in cooperation with the driving assembly, sothat the machining space is saved; in addition, the PINs can be quickly and accurately positioned through a guide plate and an air blowing pipe during feeding; and finally, feeding and discharging routes of the PINs are fixed and controllable through a limiting block, a limiting device and the guide grooves, and the production process is stable and efficient.

Owner:江苏微影智能装备有限公司

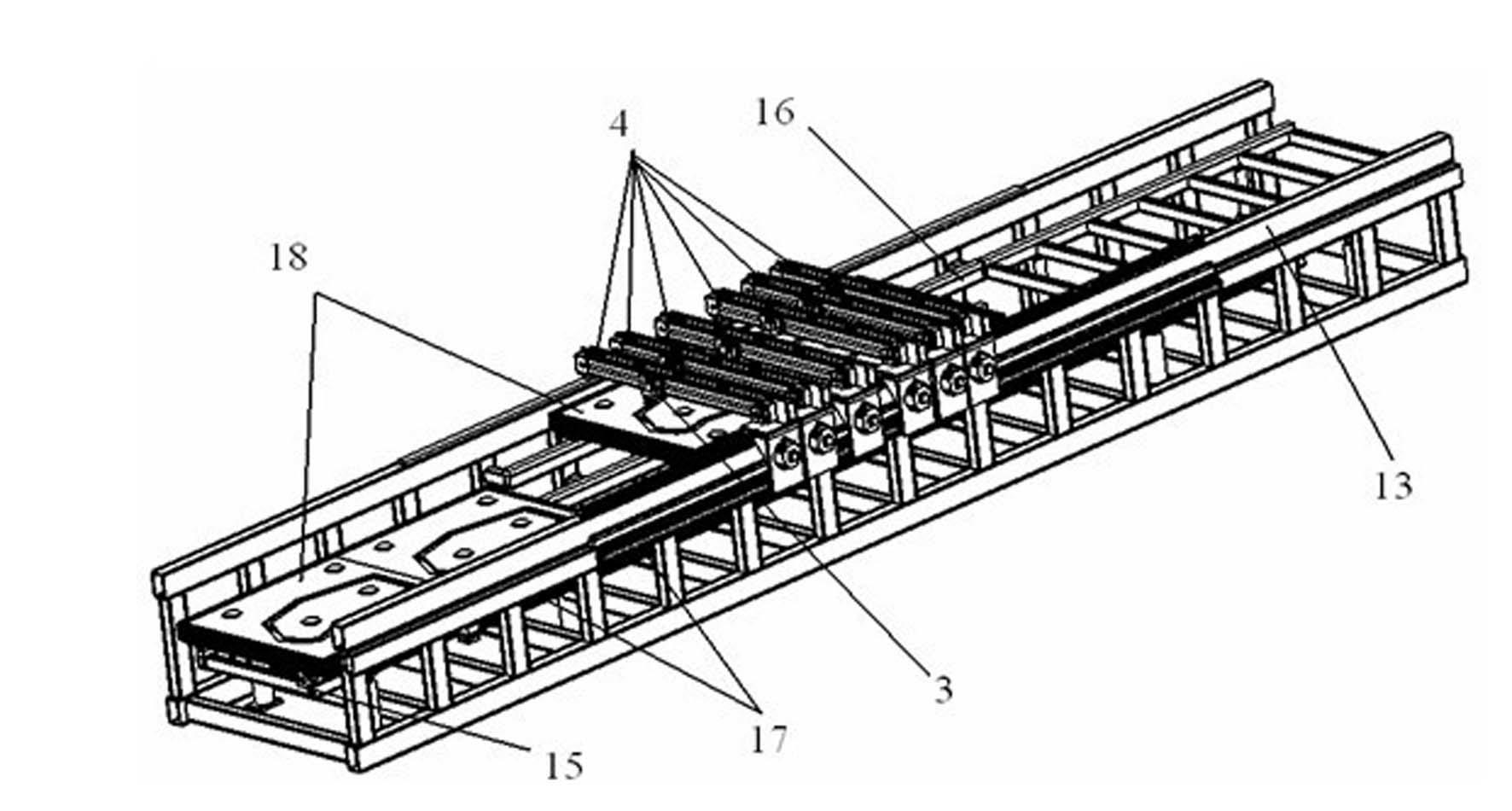

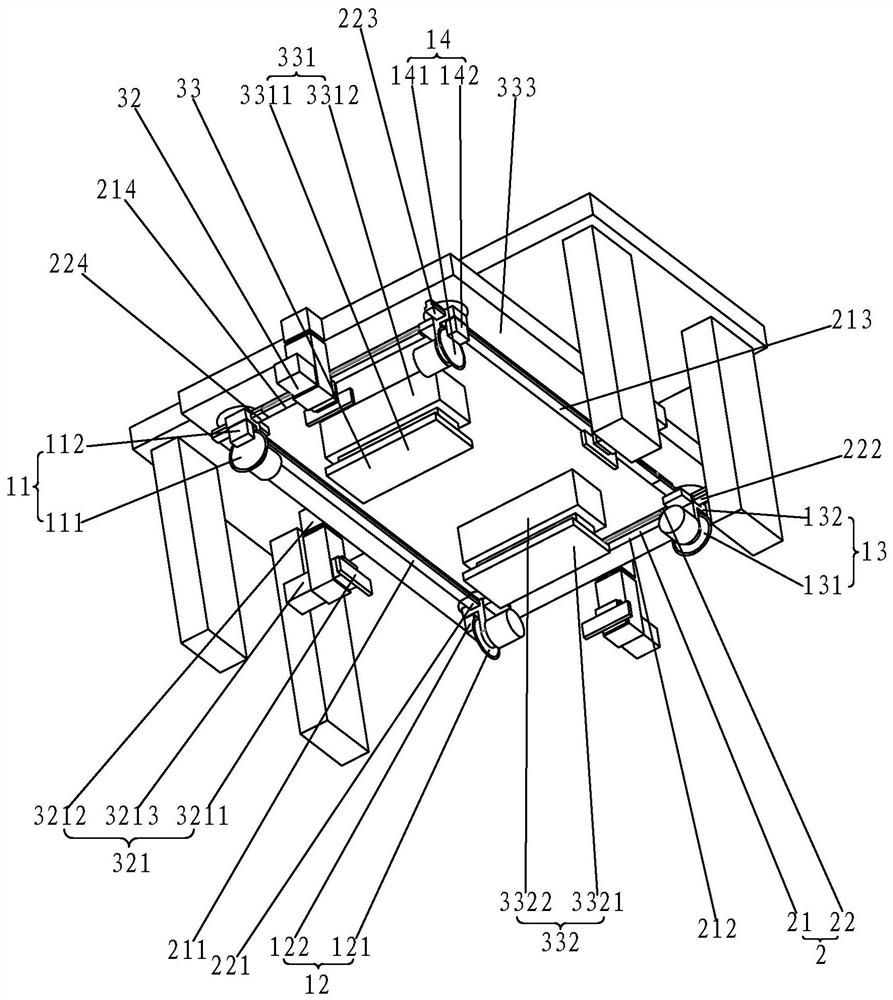

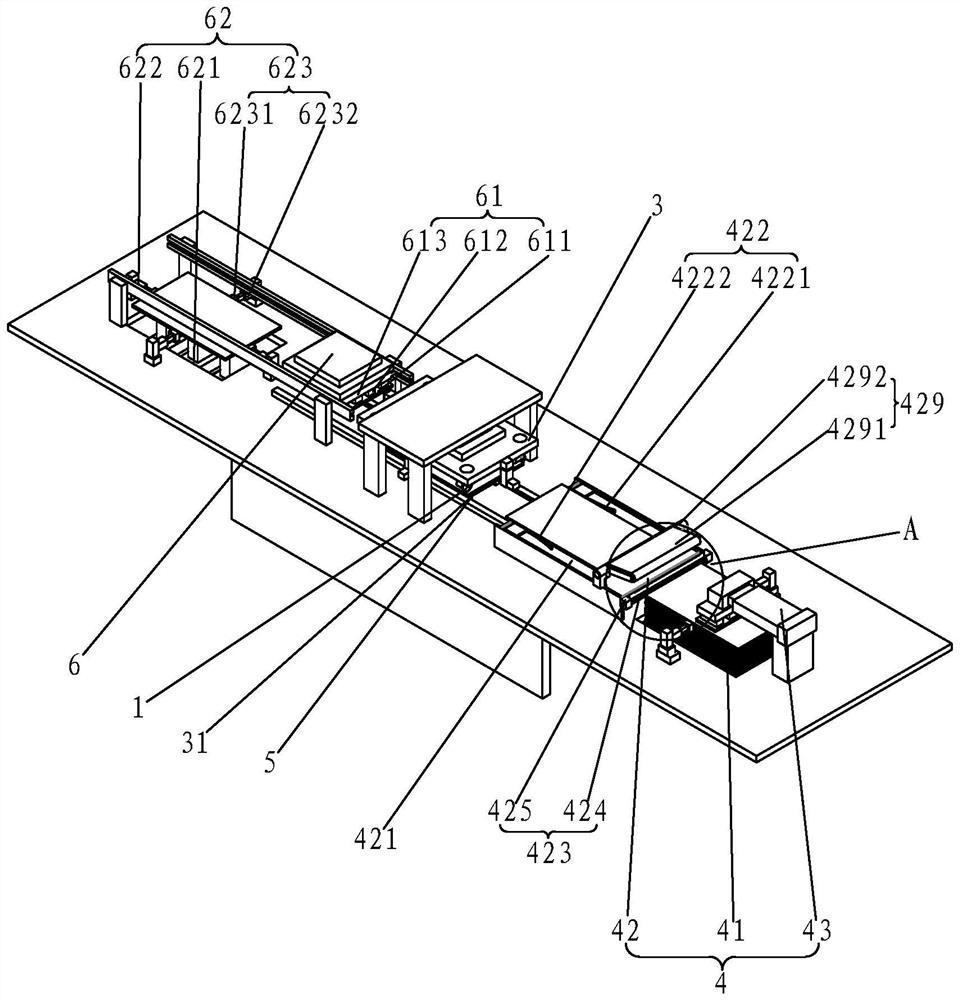

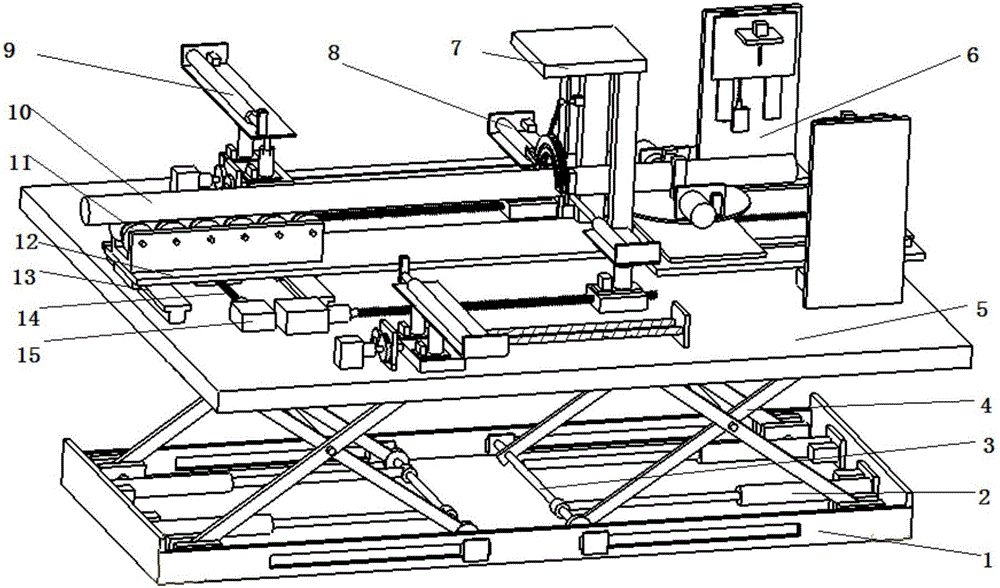

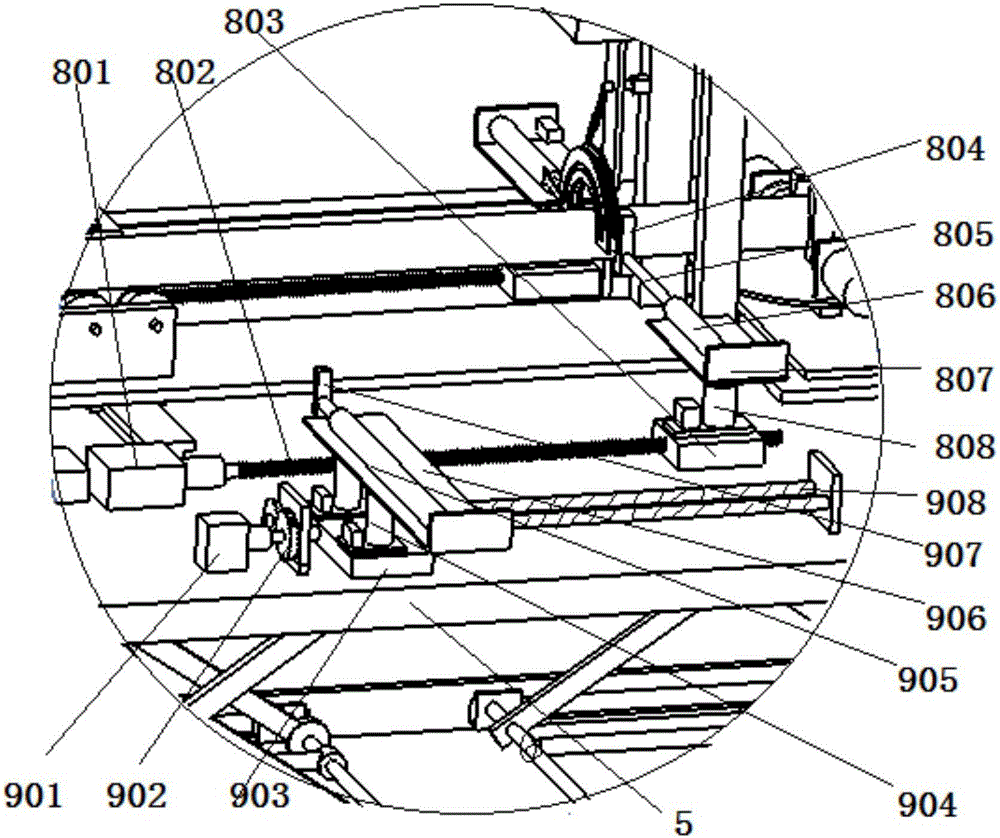

Digital intelligent longitudinal and transverse edge sawing production line

ActiveCN112847659AShorten the conveying strokeSmall processing spaceFeeding devicesCircular sawsProduction lineAgricultural engineering

The invention provides a digital intelligent longitudinal and transverse edge sawing production line. The production line comprises an edge sawing device for sawing the four edges of a wood board to be flat. The edge sawing device comprises an edge sawing mechanism for cutting the four edges of the wood board and a guide mechanism for guiding the edge sawing mechanism to move around the periphery of the wood board. The edge sawing mechanism comprises a first cutting device, a second cutting device, a third cutting device and a fourth cutting device which are used for cutting the four edges of the wood board correspondingly. The first cutting device, the second cutting device, the third cutting device and the fourth cutting device are in sliding connection with the guide mechanism. Through cooperative processing of the edge sawing mechanism and the guide mechanism, redundant edge materials of the long edges and the short edges of the wood board are processed at a time, the processing efficiency is greatly improved, the conveying stroke of the wood board is shortened, meanwhile, the processing space for sawing the wood board is saved, more assembly lines for sawing the wood board can be arranged in the same space, the processing scale of the wood board is enlarged, and great economic benefits are achieved.

Owner:福建兴恒机械科技有限公司

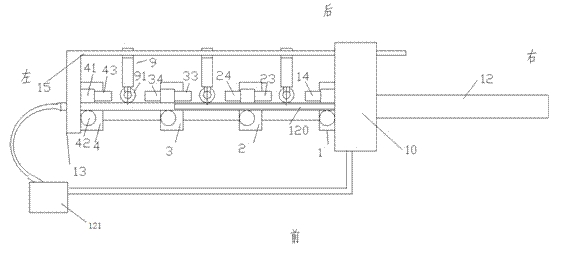

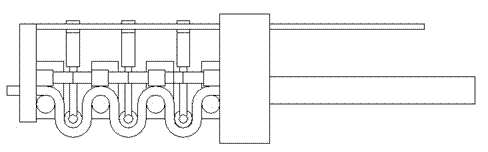

Process for bending furnace wires by using screw rod type clamping device and integrated circuit controller

The invention discloses a process for bending furnace wires by using a screw rod type clamping device and an integrated circuit controller. The furnace wire winding displacement of a heating furnace is a rectangular winding displacement formed by arranging the furnace wires of the heating furnace linearly in a longitudinal direction. In the process, a bending device is applied. The bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are arranged one after the other on the right side of the bracket; a bracket clamping device is arranged in the middle of the right side of the bracket, and is positioned between the front horizontal guide rail and the back horizontal guide rail; a first bending device is arranged on the right part of the back horizontal guide rail; a third bending device is arranged on the left part of the back horizontal guide rail; a second bending device is arranged on the right part of the front horizontal guide rail; a fourth bending device is arranged on the left part of the front horizontal guide rail; the bending devices are used for forming four U-shaped bending parts in sequence from left to right respectively on the furnace wire winding displacement of the heating furnace.

Owner:张翠翠

Furnace wire bending process with application of hydraulic cylinder type horizontal driver and integrated circuit controller

Disclosed is a furnace wire bending process with the application of a hydraulic cylinder type horizontal driver and an integrated circuit controller. The wire arrangement of a heating furnace is a rectangular wire arrangement formed by arranging linear heating furnace wires linearly in the vertical direction, and a bending device is used in the process. The bending device comprises a support, the right side of the support is provided with a front horizontal guide rail and a rear horizontal guide rail in a front position and a rear position respectively, the middle of the right side of the support is provided with a support clamping device which is arranged between the front horizontal guide rail and the rear horizontal guide rail, a first bending device is arranged on the right of the rear horizontal guide rail, a third bending device is arranged on the left of the rear horizontal guide rail, a second bending device is arranged on the right of the front horizontal guide rail, a fourth bending device is arranged on the left of the front horizontal guide rail, and the four bending devices are respectively used for sequentially forming four U-shaped bending portions from left to right on the heating furnace wire arrangement.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Furnace wire bending process adopting hydraulic cylinder type horizontal driver and bending force sensor

The invention provides a furnace wire bending process adopting a hydraulic cylinder type horizontal driver and a bending force sensor. Row wires of furnace wires of a heating furnace are rectangular row wires formed by the furnace wires of the heating furnace through linear arrangement in a vertical direction, a bending device is used in the process and comprises a support frame, a front horizontal guide rail and a back horizontal guide rail are respectively arranged in a front position and a back position of the right side of the support frame, a support frame clamping device is arranged in the middle position of the right side of the support frame and is positioned between the front horizontal guide rail and the back horizontal guide rail, a first bending device is arranged at the right part of the back horizontal guide rail, a third bending device is arranged at the left part of the back horizontal guide rail, a second bending device is arranged at the right part of the front horizontal guide rail, a fourth bending device is arranged at the left side of the front horizontal guide rail, and the bending devices are respectively used for forming four U-shaped bending parts on the row wires of the furnace wires of the heating furnace from the left side to the right side.

Owner:NANJING SERM ELECTRICAL

Milling and grinding mechanism for mass production cutting device of equal-length glass tubes

InactiveCN106514447AReduce workloadReduce time for step-by-step processingGrinding carriagesGrinding feed controlCushionPotential risk

The invention provides a milling and grinding mechanism for a mass production cutting device of equal-length glass tubes. The milling and grinding mechanism comprises a base and a lifting plate, wherein a cushion board is slidably connected to the lifting plate; a plurality of rollers which are uniformly distributed in a single rank are arranged on the cushion board; a clamping mechanism is arranged on the lifting plate; a cutting mechanism is arranged on the cushion board; a milling and grinding mechanism body, comprising a sidewall and a milling tool which is in slide connection with the sidewall, is arranged on the lifting plate; a slide plate is in slide connection with the cushion board; a circular plate is rotatably connected to the slide plate; fifth hydraulic cylinders are symmetrically arranged on the circular plate; third clamping claws are arranged at top boards of fifth hydraulic rods of the fifth hydraulic cylinders. According to the milling and grinding mechanism for the mass production cutting device of the equal-length glass tubes, two sides of each glass tube are milled and grinded once after cutting, so that the processing steps are simplified; moreover, a small space is used; the processing time can be saved; the glass tubes do not need to be manually grinded by workers, so that the potential risk in work is reduced, and the processing quality is improved.

Owner:天津南玻节能玻璃有限公司

Clamping mechanism for equal-length glass tube batch production cutting devices

InactiveCN106495456AReduce workloadHigh precisionWorking accessoriesGlass severing apparatusMachiningGlass tube

The invention provides a clamping mechanism for equal-length glass tube batch production cutting devices. The clamping mechanism comprises a base and a lift plate arranged thereon, a pad plate is slidably connected to the lift plate, a plurality of rollers evenly arrayed in single row are arranged on the pad plate, the clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism which are respectively and symmetrically arranged, the first clamping mechanism comprises a first motor and a first transmission rod, and the second clamping mechanism comprises a second motor and a first screw-nut assembly. By using the clamping mechanism, machining efficiency is guaranteed by alternative operation of the first and second clamping mechanisms, the clamping mechanism is suitable for batch production and machining of glass tubes, time is saved, efficient and highly precise machining is guaranteed, and production efficiency is improved.

Owner:天津南玻节能玻璃有限公司

Novel drill bit long scrap removing equipment

InactiveCN111644893ASmall processing spaceReduce volumeBoring/drilling componentsMaintainance and safety accessoriesElectric machineryMachine tool

The invention discloses novel drill bit long scrap removing equipment. The novel drill bit long scrap removing equipment comprises a base, four countersunk heads for locking a workbench are arranged on the base, a working column is arranged on the upper end face of the base, storage grooves are formed in the two sides of the working column, a first cavity with an upward opening is formed in the storage groove in the upper side of the working column, right fixed shafts are symmetrically and fixedly arranged on the front wall and the rear wall of the first cavity left and right, and a motor is arranged on the rear side wall body of the first cavity. According to the novel drill bit long scrap removing equipment, the equipment is installed on the machine tool workbench, and a drill bit is adjusted to a designated position, then the function of removing long scraps can be automatically started, and manual participation is not needed; moreover, the equipment can be automatically retracted when not in use, the extra size is not occupied, and the machining space of the machine tool is saved; and the equipment can clean the cleaned long scraps to the front side of the equipment, manual cleaning of the equipment is not needed, the size is small, and the operation is stable.

Owner:PAN AN AIKEN MECHANICAL EQUIP CO LTD

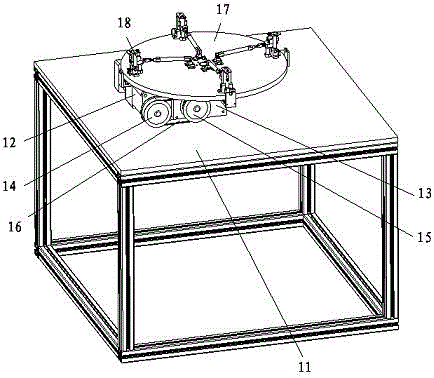

Four-station rotary plate mechanism of electromagnetic valve iron core component assembling machine

ActiveCN106392629AAutomatic clampingSmall processing spaceAssembly machinesCore componentEngineering

The invention discloses a four-station rotary plate mechanism of an electromagnetic valve iron core component assembling machine. The four-station rotary plate mechanism of the electromagnetic valve iron core component assembling machine comprises a rotary plate rack, a gear motor, a cam divider, a driving belt pulley, a driven belt pulley, a toothed belt, a rotating plate and iron mandrel clamps, wherein the gear motor and the cam divider are installed on a panel on the rotary plate rack; the driving belt pulley is installed on a motor shaft of the gear motor, the driven belt pulley is installed on an input shaft of the cam divider, and the driving belt pulley and the driven belt pulley are connected through the toothed belt; the horizontal rotating plate is installed on an output shaft of the cam divider; and the four sets of iron mandrel clamps are arranged on the identical circumference of the rotating plate at equal intervals. In this way, the area of the machining space can be reduced, iron mandrels can be clamped automatically, the production efficiency is improved, and cost is reduced.

Owner:湛江中信电磁阀有限公司

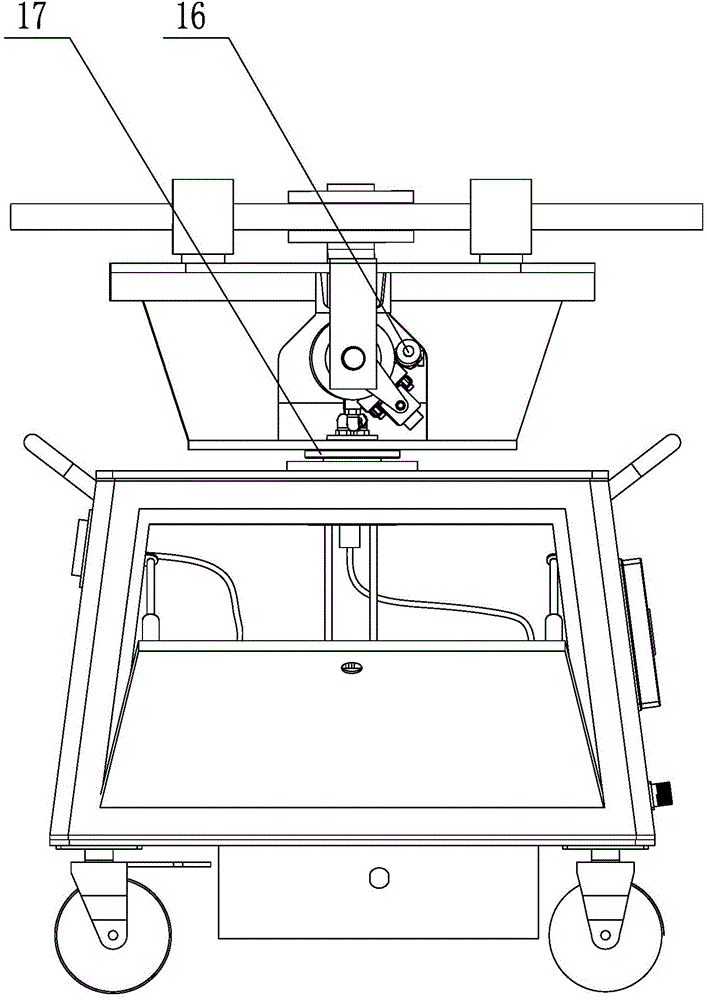

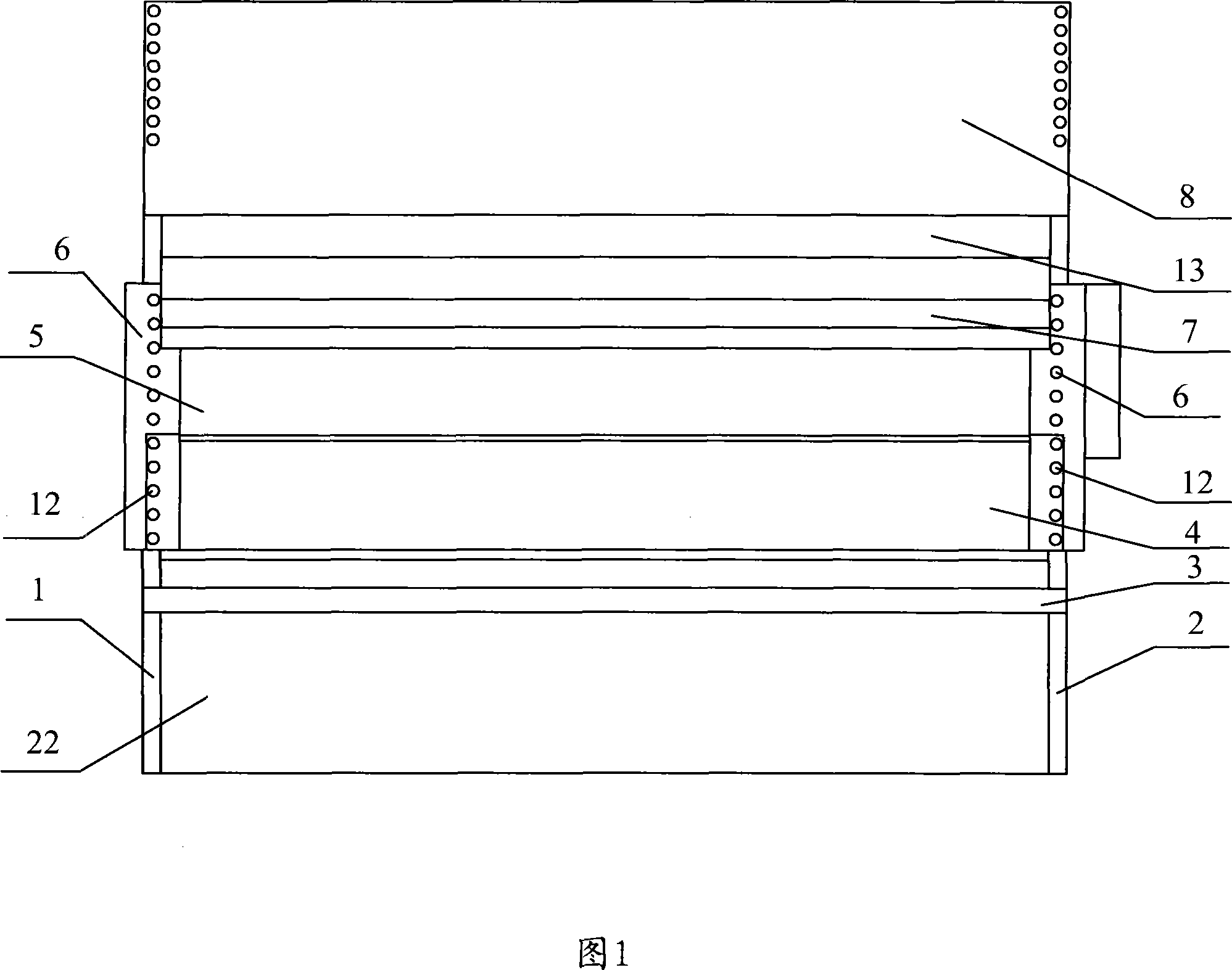

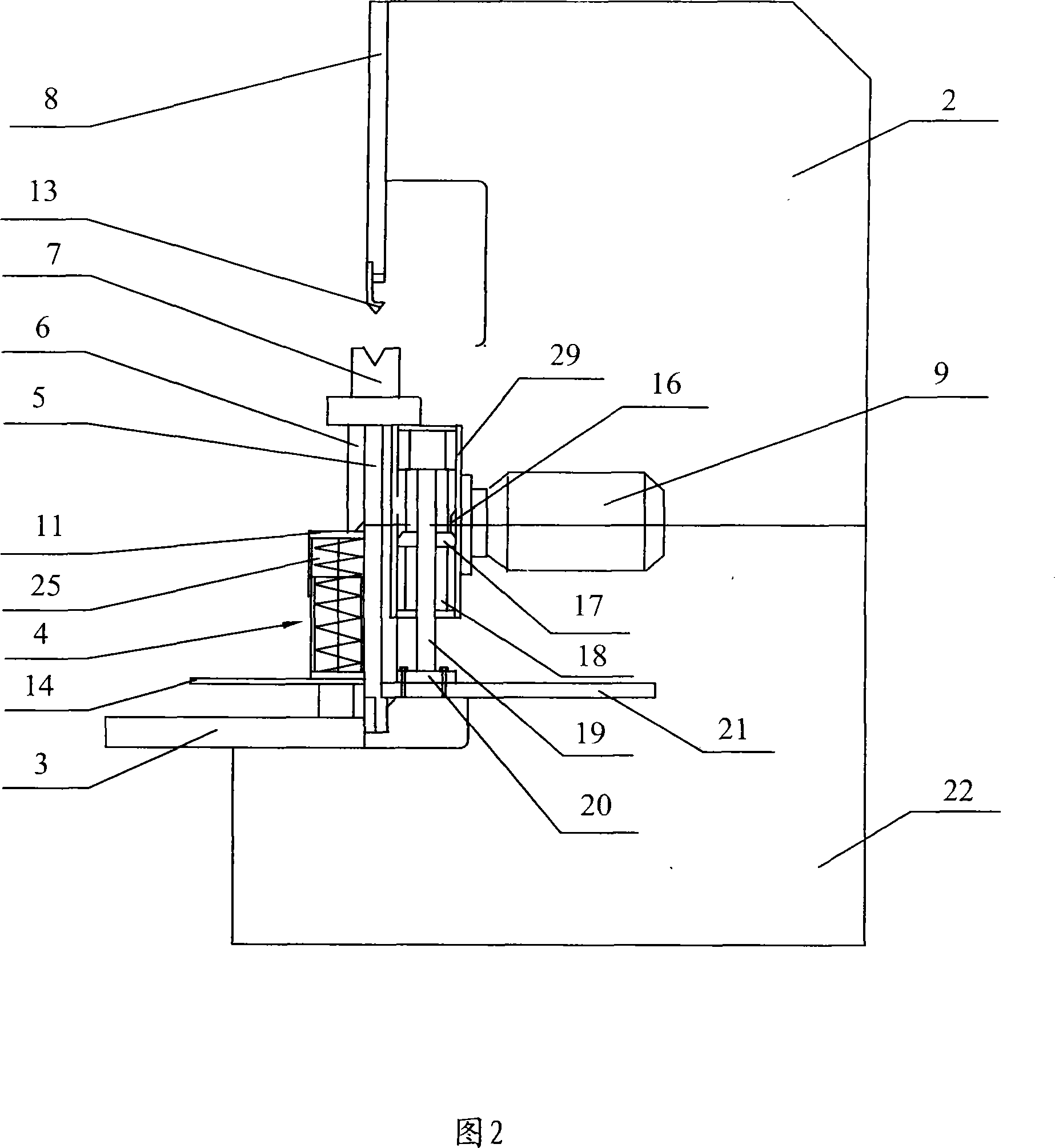

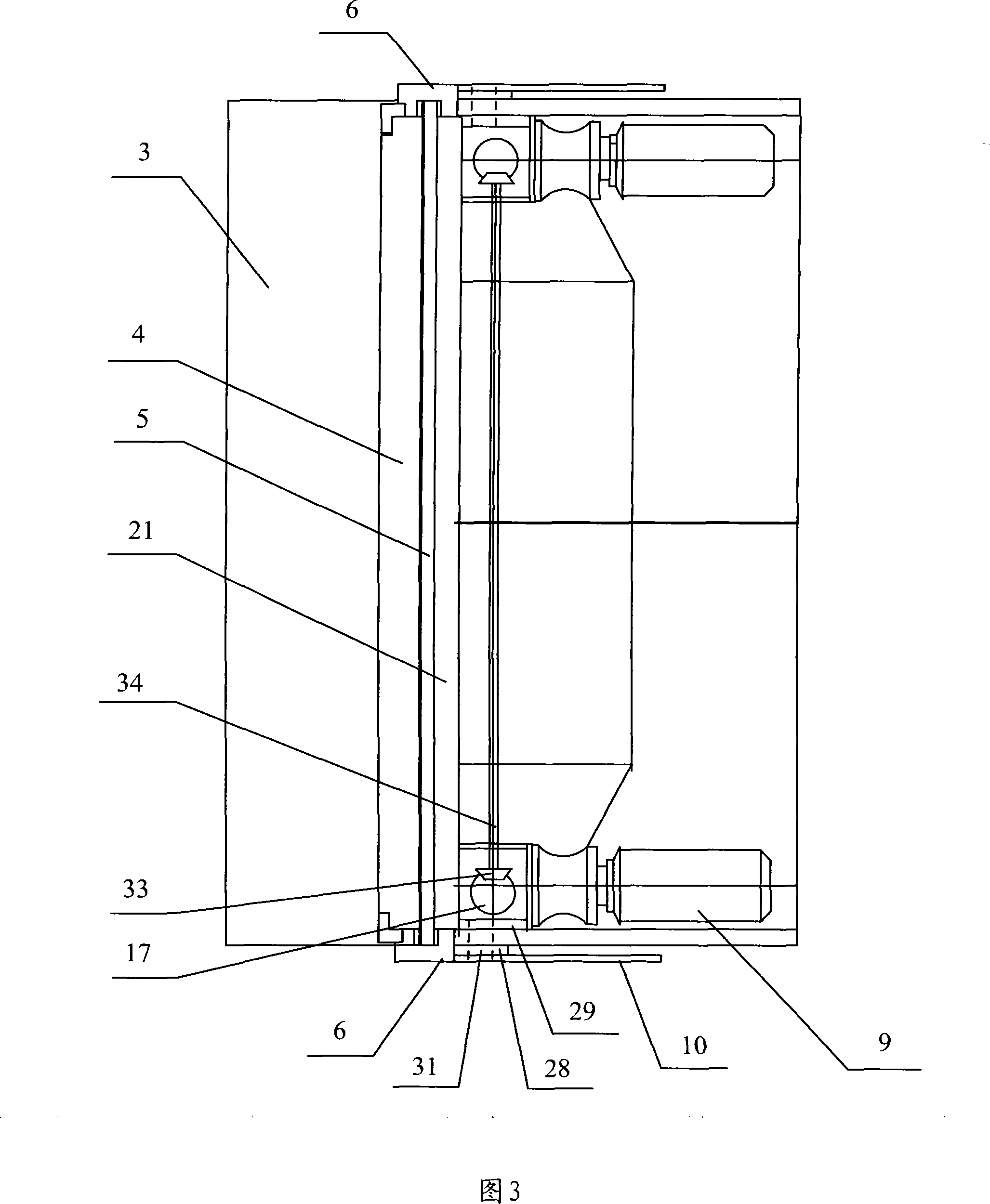

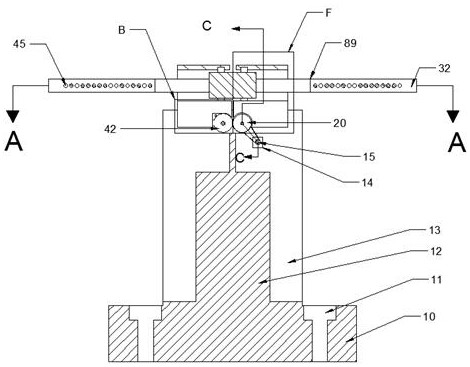

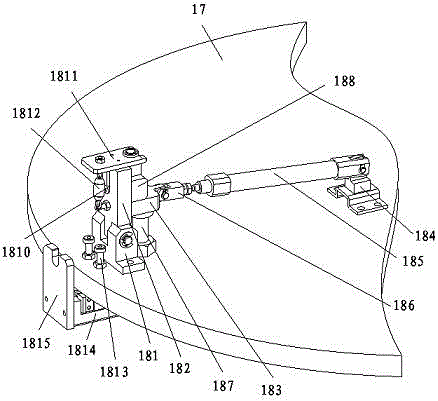

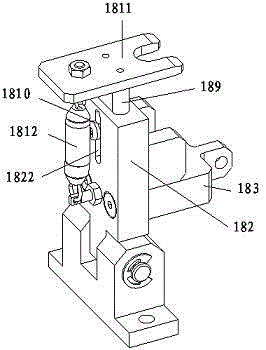

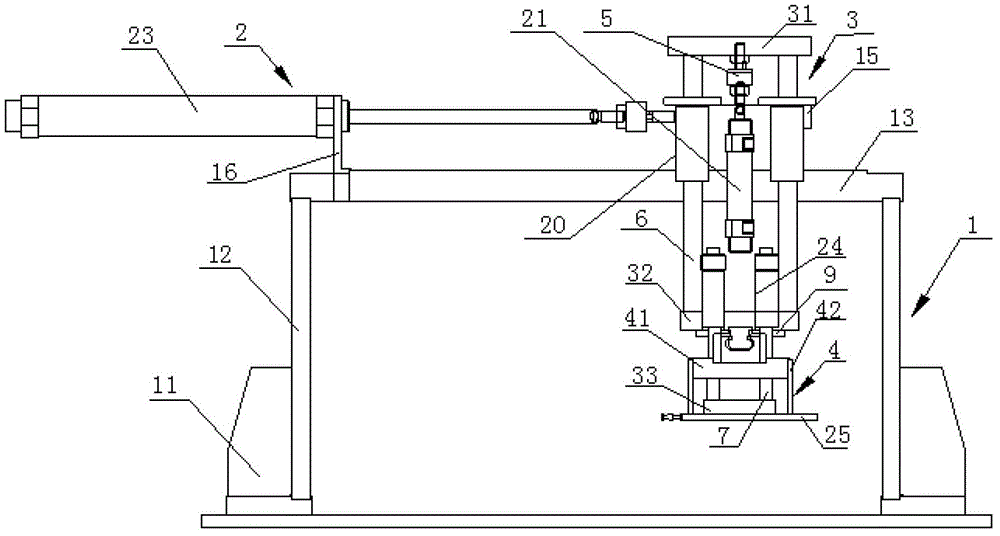

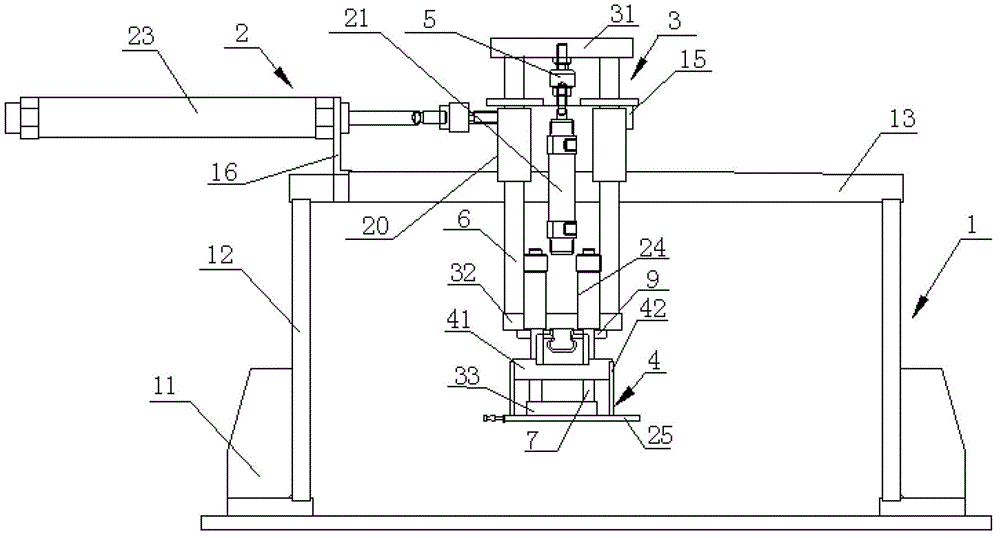

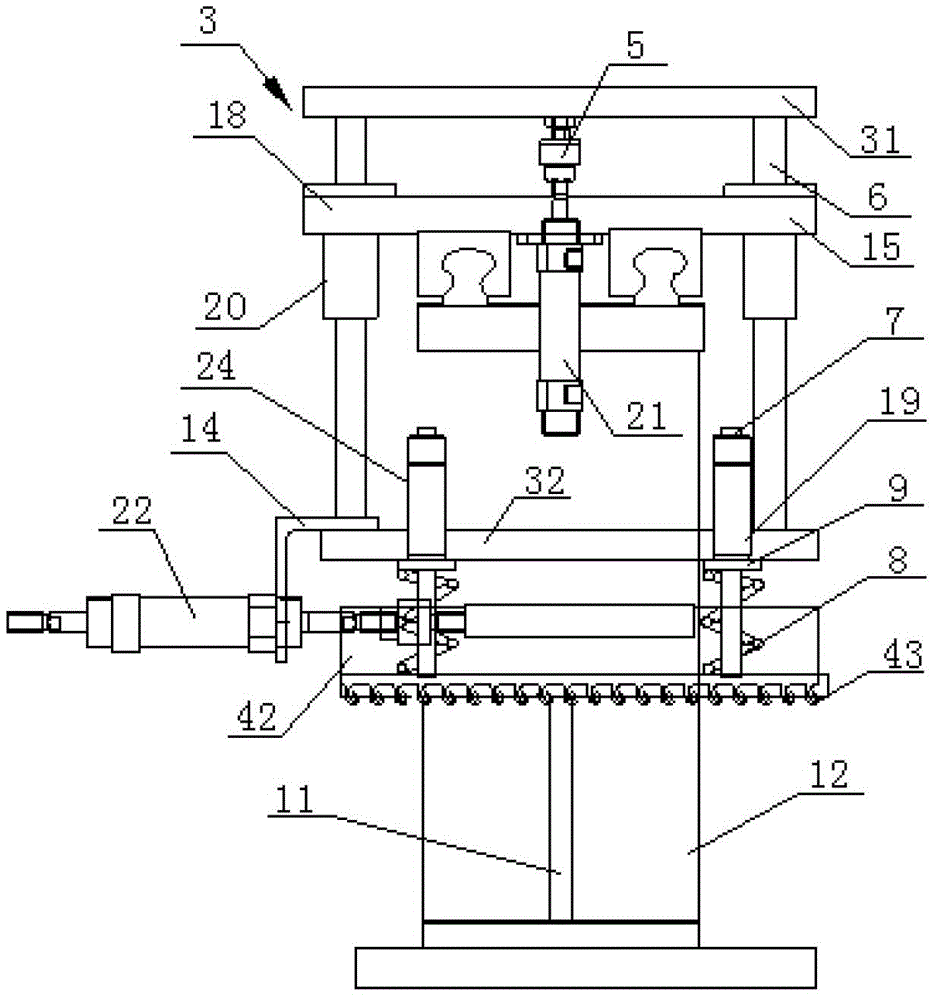

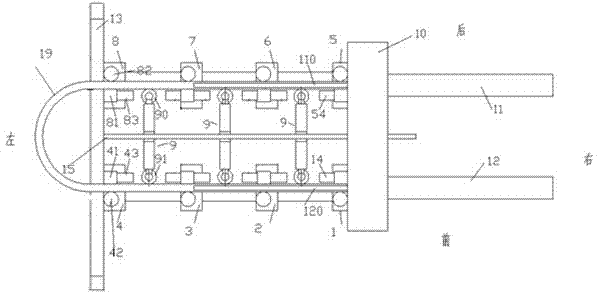

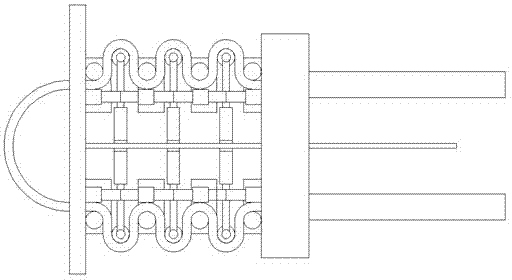

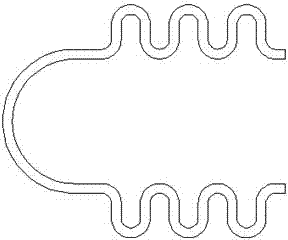

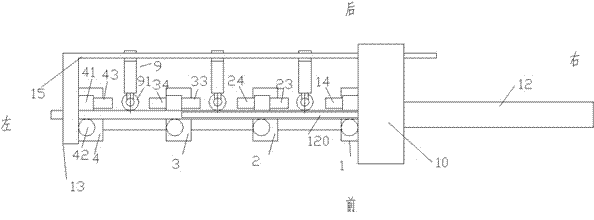

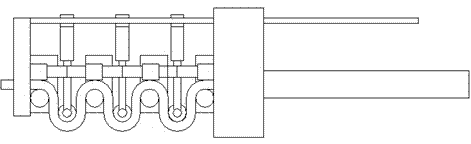

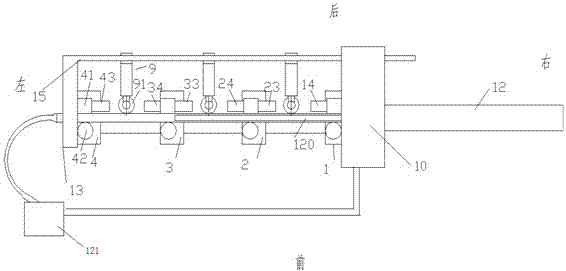

Bending technology for furnace tube of linear heating furnace

InactiveCN103920767AGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:方自成

Furnace wire bending process using hydraulic cylinder type horizontal driver and performing thermal treatment

The invention discloses a furnace wire bending process using hydraulic cylinder type horizontal driver and performing thermal treatment. The furnace wires of heating furnaces are distributed in the way that the linear furnace wires of the heating furnaces are linearly arranged up and down to form into a rectangular wire array; the process adopts bending devices, the bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are respectively arranged in the front and back of the right side of the bracket, a bracket clamping device is arranged at the middle position of the right side of the bracket and is arranged between the front and back horizontal guide rails, the right part of the back horizontal guide rail is provided with a first bending device, the left part of the back horizontal guide rail is provided with a third bending device, the right part of the front horizontal guide rail is provided with a second bending device, the left part of the front horizontal guide rail is provided with a fourth bending device, the bending devices are respectively arranged on the furnace wire array of the heating furnaces so as to form four U-shaped bending parts sequentially from left to right.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

Nickel-chromium alloy furnace wire bending process for performing stress-relieving thermal treatment

The invention discloses a nickel-chromium alloy furnace wire bending process for performing stress-relieving thermal treatment. The furnace wire winding displacement of a heating furnace is rectangular winding displacement formed by linearly arranging furnace wires of the linear heating furnace in the longitudinal direction. In the process, a bending device is used. The bending device comprises a bracket, wherein a front horizontal guide rail and a back horizontal guide rail are arranged respectively one after the other on the right side of the bracket; the middle of the right side of the bracket is provided with a bracket clamping device which is positioned between the front horizontal guide rail and the back horizontal guide rail; the right portion of the back horizontal guide rail is provided with a first bending device; the left portion of the back horizontal guide rail is provided with a third bending device; the right portion of the front horizontal guide rail is provided with a second bending device; the left portion of the front horizontal guide rail is provided with a fourth bending device. The bending device is used for forming four U-shaped bent portions in sequence from left to right on the furnace wire winding displacement of the heating furnace.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG

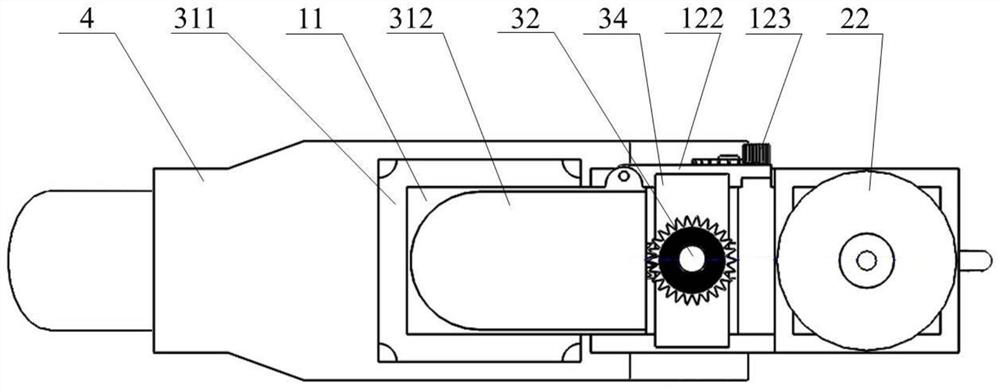

Pen core automatic displacement method and device

Owner:SUZHOU KAILEISHENG AUTOMATION TECH CO LTD

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:海门江海建设投资有限公司

U-shape Furnace Tube Bending Process Using Fixture Locking Rail Mechanism and Carrying out Pressure Keeping and Sizing

InactiveCN103894463BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

Owner:南通市海门江海建设投资有限公司

A rotary processing device for mass production of ball parts

ActiveCN104384942BAdjust processing directionLow costLarge fixed membersHigh volume manufacturingBatch processing

The invention discloses a rotary processing device for batch production of ball parts. The rotary processing device comprises a fixing end, at least one clamping part and a processing part, wherein the clamping parts are connected with the fixing end, the processing part is connected with the upper parts of the clamping parts, each clamping part is connected with the fixing end through a universal spherical head, and can swing around the fixing part, and the side surface of each clamping part is connected with the fixing end through a connecting rod. The rotary processing device has the advantages that the efficiency of surface processing treatment of the ball part is improved, the requirement of large-batch production is met, the labor cost is effectively reduced, and the better benefits are brought for enterprises.

Owner:丹阳市华丰精密配件厂

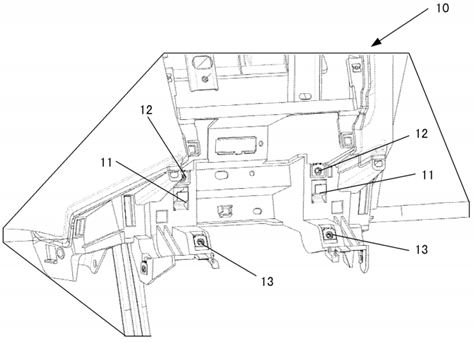

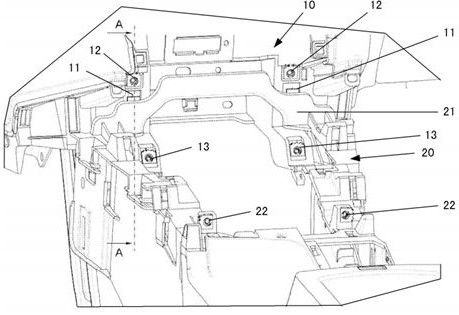

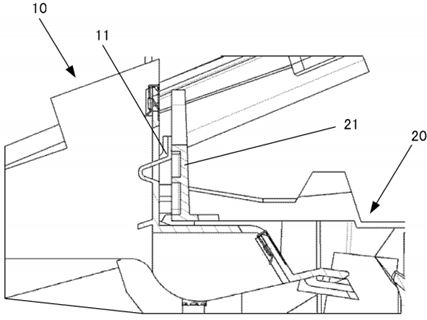

Mounting device and mounting method for mounting a main dashboard and a sub-dashboard of a vehicle

ActiveCN112622621BFully automated installationReduce labor costsDashboard fitting arrangementsEngineeringAutomation

The present invention relates to the technical field of vehicle instrument panels, and provides an installation device and an installation method for installing a vehicle main instrument panel and an auxiliary instrument panel, wherein the installation device includes a frame on which a rotating body is rotatably mounted, and the rotating body The body is fixedly connected coaxially with the output end of the intermittent drive device, and at least two sets of automatic clamping and telescopic mechanical claw mechanisms are installed on the circumferential surface of the rotating body; the invention realizes the complete automation of the installation of the main instrument panel and the auxiliary instrument panel of the vehicle , does not require manual participation, saves labor costs, the pick-up of the sub-dashboard and the triangular connector and the installation of the sub-dashboard and the triangular connector are carried out at the same time, which improves work efficiency. In the present invention, the design of the rotating part is creatively adopted , so that the conversion of the process adopts the method of rotation, which not only saves the processing space, but also realizes the cycle between the processes, and further improves the work efficiency.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

Bending Process of a Linear Heating Furnace Tube

InactiveCN103934331BGuaranteed shape accuracyAvoid insufficient clamping forceEngineeringTube bending

The invention discloses a linear type heating furnace tube bending technology. According to the technology, a furnace tube bending device is used and comprises a left machine frame (13) and a pushing and pressing mechanism (10), the pushing and pressing mechanism (10) is located on the right side of the left machine frame (13), a dovetail guide rail (15) is fixedly connected to the rear portion of the right side of the left machine frame (13) and extends horizontally in the left-right direction, the left end of the dovetail guide rail (15) is fixedly connected with the left machine frame (13), the right end of the dovetail guide rail (15) is in sliding connection with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing a furnace tube to penetrate through is formed in the front portion of the left machine frame (13), and three hydraulic bending devices (9) are arranged on the dovetail guide rail (15) from left to right in sequence in a sliding mode and located between the left machine frame (13) and the pushing and pressing mechanism (10).

Owner:董璞玉

Bending technology for furnace tube of linear heating furnace

Disclosed is a bending technology for a furnace tube of a linear heating furnace. According to the heating technology of the furnace tube of the linear heating furnace, furnace tube bending equipment is adopted and comprises a left frame (13) and a pushing and pressing mechanism (10). The pushing and pressing mechanism (10) is arranged on the right of the left frame (13), a dovetail guide rail (15) is fixedly connected on the rear portion of the right side of the left frame (13) and extends in left and right directions horizontally, the left end of the dovetail guide rail (15) is fixedly connected with the left frame (13) while the right end of the same is slidably connected with a dovetail groove in the rear portion of the pushing and pressing mechanism (10), a through hole allowing the furnace tube to penetrate through is formed in the front portion of the left frame (13), and three bent hydraulic devices (9) are sequentially slidably arranged from left to right between the left frame (13) and the pushing and pressing mechanism (10).

Owner:南通江海港建设工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com