Processing technology and embossing machine of flocking product

A processing technology and embossing machine technology, which is applied in the field of back-end processing technology and equipment to achieve the effects of wide application range, cost reduction and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A processing technique for flocking products, comprising the following steps,

[0029] Cloth feeding: conveying the cloth to the embossing machine;

[0030] Paper loading: transport the paper to the embossing machine;

[0031] Simultaneously embossing and printing patterns: the cloth and paper are conveyed to the embossing cylinder of the embossing machine at the same time, through the pressure of the embossing cylinder and the embossing roller, the cloth forms a specific pattern while transferring the pattern on the paper surface fabric surface;

[0032] Recycling and coiling: the paper is recycled and the finished cloth is coiled.

[0033] In addition, the simultaneous embossing and pattern printing steps also include a pretreatment process: pressing, that is, the cloth and paper are simultaneously transported to the pressing device, and the paper is smoothly pasted on the surface of the cloth through the pressing device and advances synchronously with the cloth.

...

Embodiment 2

[0037] A kind of embossing machine of the present invention is introduced below.

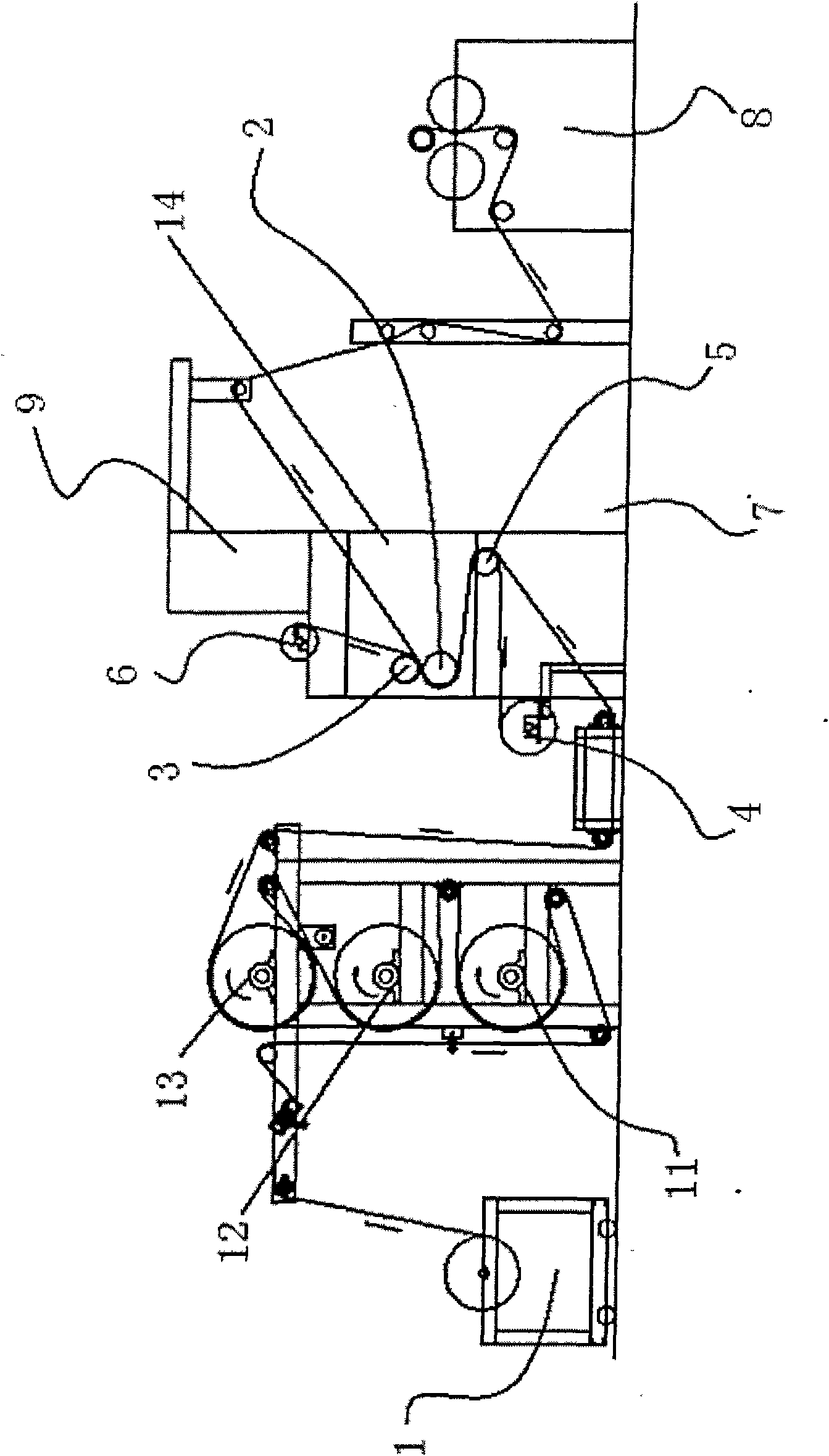

[0038] Such as figure 1As shown, an embossing machine includes a host machine 7, a frame 9, a cloth feeding device 1, an embossing cylinder 2, an embossing roller 3, a take-up device 8, and also includes a paper feeding device 4, a pressing device 5 and a recovery device 6 and various adjustment mechanisms. The frame 9 is used as the structural framework of the whole machine, on which a cloth feeding device 1, an embossing cylinder 2, an embossing roller 3, a take-up device 4 and a main machine 7 are arranged. The cloth feeding device 1 includes a cloth feeding frame, a tension frame, an ironing cylinder and an edge-to-edge device, which are used to control the tension and prevent the cloth from moving, so that the cloth can enter the embossing cylinder 2 smoothly. The embossing cylinder 2 is equipped with a heating wire and a temperature control probe, which detects the temperature state of t...

Embodiment 3

[0042] The following provides a flocking cloth production process of simultaneous embossing and thermal transfer printing:

[0043] First select the base material, choose a flocking fabric, the base fabric of the flocking fabric is T / C mesh fabric, the plush planted on the surface is nylon with a thickness of 1.9D and a length of 1.0mm, and the width of the flocking fabric is 1.4m. Imported pad printing paper is selected for the pad printing paper, and the embossing machine provided in the above embodiment 2 is used as the equipment, and the process parameters are set at a temperature of 180-200°C and a pressure of 40-50Kg / cm 2 , Embossing machine speed 3 ~ 5m / min. The flocking cloth is transported to the embossing machine through the cloth feeding device, and the pad printing paper is fed through the paper feeding device. The pad printing paper and the flocking cloth are synchronously transported to the pressing device, and the pad printing paper can be flattened by the pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com