Patents

Literature

73results about How to "Guaranteed flat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

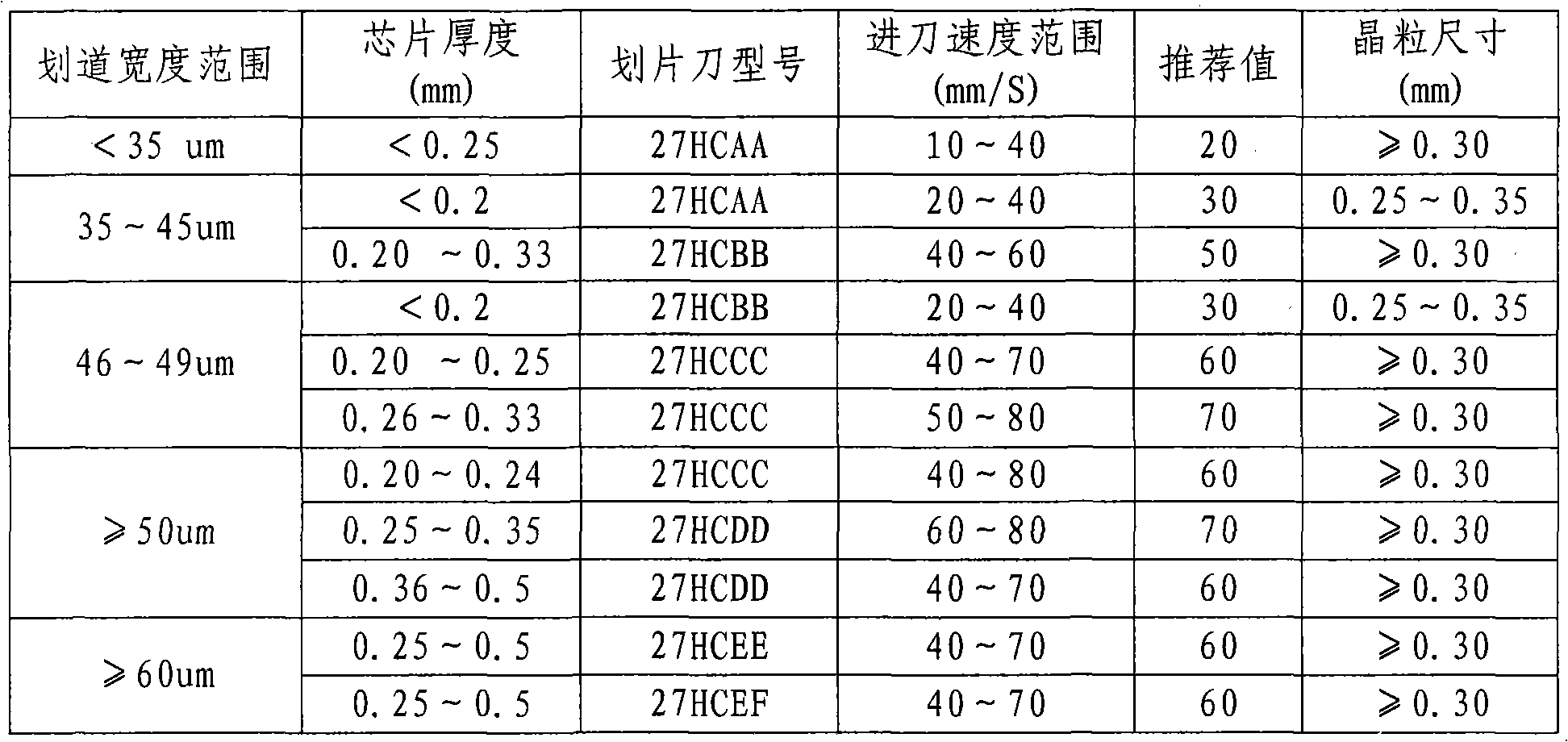

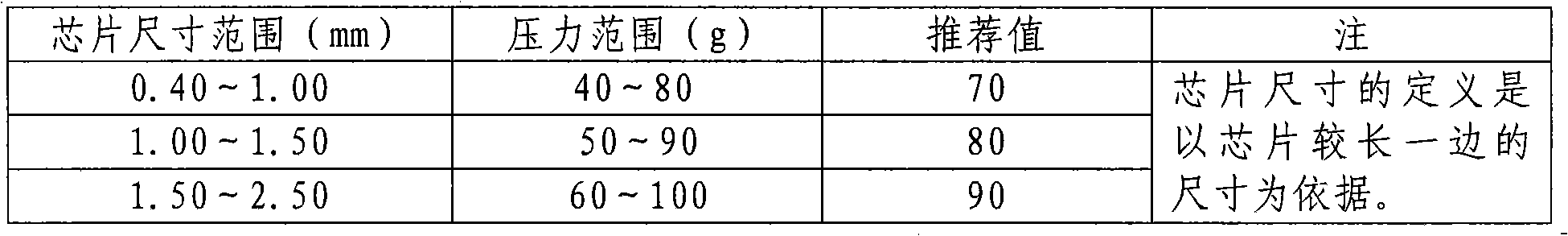

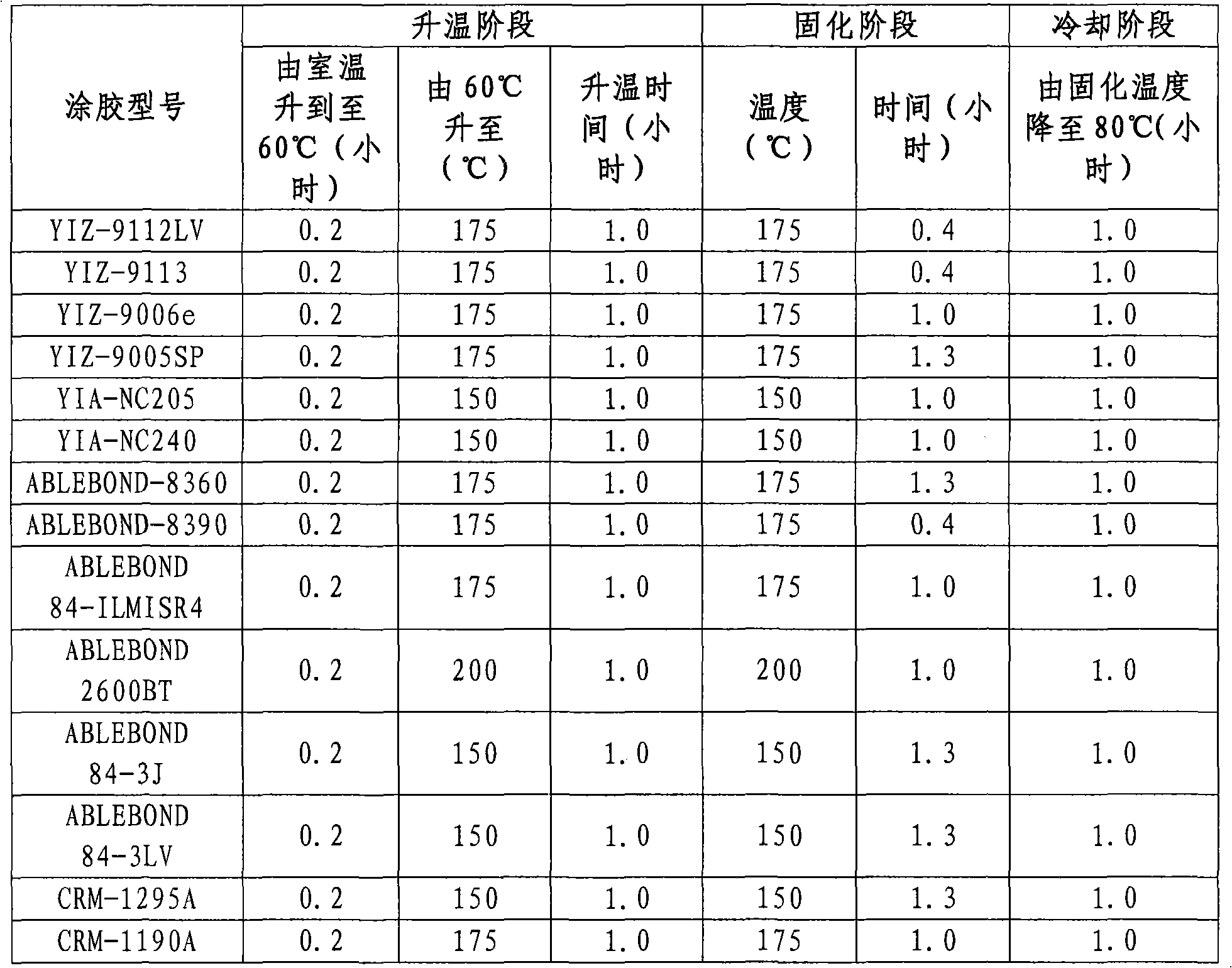

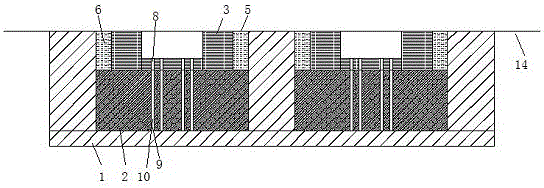

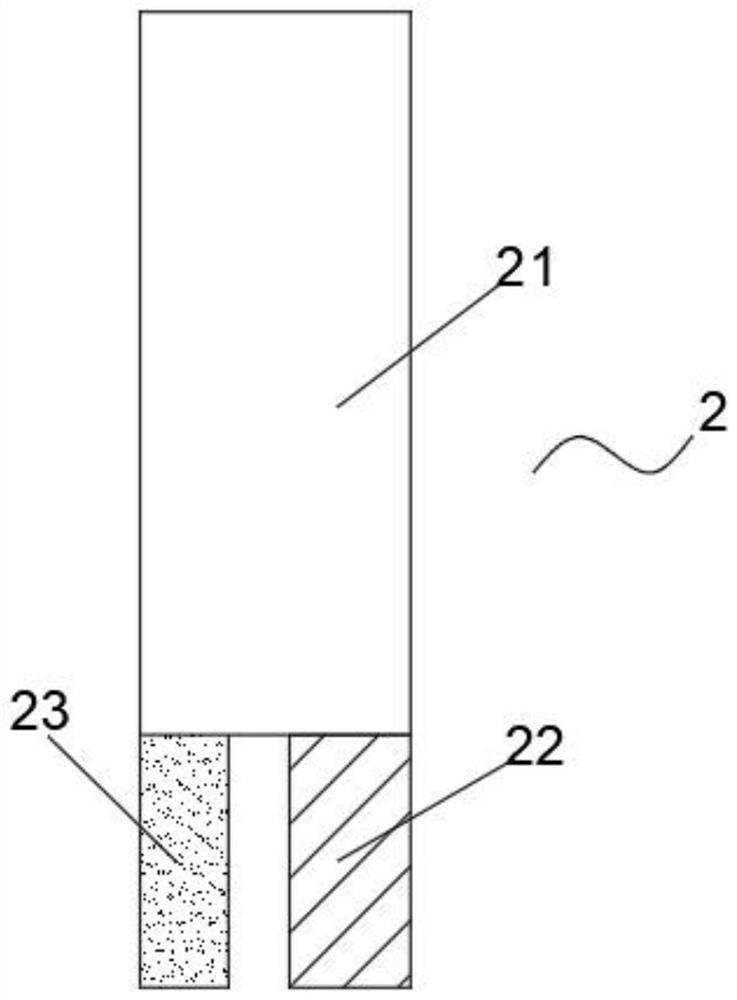

Method for preparing crystal round back electrode and crystal round

InactiveCN101350296AReduce dosageEliminate FringingSemiconductor/solid-state device manufacturingSemiconductor devicesScreen printingRound back

The invention discloses a wafer whose back side is coated with adhesive through adopting the silk screen printing and a process for preparing a back electrode of the wafer, the preparation process comprises the following five steps: preparing a wafer, and keeping the wafer flat in the subsequent steps, adopting the silk screen printing to coat the adhesive on the back side of the wafer and drying, arranging the wafer which is coated with the adhesive on a scribing blue film, separating, adhering and solidifying the separated wafer. The process eliminates the flanging phenomenon which easily occurs during the preparation of the wafer, the dosage of bonding slurry is reduced by one-third, the cost of the bonding slurry is greatly reduced by about ten percent, and the flatness of the coating surface of a back electrode of the chip is guaranteed, a scribing is easily cut, the intensity of the combination between the chip and the electrode during the eutectic welding is guaranteed, and the production time and cost are greatly saved. The wafer whose back side is coated with the adhesive of the invention can be stored for a long time, and the control to the quality of the stock is improved.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

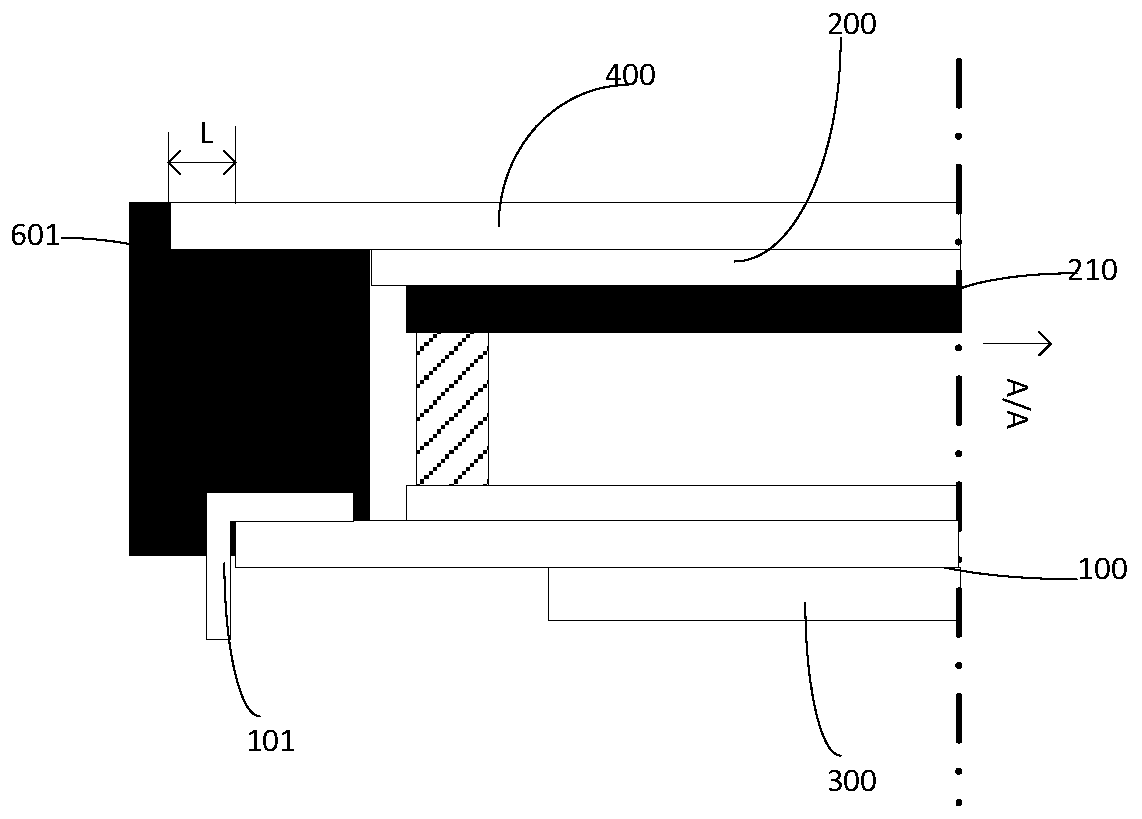

Display device

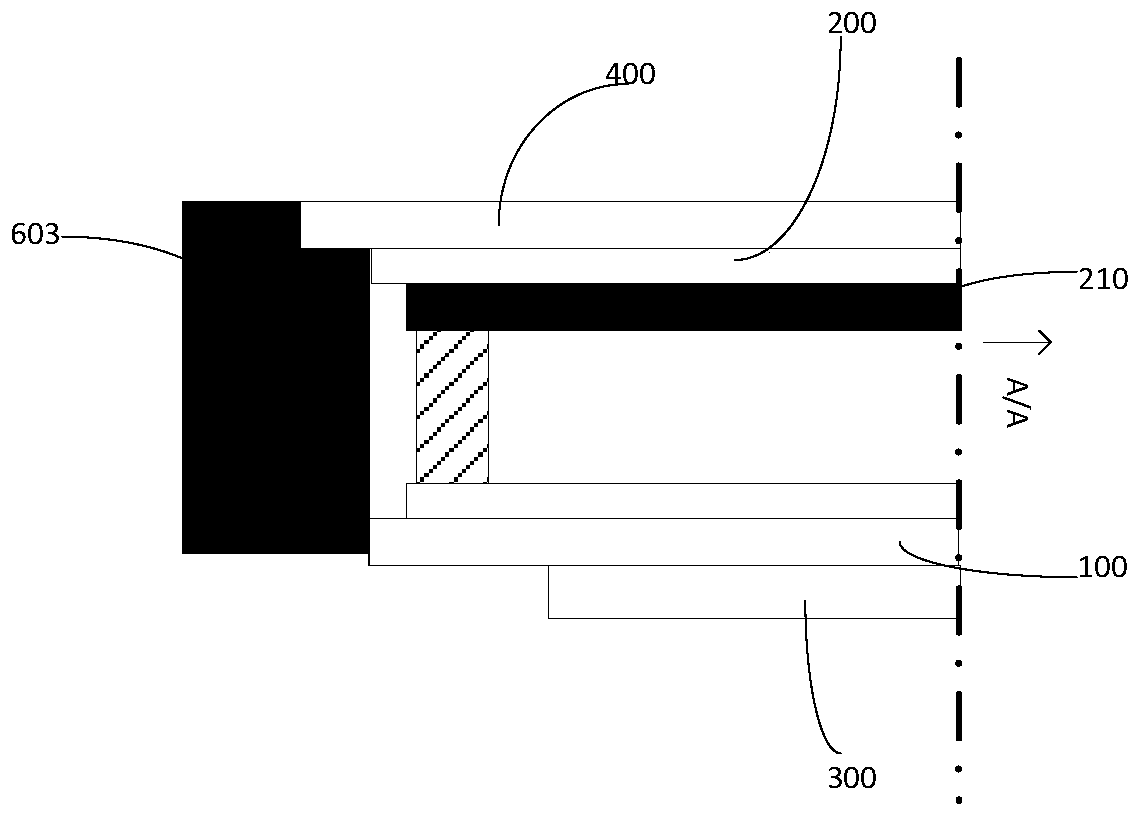

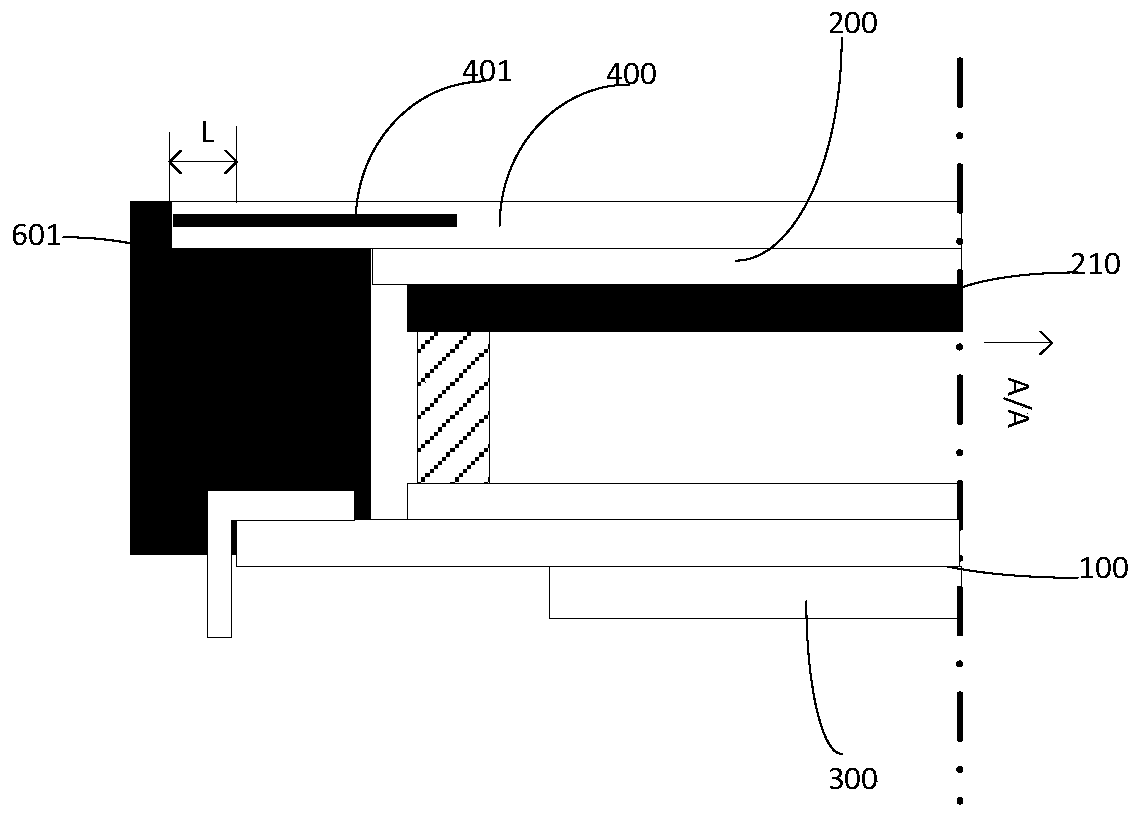

PendingCN110824750AGuaranteed flatEnsure a sense of designDigital data processing detailsOptical filtersDisplay deviceEngineering

The invention provides a display device. The display device comprises: a display panel comprising a first substrate and a second substrate which are oppositely arranged, and a binding side, wherein atthe binding side, the substrate of the first substrate exceeds the substrate of the second substrate, and a binding area is formed on the first substrate; a first polaroid arranged on one side, far away from the second substrate, of the first substrate; and a second polaroid arranged on one side, far away from the first substrate, of the second substrate, wherein at the binding side of the display panel, the edge of the second polaroid exceeds the edge of the substrate of the second substrate, a gap is formed between the part, exceeding the edge of the substrate of the second substrate, of the edge of the second polaroid and the binding area on the first substrate, and a filling part is arranged in the gap. According to the invention, the display device can achieve a four-side frameless design.

Owner:BOE TECH GRP CO LTD +1

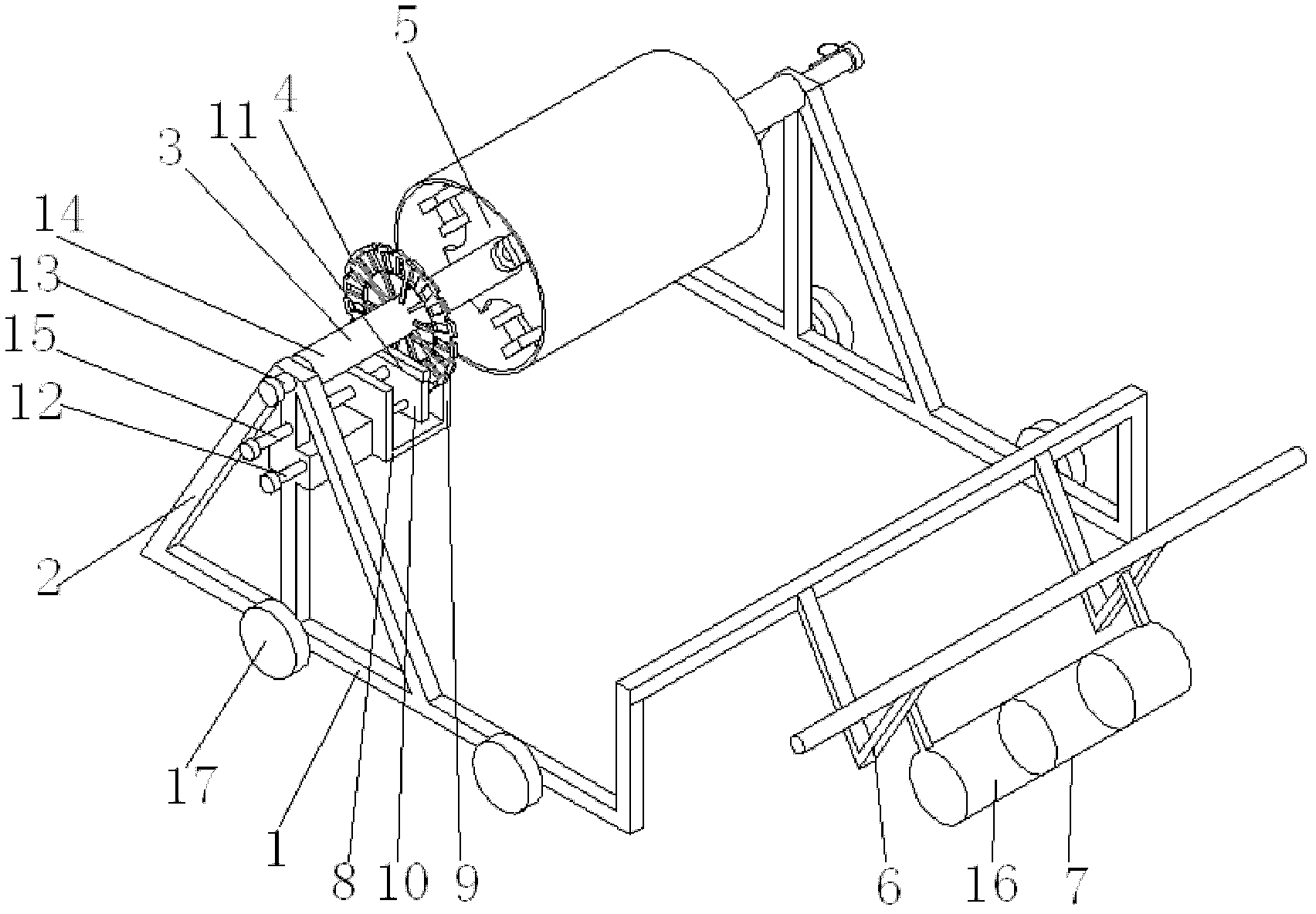

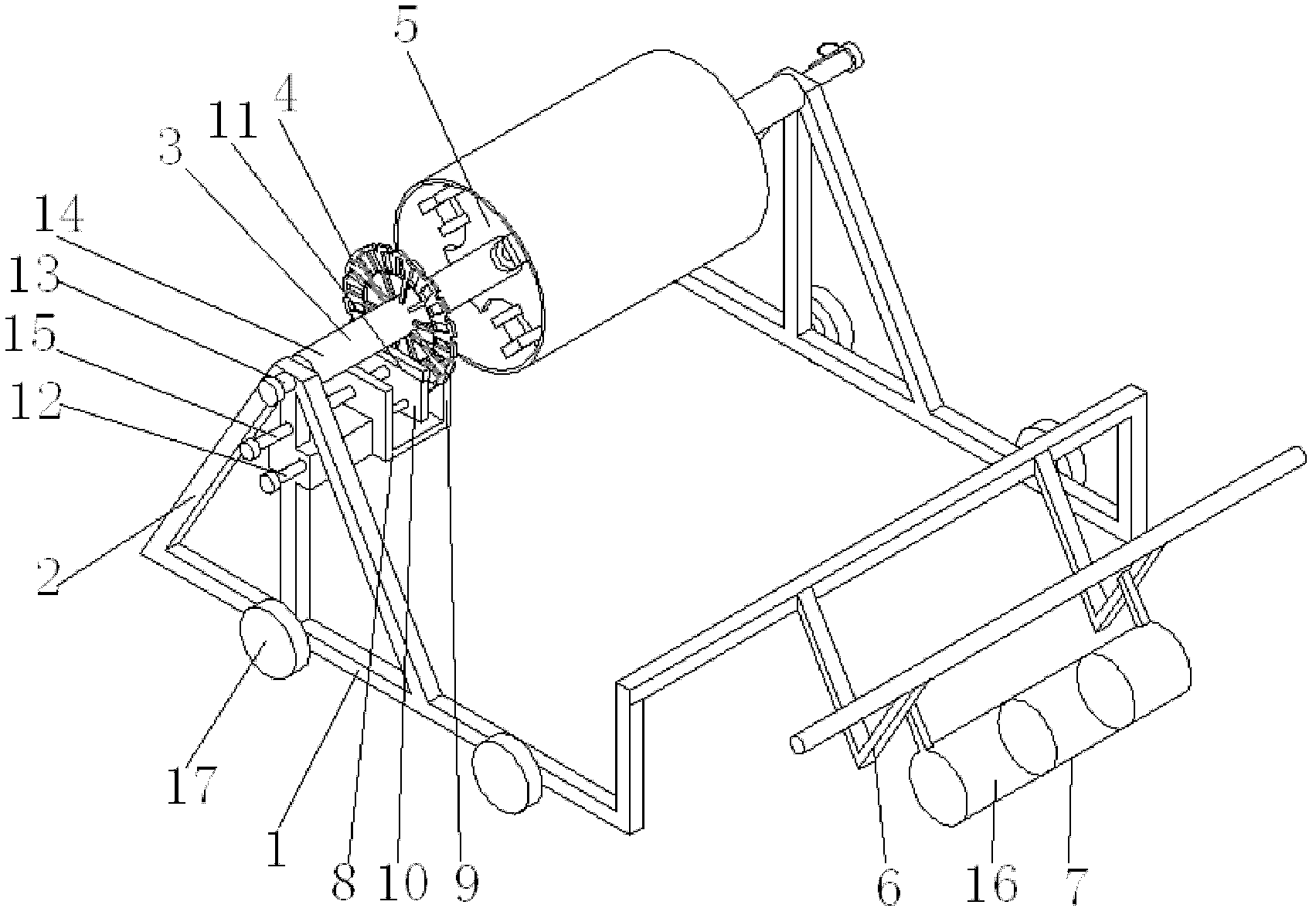

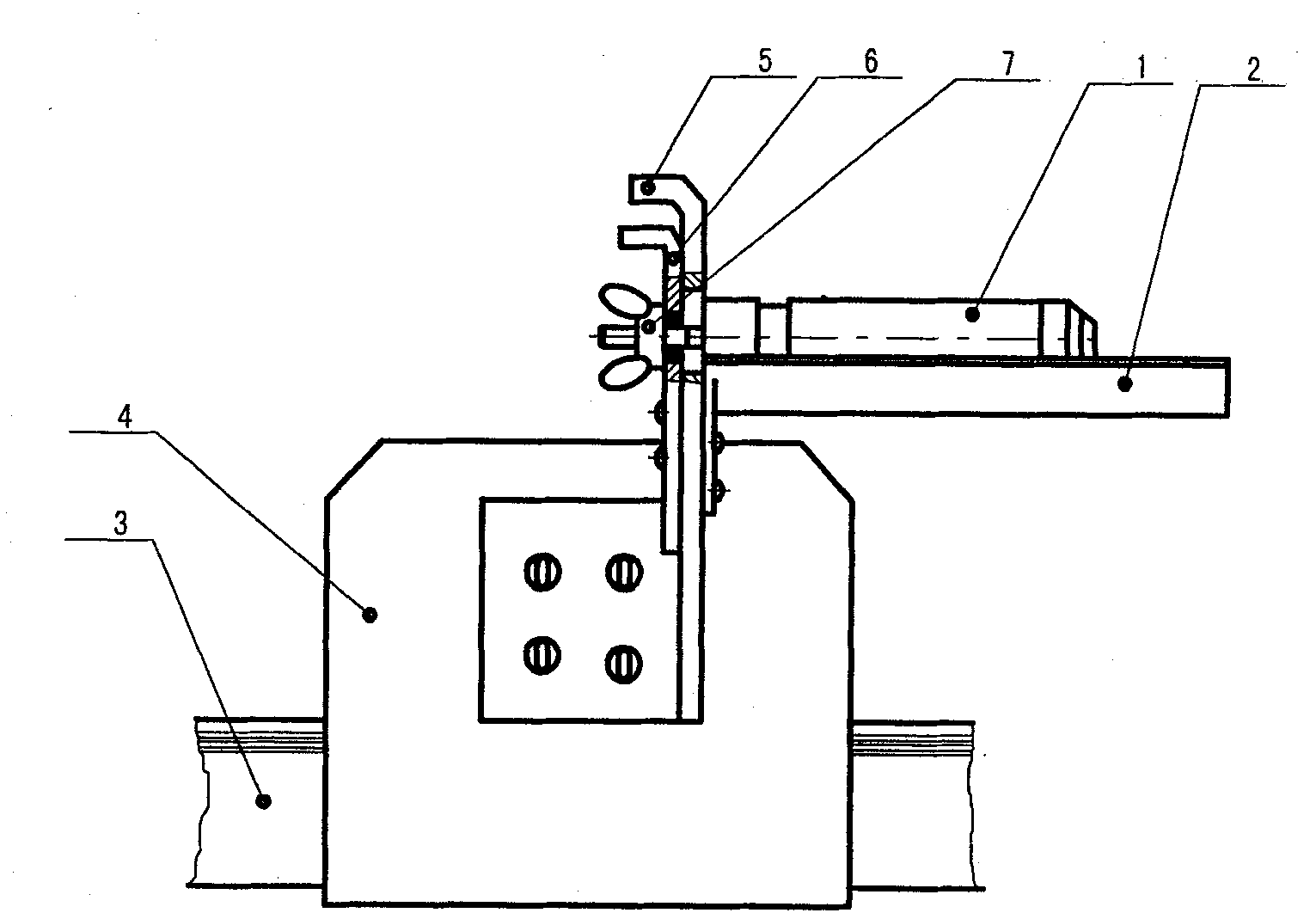

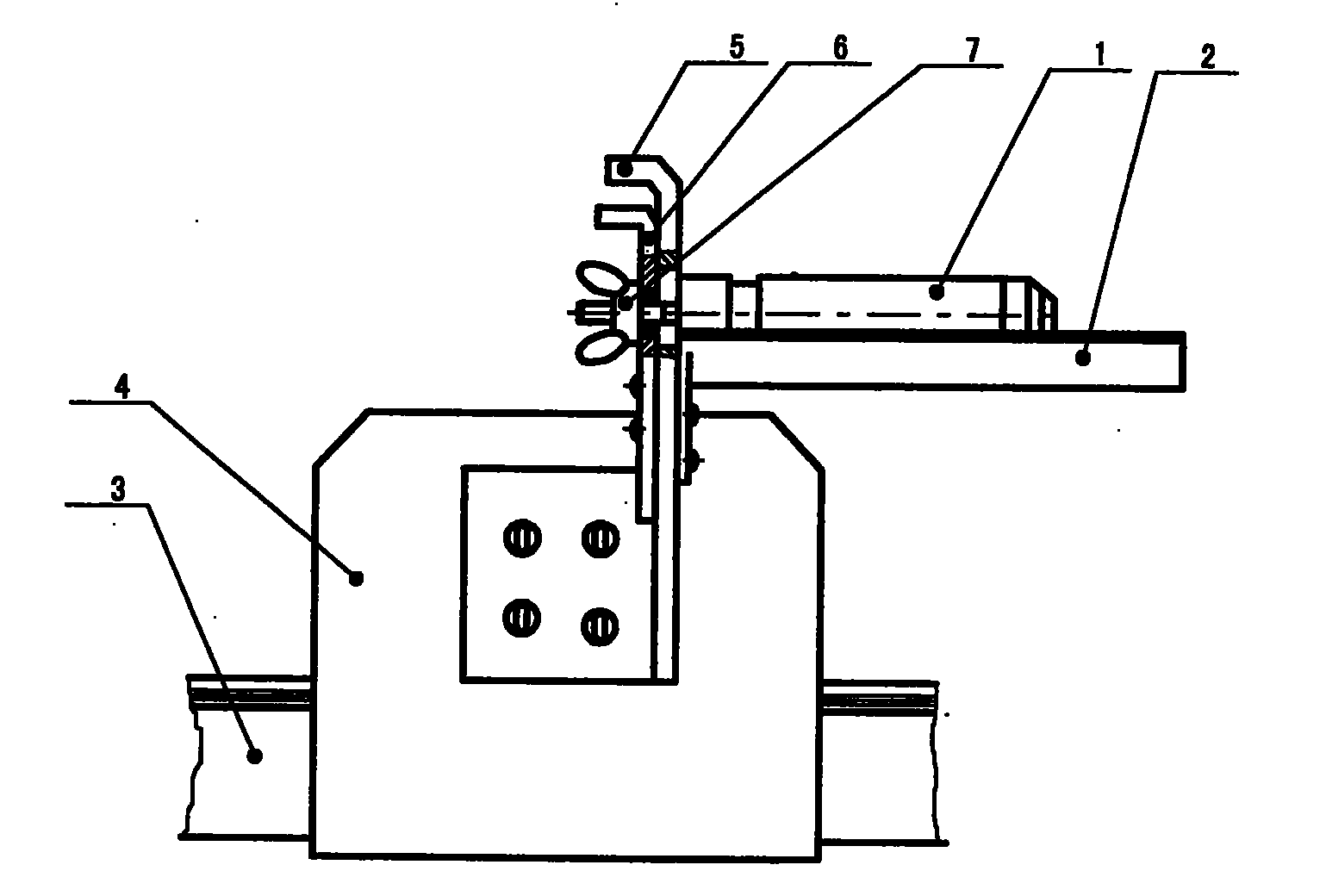

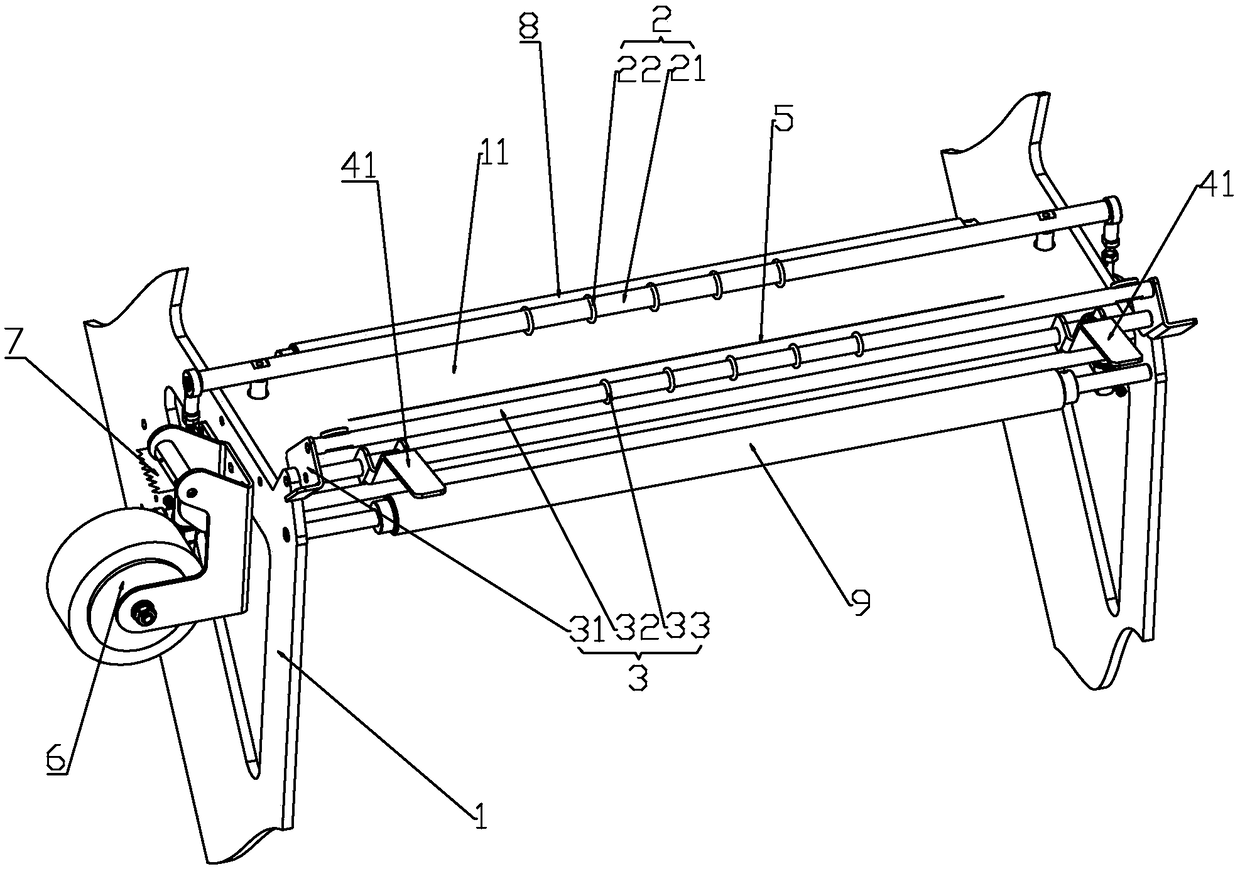

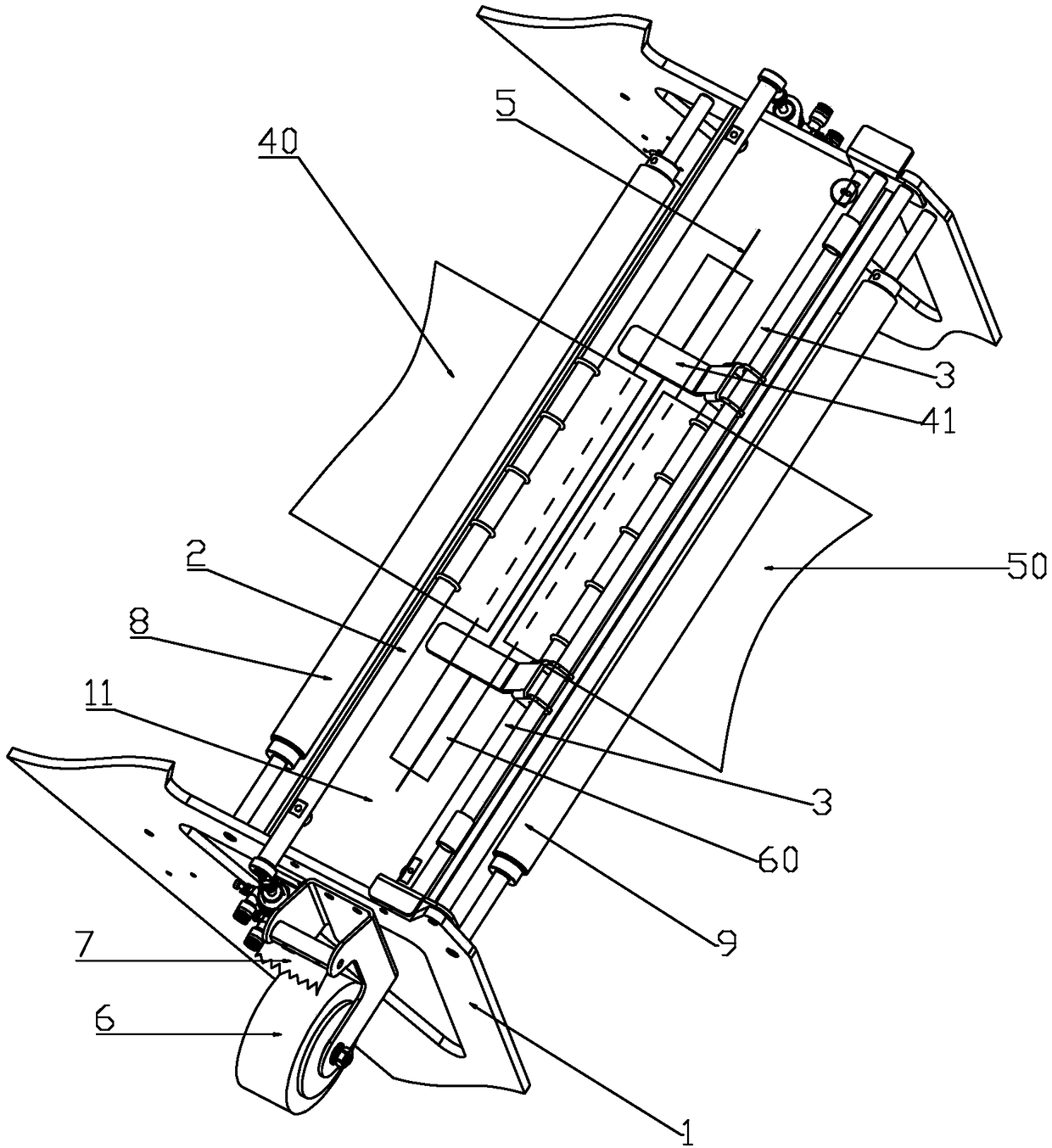

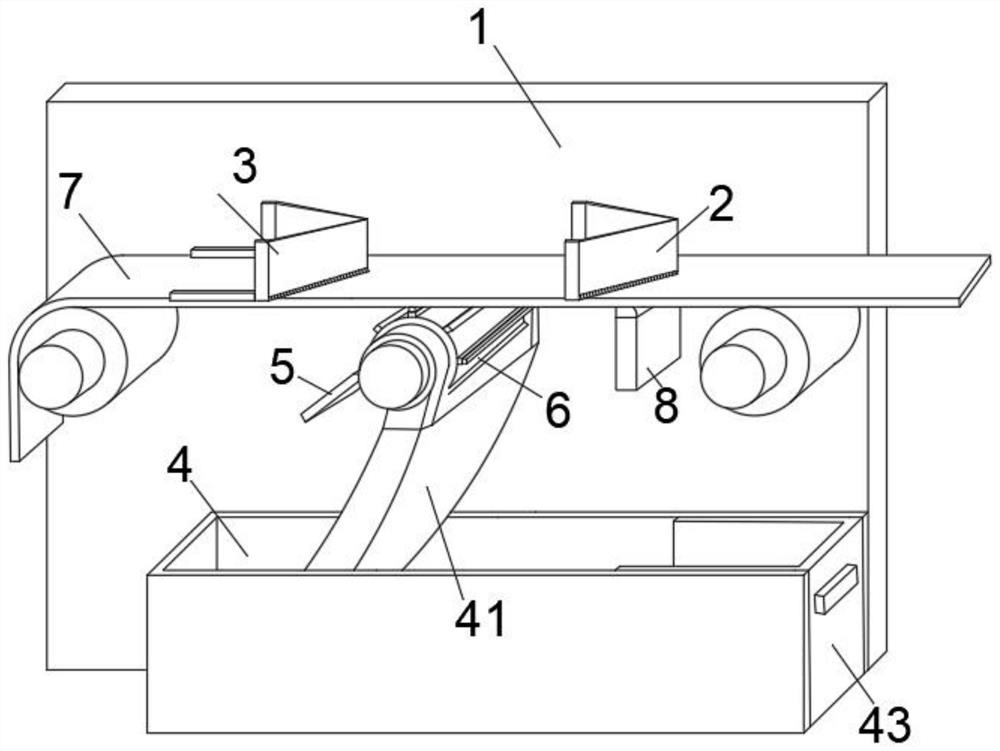

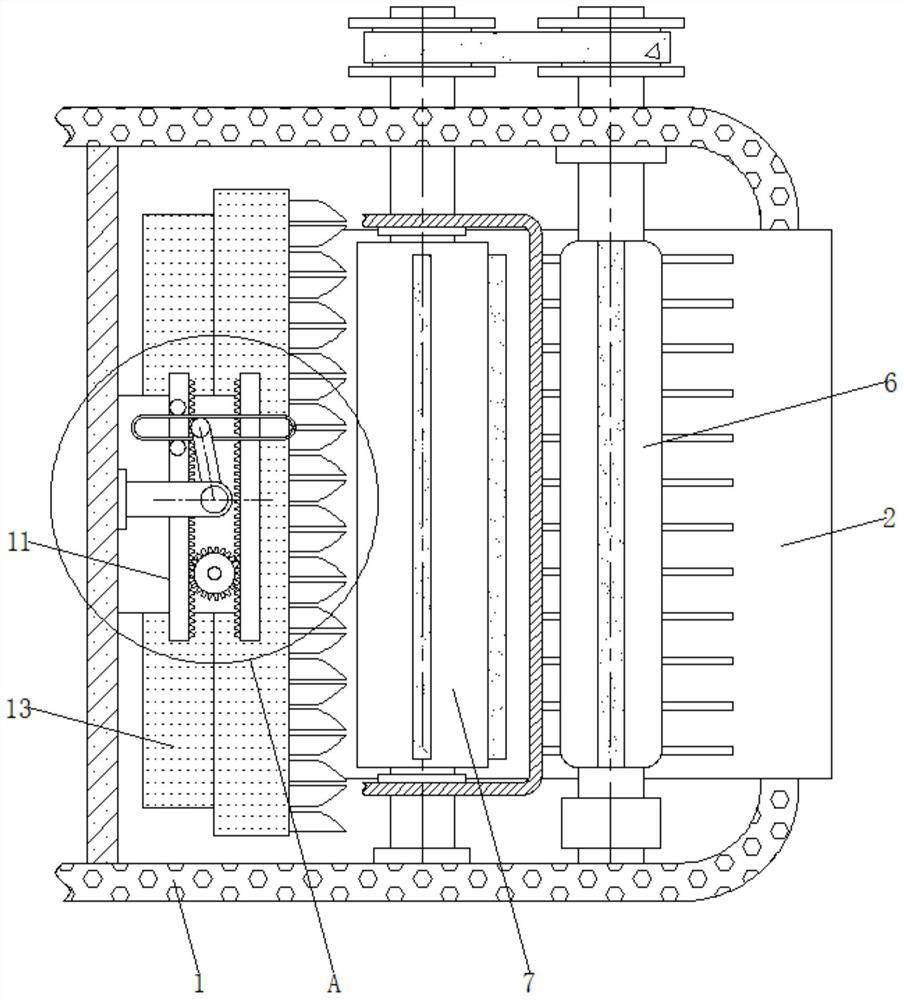

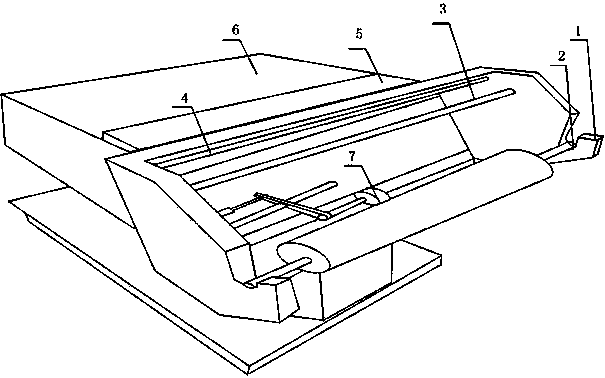

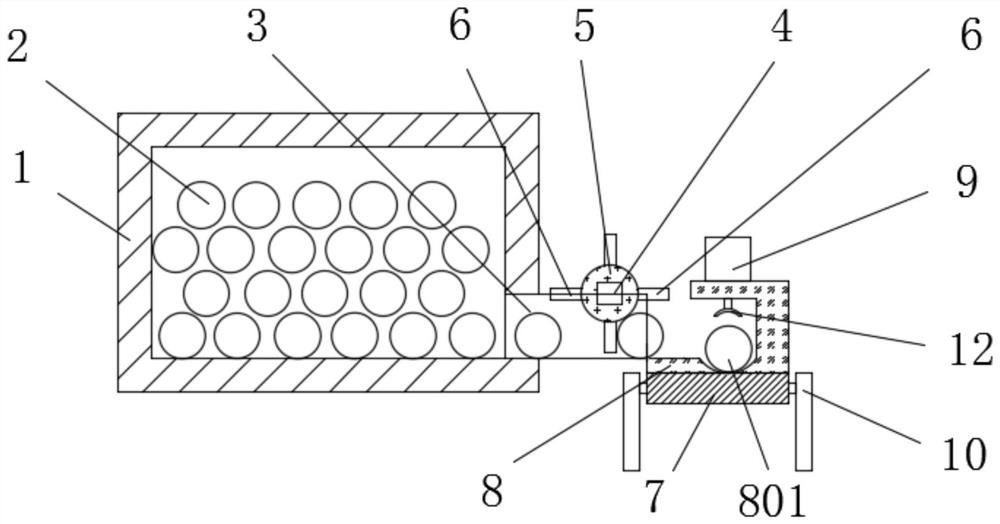

Cloth paving machine

The invention relates to a cloth paving machine which comprises a base provided with rollers, an unreeling mechanism arranged on the base and a cloth roll flattening mechanism, wherein the unreeling mechanism comprises an unreeling support, a main shaft which is arranged on the unreeling support, a friction disc which is arranged on the main shaft and used for controlling unreeling speed, and a locking disc which is used for locking a cloth roll, the unreeling support is provided with an unreeling tension regulating mechanism and an unreeling correcting mechanism, and the cloth roll flattening mechanism comprises a support and a flattening roll arranged below the support. The cloth paving machine disclosed by the invention has the advantages that the structure is simple and practical, the unreeling tension force can be regulated flexibly, and the smoothness of an unreeled cloth face can be guaranteed.

Owner:CHANGZHOU HONGFA ZONGHENG ADVANCED MATERIAL TECH

Color film base plate and manufacturing method thereof as well as display panel and display device

InactiveCN105892125AWith touch functionDoes not affect the display effectSolid-state devicesNon-linear opticsLiquid-crystal displayTouch Senses

The invention discloses a color film base plate, a manufacturing method thereof, a display panel and a display device. The color film base plate comprises a substrate base plate, sub-pixel color resistors, black matrixes and a touch electrode layer, wherein the sub-pixel color resistors are arranged on the substrate base plate and are laid in an array manner; the black matrixes are arranged on the substrate base plate and are used for separating each sub-pixel color resistor; the touch electrode layer is arranged on the substrate base plate and is used as a flat layer; the touch electrode layer is segmented into multiple mutually insulating touch sensing electrodes; the orthographic projection, on the substrate base plate, of segmentation gaps between the touch sensing electrodes are located in an area where the black matrixes are located. According to the color film base plate which is provided by an embodiment of the invention, the touch electrode layer is used as the flat layer at the same time, so as to enable the color film base plate to have a touch function at the same time; the thickness and the weight of a display screen are reduced; and the yield loss caused in a process of abutting a touch screen and a liquid crystal display screen is avoided when an externally hung touch screen is used.

Owner:BOE TECH GRP CO LTD

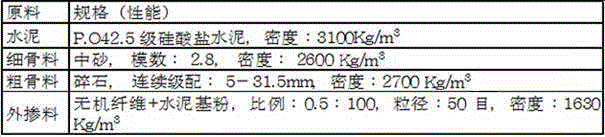

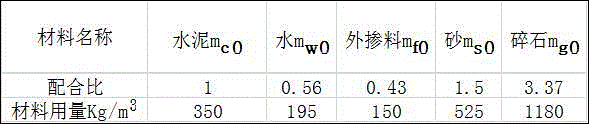

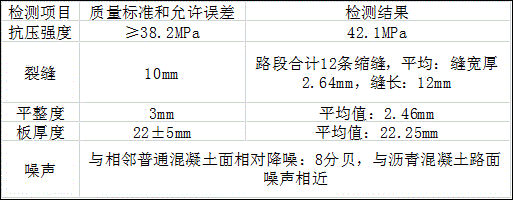

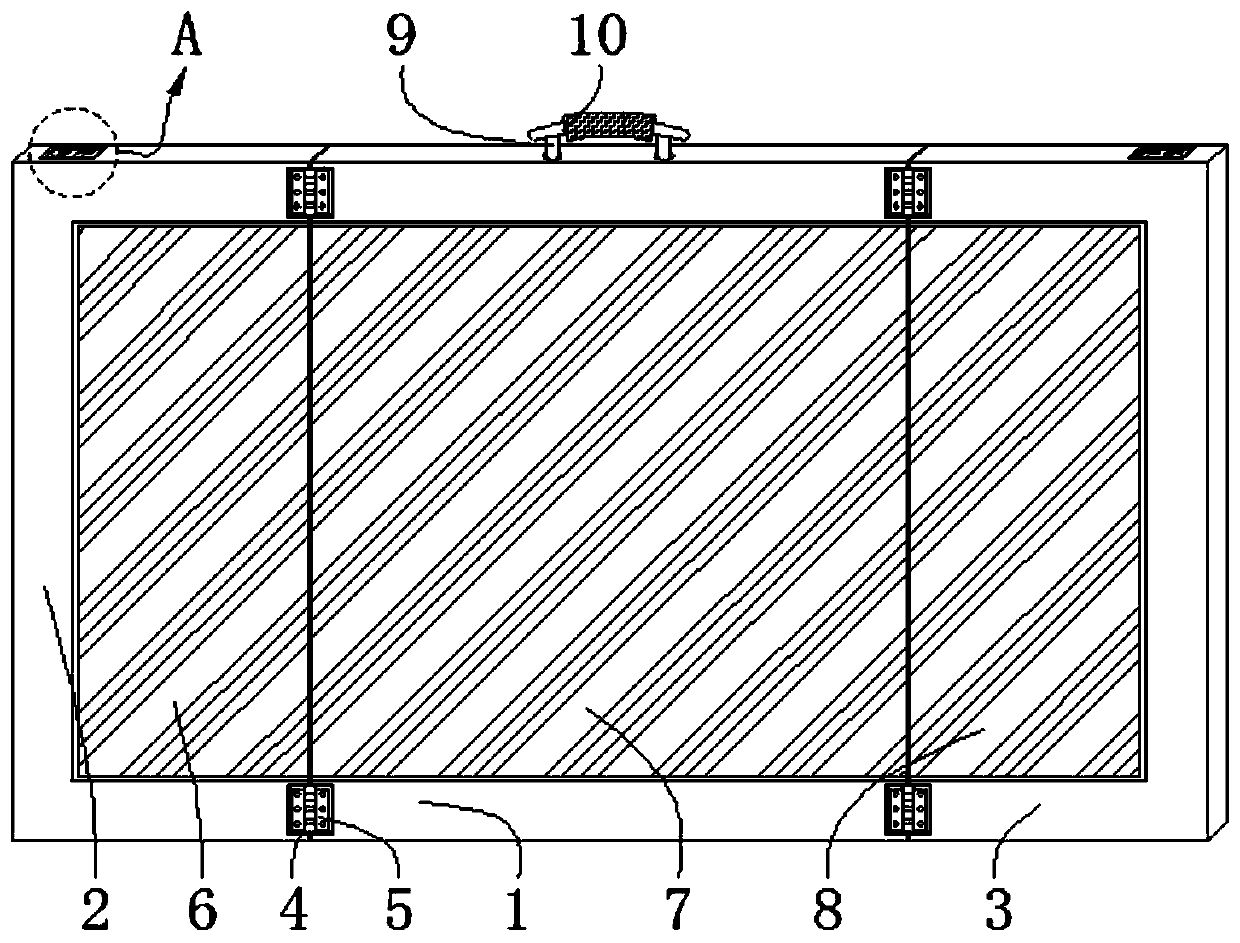

Cement based powder and application thereof in cement concrete and in highway construction

InactiveCN106082742AImprove sound absorptionReduce noiseSolid waste managementFiberBreaking strength

The invention discloses cement based powder and application thereof in cement concrete and in highway construction, belongs to the field of construction materials, and aims at solving the problem of low breaking strength of the existing cement concrete pavement, prolonging the service life, lengthening the distance of cutting joints in the cement pavement, even producing a cement pavement without cutting joints, improving the driving comfort, reducing noise and the like. The cement based powder is prepared from the following components in parts by weight: 100 parts of waste rubber granules having an average grain size not less than 10 meshes, 3-50 parts of inorganic inert powder having an average grain size not less than 10 meshes and 0.2-5 parts of a fiber material. The method for preparing the cement based powder comprises the following steps: (1) mixing and stirring the inert inorganic powder material, waste rubber granules and fiber material; and (2) treating the mixture in the step (1) by a physical method to embed the inert inorganic powder and fiber material into the waste rubber powder.

Owner:SICHUAN GOLDMILL ENVIRONMENTAL PROTECTION NEW MATERIALS

Novel folding LED display screen with protective function

The invention discloses a novel folding LED display screen with a protective function. The display screen comprises a first connecting plate, a second connecting plate and a third connecting plate; the second connecting plate and the third connecting plate are arranged on the two sides of the first connecting plate; a connecting groove is formed between the second connecting plate and the first connecting plate; a hinge is arranged in the connecting groove; a first LED screen is arranged on the second connecting plate; and a second LED screen is arranged on the first connecting plate. The invention relates to the technical field of LED display screens. According to the novel folding LED display screen with the protective function, the adjusting and clamping structures on the second connecting plate and the third connecting plate are the same, and the adjusting modes are the same; and the second connecting plate and the third connecting plate are stably fixed on the first connecting plate after being folded through the clamping structures, so that the damage to the internal LED display screen due to vibration and inversion during moving or transportation is avoided, and the stability of the folded LED display screen is guaranteed.

Owner:四川凝彩电子科技集团有限公司

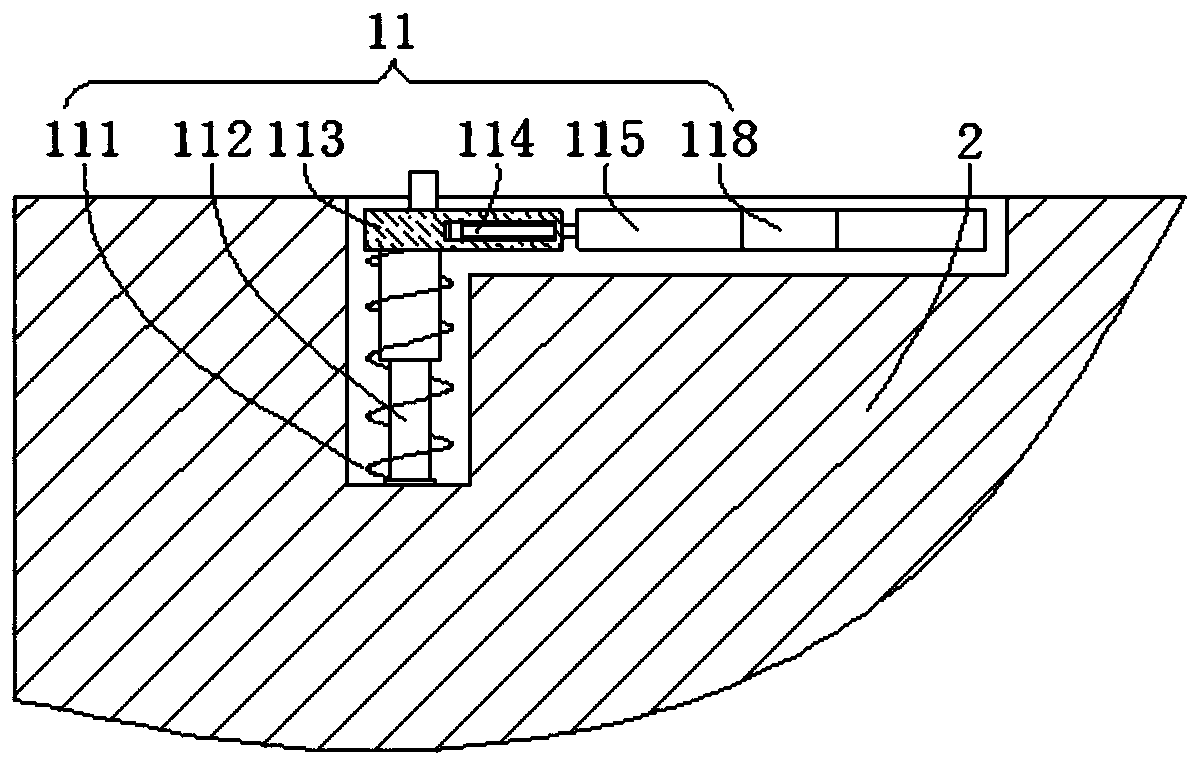

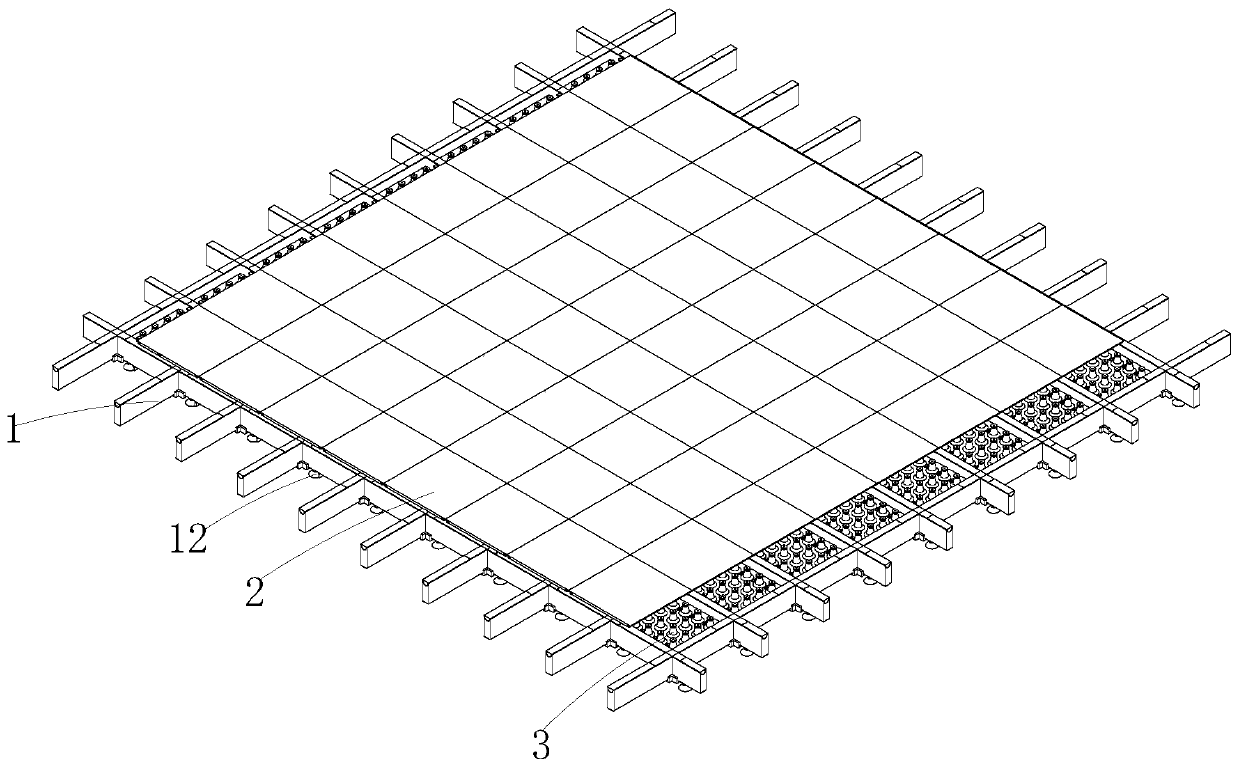

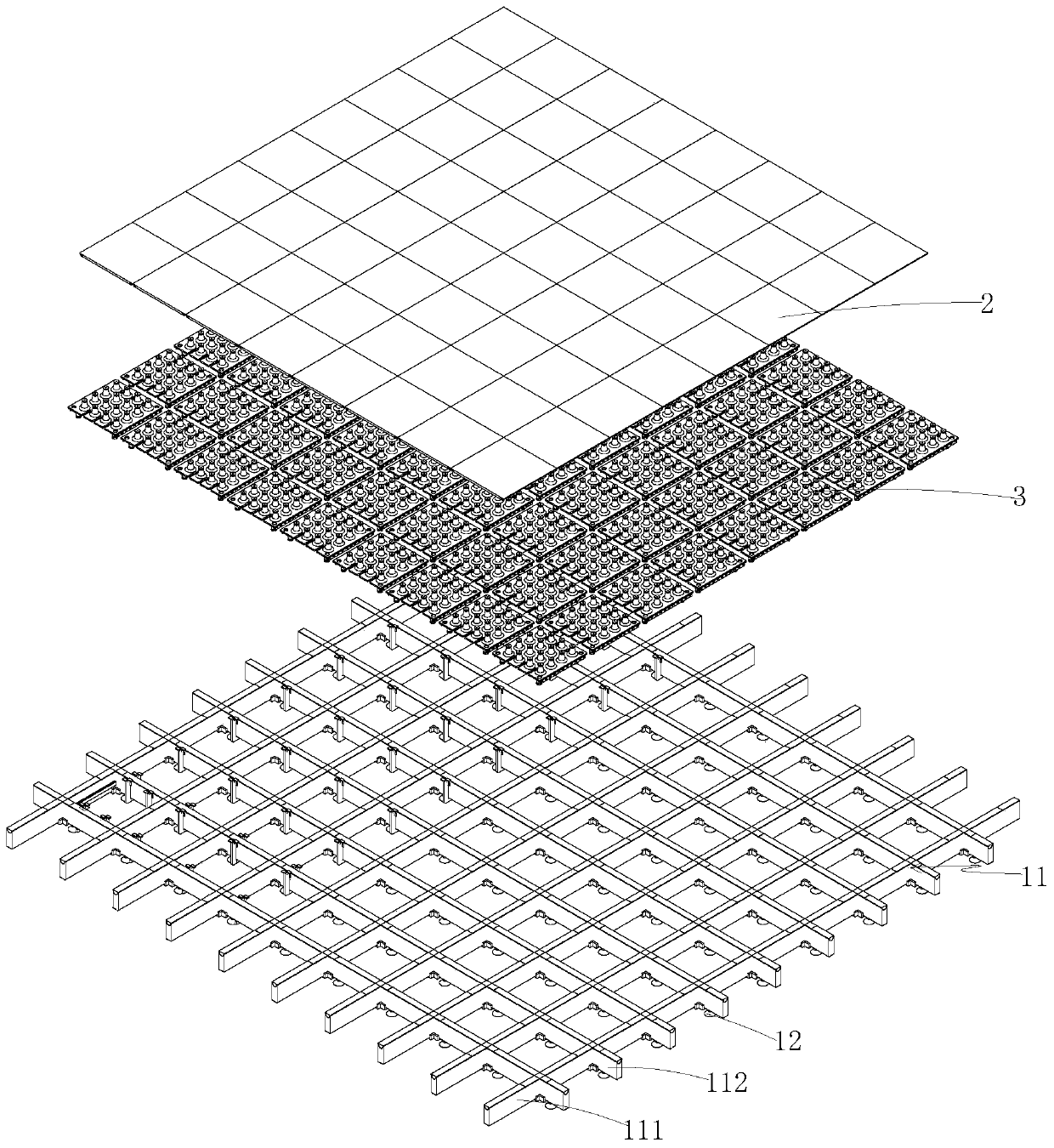

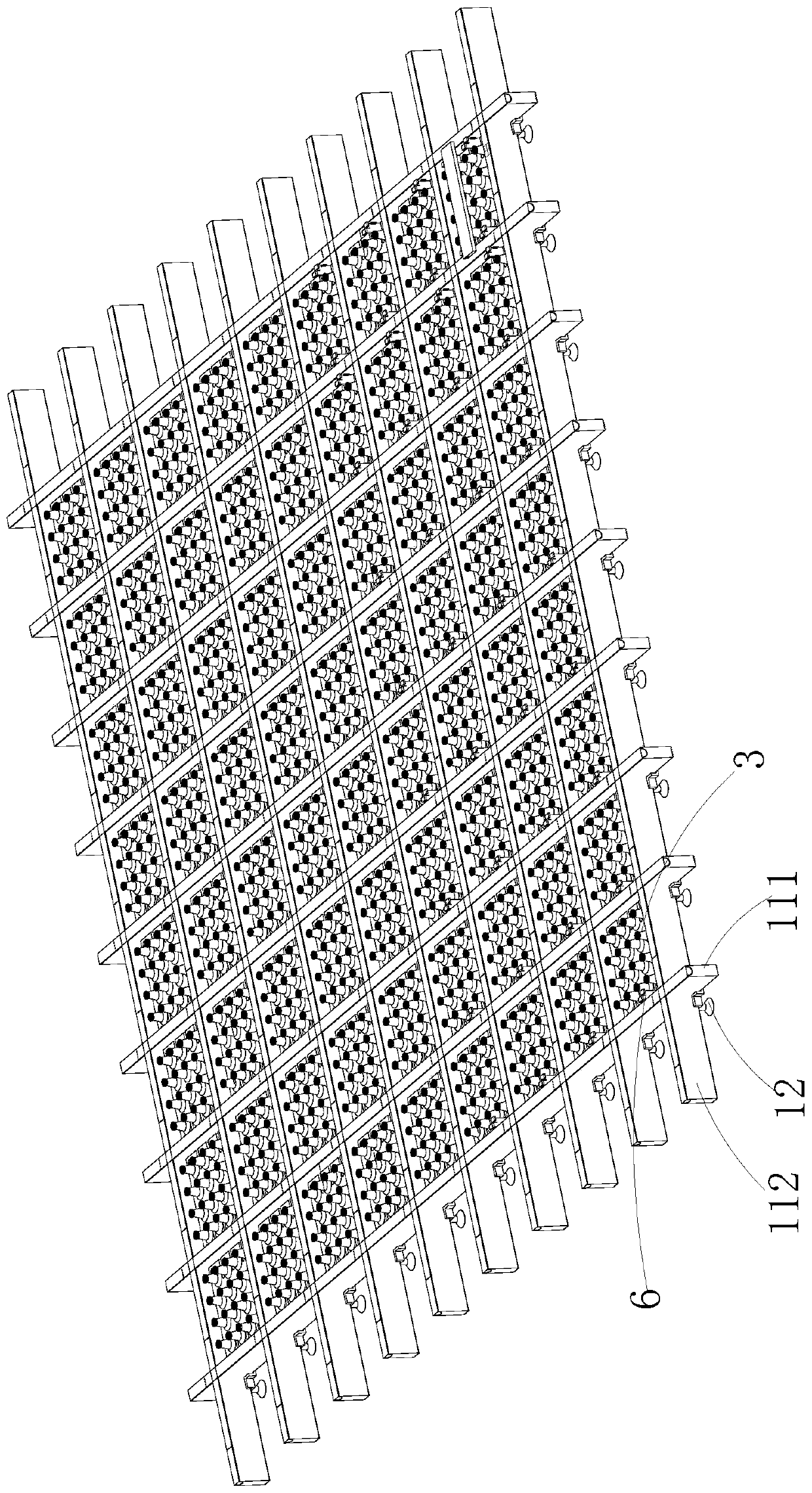

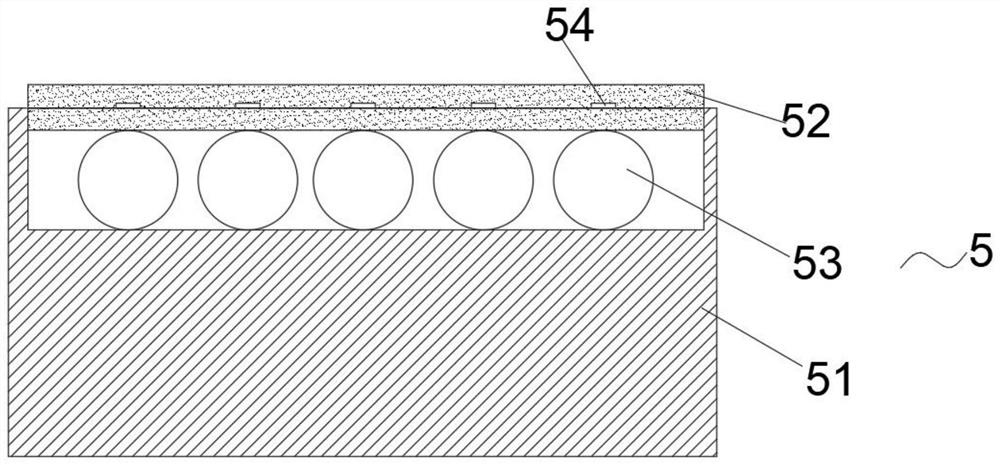

Modularly mounted indoor decoration system

ActiveCN110512825AGuaranteed flatReduce the floating areaCovering/liningsFlooring insulationsFirst FillModularity

The invention discloses a modularly mounted indoor decoration system. The system includes a grid base, floor tiles arranged on the grid base, and a filling structure filling the grid base to support the floor tiles, wherein the filling structure includes a filling body, several first filling parts arranged on the filling body at equal intervals and several second filling parts arranged on the filling body at equal intervals, and each first filling part is of a conical structure or a hemispherical structure; each second filling part is of a conical structure or a hemispherical structure; the filling body is detachably connected with the grid base. The grid base is adopted, the floor tiles can be directly paved on the grid base and can keep flat without adjustment in the paving process, thepaving effect is good, and the paving efficiency is high. The filling structure is placed on the grid base for partially supporting the floor tiles, and the situation is avoided that the floor tiles are partially cracked when heavy objects fall down.

Owner:天津安其居建筑科技有限公司

Instrument identifier for deep space probe

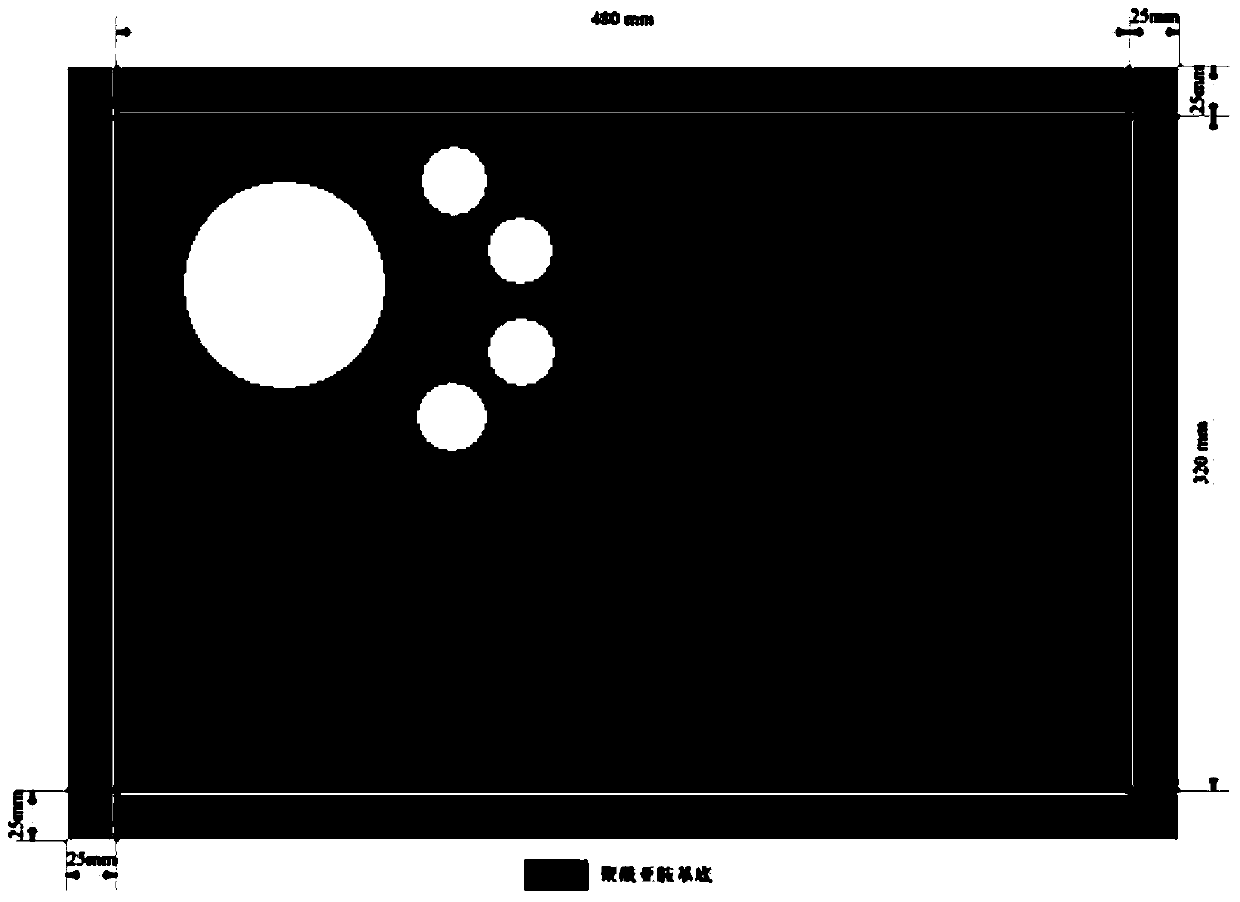

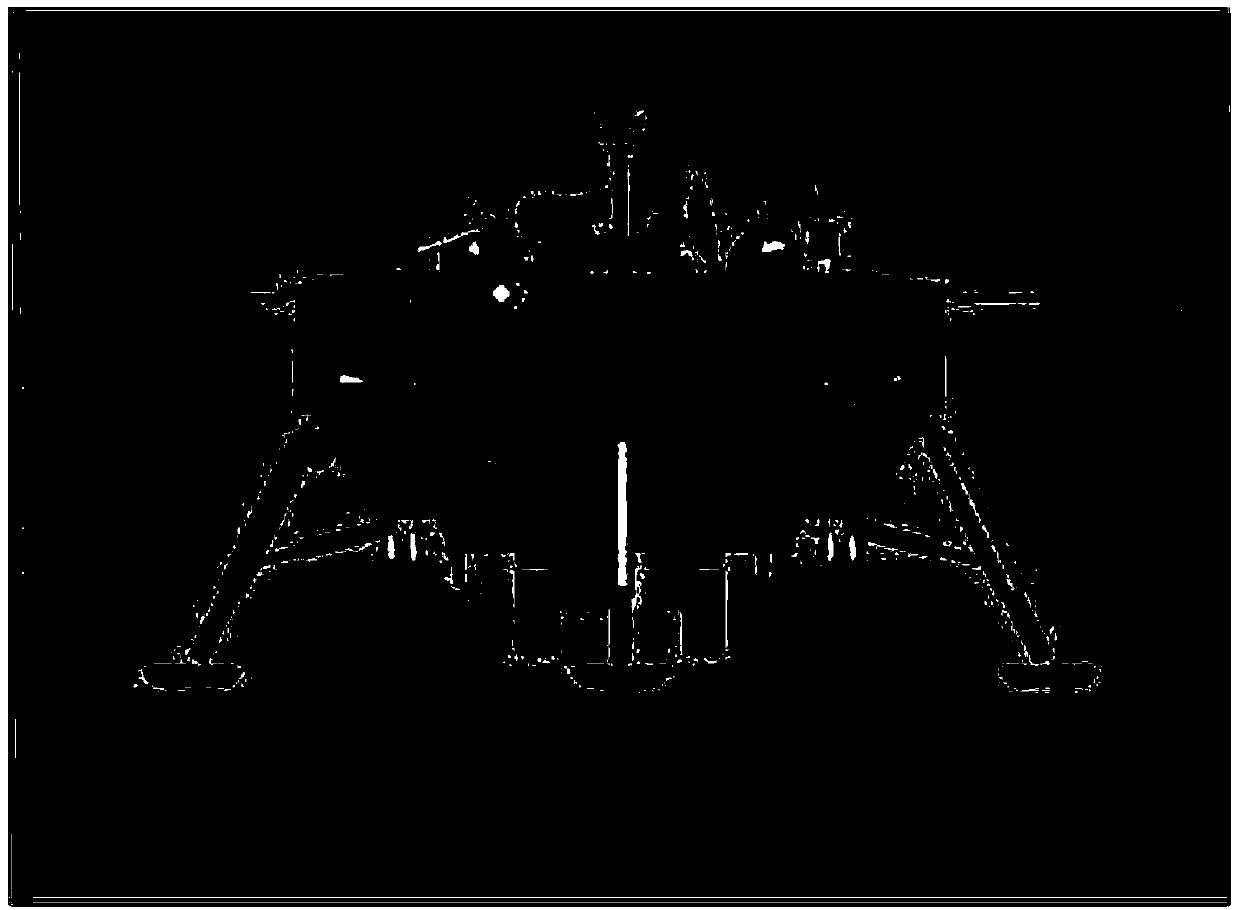

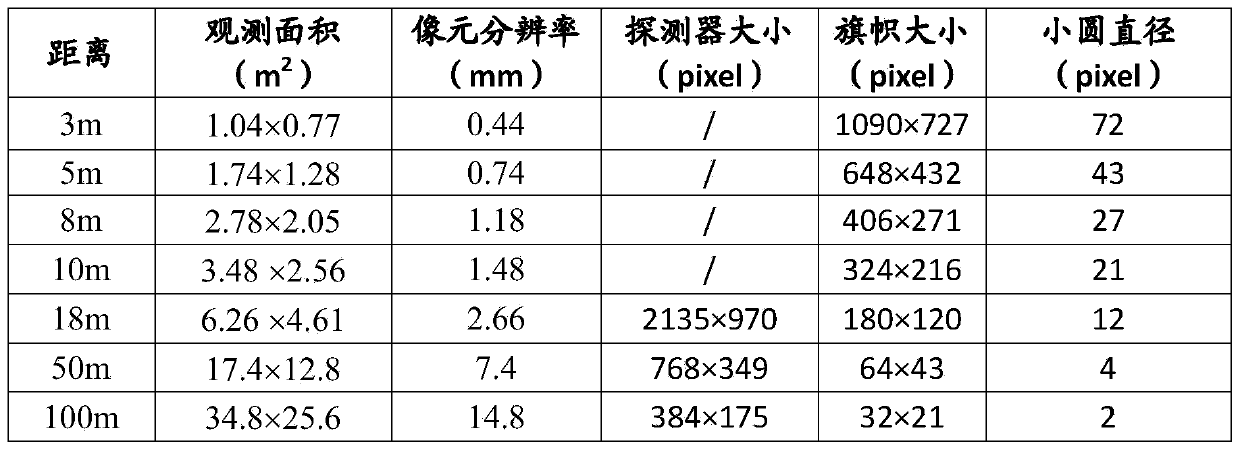

ActiveCN104183203AStrong radiation resistanceImprove high and low temperature resistanceStampsFlags/bannersPolyimideChemical composition

The invention provides an instrument identifier for a deep space probe. The instrument identifier mainly comprises a polyimide film in 125-mocrometer thickness and a surface composite coating, wherein the surface composite coating is printed onto the polyimide film by the screen printing process; taking the weight of the surface composite coating as 100%, the surface composite coating comprises the following chemical components in percentage by weight: 55-65% of organic silicon resin, 24-36% of modified resin, 3-5% of organic pigment and 4-8% of an additive. When the base material and the surface composite coating are to be selected, the environmental constraint problems of space radiation, vacuum, lunar dust, large high-low temperature differences, mechanics and the like are taken into full consideration, so that the selected composite coating is high in capability of irradiance resistance, strong in performance of high-low temperature resistance and large in intensity of mechanics resistance.

Owner:BEIJING INST OF SPACECRAFT SYST ENG

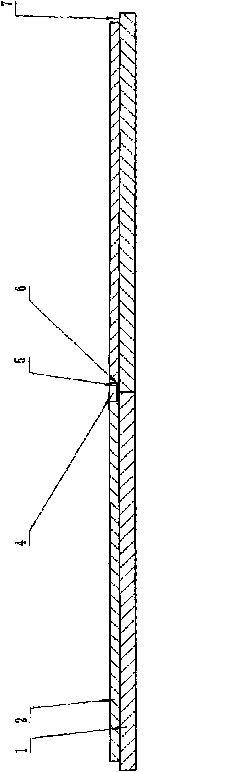

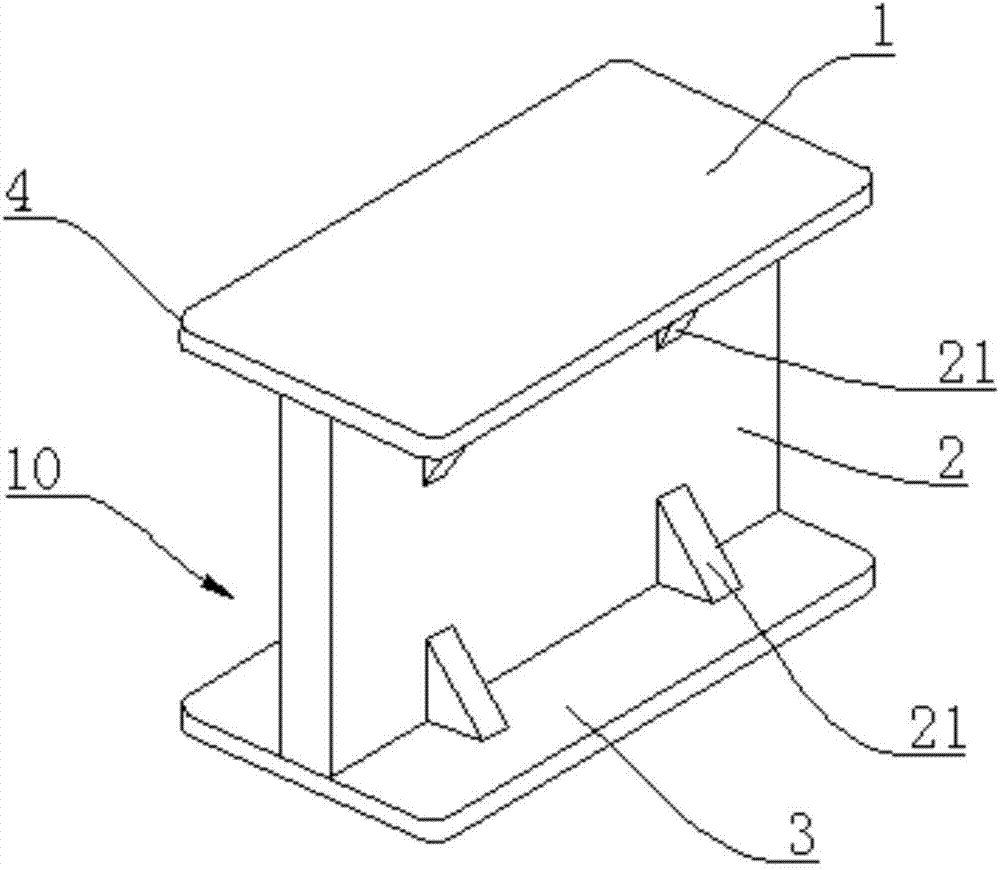

Buried ballastless track structure

ActiveCN106592345AAvoid accumulationGuaranteed flatRailway tracksElectrical and Electronics engineeringTrack bed

A buried ballastless track structure comprises a track bed, track boards and sleepers, wherein each sleeper is erected on the corresponding track board; the track bed is provided with downward concave pits; the track boards and the sleepers are arranged inside the pits; the top faces of the sleepers and the top face of the track bed are arranged on the same plane; the two sides of each track board are in seamless connection with the track bed to form an integral whole; buffer belts are arranged between the two sides of each track sleeper and the track bed; and the buffer belts are filled with shock absorption cotton. Wind-blown sand is prevented from accumulating in either the fall area between the track boards and the track bed or the fall areas between the track boards and the sleepers.

Owner:天长市西达克家居有限公司

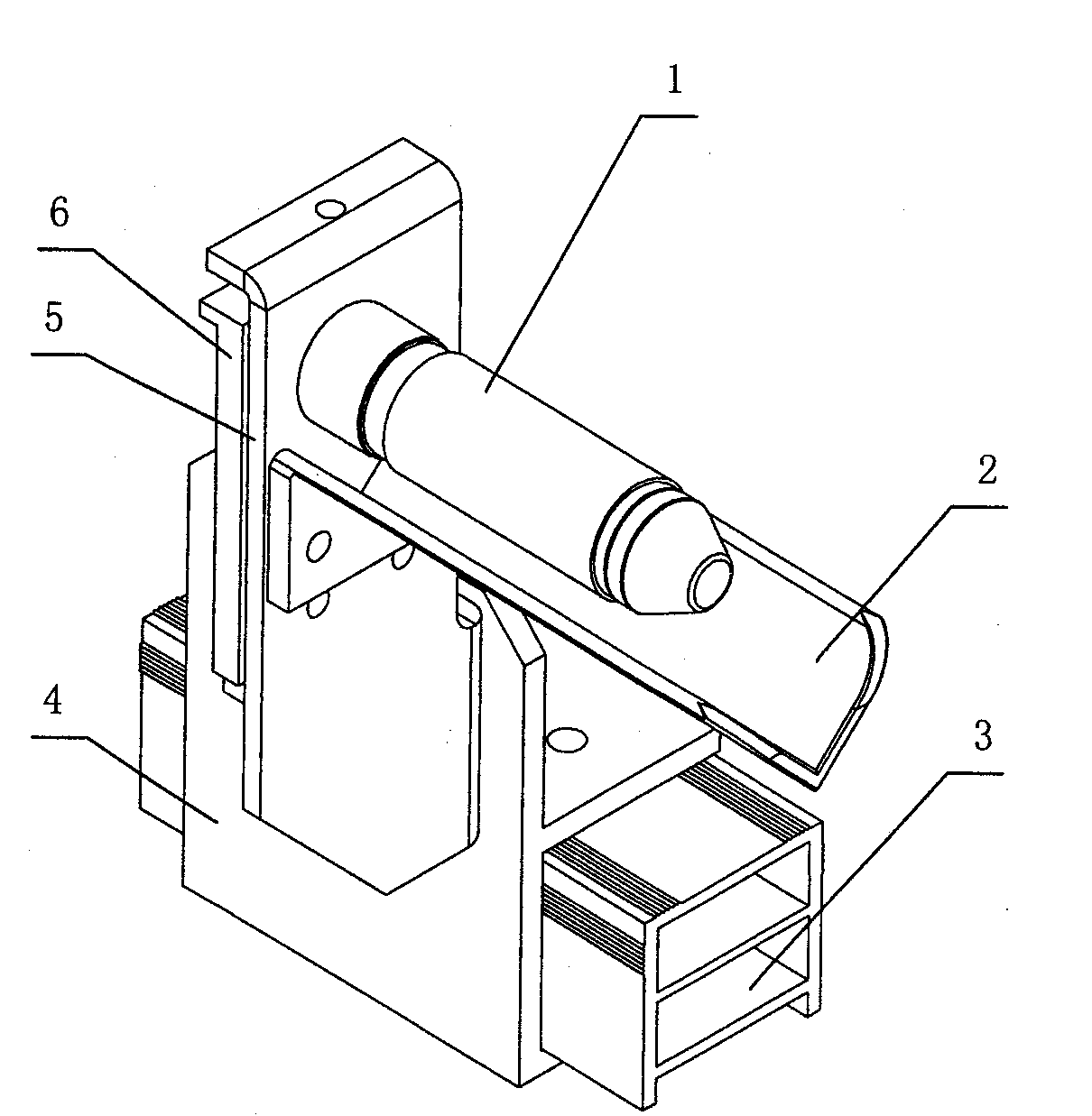

Bridge crack repairing method

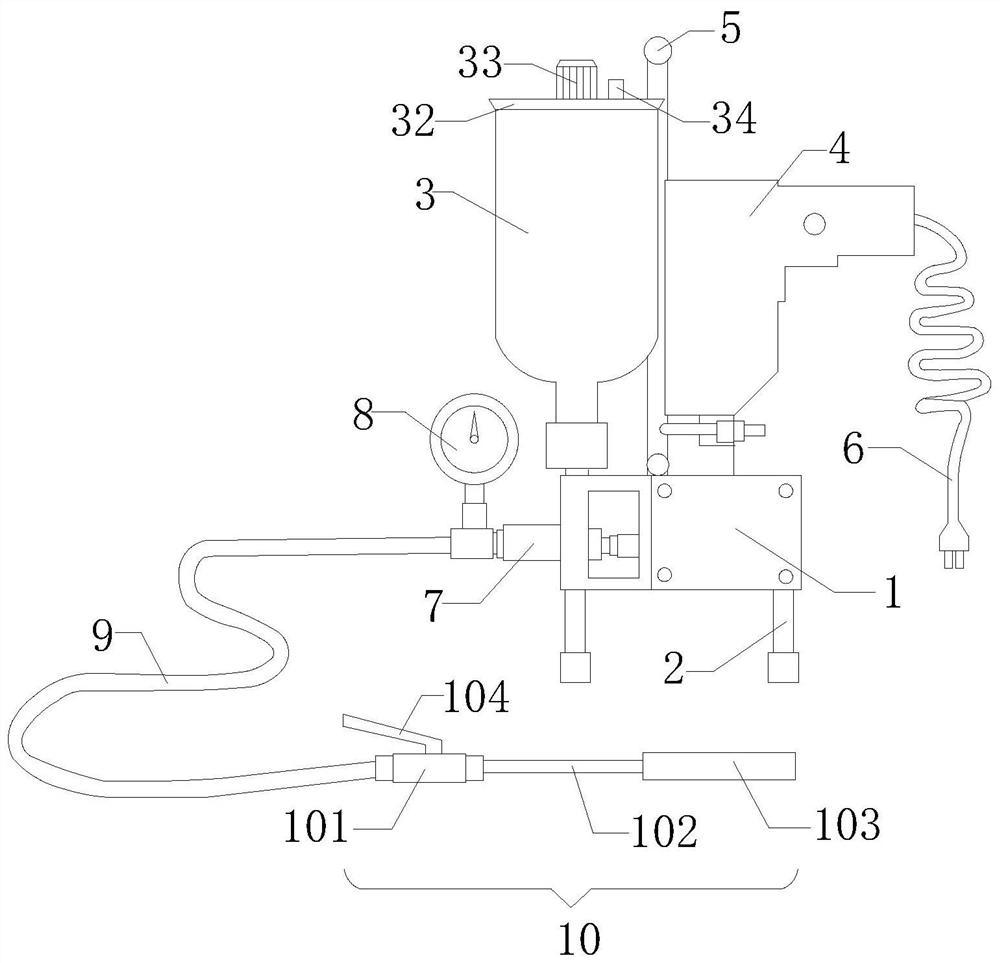

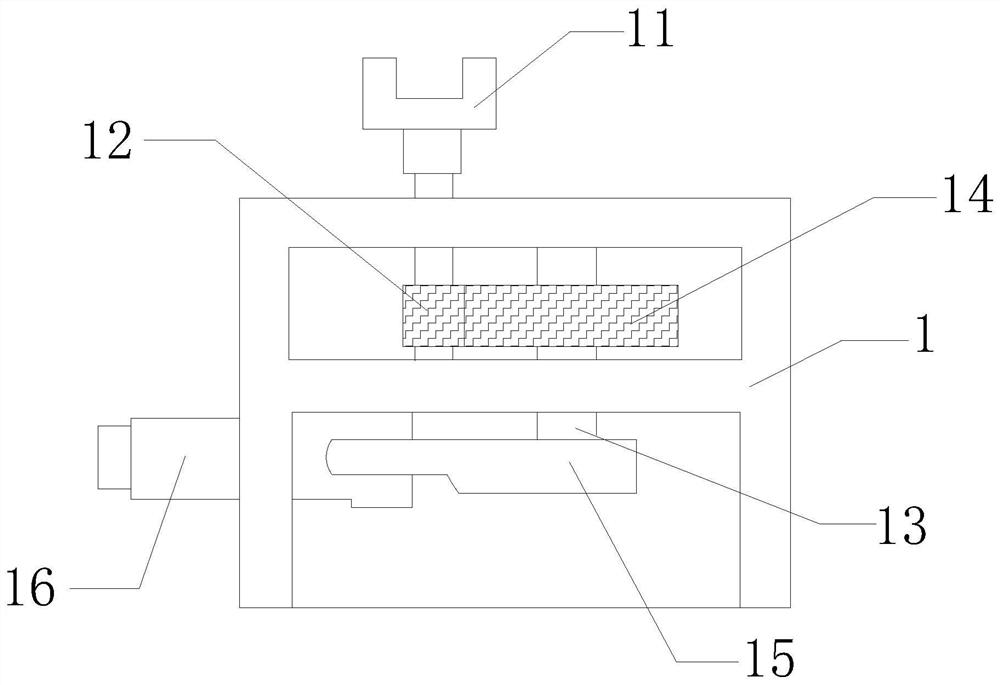

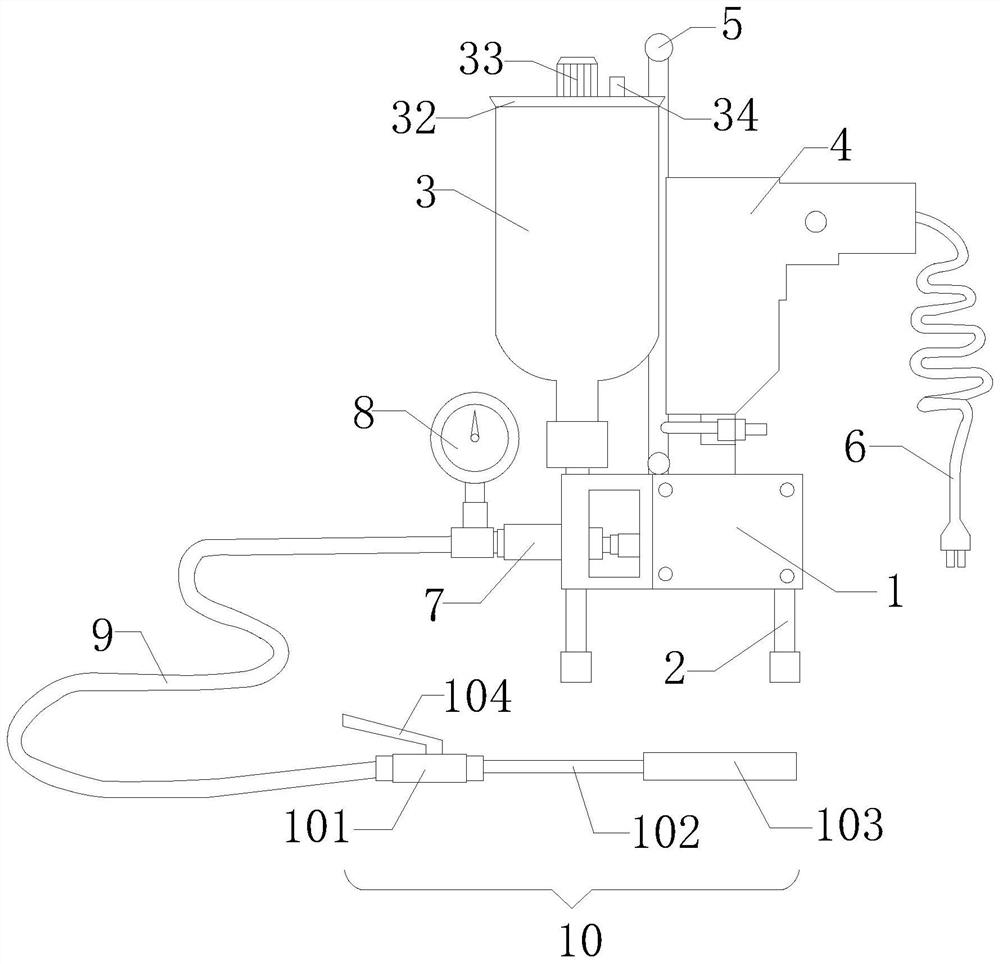

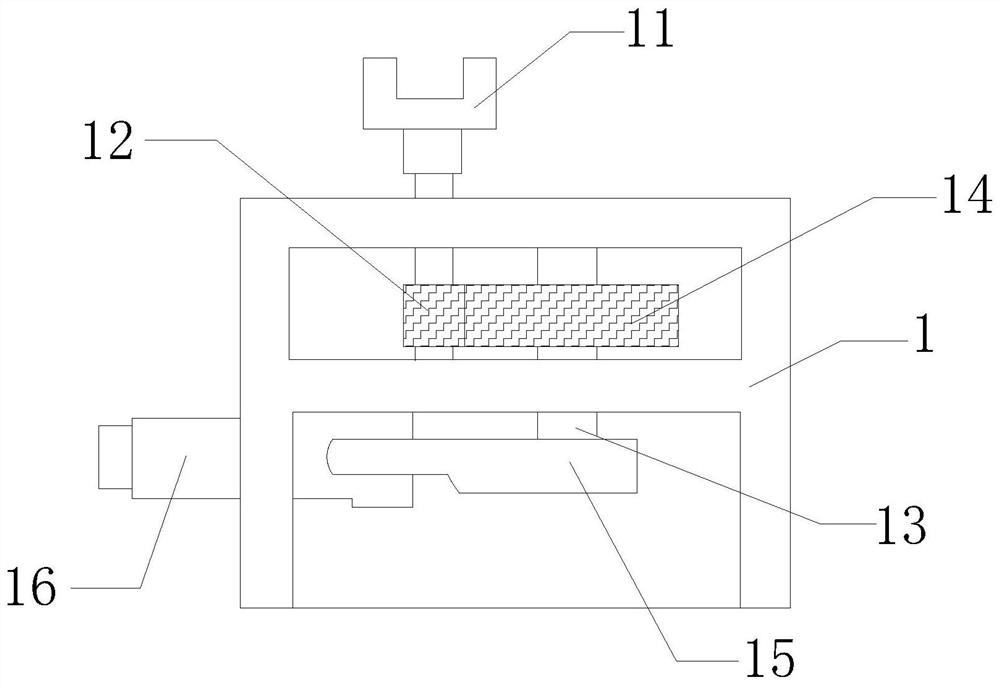

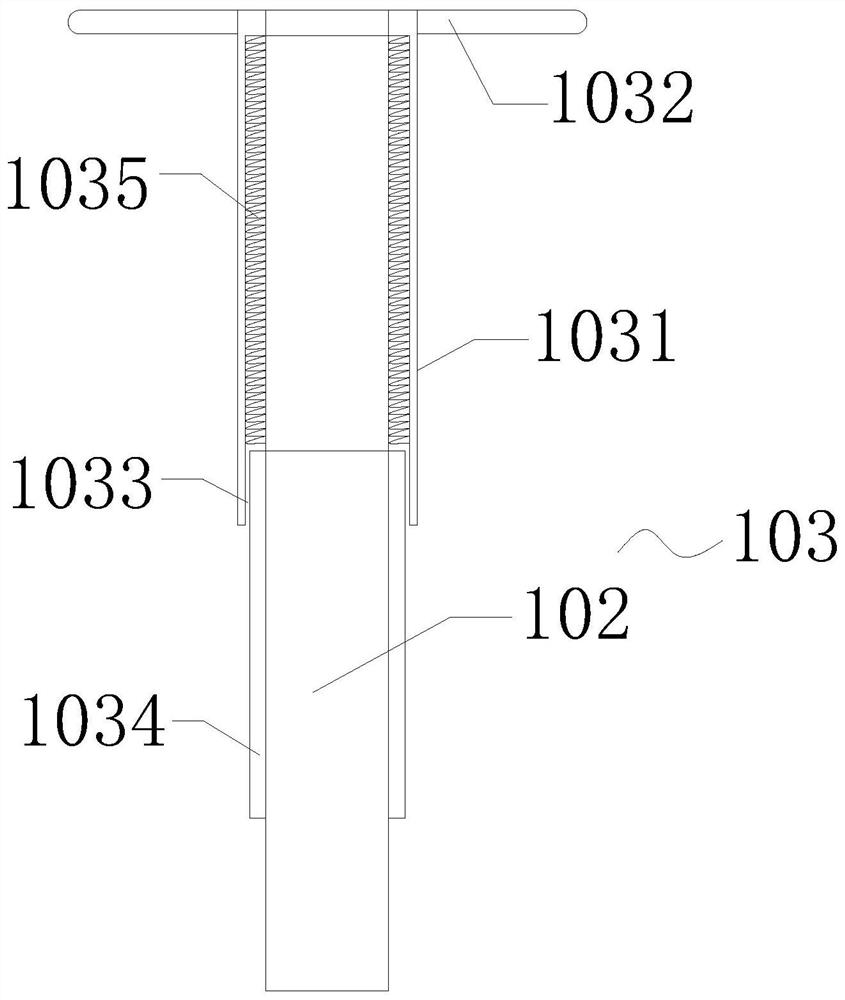

ActiveCN112195739AFast manufacturingSpeed up wettingBridge erection/assemblyRoads maintainenceMaterials preparationDrive shaft

The invention provides a bridge crack repairing method. A device adopted by the method comprises a case, and a support, a material preparation mechanism, a driving electric drill, a lifting handle, aplug, a pressure pump set, a pressure gauge, a high-pressure pipe, a repairing mechanism, an electric drill connector, a small gear, a rotating shaft, a large gear, blades and a transmission shaft aresequentially arranged on the case. The supports is fixedly installed on the two sides of the outer surface of the lower end of the case, the material preparation mechanism is arranged on one side ofthe outer surface of the upper end of the case, the driving electric drill is movably installed on the other side of the outer surface of the upper end of the case, and the plug is movably installed on the side, away from the case, of the driving electric drill. According to the bridge crack repairing device, a handle can be supported in the repairing process, the amplitude of the handle caused byslurry impact force is reduced, the labor intensity of workers is relieved, the repairing position can be leveled and cleaned, the repairing quality is improved, the material preparation box is convenient to clean, cleanliness of the material preparation box is guaranteed, discharging is stable, and blocking is not likely to happen.

Owner:武汉市市政路桥有限公司

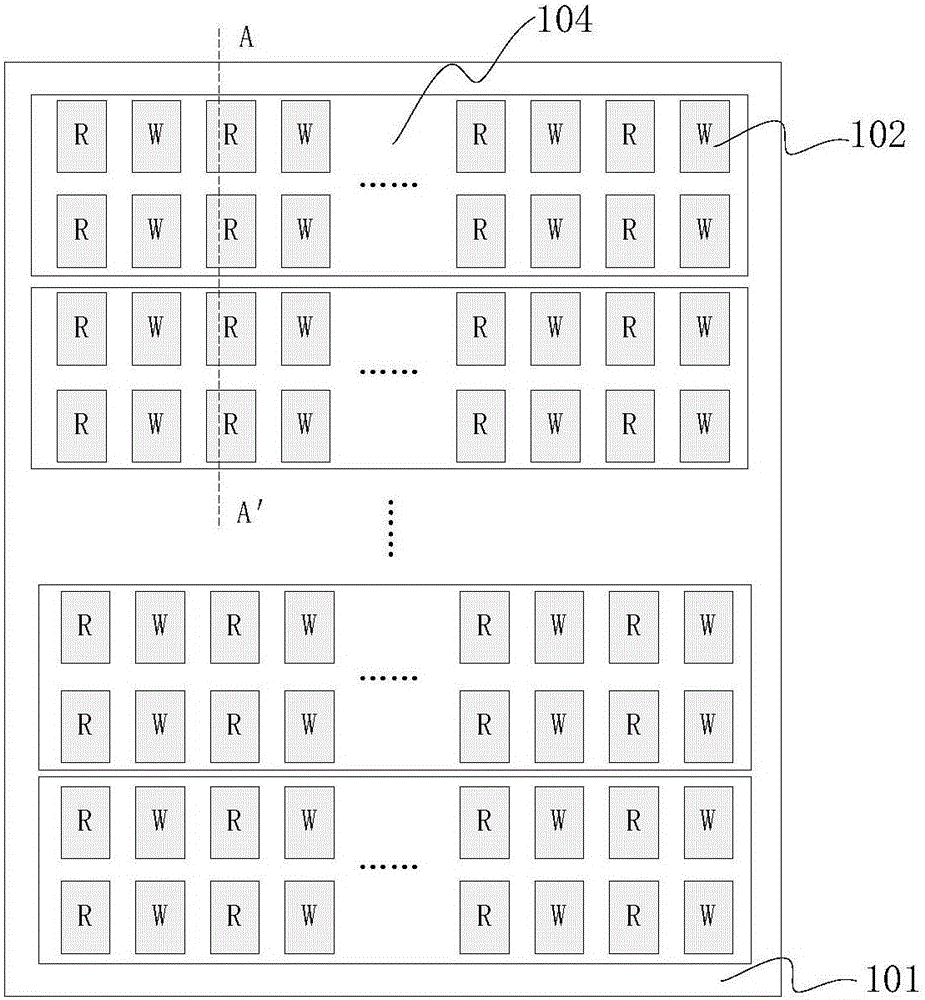

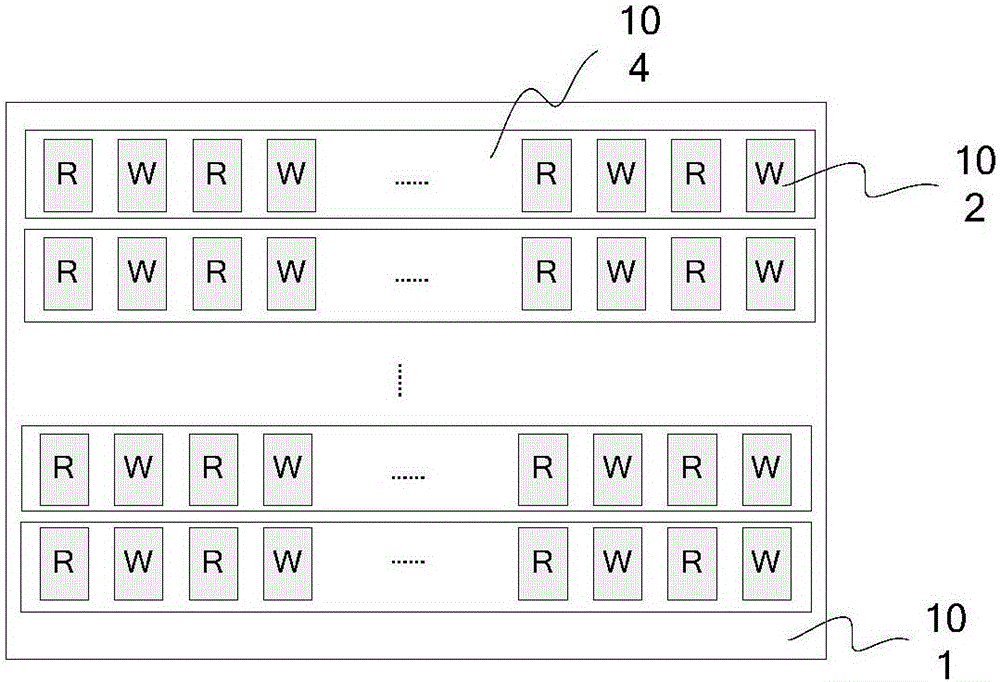

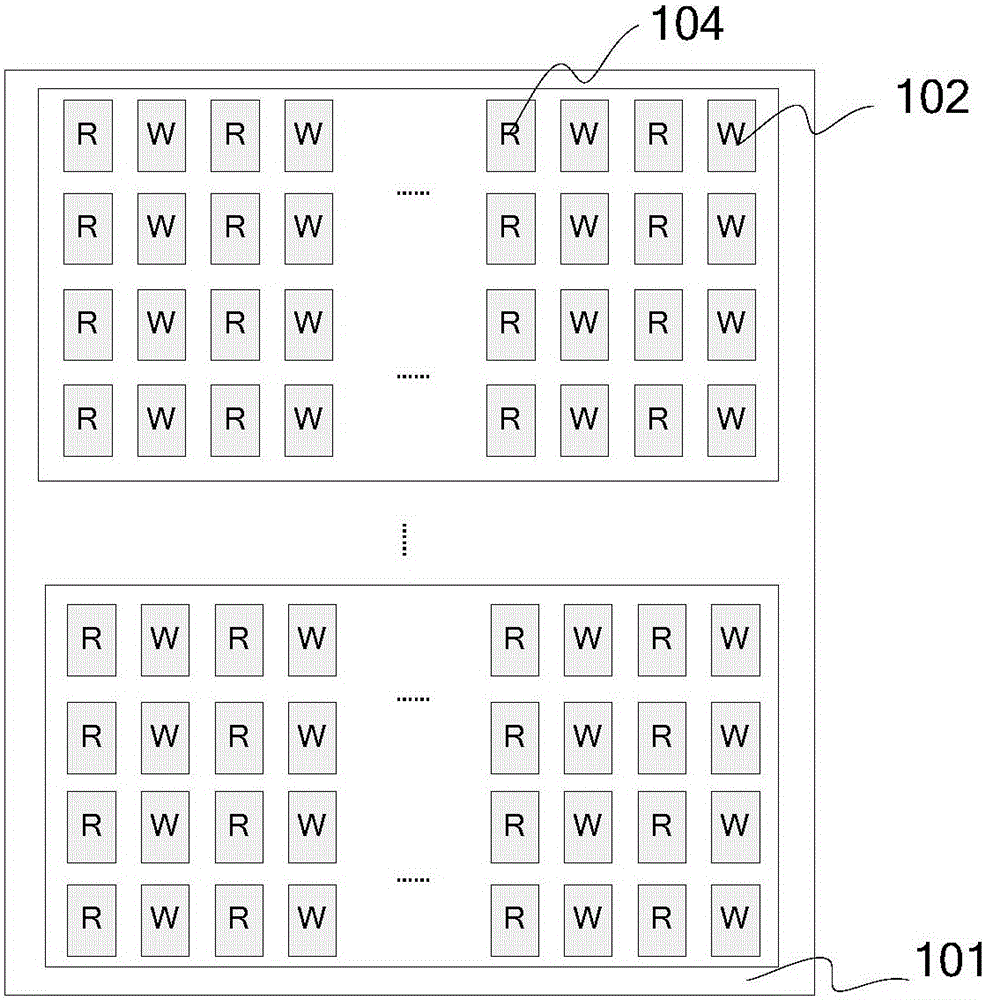

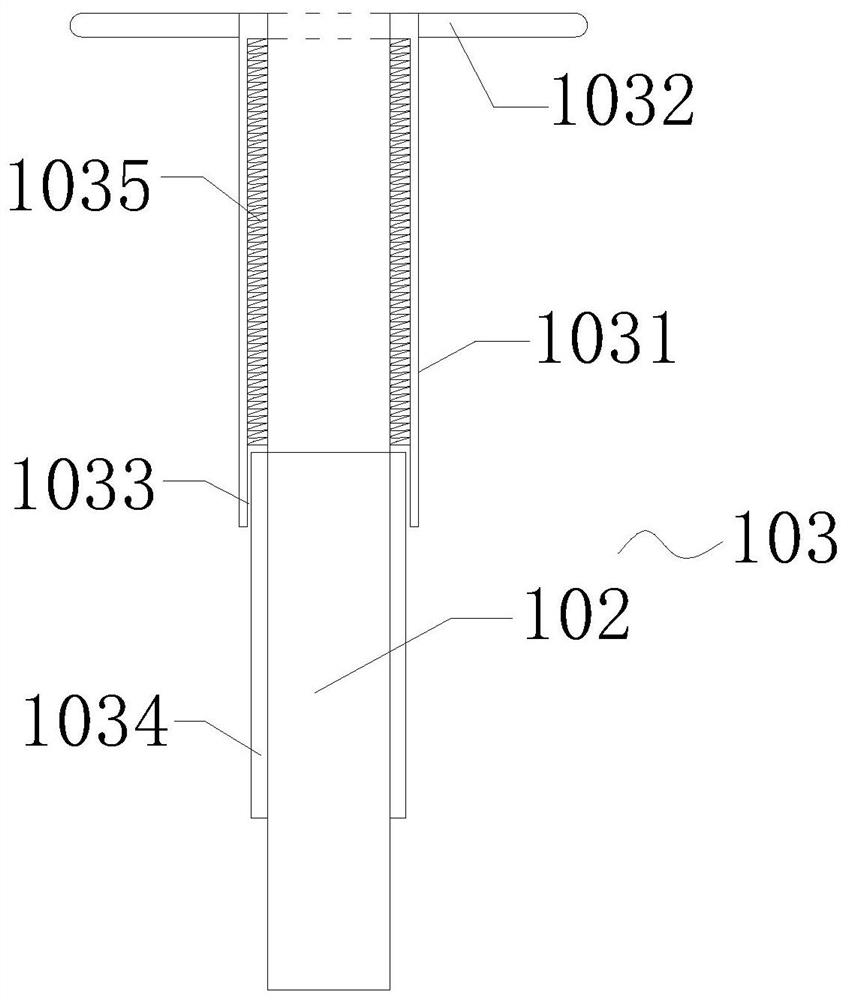

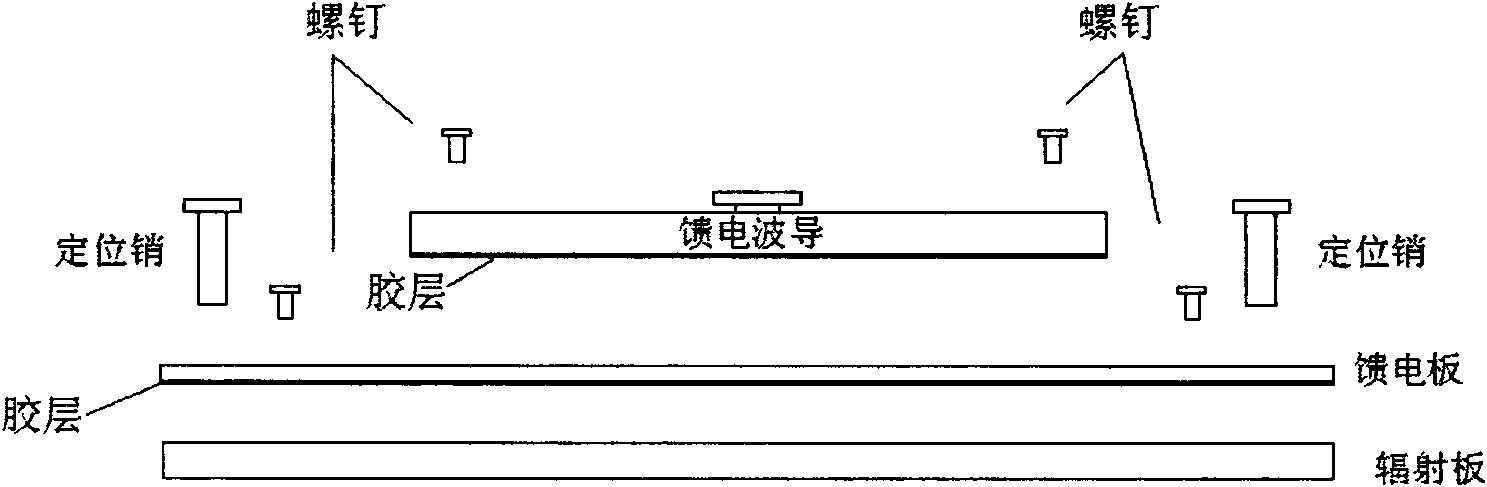

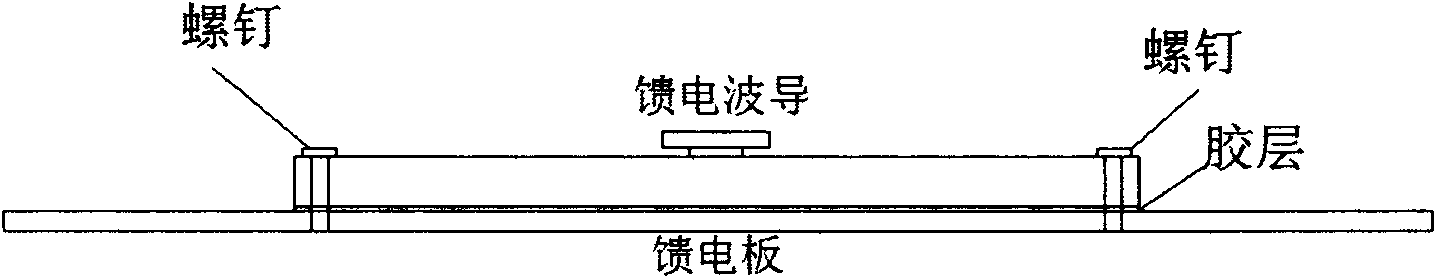

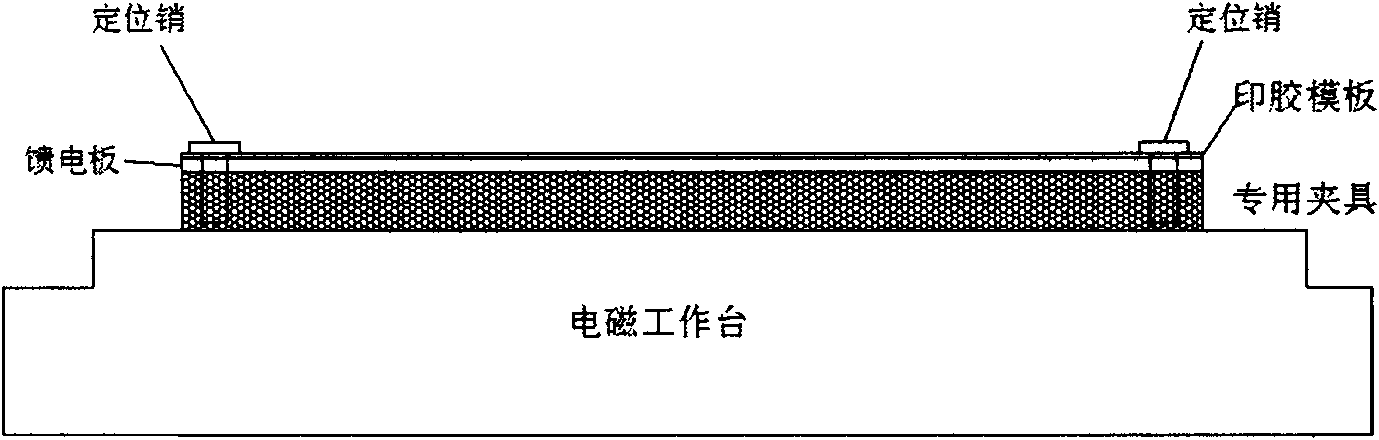

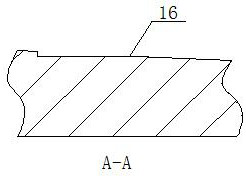

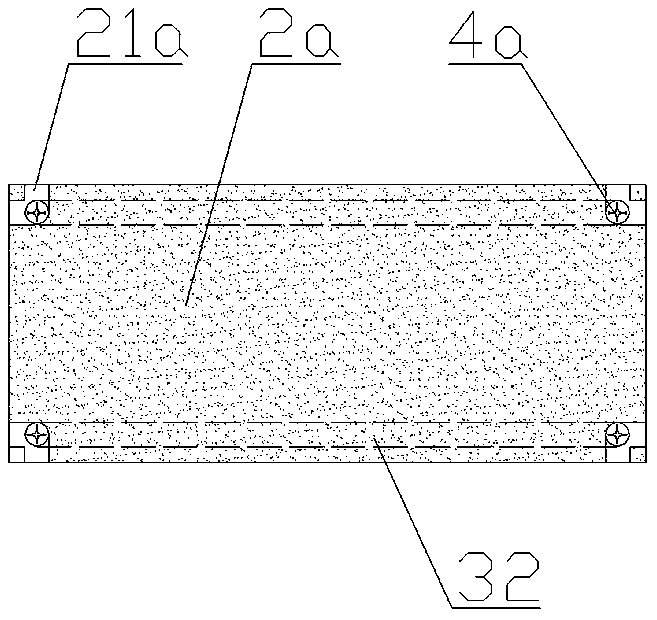

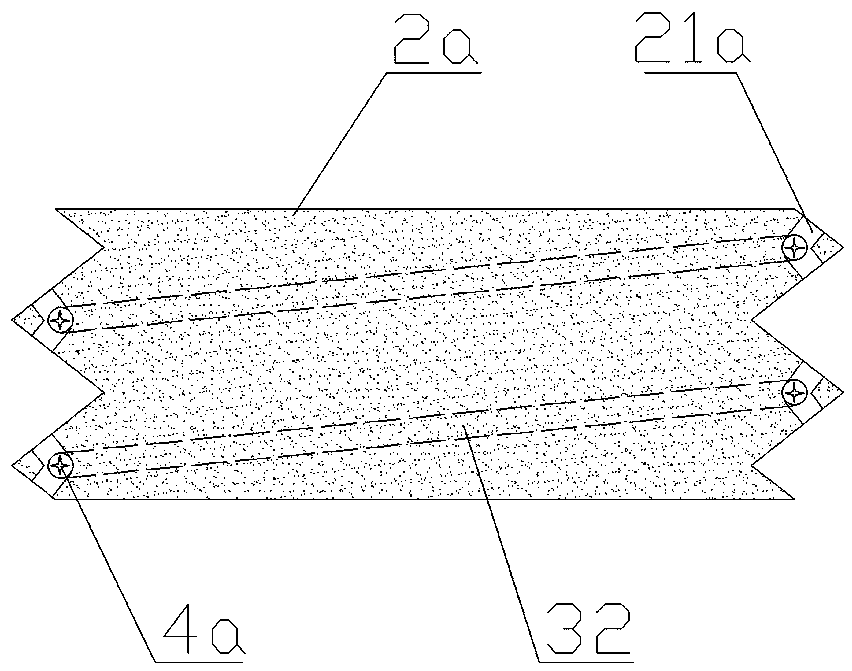

Splicing and processing method of flat crack array antenna

The invention discloses a splicing and processing method of a flat crack array antenna. In the method, the antenna is divided into a radiating plate, a feeding plate, a feeding waveguide and the like; and firstly, the feeding waveguide and the feeding plate are adhered, than an offset print template is installed, and a conductive adhesive is printed on the feeding plate by adopting a template skip printing method so as to adhere the feeding plate and the radiating plate. The method has the advantages of low technical difficulty, low cost, high qualified rate and the like.

Owner:SHAANXI CHANGLING ELECTRONICS TECH

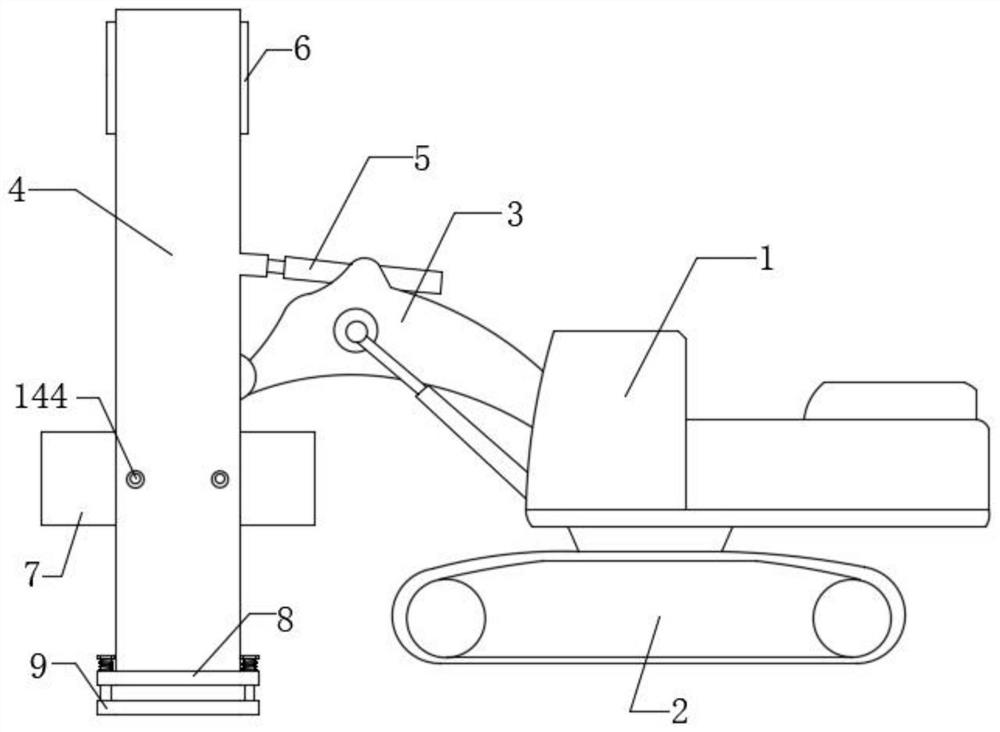

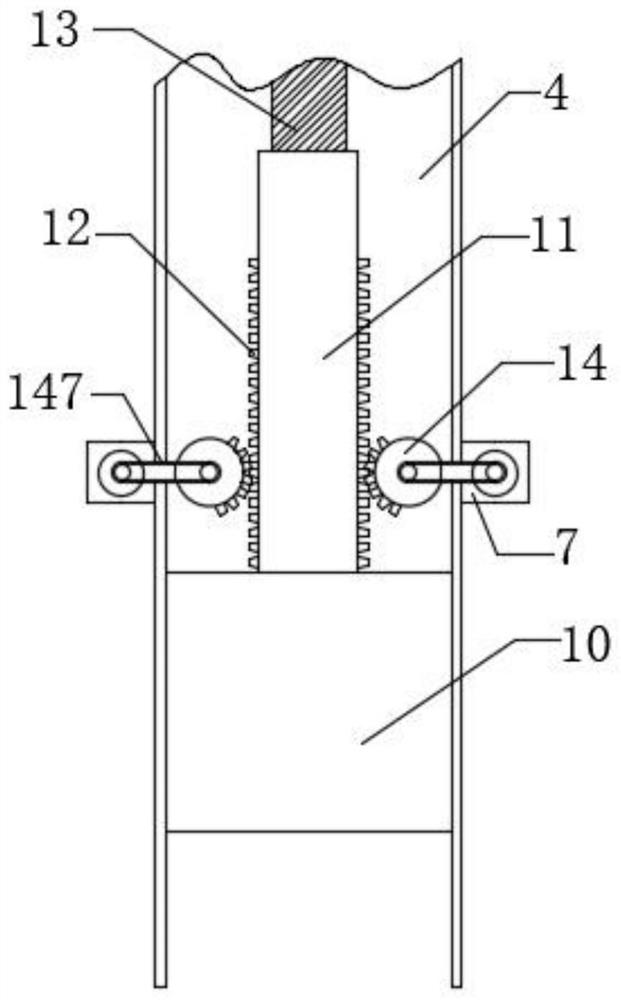

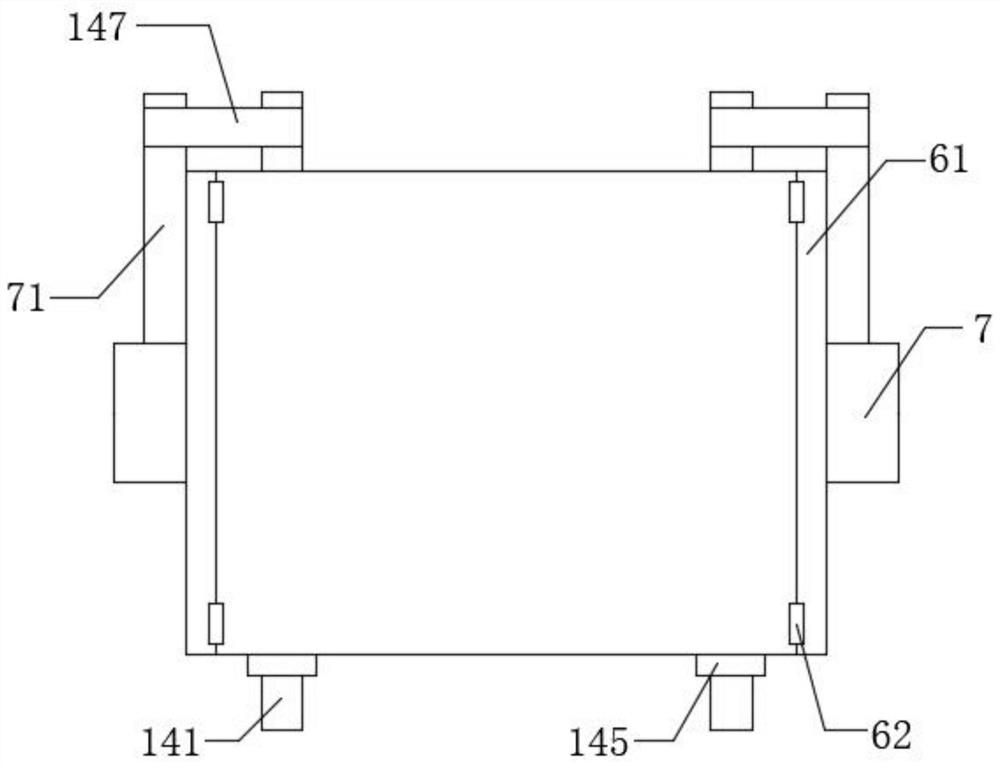

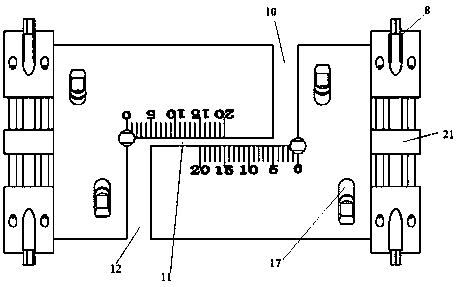

Tamping method of highway soft base structure

ActiveCN112411523AMaximum ImpactAvoid offsetRoadwaysSoil preservationGear wheelArchitectural engineering

The invention provides a tamping method of a highway soft foundation structure. The method adopts a highway soft foundation treatment structure to tamp a highway soft foundation, lifts a tamping column through a cargo boom, adjusts the orientation of the tamping column through a hydraulic press to enable the tamping column to be vertically downward, and then enables the tamping column to be in contact with a soft foundation surface through the direction of the cargo boom. Then a gear motor is started, the gear motor drives a crankshaft to rotate, the crankshaft drives a first rotating shaft torotate through a belt, the first rotating shaft drives a gear to rotate when rotating, the gear is meshed with a tooth row on a lifting arm through teeth so as to drive the lifting arm to lift upwards, and the lifting arm is used for lifting a rammer upwards. According to the tamping method of the highway soft foundation structure, the lifting height of the rammer is changed by adjusting different gears to be meshed with the tooth row and increasing or decreasing teeth, so that the impact force of the rammer is adjusted, and then tamping operation on different soft foundations is completed.

Owner:HUBEI PROVINCE FREEWAY IND DEV

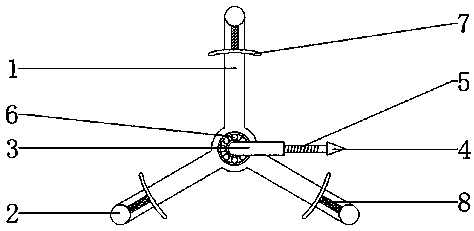

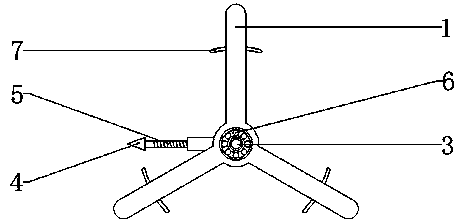

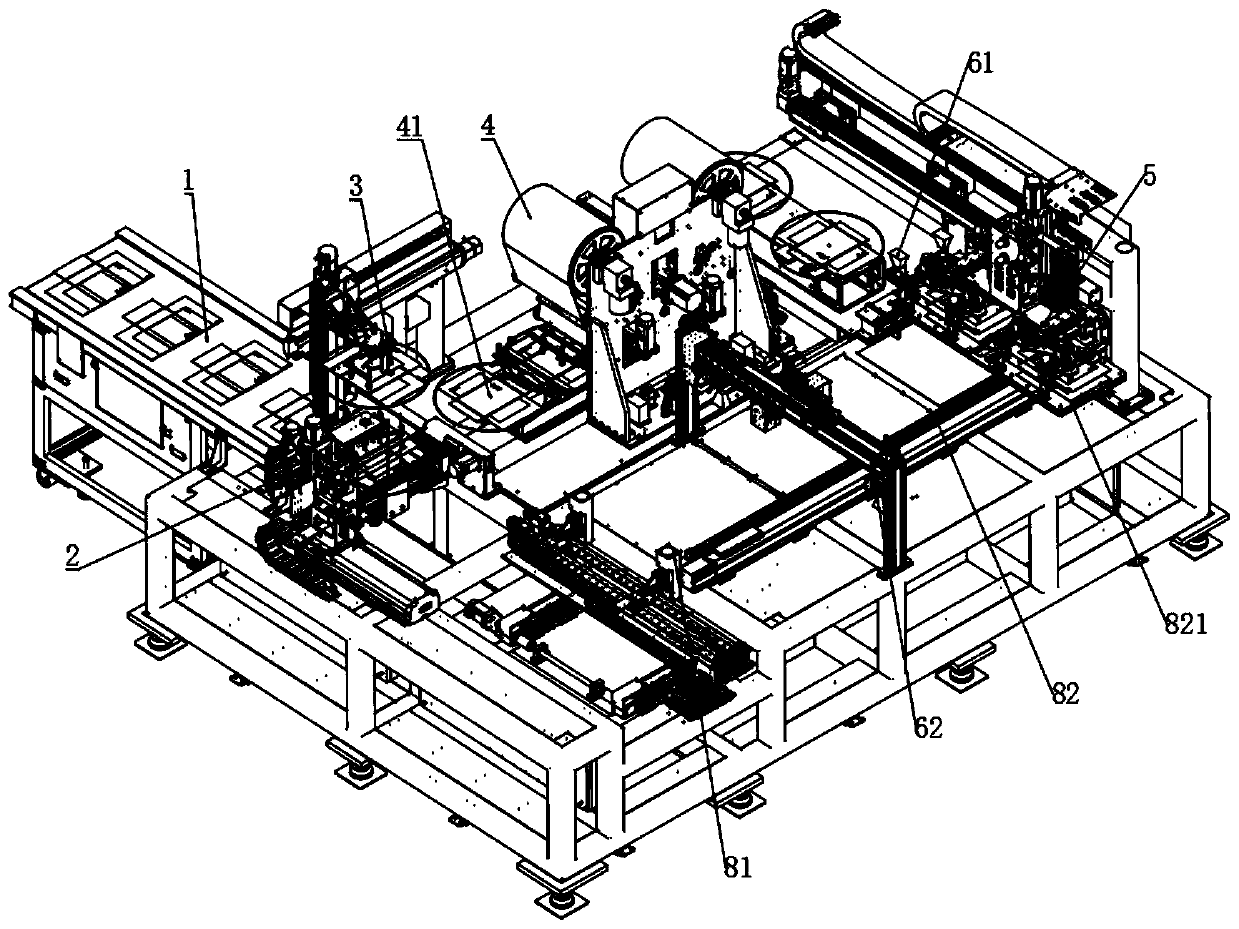

Single-layer cloth plain cloth device of computer quilting embroidery machine

InactiveCN101805967AGuaranteed flatnessUnable to overcome the problem of flatnessWork-feeding meansFeedersMechanical engineeringCotton material

The invention relates to a single-layer cloth plain cloth device of a computer quilting embroidery machine. The single-layer cloth plain cloth device consists of a saddle frame connecting rod, a cloth-supporting bracket, a spinous shaft, a support plate and a clamping element, wherein the lower end of the clamping element is fixedly installed with the saddle frame connecting rod, the support plate vertical to a side surface of the clamping element is fixedly installed on a vertical plate of the clamping element, the spinous shaft is vertically installed at the upper part in the front of the supporting plate, and the V-shaped cloth-supporting bracket is fixedly installed below the spinous shaft and is coaxial with the spinous shaft. The invention has simple integral structure and scientific and reasonable design, enables flexible objects (cloths) to realize stretching and flattening functions in the X direction under the repeated actions in the Y direction, ensures the flattening of the flexible objects (cloths), realizes the exquisite quality of an embroidery and has better creativity and practicability.

Owner:上工富怡智能制造(天津)有限公司

Barrel inner-wall cutter

The invention discloses a barrel inner-wall cutter and relates to the field of mechanical equipment. In use of the barrel inner-wall cutter, a threaded rod and a cutter bit can be inserted inside a barrel workpiece, three vertical posts keep surrounding the outer wall of the workpiece, elastic posts are stressed to be bent, and three outer-wall clamps closely fit to fix the barrel workpiece; the cutter bit is inserted to the inner wall of the barrel workpiece by screwing the threaded rod in a threaded bend, the thread bend is then rotated in a bearing to drive the threaded rod and the cutter bit to rotate a circle, and thus, the inner wall of the barrel workpiece can be cut off. With the barrel inner-wall cutter, flatness of the cutting plane of the barrel workpiece can be guaranteed, andthe barrel workpiece with thin wall is not easy to deform when cut.

Owner:苏州穹力机械科技有限公司

Bridge crack repairing method

InactiveCN112921831AReduce labor intensityEnsuring that pouring is in placeBridge erection/assemblyBridge strengtheningEngineeringClassical mechanics

The invention provides a bridge crack repairing method which comprises a case, and a support, a material preparing mechanism, a driving electric drill, a lifting handle, a plug, a pressure pump set, a pressure gauge, a high-pressure pipe, a repairing mechanism, an electric drill connector, a pinion, a rotating shaft, a large gear, blades and a transmission shaft are sequentially arranged on the case. The support is fixedly installed on the two sides of the outer surface of the lower end of the case, the material preparing mechanism is arranged on one side of the outer surface of the upper end of the case, the driving electric drill is movably installed on the other side of the outer surface of the upper end of the case, and the plug is movably installed on the side, away from the case, of the driving electric drill. According to the bridge crack repairing device, the handle can be supported during repairing, the amplitude of the handle caused by a slurry impact force is reduced, the labor intensity of workers is relieved, the repaired position can be trowelled and cleaned, the repairing quality is improved, a material preparation box can be conveniently cleaned, the cleanliness of the material preparation box is ensured, discharging is stable, and blocking is not prone to occurring.

Owner:薛章奎

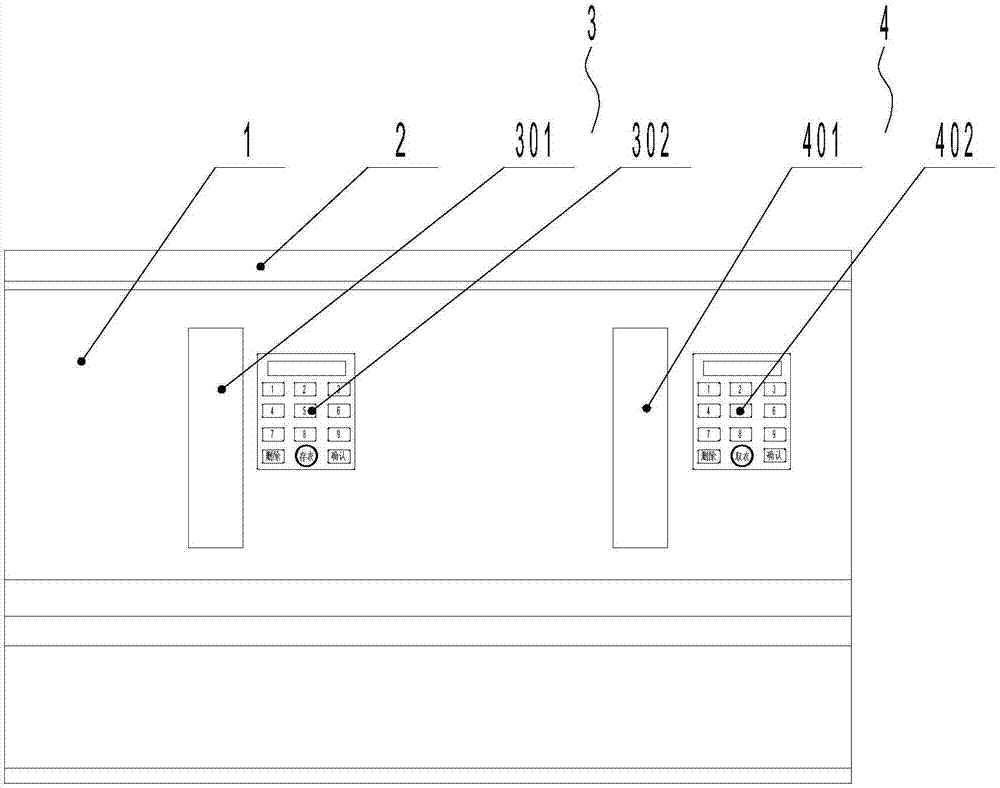

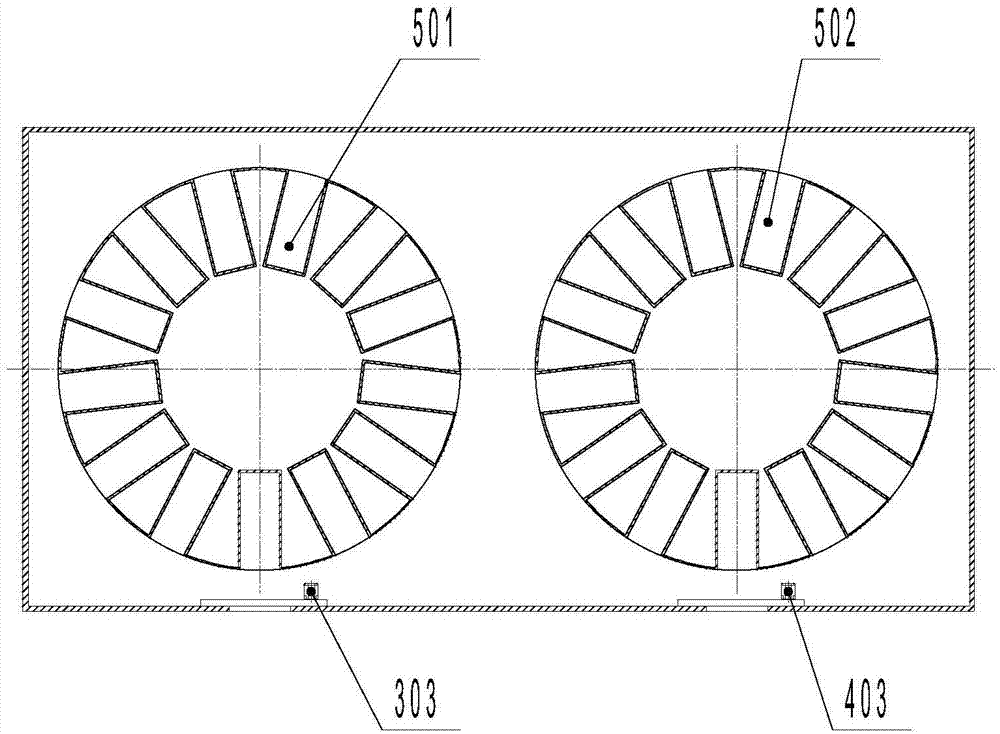

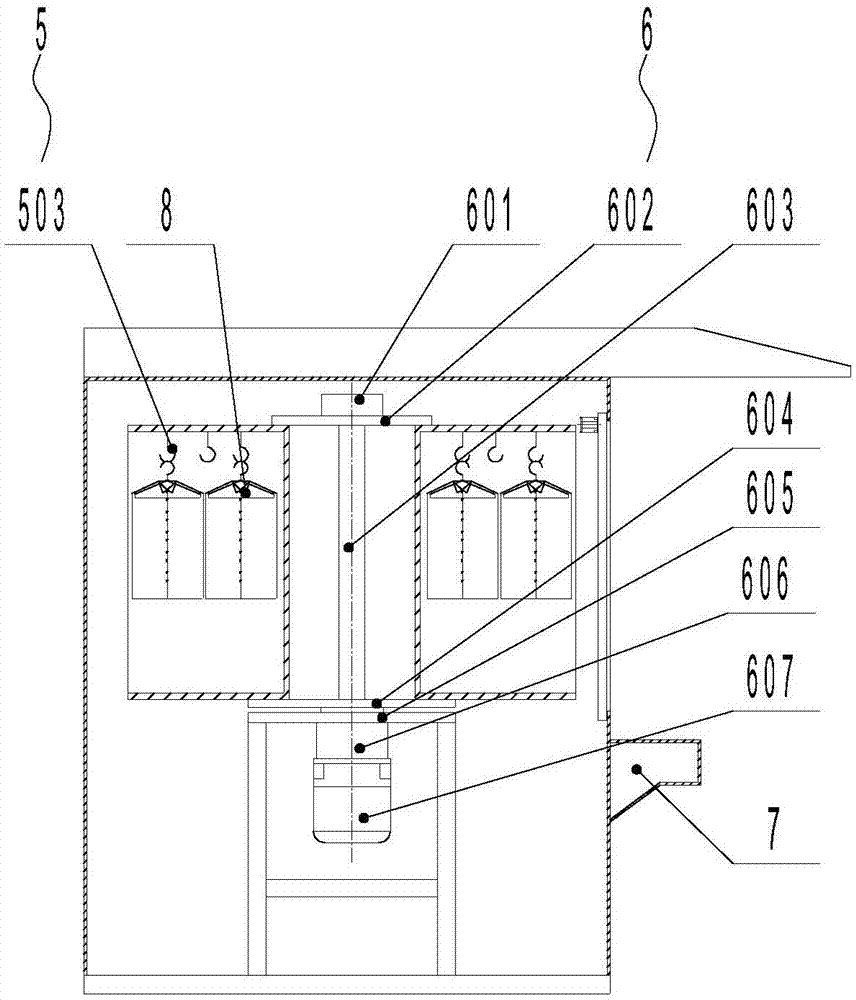

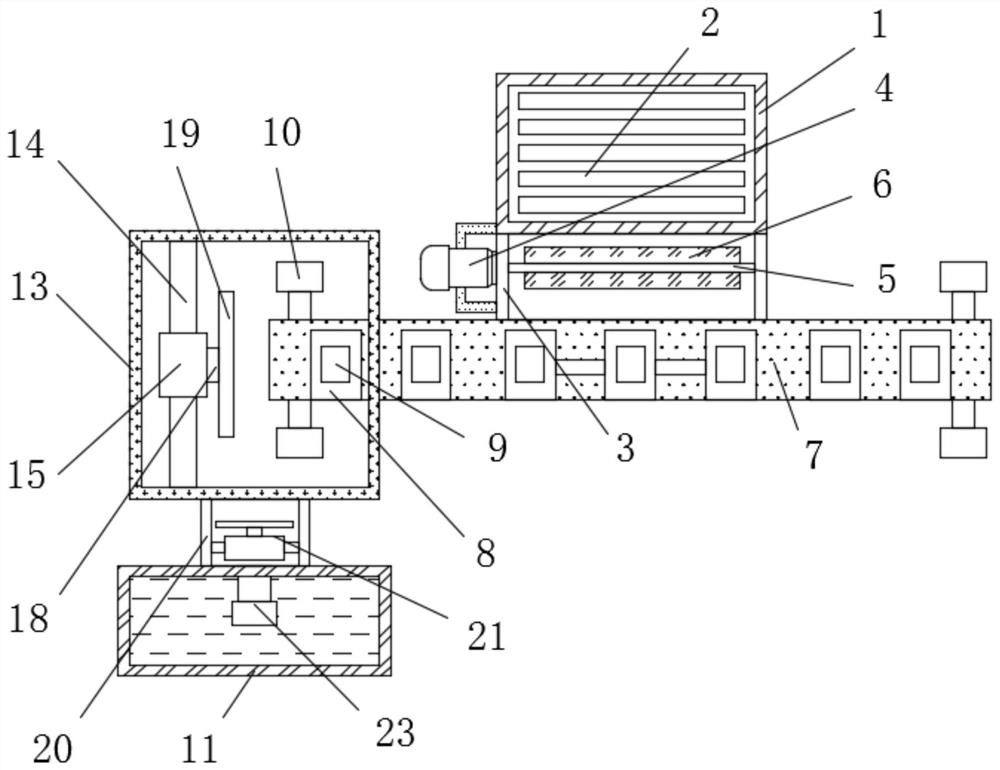

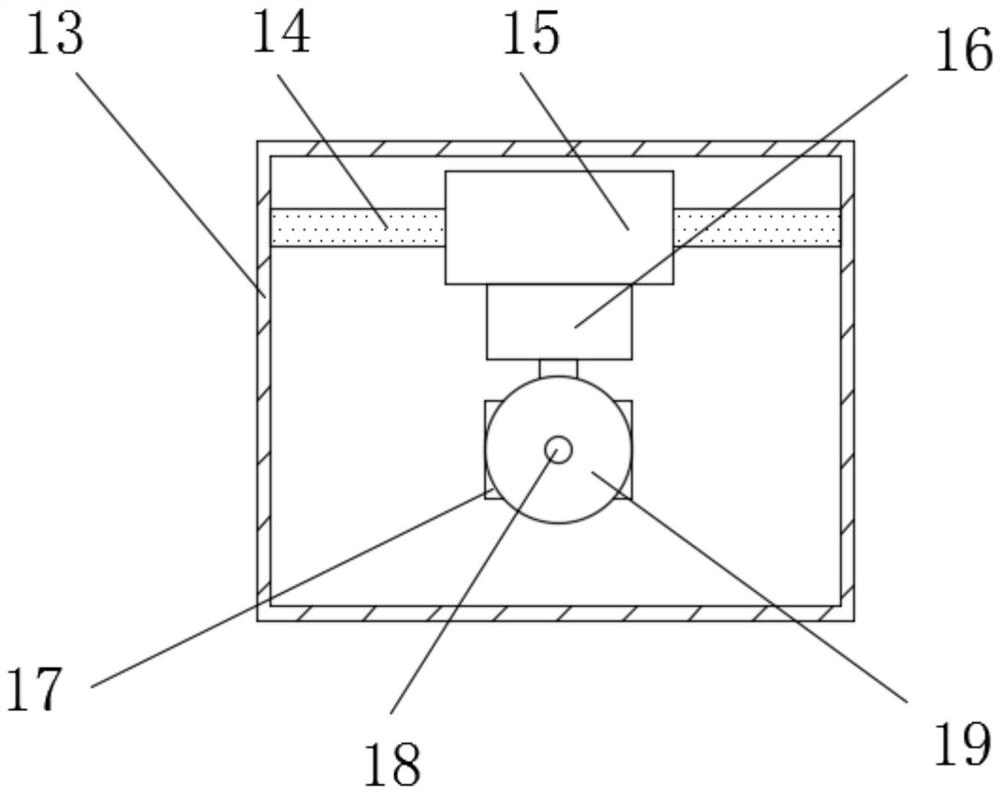

Automatic storing and taking device for clothes dry cleaning and application method of device

PendingCN107481440AEasy handoverCompensation for time misalignmentApparatus for meter-controlled dispensingLaundryEngineering

The invention discloses an automatic storing and taking device for clothes dry cleaning and an application method of the device, and relates to an automatic storing and taking device and an application method. The device comprises a shell, a clothes storage mechanism, a clothes taking mechanism, a clothes placing mechanism, a rotary storing and taking mechanism, a counter top and a central control mechanism, wherein the clothes storage mechanism, the clothes taking mechanism and the counter top are arranged on the shell; the clothes placing mechanism is fixedly connected with the rotary storing and taking mechanism, and the clothes storage mechanism, the clothes taking mechanism and the rotary storing and taking mechanism are connected with the central control mechanism separately. The method comprises the steps that a user places clothes needing to be washed in a clothes storage bin, and a mobile phone number is input to generate a corresponding order; after the clothes are washed in a laundry, a payment instruction is sent to a mobile phone of the user, the user pays through an online payment platform and receives a starting password after payment is completed, the user obtains the clothes through the starting password, and then one time of clothes cleaning can be completed. By means of the device, the handover work between the user and the laundry is facilitated, the time warp problem is effectively compensated for, and market prospects are wide.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

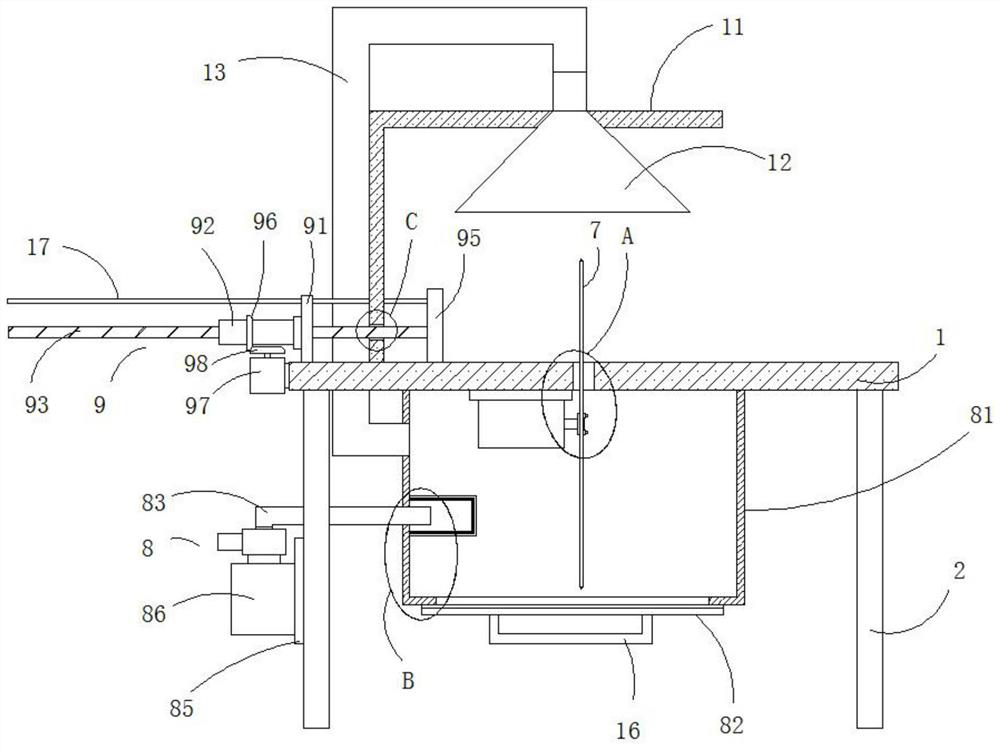

Industrial design foam plastic saw bench with adsorption function

InactiveCN112060157AWith adsorption functionImprove stabilityHuman health protectionDispersed particle filtrationElectric machineryStructural engineering

The invention relates to the technical field of foam plastic saw benches, and discloses an industrial design foam plastic saw bench with an adsorption function. The industrial design foam plastic sawbench comprises a workbench, supporting legs are fixedly connected to the four corners of the lower surface of the workbench, a rectangular through hole is fixedly connected to the upper surface of the workbench, a driving motor is fixedly connected to the lower surface of the workbench, the output end of the driving motor is fixedly sleeved with a baffle ring, two connecting screw rods are fixedly connected to the outer wall of the baffle ring, the rod walls of the two connecting screw rods are jointly sleeved with a saw blade, the saw blade is located inside the rectangular through hole, andthe rod walls of the connecting screw rods are in threaded connection with fixing nuts. The industrial design foam plastic saw bench with the adsorption function has the advantages that the quality of foam plastic cut by the foam plastic saw bench can be effectively improved, the situation that foam plastic cutting chippings drift away and pollute the environment can be avoided, the environmental-friendly performance of the foam plastic saw bench can be effectively improved, and meanwhile the health of workers is guaranteed.

Owner:XI'AN POLYTECHNIC UNIVERSITY

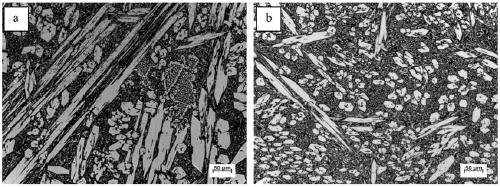

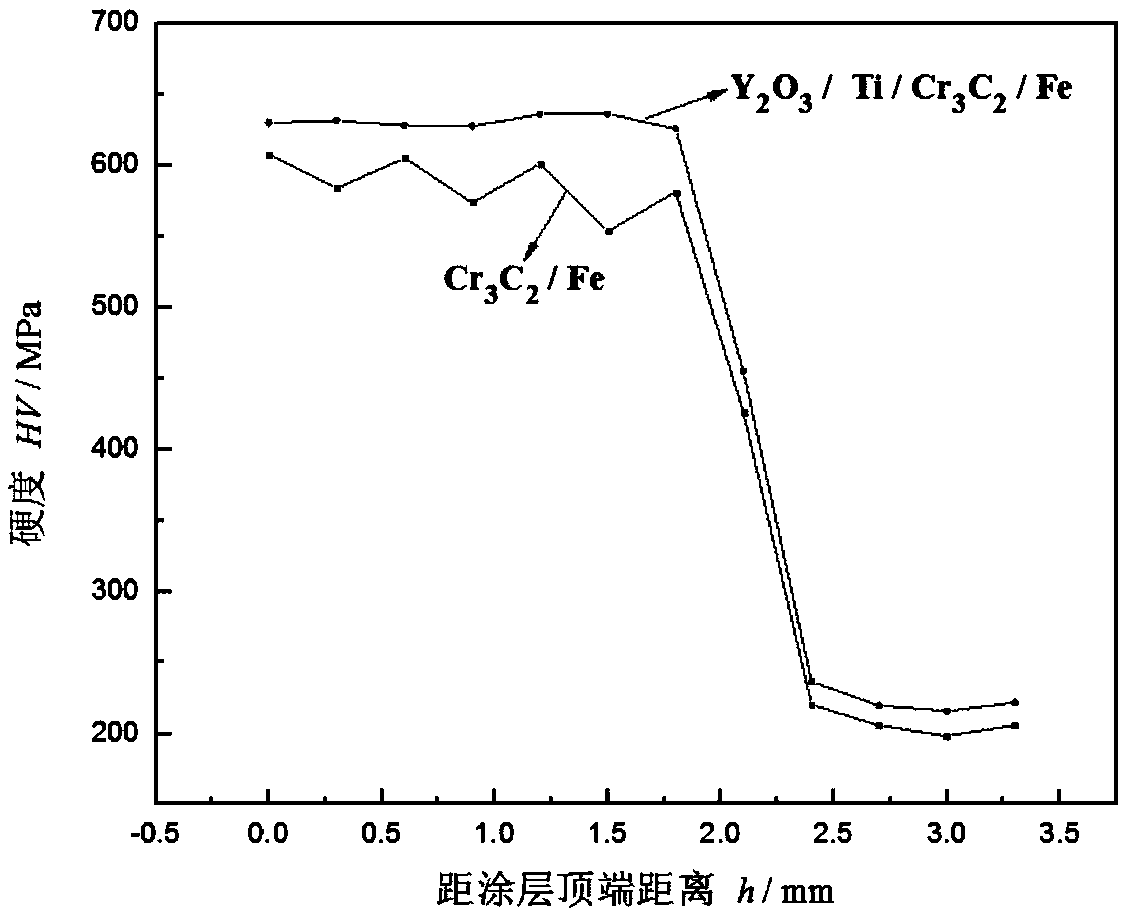

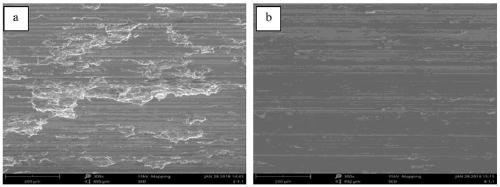

Multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and preparation method thereof

ActiveCN109023355AImprove liquidityInhibit growthMetallic material coating processesCrazingWear resistance

The invention discloses a multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating and a preparation method thereof, and belongs to the technical field of surface wear-resistant coatings. The plasma surfacing iron-based hypereutectic wear-resistant coating is prepared from the following components in a plasma surfacing mode, and wherein the components comprise, by mass, 48-69% of iron-based self-fluxing alloy powder, 30-50% of micron Cr3C2 powder, 0.5-1% of micron Ti powder, and 0.5-1% of nano Y2O3 powder. The preparation method of the plasma surfacing iron-based hypereutectic wear-resistant coating comprises the following steps of substrate pretreatment, preparation and drying of composite powder, preparation of the coating and post-heat treatment.By using the technical scheme, on the basis that hardness and wear resistance of the multi-scale particle reinforced plasma surfacing iron-based hypereutectic wear-resistant coating can be further improved, the process performance of the coating can be improved obviously, and cracks of the coating are effectively prevented.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

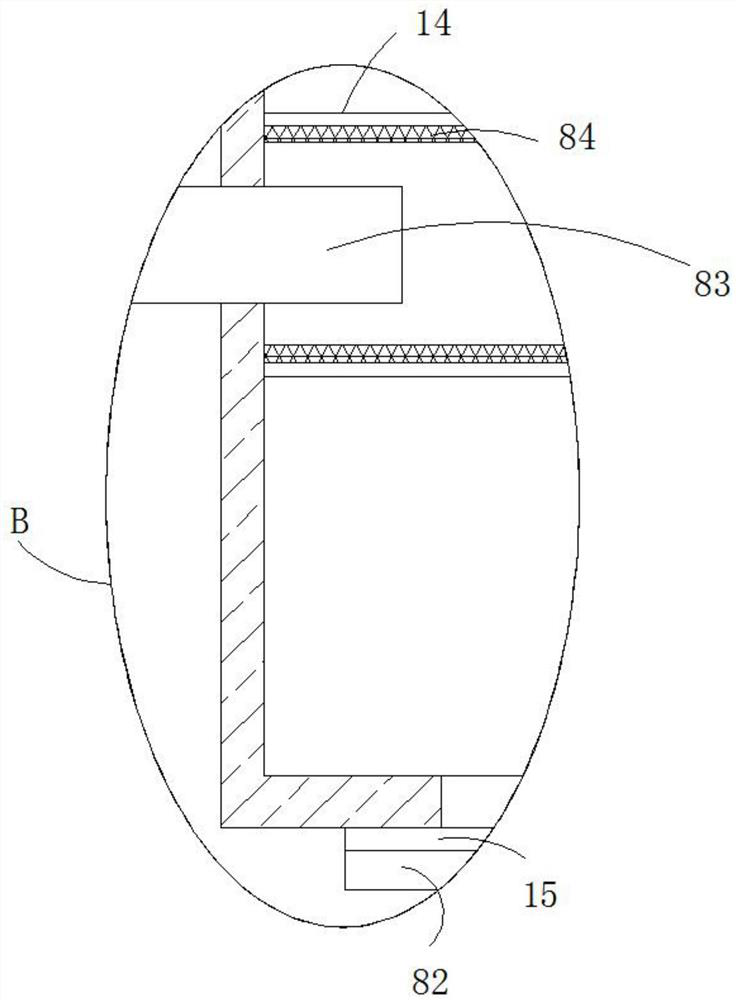

Packaging film receiving device

The invention discloses a packaging film receiving device, which comprises a mounting frame, wherein a front area, a film connecting area and a rear area are sequentially arranged on the mounting frame along the conveying direction of the packaging film, when the device is in use, the packaging film on the coil material to be replaced is cut off, the packaging film which is retained on a transmission roller after being cut off is pressed on the front area by using a first film pressing mechanism, and then the free end of the packaging film on the replaced coil material is pressed on the rear area by using a second film pressing mechanism, finally, adhesive film is laid on the film receiving area through an adhesive film feeding mechanism, and the adhesive surface faces upwards, so that thefree end of the packaging film which is retained on the transmission roller after being cut off is connected with the free end of the packaging film on the replaced coil material, the leveling precision of the connection position of the packaging film is ensured, the packaging film of the replaced coiled material is not required to be wound through various transmission rollers sequentially, the raw materials and the time are saved.

Owner:中山市科莱森自动化机械有限公司

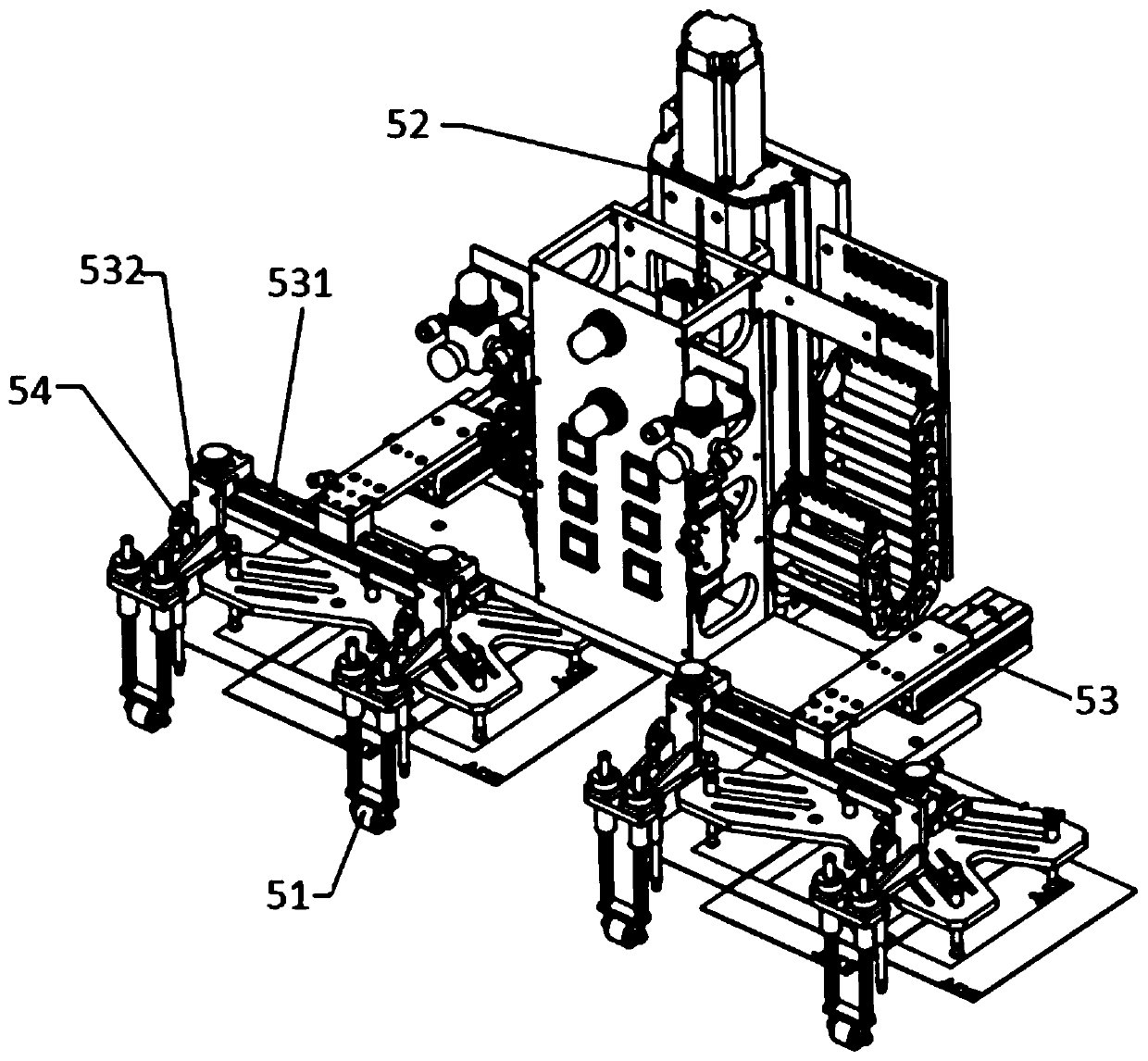

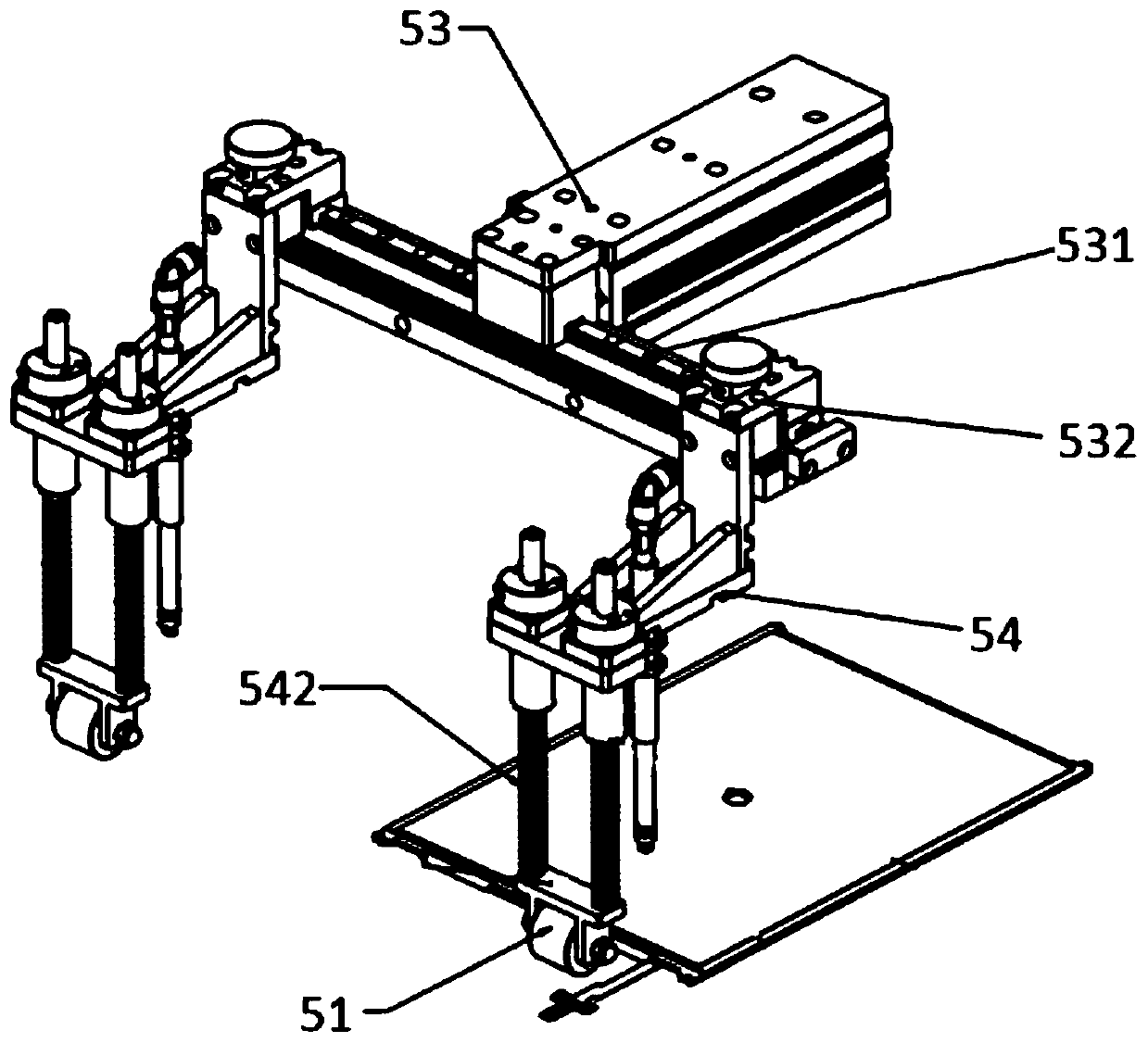

Module screen automatic inspection machine feeding station

ActiveCN111115181AEasy to grabGuaranteed cleanlinessConveyorsConveyor partsManufacturing engineeringMechanical engineering

The application relates to a module screen automatic inspection machine feeding station, which comprises a feeding conveying line capable of conveying products with front faces up or reverse faces up,a turning mechanism capable of grabbing products from the feeding conveying line and turning the products to change orientations of the products, a cleaning mechanism capable of cleaning the productsand provided with a cleaning conveying line capable of conveying the products to make the product pass through a cleaning path, a feeding manipulator capable of grabbing the products from the turningmechanism or the feeding conveying line and placing the products on the cleaning conveying line for transmission, a smoothing mechanism connected at the back end of the cleaning conveying line in a conveying direction, provided with a manipulator capable of grabbing the products from the cleaning conveying line, and used for levelling the deformed parts of the products and an alignment mechanismused for aligning the positions of the products. The module screen automatic inspection machine feeding station has the beneficial effects that when the orientations of the front and back faces of theproducts are not uniform due to manual feeding, and the turning mechanism can unify the orientations of the front and back faces of the product, so as to facilitate the feeding and grabbing manipulator to grab the products.

Owner:SUZHOU JINGLAI OPTO CO LTD

Weaving method for polyester fabric

InactiveCN112760788AKeep tidyAvoid influenceMechanical cleaningPressure cleaningPolyesterEngineering

The invention discloses a weaving method for a polyester fabric. A finishing device used in the method comprises a main frame, a first cleaning plate, an adjusting plate, a cloth belt and a roller, wherein the first cleaning plate and the adjusting plate are both fixedly connected with the inner surface of the main frame; the outer surfaces of the lower ends of the first cleaning plate and the adjusting plate are both tightly attached to the cloth belt; the inner surface of the cloth belt is tightly attached to the roller; a second cleaning plate fixedly connected with the main frame is arranged at the position, corresponding to the first cleaning plate, of the outer surface of the lower end of the cloth belt; and a storage box fixedly connected with the inner surface of the main frame is arranged below the second cleaning plate. According to the invention, the surface of the fabric can be cleaned at the first time after the fabric is produced, so that the surface of the fabric can be kept clean and tidy; and while the surface of the fabric is cleaned through the first cleaning plate, the second cleaning plate which is located below the first cleaning plate and fixedly connected with the main frame can also clean the lower end of the cloth belt when the cloth belt runs.

Owner:宋悦

Putty-less plate processing technology and products of putty-less plates

InactiveCN101798864ALow costImprove the quality of decorationCovering/liningsCalcium silicateMaterials science

The invention relates to putty-less plate processing technology and products of putty-less plates. The putty-less plate processing technology is characterized by being implemented by the following steps of: (1) presetting a substrate; (2) coating a wet powder bonding layer on the substrate; (3) pressing, drying and polishing the substrate which is coated with the bonding layer to obtain finished plates of the putty-less plates. The processing technology has the advantages of saving working time, saving materials, reducing the entire cost of projects and overcoming the deflects caused by the operation of two project teams of the traditional calcium silicate plate installation and putty coating due to fully mechanized production. The products can be widely applied in work sites such as buildings, ships and tunnels.

Owner:余文

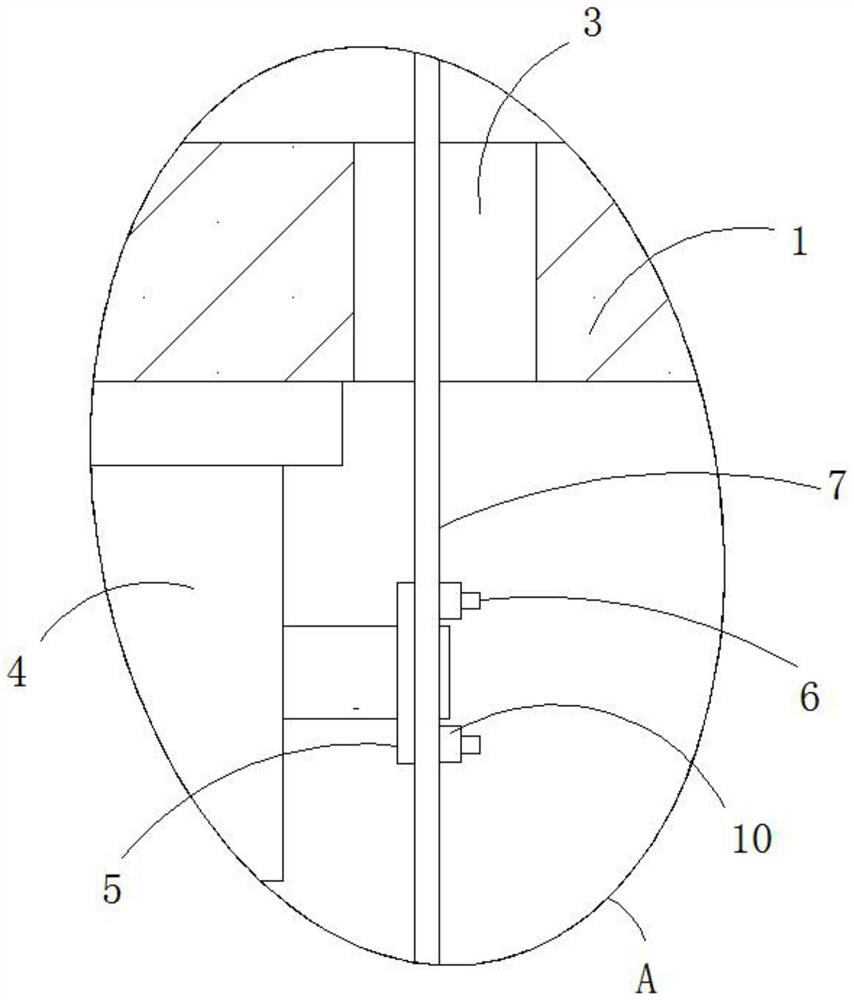

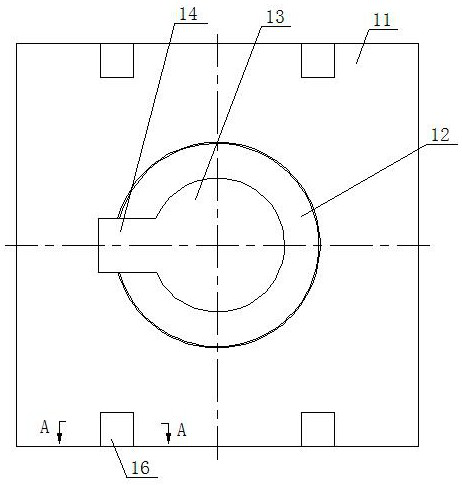

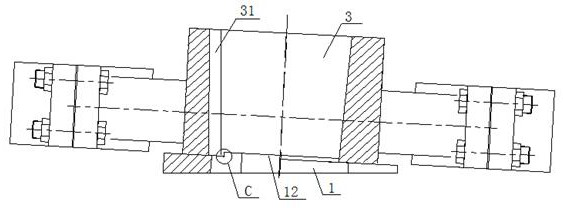

Tiller key groove grooving device and using method thereof

ActiveCN112846430AImprove processing efficiencyReduce processing timeElectrical-based auxillary apparatusWire cuttingEngineering

A tiller key groove grooving device comprises a bottom plate and a tiller linear cutting correction disc, a boss matched with the small-diameter end of a tiller taper hole is arranged at the center of the upper end face of the bottom plate, a machining hole and a key groove machining groove are axially formed in the boss, the key groove machining groove is located on the outer side of the machining hole and communicates with the machining hole, and the correction disc is in a T shape and comprises a flange and a correction part which are coaxially arranged, the correction part is of a conical structure matched with the large-diameter end of the tiller taper hole in an inserted mode, and a correction hole is axially formed in the center of the correction disc. During usage, the correction disc is fixed to a workbench after being assembled on a tiller, then, the perpendicularity of the center line of the tiller taper hole and the workbench is corrected, a plurality of key grooves are roughly machined through linear cutting, then the bottom plate is fixed to the workbench, the tiller is assembled on the bottom plate, and finish machining is carried out after the perpendicularity of the bottom planes of the key grooves and the workbench is corrected. By means of the design, linear cutting machining of the tiller key grooves is achieved, machining cost is reduced, and machining efficiency is improved.

Owner:WUHAN MARINE MACHINERY PLANT

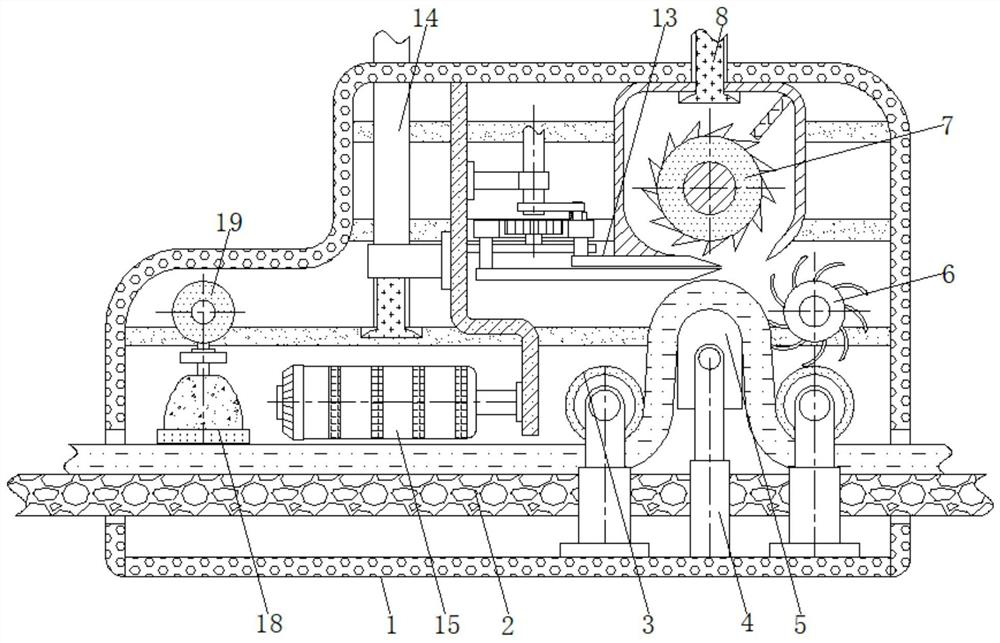

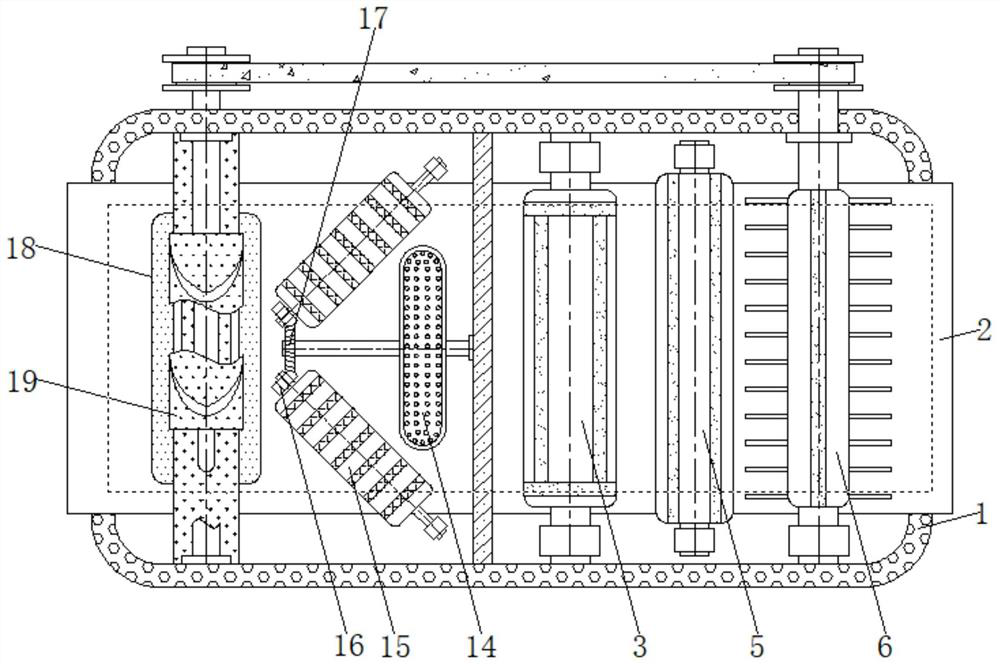

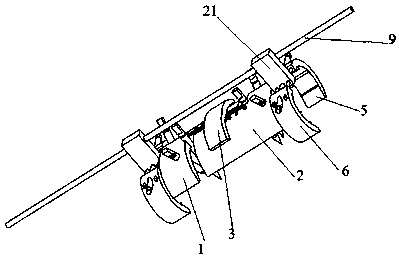

Apparatus for surface fluff treatment and surface flattening before cloth printing

PendingCN112962261AQuality improvementGuaranteed flatCleaning using gasesFabric steaming/decatisingGear wheelEngineering

The invention relates to the technical field of printing, and discloses an apparatus for surface fluff treatment and surface flattening before cloth printing. The apparatus comprises a shell; a conveying device is arranged in the shell; a pressing cylinder is arranged on the surface of the conveying device; a driving rod is arranged in the shell; a convex plate is arranged at the upper end of the driving rod; a comb wheel is arranged in the shell; an auxiliary cutting wheel is arranged on the upper portion of the convex plate; a negative pressure pipe is arranged on the upper portion of the auxiliary cutting wheel; a rotating rod is arranged in the shell; and a push plate is arranged on the surface of the rotating rod. According to the apparatus for surface fluff treatment and surface flattening before cloth printing, through cooperative use of the pressing cylinder and the comb wheel, cooperative use of the comb wheel and the auxiliary cutting wheel, cooperative use of the rotating rod and the push plate, cooperative use of a rack and a first gear and cooperative use of the rack and a cutting piece, fluffs on the surface of cloth can be trimmed and processed, so that the printing effect of the surface of the cloth can be effectively improved.

Owner:嘉兴倍创网络科技有限公司

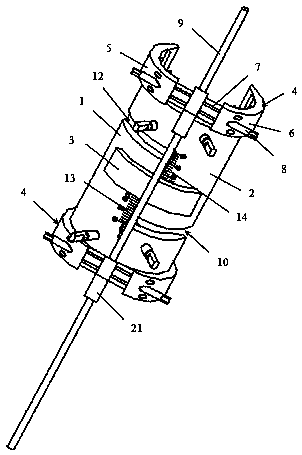

Osteotomy guider and osteotomy surgical instrument

PendingCN110859655AGood anti-rotation and canal concentricityGuaranteed flatBone drill guidesMedullary cavitySurgical instrument

The invention provides an osteotomy guider and an osteotomy surgical instrument. Wherein the osteotomy guide module comprises a first osteotomy guide block and a second osteotomy guide block, the first osteotomy guide block and the second osteotomy guide block are fixed on an osteotomy to-be-cut at an interval, the interval comprises a first gap, a second gap and a third gap which are sequentiallyconnected, and the first gap and the third gap are positioned on two sides of a straight line where the second gap is positioned. The osteotomy guider and the osteotomy surgical instrument have the advantages of good rotation resistance and medullary cavity concentricity; the osteotomy guide and osteotomy length measurement can be realized, so that the flatness of an osteotomy surface is guaranteed, the two ends of the osteotomy to-be-cut are in stable contact, the effective conduction of force is facilitated, osteoporosis is reduced, the skeletal development is promoted, bones can be healedas soon as possible, a postoperative patient can walk as soon as possible, and the early load of the patient is realized.

Owner:TIANJIN ZHENGTIAN MEDICAL INSTR CO LTD

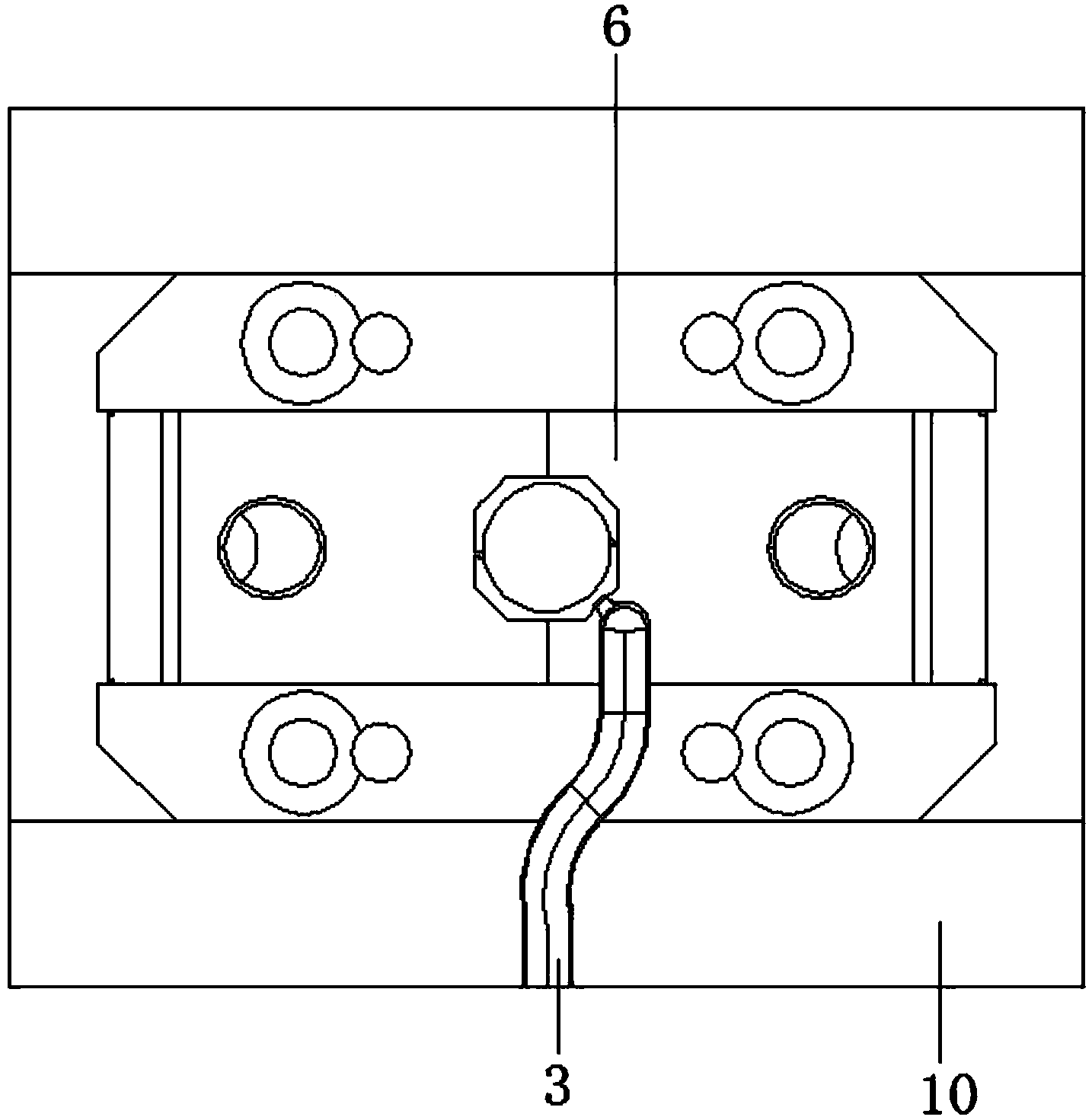

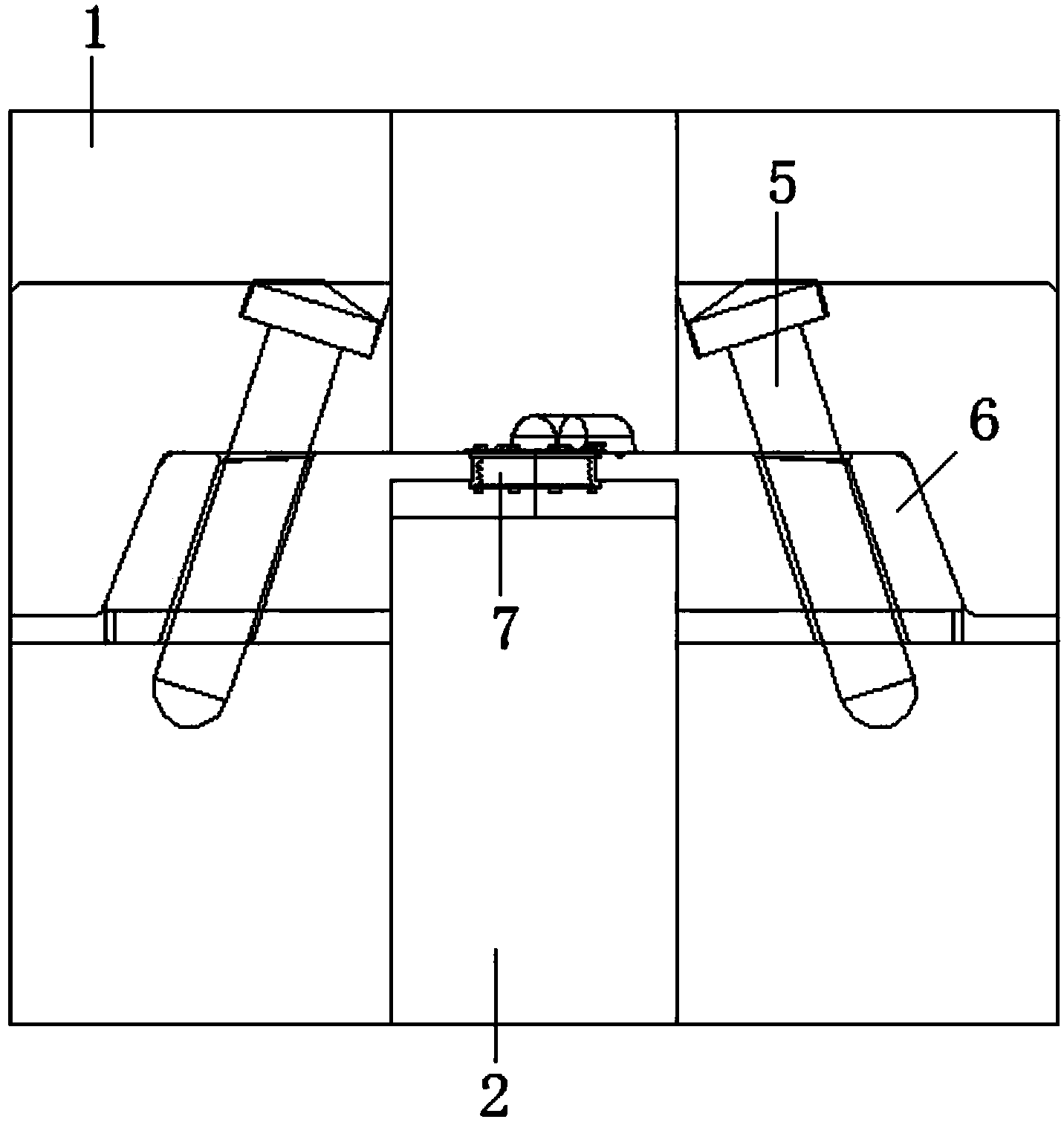

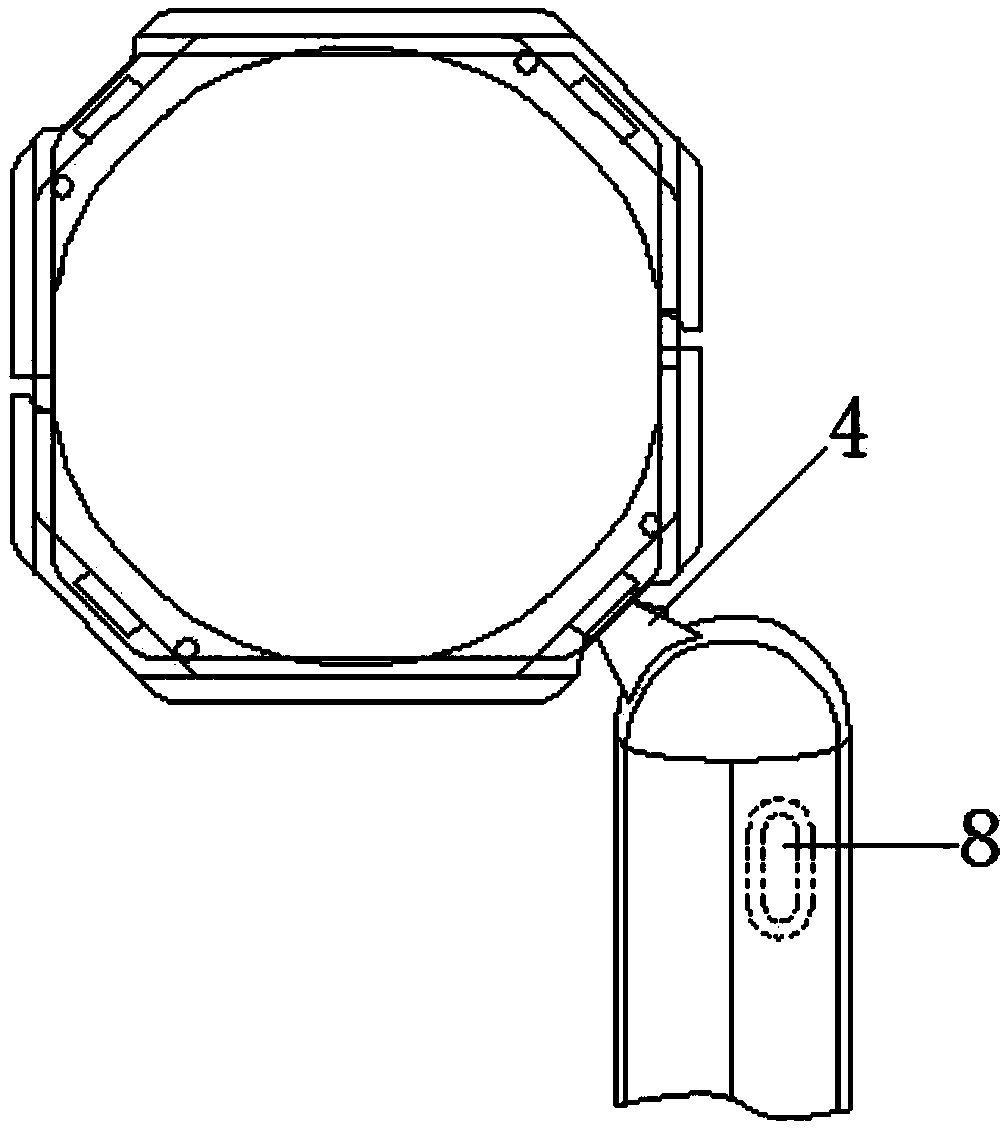

Mould for producing precise plastic parts

The invention discloses a mould for producing precise plastic parts, and aims to provide a mould, which can automatically separate the product and the plastic in the flow channel during the mould-splitting process, can guarantee the complete and stable separation, and maintains an intact appearance. The mould comprising a upper mould, a lower mould, a mould cavity, and a flow channel; a submergence section is arranged on the joint part between the mould cavity and the flow channel; a upper contour line, which locates in the highest part of the submergence section, and a lower contour line, which locates in the lowest part of the submergence section, are both straight lines, wherein the angle difference between the angle that is formed by the upper contour line and the horizontal plane and the angel that is formed by the lower contour line and the horizontal plane is more than 5 degrees; two opposite slide blocks are arranged in the upper mould, the two slide blocks move in a same straight line but in different directions; two inclined guide pillars, whose upper ends are inward inclined, are arranged in the upper mould, the inclined guide pillars penetrate the upper surfaces and the lower surfaces of the slide blocks; the flow channel is connected to a recessed groove, and the recessed groove is arranged below the flow channel, and communicates with the flow channel. The mould has the advantages that: during a mould splitting process of thin-wall products, automatic separation between the products and the plastic in the flow channel can be successfully achieved, the separation process is rapid and complete, furthermore, the fracture surface is smooth, the products are intact, and the mould splitting process is stable.

Owner:NINGBO BEILONG PRECISION MOLDING

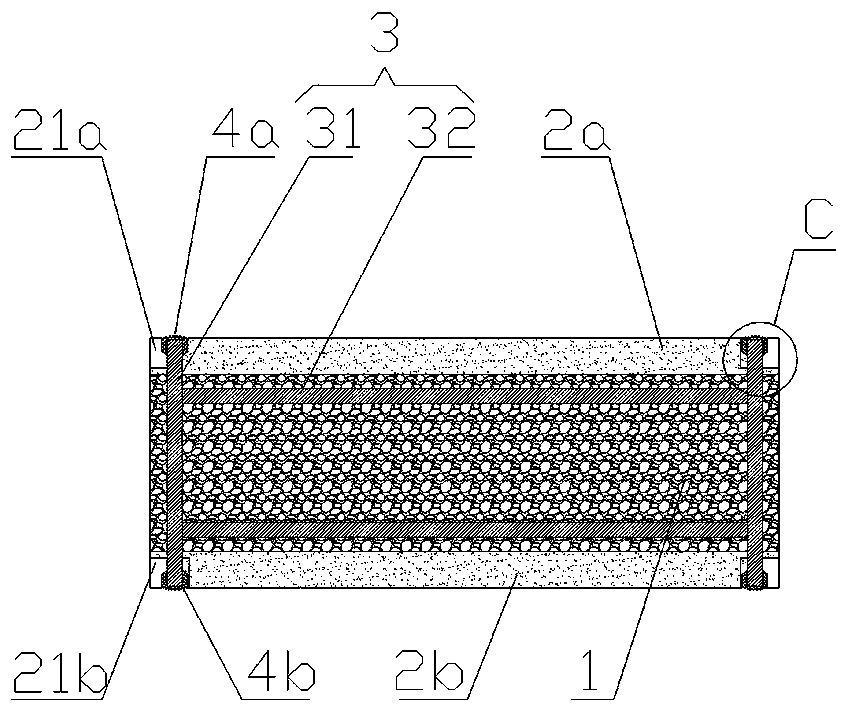

Landscape road floor tile and construction method thereof

ActiveCN110983906AHigh strengthNot easy to damageSingle unit pavingsPaving gutters/kerbsArchitectural engineeringMechanical engineering

The invention relates to a landscape road floor tile, which comprises a supporting layer, water guide layers and a steel support arranged on the supporting layer, wherein the supporting layer is a blocky body which is formed by bonding hard particles and is provided with gaps, and the upper surface and the lower surface of the supporting layer are parallel to each other; the water guide layers aresheet-shaped bodies which are formed by bonding an elastic particle material and are provided with gaps; the water guide layers are respectively fixed on the upper surface and the lower surface of the supporting layer; and cross rods of the steel support are embedded in the supporting layer, the end parts of vertical rods of the steel support penetrate through the supporting layer upwards or downwards in the vertical direction and extend into the water guide layer. The floor tile further comprises a protective cap and a connecting accessory. The floor tiles can be connected with each other toform a whole, and individual floor tiles can be replaced quickly when being damaged. The floor tile is simple in structure, firm, durable and convenient to use.

Owner:河南华植市政园林工程有限公司

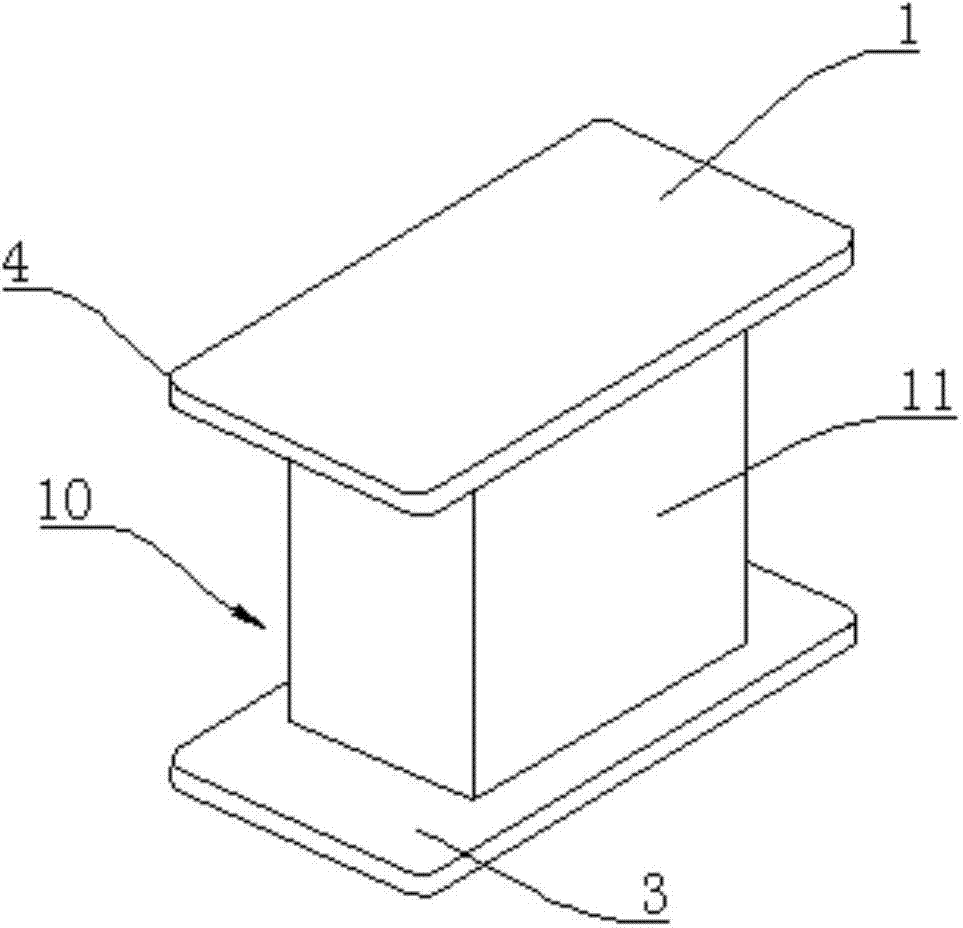

Delivery mechanism enabling reel to be compressed

InactiveCN104139886AGuaranteed flatLow costWrapping material feeding apparatusConductor CoilBilateral symmetry

The invention discloses a delivery mechanism enabling a reel to be compressed. The delivery mechanism comprises a feed-in part and a working table. The feed-in part comprises two film winding drum placement positions which are arranged in a bilateral symmetry mode. The film winding drum placement positions are arranged on symmetric plates at the two ends of the upper portion of the feed-in part, U-shaped grooves are formed in the film winding drum placement positions, a compressing device is further arranged on a symmetric plate on one side of the upper portion of the feed-in part, and a storage and release device is further connected between the compressing device and a symmetric plate at the upper end of the feed-in part. The compressing device is arranged on the symmetric plate at the upper end of the feed-in part and above the film winding drum placement positions, films can be compressed in the release process of the films and can be delivered smoothly in the moving process, and therefore it is guaranteed that the films can be flatly spread in the packaging process; furthermore, packaged products can be completed in an attractive and orderly mode, cost is saved, and attractiveness and orderliness of the packaged products are guaranteed.

Owner:成都昱阳鑫达实业有限公司

A steel pipe cutting device

ActiveCN108296546BEasy to cutRealize automatic feeding processTube shearing machinesMaintainance and safety accessoriesElectric machineLinear motor

The invention discloses a steel tube cutting device. The steel tube cutting device comprises a main shell, a steel tube, a tube bank shell, a first motor, a first rotating shaft, a rotating piece, a conveyor belt, a steel tube fixing clamping block, a steel tube storing groove, a first electric pushing rod, a supporting column, a water storage box, a circular arc clamping plate, a cutting shell, ascrew rod, a linear motor, a second electric pushing rod, a second motor, a second rotating shaft, a cutting tool, a dust discharging tube, an exhaust fan, and an exhaust and connecting tube. The steel tube cutting device has the simple structure and novel design, and realizes automatic feeding of a steel tube, it is ensured that the steel tube is fixed and cut stably and orderly one by one, andmeanwhile, stabilizing of the steel tube in the cutting process is ensured, so that cutting of the steel tube is facilitated; effective fixing of the steel tube is achieved, so that using is facilitated; automatic cutting of different lengths of the steel tube is achieved, so that effective cutting treatment is conducted conveniently according to the storing condition of the steel tube; and flatness of the steel tube cutting end face is ensured, so that later grinding treatment of the steel tube end face is facilitated, and using is facilitated.

Owner:南京平达绿色建材科技有限公司

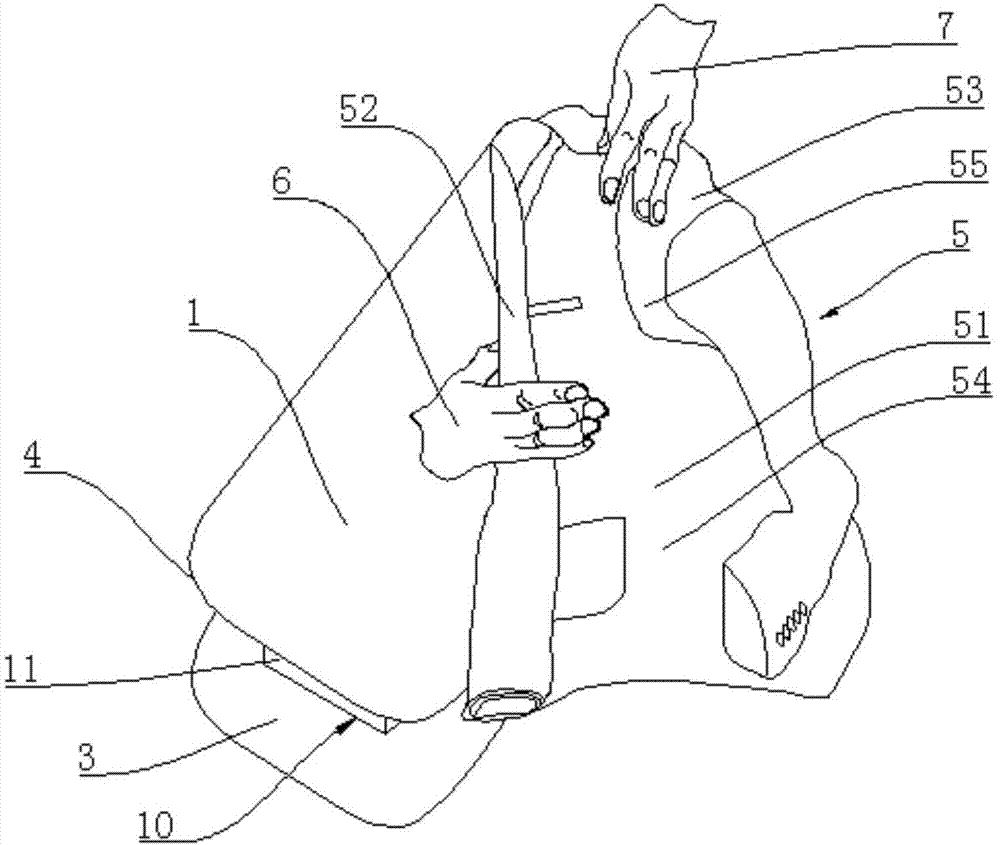

Chest interlining sewing thread fixing supporting platform and using method

The invention discloses a chest interlining sewing thread fixing supporting platform and a using method. The chest interlining sewing thread fixing supporting platform comprises a supporting panel and a supporting frame, wherein the supporting panel is used for supporting fabrics of the shoulders and the front of a suit and comprises at least two adjacent sides which are vertically connected with each other and are used for supporting a front wide sleeve and positioning the front wide sleeve; the supporting frame is used for supporting the bottom of the supporting panel. The chest interlining sewing thread fixing supporting platform can be used for pushing the loose part reserved on a suit chest interlining to the sleeve, so that an outer layer of fabric and the chest interlining after the chest interlining is fixed are flatter, drape does not appear, the fabric of the suit is smooth and shaped, and the production quality is improved.

Owner:BEIJING WUMU GARMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com