Module screen automatic inspection machine feeding station

An automatic inspection and module technology, applied in conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of inconsistent front and back orientations of products, inconvenient detection of assembly line operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

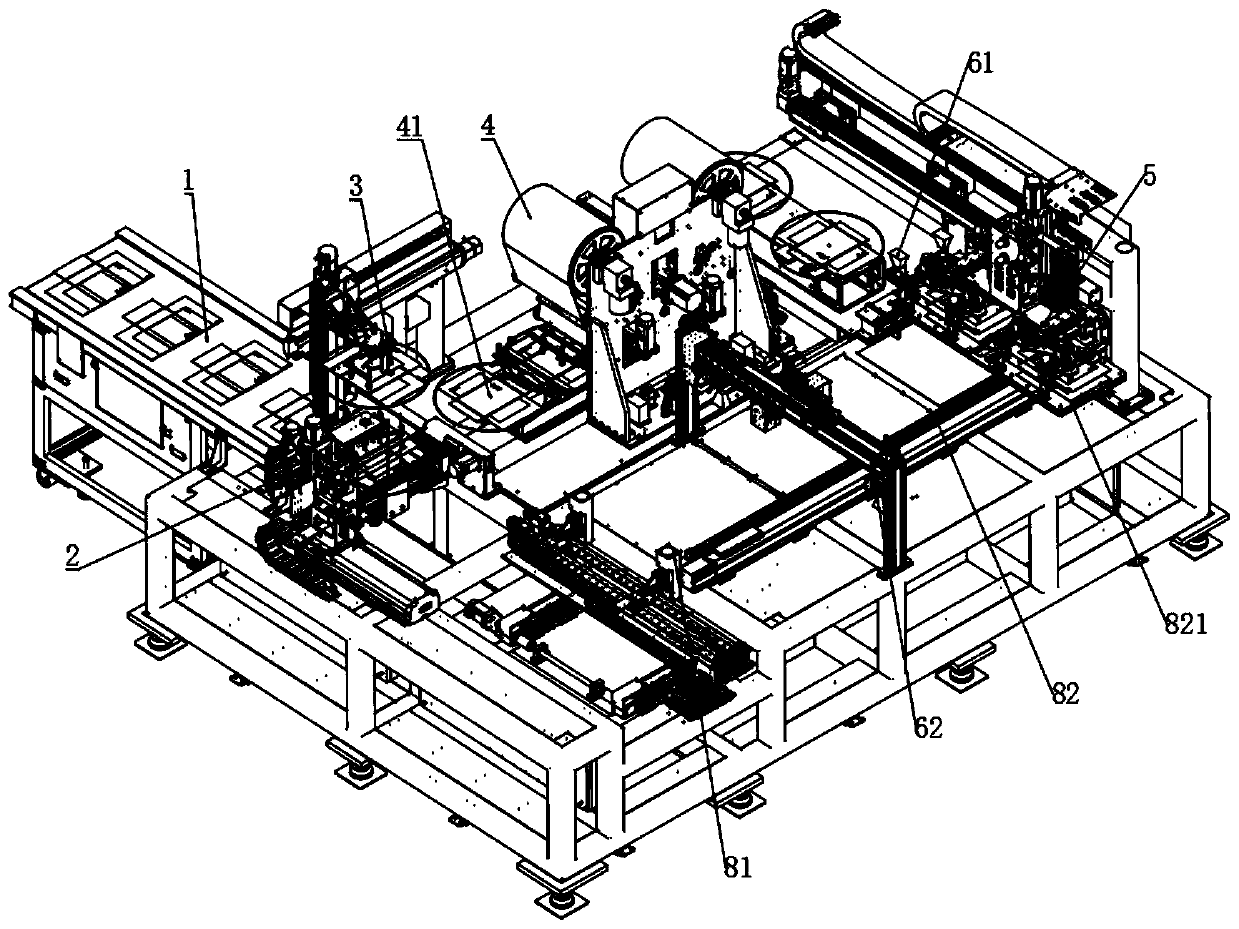

[0079] This embodiment provides a module screen automatic inspection machine feeding station, such as figure 1 , 6 shown, including:

[0080] Feeding conveyor line 1, capable of conveying products with the front side up or the back side up;

[0081] Turning mechanism 2, capable of grabbing products from the feeding conveying line 1 and turning them over to change the orientation of the products;

[0082] Cleaning mechanism 4, described cleaning mechanism 4 can clean product, has the cleaning conveying line 41 that can transport product to make product pass through cleaning path;

[0083] The feeding manipulator 3 can grab the product from the turning mechanism 2 or the feeding conveying line 1, and place it on the cleaning conveying line 41 for transmission;

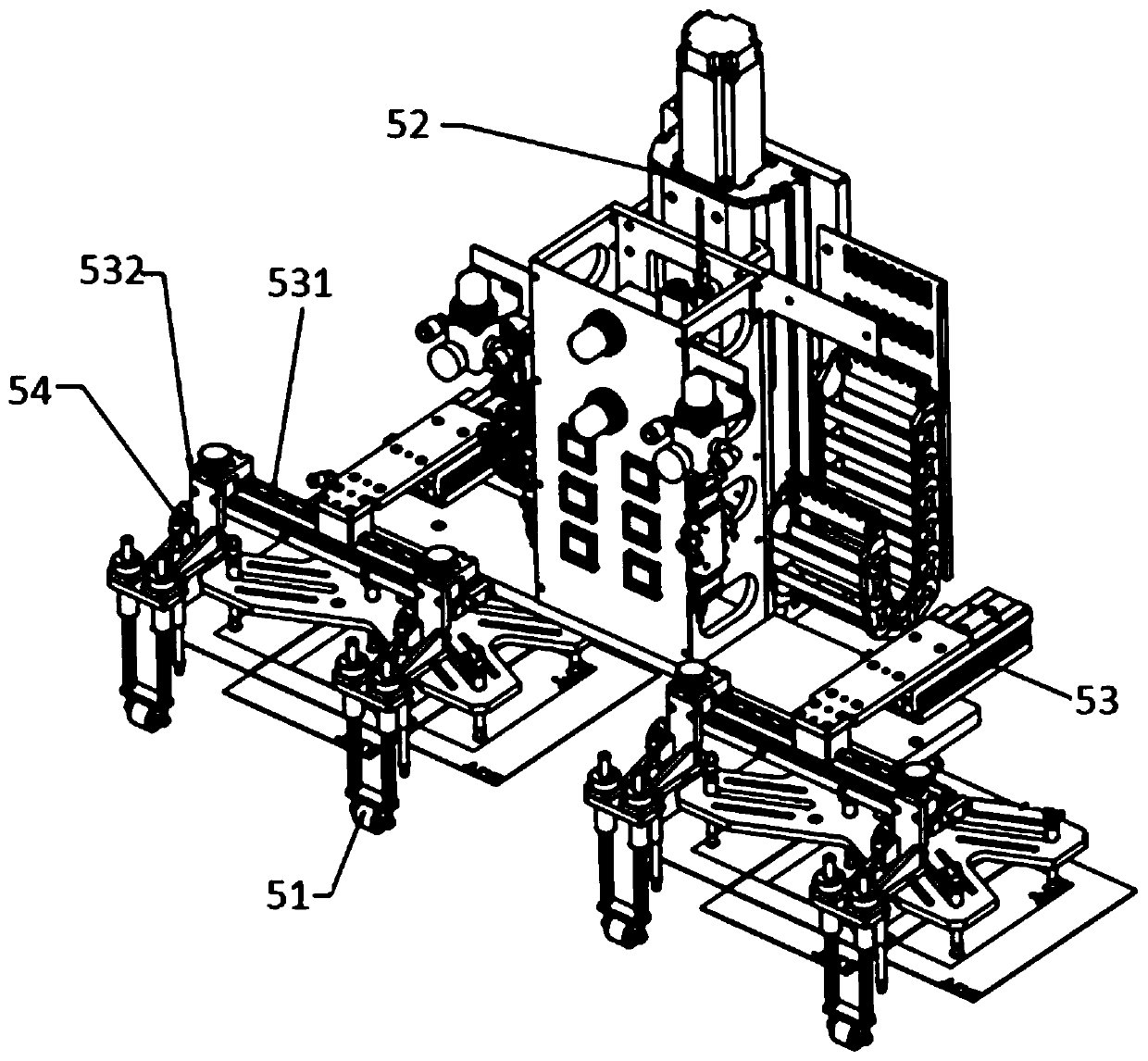

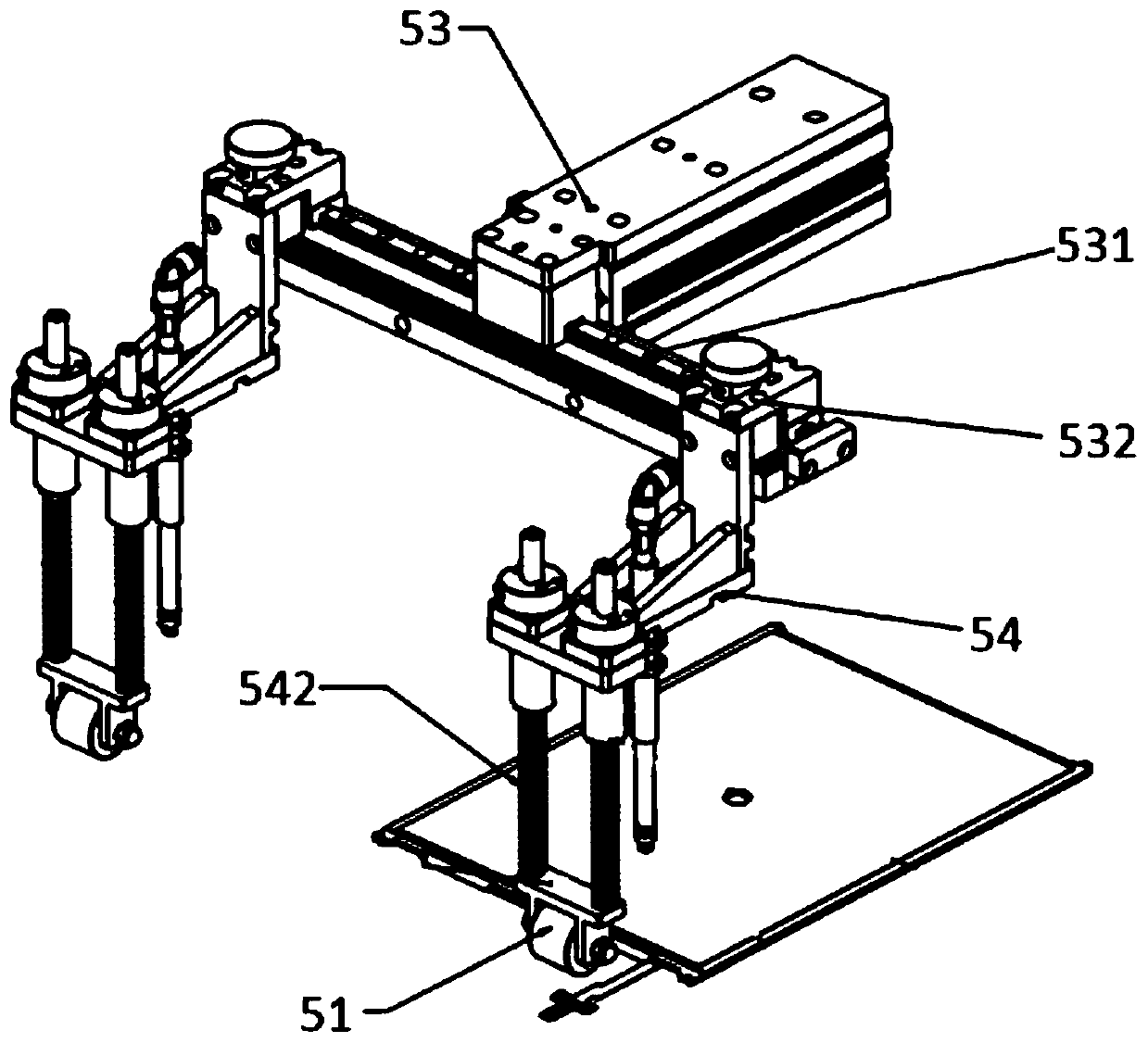

[0084] The smoothing mechanism 5 is connected to the rear end of the cleaning conveying line 41 along the conveying direction, and has a manipulator 50 capable of grabbing products from the cleaning conveying line 41....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com